Manufacturing of Diamond Tool Segments via Microwave–Hybrid Sintering

Abstract

1. Introduction

- Investigating the feasibility of microwave-assisted sintering for fabricating Fe–Cu-based DIT segments.

- Evaluating the densification behavior, microstructure, and mechanical performance of the microwave-sintered segments.

- Comparing these results with conventionally sintered (HP) counterparts.

2. Materials and Methods

2.1. Matrix and MMC Compacts

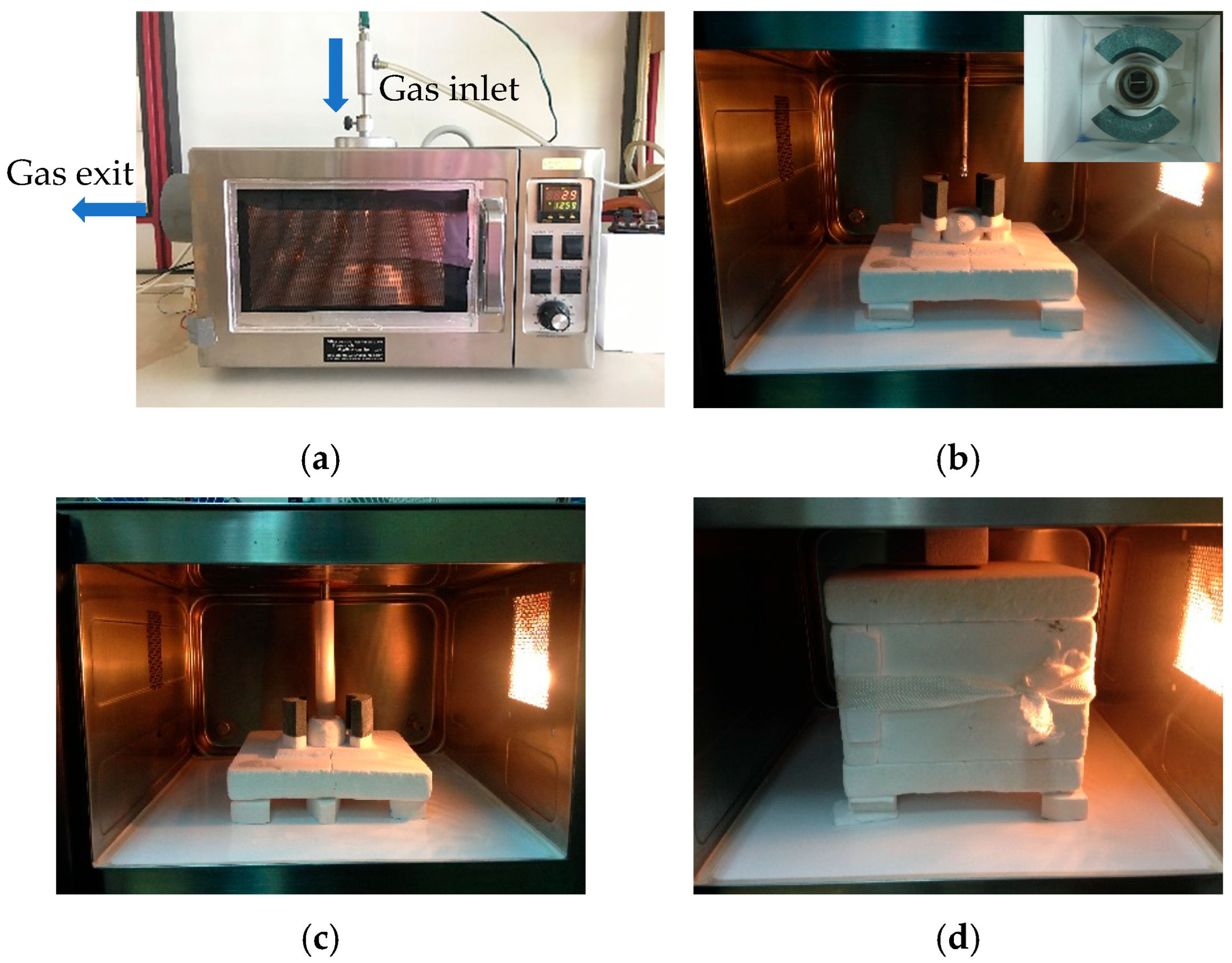

2.2. Sintering Experiments

2.3. Physical and Mechanical Characterization

3. Results and Discussion

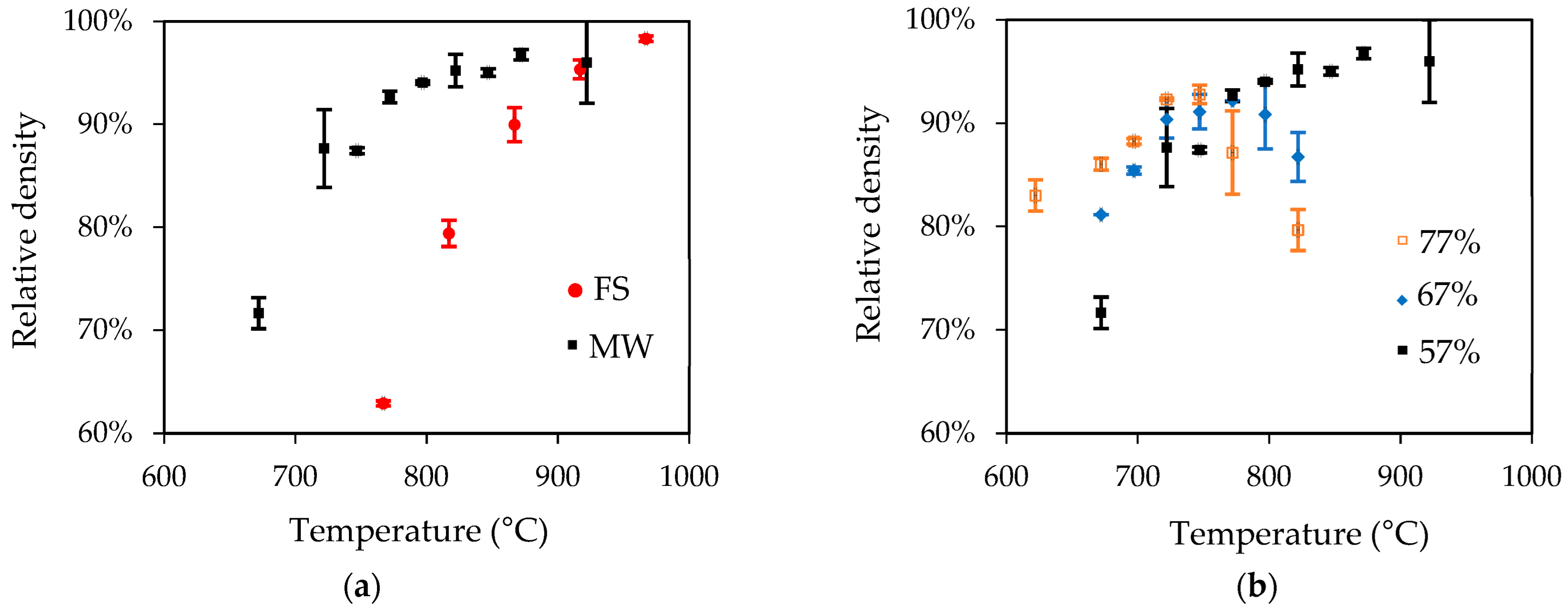

3.1. Optimization of MW Thermal Cycle

- ▪

- MW–77%: between 720 °C (92%) and 750 °C (93%);

- ▪

- MW–67%: between 720 °C and 770 °C (both at 92%);

- ▪

- MW–57%: widest sintering plateau, ranging from 800 °C to 870 °C with relative densities above 94%.

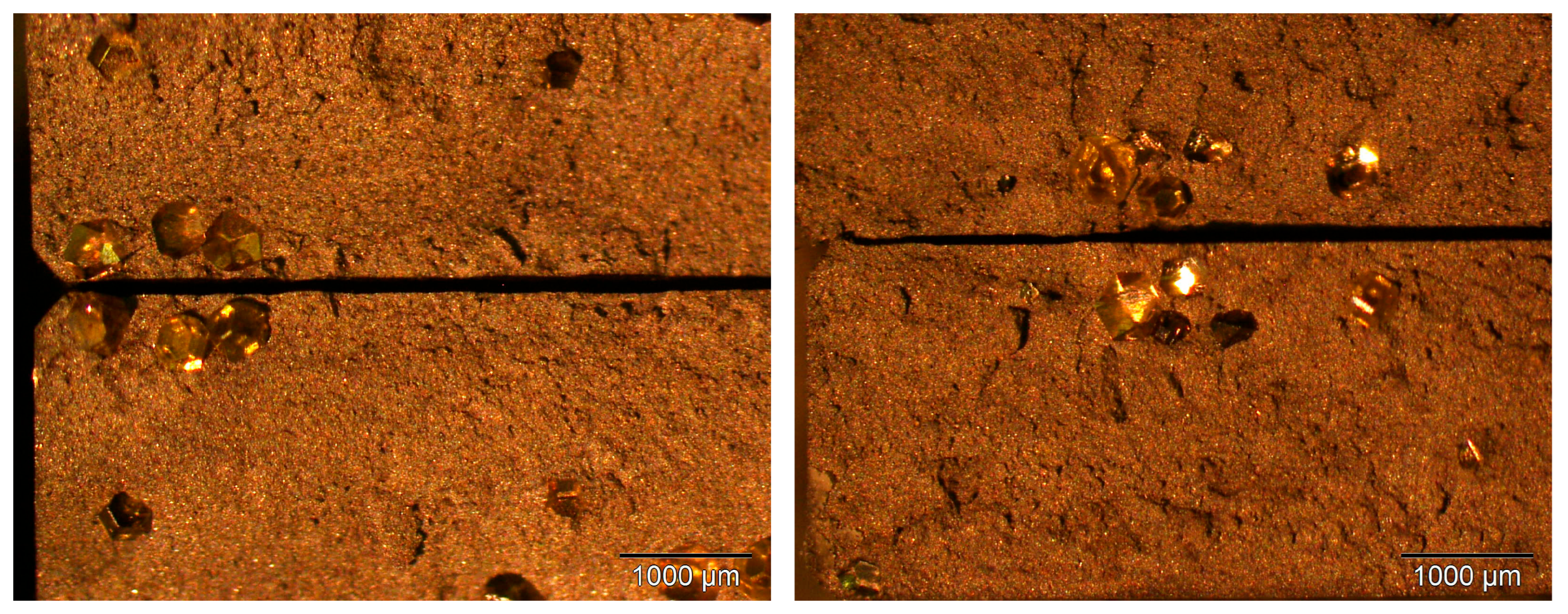

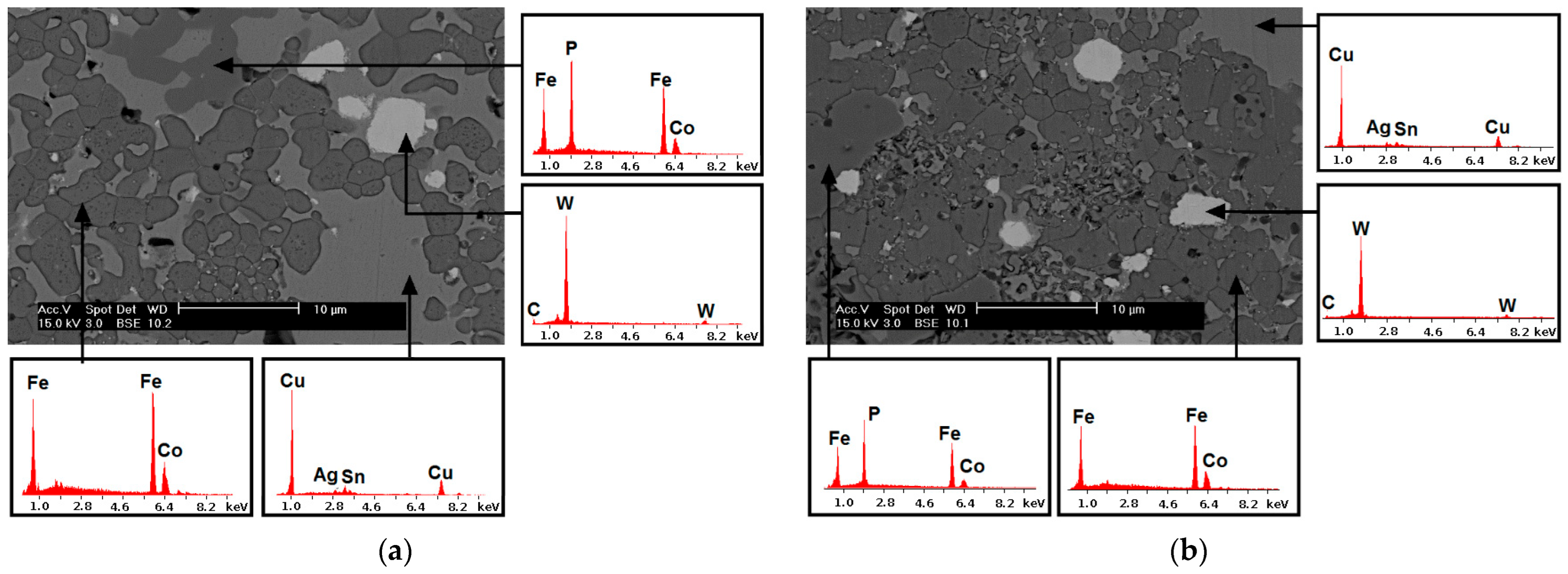

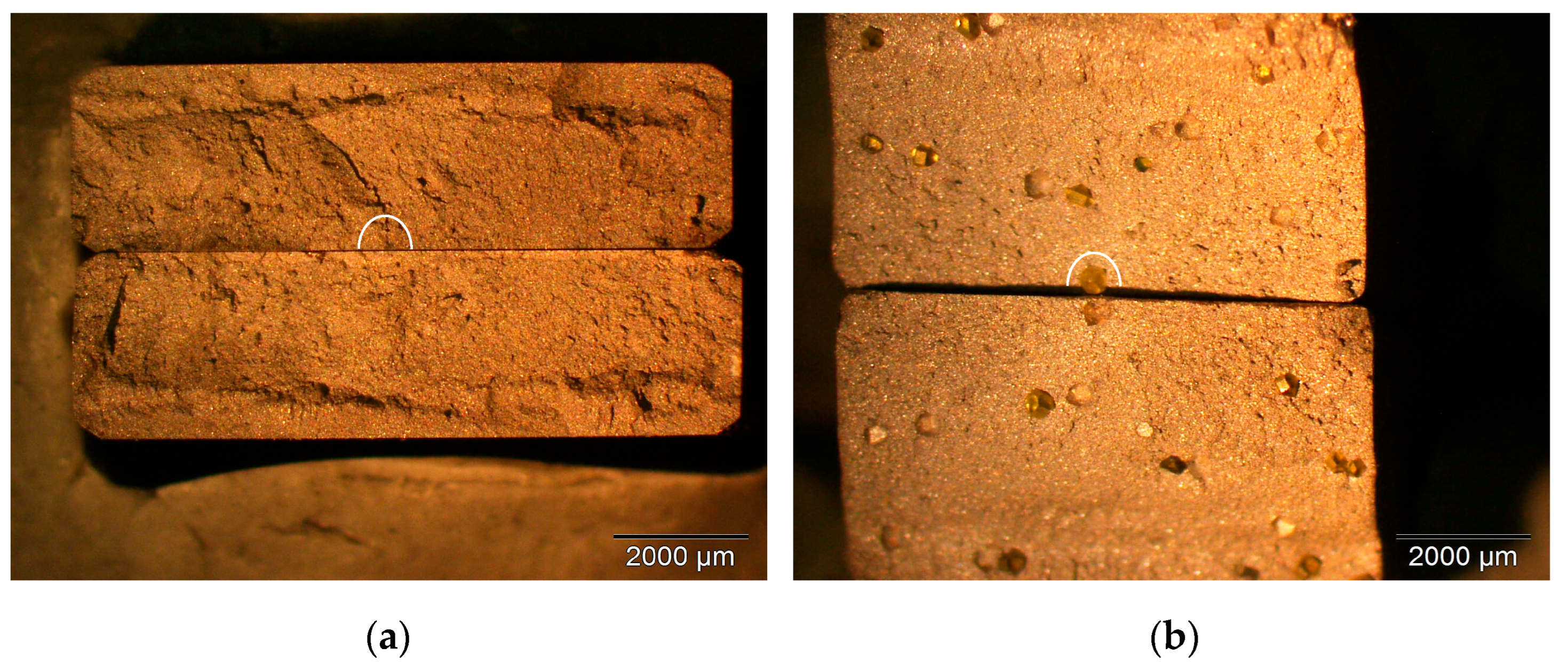

3.2. Physical and Mechanical Properties of HP and MW Sintered Segments

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Diamond Segments Market Size by Product by Application by Geography Competitive Landscape and Forecast. Report ID: 452483; Market Research Intellect: Washington, DC, USA, 2025; Available online: https://www.marketresearchintellect.com/product/global-diamond-segments-market-size-and-forecast.

- Konstanty, J. Sintered diamond tools: Trends, challenges and prospects. Powder Metall. 2013, 56, 182–188. [Google Scholar] [CrossRef]

- Konstanty, J.S. Sintered diamond tools: The past, present and future. Arch. Metall. Mater. 2021, 66, 593–599. [Google Scholar] [CrossRef]

- Costa Oliveira, F.A.; Anjinho, C.A.; Coelho, A.; Amaral, P.M.; Coelho, M. PM materials selection: The key for improved performance of diamond tools. Met. Powder Rep. 2017, 72, 339–344. [Google Scholar] [CrossRef]

- Artini, C.; Muolo, M.L.; Passerone, A. Diamond–metal interfaces in cutting tools: A review. J. Mater. Sci. 2012, 47, 3252–3264. [Google Scholar] [CrossRef]

- Ersoy, A.; Buyuksagic, S.; Atici, U. Wear characteristics of circular diamond saws in the cutting of different hard abrasive rocks. Wear 2005, 258, 1422–1436. [Google Scholar] [CrossRef]

- Rosa, L.G.; Fernandes, J.C.; Anjinho, C.A.; Coelho, A.; Amaral, P.M. Long-term performance of stone-cutting tools. Int. J. Refract. Met. Hard Mater. 2015, 49, 276–282. [Google Scholar] [CrossRef]

- Lison, D. Human toxicity of cobalt-containing dust and experimental studies on the mechanism of interstitial lung disease (hard metal disease). Crit. Rev. Toxicol. 1996, 26, 585–616. [Google Scholar] [CrossRef]

- Gál, J.; Hursthouse, A.; Tatner, P.; Stewart, F.; Welton, R. Cobalt and secondary poisoning in the terrestrial food chain: Data review and research gaps to support risk assessment. Environ. Int. 2008, 34, 821–838. [Google Scholar] [CrossRef]

- Spriano, S.; Chen, Q.; Settineri, L.; Bugliosi, S. Low content and free cobalt matrixes for diamond tools. Wear 2005, 259, 1190–1196. [Google Scholar] [CrossRef]

- Hsieh, Y.Z.; Chen, J.F.; Lin, S.T. Pressureless sintering of metal-bonded diamond particle composite blocks. J. Mater. Sci. 2000, 35, 5383–5387. [Google Scholar] [CrossRef]

- Anklekar, R.M.; Agrawal, D.K.; Roy, R. Microwave sintering and mechanical properties of PM copper steel. Powder Metall. 2001, 44, 355–362. [Google Scholar] [CrossRef]

- Borowiecka-Jamrozek, J.M.; Konstanty, J.S. Sintered steels intended for fabrication of metal-diamond composites. Adv. Sci. Technol. Res. J. 2025, 19, 291–300. [Google Scholar] [CrossRef] [PubMed]

- Cygan-Bączek, E.; Wyżga, P.; Cygan, S.; Bała, P.; Romański, A. Improvement in hardness and wear behaviour of iron-based Mn–Cu–Sn matrix for sintered diamond tools by dispersion strengthening. Materials 2021, 14, 1774. [Google Scholar] [CrossRef]

- Mancisidor, A.; Luno-Bilbao, C.; Vielma, N.J.; Sanchez, J.M.; Iturriza, I. Effect of sintering atmosphere on densification, mechanical properties and diamond stability of prealloyed diamond impregnated composites obtained by free sintering. Powd. Metal. 2013, 56, 362–373. [Google Scholar] [CrossRef]

- Li, W.; Zhan, J.; Wang, S.; Dong, H.; Li, Y.; Liu, Y. Characterizations and mechanical properties of impregnated diamond segment using Cu-Fe-Co metal matrix. Rare Met. 2012, 31, 81–87. [Google Scholar] [CrossRef]

- Tyrala, D.; Romanski, A.; Konstanty, J. The effects of powder composition on microstructure and properties of hot-pressed matrix materials for sintered diamond tools. J. Mater. Eng. Perform. 2020, 29, 1467–1472. [Google Scholar] [CrossRef]

- Oghbaei, M.; Mirzaee, O. Microwave versus conventional sintering: A review of fundamentals, advantages and applications. J. Alloys Compd. 2010, 494, 175–189. [Google Scholar] [CrossRef]

- Hossain, F.; Turner, J.V.; Wilson, R.; Chen, L.; de Looze, G.; Kingman, S.W.; Dodds, C.; Dimitrakis, G. State-of-the-art in microwave processing of metals, metal powders and alloys. Renew. Sustain. Energy Rev. 2024, 202, 114650. [Google Scholar] [CrossRef]

- Wang, L.; Guo, S.; Gao, J.; Yang, L.; Hu, T.; Peng, J.; Hou, M.; Jiang, C. Microwave sintering behavior of FeCuCo based metallic powder for diamond alloy tool bit. J. Alloys Compd. 2017, 727, 94–99. [Google Scholar] [CrossRef]

- Yang, L.; Wang, L.; Gao, J.; Guo, S.; Ye, X.; Koppala, S.; Hu, T.; Hou, M.; Hu, L. Optimization of process parameters for preparing metallic matrix diamond tool bits by microwave pressureless sintering using response surface methodology. Materials 2018, 11, 2185. [Google Scholar] [CrossRef]

- Roy, R.; Agrawal, D.; Cheng, J.; Gedevanishvili, S. Full sintering of powdered-metal bodies in a microwave field. Nature 1999, 401, 668–670. [Google Scholar] [CrossRef]

- Ye, X.; Guo, S.; Yang, L.; Gao, J.; Peng, J.; Hu, T.; Wang, L.; Hou, M.; Luo, Q. New utilization approach of microwave thermal energy: Preparation of metallic matrix diamond tool bit by microwave hot-press sintering. J. Alloys Compd. 2018, 748, 645–652. [Google Scholar] [CrossRef]

- Hou, M.; Wang, L.; Guo, S.; Yang, L.; Gao, J.; Hu, T.; Ye, X. Fabrication of FeCu matrixed diamond tool bits using microwave hot-press sintering. Arab. J. Sci. Eng. 2019, 44, 6277–6284. [Google Scholar] [CrossRef]

- Tillmann, W.; Kronholz, C.; Ferreira, M.; Knote, A.; Theisen, W.; Schütte, P. Comparison of different metal matrix systems for diamond tools fabricated by new current induced short-time sintering processes. In Proceedings of the World Powder Metallurgy Congress & Exhibition (PM2010), Florence, Italy, 10–14 October 2010; Volume 3: Sintered Steels/PM Tool Materials (Hard Materials & Diamond Tools). European Powder Metallurgy Association (EPMA): Shrewsbury, UK, 2010; pp. 531–538. [Google Scholar]

- Bączek, E. Technological properties of metallic–diamond tools manufactured by SPS process. Mechanik 2018, 91, 1140–1143. [Google Scholar] [CrossRef]

- Wang, J.; Gao, K.; Li, P.; Zhao, Y. Research on low-carbon, energy-saving sintering process with uniform temperature for drill bits. Energies 2023, 16, 6205. [Google Scholar] [CrossRef]

- Roy, R.; Peelamedu, R.; Hurtt, L.; Cheng, J.; Agrawal, D. Definitive experimental evidence for microwave effects: Radically new effects of separated E and H fields, such as decrystallization of oxides in seconds. Mater. Res. Innov. 2002, 6, 128–140. [Google Scholar] [CrossRef]

- Mishra, R.R.; Sharma, A.K. Microwave–material interaction phenomena: Heating mechanisms, challenges and opportunities in material processing. Compos. Part A Appl. Sci. Manuf. 2016, 81, 78–97. [Google Scholar] [CrossRef]

- Borges, P.F. Caracterização de Ligas Metálicas Produzidas Por via Pulverometalúrgica Através de Tecnologia Micro-Ondas. Master’s Thesis, Instituto Superior Técnico, University of Lisboa, Lisboa, Portugal, 2016. (In Portuguese). [Google Scholar]

- ASTM C1259-96; Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration. ASTM International: West Conshohocken, PA, USA, 1996.

- ISO 6507-1:2005; Metallic Materials—Vickers Hardness Test, Part 1: Test Method. International Organization for Standardization: Geneve, Switzerland, 2005.

- ISO 3327:2009; Hardmetals—Determination of Transverse Rupture Strength. International Organization for Standardization: Geneve, Switzerland, 2009.

- ASTM C1239-06A; Standard Practice for Reporting Uniaxial Strength Data and Estimating Weibull Distribution Parameters for Advanced Ceramics. ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM C1322-05B; Standard Practice for Fractography and Characterization of Fracture Origins in Advanced Ceramics. ASTM International: West Conshohocken, PA, USA, 2005.

- Takayama, S.; Link, G.; Miksch, S.; Sato, M.; Ichikawa, J.; Thumm, M. Millimetre wave effects on sintering behaviour of metal powder compacts. Powder Metall. 2006, 49, 274–280. [Google Scholar] [CrossRef]

- Mondal, A.; Shukla, A.; Upadhyaya, A.; Agrawal, D. Effect of porosity and particle size on microwave heating of copper. Sci. Sint. 2010, 42, 169–182. [Google Scholar] [CrossRef]

- Pozar, D.M. Microwave Engineering, 4th ed.; J. Wiley & Sons Inc.: New York, NY, USA, 2012. [Google Scholar]

- Schmidt, J.; Schmid, P.; Schubert, T.; Weißgärber, T.; Kieback, B. Microwave-assisted sintering of Co-based composites. In Proceedings of the 4th International Conference on Science, Technology and Applications of Sintering, Grenoble, France, 29 August–1 September 2005; pp. 72–75. [Google Scholar]

- Rosa, L.G.; Amaral, P.M.; Fernandes, J.C. Experimental determination of Young’s modulus in PM metal matrices used in diamond impregnated tools for cutting hard materials. Powder Metall. 2008, 51, 46–52. [Google Scholar] [CrossRef]

- Konstanty, J.; Tyrala, D. Easily sinterable low-alloy steel powders for P/M diamond tools. Metals 2021, 11, 1204. [Google Scholar] [CrossRef]

- Peng, Y.; Yi, J.; Luo, S.; Guo, Y.; Li, L. Microstructure analysis of microwave sintered ferrous PM alloys. J. Wuhan Univ. Technol. Mat. Sci. Edit. 2009, 24, 214–217. [Google Scholar] [CrossRef]

- Griffith, A.A. The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. Lond. Ser. A 1921, 221, 163–198. [Google Scholar]

- Deng, X.; Bitler, J.; Chawla, K.K.; Patterson, B.R. Toughness measurement of cemented carbides with chevron-notched three-point bend test. Adv. Eng. Mater. 2010, 12, 948–952. [Google Scholar] [CrossRef]

- Žmak, I.; Ćorić, D.; Mandić, V.; Ćurković, L. Hardness and indentation fracture toughness of slip cast alumina and alumina-zirconia ceramics. Materials 2019, 13, 122. [Google Scholar] [CrossRef] [PubMed]

- Piconi, C.; Maccauro, G. Zirconia as a ceramic biomaterial. Biomaterials 1999, 20, 1–25. [Google Scholar] [CrossRef] [PubMed]

- Armstrong, R.W. The hardness and strength properties of WC-Co composites. Materials 2011, 4, 1287–1308. [Google Scholar] [CrossRef]

| Series | n | ρ (Mg m−3) | Rel.Dens. (%) | ε (%) | E (GPa) | G (GPa) | σr (MPa) | KIC | HV1 |

|---|---|---|---|---|---|---|---|---|---|

| MW–Matrix | 15 | 1106120 | 14.01.5 | ||||||

| HP–Matrix | 12 | 124678 | 14.41.9 | ||||||

| MW–MMC | 14 | 103983 | 14.81.7 | ||||||

| HP–MMC | 13 | 986120 | 15.81.5 |

| Serie | U | σ0 (MPa) | upper | lower | σ0,upper (MPa) | σ0,lower (MPa) |

|---|---|---|---|---|---|---|

| MW matrix | 11.3 | 1157 | 13.8 | 8.4 | 1193 | 1123 |

| HP matrix | 16.8 | 1283 | 20.5 | 12.6 | 1309 | 1258 |

| MW–MMC | 16.4 | 1074 | 20.5 | 11.5 | 1101 | 1048 |

| HP–MMC | 9.4 | 1058 | 11.8 | 6.6 | 1105 | 1014 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costa Oliveira, F.A.; Borges, P.F.; Coelho, A.; Amaral, P.M.; Cruz Fernandes, J. Manufacturing of Diamond Tool Segments via Microwave–Hybrid Sintering. J. Manuf. Mater. Process. 2025, 9, 370. https://doi.org/10.3390/jmmp9110370

Costa Oliveira FA, Borges PF, Coelho A, Amaral PM, Cruz Fernandes J. Manufacturing of Diamond Tool Segments via Microwave–Hybrid Sintering. Journal of Manufacturing and Materials Processing. 2025; 9(11):370. https://doi.org/10.3390/jmmp9110370

Chicago/Turabian StyleCosta Oliveira, Fernando A., Pedro F. Borges, Adriano Coelho, Pedro M. Amaral, and Jorge Cruz Fernandes. 2025. "Manufacturing of Diamond Tool Segments via Microwave–Hybrid Sintering" Journal of Manufacturing and Materials Processing 9, no. 11: 370. https://doi.org/10.3390/jmmp9110370

APA StyleCosta Oliveira, F. A., Borges, P. F., Coelho, A., Amaral, P. M., & Cruz Fernandes, J. (2025). Manufacturing of Diamond Tool Segments via Microwave–Hybrid Sintering. Journal of Manufacturing and Materials Processing, 9(11), 370. https://doi.org/10.3390/jmmp9110370