Investigation of the Thermo-Mechanical Modeling of the Manufacturing of Large-Scale Wire Arc Additive Manufacturing Components with an Outlook Towards Industrial Applications

Abstract

1. Introduction

1.1. Simulation of Additive Manufacturing

1.2. Simulation of WAAM

1.3. Motivation and Objectives

2. Materials and Methods

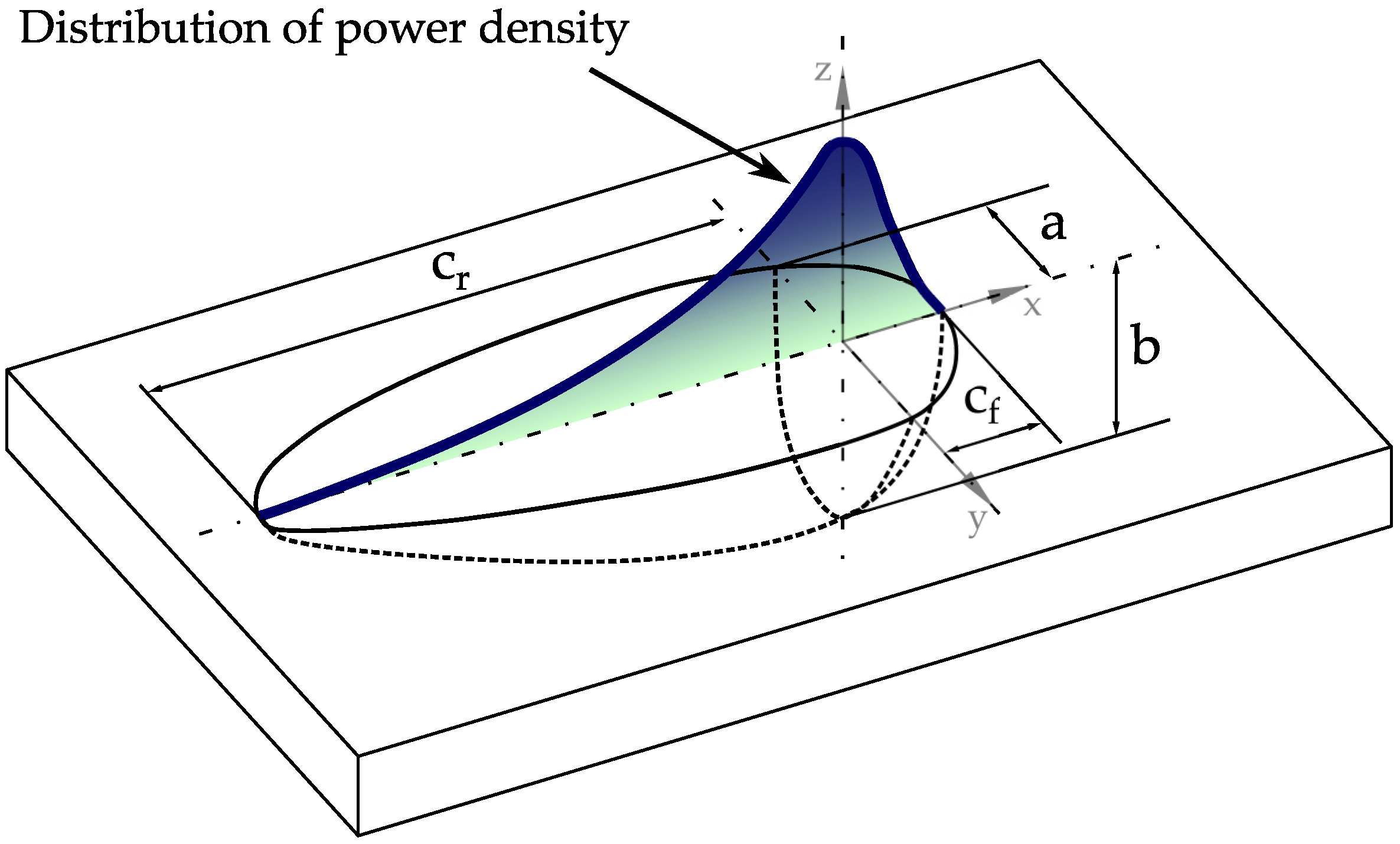

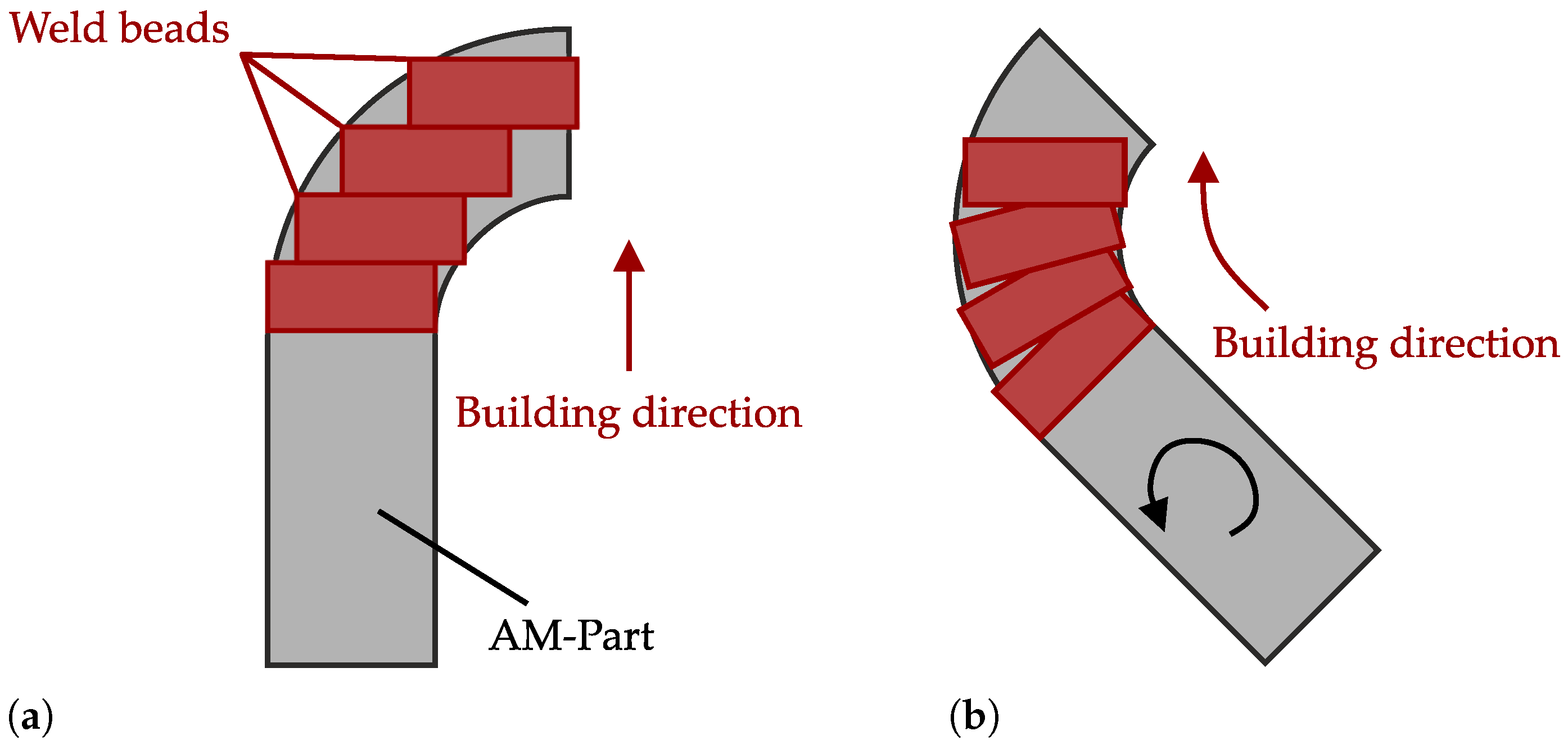

2.1. Modeling Approach

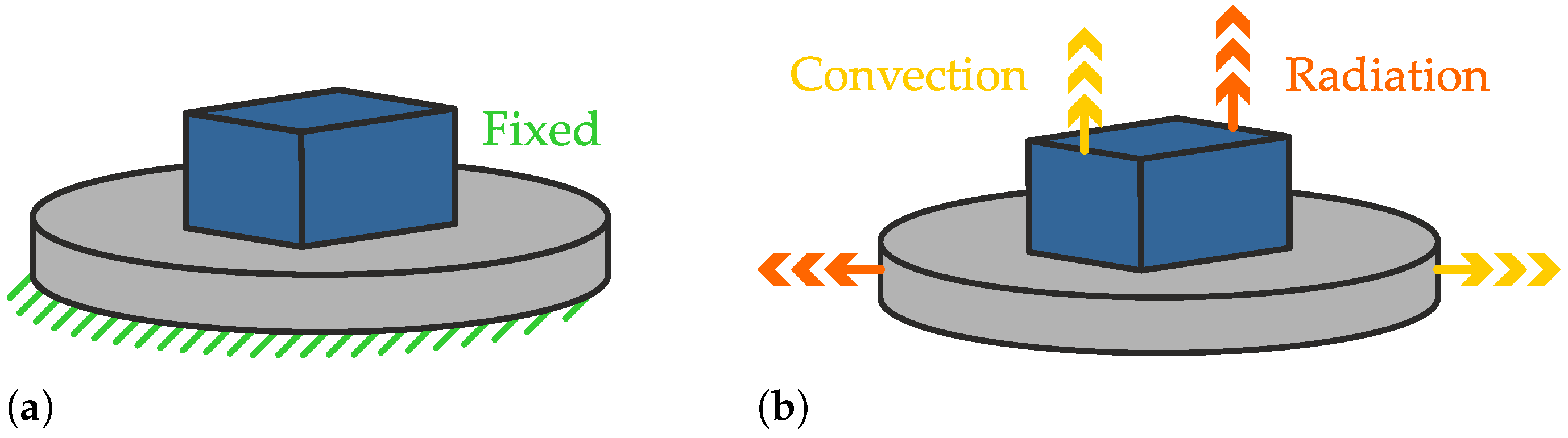

2.2. Boundary Conditions

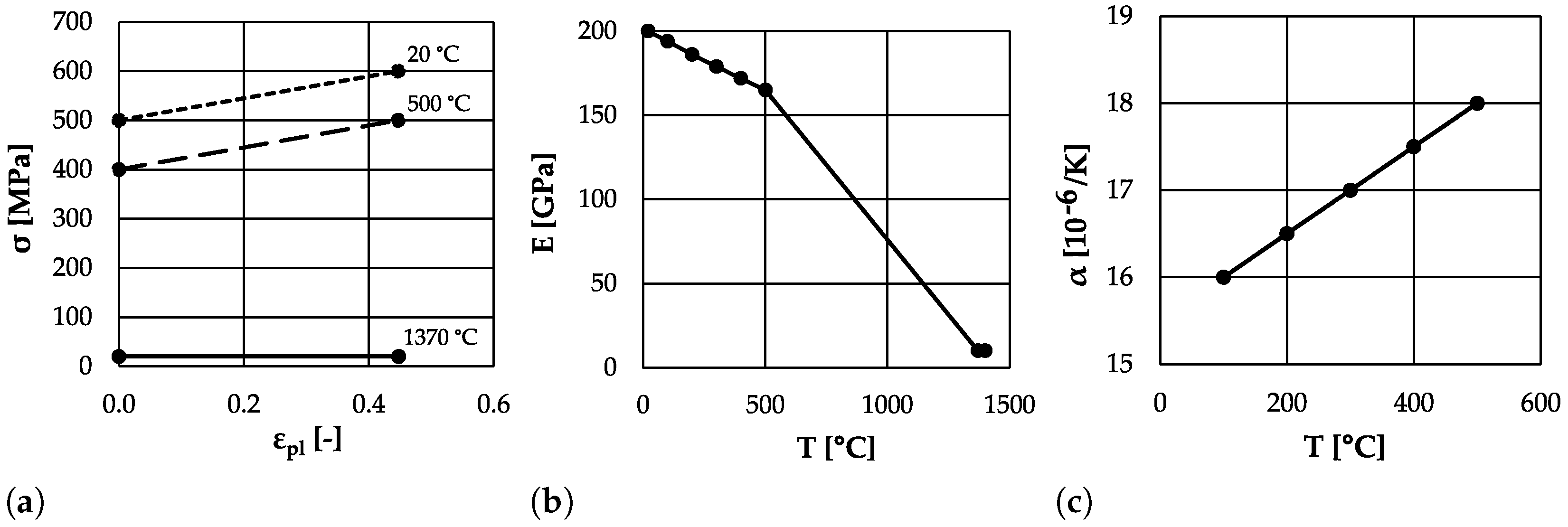

2.3. Material

3. Numerical Studies

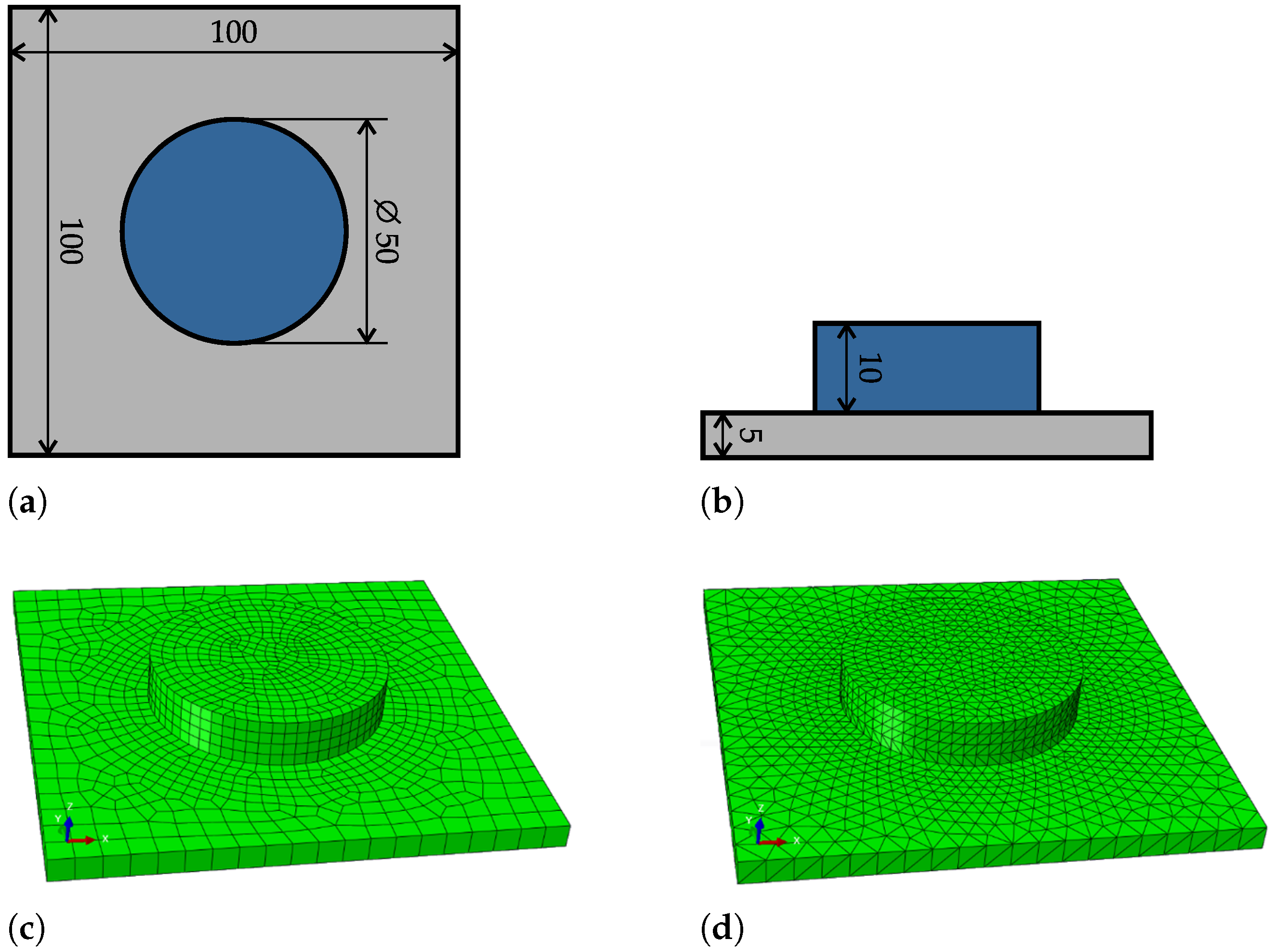

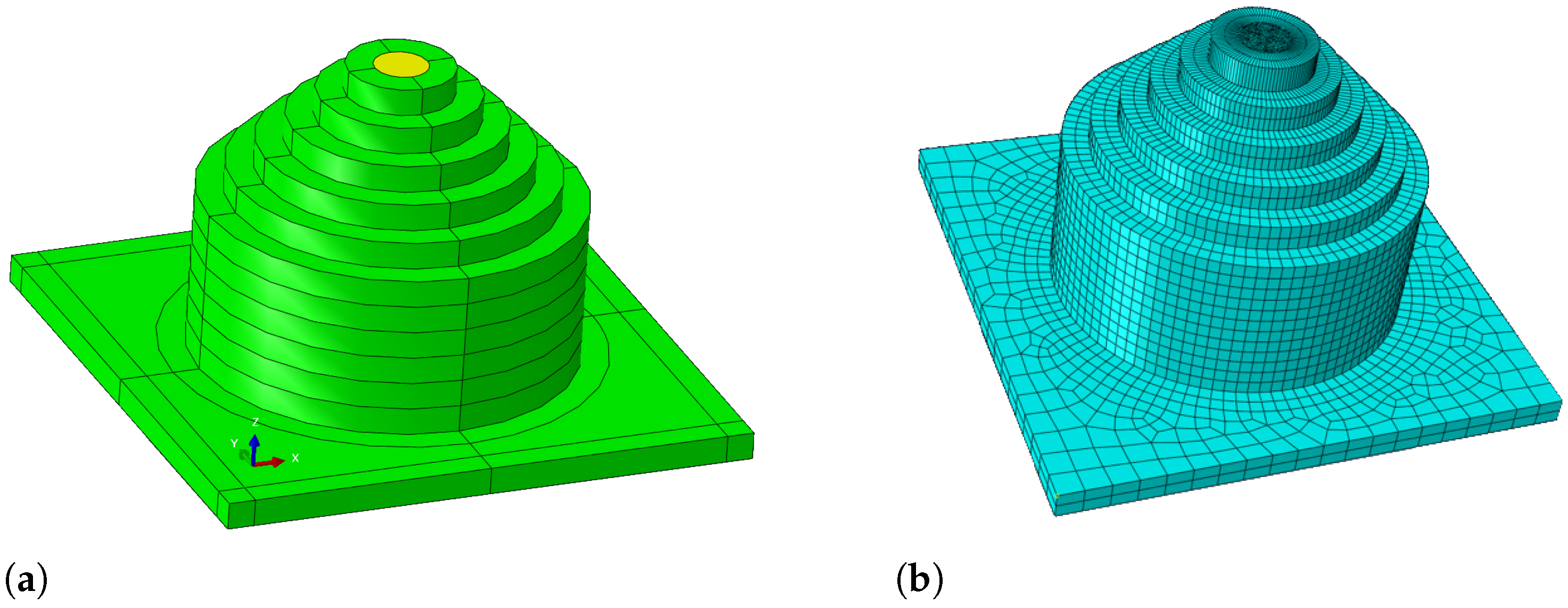

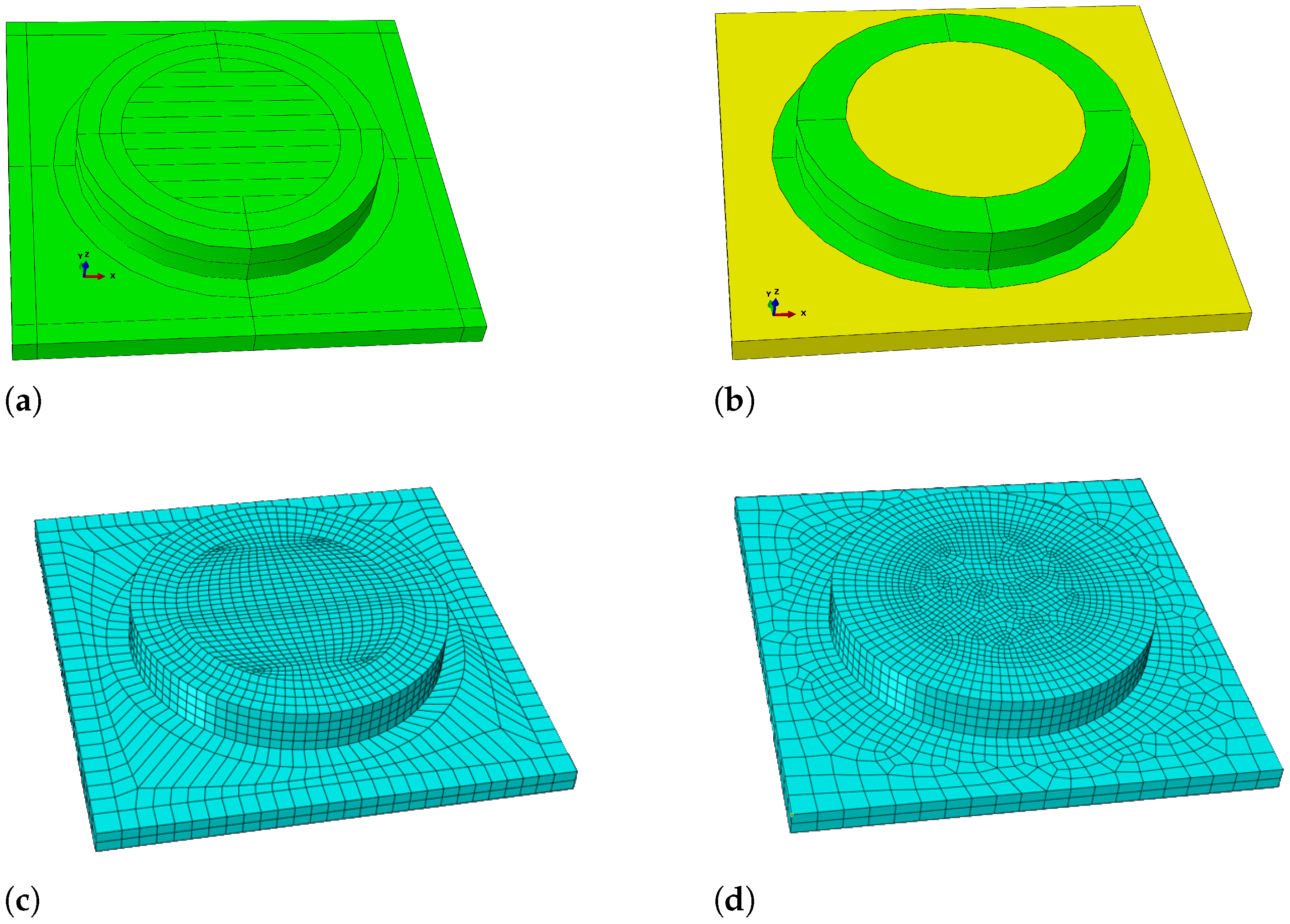

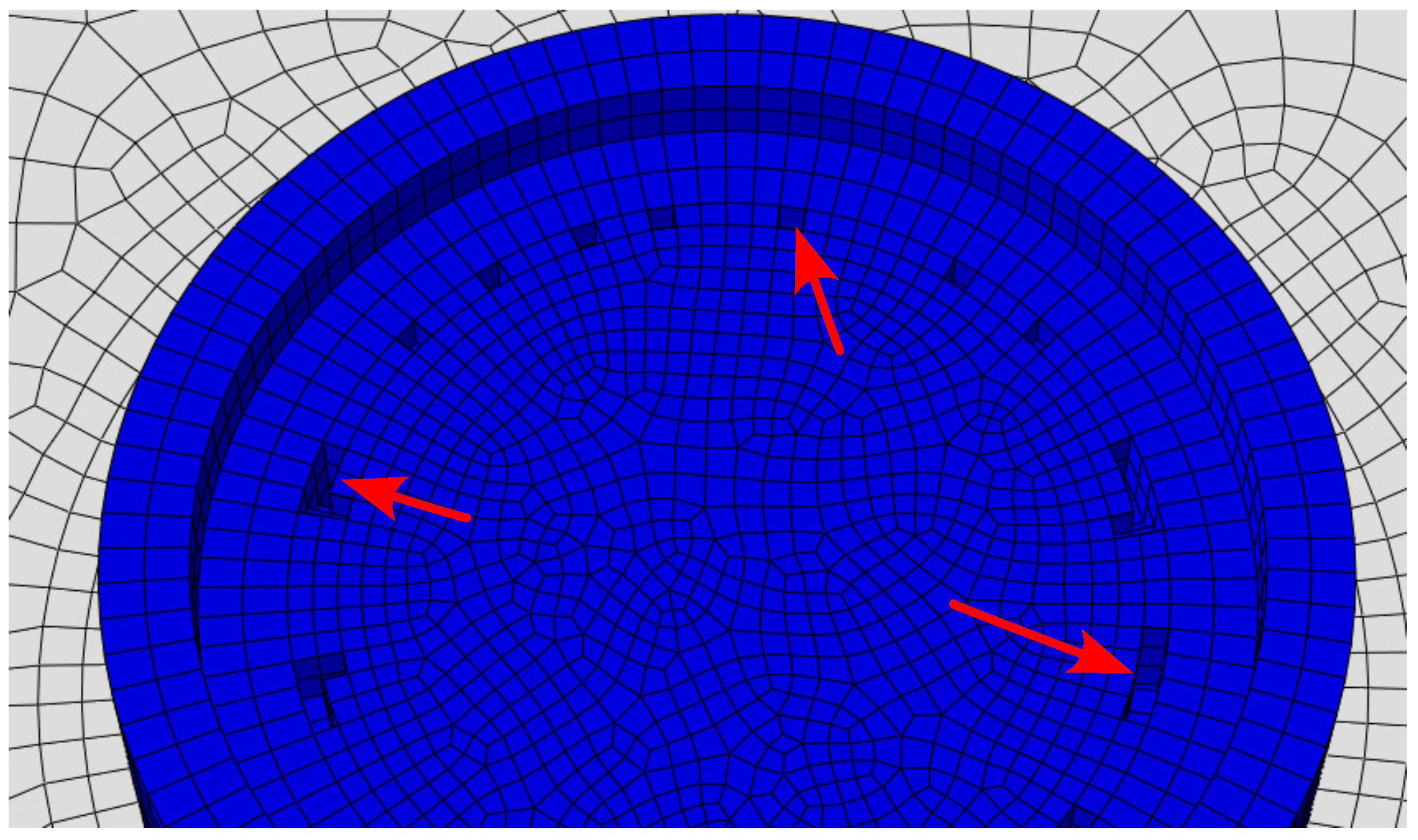

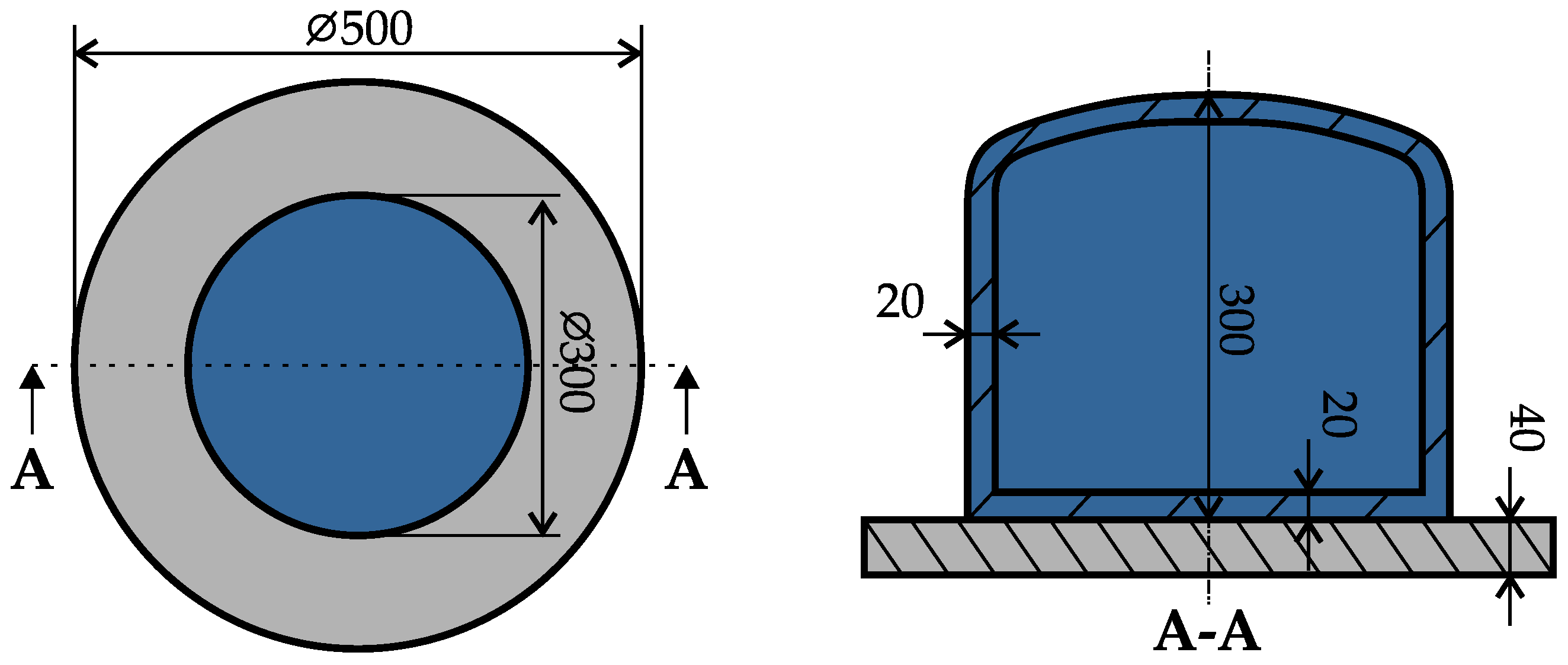

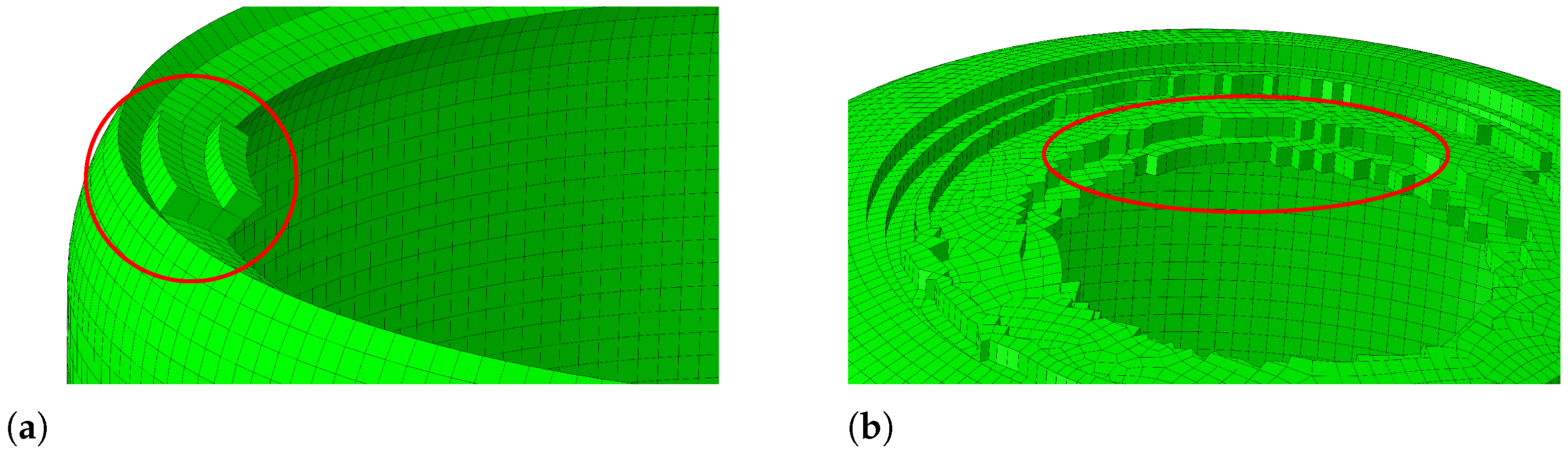

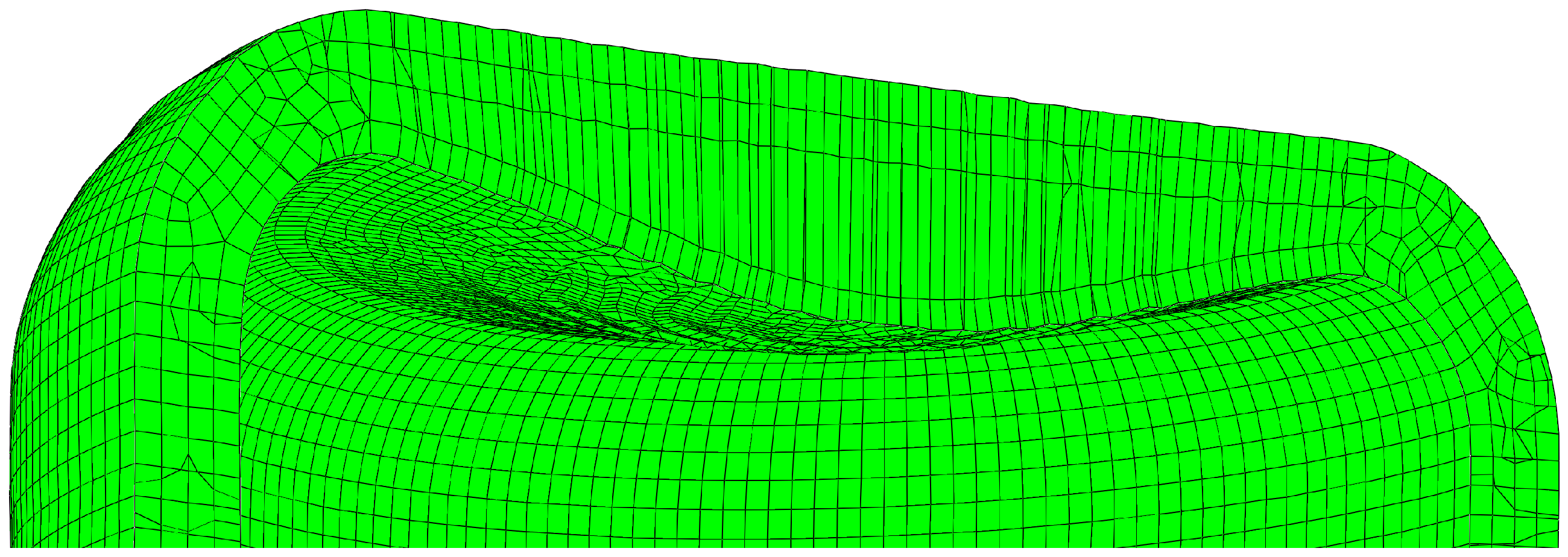

3.1. Meshing

- Mesh type:

- Mesh size:

- Meshing technique:

3.2. Element Activation

3.3. Variation of Process Parameters

4. Discussion and Conclusions

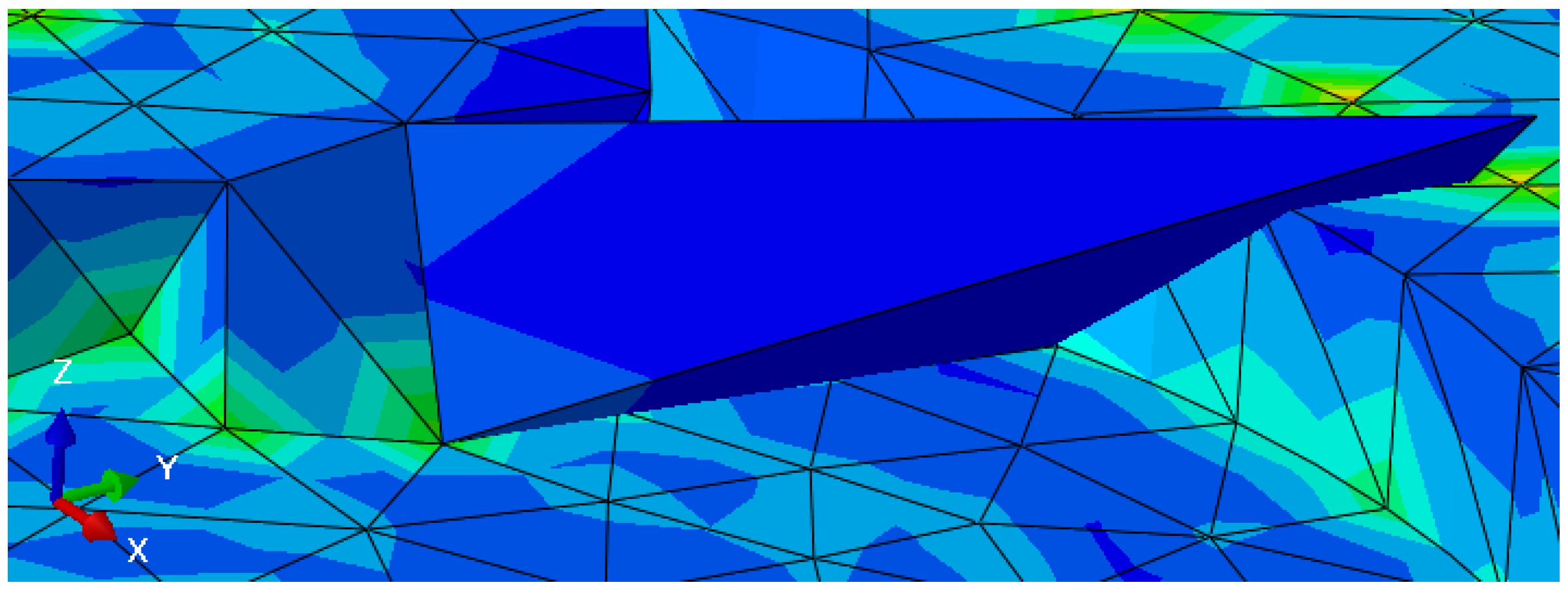

- The investigations into component discretization have revealed various problems that limit the realistic simulation of WAAM with FE modeling. The discretization of components for WAAM can generally be highlighted as a problem in ABAQUS. Depending on the component geometry, the meshing tools provided by ABAQUS are only to a certain extend usable for meshing WAAM components.

- It was also shown that not all element types are suitable for meshing complex, large-scale WAAM components. Here, dedicated meshing programs offer a potential strategy to enable higher quality and more time-efficient meshing in the future.

- Limits in the maximum element size recognized from the investigations further restrict the simulation of WAAM. However, the investigated component geometries are already in a size range that is larger than most of the geometries investigated in the literature. This suggests that similar problems occurred in the studies examined. Extrapolation of the simulation results of individual weld beads to a package of weld beads is conceivable here, which can then be provided with a coarser mesh. In general, simulations of the process in other orders of magnitude offer further potential for a better understanding of the WAAM process.

- Another disadvantage was found in the restriction of the simulation’s axes of motion, which also limits the component geometries that can be simulated with ABAQUS 2020. Here, too, the literature does not yet offer a solution to the problem, as very simple geometries are usually simulated. If geometries with overhangs are also to be simulated in the future, the updated ABAQUS versions must be checked for usability in simulating WAAM. This marks one of the important further developments of the model that would make it possible to model realistic behavior.

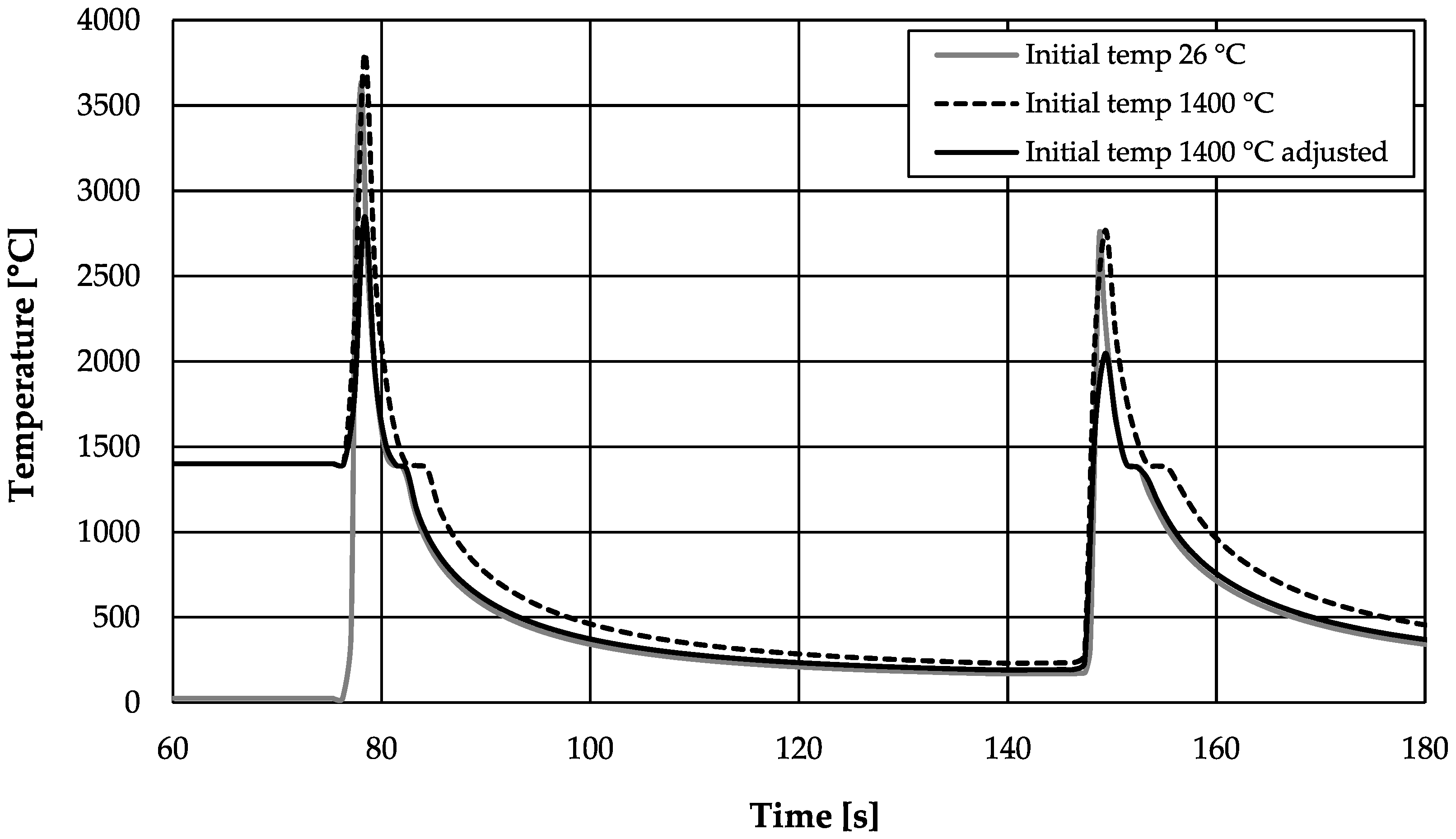

- A use of a high element start temperature in combination with an adapted welding power has proven to be advantageous for process modeling and the stability of the simulation. It is necessary to check whether temperatures even higher than the melting temperature represent the process even better.

- With the AM Modeler, an integrated parameter variation for different areas, which can also occur in the WAAM process, could be realized very easily. Although this is not possible with the AM Modeler by continuously changing the parameters, it still helps to map the WAAM process more realistically.

- An important further step in the development of the simulation model for WAAM is to validate the results using real test components. Here, the component temperature over time can be recorded using thermocouples or thermography and compared with the results of the simulation. Metallography and residual stress measurements also offer the possibility of comparing the real values of mechanical parameters with the simulation results.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Statistisches Bundesamt, Beschäftigte und Umsatz der Betriebe im Verarbeitenden Gewerbe: Deutschland, Jahre, Wirtschaftszweige. Available online: https://www-genesis.destatis.de/datenbank/online/url/9dbed29c (accessed on 15 March 2025).

- Kusch, M.; Matthes, K.-J.; Schneider, W. Schweißtechnik: Schweißen von Metallischen Konstruktionswerkstoffen, 7., überarbeitete und Erweiterte Auflage; Hanser: München, Germany, 2022; ISBN 9783446467453. [Google Scholar]

- Mandeville, M.K.; Brongers, M.P.H.; Tang, F. Quality Assurance and Technology Qualification for Additive Manufacturing of Metallic Pressure Components. In Proceedings of the ASME Pressure Vessels and Piping Conference, Waikoloa, HI, USA, 16–20 July 2017; Zhu, X.-K., Brongers, M., Qian, H., Eds.; The American Society of Mechanical Engineers: New York, NY, USA, 2017. ISBN 978-0-7918-5799-1. [Google Scholar]

- Bayat, M.; Dong, W.; Thorborg, J.; To, A.C.; Hattel, J.H. A review of multi-scale and multi-physics simulations of metal additive manufacturing processes with focus on modeling strategies. Addit. Manuf. 2021, 47, 102278. [Google Scholar] [CrossRef]

- Huang, S.; Zhang, T.; Wang, Z.; Cheng, L.; Zha, X.; Guo, B.; Zheng, D.; Xie, H.; Xiang, Z.; Chen, Y.; et al. Asymmetrical cutting-edge design of broaching tool based on FEM simulation. J. Mater. Res. Technol. 2023, 25, 68–82. [Google Scholar] [CrossRef]

- Almonti, D.; Baiocco, G.; Salvi, D.; Ucciardello, N. Innovative approach for enhancing thermal diffusivity in metal matrix composites using graphene electrodeposition and multi-coating. Int. J. Adv. Manuf. Technol. 2024, 135, 1633–1646. [Google Scholar] [CrossRef]

- Francois, M.M.; Sun, A.; King, W.E.; Henson, N.J.; Tourret, D.; Bronkhorst, C.A.; Carlson, N.N.; Newman, C.K.; Haut, T.; Bakosi, J.; et al. Modeling of additive manufacturing processes for metals: Challenges and opportunities. Curr. Opin. Solid State Mater. 2017, 21, 198–206. [Google Scholar] [CrossRef]

- Bargel, H.-J.; Schulze, G. Werkstoffkunde; Eds., 12., bearb. Aufl. 2018; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 9783662486283. [Google Scholar]

- Karma, A.; Tourret, D. Atomistic to continuum modeling of solidification microstructures. Curr. Opin. Solid State Mater. Sci. 2016, 20, 25–36. [Google Scholar] [CrossRef]

- Hoyt, J. Atomistic and continuum modeling of dendritic solidification. Mater. Sci. Eng. Rep. 2003, 41, 121–163. [Google Scholar] [CrossRef]

- Rodgers, T.M.; Madison, J.D.; Tikare, V.; Maguire, M.C. Predicting Mesoscale Microstructural Evolution in Electron Beam Welding. JOM 2016, 68, 1419–1426. [Google Scholar] [CrossRef]

- Lim, H.; Abdeljawad, F.; Owen, S.J.; Hanks, B.W.; Foulk, J.W.; Battaile, C.C. Incorporating physically-based microstructures in materials modeling: Bridging phase field and crystal plasticity frameworks. Model. Simul. Mater. Sci. Eng. 2016, 24, 45016. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Traxel, K.D. Invited Review Article: Metal-additive manufacturing-Modeling strategies for application-optimized designs. Addit. Manuf. 2018, 22, 758–774. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, G.; Yin, Z.; Wu, L. Three-dimensional finite element analysis of thermal stress in single-pass multi-layer weld-based rapid prototyping. J. Mater. Process. Technol. 2012, 212, 276–285. [Google Scholar] [CrossRef]

- Kaess, M.; Werz, M.; Weihe, S. Residual Stress Formation Mechanisms in Laser Powder Bed Fusion-A Numerical Evaluation. Materials 2023, 16, 2321. [Google Scholar] [CrossRef]

- Ding, J.; Colegrove, P.; Mehnen, J.; Ganguly, S.; Sequeira Almeida, P.M.; Wang, F.; Williams, S. Thermo-mechanical analysis of Wire and Arc Additive Layer Manufacturing process on large multi-layer parts. Comput. Mater. Sci. 2011, 50, 3315–3322. [Google Scholar] [CrossRef]

- Fan, Z.; Liou, F. Numerical Modeling of the Additive Manufacturing (AM) Processes of Titanium Alloy. In Titanium Alloys-Towards Achieving Enhanced Properties for Diversified Applications; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- Mughal, M.P.; Fawad, H.; Mufti, R. Finite element prediction of thermal stresses and deformations in layered manufacturing of metallic parts. Acta Mech. 2006, 183, 61–79. [Google Scholar] [CrossRef]

- Montevecchi, F.; Venturini, G.; Scippa, A.; Campatelli, G. Finite Element Modelling of Wire-arc-additive-manufacturing Process. Procedia CIRP 2016, 55, 109–114. [Google Scholar] [CrossRef]

- Chergui, A.; Villeneuve, F.; Béraud, N.; Vignat, F. Thermal simulation of wire arc additive manufacturing: A new material deposition and heat input modelling. Int. J. Interact. Des. Manuf. 2022, 16, 227–237. [Google Scholar] [CrossRef]

- Ge, J.; Ma, T.; Han, W.; Yuan, T.; Jin, T.; Fu, H.; Xiao, R.; Lei, Y.; Lin, J. Thermal-induced microstructural evolution and defect distribution of wire-arc additive manufacturing 2Cr13 part: Numerical simulation and experimental characterization. Appl. Therm. Eng. 2019, 163, 114335. [Google Scholar] [CrossRef]

- Graf, M.; Pradjadhiana, K.P.; Hälsig, A.; Manurung, Y.H.P.; Awiszus, B. Numerical simulation of metallic wire arc additive manufacturing (WAAM). Aip Conf. Proc. 2018, 1960, 140010. [Google Scholar]

- Graf, M.; Hälsig, A.; Höfer, K.; Awiszus, B.; Mayr, P. Thermo-Mechanical Modelling of Wire-Arc Additive Manufacturing (WAAM) of Semi-Finished Products. Metals 2018, 8, 1009. [Google Scholar] [CrossRef]

- Mughal, M.P.; Mufti, R.A.; Fawad, H. The mechanical effects of deposition patterns in welding-based layered manufacturing. Proc. Inst. Mech. Eng. Part J. Eng. Manuf. 2007, 221, 1499–1509. [Google Scholar] [CrossRef]

- Zhao, X.F.; Wimmer, A.; Zaeh, M.F. Experimental and simulative investigation of welding sequences on thermally induced distortions in wire arc additive manufacturing. RPJ 2023, 29, 53–63. [Google Scholar] [CrossRef]

- Amal, M.S.; Justus Panicker, C.T.; Senthilkumar, V. Simulation of wire arc additive manufacturing to find out the optimal path planning strategy. Mater. Today Proc. 2022, 66, 2405–2410. [Google Scholar] [CrossRef]

- Chiumenti, M.; Cervera, M.; Salmi, A.; Agelet de Saracibar, C.; Dialami, N.; Matsui, K. Finite element modeling of multi-pass welding and shaped metal deposition processes. Comput. Methods Appl. Mech. Eng. 2010, 199, 2343–2359. [Google Scholar] [CrossRef]

- Israr, R.; Buhl, J.; Elze, L.; Bambach, M. Simulation of different path strategies for wire-arc additive manufacturing with Lagrangian finite element methods. In Proceedings of the LS-Dyna Forum 2018, Bamberg, Germany, 15 October 2018. [Google Scholar]

- Zhao, Y.; Jia, Y.; Chen, S.; Shi, J.; Li, F. Process planning strategy for wire-arc additive manufacturing: Thermal behavior considerations. Addit. Manuf. 2020, 32, 100935. [Google Scholar] [CrossRef]

- Xiong, J.; Lei, Y.; Li, R. Finite element analysis and experimental validation of thermal behavior for thin-walled parts in GMAW-based additive manufacturing with various substrate preheating temperatures. Appl. Therm. Eng. 2017, 126, 43–52. [Google Scholar] [CrossRef]

- Huang, H.; Ma, N.; Chen, J.; Feng, Z.; Murakawa, H. Toward large-scale simulation of residual stress and distortion in wire and arc additive manufacturing. Addit. Manuf. 2020, 34, 101248. [Google Scholar] [CrossRef]

- Goldak, J.; Chakravarti, A.; Bibby, M. A new finite element model for welding heat sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

- Baehr, H.D.; Stephan, K. Wärme- und Stoffübertragung, 10. Auflage; Springer: Berlin/Heidelberg, Germany, 2019; ISBN 978-3-662-58440-8. [Google Scholar]

- Kuchling, H.; Kuchling, T. Taschenbuch der Physik, 22., Aktualisierte Auflage; Hanser: München, Germany, 2022; ISBN 9783446472747. [Google Scholar]

- Schuler, V.; Twrdek, J. Praxiswissen Schweißtechnik: Werkstoffe, Prozesse, Fertigung, 6., Vollständig überarbeitete Auflage; Springer: Wiesbaden, Germany; Heidelberg, Germany, 2019. [Google Scholar]

- 3DA, Materialdatenblatt Edelstahl 316L. Available online: https://www.3d-activation.de/wp-content/uploads/2018/05/1.4404-316L-D.pdf (accessed on 26 March 2025).

| Parameter | Value | Unit |

|---|---|---|

| Thermal conductivity | 16.2 | |

| Specific heat capacity | 500 | |

| Specific melting heat | 270,000 | |

| Solidus temperature | 1644.15 | K |

| Liquidus temperature | 1673.15 | K |

| Density | 7900 | |

| Poisson’s ratio | 0.3 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fritschle, T.; Kaess, M.; Weihe, S.; Werz, M. Investigation of the Thermo-Mechanical Modeling of the Manufacturing of Large-Scale Wire Arc Additive Manufacturing Components with an Outlook Towards Industrial Applications. J. Manuf. Mater. Process. 2025, 9, 166. https://doi.org/10.3390/jmmp9050166

Fritschle T, Kaess M, Weihe S, Werz M. Investigation of the Thermo-Mechanical Modeling of the Manufacturing of Large-Scale Wire Arc Additive Manufacturing Components with an Outlook Towards Industrial Applications. Journal of Manufacturing and Materials Processing. 2025; 9(5):166. https://doi.org/10.3390/jmmp9050166

Chicago/Turabian StyleFritschle, Tim, Moritz Kaess, Stefan Weihe, and Martin Werz. 2025. "Investigation of the Thermo-Mechanical Modeling of the Manufacturing of Large-Scale Wire Arc Additive Manufacturing Components with an Outlook Towards Industrial Applications" Journal of Manufacturing and Materials Processing 9, no. 5: 166. https://doi.org/10.3390/jmmp9050166

APA StyleFritschle, T., Kaess, M., Weihe, S., & Werz, M. (2025). Investigation of the Thermo-Mechanical Modeling of the Manufacturing of Large-Scale Wire Arc Additive Manufacturing Components with an Outlook Towards Industrial Applications. Journal of Manufacturing and Materials Processing, 9(5), 166. https://doi.org/10.3390/jmmp9050166