Cutting Fluid Effectiveness in the High-Speed Finish Machining of Inconel 718 Using a Whisker-Reinforced Ceramic Tool

Abstract

1. Introduction

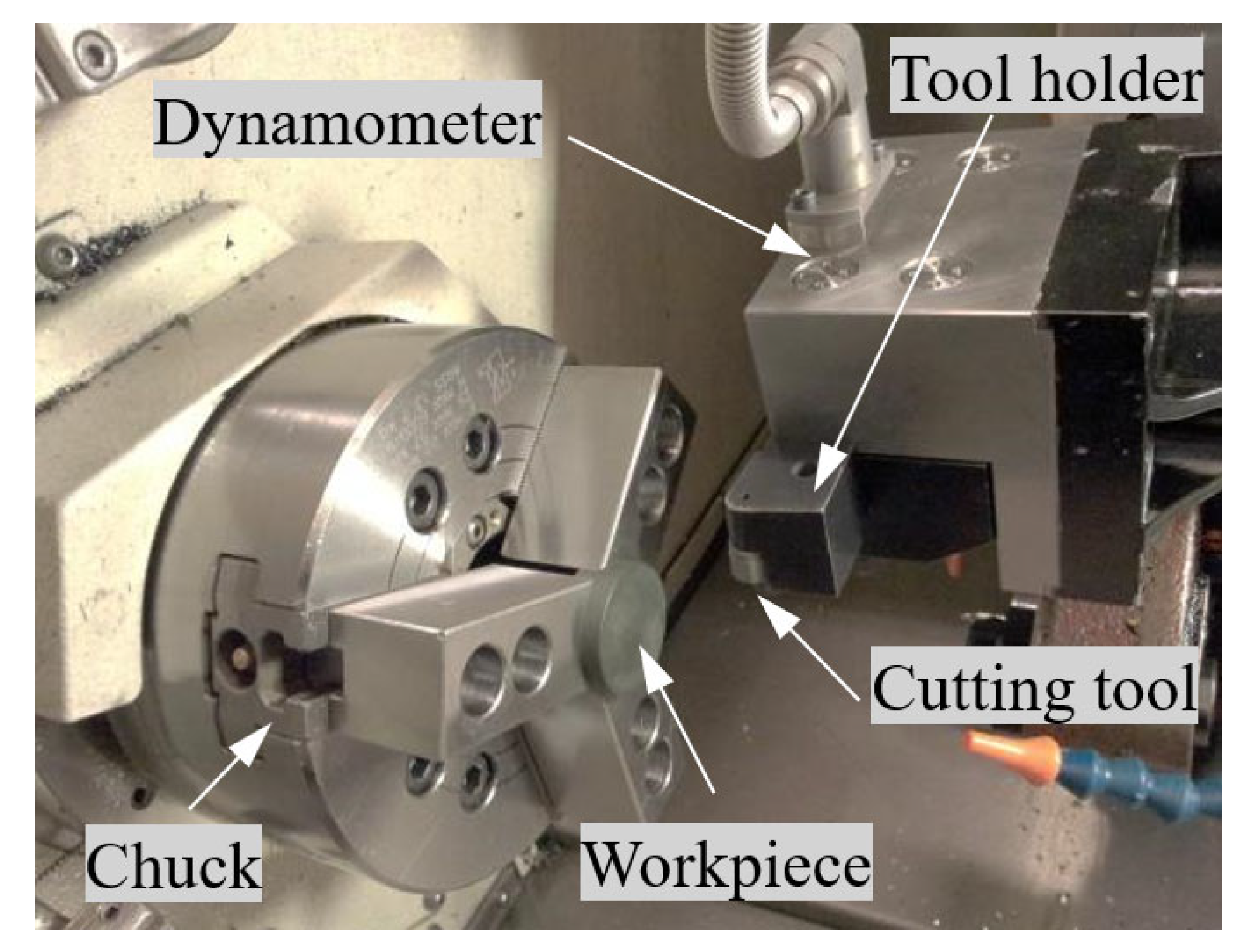

2. Materials and Experimental Procedures

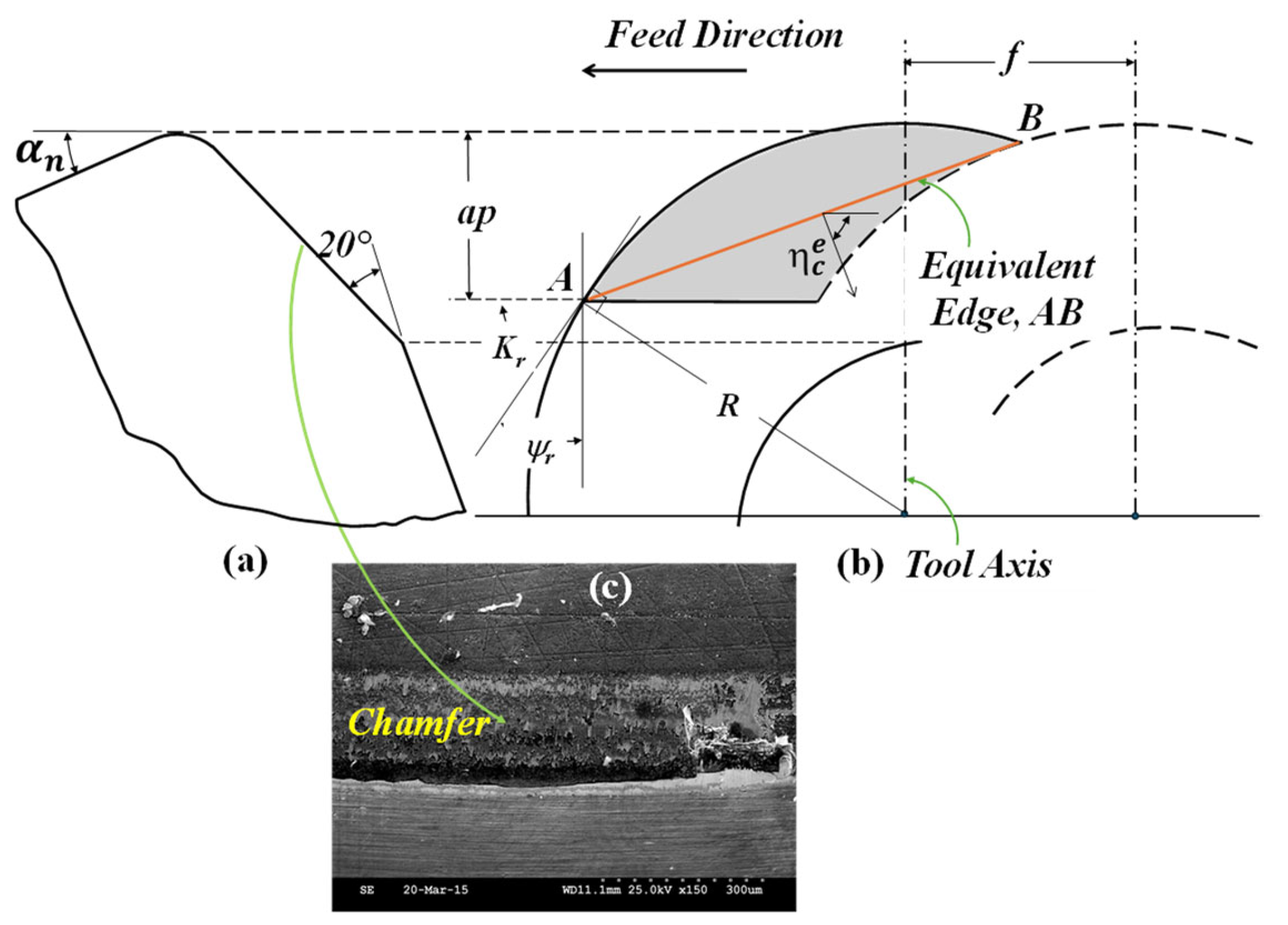

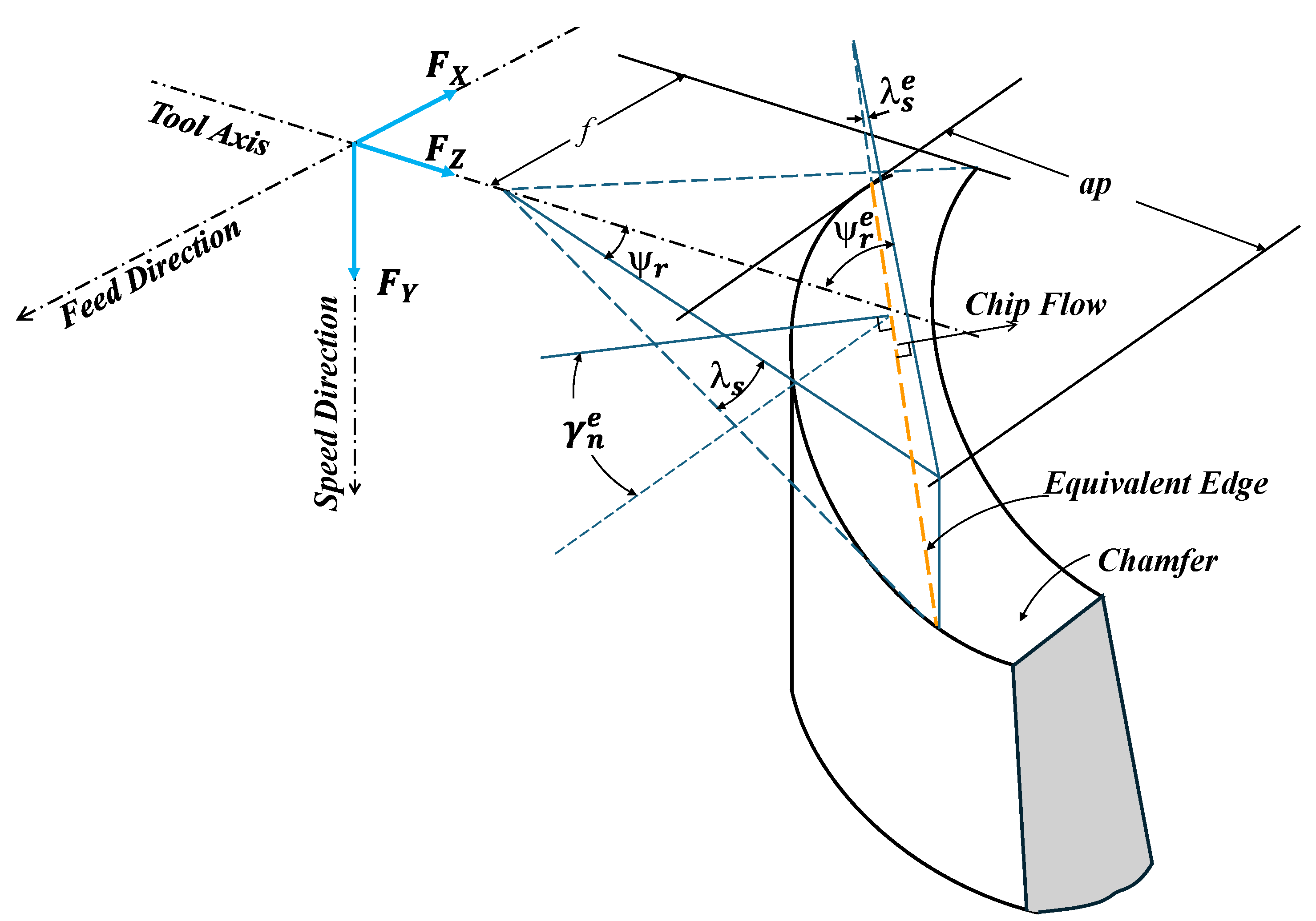

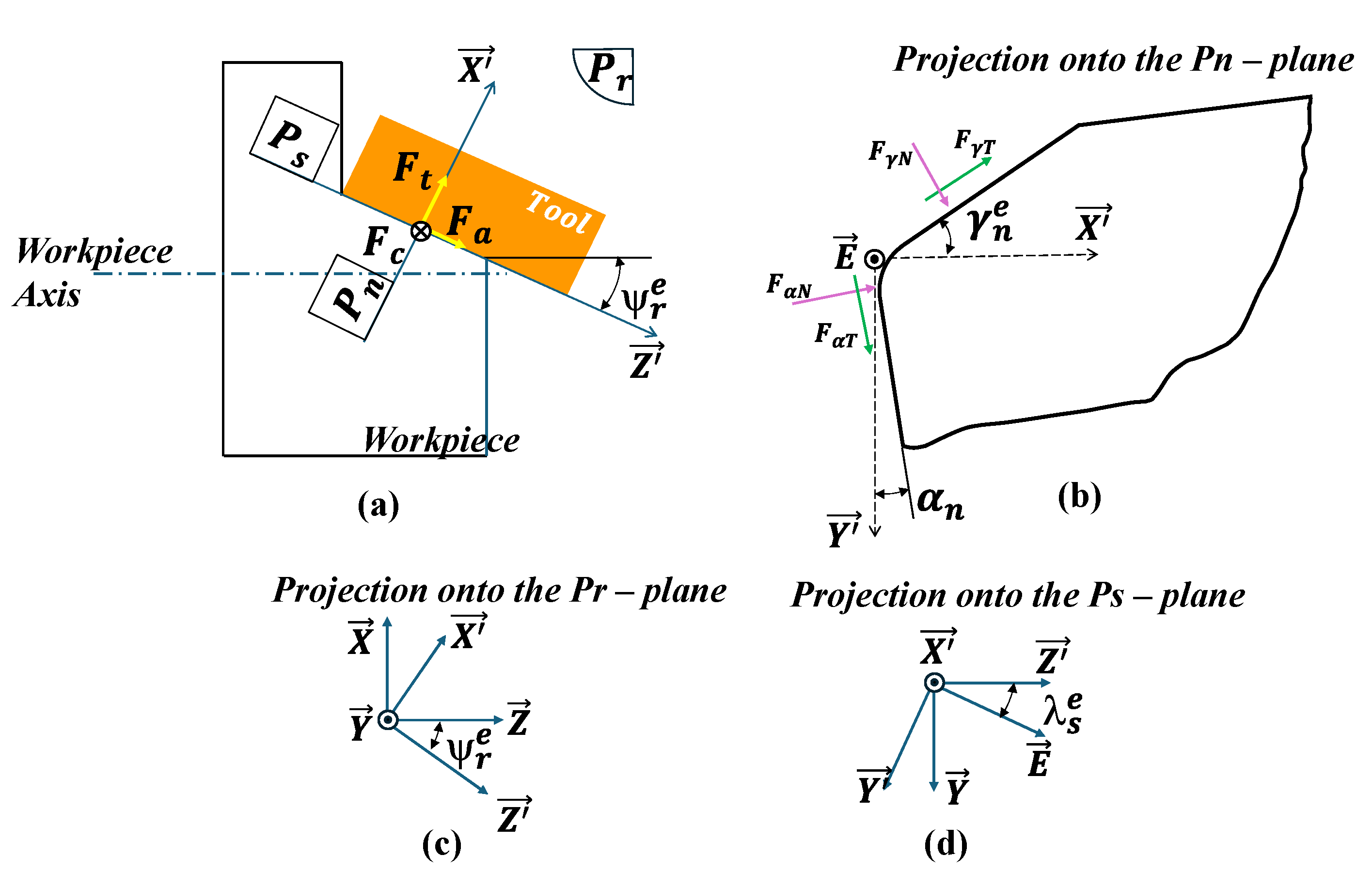

3. Friction Modeling for Turning with a Round Chamfered Insert

4. Results

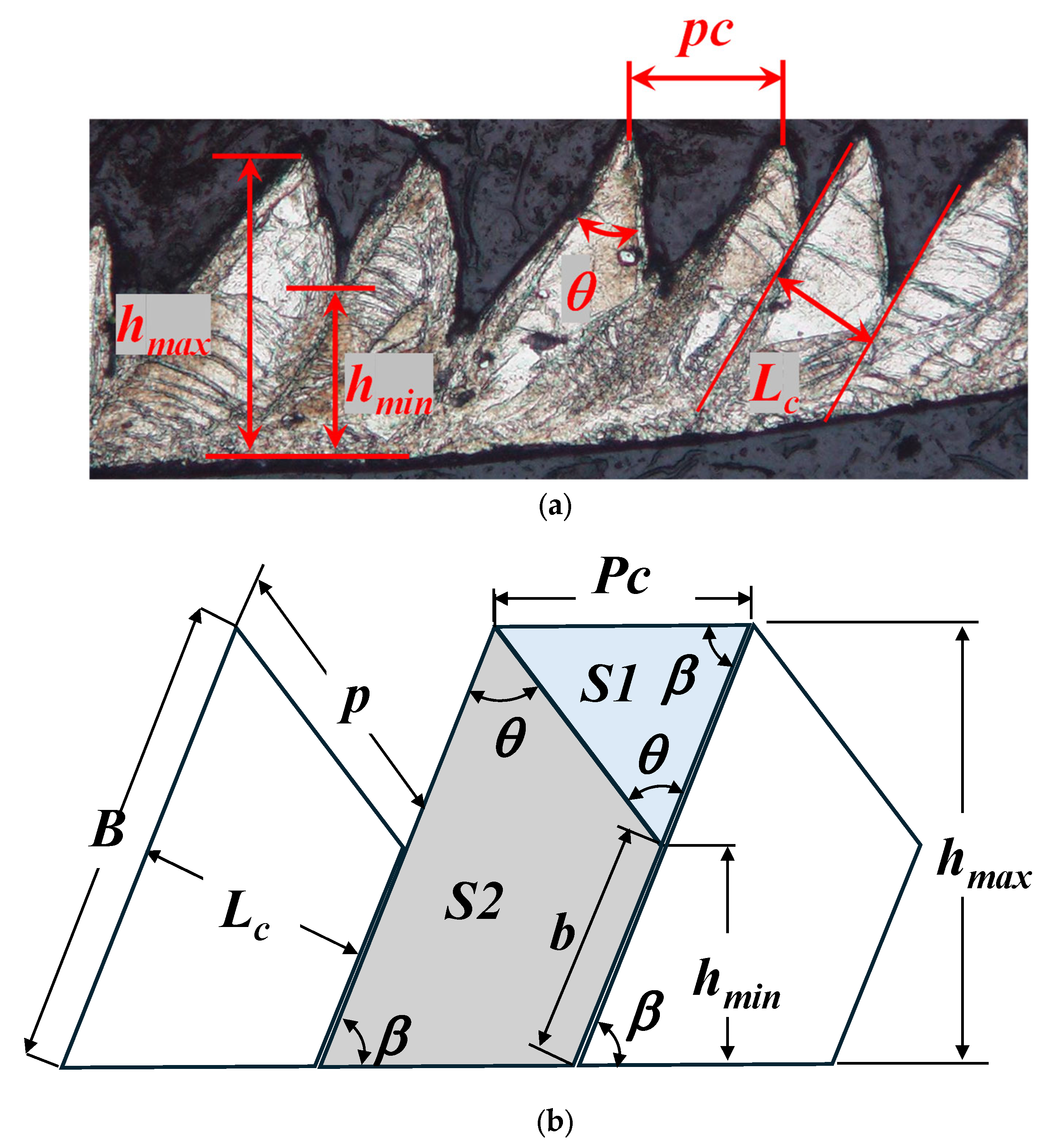

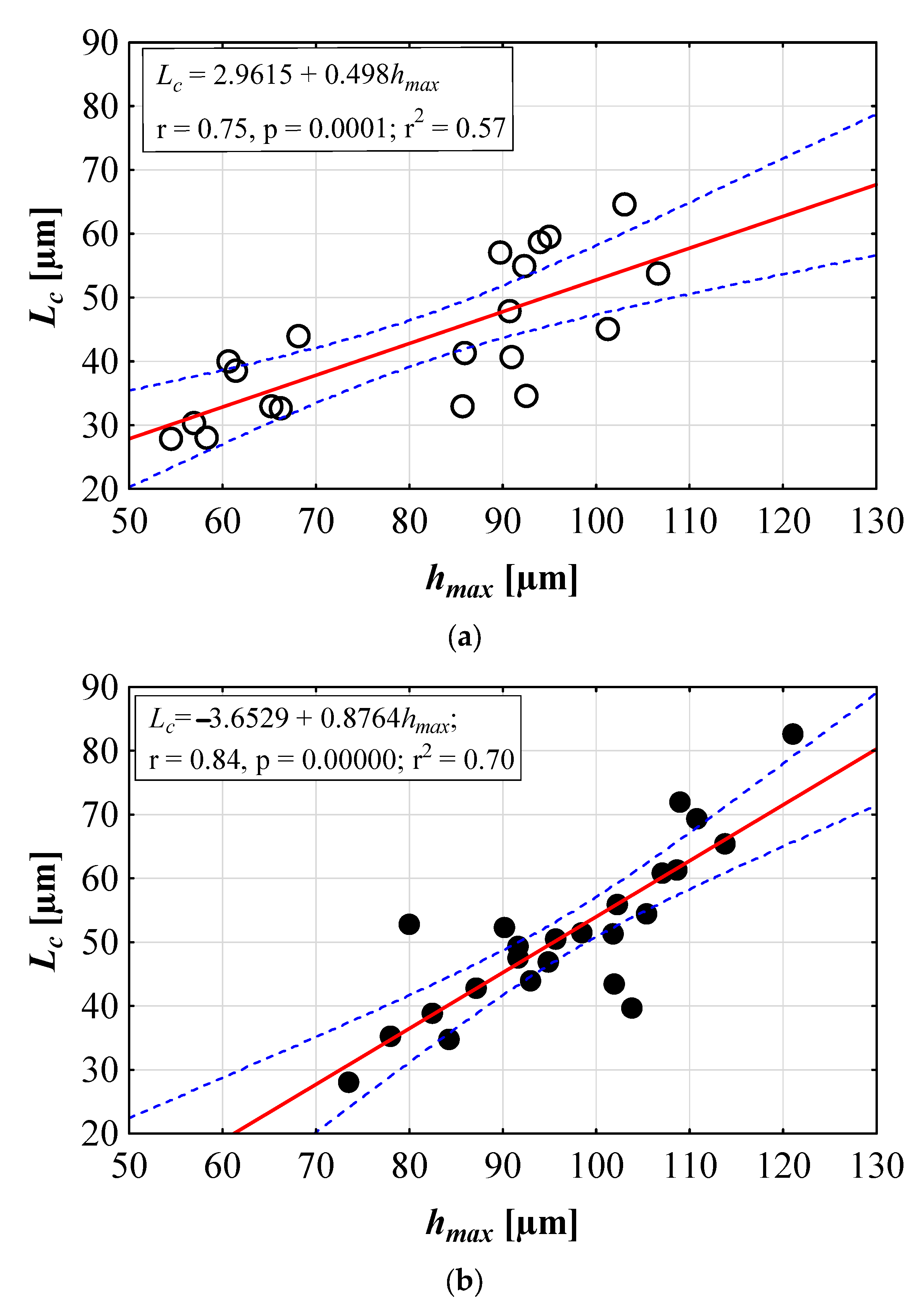

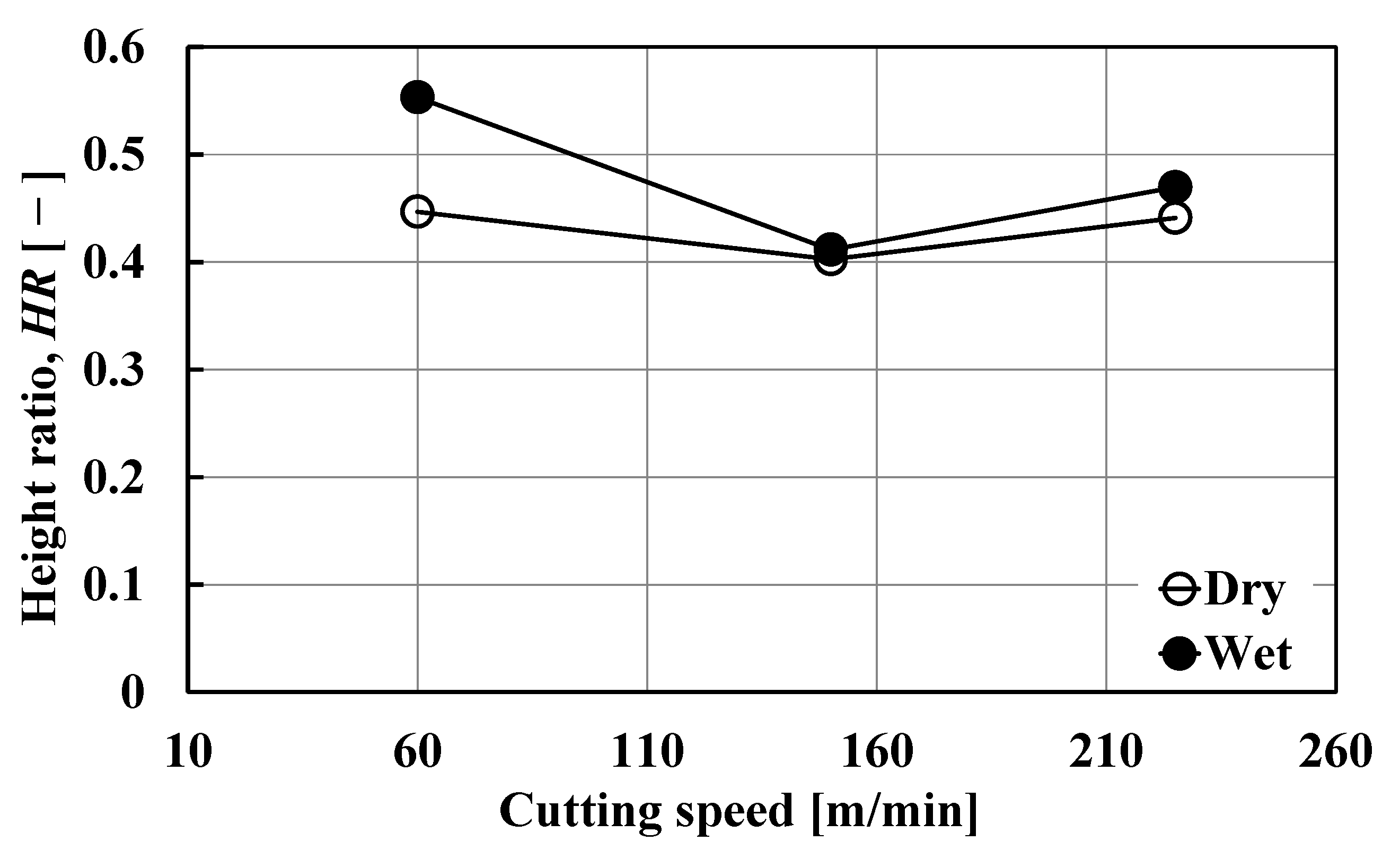

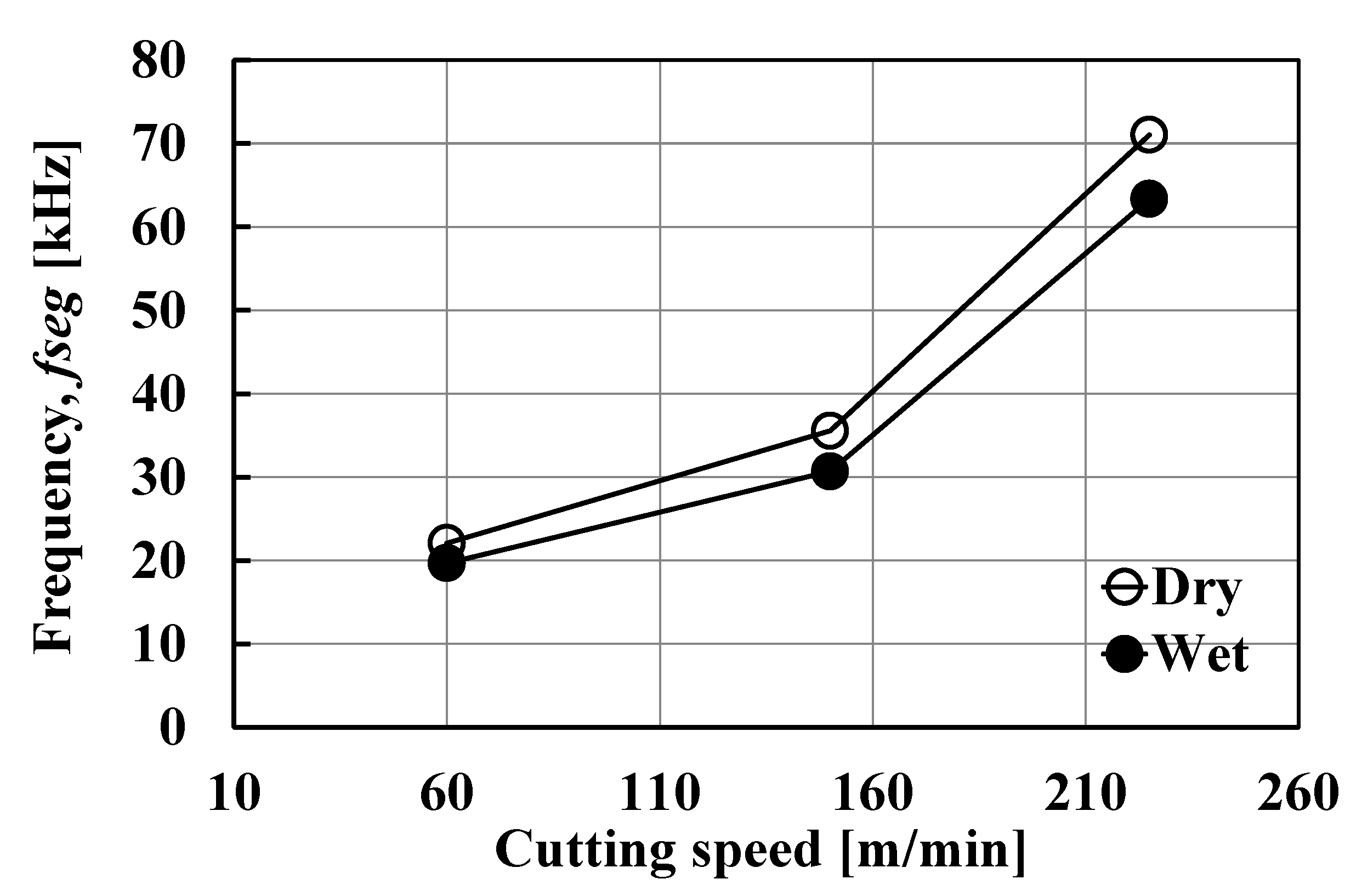

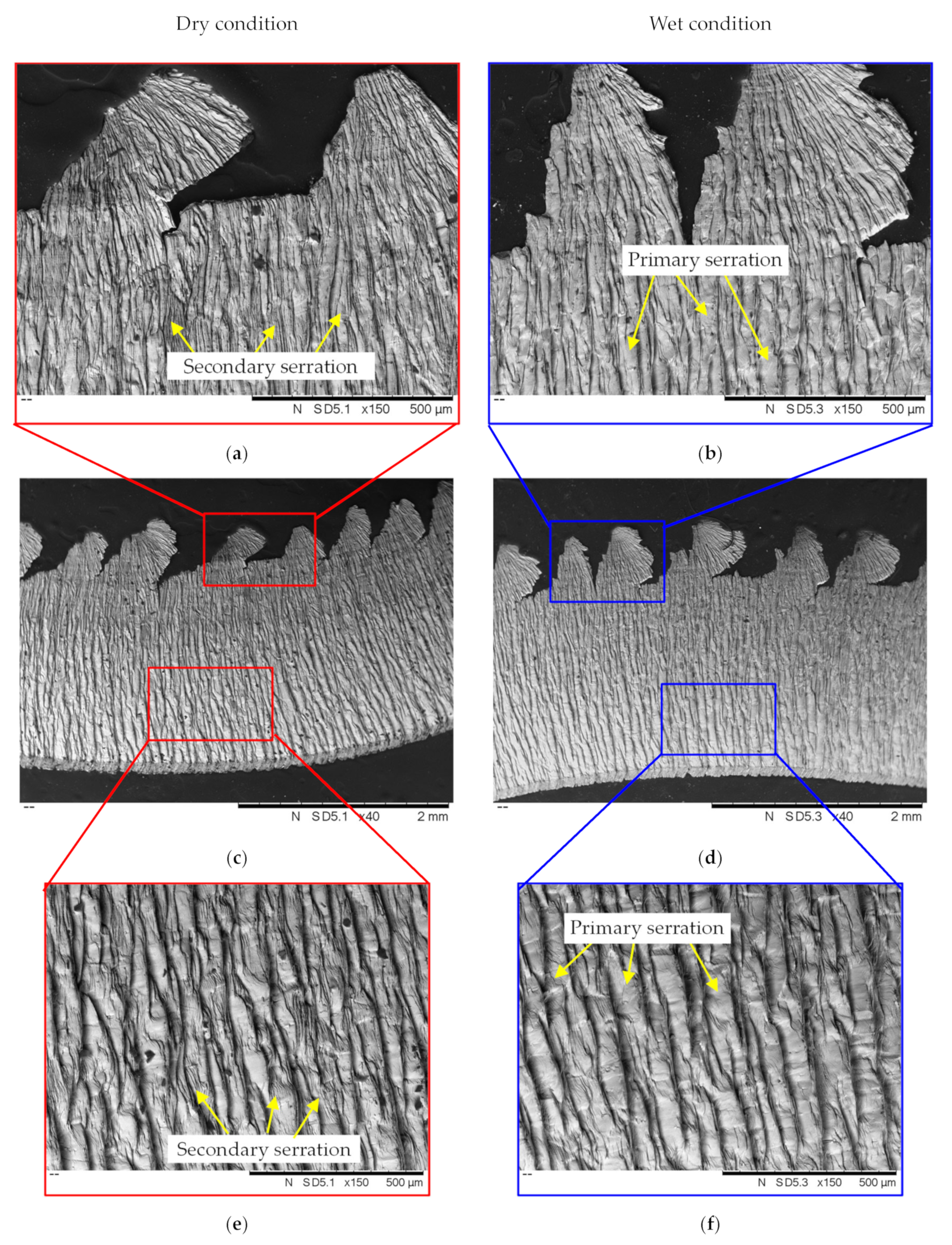

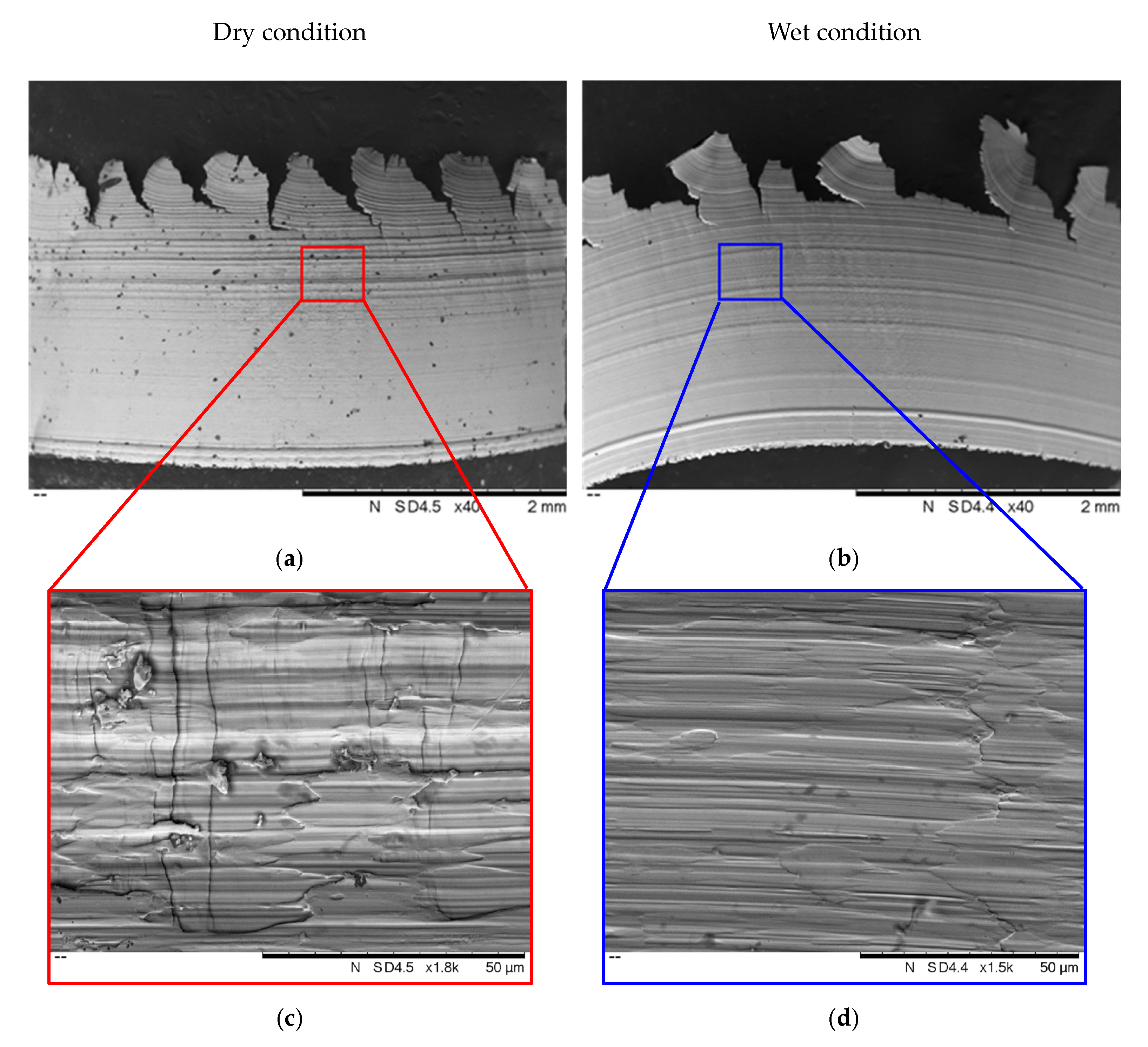

4.1. Chip Morphology

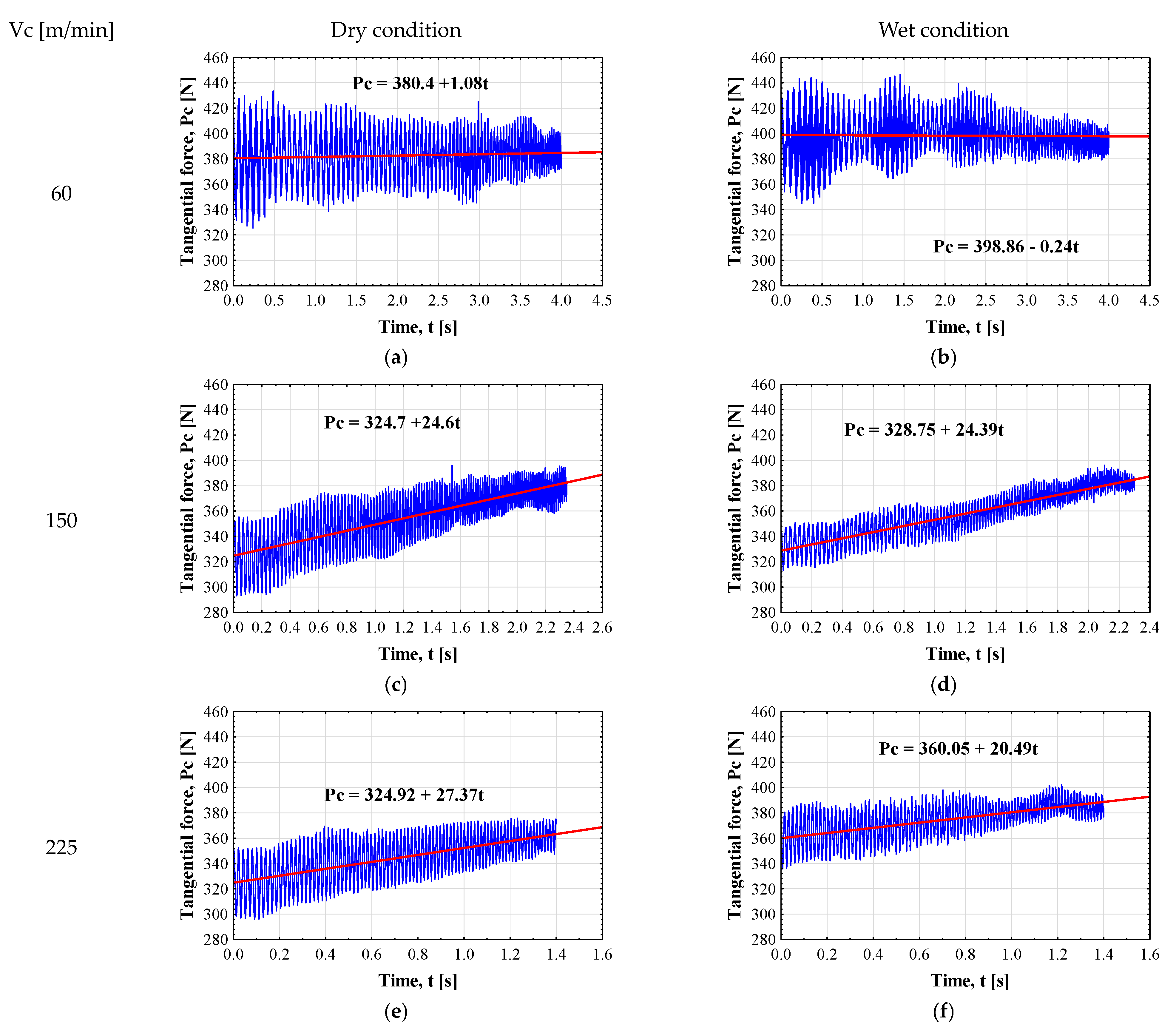

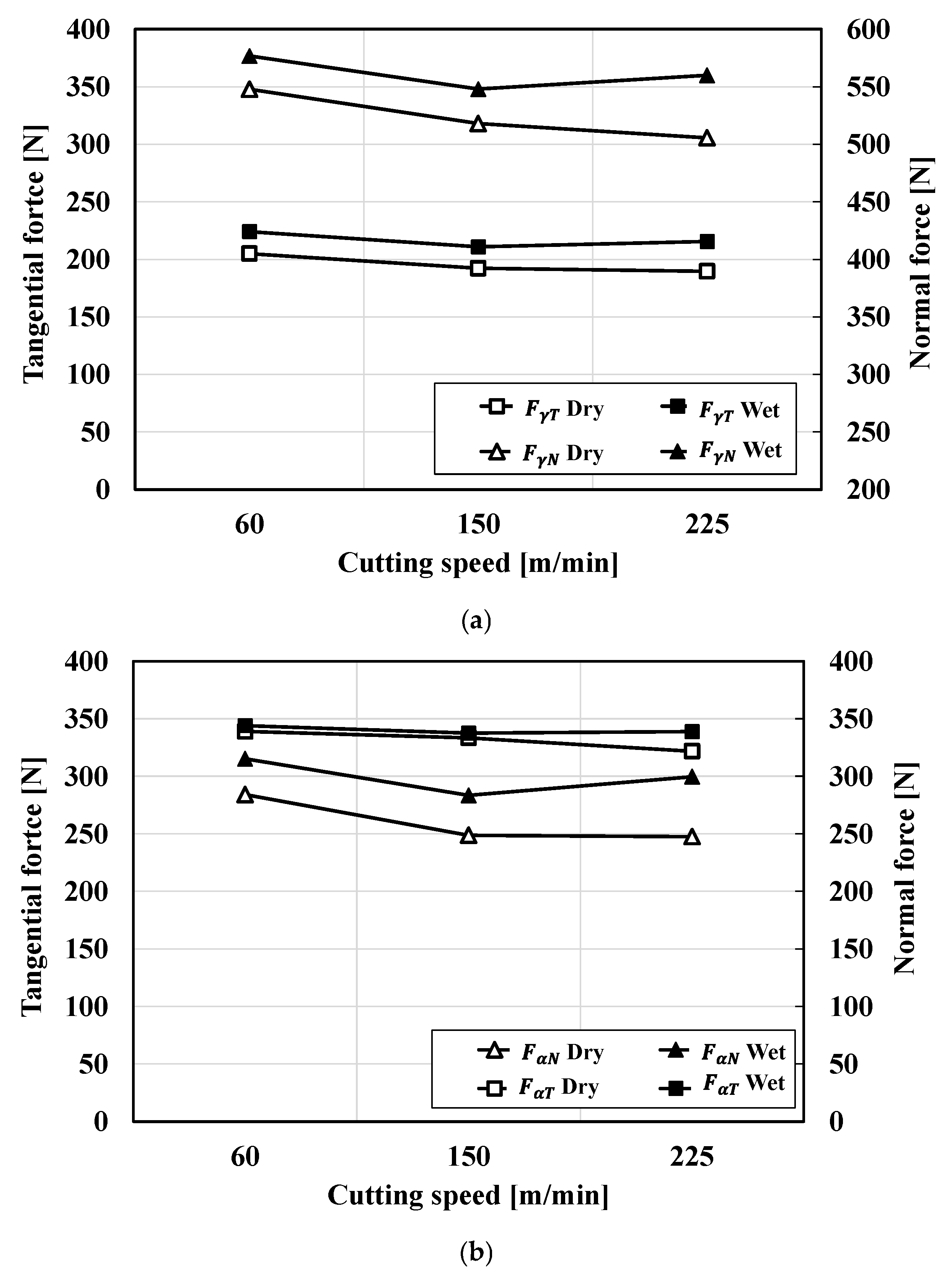

4.2. Cutting Forces

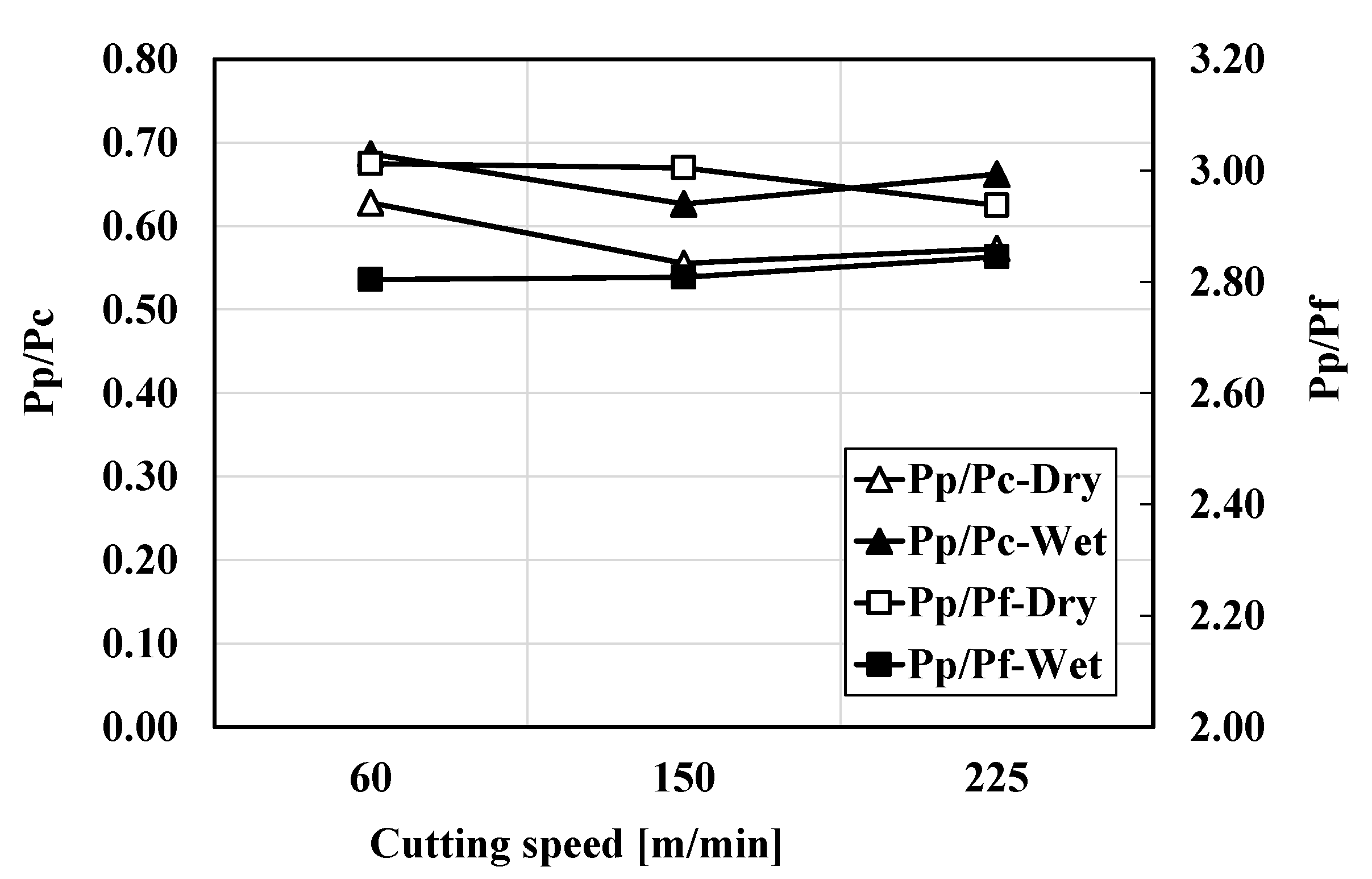

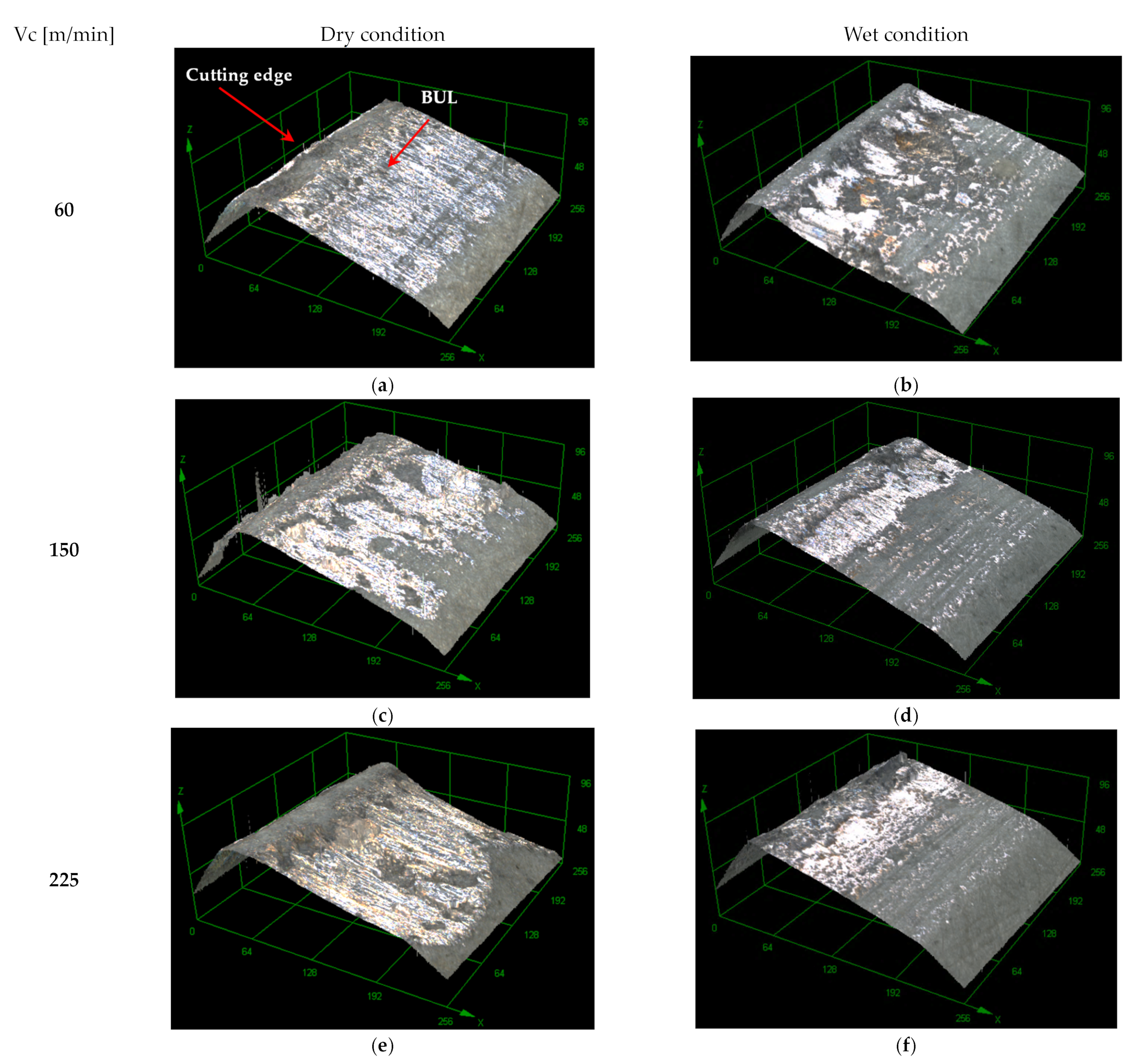

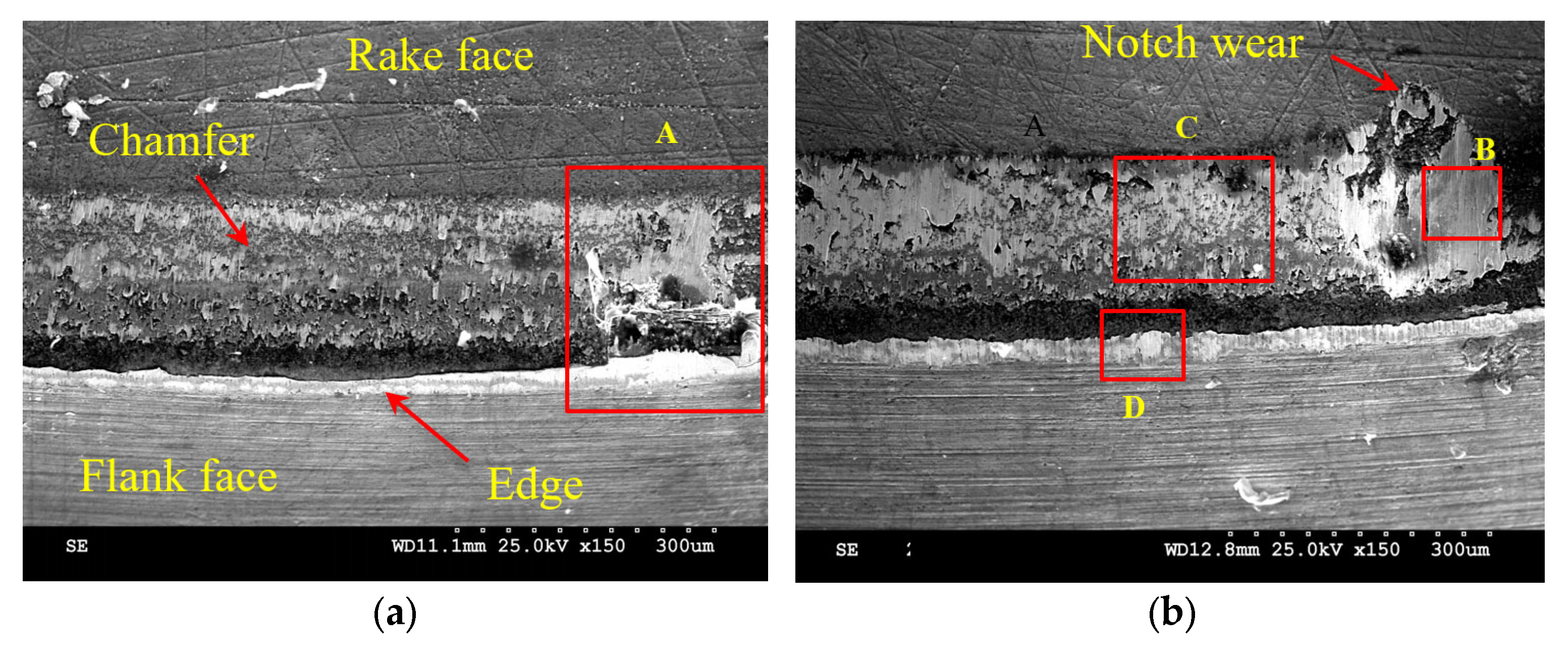

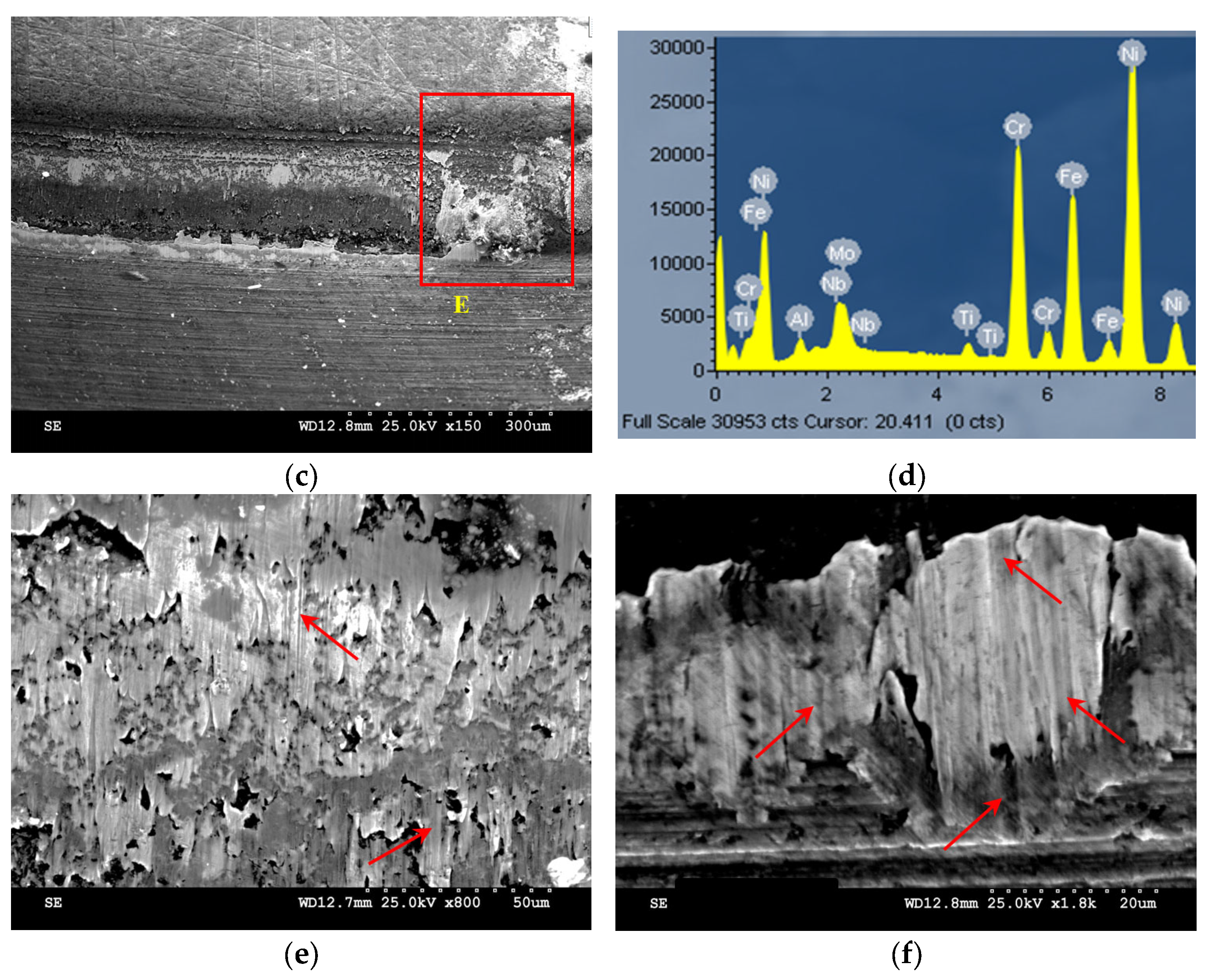

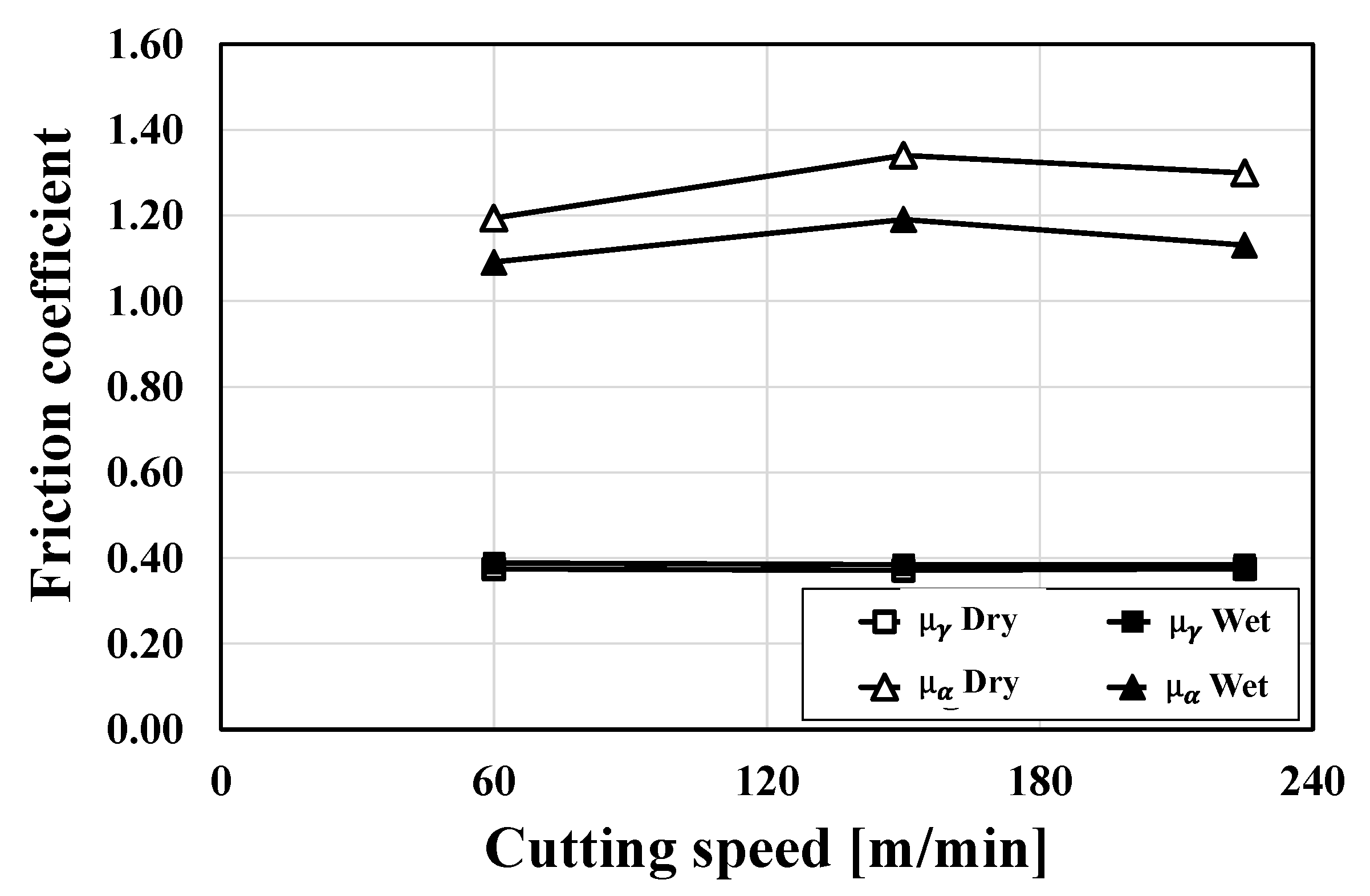

4.3. Tool Wear and Friction

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AF | Area Function |

| BUE | Build-up-edge |

| BUL | Build-up layer |

| DOC | Depth of cut |

| ECE | Equivalent cutting-edge |

| EDS | Electron-Dispersive Spectroscopy |

| EDX | Energy dispersive X-ray spectroscopy |

| MQL | Minimum quantity lubrication |

| SEM | Scanning electron microscopy |

| SF | Shape Function |

| TM | Transformation matrix |

| WC | Cemented carbide |

References

- Imbrogno, S.; Rinaldi, S.; Umbrello, D.; Filice, L.; Franchi, R.; Del Prete, A. A physically based constitutive model for predicting the surface integrity in machining of Waspaloy. Mater. Des. 2018, 152, 140–155. [Google Scholar]

- Su, R.; Hao, D.; He, P.; Wu, D.; Wang, Q.; Dong, H.; Ma, H. Effect of Co on creep and stress rupture properties of nickel-based superalloys—A review. J. Alloy. Compd. 2023, 967, 171744. [Google Scholar] [CrossRef]

- Tu, L.; Lin, L.; Liu, C.; Zheng, T.; Deng, Y.; Han, L.; An, Q.; Ming, W.; Chen, M. Tool wear characteristics analysis of cBN cutting tools in high-speed turning of Inconel 718. Ceram. Int. 2023, 49, 635–658. [Google Scholar] [CrossRef]

- De Bartolomeis, A.; Newman, S.T.; Jawahir, I.S.; Biermann, D.; Shokrani, A. Future research directions in the machining of Inconel 718. J. Mater. Process. Technol. 2021, 297, 117260. [Google Scholar] [CrossRef]

- Gao, C.; Wei, P.; Jin, S.; Zhang, J. Parametric investigation of laser incidence geometry in laser-assisted milling of Inconel 718. J. Mater. Res. Technol. 2024, 33, 2442–2454. [Google Scholar] [CrossRef]

- Moon, S.-H.; Lee, C.-M. A study on the machining characteristics using plasma assisted machining of AISI 1045 steel and Inconel 718. Int. J. Mech. Sci. 2018, 142, 595–602. [Google Scholar]

- Wang, Z.Y.; Rajurkar, K.P.; Fan, J.; Lei, S.; Shin, Y.C.; Petrescu, G. Hybrid machining of Inconel 718. Int. J. Mach. Tools Manuf. 2003, 43, 1391–1396. [Google Scholar]

- Qiu, W.; Pan, D.; Li, J.; Guo, P.; Qiao, Y.; Wang, X. Chip formation mechanism in cryogenic machining of high temperature alloy-Inconel 718 and Ti-47.5Al-2.5V-1.0Cr. J. Manuf. Process. 2023, 97, 35–47. [Google Scholar] [CrossRef]

- Damir, A.; Shi, B.; Elsayed, A.; Thelin, J.; M’saoubi, R.; Attia, H. On the tribological and thermal aspects of cryogenic machining of inconel 718 and Their Effects on Surface Integrity. Wear 2025, 205855. [Google Scholar] [CrossRef]

- Liu, H.; Meurer, M.; Bergs, T. Experimental and Finite Element Analysis of adapted cutting fluid supply on tool temperature and wear progression in Inconel 718 turning. J. Manuf. Process. 2025, 137, 166–180. [Google Scholar] [CrossRef]

- Amrita, M.; Kamesh, B. Optimization of graphene based minimum quantity lubrication of Inconel718 turning with multiple machining performances. Mater. Today Proc. 2021, 39, 1337–1344. [Google Scholar]

- Dudzinski, D.; Devillez, A.; Moufki, A.; Larrouquère, D.; Zerrouki, V.; Vigneau, J. A review of developments towards dry and high speed machining of Inconel 718 alloy. Int. J. Mach. Tools Manuf. 2004, 44, 439–456. [Google Scholar]

- Kui, G.W.A.; Islam, S.; Reddy, M.M.; Khandoker, N.; Chen, V.L.C. Recent progress and evolution of coolant usages in conventional machining methods: A comprehensive review. Int. J. Adv. Manuf. Technol. 2022, 119, 3–40. [Google Scholar]

- Wang, B.; Wang, Z.; Yin, Z.; Yuan, J. Wear behavior of ultrafine WC-Co cemented carbide end mills during milling of Inconel 718. Wear 2024, 546, 205359. [Google Scholar]

- Zhao, J.; Liu, Z. Influences of coating thickness on cutting temperature for dry hard turning Inconel 718 with PVD TiAlN coated carbide tools in initial tool wear stage. J. Manuf. Process. 2020, 56, 1155–1165. [Google Scholar]

- Jindal, P.C.; Santhanam, A.T.; Schleinkofer, U.; Shuster, A.F. Performance of PVD TiN, TiCN, and TiAlN coated cemented carbide tools in turning. Int. J. Refract. Met. Hard Mater. 1999, 17, 163–170. [Google Scholar]

- Ucun, I.; Aslantas, K.; Bedir, F. An experimental investigation of the effect of coating material on tool wear in micro milling of Inconel 718 super alloy. Wear 2013, 300, 8–19. [Google Scholar]

- Zhao, J.; Liu, Z.; Ren, X.; Wang, B.; Cai, Y.; Song, Q.; Wan, Y. Coating-thickness-dependent physical properties and cutting temperature for cutting Inconel 718 with TiAlN coated tools. J. Adv. Res. 2022, 38, 191–199. [Google Scholar]

- Kurian, M.; Thankachan, S. 1—Introduction: Ceramics classification and applications. In Ceramic Catalysts; Kurian, M., Thankachan, S., Nair, S.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–17. [Google Scholar]

- Pozzato, N.; Bertolini, R.; Moro, L.; Ghiotti, A.; Bruschi, S.; Tagarelli, L. On the wear mechanisms of ceramic round inserts in high-speed turning of Inconel 718. Wear 2025, 205866. [Google Scholar] [CrossRef]

- Li, L.; Li, Y. Development and trend of ceramic cutting tools from the perspective of mechanical processing. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2017. [Google Scholar]

- Upadhyay, C.; Rajput, S.S.; Kumar, C.S.; Gangopadhyay, S.; Sahoo, S.K. Performance evaluation of WC, SiAlON and SiCw + Al2O3 tools in dry machining of Inconel 617. J. Manuf. Process. 2024, 109, 235–249. [Google Scholar]

- Song, X.; He, W.; Ihara, T. A novel approach for dry cutting inconel 718 in a more sustainable and low-cost way by actively and purposely utilizing the built-up layer. Micromachines 2023, 14, 1787. [Google Scholar] [CrossRef] [PubMed]

- Zeilmann, R.P.; Fontanive, F.; Soares, R.M. Wear mechanisms during dry and wet turning of Inconel 718 with ceramic tools. Int. J. Adv. Manuf. Technol. 2017, 92, 2705–2714. [Google Scholar]

- Marques, A.; Suarez, M.P.; Sales, W.F.; Machado, Á.R. Turning of Inconel 718 with whisker-reinforced ceramic tools applying vegetable-based cutting fluid mixed with solid lubricants by MQL. J. Mater. Process. Technol. 2019, 266, 530–543. [Google Scholar]

- Xue, C.; Wang, D.; Zhang, J. Wear Mechanisms and notch formation of whisker-reinforced alumina and sialon ceramic tools during high-speed turning of inconel 718. Materials 2022, 15, 3860. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Xu, X.; Huang, X.; Ming, W.; An, Q.; Chen, M. Cutting performance and tool wear of SiAlON and TiC-whisker-reinforced Si3N4 ceramic tools in side milling Inconel 718. Ceram. Int. 2022, 48, 3096–3108. [Google Scholar]

- Colwell, L.V. Predicting the angle of chip flow for single-point cutting tools. J. Fluids Eng. 1954, 76, 199–203. [Google Scholar]

- Parakkal, G.; Zhu, R.; Kapoor, S.G.; DeVor, R.E. Modeling of turning process cutting forces for grooved tools. Int. J. Mach. Tools Manuf. 2002, 42, 179–191. [Google Scholar]

- Outeiro, J.C.; Dillon, O.W.; Jawahir, I.S. On Designing for Enhanced Product Sustainability by Considering the Induced Residual Stresses in Machining Operations. In Proceedings of the ASME 2007 International Mechanical Engineering Congress and Exposition, Seattle, WA, USA, 11–15 November 2007. [Google Scholar]

- Armarego, E.J.A.; Brown, R.H. The Machining of Metals; Prentice-Hall: Hoboken, NJ, USA, 1969. [Google Scholar]

- Jomaa, W.; Mechri, O.; Lévesque, J.; Songmene, V.; Bocher, P.; Gakwaya, A. Finite element simulation and analysis of serrated chip formation during high–speed machining of AA7075–T651 alloy. J. Manuf. Process. 2017, 26, 446–458. [Google Scholar]

- Liu, M.; Li, G.; Zhao, S.; Cai, Y.; Duan, C. Serrated chips morphology and formation mechanism of laser additive manufactured materials for subtractive machining. J. Mater. Res. Technol. 2025, 35, 250–264. [Google Scholar]

- Vyas, A.; Shaw, M.C. Mechanics of saw-tooth chip formation in metal cutting. J. Manuf. Sci. Eng. 1999, 121, 163–172. [Google Scholar]

- Ye, G.; Jiang, M.; Xue, S.; Ma, W.; Dai, L. On the instability of chip flow in high-speed machining. Mech. Mater. 2018, 116, 104–119. [Google Scholar]

- Selvakumar, S.J.; Raj, D.S. Tribological characteristics of SiALON ceramic inserts during sustainable machining of Inconel 625 based on comprehensive chip morphology analysis. Wear 2025, 562, 205626. [Google Scholar]

- Flom, D.; Komanduri, R.; Lee, M. High-speed machining of metals. Annu. Rev. Mater. Sci. 1984, 14, 231–278. [Google Scholar]

- Zhang, S.; Li, J.; Zhu, X.; Lv, H. Saw-tooth chip formation and its effect on cutting force fluctuation in turning of Inconel 718. Int. J. Precis. Eng. Manuf. 2013, 14, 957–963. [Google Scholar]

- Pawade, R.S.; Joshi, S.S. Mechanism of chip formation in high-speed turning of inconel 718. Mach. Sci. Technol. 2011, 15, 132–152. [Google Scholar]

- Recht, R.F. Catastrophic Thermoplastic Shear. J. Appl. Mech. 1964, 31, 189–193. [Google Scholar]

- Yadav, S.; Feng, G.; Sagapuram, D. Dynamics of shear band instabilities in cutting of metals. CIRP Ann. 2019, 68, 45–48. [Google Scholar]

- Sun, S.; Brandt, M.; Dargusch, M. Characteristics of cutting forces and chip formation in machining of titanium alloys. Int. J. Mach. Tools Manuf. 2009, 49, 561–568. [Google Scholar]

- Pedroso, A.F.V.; Sousa, V.F.C.; Sebbe, N.P.V.; Silva, F.J.G.; Campilho, R.D.S.G.; Martinho, R.P.; de Jesus, A.M.P.; Sales-Contini, R.d.C. Cooling and Lubricating Strategies for INCONEL® Alloys Machining: A Comprehensive Review on Recent Advances. J. Tribol. 2024, 147, 060801. [Google Scholar]

- Kurt, A.; Yalçin, B.; Yilmaz, N. The cutting tool stresses in finish turning of hardened steel with mixed ceramic tool. Int. J. Adv. Manuf. Technol. 2015, 80, 315–325. [Google Scholar]

- Toubhans, B.; Fromentin, G.; Viprey, F.; Karaouni, H.; Dorlin, T. Machinability of inconel 718 during turning: Cutting force model considering tool wear, influence on surface integrity. J. Mech. Work. Technol. 2020, 285, 116809. [Google Scholar]

- Grzesik, W.; Denkena, B.; Żak, K.; Grove, T.; Bergmann, B. Energy consumption characterization in precision hard machining using CBN cutting tools. Int. J. Adv. Manuf. Technol. 2016, 85, 2839–2845. [Google Scholar]

- Grzesik, W.; Rech, J.; Żak, K. Determination of friction in metal cutting with tool wear and flank face effects. Wear 2014, 317, 8–16. [Google Scholar]

- Komanduri, R.; Von Turkovich, B. New observations on the mechanism of chip formation when machining titanium alloys. Wear 1981, 69, 179–188. [Google Scholar]

- Pimenov, D.Y.; da Silva, L.R.R.; Machado, A.R.; França, P.H.P.; Pintaude, G.; Unune, D.R.; Kuntoğlu, M.; Krolczyk, G.M. A comprehensive review of machinability of difficult-to-machine alloys with advanced lubricating and cooling techniques. Tribol. Int. 2024, 196, 109677. [Google Scholar]

- Alagan, N.T.; Zeman, P.; Mara, V.; Beno, T.; Wretland, A. High-pressure flank cooling and chip morphology in turning Alloy 718. CIRP J. Manuf. Sci. Technol. 2021, 35, 659–674. [Google Scholar]

- Cantero, J.L.; Diaz-Álvarez, J.; Miguélez, M.H.; Marín, N.C. Analysis of tool wear patterns in finishing turning of Inconel 718. Wear 2013, 297, 885–894. [Google Scholar]

| Element | Ni | Cr | Fe | Mo | Al | Mn | Si | Cu | C | Co |

| Inconel 718 | 50–55 | 17–21 | 15.65 | 2.8–3.3 | 0.95 | 0.35 | 0.35 | 0.3 | 0.08 | 1.0 |

| Machining parameters | Cutting speed, V [m/min] Feed rate, f [mm/rev] Depth of cut, ap [mm] Machining mode Coolant characteristics | 60, 150, 225 0.1 0.5 dry, wet synthetic oil–water emulsion, 10%, 5 L/min |

| Cutting tool | Holder:

| KPGNR-164D from Kennametal. −5 −5 RNGN120700 from Greenleaf Silicon carbide whisker-reinforced ceramic -Grade WG300 Chamfer (−20°) + hone (20 µm) |

| Machine tool | CNC lathe | QTN100 from Mazak Corp. |

| 1.00 | 0.70 | 0.65 | 0.36 | 0.75 | |

| 1.00 | 0.33 | 0.45 | 0.50 | ||

| 1.00 | 0.41 | 0.81 | |||

| 1.00 | 0.58 | ||||

| 1.00 |

| 1.00 | −0.06 | 0.35 | −0.05 | 0.84 | |

| 1.00 | −0.24 | 0.53 | −0.26 | ||

| 1.00 | −0.14 | 0.49 | |||

| 1.00 | −0.10 | ||||

| 1.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jomaa, W.; Daoud, M.; Javadi, H.; Bocher, P. Cutting Fluid Effectiveness in the High-Speed Finish Machining of Inconel 718 Using a Whisker-Reinforced Ceramic Tool. J. Manuf. Mater. Process. 2025, 9, 123. https://doi.org/10.3390/jmmp9040123

Jomaa W, Daoud M, Javadi H, Bocher P. Cutting Fluid Effectiveness in the High-Speed Finish Machining of Inconel 718 Using a Whisker-Reinforced Ceramic Tool. Journal of Manufacturing and Materials Processing. 2025; 9(4):123. https://doi.org/10.3390/jmmp9040123

Chicago/Turabian StyleJomaa, Walid, Monzer Daoud, Hamid Javadi, and Philippe Bocher. 2025. "Cutting Fluid Effectiveness in the High-Speed Finish Machining of Inconel 718 Using a Whisker-Reinforced Ceramic Tool" Journal of Manufacturing and Materials Processing 9, no. 4: 123. https://doi.org/10.3390/jmmp9040123

APA StyleJomaa, W., Daoud, M., Javadi, H., & Bocher, P. (2025). Cutting Fluid Effectiveness in the High-Speed Finish Machining of Inconel 718 Using a Whisker-Reinforced Ceramic Tool. Journal of Manufacturing and Materials Processing, 9(4), 123. https://doi.org/10.3390/jmmp9040123