Assessment of Causes of Precision and Accuracy Loss in Metal Binder Jetting Additive Manufacturing Technology

Abstract

1. Introduction

2. Materials and Methods

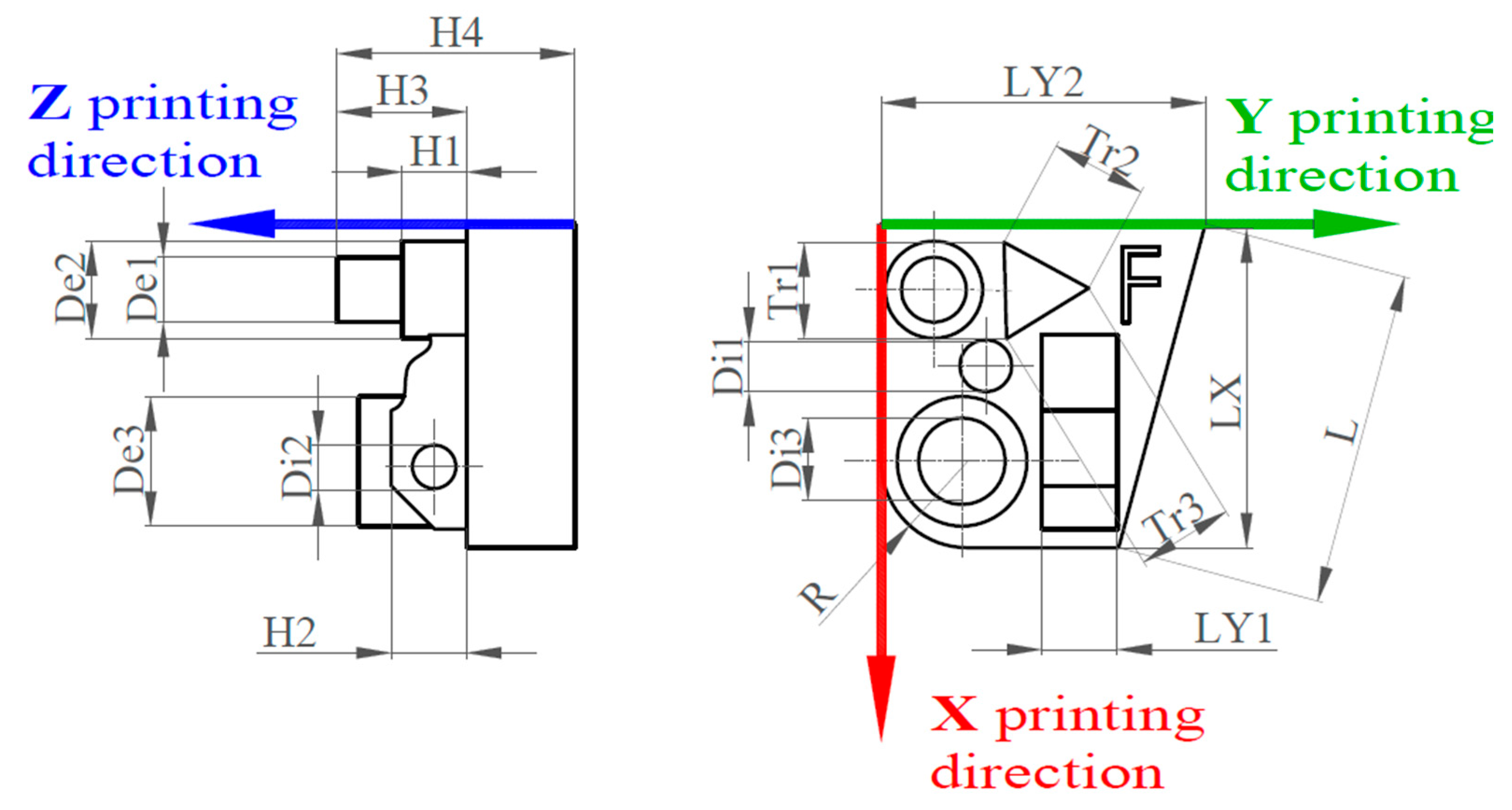

2.1. Sample Geometry

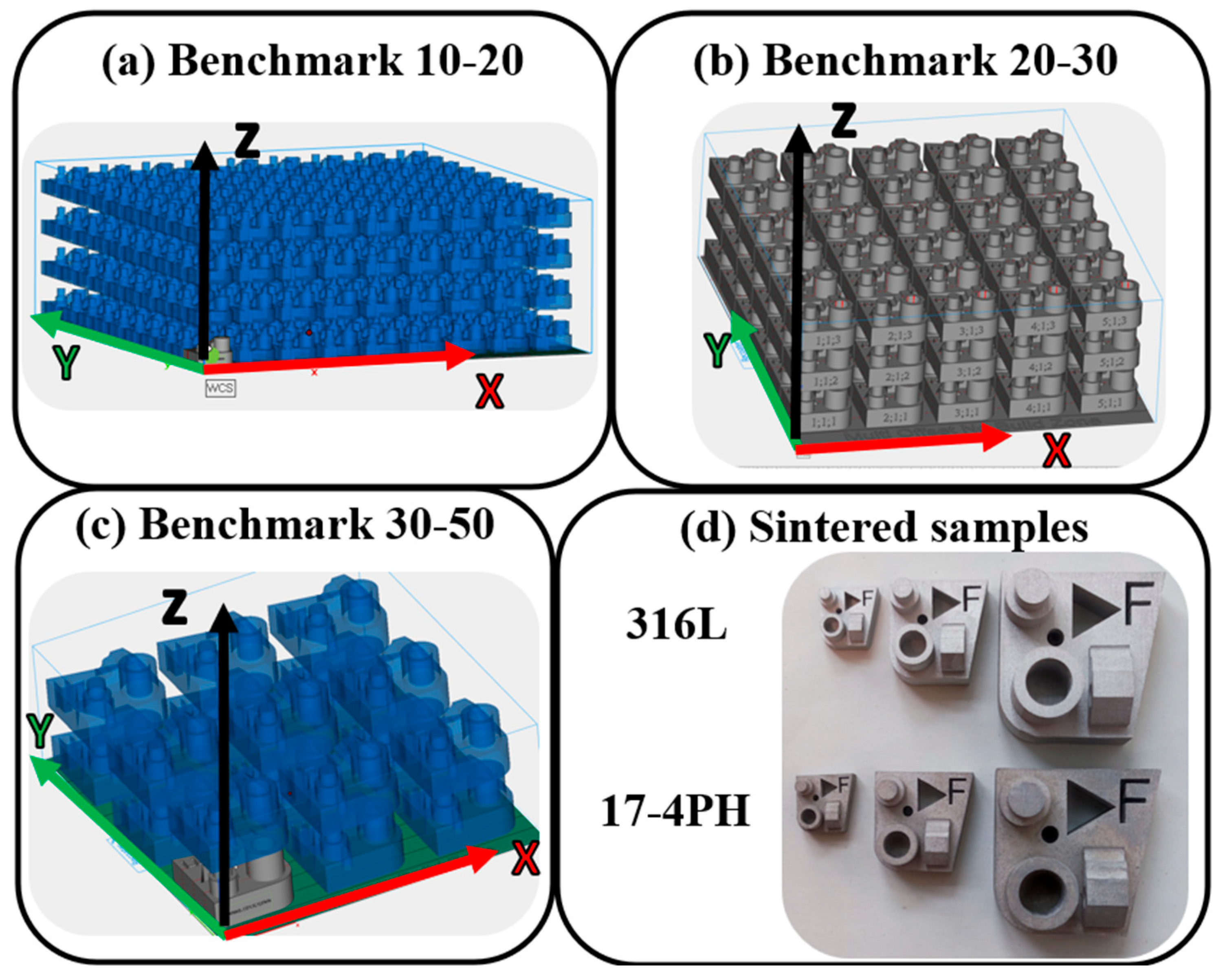

2.2. Printing and Sintering

- The X direction corresponds to the movement direction of the printhead.

- The Y direction corresponds to the movement direction of the blade for spreading the powder.

- The Z direction corresponds to the building direction.

2.3. Dimensions Measurement and Tolerance Evaluation

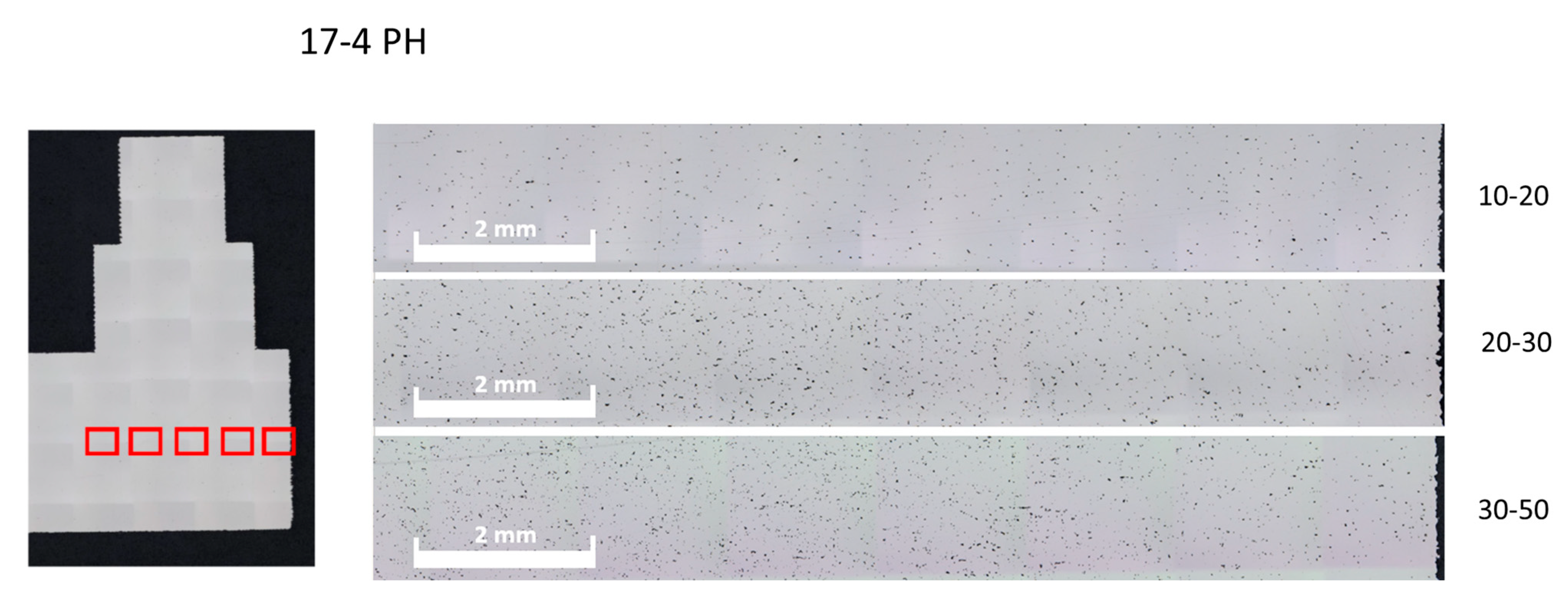

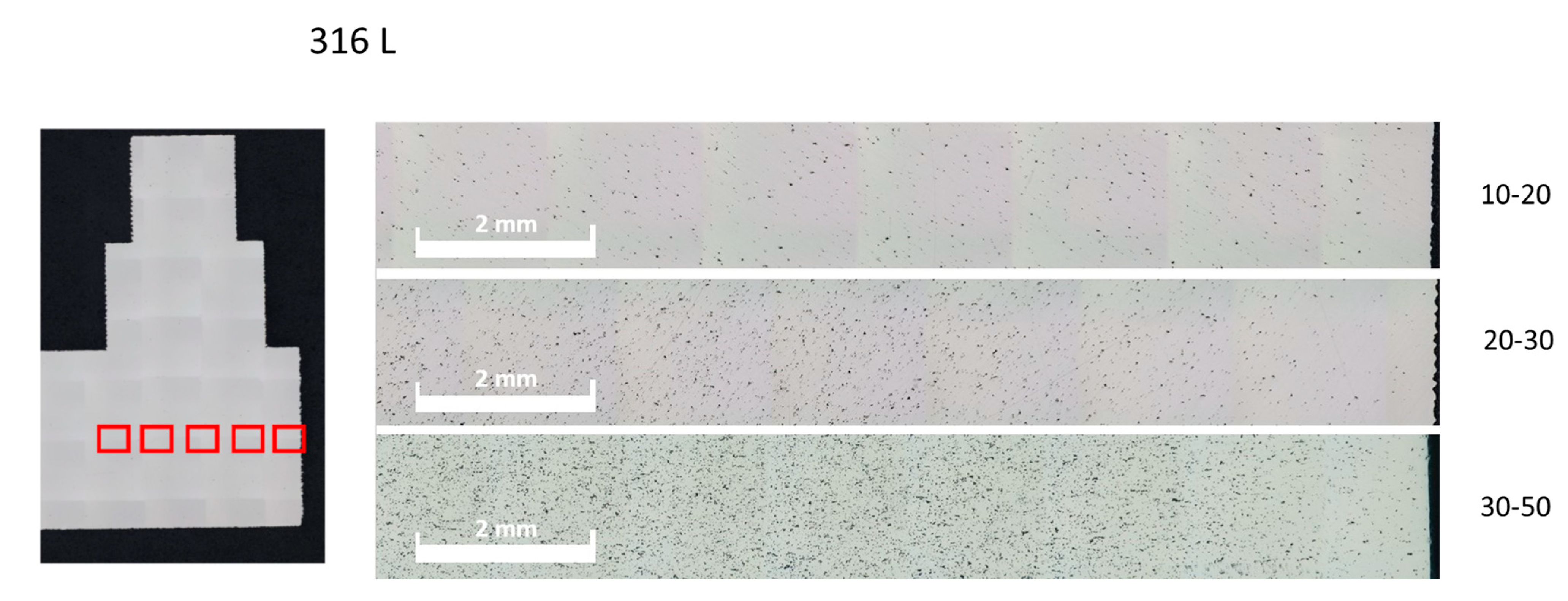

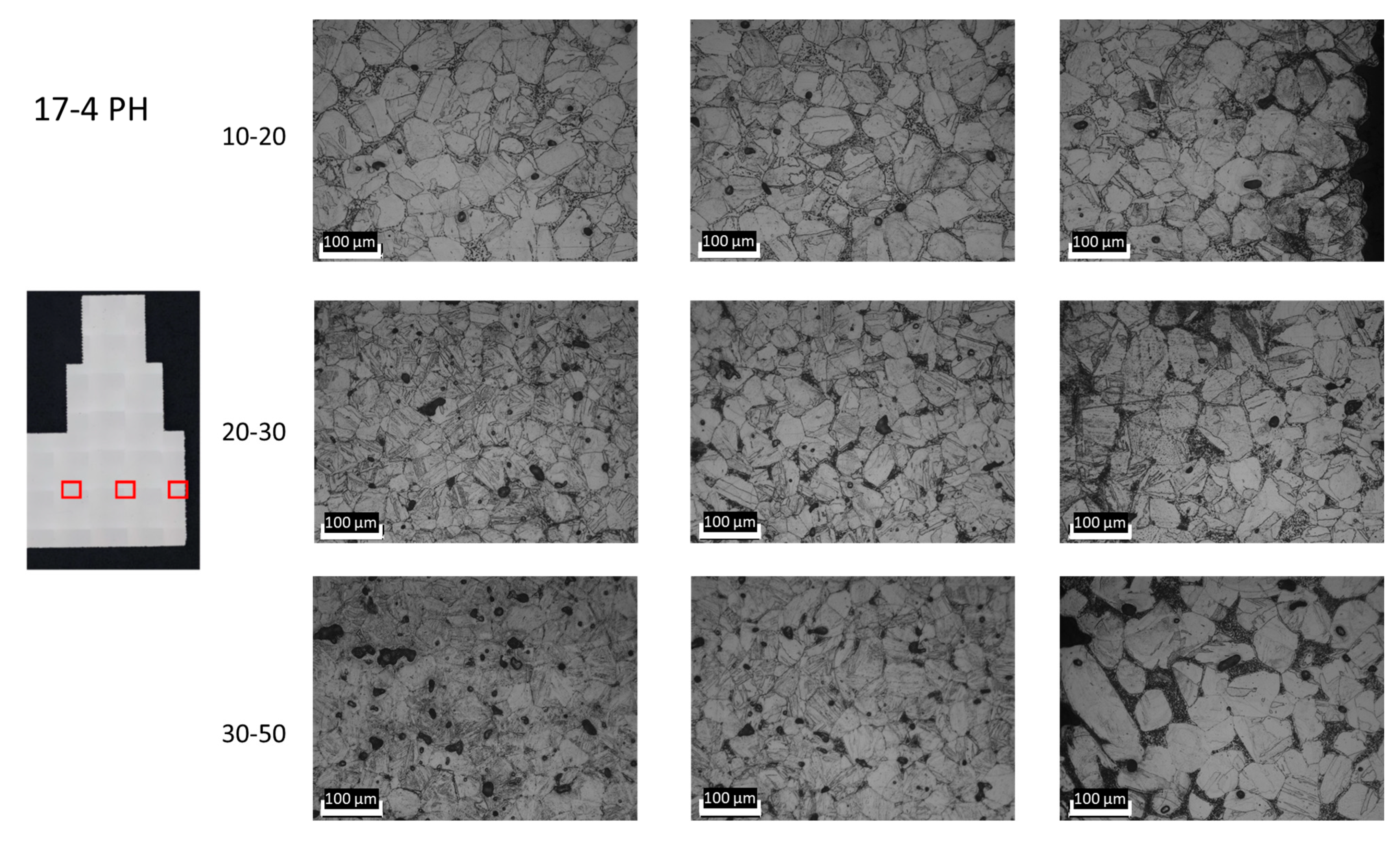

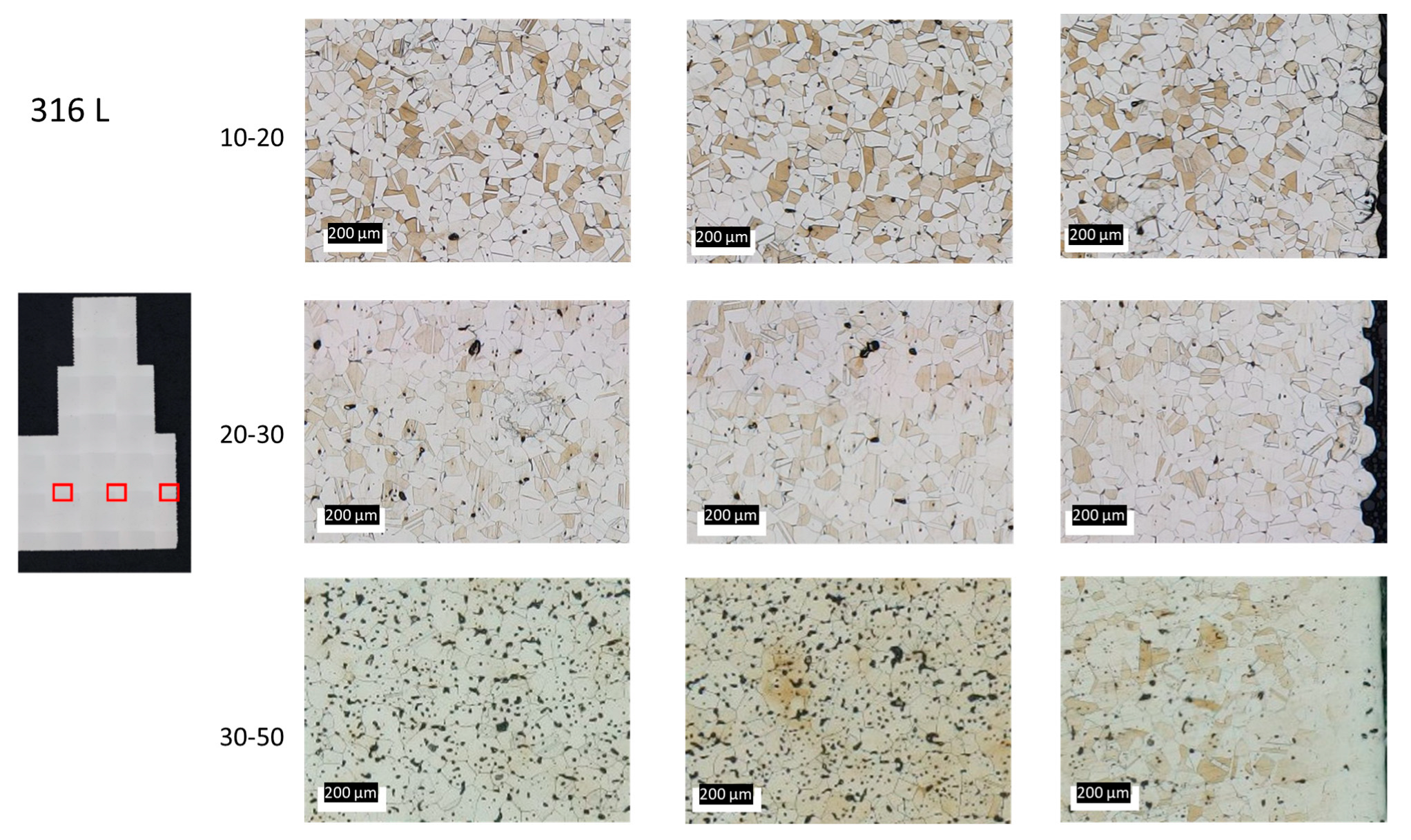

2.4. Density Measurement and Microstructural Analysis

3. Results and Discussion

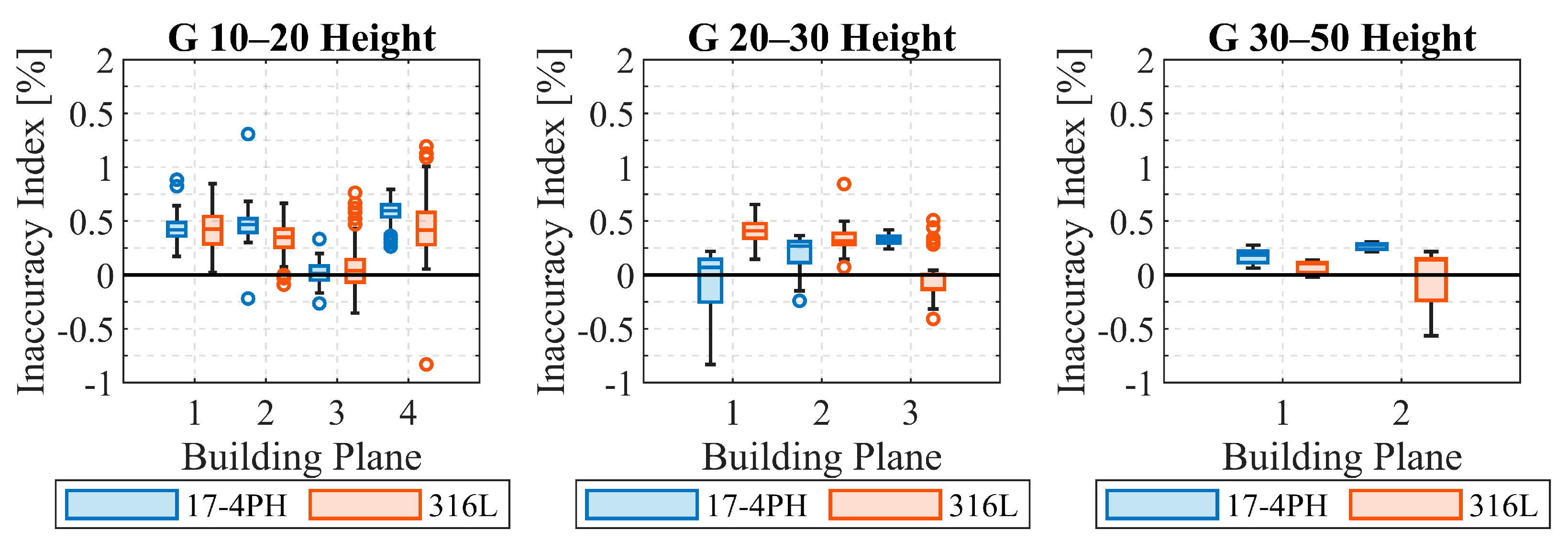

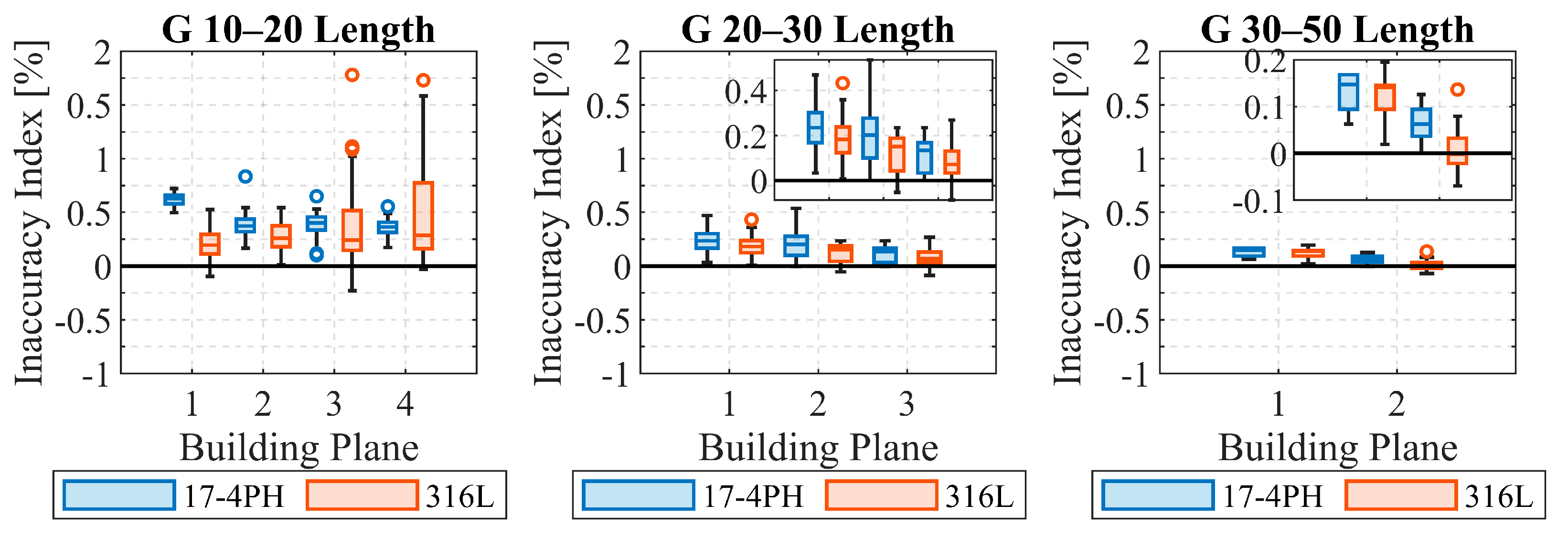

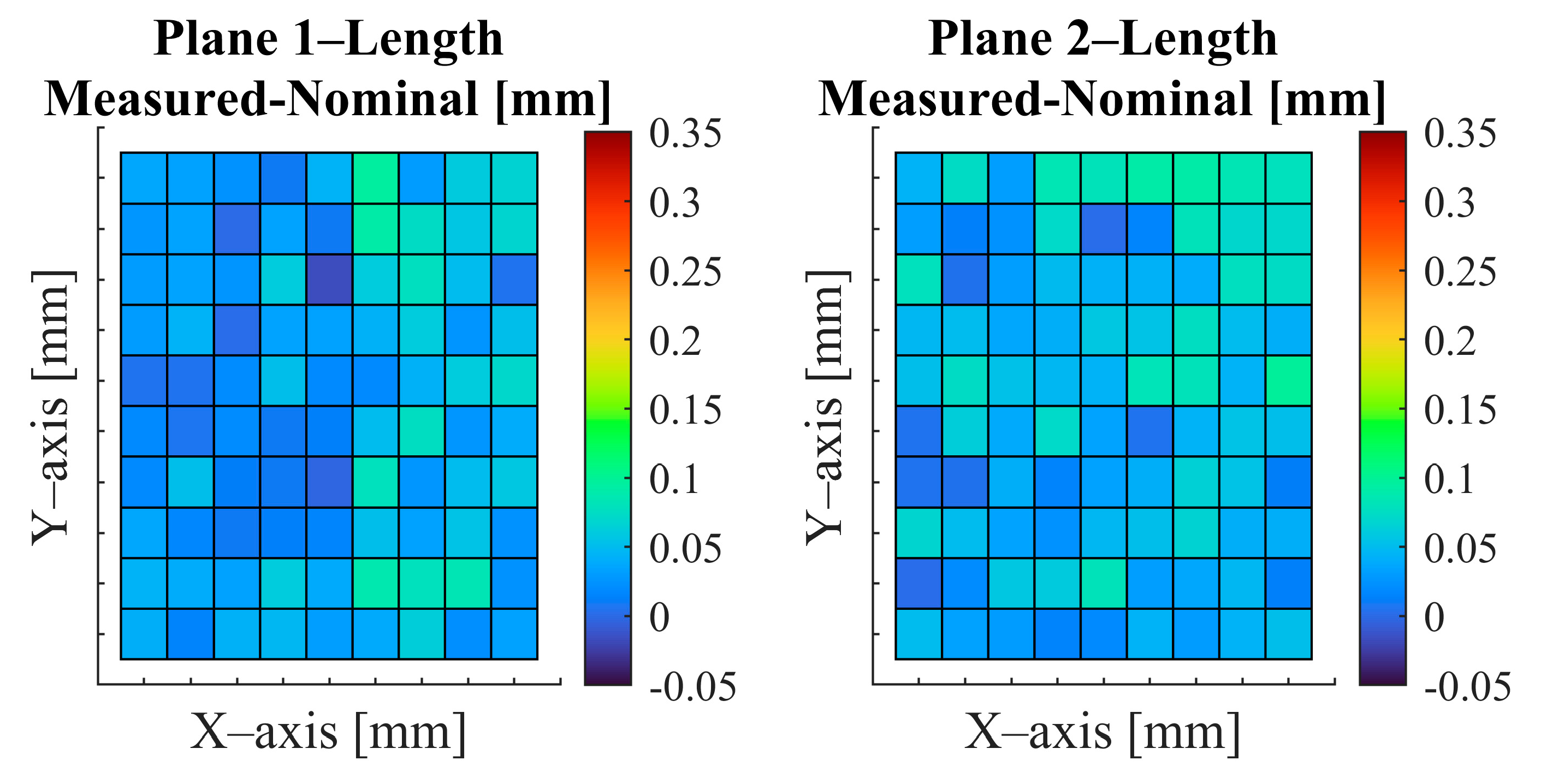

3.1. Accuracy and Spatial Repeatability—Green State

3.2. IT Tolerance Grades—Green State

3.3. IT Tolerance Grades—Sintered State

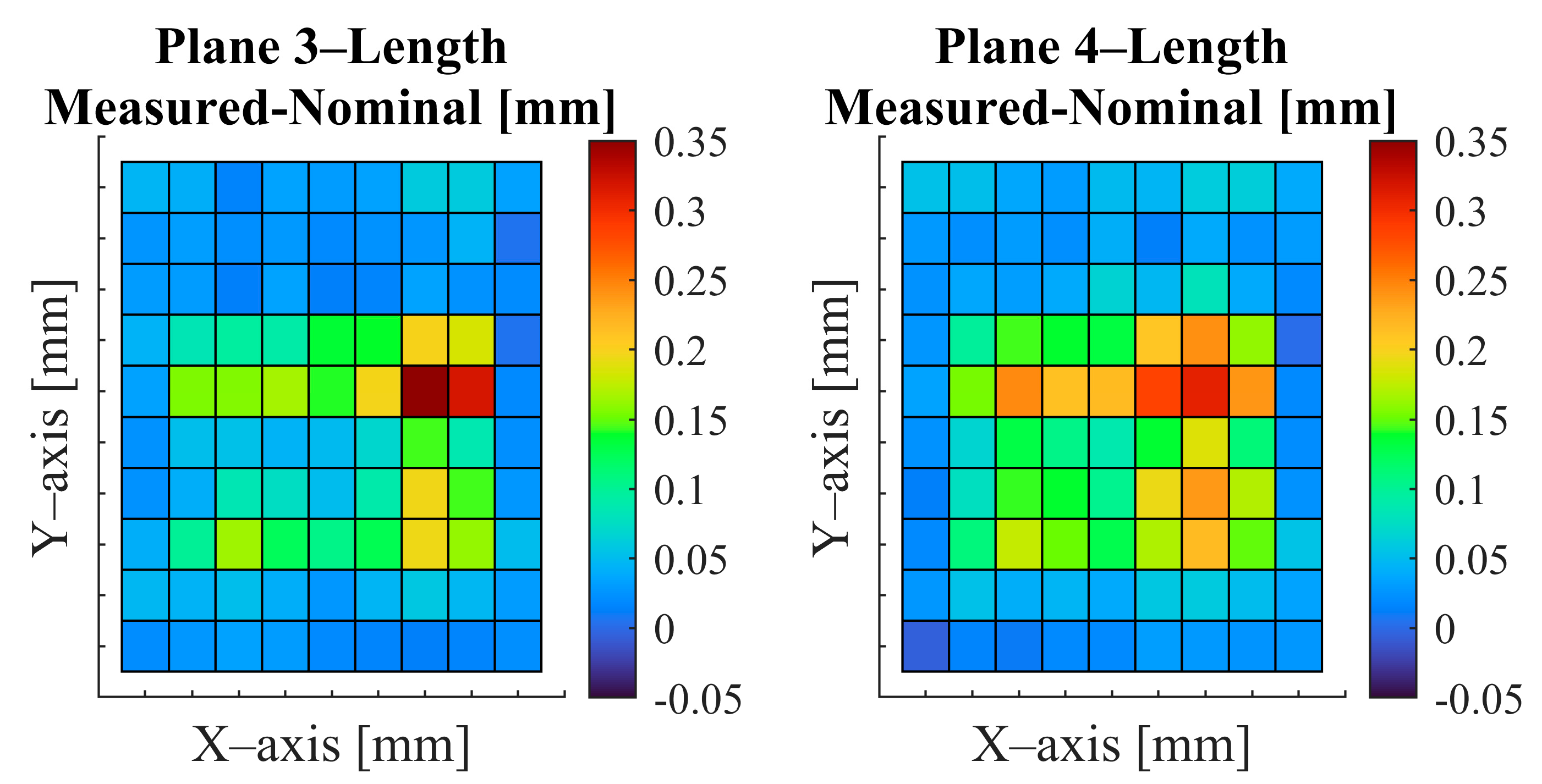

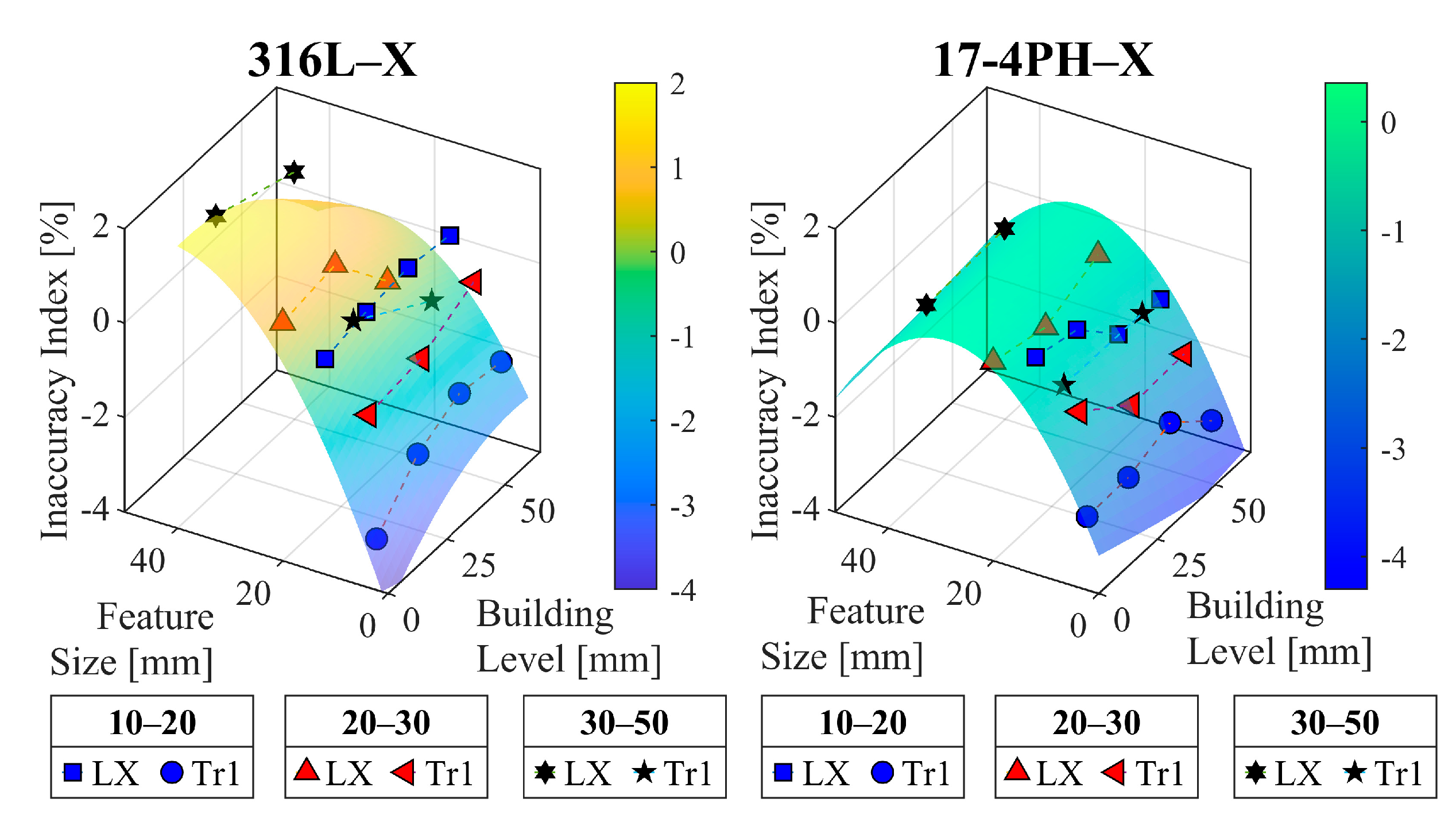

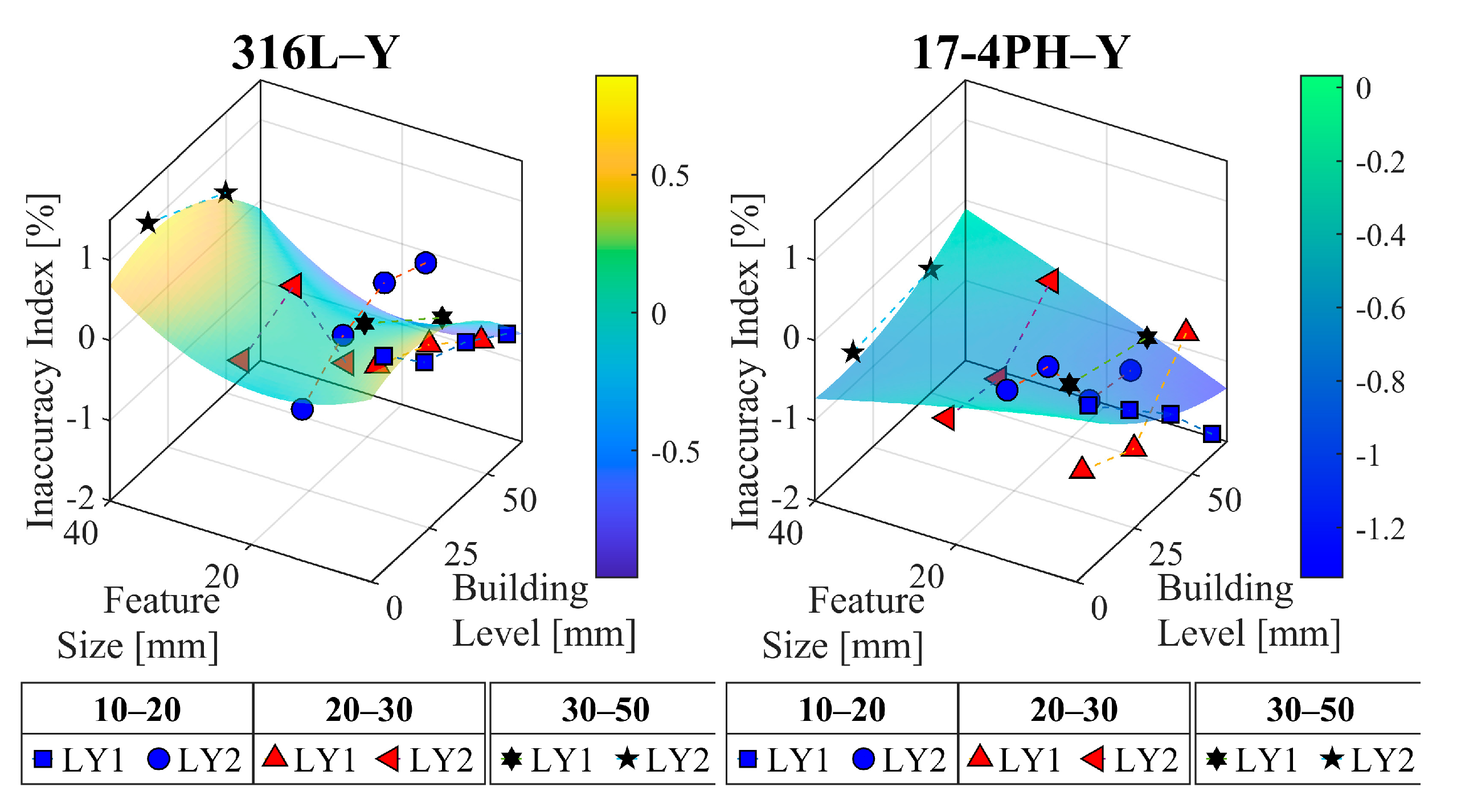

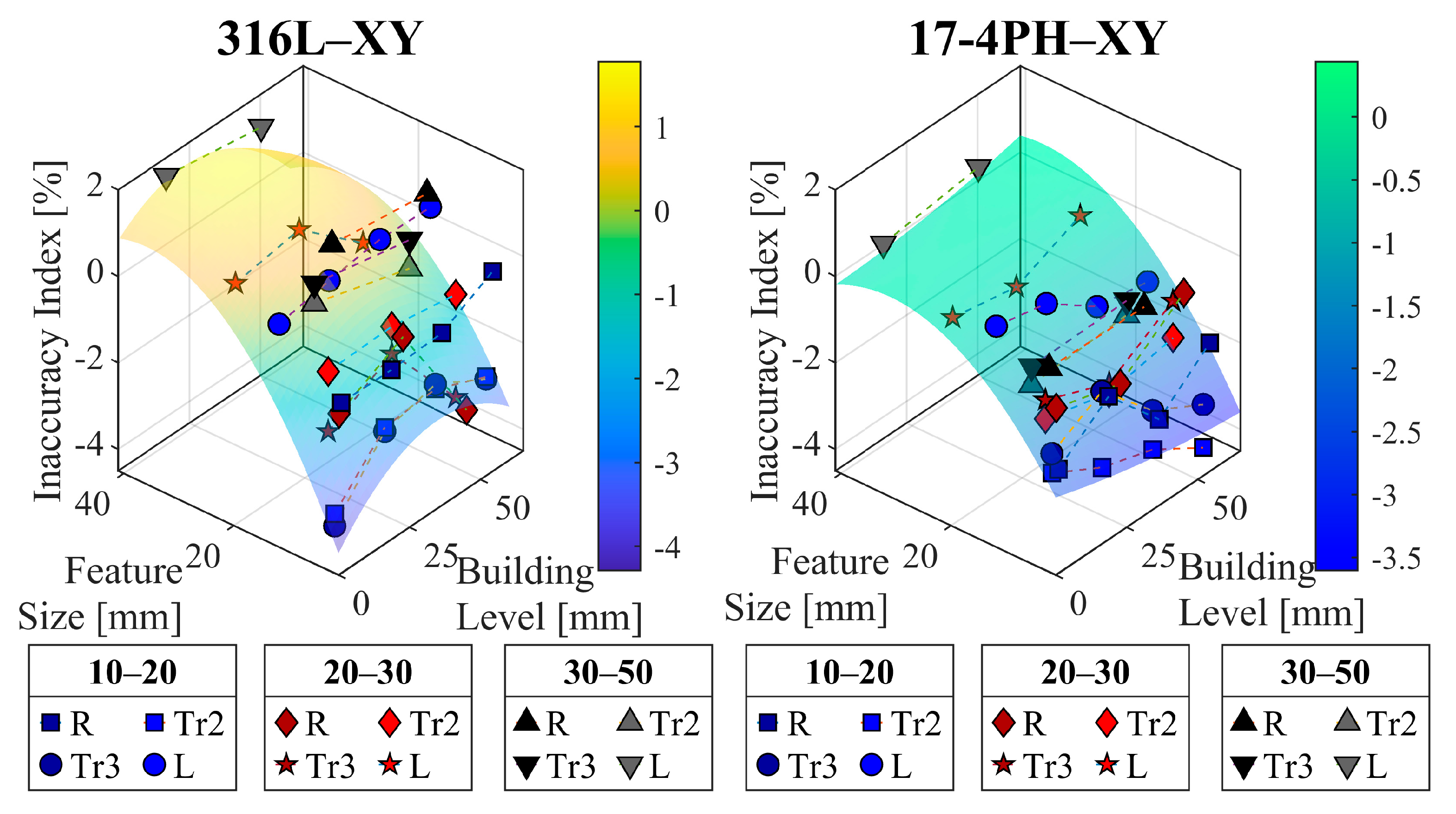

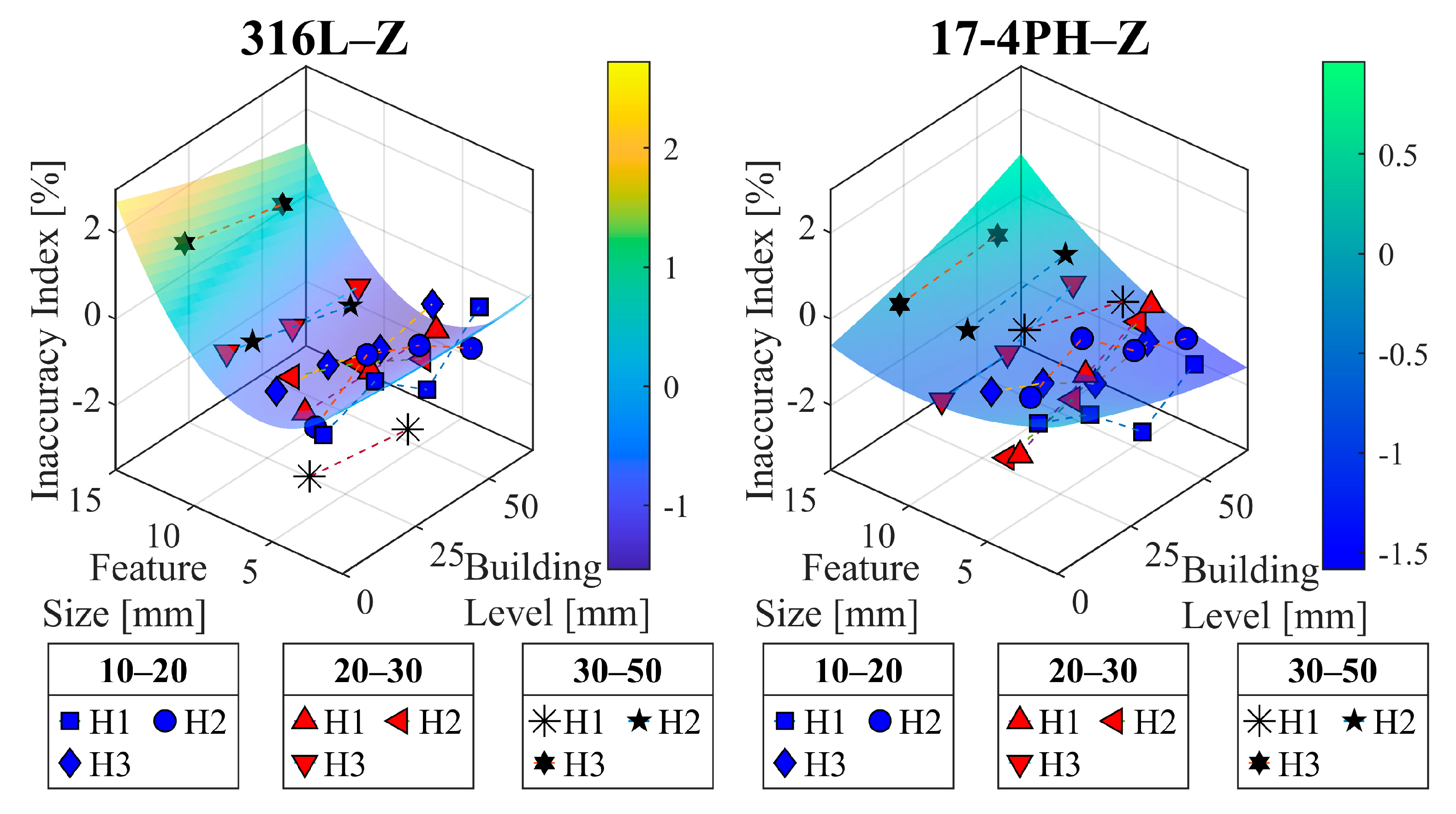

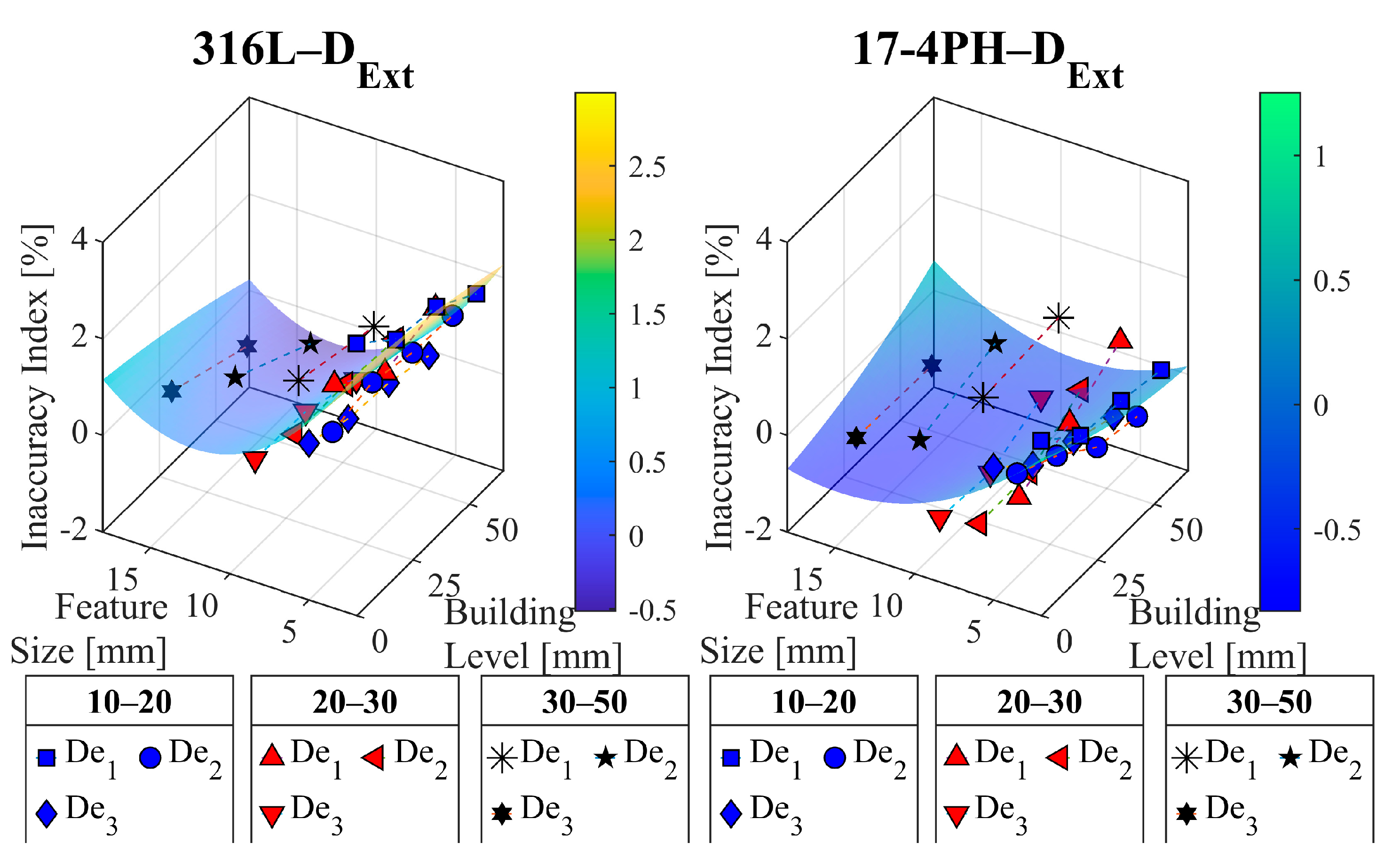

3.4. Accuracy and Spatial Repeatability—Sintered State

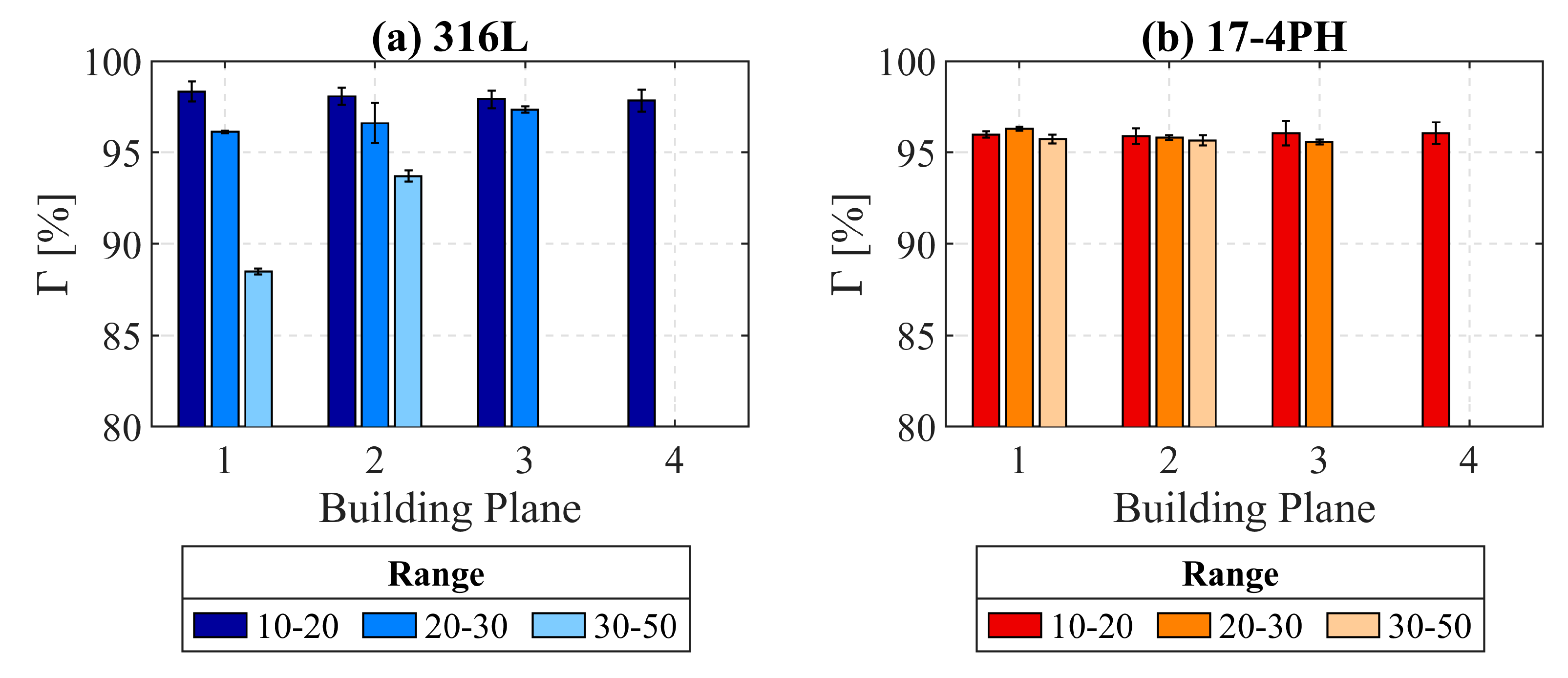

3.5. Green and Sintered Density

3.6. Microstructural Analysis

4. Conclusions

- In the green state, the inaccuracy index varied between −0.5% and 1%. It tends to decrease with feature size, and spatial repeatability is not constant but depends on the building plane. The loss of accuracy was attributed to the particle–binder interaction. Binder saturation and drying operations should be optimized, mainly when printing a large number of samples. Other sources of inaccuracy can be ascribed to gravitational and compaction forces acting on the powder bed.

- In the green state, the IT tolerance grades varied between IT08 and IT13. The result was attributed to the non-uniform spatial repeatability function of the XYZ position in the building box. Specifically, a broadening of dimensional scatter was observed in the last building planes.

- In the sintered state, the accuracy is significantly affected by the printing direction feature size, and slightly by the building level. Small features showed a high negative deviation from nominal values, likely due to shrinkage affected by the feature size, according to the density and microstructure analysis. Small features reached a higher density and, consequently, a higher dimensional change.

- In the sintered state, IT tolerance grades between IT10 and IT16 were found. Sintering generally produced a broadening of scatter of dimensions, as is generally observed in powder metallurgy technologies.

- A homogeneous sintered density was observed in the 17-4 PH samples, while it was influenced by the size in 316L (higher density in small samples). This is attributed to the different sintering mechanisms (solid state sintering in 316L, liquid phase sintering in 17-4 PH).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Prashar, G.; Vasudev, H.; Bhuddhi, D. Additive manufacturing: Expanding 3D printing horizon in industry 4.0. Int. J. Interact Des. Manuf. 2023, 17, 2221–2235. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2021; Additive Manufacturing—General principles—Fundamentals and Vocabulary. ISO: Geneva, Switzerland, 2021.

- Chen, L.; Chen, W.; Fu, Z.; Ding, G.; Chen, Z.; Zhu, D. Binder Jet 3D Printing of 316L Stainless Steel: Orthogonal Printing and Sintering Process Optimization. Adv. Eng. Mater. 2023, 25, 2200641. [Google Scholar] [CrossRef]

- Chen, W.; Chen, Z.; Chen, L.; Zhu, D.; Fu, Z. Optimization of Printing Parameters to Achieve High-Density 316L Stainless Steel Manufactured by Binder Jet 3D Printing. J. Mater. Eng. Perform. 2023, 32, 3602–3616. [Google Scholar] [CrossRef]

- Bai, Y.; Wagner, G.; Williams, C.B. Effect of particle size distribution on powder packing and sintering in binder jetting additive manufacturing of metals. J. Manuf. Sci. Eng. Trans. ASME 2017, 139, 081019. [Google Scholar] [CrossRef]

- Mostafaei, A.; Rodriguez De Vecchis, P.; Nettleship, I.; Chmielus, M. Effect of powder size distribution on densification and microstructural evolution of binder-jet 3D-printed alloy 625. Mater. Des. 2019, 162, 375–383. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Y.F. Investigation of Sintering Shrinkage in Binder Jetting Additive Manufacturing Process. Procedia Manuf. 2017, 10, 779–790. [Google Scholar] [CrossRef]

- Do, T.; Kwon, P.; Shin, C.S. Process development toward full-density stainless steel parts with binder jetting printing. Int. J. Mach. Tools Manuf. 2017, 121, 50–60. [Google Scholar] [CrossRef]

- Mao, Y.; Cai, C.; Zhang, J.; Heng, Y.; Feng, K.; Cai, D.; Wei, Q. Effect of sintering temperature on binder jetting additively manufactured stainless steel 316L: Densification, microstructure evolution and mechanical properties. J. Mater. Res. Technol. 2023, 22, 2720–2735. [Google Scholar] [CrossRef]

- Huber, D.; Vogel, L.; Fischer, A. The effects of sintering temperature and hold time on densification, mechanical properties and microstructural characteristics of binder jet 3D printed 17-4 PH stainless steel. Addit. Manuf. 2021, 46, 102114. [Google Scholar] [CrossRef]

- Mirzababaei, S.; Pasebani, S. A review on binder jet additive manufacturing of 316L stainless steel. J. Manuf. Mater. Process. 2019, 3, 82. [Google Scholar] [CrossRef]

- Zago, M.; Lecis, N.; Mariani, M.; Cristofolini, I. Analysis of the causes determining dimensional and geometrical errors in 316L and 17-4PH stainless steel parts fabricated by metal binder jetting. Int. J. Adv. Manuf. Technol. 2024, 132, 835–851. [Google Scholar] [CrossRef]

- Sadeghi Borujeni, S.; Saluja, G.S.; Ploshikhin, V. Compensation of sintering deformation for components manufactured by metal binder jetting using numerical simulations. Rapid Prototyp. J. 2023, 29, 612–625. [Google Scholar] [CrossRef]

- Sadeghi Borujeni, S.; Shad, A.; Abburi Venkata, K.; Günther, N.; Ploshikhin, V. Numerical simulation of shrinkage and deformation during sintering in metal binder jetting with experimental validation. Mater. Des. 2022, 216, 110490. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, W.; Brune, R.; Herderick, E.; Zhang, X.; Cornell, J.; Forsmark, J. Numerical simulation and experimental measurement of pressureless sintering of stainless steel part printed by Binder Jetting Additive Manufacturing. Addit. Manuf. 2021, 47, 102330. [Google Scholar] [CrossRef]

- Paudel, B.J.; Conover, D.; Lee, J.K.; To, A.C. A computational framework for modeling distortion during sintering of binder jet printed parts. J. Micromech. Mol. Phys. 2021, 6, 95–102. [Google Scholar] [CrossRef]

- Jamalkhani, M.; Deng, Z.; Sossong, D.; Dashtgerd, I.; Martiska, G.; Mostafaei, A. In-situ monitoring of sintering and analytical modeling of densification and shrinkage in binder jetted 316L stainless steel. Materialia 2024, 36, 102131. [Google Scholar] [CrossRef]

- Sajgalik, M.; Matus, M.; Spuro, P.; Joch, R.; Czan, A.; Beranek, L. Analysis of the Suitability of Additive Technologies for the Production of Stainless Steel Components. J. Manuf. Mater. Process. 2025, 9, 283. [Google Scholar] [CrossRef]

- Yap, Y.L.; Wang, C.; Sing, S.L.; Dikshit, V.; Yeong, W.Y.; Wei, J. Material jetting additive manufacturing: An experimental study using designed metrological benchmarks. Precis. Eng. 2017, 50, 275–285. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, Y.F. Process parameters optimization for improving surface quality and manufacturing accuracy of binder jetting additive manufacturing process. Rapid Prototyp. J. 2016, 22, 527–538. [Google Scholar] [CrossRef]

- Sahu, K.K.; Modi, Y.K. Multi response optimization for compressive strength, porosity and dimensional accuracy of binder jetting 3D printed ceramic bone scaffolds. Ceram. Int. 2022, 48, 26772–26783. [Google Scholar] [CrossRef]

- Rebaioli, L.; Fassi, I. A review on benchmark artifacts for evaluating the geometrical performance of additive manufacturing processes. Int. J. Adv. Manuf. Technol. 2017, 93, 2571–2598. [Google Scholar] [CrossRef]

- de Pastre, M.A.; Toguem Tagne, S.C.; Anwer, N. Test artefacts for additive manufacturing: A design methodology review. CIRP J. Manuf. Sci. Technol. 2020, 31, 14–24. [Google Scholar] [CrossRef]

- Minetola, P.; Galati, M.; Calignano, F.; Iuliano, L.; Rizza, G.; Fontana, L. Comparison of dimensional tolerance grades for metal AM processes. Procedia CIRP 2020, 88, 399–404. [Google Scholar] [CrossRef]

- Piscopo, G.; Salmi, A.; Atzeni, E. Investigation of dimensional and geometrical tolerances of laser powder directed energy deposition process. Precis. Eng. 2024, 85, 217–225. [Google Scholar] [CrossRef]

- Gruber, S.; Grunert, C.; Riede, M.; López, E.; Marquardt, A.; Brueckner, F.; Leyens, C. Comparison of dimensional accuracy and tolerances of powder bed based and nozzle based additive manufacturing processes. J. Laser Appl. 2020, 32, 032016. [Google Scholar] [CrossRef]

- Dimitrov, D.; Van Wijck, W.; Schreve, K.; De Beer, N. Investigating the achievable accuracy of three dimensional printing. Rapid Prototyp. J. 2006, 12, 42–52. [Google Scholar] [CrossRef]

- Kim, G.D.; Oh, Y.T. A benchmark study on rapid prototyping processes and machines: Quantitative comparisons of mechanical properties, accuracy, roughness, speed, and material cost. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2008, 222, 201–215. [Google Scholar] [CrossRef]

- Dahmen, T.; Klingaa, C.G.; Baier-Stegmaier, S.; Lapina, A.; Pedersen, D.B.; Hattel, J.H. Characterization of channels made by laser powder bed fusion and binder jetting using X-ray CT and image analysis. Addit. Manuf. 2020, 36, 101445. [Google Scholar] [CrossRef]

- Modi, Y.K.; Sahu, K.K. Process capability analysis of binder jetting 3D printing process for fabrication of calcium sulphate based porous bone scaffolds. Aust. J. Mech. Eng. 2023, 21, 270–278. [Google Scholar] [CrossRef]

- Ollison, T.; Berisso, K. Three-dimensional printing build variables that impact cylindricity. J. Ind. Technol. 2010, 26, 1–10. [Google Scholar]

- Zago, M.; Lecis, N.F.M.; Vedani, M.; Cristofolini, I. Dimensional and geometrical precision of parts produced by Binder Jetting process as affected by the anisotropic shrinkage on sintering. Addit. Manuf. 2021, 43, 102007. [Google Scholar] [CrossRef]

- Yang, M.; Keshavarz, M.K.; Vlasea, M.; Molavi-Kakhki, A. Towards full-dense high geometric fidelity parts via binder jetting and controlled sintering. J. Manuf. Process. 2024, 115, 180–191. [Google Scholar] [CrossRef]

- Islam, M.N.; Sacks, S. An experimental investigation into the dimensional error of powder-binder three-dimensional printing. Int. J. Adv. Manuf. Technol. 2016, 82, 1371–1380. [Google Scholar] [CrossRef]

- Dahmen, T.; Henriksen, N.G.; Dahl, K.V.; Lapina, A.; Pedersen, D.B.; Hattel, J.H.; Christiansen, T.; Somers, M. Densification, microstructure, and mechanical properties of heat-treated MAR-M247 fabricated by Binder Jetting. Addit. Manuf. 2021, 39, 101912. [Google Scholar] [CrossRef]

- ISO 10360-5:2020; Geometrical Product Specifications (GPS)—Acceptance and Reverification Tests for Coordinate Measuring Systems (CMS) Part 5: Coordinate Measuring Machines (CMMs) Using Single and Multiple Stylus Contacting Probing Systems Using Discrete Point and/or Scanning Measuring Mode. ISO: Geneva, Switzerland, 2020.

- ISO 286-1:2010; Geometrical Product Specifications (GPS)—ISO Code System for Tolerances on Linear Sizes Part 1: Basis of Tolerances, Deviations and Fits. ISO: Geneva, Switzerland, 2010.

- ISO 286-2:2010; Geometrical Product Specifications (GPS)—ISO Code System for Tolerances on LINEAR sizes Part 2: Tables of Standard Tolerance Classes and Limit Deviations for Holes and Shafts. ISO: Geneva, Switzerland, 2010.

- Liang, X.; Meng, X.; Ni, P.; Zhao, Z.; Deng, X.; Chen, G.; Chen, Y.; Li, S.; Wu, S.; Liu, J.; et al. Effect of feedstock bimodal powder mixture and infiltration process on mechanical behaviour of binder jetting processed 316L stainless steel. Powder Metall. 2023, 66, 387–402. [Google Scholar] [CrossRef]

- Dorula, M.; Khademitab, M.; Jamalkhani, M.; Mostafaei, A. Location dependency of green density and dimension variation in binder jetted parts. Int. J. Adv. Manuf. Technol. 2024, 132, 2853–2861. [Google Scholar] [CrossRef]

- Crane, N.B. Impact of part thickness and drying conditions on saturation limits in binder jet additive manufacturing. Addit. Manuf. 2020, 33, 101127. [Google Scholar] [CrossRef]

- Colton, T.; Inkley, C.; Berry, A.; Crane, N.B. Impact of inkjet printing parameters and environmental conditions on formation of 2D and 3D binder jetting geometries. J. Manuf. Process. 2021, 71, 187–196. [Google Scholar] [CrossRef]

- Miyanaji, H.; Zhang, S.; Yang, L. A new physics-based model for equilibrium saturation determination in binder jetting additive manufacturing process. Int. J. Mach. Tools Manuf. 2018, 124, 1–11. [Google Scholar] [CrossRef]

- Charnnarong, J. The Drying Shrinkage in Three-Dimensional Printing and Its Dependence on the Properties of the Powder and the Binder. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1996. [Google Scholar]

- Cheny, T.; Colin, C.; Verquin, B. Experimental evaluation of binder infiltration depth and axial overlap to control properties of green parts produced by Binder Jetting. Addit. Manuf. 2024, 87, 104231. [Google Scholar] [CrossRef]

- Lores, A.; Azurmendi, N.; Agote, I.; Andrés, U. A Step towards A Robust Binder Jetting Technology: Process Parameter Optimization for 17-4PH Steel to Increase Powder Bed Homogeneity. In Proceedings of the Euro PM2020 Congress Exhibition, Online, 5–7 October 2020; p. 4849277. Available online: https://www.publications.epma.com/product/euro-pm2020-proceedings/ (accessed on 28 October 2025).

- Do, T.; Shin, C.S.; Stetsko, D.; Vanconant, G.; Vartanian, A.; Pei, S.; Kwon, P. Improving Structural Integrity with Boron-Based Additives for 3D printed 420 Stainless Steel. Procedia Manuf. 2015, 1, 263–272. [Google Scholar] [CrossRef]

- Zago, M.; Lecis, N.; Mariani, M.; Uçak, O.U.; Cristofolini, I. Influence of shape distortion on the precision of holes in parts fabricated by metal binder jetting. Int. J. Interact. Des. Manuf. 2024, 18, 5789–5800. [Google Scholar] [CrossRef]

- Lee, Y.; Gurnon, A.K.; Bodner, D.; Simunovic, S. Effect of Particle Spreading Dynamics on Powder Bed Quality in Metal Additive Manufacturing. Integr. Mater. Manuf. Innov. 2020, 9, 410–422. [Google Scholar] [CrossRef]

- Lee, Y.; Nandwana, P.; Simunovic, S. Powder spreading, densification, and part deformation in binder jetting additive manufacturing. Prog. Addit. Manuf. 2021, 7, 111–125. [Google Scholar] [CrossRef]

- Cristofolini, I.; Molinari, A.; Zago, M.; Amirabdollahian, S.; Coube, O.; Dougan, M.J.; Larsson, M.; Schneider, M.; Valler, P.; Voglhuber, J.; et al. Design for Powder Metallurgy: Predicting Anisotropic Dimensional Change on Sintering of Real Parts. Int. J. Precis. Eng. Manuf. 2019, 20, 619–630. [Google Scholar] [CrossRef]

- Barthel, B.; Janas, F.; Wieland, S. Powder condition and spreading parameter impact on green and sintered density in metal binder jetting. Powder Metall. 2021, 64, 378–386. [Google Scholar] [CrossRef]

- Stevens, E.; Schloder, S.; Bono, E.; Schmidt, D.; Chmielus, M. Density variation in binder jetting 3D-printed and sintered Ti-6Al-4V. Addit. Manuf. 2018, 22, 746–752. [Google Scholar] [CrossRef]

- Lecis, N.; Mariani, M.; Beltrami, R.; Emanuelli, L.; Casati, R.; Vedani, M.; Molinari, A. Effects of process parameters, debinding and sintering on the microstructure of 316L stainless steel produced by binder jetting. Mater. Sci. Eng. A 2021, 828, 142108. [Google Scholar] [CrossRef]

- Cabo Rios, A.; Persson, M.; Hryha, E.; Olevsky, E. Phenomenological sintering model and experimental validation of gravity-induced distortions in binder-jetted stainless steel components. Ceram. Int. 2024, 50, 37268–37281. [Google Scholar] [CrossRef]

- Atzeni, E.; Salmi, A. Study on unsupported overhangs of AlSi10Mg parts processed by Direct Metal Laser Sintering (DMLS). J. Manuf. Process. 2015, 20, 500–506. [Google Scholar] [CrossRef]

- ISO 2768-1:1989; General Tolerances Part 1: Tolerances for Linear and Angular Dimensions Without Individual Tolerance Indications. ISO: Geneva, Switzerland, 1989.

- German, R.M.; Bose, A. Injection Molding of Metals and Ceramics; Metal Powder Industries Federation: Princeton, NJ, USA, 1997. [Google Scholar]

- EPMA. Introduction to Metal Injection Moulding. A Manufacturing Process for Precision Engineering Components. 2018. Available online: https://www.publications.epma.com/product/introduction-to-metal-injection-moulding/ (accessed on 1 October 2025).

- Zago, M.; Lecis, N.F.M.; Vedani, M.; Cristofolini, I. Geometrical Issues in Design for Binder Jetting—The Effect of Anisotropic Dimensional Change on Sintering. In Design Tools and Methods in Industrial Engineering II; Rizzi, C., Campana, F., Bici, M., Gherardini, F., Ingrassia, T., Cicconi, P., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 410–421. [Google Scholar] [CrossRef]

| Feature | Benchmark | ||

|---|---|---|---|

| 10–20 | 20–30 | 30–50 | |

| LX [mm] | 15 | 25 | 40 |

| Tr1 [mm] | 5.2 | 8.66 | 13.86 |

| Feature | Benchmark | ||

|---|---|---|---|

| 10–20 | 20–30 | 30–50 | |

| LY1 [mm] | 3.5 | 5.83 | 9.33 |

| LY2 [mm] | 15 | 25 | 40 |

| Feature | Benchmark | ||

|---|---|---|---|

| 10–20 | 20–30 | 30–50 | |

| H1 [mm] | 3 | 5 | 5.67 |

| H2 [mm] | 3.5 | 5.83 | 9.33 |

| H3 [mm] | 6 | 10 | 13.67 |

| H4 [mm] | 11 | 18.33 | 27 |

| Feature | Benchmark | ||

|---|---|---|---|

| 10–20 | 20–30 | 30–50 | |

| R [mm] | 4 | 6.67 | 10.67 |

| Tr2 [mm] | 5.2 | 8.66 | 13.86 |

| Tr3 [mm] | 5.2 | 8.66 | 13.86 |

| L [mm] | 15.3 | 25.5 | 40.79 |

| Feature | Benchmark | ||

|---|---|---|---|

| 10–20 | 20–30 | 30–50 | |

| De1 [mm] | 3 | 5 | 8 |

| De2 [mm] | 4.5 | 7.5 | 12 |

| De3 [mm] | 6 | 10 | 16 |

| Feature | Benchmark | ||

|---|---|---|---|

| 10–20 | 20–30 | 30–50 | |

| Di1 [mm] | 1.6 | 2.67 | 4.26 |

| Di2 [mm] | 2 | 3.33 | 5.33 |

| Di3 [mm] | 4 | 6.67 | 10.67 |

| Layer Thickness | Dark Body | Printhead Speed | Powder Applicator Speed | Bed Temperature | Resolution |

|---|---|---|---|---|---|

| 42 μm | 3 | 200 mm/s | 30 mm/s | 80 °C | 1200 dpi |

| Basic Size | ||||||

|---|---|---|---|---|---|---|

| Lower limit (Lupper) [mm] | 1 | 3 | 6 | 10 | 18 | 30 |

| Upper Limit (Llower) [mm] | 3 | 6 | 10 | 18 | 30 | 50 |

| Standard tolerance factor i [-] | 0.542 | 0.733 | 0.898 | 1.083 | 1.307 | 1.561 |

| IT5 | IT6 | IT7 | IT8 | IT9 | IT10 | IT11 | IT12 | IT13 | IT14 | IT15 | IT16 | IT17 | IT18 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7i | 10i | 16i | 25i | 40i | 64i | 100i | 160i | 250i | 400i | 640i | 1000i | 1600i | 2500i |

| Range | Material | Plane 1 | Plane 2 | Plane 3 | Plane 4 |

|---|---|---|---|---|---|

| 10–20 | 17-4PH | IT11 | IT11 | IT08 | IT11 |

| 10–20 | 316L | IT11 | IT10 | IT10 | IT12 |

| 20–30 | 17-4PH | IT12 | IT10 | IT11 | / |

| 20–30 | 316L | IT12 | IT11 | IT11 | / |

| 30–50 | 17-4PH | IT10 | IT10 | / | / |

| 30–50 | 316L | IT09 | IT12 | / | / |

| Range | Material | Plane 1 | Plane 2 | Plane 3 | Plane 4 |

|---|---|---|---|---|---|

| 10–20 | 17-4PH | IT12 | IT11 | IT11 | IT11 |

| 10–20 | 316L | IT11 | IT11 | IT13 | IT13 |

| 20–30 | 17-4PH | IT11 | IT12 | IT10 | / |

| 20–30 | 316L | IT11 | IT10 | IT10 | / |

| 30–50 | 17-4PH | IT10 | IT09 | / | / |

| 30–50 | 316L | IT10 | IT10 | / | / |

| Range | Material | Plane 1 | Plane 2 | Plane 3 | Plane 4 |

|---|---|---|---|---|---|

| 10–20 | 17-4PH | IT10 (−1) | IT10 (−1) | IT13 (+5) | IT13 (+2) |

| 10–20 | 316L | IT10 (−1) | IT15 (+5) | IT14 (+4) | IT13 (+1) |

| 20–30 | 17-4PH | IT14 (+2) | IT12 (+2) | IT12 (+1) | / |

| 20–30 | 316L | IT11 (−1) | IT12 (+1) | IT14 (+3) | / |

| 30–50 | 17-4PH | IT13 (+3) | IT13 (+3) | / | / |

| 30–50 | 316L | IT15 (+6) | IT14 (+2) | / | / |

| Range | Material | Plane 1 | Plane 2 | Plane 3 | Plane 4 |

|---|---|---|---|---|---|

| 10–20 | 17-4PH | IT13 (+1) | IT12 (+1) | IT13 (+2) | IT13 (+2) |

| 10–20 | 316L | IT13 (+2) | IT15 (+4) | IT16 (+3) | IT15 (+3) |

| 20–30 | 17-4PH | IT11 (0) | IT12 (0) | IT12 (+2) | / |

| 20–30 | 316L | IT12 (+1) | IT14 (+4) | IT12 (+2) | / |

| 30–50 | 17-4PH | IT12 (+2) | IT14 (+5) | / | / |

| 30–50 | 316L | IT13 (+3) | IT15 (+5) | / | / |

| AM Process | Machine Manufacturer | Machine | Material | Dimensional Interval [mm] | Reference | |||

|---|---|---|---|---|---|---|---|---|

| <10 | 10–20 | 20–30 | 30–50 | |||||

| BJ (green) | Z-Corp | Z400 | ZP14 (starch-based powder) | / | IT14-IT15 | IT14 | IT09-IT14 | [27] |

| Z-Corp | Z400 | ZP100 (plaster-based powder) | / | IT14-IT15 | IT13-IT14 | IT09-IT14 | [27] | |

| BJ (sintered) | ExOne | Innovent+ | 17-4PH | IT14-IT16 | / | / | / | [29] |

| Digital Metal | DM P2500 | 17-4PH | IT13-IT14 | / | / | / | [29] | |

| L-PBF | EOS | EOSINT M270 | Ti6AlV4 | IT12-IT13 | IT12-IT13 | IT12-IT13 | IT12-IT13 | [24] |

| Renishaw | AM250 | IN728 | Medium-coarse 1 | Medium-coarse | / | / | [26] | |

| SLM | 250HL | Ti6Al4V | Fine | / | / | / | [26] | |

| SLM Solutions | SLM280 2.0 Twin | 17-4PH | IT14-IT16 | / | / | / | [29] | |

| EOS | M290 | 17-4PH | IT14-IT17 | / | / | / | [29] | |

| EBM | Arcam AB | A2X | Ti6Al4V | IT15 | IT13-IT14 | IT13-IT14 | IT14-IT15 | [24] |

| Arcam | A2X | Ti-5553 | Coarse | / | / | / | [26] | |

| LMD | Lasertec | Lasertec 65 | IN728 | Coarse | / | / | / | [26] |

| DLMS | EOSINT | M270 | AlSi10Mg | IT10-IT14 | / | / | / | [56] |

| DED | Prima Additive | Laserdyne 430 system | 316L | / | IT16 | IT16 | / | [25] |

| Dimension Range [mm] | Tolerance Range for | ||

|---|---|---|---|

| No Cpk | Cpk = 1.33 | Cpk = 2.00 | |

| 3–6 | 1.7% | 2.9% | 4.1% |

| 6–50 | 1.6% | 2.8% | 4.0% |

| Building Plane | RD Green [%] | RD Sintered [%] | ||||

|---|---|---|---|---|---|---|

| Range 10–20 | Range 20–30 | Range 30–50 | Range 10–20 | Range 20–30 | Range 30–50 | |

| 1 | 57.89 ± 0.65 | 58.49 ± 0.30 | 58.90 ± 0.52 | 99.30 ± 0.09 | 98.39 ± 0.22 | 95.27 ± 0.68 |

| 2 | 57.89 ± 0.57 | 58.43 ± 0.48 | 58.67 ± 0.47 | 99.19 ± 0.09 | 98.59 ± 0.39 | 97.40 ± 0.79 |

| 3 | 57.40 ± 0.58 | 55.88 ± 0.50 | / | 99.11 ± 0.10 | 98.83 ± 0.34 | / |

| 4 | 57.05 ± 0.67 | / | / | 99.07 ± 0.06 | / | / |

| Building Plane | RD Green [%] | RD Sintered [%] | ||||

|---|---|---|---|---|---|---|

| Range 10–20 | Range 20–30 | Range 30–50 | Range 10–20 | Range 20–30 | Range 30–50 | |

| 1 | 56.94 ± 0.37 | 55.25 ± 0.21 | 56.43 ± 0.42 | 98.27 ± 0.21 | 98.34 ± 0.10 | 98.14 ± 0.18 |

| 2 | 56.38 ± 0.58 | 55.22 ± 0.32 | 56.63 ± 0.60 | 98.21 ± 0.16 | 98.13 ± 0.19 | 98.12 ± 0.32 |

| 3 | 54.82 ± 0.79 | 56.04 ± 0.25 | / | 98.22 ± 0.12 | 98.06 ± 0.12 | / |

| 4 | 54.59 ± 0.71 | / | / | 98.21 ± 0.13 | / | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zago, M.; Segata, G.; Perina, M.; Cristofolini, I. Assessment of Causes of Precision and Accuracy Loss in Metal Binder Jetting Additive Manufacturing Technology. J. Manuf. Mater. Process. 2025, 9, 363. https://doi.org/10.3390/jmmp9110363

Zago M, Segata G, Perina M, Cristofolini I. Assessment of Causes of Precision and Accuracy Loss in Metal Binder Jetting Additive Manufacturing Technology. Journal of Manufacturing and Materials Processing. 2025; 9(11):363. https://doi.org/10.3390/jmmp9110363

Chicago/Turabian StyleZago, Marco, Giacomo Segata, Matteo Perina, and Ilaria Cristofolini. 2025. "Assessment of Causes of Precision and Accuracy Loss in Metal Binder Jetting Additive Manufacturing Technology" Journal of Manufacturing and Materials Processing 9, no. 11: 363. https://doi.org/10.3390/jmmp9110363

APA StyleZago, M., Segata, G., Perina, M., & Cristofolini, I. (2025). Assessment of Causes of Precision and Accuracy Loss in Metal Binder Jetting Additive Manufacturing Technology. Journal of Manufacturing and Materials Processing, 9(11), 363. https://doi.org/10.3390/jmmp9110363