Review of Applications of Digital Twins and Industry 4.0 for Machining

Abstract

1. Introduction

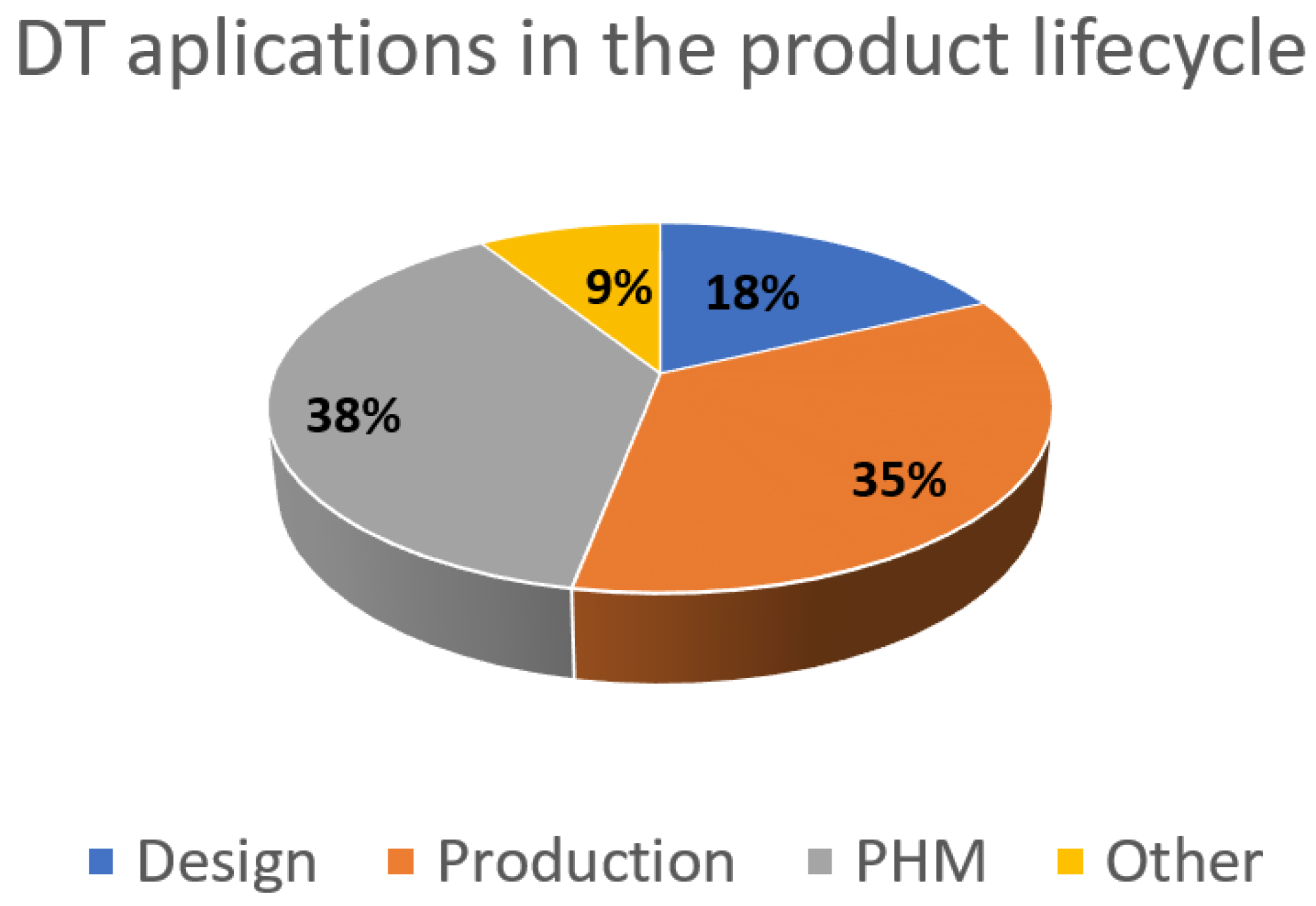

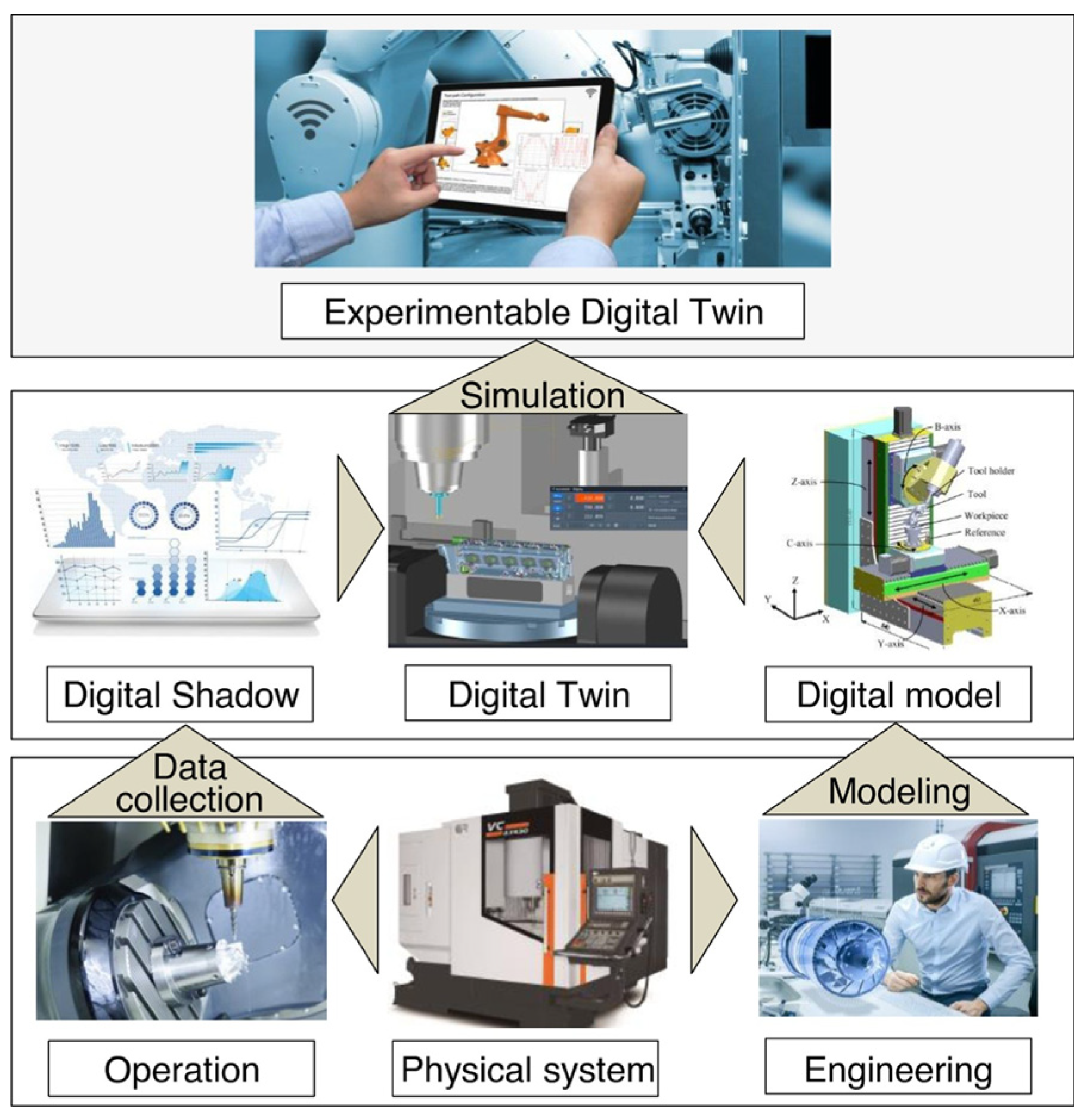

2. Digital Twin Concepts for Smart Manufacturing

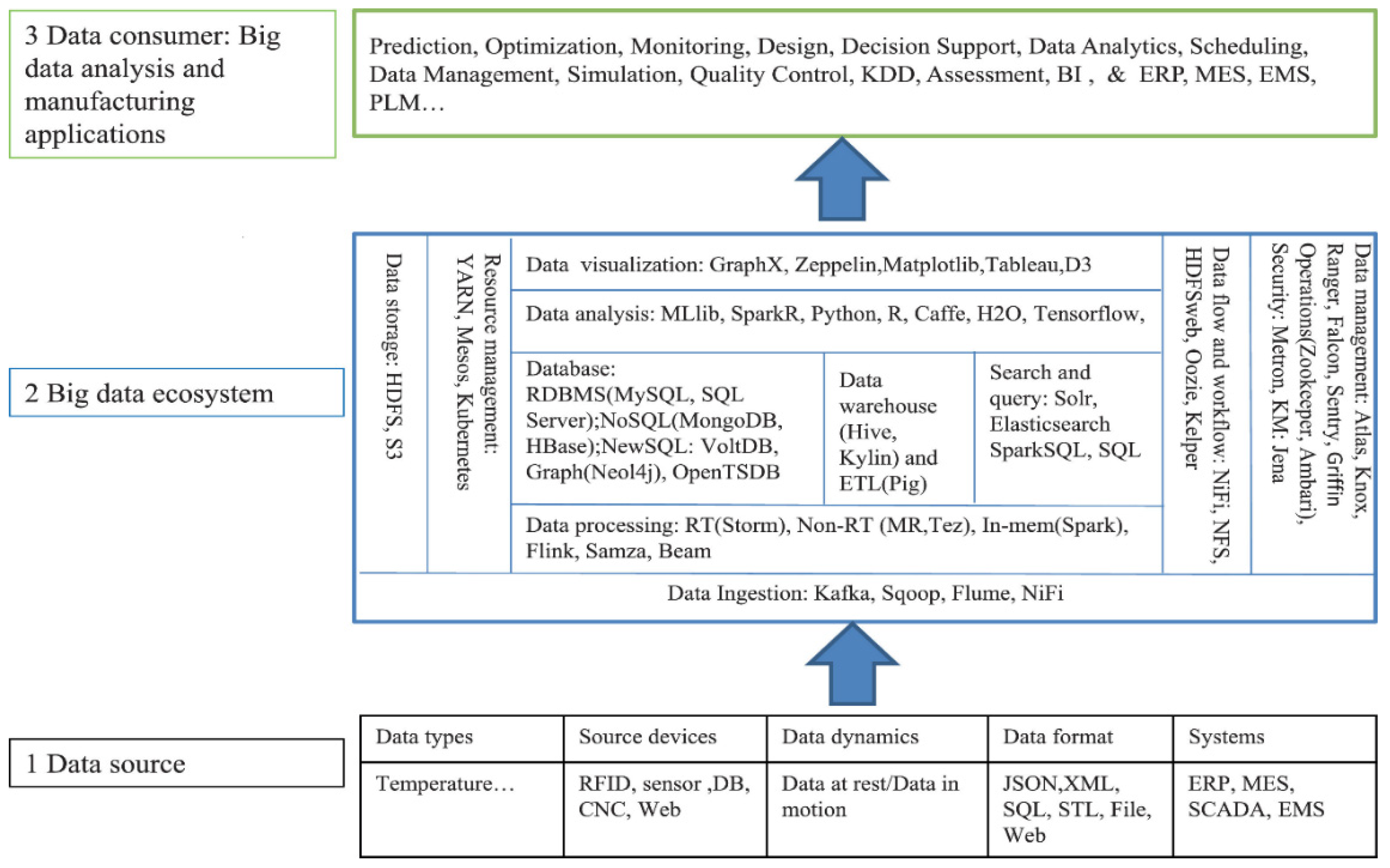

2.1. Big Data (BD)

2.2. Internet of Things (IoT)

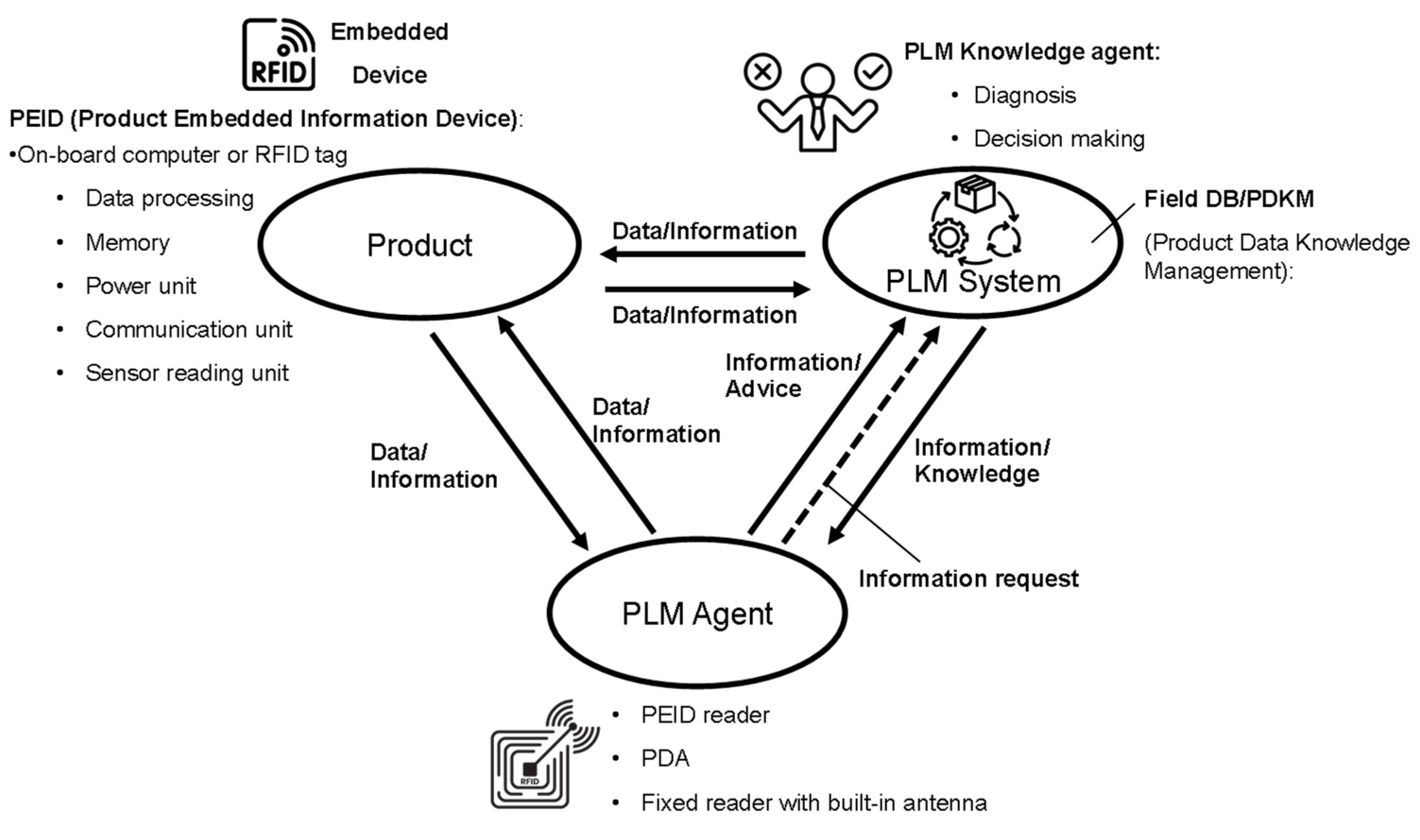

2.3. Product Lifecycle Management (PLM)

2.4. Continuous Acquisition and Lifecycle Support (CALS)

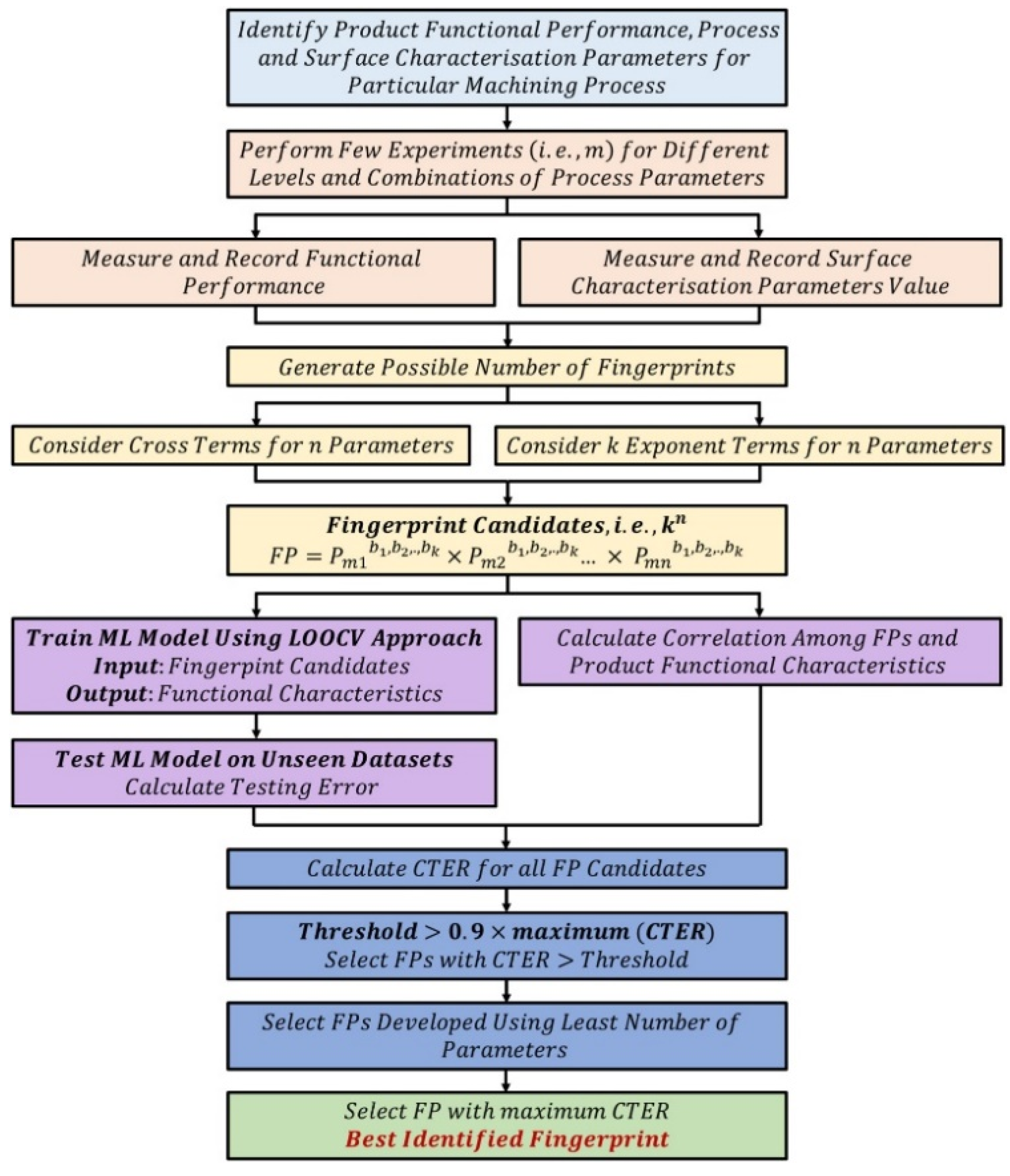

2.5. Machine Learning (ML)

- Digital Twin Aggregate (DTA)

- 2.

- DT Environments (DTEs)

- 3.

- DT Instance (DTI)

- 4.

- DT Prototype (DTP)

3. Applications of DTs in Machining

3.1. BD in Machining

3.2. Internet of Things (IoT) in Machining

3.3. Product Lifecycle Management in Machining

3.4. Continuous Acquisition and Life Cycle Support in Machining

3.5. Machine Learning in Machining

4. Challenges and Future Trends

4.1. Challenges

- Technological Challenges

- Alignment Between Physical and Virtual Systems: Digital models often fail to replicate physical machining processes due to the complexity of operations and the limitations in processing large-scale data in real real-time.

- Data Processing: Real-time data collection frequently results in incomplete or unstructured datasets, which limit the accuracy of virtual models in reflecting operational conditions such as tool wear and vibrations.

- Infrastructure and Security

- Implementation Costs: The adoption of DTs requires advanced networks, cloud storage, and computational resources, which may not be accessible to smaller enterprises.

- Cybersecurity Risks: Storing industrial data in cloud systems increases exposure to cyber threats, requiring robust security measures. As DT systems rely heavily on real-time data transmission, they are particularly vulnerable to potential cyberattacks. Implementing encryption, secure access controls, and regular vulnerability assessments is imperative to mitigate these risks.

- Operational Challenges

- Integration with Existing Processes: Limitations in real-time problem simulation reduce the practical application of DTs for predictive maintenance and process optimization.

- Standardization Issues: A critical barrier to broader adoption is the lack of standardization in communication protocols, such as OPC-UA. Standardization is essential to ensure interoperability between machines, sensors, and software, reducing deployment complexity and improving system compatibility.

- Scalability: Deployment costs and scalability remain significant challenges, especially for Small and Medium-sized Enterprises (SMEs). Tailored, cost-effective solutions such as open-source platforms, government incentives, and flexible subscription models could help overcome these barriers.

4.2. Future Trends

- Hybrid Machining Integration

- Combining CNC machining with additive manufacturing through DTs can enhance flexibility and quality in production processes.

- Predictive Maintenance

- Advanced algorithms for fault detection in real-time can reduce downtime and extend equipment life.

- Automation and Robotics

- Collaborative robots are expected to integrate with DTs more effectively as interfaces and safety mechanisms improve.

- Sustainability

- DTs can support the optimization of machining practices to reduce material waste and energy consumption, aligning with environmental goals.

- Real-Time Simulations

- Models capable of handling complex data in real-time can improve the accuracy of simulations and decision-making processes.

- Data Security

- Enhanced encryption and secure data transmission methods can mitigate risks associated with cyber threats, ensuring safe and reliable DT operations.

- Standardization and Accessibility

- Establishing clear industry standards for communication protocols will streamline data exchange and facilitate smoother integration across diverse manufacturing environments. Furthermore, scalable solutions tailored to SMEs will enable broader adoption of DT technology, fostering innovation and competitiveness in smaller enterprises.

4.3. Research Opportunities

- Model Development and Data Processing: Artificial intelligence can improve the precision of digital models and their ability to process complex datasets.

- Sustainable Practices: Research into energy-efficient processes and materials can support the integration of sustainability into machining.

- Automation Interactions: Exploring the interaction between DTs and autonomous systems can lead to advancements in manufacturing.

5. Conclusions

- The integration of advanced technologies such as BD, IoT, PLM, CALS, and ML within the DT framework highlights the multifaceted nature and expansive potential of these innovations. Together, these technologies enhance manufacturing processes by optimizing operations, improving product quality, and minimizing downtime through predictive maintenance and real-time process adjustments.

- This comprehensive review highlights the significant advantages of DTs, particularly their ability to create virtual replicas of physical systems. This capability facilitates extensive analysis and allows for the testing and refinement of processes in a cost-effective and risk-free virtual environment, which is especially beneficial in machining operations such as turning, milling, drilling, and grinding, where precision and efficiency are paramount.

- Despite these benefits, implementing DTs comes with several challenges. Chief among these is the need for robust and scalable infrastructure capable of handling vast volumes of data generated and processed in real-time. Furthermore, the seamless integration of diverse technological components is imperative to fully realize the benefits of DTs.

- Looking ahead, the future of DTs in smart manufacturing appears promising, with trends suggesting increased adoption and integration across various industries. The focus is likely to be on enhancing sustainability, reducing operational costs, and increasing the flexibility and adaptability of manufacturing processes. As industries continue to evolve, DTs are poised to play a crucial role in driving innovation and maintaining a competitive advantage.

- In summary, DTs represent a significant advancement in the evolution of smart manufacturing, with the potential to redefine industrial practices and foster continuous innovation. Continued research and technological advancements are essential to overcome existing challenges and fully exploit the capabilities of DTs across diverse industrial applications. By embracing these technologies, manufacturers can achieve enhanced efficiency, resilience, and responsiveness in an increasingly dynamic global market.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Singh, M.; Fuenmayor, E.; Hinchy, E.P.; Qiao, Y.; Murray, N.; Devine, D. Digital twin: Origin to future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Springer: Berlin/Heidelberg, Germany, 2016; pp. 85–113. [Google Scholar]

- Tao, F.; Zhang, M. Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Kevin, I.; Wang, K.; Huang, H.; Xu, X. Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput. Integr. Manuf. 2019, 61, 101837. [Google Scholar] [CrossRef]

- Gampfer, F.; Jürgens, A.; Müller, M.; Buchkremer, R. Past, current and future trends in enterprise architecture—A view beyond the horizon. Comput. Ind. 2018, 100, 70–84. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, X.; Zhou, W.; Cheng, T.; Chen, L.; Guo, Z.; Han, B.; Lu, L. Digital twins for additive manufacturing: A state-of-the-art review. Appl. Sci. 2020, 10, 8350. [Google Scholar] [CrossRef]

- Jiang, Y.; Yin, S.; Li, K.; Luo, H.; Kaynak, O. Industrial applications of digital twins. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2021, 379, 20200360. [Google Scholar] [CrossRef]

- Akintseva, A.V.; Pereverzev, P.P.; Omel’chenko, S.V.; Kopyrkin, A.A. Digital Twins and Multifactorial Visualization of Shaping in CNC Plunge-Cut Grinding. Russ. Eng. Res. 2021, 41, 671–675. [Google Scholar] [CrossRef]

- Zakharov, O.V.; Pugin, K.G.; Seliverstova, L.V. Mathematical Model of Cylindrical Parts Assembly using Digital Twins. In Proceedings of the 2022 International Russian Automation Conference (RusAutoCon), Sochi, Russia, 4–10 September 2022; pp. 40–44. [Google Scholar]

- Attia, H.; Sadek, A.; Altintas, Y.; Matsubara, A.; Umbrello, D.; Wegener, K.; Eisseler, R.; Ducobu, F.; Ghadbeigi, H. Physics based models for characterization of machining performance—A critical review. CIRP J. Manuf. Sci. Technol. 2024, 51, 161–189. [Google Scholar] [CrossRef]

- Fu, X.; Li, S.; Song, H.; Lu, Y. Digital Twin-driven multi-scale characterization of machining quality: Current status, challenges, and future perspectives. Robot. Comput. Manuf. 2025, 93, 102902. [Google Scholar] [CrossRef]

- Huang, Z.; Shen, Y.; Li, J.; Fey, M.; Brecher, C. A survey on AI-driven digital twins in industry 4.0: Smart manufacturing and advanced robotics. Sensors 2021, 21, 6340. [Google Scholar] [CrossRef]

- Perno, M.; Hvam, L.; Haug, A. Implementation of digital twins in the process industry: A systematic literature review of enablers and barriers. Comput. Ind. 2022, 134, 103558. [Google Scholar] [CrossRef]

- Liu, S.; Lu, Y.; Li, J.; Song, D.; Sun, X.; Bao, J. Multi-scale evolution mechanism and knowledge construction of a digital twin mimic model. Robot. Comput. Manuf. 2021, 71, 102123. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Afazov, S.; Scrimieri, D. Chatter model for enabling a digital twin in machining. Int. J. Adv. Manuf. Technol. 2020, 110, 2439–2444. [Google Scholar] [CrossRef]

- Zhou, Y.; Xing, T.; Song, Y.; Li, Y.; Zhu, X.; Li, G.; Ding, S. Digital-twin-driven geometric optimization of centrifugal impeller with free-form blades for five-axis flank milling. J. Manuf. Syst. 2021, 58, 22–35. [Google Scholar] [CrossRef]

- Liu, S.; Bao, J.; Zheng, P. A review of digital twin-driven machining: From digitization to intellectualization. J. Manuf. Syst. 2023, 67, 361–378. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2021, 58, 3–21. [Google Scholar] [CrossRef]

- Arunachalam, D.; Kumar, N.; Kawalek, J.P. Understanding big data analytics capabilities in supply chain management: Unravelling the issues, challenges and implications for practice. Transp. Res. Part E Logist. Transp. Rev. 2018, 114, 416–436. [Google Scholar] [CrossRef]

- Chen, H.; Chiang, R.H.L.; Storey, V.C. Business intelligence and analytics: From big data to big impact. MIS Q. 2012, 36, 1165–1188. [Google Scholar] [CrossRef]

- Morabito, V. Big Data and Analytics: Strategic and Organizational Impacts; Springer Nature: Dordrecht, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Yang, H.; Kumara, S.; Bukkapatnam, S.T.; Tsung, F. The internet of things for smart manufacturing: A review. IISE Trans. 2019, 51, 1190–1216. [Google Scholar] [CrossRef]

- Wang, Y.; Kung, L.; Byrd, T.A. Big data analytics: Understanding its capabilities and potential benefits for healthcare organizations. Technol. Forecast. Soc. Change 2018, 126, 3–13. [Google Scholar] [CrossRef]

- Petrenko, S. Big Data Technologies for Monitoring of Computer Security: A Case Study of the Russian Federation; Springer Nature: Dordrecht, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Cui, Y.; Kara, S.; Chan, K.C. Manufacturing big data ecosystem: A systematic literature review. Robot. Comput. Manuf. 2020, 62, 101861. [Google Scholar] [CrossRef]

- Jacoby, M.; Usländer, T. Digital twin and internet of things—Current standards landscape. Appl. Sci. 2020, 10, 6519. [Google Scholar] [CrossRef]

- Mishra, A.; Jha, A.V.; Appasani, B.; Ray, A.K.; Gupta, D.K.; Ghazali, A.N. Emerging technologies and design aspects of next generation cyber physical system with a smart city application perspective. Int. J. Syst. Assur. Eng. Manag. 2023, 14, 699–721. [Google Scholar] [CrossRef]

- Park, V.; Datnow, A. Co-constructing distributed leadership: District and school connections in data-driven decision-making. Sch. Leadersh. Manag. 2009, 29, 477–494. [Google Scholar] [CrossRef]

- Lee, J.; Ardakani, H.D.; Yang, S.; Bagheri, B. Industrial Big Data Analytics and Cyber-physical Systems for Future Maintenance & Service Innovation. Procedia CIRP 2015, 38, 3–7. [Google Scholar] [CrossRef]

- Aheleroff, S.; Xu, X.; Lu, Y.; Aristizabal, M.; Velásquez, J.P.; Joa, B.; Valencia, Y. IoT-enabled smart appliances under industry 4.0: A case study. Adv. Eng. Inform. 2020, 43, 1010. [Google Scholar] [CrossRef]

- Walker, J.; Coraddu, A.; Collu, M.; Oneto, L. Digital twins of the mooring line tension for floating offshore wind turbines to improve monitoring, lifespan, and safety. J. Ocean Eng. Mar. Energy 2021, 8, 1–16. [Google Scholar] [CrossRef]

- Naseem, A.; Ahmad, Y.; Zaman, U.K.U. Product Life Cycle Management and Cloud Manufacturing. In Handbook of Manufacturing Systems and Design: An Industry 4.0 Perspective; Taylor & Francis Group: Abingdon, UK, 2023. [Google Scholar] [CrossRef]

- Gräßler, I.; Pottebaum, J. Generic product lifecycle model: A holistic and adaptable approach for multi-disciplinary product–service systems. Appl. Sci. 2021, 11, 4516. [Google Scholar] [CrossRef]

- Croteau, A.; Léger, P.; Cassivi, L. The role of life cycle concepts in the assessment of interorganizational alignment. Ind. Manag. Data Syst. 2008, 108, 145–161. [Google Scholar] [CrossRef]

- Ren, S.; Zhang, Y.; Liu, Y.; Sakao, T.; Huisingh, D.; Almeida, C.M. A comprehensive review of big data analytics throughout product lifecycle to support sustainable smart manufacturing: A framework, challenges and future research directions. J. Clean. Prod. 2019, 210, 1343–1365. [Google Scholar] [CrossRef]

- Lim, K.Y.H.; Zheng, P.; Chen, C.-H. A state-of-the-art survey of Digital Twin: Techniques, engineering product lifecycle management and business innovation perspectives. J. Intell. Manuf. 2020, 31, 1313–1337. [Google Scholar] [CrossRef]

- Leng, J.; Ruan, G.; Jiang, P.; Xu, K.; Liu, Q.; Zhou, X.; Liu, C. Blockchain-empowered sustainable manufacturing and product lifecycle management in industry 4.0: A survey. Renew. Sustain. Energy Rev. 2020, 132, 110112. [Google Scholar] [CrossRef]

- Kiritsis, D. Closed-loop PLM for intelligent products in the era of the Internet of things. Comput. Des. 2011, 43, 479–501. [Google Scholar] [CrossRef]

- Minagawa, M.; Kusayanagi, S. Study on BIM utilization for design improvement of infrastructure project. Procedia Eng. 2015, 125, 431–437. [Google Scholar] [CrossRef]

- Rigby, B. Continuous acquisition and life-cycle support: The risks and benefits of early supplier involvement in the development process. Logist. Inf. Manag. 1996, 9, 22–26. [Google Scholar] [CrossRef]

- Bu, L.; Zhang, Y.; Liu, H.; Yuan, X.; Guo, J.; Han, S. An IIoT-driven and AI-enabled framework for smart manufacturing system based on three-terminal collaborative platform. Adv. Eng. Inform. 2021, 50, 10137. [Google Scholar] [CrossRef]

- Spinardi, G.; Graham, I.; Williams, R. A comment on Standish et al.: The problem with CALS: Barriers to the development of product data exchange and the US continuous acquisition and life-cycle support programme. Int. J. Prod. Econ. 1996, 44, 201–206. [Google Scholar] [CrossRef]

- Daniyan, I.; Mpofu, K.; Ramatsetse, B.; Gupta, M. Review of life cycle models for enhancing machine tools sustaina-bility: Lessons, trends and future directions. Heliyon 2021, 7, e06790. [Google Scholar] [CrossRef]

- Serres, N.; Tidu, D.; Sankare, S.; Hlawka, F. Environmental comparison of MESO-CLAD® process and conventional machining implementing life cycle assessment. J. Clean. Prod. 2011, 19, 1117–1124. [Google Scholar] [CrossRef]

- Brenner, D.; Kleinert, F.; Imiela, J.; Westkämper, E. Life Cycle Management of Cutting Tools: Comprehensive Acquisition and Aggregation of Tool Life Data. Procedia CIRP 2017, 61, 311–316. [Google Scholar] [CrossRef]

- Xie, Y.; Lian, K.; Liu, Q.; Zhang, C.; Liu, H. Digital twin for cutting tool: Modeling, application and service strategy. J. Manuf. Syst. 2021, 58, 305–312. [Google Scholar] [CrossRef]

- Kundu, P.; Luo, X.; Qin, Y.; Cai, Y.; Liu, Z. A machine learning-based framework for automatic identification of process and product fingerprints for smart manufacturing systems. J. Manuf. Process. 2022, 73, 128–138. [Google Scholar] [CrossRef]

- Tan, D.; Suvarna, M.; Tan, Y.S.; Li, J.; Wang, X. A three-step machine learning framework for energy profiling, activity state prediction and production estimation in smart process manufacturing. Appl. Energy 2021, 291, 116808. [Google Scholar] [CrossRef]

- Fan, Y.; Yang, J.; Chen, J.; Hu, P.; Wang, X.; Xu, J.; Zhou, B. A digital-twin visualized architecture for Flexible Manufacturing System. J. Manuf. Syst. 2021, 60, 176–201. [Google Scholar] [CrossRef]

- Mathupriya, S.; Banu, S.S.; Sridhar, S.; Arthi, B. WITHDRAWN: Digital twin technology on IoT, industries & other smart environments: A survey. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Huang, Z.; Fey, M.; Liu, C.; Beysel, E.; Xu, X.; Brecher, C. Hybrid learning-based digital twin for manufacturing process: Modeling framework and implementation. Robot. Comput. Manuf. 2023, 82, 102545. [Google Scholar] [CrossRef]

- Vishnu, V.; Varghese, K.G.; Gurumoorthy, B. A Data-driven Digital Twin of CNC Machining Processes for Predicting Surface Roughness. Procedia CIRP 2021, 104, 1065–1070. [Google Scholar] [CrossRef]

- Natarajan, S.; Thangamuthu, M.; Gnanasekaran, S.; Rakkiyannan, J. Digital Twin-Driven Tool Condition Monitoring for the Milling Process. Sensors 2023, 23, 5431. [Google Scholar] [CrossRef]

- Jin, L.; Zhai, X.; Wang, K.; Zhang, K.; Wu, D.; Nazir, A.; Jiang, J.; Liao, W.-H. Big data, machine learning, and digital twin assisted additive manufacturing: A review. Mater. Des. 2024, 244, 113086. [Google Scholar] [CrossRef]

- Liu, S.; Bao, J.; Lu, Y.; Li, J.; Lu, S.; Sun, X. Digital twin modeling method based on biomimicry for machining aerospace components. J. Manuf. Syst. 2021, 58, 180–195. [Google Scholar] [CrossRef]

- Corallo, A.; Del Vecchio, V.; Lezzi, M.; Morciano, P. Shop Floor Digital Twin in Smart Manufacturing: A Systematic Literature Review. Sustainability 2021, 13, 12987. [Google Scholar] [CrossRef]

- He, Y.; Guo, J.; Zheng, X. From Surveillance to Digital Twin: Challenges and Recent Advances of Signal Processing for In-dus-trial Internet of Things. IEEE Signal Process. Mag. 2018, 35, 120–129. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, H.; Tian, G.; Liu, X.; Jing, X. Digital twin-based process reuse and evaluation approach for smart process planning. Int. J. Adv. Manuf. Technol. 2019, 100, 1619–1634. [Google Scholar] [CrossRef]

- Kong, T.; Hu, T.; Zhou, T.; Ye, Y. Data Construction Method for the Applications of Workshop Digital Twin System. J. Manuf. Syst. 2021, 58, 323–328. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, L.; Fan, W.; Ji, W.; Mao, L.; Wang, L. Knowledge graph and function block based Digital Twin modeling for robotic machining of large-scale components. Robot. Comput. Manuf. 2023, 85, 102609. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, S.; Yang, B.; Zhu, L.; Liu, F. Big data driven Hierarchical Digital Twin Predictive Remanufacturing paradigm: Architecture, control mechanism, application scenario and benefits. J. Clean. Prod. 2020, 248, 119299. [Google Scholar] [CrossRef]

- Zhang, C.; Zhou, G.; He, J.; Li, Z.; Cheng, W. A data- and knowledge-driven framework for digital twin manufacturing cell. Procedia CIRP 2019, 83, 345–350. [Google Scholar] [CrossRef]

- Dai, S.; Zhao, G.; Yu, Y.; Zheng, P.; Bao, Q.; Wang, W. Ontology-based information modeling method for digital twin creation of as-fabricated machining parts. Robot. Comput. Manuf. 2021, 72, 102173. [Google Scholar] [CrossRef]

- Heo, E.; Yoo, N. Numerical Control Machine Optimization Technologies through Analysis of Machining History Data Using Digital Twin. Appl. Sci. 2021, 11, 3259. [Google Scholar] [CrossRef]

- Wang, P.; Luo, M. A digital twin-based big data virtual and real fusion learning reference framework supported by industrial internet towards smart manufacturing. J. Manuf. Syst. 2021, 58, 16–32. [Google Scholar] [CrossRef]

- Liu, J.; Cao, X.; Zhou, H.; Li, L.; Liu, X.; Zhao, P.; Dong, J. A digital twin-driven approach towards traceability and dynamic control for processing quality. Adv. Eng. Inform. 2021, 50, 101395. [Google Scholar] [CrossRef]

- Zhang, H.; Yan, Q.; Wen, Z. Information modeling for cyber-physical production system based on digital twin and AutomationML. Int. J. Adv. Manuf. Technol. 2020, 107, 1927–1945. [Google Scholar] [CrossRef]

- Qiao, Q.; Wang, J.; Ye, L.; Gao, R.X. Digital twin for machining tool condition prediction. Procedia CIRP 2019, 81, 1388–1393. [Google Scholar] [CrossRef]

- Zhu, Z.; Xi, X.; Xu, X.; Cai, Y. Digital Twin-driven machining process for thin-walled part manufacturing. J. Manuf. Syst. 2021, 59, 453–466. [Google Scholar] [CrossRef]

- Wu, Q.; Mao, Y.; Chen, J.; Wang, C. Application research of digital twin-driven ship intelligent manufacturing system: Pipe machining production line. J. Mar. Sci. Eng. 2021, 9, 338. [Google Scholar] [CrossRef]

- Xi, T.; Benincá, I.M.; Kehne, S.; Fey, M.; Brecher, C. Tool wear monitoring in roughing and finishing processes based on machine internal data. Int. J. Adv. Manuf. Technol. 2021, 113, 3543–3554. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Xie, N.; Kou, R.; Yao, Y. Tool condition prognostic model based on digital twin system. Procedia CIRP 2020, 93, 1502–1507. [Google Scholar] [CrossRef]

- Botkina, D.; Hedlind, M.; Olsson, B.; Henser, J.; Lundholm, T. Digital Twin of a Cutting Tool. Procedia CIRP 2018, 72, 215–218. [Google Scholar] [CrossRef]

- Liu, J.; Du, X.; Zhou, H.; Liu, X.; Li, L.E.; Feng, F. A digital twin-based approach for dynamic clamping and positioning of the flexible tooling system. Procedia CIRP 2019, 80, 746–749. [Google Scholar] [CrossRef]

- Hänel, A.; Schnellhardt, T.; Wenkler, E.; Nestler, A.; Brosius, A.; Corinth, C.; Fay, A.; Ihlenfeldt, S. The development of a digital twin for machining processes for the application in aerospace industry. Procedia CIRP 2020, 93, 1399–1404. [Google Scholar] [CrossRef]

- Cheng, D.-J.; Zhang, J.; Hu, Z.-T.; Xu, S.-H.; Fang, X.-F. A Digital Twin-Driven Approach for On-line Controlling Quality of Marine Diesel Engine Critical Parts. Int. J. Precis. Eng. Manuf. 2020, 21, 1821–1841. [Google Scholar] [CrossRef]

- Zhao, L.; Fang, Y.; Lou, P.; Yan, J.; Xiao, A. Cutting Parameter Optimization for Reducing Carbon Emissions Using Digital Twin. Int. J. Precis. Eng. Manuf. 2021, 22, 933–949. [Google Scholar] [CrossRef]

- Liu, C.; Hong, X.; Zhu, Z.; Xu, X. Machine Tool Digital Twin: Modelling Methodology and Applications. 2018. Available online: https://www.researchgate.net/publication/332606463 (accessed on 19 June 2025).

- Tong, X.; Liu, Q.; Pi, S.; Xiao, Y. Real-time machining data application and service based on IMT digital twin. J. Intell. Manuf. 2020, 31, 1113–1132. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, W. Application framework of digital twin-driven product smart manufacturing system: A case study of aeroengine blade manufacturing. Int. J. Adv. Robot. Syst. 2019, 16, 1729881419880663. [Google Scholar] [CrossRef]

- Armendia, M.; Cugnon, F.; Berglind, L.; Ozturk, E.; Gil, G.; Selmi, J. Evaluation of Machine Tool Digital Twin for machining operations in industrial environment. Procedia CIRP 2019, 82, 231–236. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, C.; Xu, X. Visualisation of the Digital Twin data in manufacturing by using Augmented Reality. Procedia CIRP 2019, 81, 898–903. [Google Scholar] [CrossRef]

- Liu, S.; Lu, S.; Li, J.; Sun, X.; Lu, Y.; Bao, J. Machining process-oriented monitoring method based on digital twin via augmented reality. Int. J. Adv. Manuf. Technol. 2021, 113, 3491–3508. [Google Scholar] [CrossRef]

- Liu, J.; Ma, C.; Gui, H.; Wang, S. A four-terminal-architecture cloud-edge-based digital twin system for thermal error control of key machining equipment in production lines. Mech. Syst. Signal Process. 2022, 166, 108488. [Google Scholar] [CrossRef]

- Luo, W.; Hu, T.; Ye, Y.; Zhang, C.; Wei, Y. A hybrid predictive maintenance approach for CNC machine tool driven by Digital Twin. Robot. Comput. Manuf. 2020, 65, 101974. [Google Scholar] [CrossRef]

- Cao, X.; Zhao, G.; Xiao, W. Digital Twin–oriented real-time cutting simulation for intelligent computer numerical control machining. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 236, 5–15. [Google Scholar] [CrossRef]

- Jain, S.; Shao, G.; Shin, S.-J. Manufacturing data analytics using a virtual factory representation. Int. J. Prod. Res. 2017, 55, 5450–5464. [Google Scholar] [CrossRef]

- Bustillo, A.; Reis, R.; Machado, A.R.; Pimenov, D.Y. Improving the accuracy of machine-learning models with data from machine test repetitions. J. Intell. Manuf. 2022, 33, 203–221. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Bustillo, A.; Mikolajczyk, T. Artificial intelligence for automatic prediction of required surface roughness by monitoring wear on face mill teeth. J. Intell. Manuf. 2018, 29, 1045–1061. [Google Scholar] [CrossRef]

- Walia, A.S.; Srivastava, V.; Rana, P.S.; Somani, N.; Gupta, N.K.; Singh, G.; Pimenov, D.Y.; Mikolajczyk, T.; Khanna, N. Prediction of tool shape in electrical discharge machining of en31 steel using machine learning techniques. Metals 2021, 11, 1668. [Google Scholar] [CrossRef]

- Ladj, A.; Wang, Z.; Meski, O.; Belkadi, F.; Ritou, M.; Da Cunha, C. A knowledge-based Digital Shadow for machining industry in a Digital Twin perspective. J. Manuf. Syst. 2021, 58, 168–179. [Google Scholar] [CrossRef]

- Deebak, B.D.; Al-Turjman, F. Digital-twin assisted: Fault diagnosis using deep transfer learning for machining tool condition. Int. J. Intell. Syst. 2021, 37, 10289–10316. [Google Scholar] [CrossRef]

- Ma, C.; Gui, H.; Liu, J. Self learning-empowered thermal error control method of precision machine tools based on digital twin. J. Intell. Manuf. 2021, 34, 695–717. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, X.; Wan, X.; Zhou, S.; Gao, Z. Digital twin-driven surface roughness prediction and process parameter adaptive optimization. Adv. Eng. Inform. 2022, 51, 101470. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, S.; Wang, Z.; Wang, S.; Ma, C.; Yang, B. Surface roughness stabilization method based on digital twin-driven machining parameters self-adaption adjustment: A case study in five-axis machining. J. Intell. Manuf. 2020, 33, 943–952. [Google Scholar] [CrossRef]

- Sun, C.; Dominguez-Caballero, J.; Ward, R.; Ayvar-Soberanis, S.; Curtis, D. Machining cycle time prediction: Data-driven modelling of machine tool feedrate behavior with neural networks. Robot. Comput. Manuf. 2022, 75, 102293. [Google Scholar] [CrossRef]

- Ward, R.; Sun, C.; Dominguez-Caballero, J.; Ojo, S.; Ayvar-Soberanis, S.; Curtis, D.; Ozturk, E. Machining Digital Twin using real-time model-based simulations and lookahead function for closed loop machining control. Int. J. Adv. Manuf. Technol. 2021, 117, 3615–3629. [Google Scholar] [CrossRef]

| Ref. | Type of Machining | Application | Technologies Applied | Key Benefits |

|---|---|---|---|---|

| [59] | General Machining | Data gathering and real-time representation using DT | Cloud storage, 5G technologies, advanced sensors | Improved fidelity, reduced production time, and tool damage |

| [65] | CNC Machining | Tool path optimization and vibration analysis | Big Data (BD), DT, numerical control | Reduced processing time by 50%, improved rentability |

| [53] | Milling | Surface roughness prediction using BD-driven DT | IoT, BD, machine learning | Enhanced surface quality |

| [60] | CNC Machining Centers | Data construction for DT applications | Random Forest algorithm, BD, hierarchical data representation | Improved tool wear and pre-load condition modeling with 99.7% accuracy |

| [62] | Remanufacturing | Predictive remanufacturing framework using BD-driven DT | IoT, machine learning, CPS, VR/AR, advanced fusion sensors | Optimized operations, reduced uncertainties, greener manufacturing practices |

| [63] | Cellular Manufacturing | DT manufacturing cell framework for responsive Just-In-Time (JIT) operations | BD, IoT, deep learning, milling and turning machines, robotic material handling | Increased flexibility, reduced production cost, better optimization strategies |

| [64] | Aviation Machining | Virtualization of machined parts for DT modeling | Machine learning, dimensional and tolerance data, inspection data | Improved production lifecycle optimization |

| Ref. | Type of Machining | Application | Technologies Used | Key Benefits |

|---|---|---|---|---|

| [58] | General machining | IoT integration with Digital Twin (DT) | Sensors, real-time data gathering | Precise representation of physical parts, enhanced data variability for Big Data (BD) processing |

| [67] | Milling and quality monitoring | IoT-enabled framework for dynamic control and processing in DT manufacturing | IoT, ERP, CAPP, MES, perception database, process knowledge database, quality inspection algorithm library | Improved process monitoring, quality assurance, and dynamic control during machining |

| [68] | Turbine blade machining | Expansion of IoT to ICT for turbine blade manufacturing | IoT, Virtual Reality (VR), Big Data, 5G, Artificial Intelligence (AI) | Enhanced process control and management from raw material forging to final machining steps |

| [69] | Milling | Tool condition prediction model using IoT and DT | Deep Stacked GRU, vibration, acoustic emission, force sensors | Real-time tool wear prediction, improved accuracy over standard machine learning methods |

| [70] | Thin-walled machining (e.g., turbine parts) | Thin-walled part machining using IoT-driven DT | IoT, 2D image to 3D space conversion, ANSYS simulation, force and vibration sensors | Optimization of cutting forces, machining parameters, and tool paths for high-complexity parts |

| [71] | Pipe cutting | Pipe-cutting production line optimization | IoT, MySQL database, neural networks | Real-time data gathering and optimized Gantt chart generation, leading to increased process efficiency |

| [72] | Roughing and finishing milling | IoP (Internet of Production) for roughing and finishing milling processes | Built-in sensors, numerical control data | Process quality improvement from 30% to over 70% through real-time data gathering and modeling |

| Ref. | Type of Machining | Application | Technologies Used | Key Benefits |

|---|---|---|---|---|

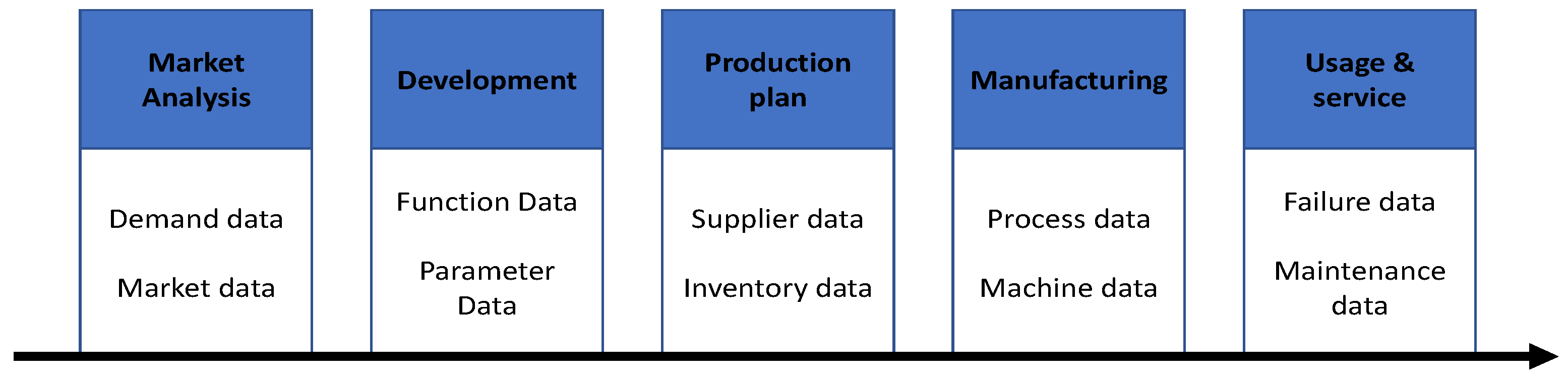

| [73] | General machining | Product lifecycle management with Digital Twin (DT) | DT, market analysis, process monitoring, predictive modeling | Improved reliability, flexibility, and responsiveness to market needs |

| [74] | Design and manufacturing | Lifecycle divided into design, manufacturing, service, and retirement stages | DT, task clarification, conceptual design, embodiment design, detail design | Enhanced decision-making, self-aware machines, and intelligent production control |

| [75] | Tool lifecycle management | Data-driven management of cutting tools | DT, force, thermal, acoustic emission, electric power, and vibration sensors | Optimized tool development, manufacturing, usage, and service; improved failure prediction and maintenance |

| [76] | Cylinder head machining | Digital twin-based modeling of cutting tools | ISO 13399, CAD, CAM, ToolMaker®, machine learning | Increased productivity (up to 15%), optimized machining parameters, and reduced setup time |

| [77] | Cylinder head clamping and positioning | Dynamic clamping and positioning system for flexible tooling | DT, pressure sensors, hydraulic cylinders, data acquisition, fusion, and decision layers | Reduced setup time (from 30 to 20 min), improved reliability and flexibility |

| [78] | Aerospace component machining | Production lifecycle control for machining stainless steel levers | DT, acoustic emission, vibration, and force sensors | Improved cutting force modeling, tool life, and production time |

| [79] | Marine diesel engine machining | Online quality control of machining processes | DT, workshop-wide process modeling | Accurate tool life prediction (mean average error of 5.223%), enhanced process representation |

| [80] | Milling of S45C carbon steel | Optimization for energy efficiency and reduced carbon emissions | DT, spindle speed, feed rate, cutting forces, processing time | Decreased carbon emissions by 6.1%, improved energy efficiency |

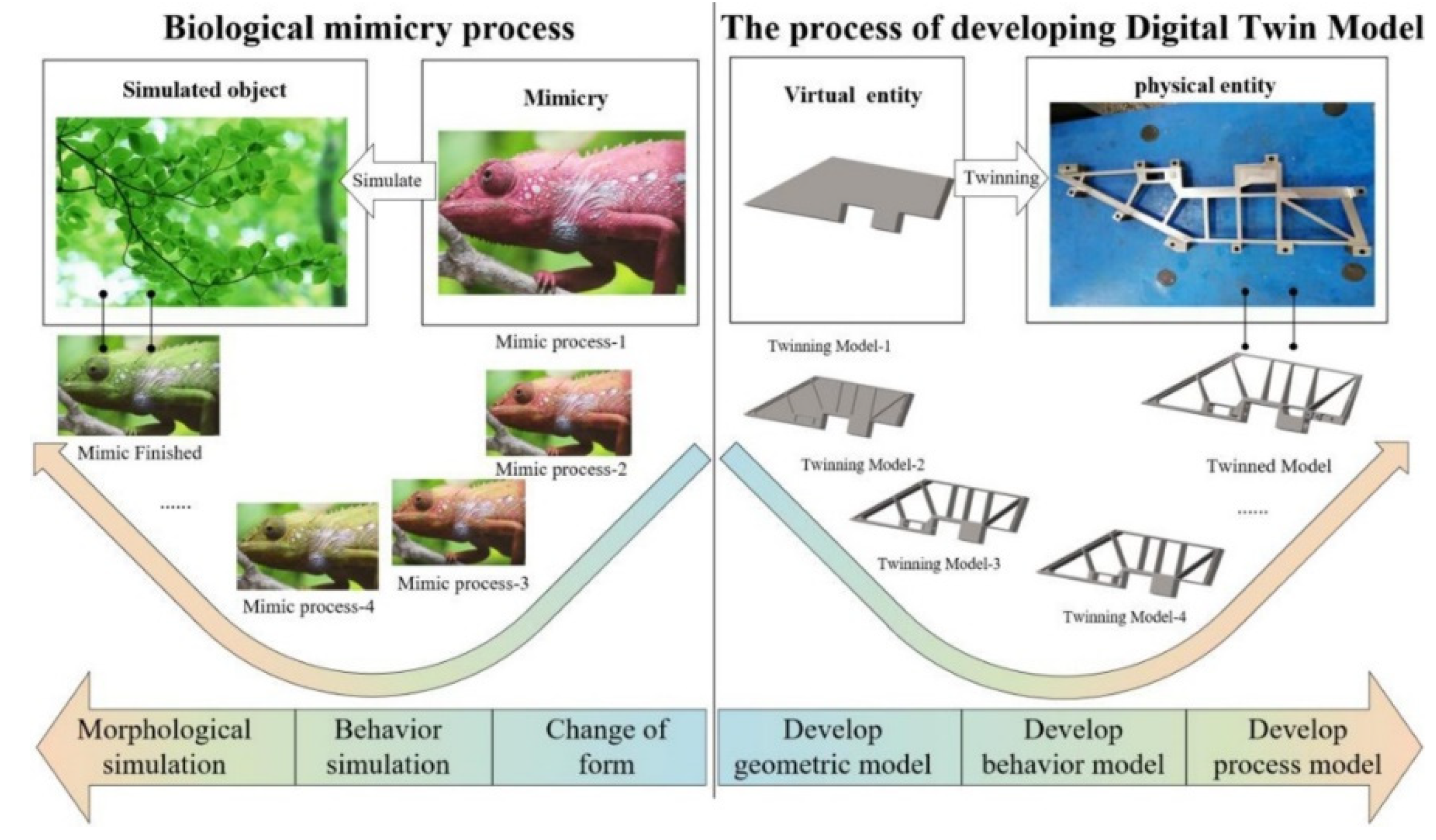

| [56] | Missile air rudder machining | Biomimicry-based digital twin modeling | DT sub-models, geometry, behavior, and context evaluation | Simulation of machine/tool pairs, enhanced process modeling, but challenges with simulation lag and modeling speed |

| Ref. | Type of Machining | Application | Technologies Used | Key Benefits |

|---|---|---|---|---|

| [81] | Machine tool condition monitoring | Real-time web-based monitoring of machining forces | DT, web-based monitoring | Enhanced system reliability through continuous monitoring |

| [82] | Turbine blade machining | Intelligent Machine Tool (IMT) for real-time process optimization | DT, multisensory fusion: encoders, torque, current, voltage, accelerometers, acoustic emission, cameras | Improved surface finish, reduced contour errors, and vibration control |

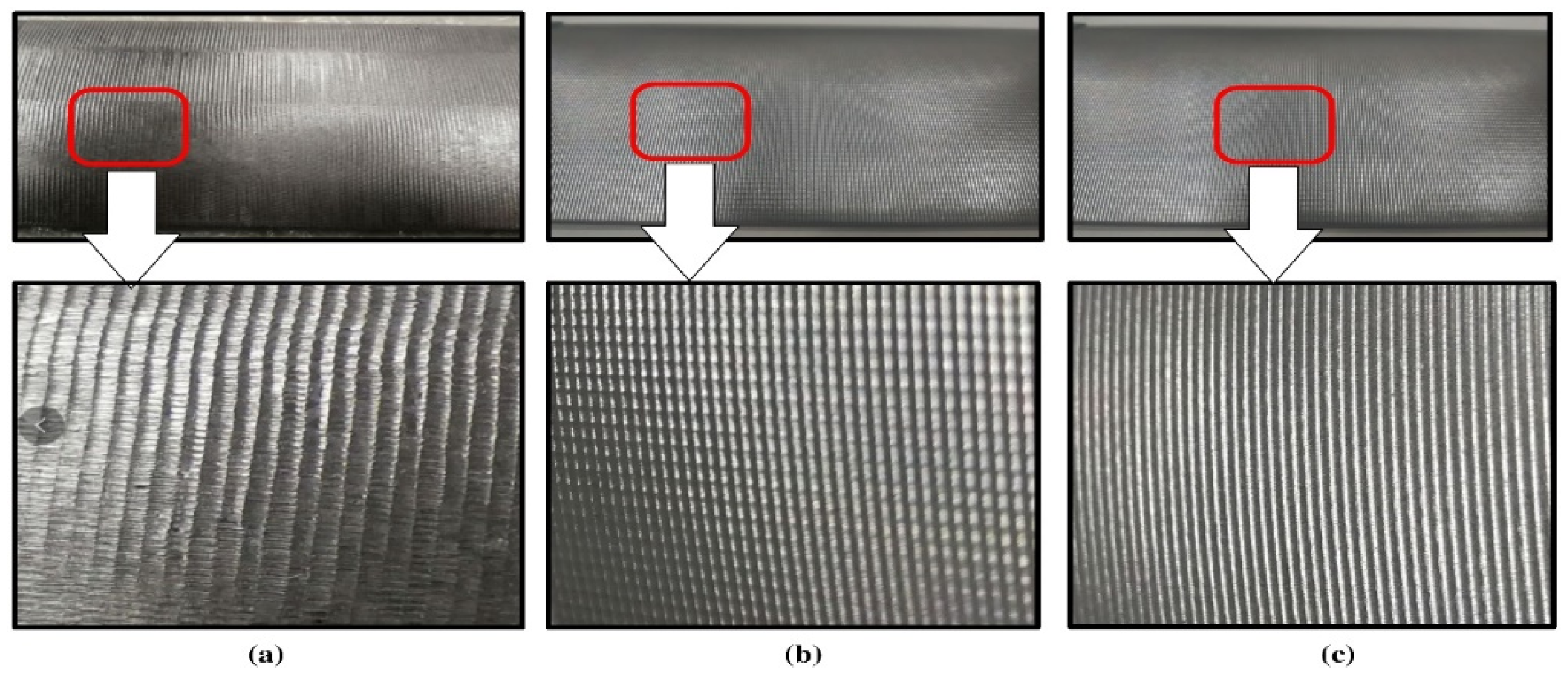

| [83] | Turbine blade machining | Application of DT feedback for surface finish optimization | DT, real-time feedback | Enhanced machining accuracy and quality |

| [84] | Milling process | DT for industrial milling process lifecycle optimization | DT, 3D multi-body simulation, finite element method | Decreased machining time (4%), setup time (11%), and tooling costs (1.1%) |

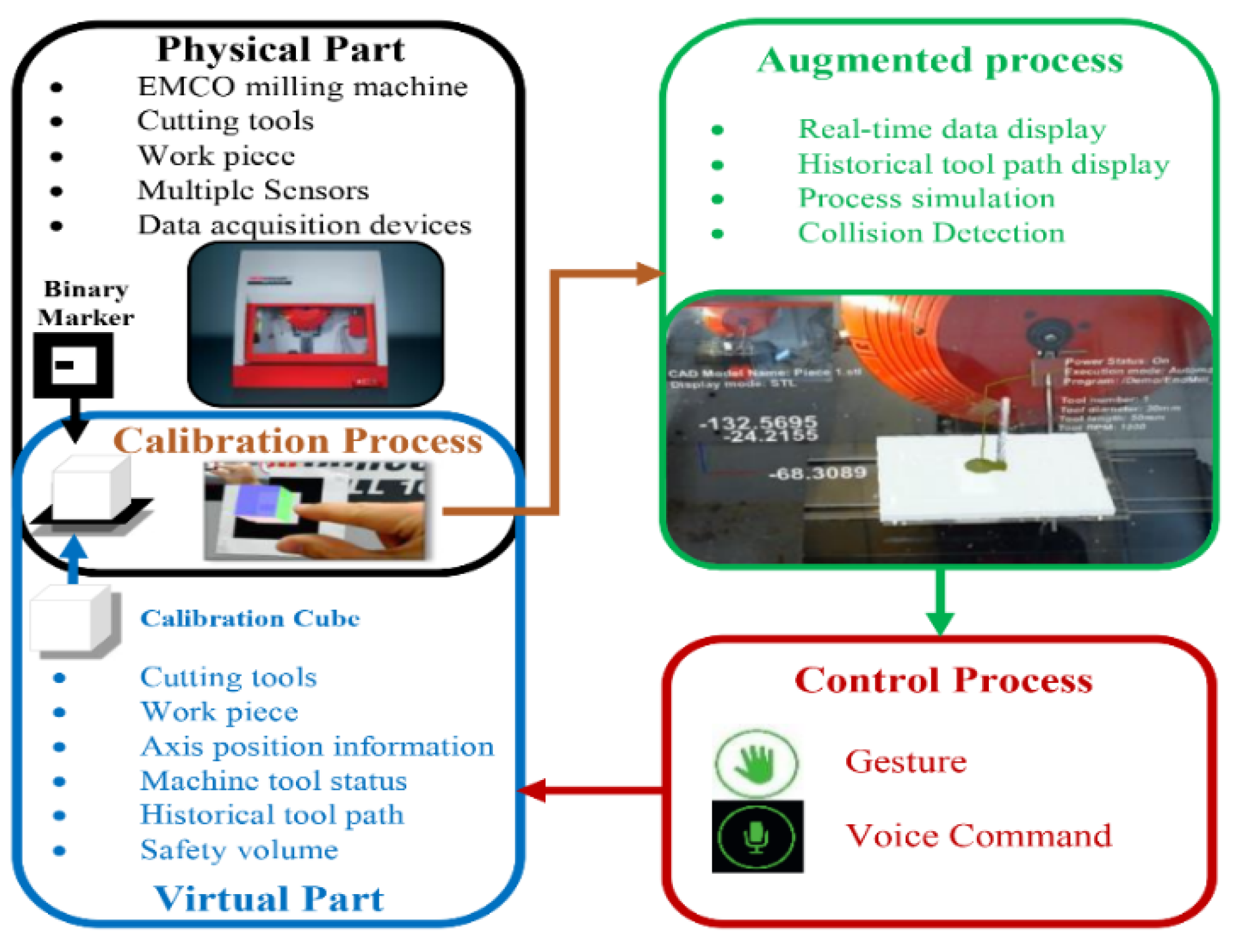

| [85] | General machining | Visualization of DT data using Augmented Reality (AR) | AR, real-time data calibration | Increased process awareness and interactive control via voice commands or gestures |

| [86] | Carrier box machining | DT-driven augmented reality for process monitoring | DT, AR, CAD/CAM data, force, temperature, vibration sensors | Improved system responsiveness and interactive process control |

| [87] | Thermal error control in machining | Four-terminal architecture for thermal error prediction | DT, extended short-term memory network, sensors (stress, audio, temperature, deformation, etc.), GPU computing | Thermal error prediction accuracy exceeding 90%, improved process reliability |

| [88] | CNC machining tool maintenance | Hybrid predictive maintenance approach | DT, Multiphysics simulation, data-driven and model-based techniques | Increased DT fidelity, reduced model deviation |

| [89] | CNC machining | Real-time cutting simulation and CNC control | DT, CAD/CAM data, real-time monitoring | Improved machinability monitoring; identified need for simulation update improvements |

| Ref. | Application | Machine Learning Techniques | Key Benefits |

|---|---|---|---|

| [90] | Data processing for DT modeling | General ML techniques | Improved data concatenation and processing for DT modeling |

| [91] | Machine test repetitions for model accuracy improvement | No specific technique mentioned | Increased accuracy of ML models by utilizing repeated testing |

| [92] | Surface roughness prediction | Random forest, decision tree, neural network, genetic algorithm, generalized linear model | Correlation of indirect variables (e.g., power consumption) with machinability standards |

| [93] | Tool shape prediction in electrical discharge machining | Machine learning techniques (specific type not mentioned) | Enhanced prediction capabilities for tool shape in non-conventional machining |

| [94] | Digital shadow for aeronautic machining | Gaussian Mixture Model | Effective tool failure detection, chatter reduction, and faulty programming correction |

| [95] | Fault diagnosis in milling and drilling processes | Deep Transfer Learning (DTL) | Improved fault diagnosis accuracy (92.33%) compared to traditional deep neural networks |

| [96] | Self-learning DT framework for thermal error control | Long Short-Term Memory (LSTM), neural network, Bayesian algorithm | Self-learning error prediction model with reduced incoming data errors |

| [97] | Surface roughness prediction and adaptive optimization | Improved Particle Swarm Optimization-Generalized Regression Neural Networks | Reduced surface roughness and tool wear through adaptive optimization |

| [98] | Roughness stabilization in 5-axis machining | Pigeon-inspired Optimization, Support Vector Machine | Prediction errors below 9%, improved machining parameter adjustment |

| [99] | Feed rate and cycle time prediction | Neural networks | Accurate cycle time prediction (up to 90%) using feed rate, tool acceleration, and toolpath |

| [100] | Real-time DT-based machining control | Adaptive feed rate control, residual stress simulation, chatter prediction | Enhanced closed-loop machining control with real-time simulations |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Silva, L.R.R.; Pimenov, D.Y.; da Silva, R.B.; Ercetin, A.; Giasin, K. Review of Applications of Digital Twins and Industry 4.0 for Machining. J. Manuf. Mater. Process. 2025, 9, 211. https://doi.org/10.3390/jmmp9070211

da Silva LRR, Pimenov DY, da Silva RB, Ercetin A, Giasin K. Review of Applications of Digital Twins and Industry 4.0 for Machining. Journal of Manufacturing and Materials Processing. 2025; 9(7):211. https://doi.org/10.3390/jmmp9070211

Chicago/Turabian Styleda Silva, Leonardo Rosa Ribeiro, Danil Yurievich Pimenov, Rosemar Batista da Silva, Ali Ercetin, and Khaled Giasin. 2025. "Review of Applications of Digital Twins and Industry 4.0 for Machining" Journal of Manufacturing and Materials Processing 9, no. 7: 211. https://doi.org/10.3390/jmmp9070211

APA Styleda Silva, L. R. R., Pimenov, D. Y., da Silva, R. B., Ercetin, A., & Giasin, K. (2025). Review of Applications of Digital Twins and Industry 4.0 for Machining. Journal of Manufacturing and Materials Processing, 9(7), 211. https://doi.org/10.3390/jmmp9070211