Temperature Assessment Through Decal Color in Microwave-Fired Porcelain

Abstract

1. Introduction

1.1. Conventional Firing Technologies and Ceramic Ware Particularities

1.2. Microwave Firing

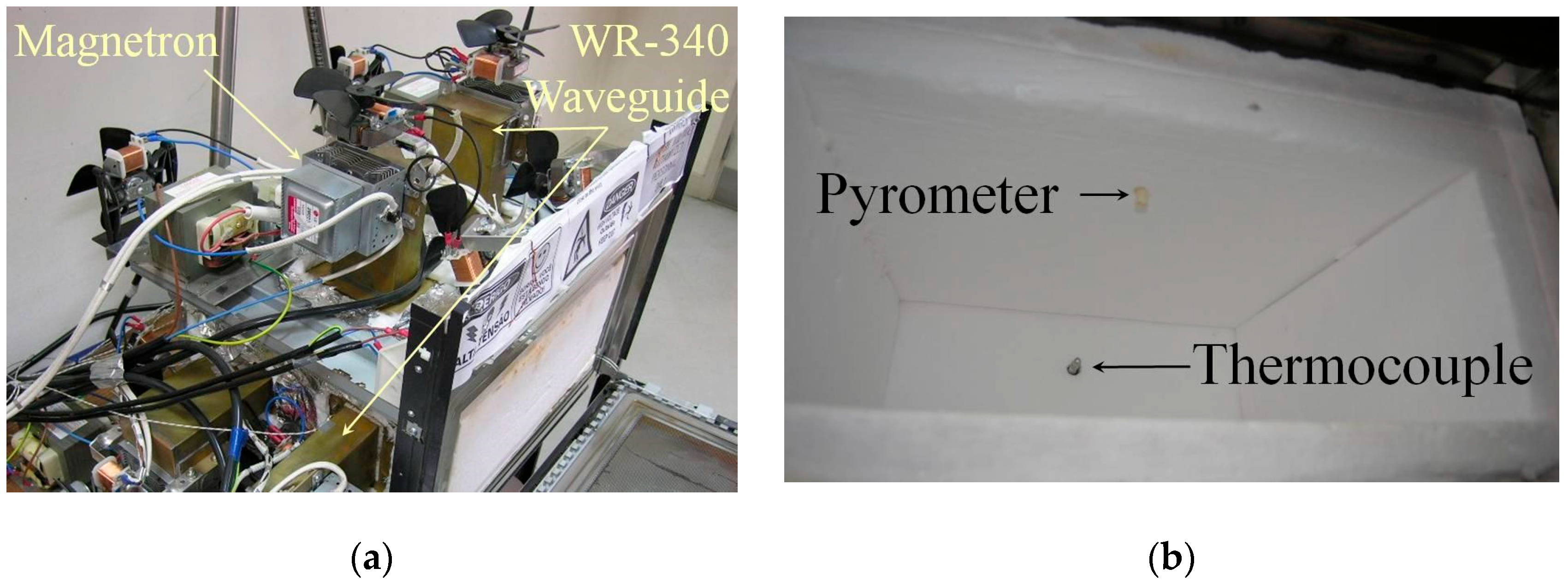

2. Materials and Methods

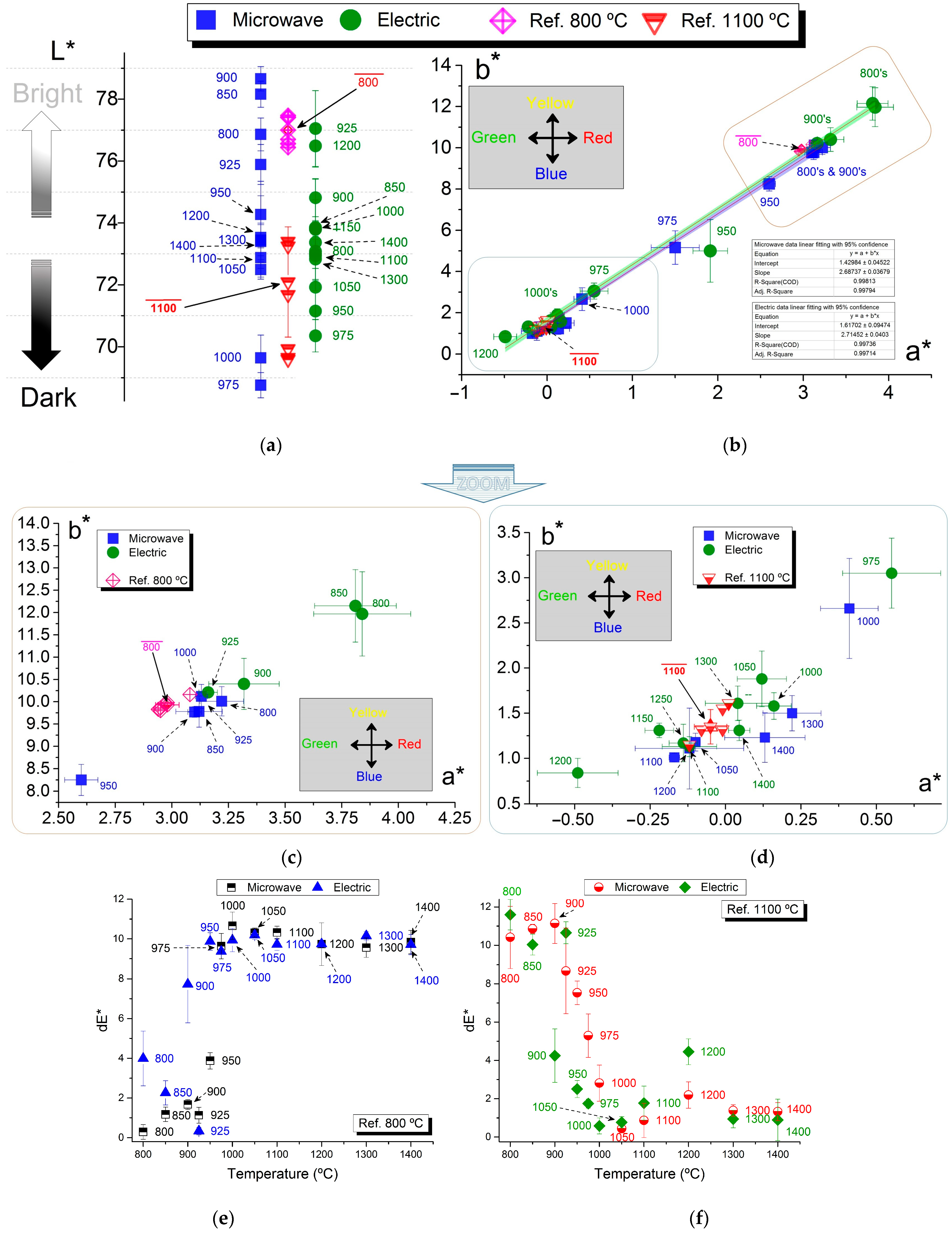

- L* represents lightness/whiteness (0 = dark, 100 = light).

- a* ranges from green to red (negative values indicate a shift toward green, while positive values indicate a shift toward red).

- b* ranges from blue to yellow (negative values indicate a shift toward blue, while positive values indicate a shift toward yellow).

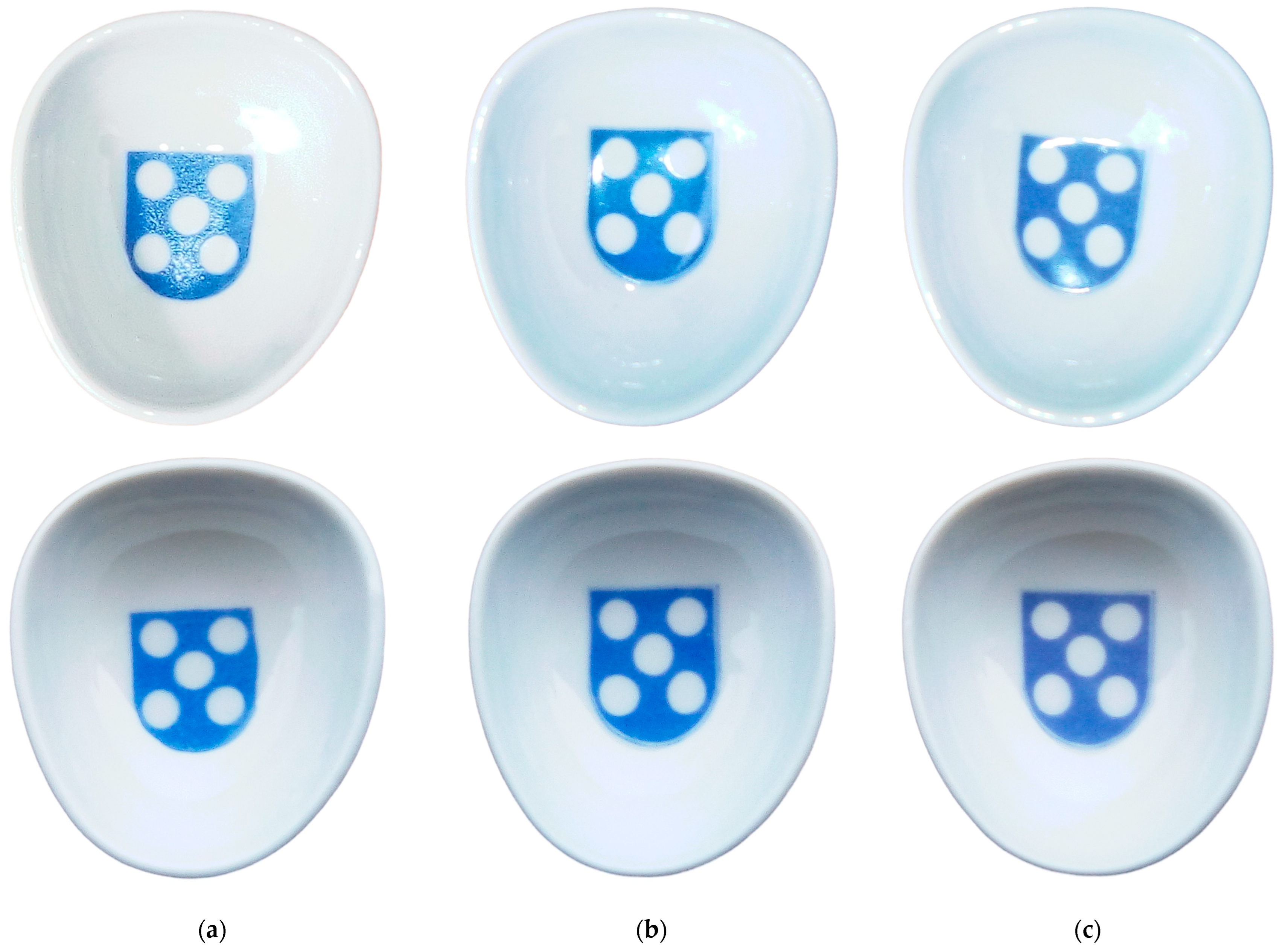

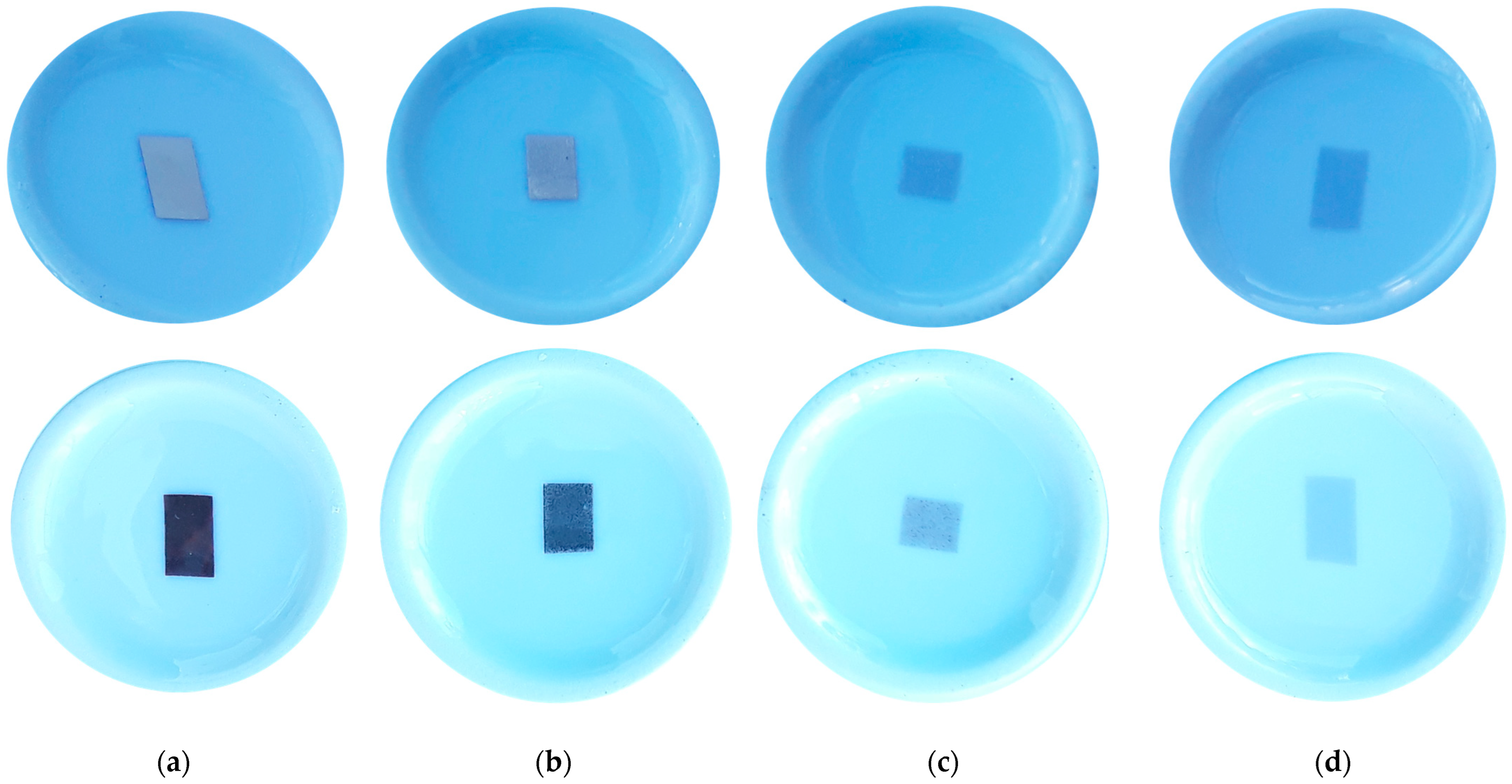

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PTCR | Process Temperature Control Ring |

| RFBG | Regenerated Bragg fiber |

| EMF | Electromagnetic field |

| SiC | Silicon carbide |

| TP | Temperature measured by the pyrometer (microwave-related) |

| TT | Temperature measured by the thermocouple(s) (electric- and gas-related) |

References

- António Tomás da, F. Tecnologia Do Processamento Cerâmico; Universidade Aberta: Lisboa, Portugal, 2000; ISBN 972-674-320-6. [Google Scholar]

- Reed, J.S. Introduction to the Principles of Ceramic Processing; Wiley: Hoboken, NJ, USA, 1988; ISBN 047184554X. [Google Scholar]

- Ryan, W.; Radford, C. Whitewares Production, Testing, and Quality Control: Including Materials, Body Formulations, and Manufacturing Processes; Freer, R., Ed.; Pergamon Press: Oxford, UK, 1987; ISBN 0080349285. [Google Scholar]

- Costa Verde SA. Available online: https://costa-verde.com/costaverde/# (accessed on 21 May 2019).

- Royal Copenhagen. General Information about Porcelain-Report.

- Schüller, K.H. Porcelain: Ceramics Monographs–Handbook of Ceramics; Verlag Schmidt GmbH: Freiburg, Germany, 1979. [Google Scholar]

- Vista Alegre SA: Porcelana, Cristal Desde. 1824. Available online: https://vistaalegre.com/pt/ (accessed on 5 April 2019).

- Bordallo Pinheiro. Available online: https://pt.bordallopinheiro.com/ (accessed on 5 April 2019).

- Molinari, C.; Conte, S.; Zanelli, C.; Ardit, M.; Cruciani, G.; Dondi, M. Ceramic Pigments and Dyes beyond the Inkjet Revolution: From Technological Requirements to Constraints in Colorant Design. Ceram. Int. 2020, 46, 21839–21872. [Google Scholar] [CrossRef]

- Freiman, S.; Rumble, J. Current Availability of Ceramic Property Data and Future Opportunities. Am. Ceram. Soc. Bull. 2013, 92, 34–38. [Google Scholar]

- Tozzi, N. Glaze and Body Pigments and Stains in the Ceramic Tile Industry. Available online: https://digitalfire.com/article/glaze+and+body+pigments+and+stains+in+the+ceramic+tile+industry (accessed on 5 June 2025).

- Katsuki, H.; Shiraishi, A.; Pee, J.H.; Cho, W.S.; Takashi, Y.; Kubuki, S. A Relationship between Oxidation State of Iron and Color of Arita Celadon Glaze Characterized by 57Fe-Mossbauer Spectroscopy. J. Ceram. Soc. Jpn. 2014, 122, 520–522. [Google Scholar] [CrossRef]

- Williams, J. Reworking the Rainbow: Printing on Ceramics and Glass. Available online: https://screenprintingmag.com/reworking-the-rainbow/amp/ (accessed on 5 June 2025).

- Partyka, J.; Gajek, M. Effect of Firing Condition on Ceramic Glaze Colour Tonality. InterCeram Int. Ceram. Rev. 2012, 61, 270–276. [Google Scholar]

- Santos, T.; Hennetier, L.; Costa, V.A.F.; Costa, L.C. Microwave versus Conventional Porcelain Firing: Colour Analysis. Mater. Chem. Phys. 2022, 275, 125265. [Google Scholar] [CrossRef]

- FERRO GmbH Process Temperature Control Rings (PTCR), Technical Information IS05 n.d. 2019, 1–6. Available online: www.therseruk.com/ferro-rings/ (accessed on 20 June 2025).

- Guan, Y.; Nikawa, Y. Measurement of Temperature-Dependent Complex Permittivity for Materials Using Cylindrical Resonator under Microwave Irradiation. Electron. Commun. Japan Part II Electron. 2007, 90, 1–8. [Google Scholar] [CrossRef]

- Pert, E.; Carmel, Y.; Birnboim, A.; Olorunyolemi, T.; Gershon, D.; Calame, J.; Lloyd, I.K.; Wilson, O.C. Temperature Measurements during Microwave Processing: The Significance of Thermocouple Effects. J. Am. Ceram. Soc. 2001, 84, 1981–1986. [Google Scholar] [CrossRef]

- Santos, T.; Hennetier, L.; Costa, V.A.F.; Costa, L.C. Microwave versus Conventional Porcelain Firing: Temperature Measurement. J. Manuf. Process. 2019, 41, 92–100. [Google Scholar] [CrossRef]

- Santos, T.; Hennetier, L.; Costa, V.A.F.; Costa, L.C. Microwave vs Conventional Porcelain Firing: Macroscopic Properties. Int. J. Appl. Ceram. Technol. 2020, 17, 2277–2285. [Google Scholar] [CrossRef]

- Clark, D.E.; Sutton, W.H. Microwave Processing of Materials. Annu. Rev. Mater. Sci. 1996, 26, 299–331. [Google Scholar] [CrossRef]

- Janney, M.A.; Kimrey, H.D.; Kiggans, J.O. Microwave Processing of Ceramics: Guidelines Used at the Oak Ridge National Laboratory. In Microwave Processing of Materials III; Beatty, R.L., Sutton, W.H., Iskander, M.F., Eds.; Materials Research Society: Pittsburg, PA, USA, 1992; Volume 269, pp. 173–185. ISBN 1558991646. [Google Scholar] [CrossRef]

- Sutton, W.H. Microwave Processing of Ceramics-an Overview. In Microwave Processing of Materials III; Beatty, R.L., Sutton, W.H., Iskander, M.F., Eds.; Materials Research Society: Pittsburg, PA, USA, 1992; Volume 269, pp. 3–20. ISBN 1558991646. [Google Scholar] [CrossRef]

- Keyson, D.; Longo, E.; Vasconcelos, J.S.; Varela, J.A.; Éber, S.; DerMaderosian, A. Síntese e Processamento de Cerâmicas Em Forno de Microondas Doméstico. Cerâmica 2006, 52, 50–56. [Google Scholar] [CrossRef]

- Levinson, M.L. Method of Firing Ceramic Articles Utilizing Microwave Energy. U.S. Patent No. 3,585,258, 15 June 1971. [Google Scholar]

- Metaxas, A.C. Microwave Heating. Power Eng. J. 1991, 5, 237. [Google Scholar] [CrossRef]

- Clark, D.E.; Folz, D.C. What Is Microwave Processing? Available online: https://www.researchgate.net/publication/290488291_Introduction_What_is_Microwave_Processing (accessed on 25 December 2018).

- Thostenson, E.T.; Chou, T.-W. Microwave Processing: Fundamentals and Applications. Compos. Part A Appl. Sci. Manuf. 1999, 30, 1055–1071. [Google Scholar] [CrossRef]

- Oghbaei, M.; Mirzaee, O. Microwave versus Conventional Sintering: A Review of Fundamentals, Advantages and Applications. J. Alloys Compd. 2010, 494, 175–189. [Google Scholar] [CrossRef]

- Rybakov, K.I.; Olevsky, E.A.; Krikun, E.V. Microwave Sintering: Fundamentals and Modeling. J. Am. Ceram. Soc. 2013, 96, 1003–1020. [Google Scholar] [CrossRef]

- Mishra, R.R.; Sharma, A.K. Microwave–Material Interaction Phenomena: Heating Mechanisms, Challenges and Opportunities in Material Processing. Compos. Part A Appl. Sci. Manuf. 2016, 81, 78–97. [Google Scholar] [CrossRef]

- Meredith, R.J.; Metaxas, A.C. Industrial Microwave Heating; The Institution of Engineering and Technology: London, UK, 1988. [Google Scholar]

- Meredith, R. Engineers’ Handbook of Industrial Microwave Heating; Johns, A.T., Warne, D.F., Eds.; Institution of Electrical Engineers: London, UK, 1998; Volume 25, ISBN 0852969163. [Google Scholar]

- Oliveira, F.M.; Azadmanjiri, J.; Wang, X.; Yu, M.; Sofer, Z. Structure Design and Processing Strategies of MXene-Based Materials for Electromagnetic Interference Shielding. Small Methods 2023, 7, 2300112. [Google Scholar] [CrossRef]

- Herrero, M.A.; Kremsner, J.M.; Kappe, C.O. Nonthermal Microwave Effects Revisited: On the Importance of Internal Temperature Monitoring and Agitation in Microwave Chemistry. J. Org. Chem. 2008, 73, 36–47. [Google Scholar] [CrossRef] [PubMed]

- Wroe, R. Microwave-Assisted Firing of Ceramics. Power Eng. J. 1996, 10, 181–183. [Google Scholar] [CrossRef]

- Bao, R.; Yi, J.H.; Peng, Y.D.; Zhang, H.Z. Effects of Microwave Sintering Temperature and Soaking Time on Microstructure of WC-8Co. Trans. Nonferrous Met. Soc. China Engl. Ed. 2013, 23, 372–376. [Google Scholar] [CrossRef]

- Fernandes, J.P.C.; Gunnewiek, R.F.K.; Souto, P.M.; Kiminami, R.H.G.A. Monoqueima de Porcelanas Esmaltadas Em Forno de Micro-Ondas. Cerâmica 2014, 59, 545–550. [Google Scholar] [CrossRef]

- Lerdprom, W.; Zapata-Solvas, E.; Jayaseelan, D.D.; Borrell, A.; Salvador, M.D.; Lee, W.E. Impact of Microwave Processing on Porcelain Microstructure. Ceram. Int. 2017, 43, 13765–13771. [Google Scholar] [CrossRef]

- Santos, T.; Gomes, C.S.F.; Costa, V.A.F.; Costa, L.C. Microwave Versus Conventional Porcelain Firing: Greenware to Biscuit Crystallochemical Transformations. J. Manuf. Sci. Eng. 2021, 143, 121001. [Google Scholar] [CrossRef]

- Santos, T.; Gomes, C.S.F.; Santos, N.F.; Costa, V.A.F.; Costa, L.C. Global Insight into Microwave Stoneware Firing: Crystallochemical Transformations. Ceram. Int. 2022, 48, 21492–21501. [Google Scholar] [CrossRef]

- Moratal, S.; Gil-Flores, L.; Salvador, M.D.; Suarez, M.; Penaranda-Foix, F.L.; Borrell, A. Study of Colored on the Microwave Sintering Behavior of Dental Zirconia Ceramics. J. Asian Ceram. Soc. 2021, 9, 188–196. [Google Scholar] [CrossRef]

- Santos, T.A.C.; Costa, V.A.F.; Costa, L.M.C.M. Microstructure Analysis of Microwave and Conventionally Fired Porcelain. Fire Mater. 2023, 47, 375–385. [Google Scholar] [CrossRef]

- Demirel, M.G.; Tunçdemir, A.R. The Effect of Repeated Firings on the Color Change of Metal Based Ceramics Produced with Different Techniques. Necmettin Erbakan Univ. Dis Hekim. Derg. NEU Dent. J. 2023, 5, 67–74. [Google Scholar] [CrossRef]

- Ramos, P.A.V.; Albuquerque, D.M.S.; Pereira, J.C.F. Enhancing the Efficiency of Brown 24 Pigment Production through Continuous Microwave Heating in Conveyor Belt and Rotary Kiln Systems: A Design and Optimization Study. Energy 2024, 309, 133123. [Google Scholar] [CrossRef]

- García-Baños, B.; Sánchez, J.R.; Godes, J.L.; Leonelli, C.; Catalá-Civera, J.M. Evaluation of Microwave Synthesis of Ceramic Pigments Based on In Situ Dielectric Characterization. Materials 2023, 16, 2976. [Google Scholar] [CrossRef]

- Miguel, E.; Paulo-Redondo, G.; Carda Castelló, J.B.; Nebot-Díaz, I. Comparative Study of the Synthesis of a Red Ceramic Pigment Using Microwave Heat Treatment. Colorants 2023, 2, 518–532. [Google Scholar] [CrossRef]

- LG Electronics Inc. Magnetron 2M226 Model-Specifications. 2015. Available online: https://uniservice.msk.ru/docs/2M226-23TAG.pdf (accessed on 20 June 2025).

- C.M.I., K. Kapyrok Product Information 1.

- Malacara, D.; Daniel, M. Color Vision and Colorimetry: Theory and Applications; SPIE Press: Bellingham, WA, USA, 2002; ISBN 0819442283. [Google Scholar]

- McLaren, K. XIII—The Development of the CIE 1976 (L* A* B*) Uniform Colour Space and Colour-Difference Formula. J. Soc. Dye. Colour. 1976, 92, 338–341. [Google Scholar] [CrossRef]

- Pereira, D.; Santos, T.; Nogueira, R.; Costa, L.C.; Alberto, N. High Temperatures (>1000 °C) Monitoring during the Sintering Process in Microwave Oven Using RFBGs. Opt. Quantum Electron 2016, 48, 304. [Google Scholar] [CrossRef]

- Wiśniewska, K.; Pichór, W.; Kłosek-Wawrzyn, E. Influence of Firing Temperature on Phase Composition and Color Properties of Ceramic Tile Bodies. Materials 2021, 14, 6380. [Google Scholar] [CrossRef] [PubMed]

- Blonski, R.P. Higher-Chroma Zircon Colors for Glaze Applications. In Ceramic Engineering and Science Proceedings; Wachtman, J.B., Jr., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1994; pp. 266–280. [Google Scholar] [CrossRef]

- Durka, T.; Stefanidis, G.D.; Van Gerven, T.; Stankiewicz, A. On the Accuracy and Reproducibility of Fiber Optic (FO) and Infrared (IR) Temperature Measurements of Solid Materials in Microwave Applications. Meas. Sci. Technol. 2010, 21, 1–8. [Google Scholar] [CrossRef]

- Santos, T.; Ramani, M.; Devesa, S.; Batista, C.; Franco, M.; Duarte, I.; Costa, L.; Ferreira, N.; Alves, N.; Pascoal-Faria, P. A 3D-Printed Ceramics Innovative Firing Technique: A Numerical and Experimental Study. Materials 2023, 16, 6236. [Google Scholar] [CrossRef]

| Batch Firing Tests | PTCR’s Position Inside the Microwave Furnace | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| ETH-M1 | 886 | 877 | 887 | 888 | 894 | 906 | 895 | 906 | 893 | 900 | 891 | 881 |

| ETH-M2 | - | 938 | - | - | - | - | 944 | - | - | - | - | - |

| ETH-M3 | 989 | 993 | 996 | 995 | 1003 | 1047 | 1006 | 1035 | 1037 | 1030 | 1006 | 989 |

| ETH-M4 | 1099 | 1098 | error * | 1083 | error | error | 1100 | error | error | error | error | error |

| LTH-M1 | 1163 | 1162 | 1171 | 1164 | 1171 | 1177 | 1169 | 1182 | 1174 | 1171 | 1169 | 1166 |

| Batch Firing Test | Tp (°C) | Time (min) | Average PTCR (°C) | ΔT1 (°C) | ΔT2 (°C) |

|---|---|---|---|---|---|

| ETH-M1 | 900 | 91 | 892 | 25 | 8 |

| ETH-M2 | 950 | 92 | 941 | - | 9 |

| ETH-M3 | 1000 | 85 | 1011 | 58 | -11 |

| ETH-M4 | 1100 | 92 | 1095 | - | 5 |

| LTH-M1 | 1200 | 99 | 1170 | 20 | 30 |

| PTCR Temperature and Position in the Electric Furnace | ||||||||

|---|---|---|---|---|---|---|---|---|

| Batch Firing Test | TT (°C) | Time (min) | 1° PTCR (°C) | 2° PTCR (°C) | 3° PTCR (°C) | Average PTCR (°C) | ΔT1 (°C) | ΔT2 (°C) |

| ETH-E1 | 900 | 85 | 873 | 864 | - | 869 | 5 | 31 |

| ETH-E2 | 950 | 88 | 931 | 909 | - | 921 | 10 | 29 |

| ETH-E3 | 1000 | 91 | 983 | 978 | 958 | 973 | 15 | 27 |

| ETH-E4 | 1050 | 95 | 1047 | - | - | - | - | 3 |

| LTH-E1 | 1050 | 89 | 1043 | - | - | - | - | 7 |

| ETH-E5 | 1100 | 90 | 1087 | 1086 | 1079 | 1084 | 5 | 16 |

| LTH-E2 | 1100 | 92 | 1083 | 1106 | 1010 | 1063 | 56 | 37 |

| LTH-E3 | 1200 | 91 | 1171 | 1171 | - | 1171 | 0 | 29 |

| LTH-E4 | 1250 | 93 | 1212 | - | - | - | - | 38 |

| ETH-Ref.1 ■ | 880 | 90 | <837 ○ | 43 | ||||

| LTH-Ref.1 ■ | 1180 | 90 | 1145 | 1143 | - | 1144 | 1 | 36 |

| Sensor Type | Thermocouple | Pyrometer | PTCR | RFBGs | Decal Color |

|---|---|---|---|---|---|

| Ease of handling | Yes | Yes | Yes | No * | Yes |

| Contact measurement | Both ɸ | No | Both ɸ | Both ɸ | Yes |

| Precision | Yes | Yes | Yes ■ | Yes | Yes |

| Accuracy | +/− ɸ | Yes Ψ | Yes ■ | +/− ɸ | Yes |

| Mapping capability | No | No | Yes | Yes | Yes |

| Flexibility | No | No | Yes | Yes * | Yes |

| EMF interference | Yes | No | No ∆ | No ∆ | No ∆ |

| Temporal delay in measurement | Yes | No | Yes Ƨ | No | Yes |

| Measurement area | Small (at the thermocouple tip) | Small (only at the sample surface spot area) | Relatively volumetric (size of the PTCR) | Area/length of the FBG recording □ | All surface |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, T.; Hennetier, L.; Costa, V.A.F.; Costa, L.C. Temperature Assessment Through Decal Color in Microwave-Fired Porcelain. J. Manuf. Mater. Process. 2025, 9, 213. https://doi.org/10.3390/jmmp9070213

Santos T, Hennetier L, Costa VAF, Costa LC. Temperature Assessment Through Decal Color in Microwave-Fired Porcelain. Journal of Manufacturing and Materials Processing. 2025; 9(7):213. https://doi.org/10.3390/jmmp9070213

Chicago/Turabian StyleSantos, Tiago, Luc Hennetier, Vítor A. F. Costa, and Luís C. Costa. 2025. "Temperature Assessment Through Decal Color in Microwave-Fired Porcelain" Journal of Manufacturing and Materials Processing 9, no. 7: 213. https://doi.org/10.3390/jmmp9070213

APA StyleSantos, T., Hennetier, L., Costa, V. A. F., & Costa, L. C. (2025). Temperature Assessment Through Decal Color in Microwave-Fired Porcelain. Journal of Manufacturing and Materials Processing, 9(7), 213. https://doi.org/10.3390/jmmp9070213