Enhancing Micro-Milling Performance of Ti6Al4V: An Experimental Analysis of Ultrasonic Vibration Effects on Forces, Surface Topography, and Burr Formation

Abstract

1. Introduction

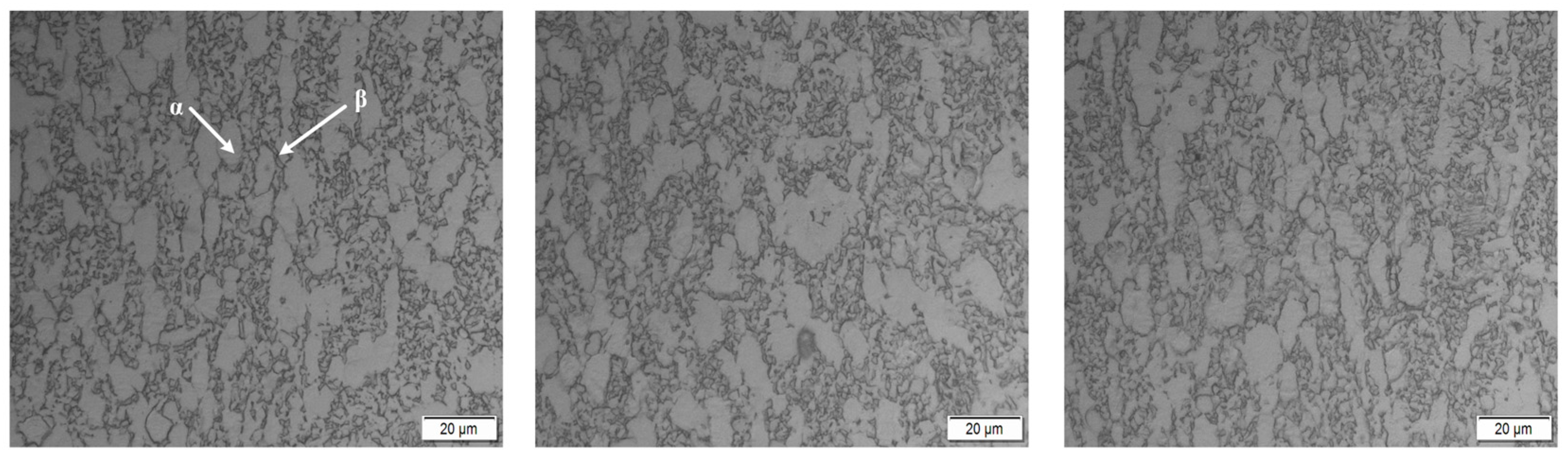

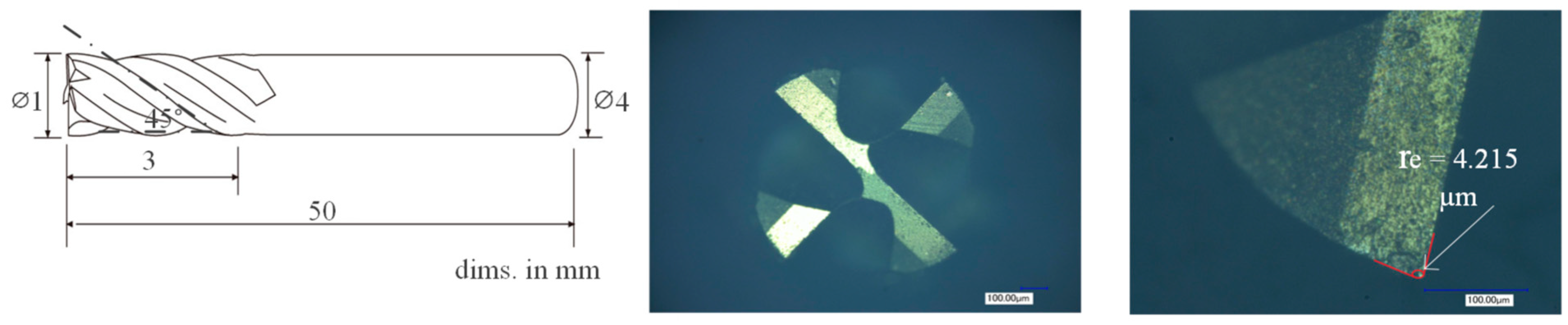

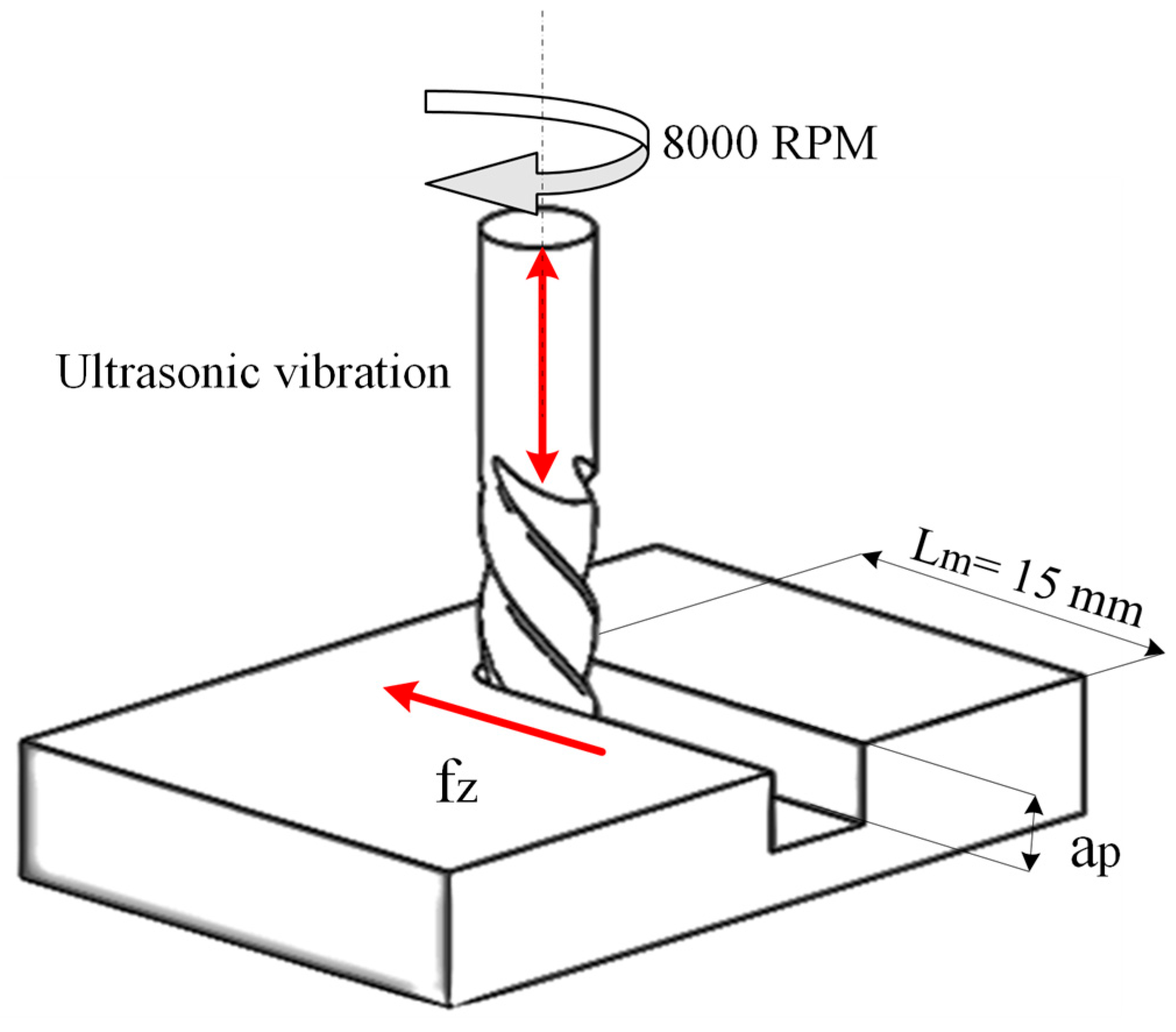

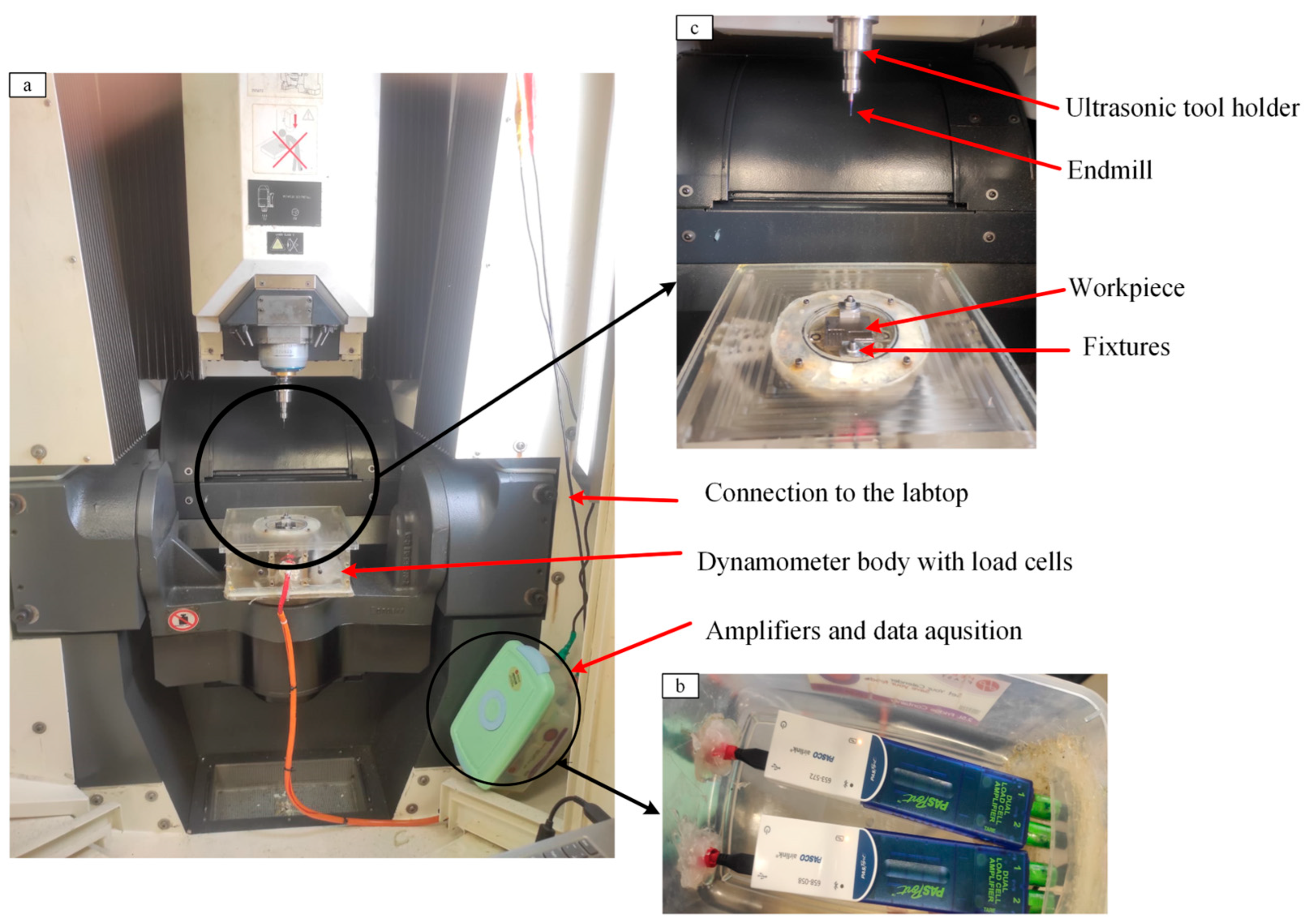

2. Materials and Methods

3. Results and Discussion

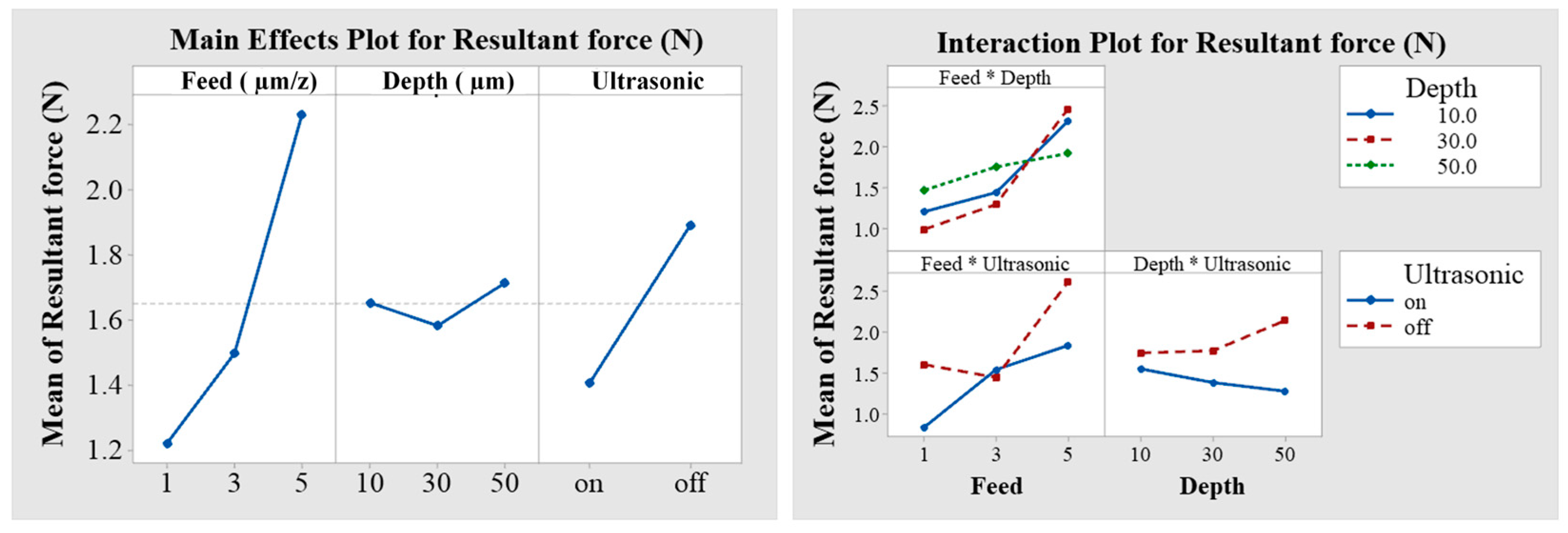

3.1. Cutting Forces

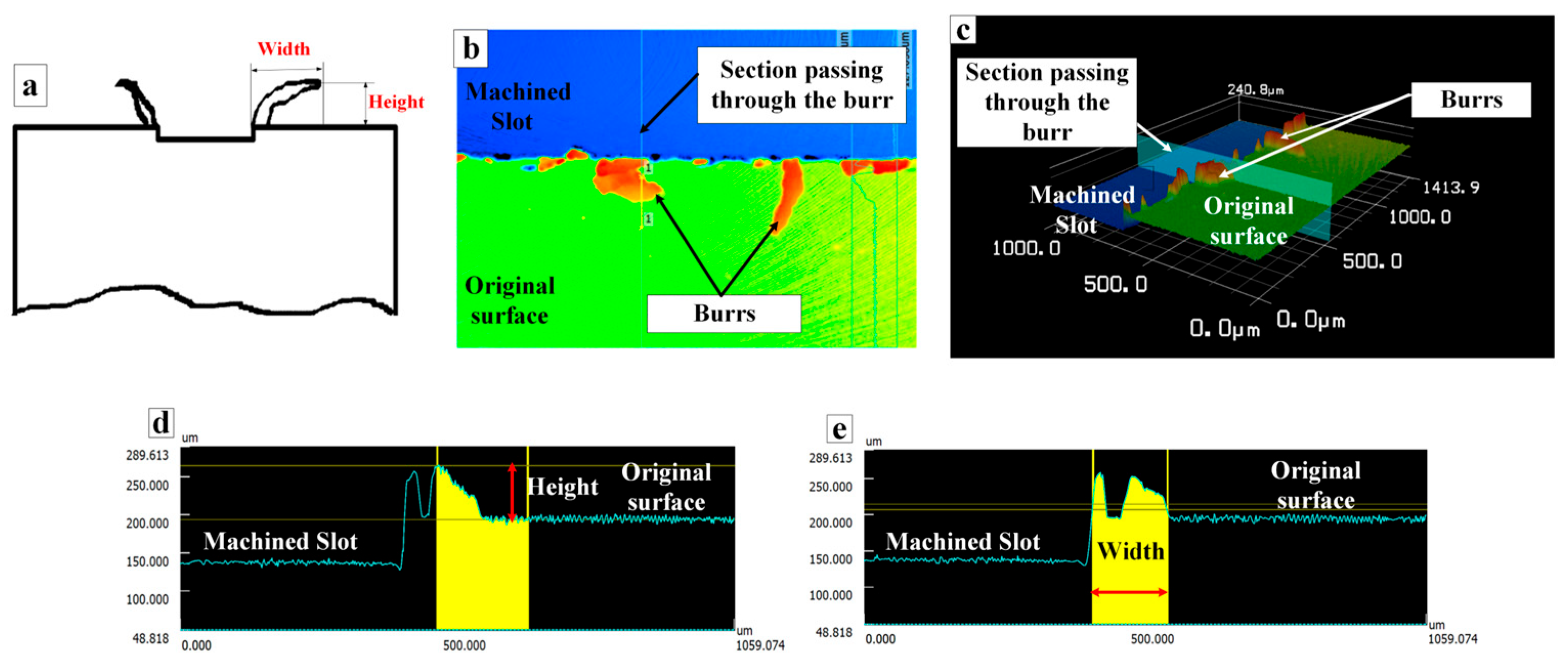

3.2. Burr Formation

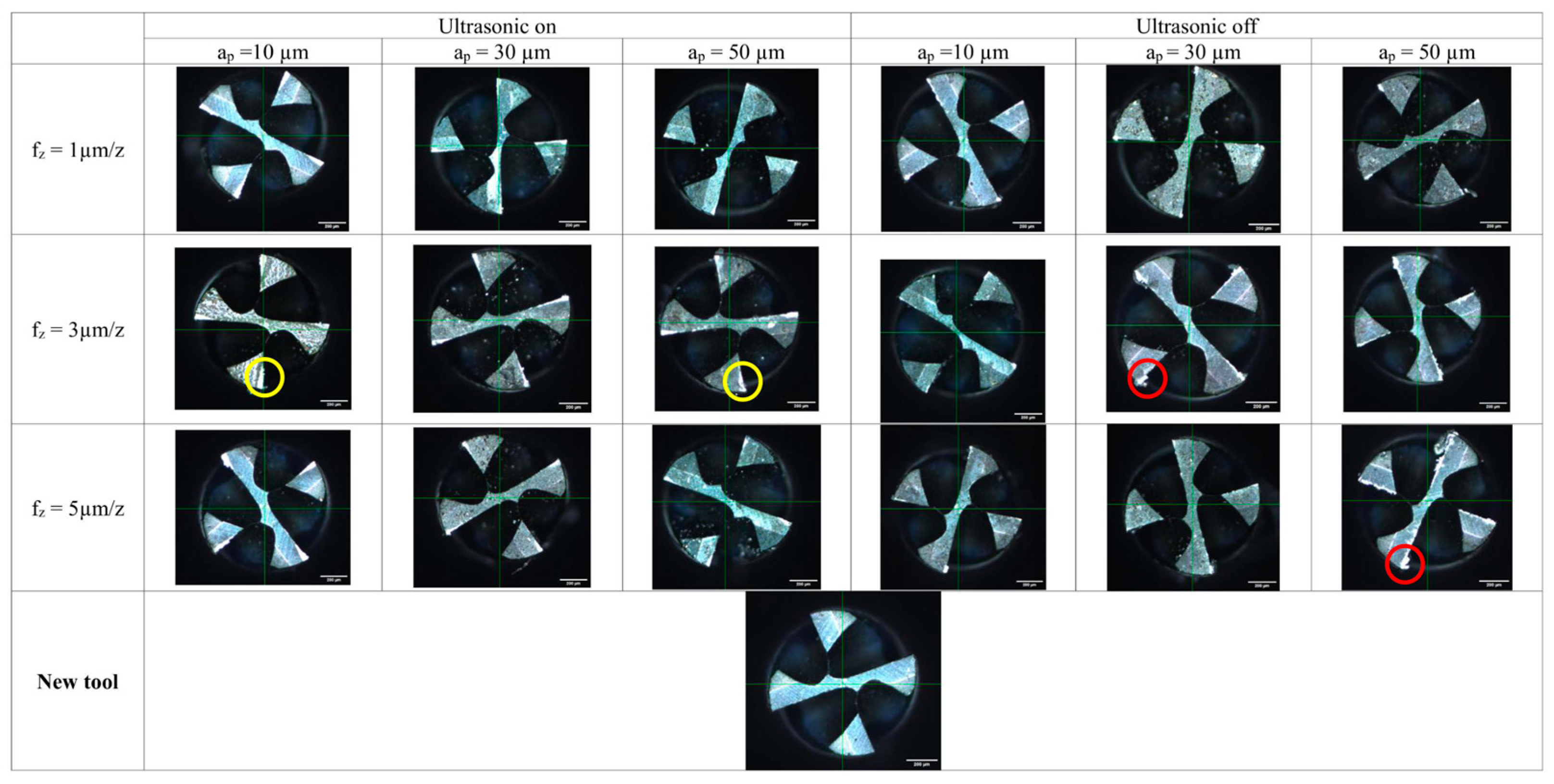

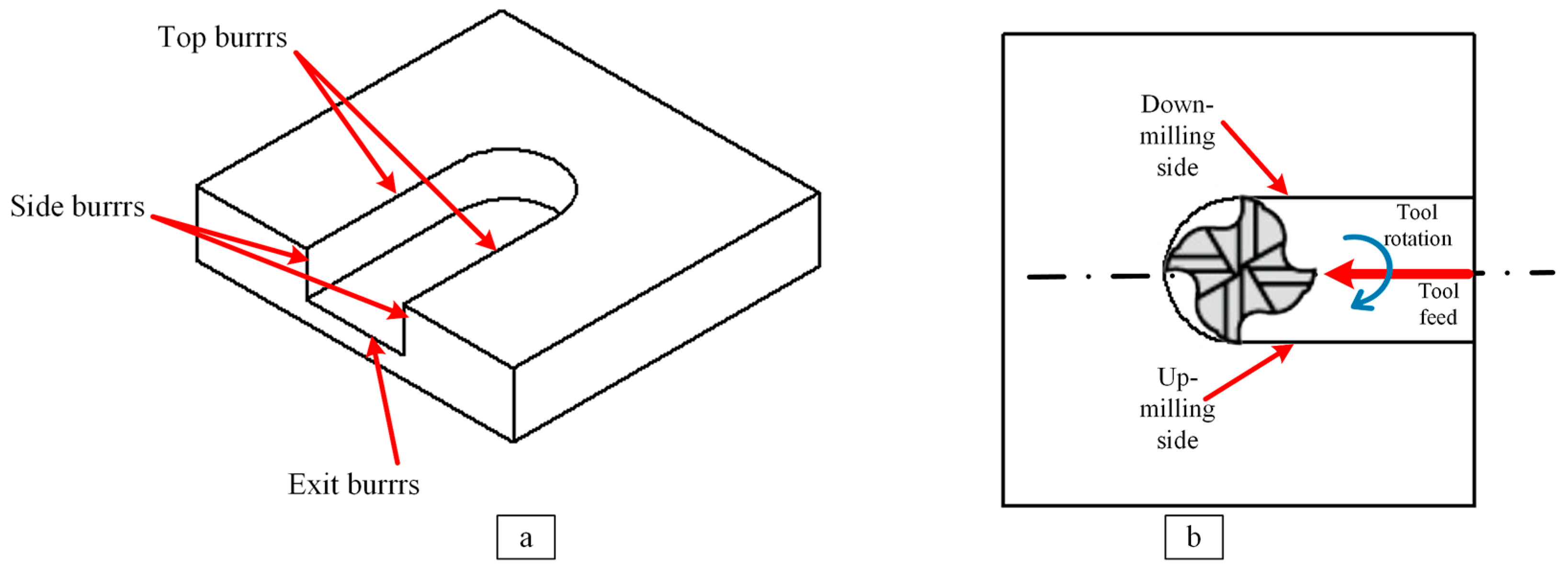

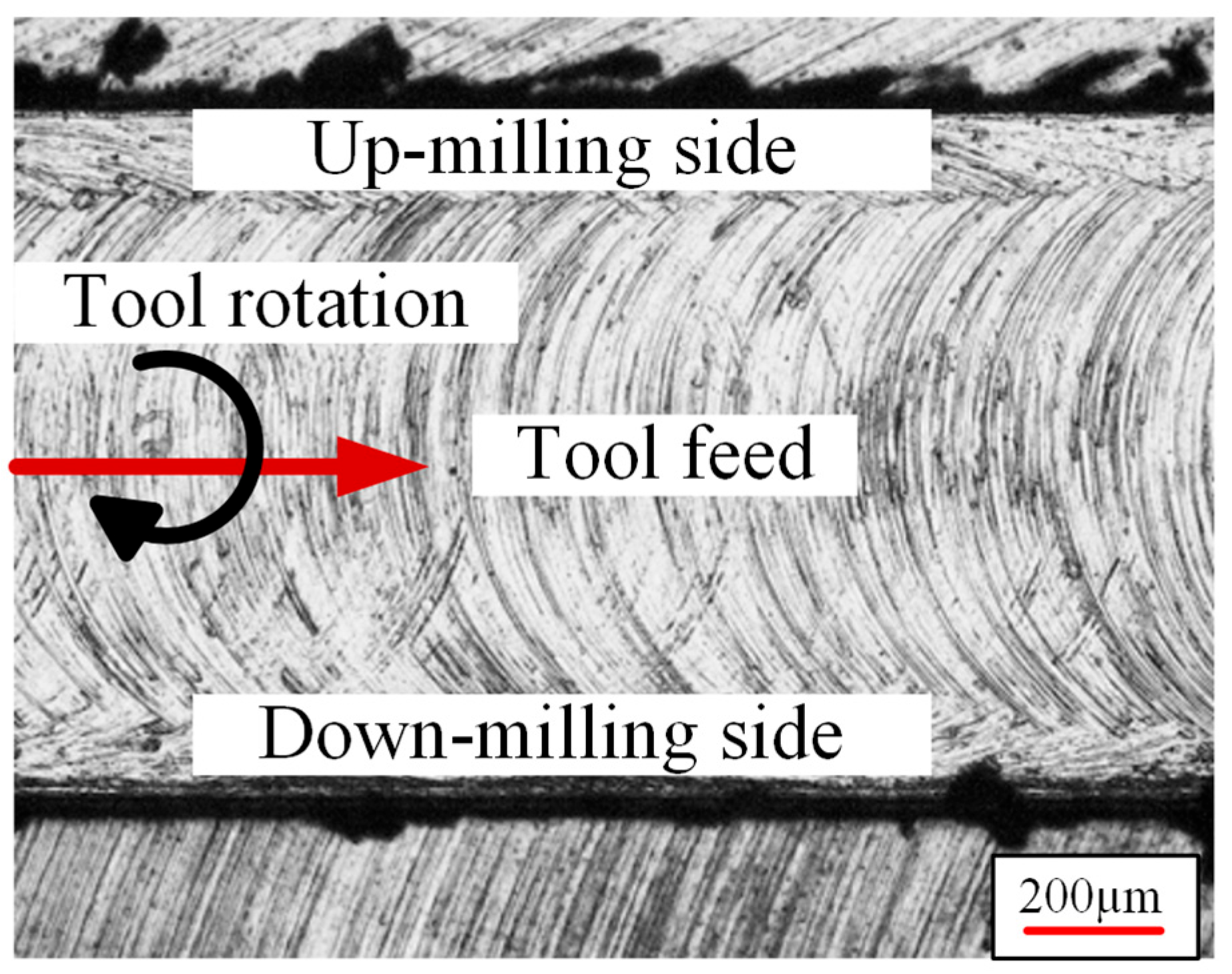

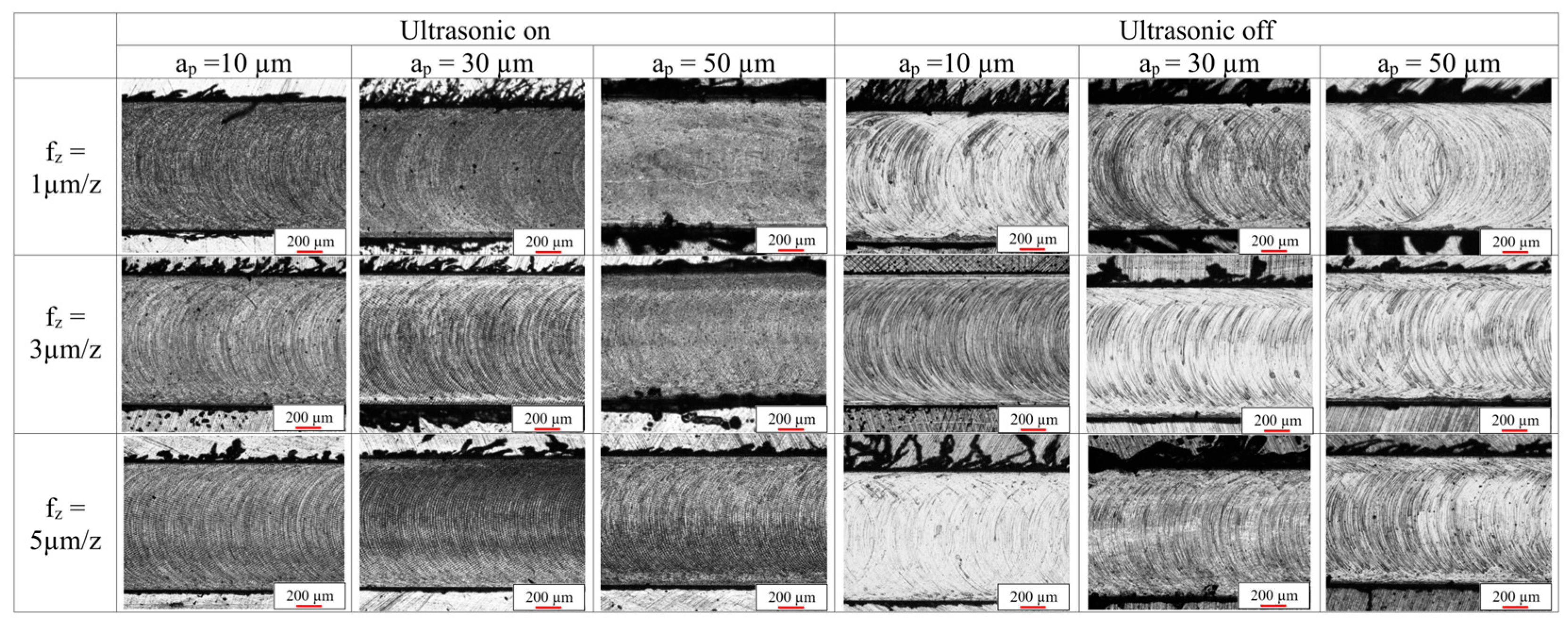

3.2.1. Burrs Types and Chip Formation

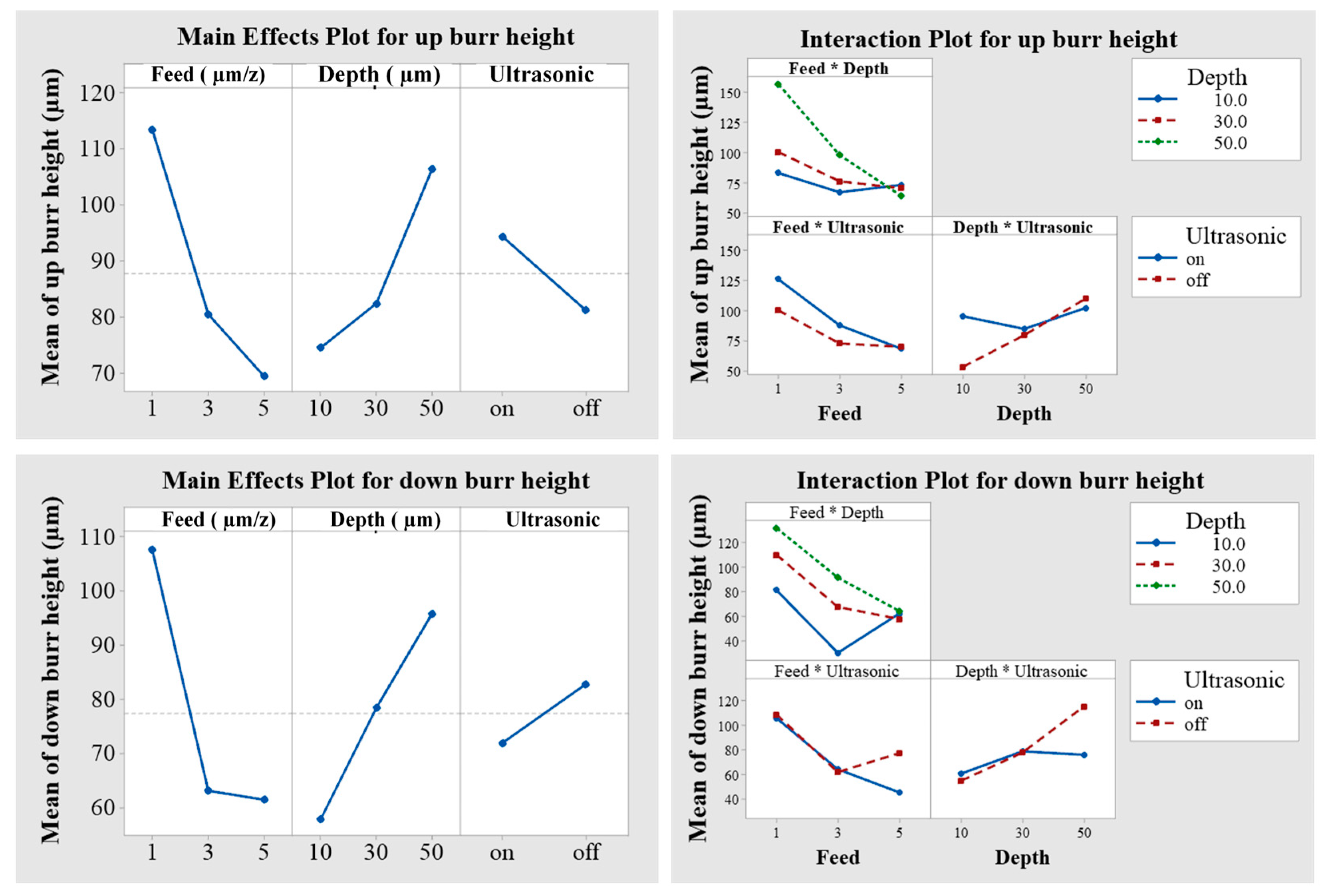

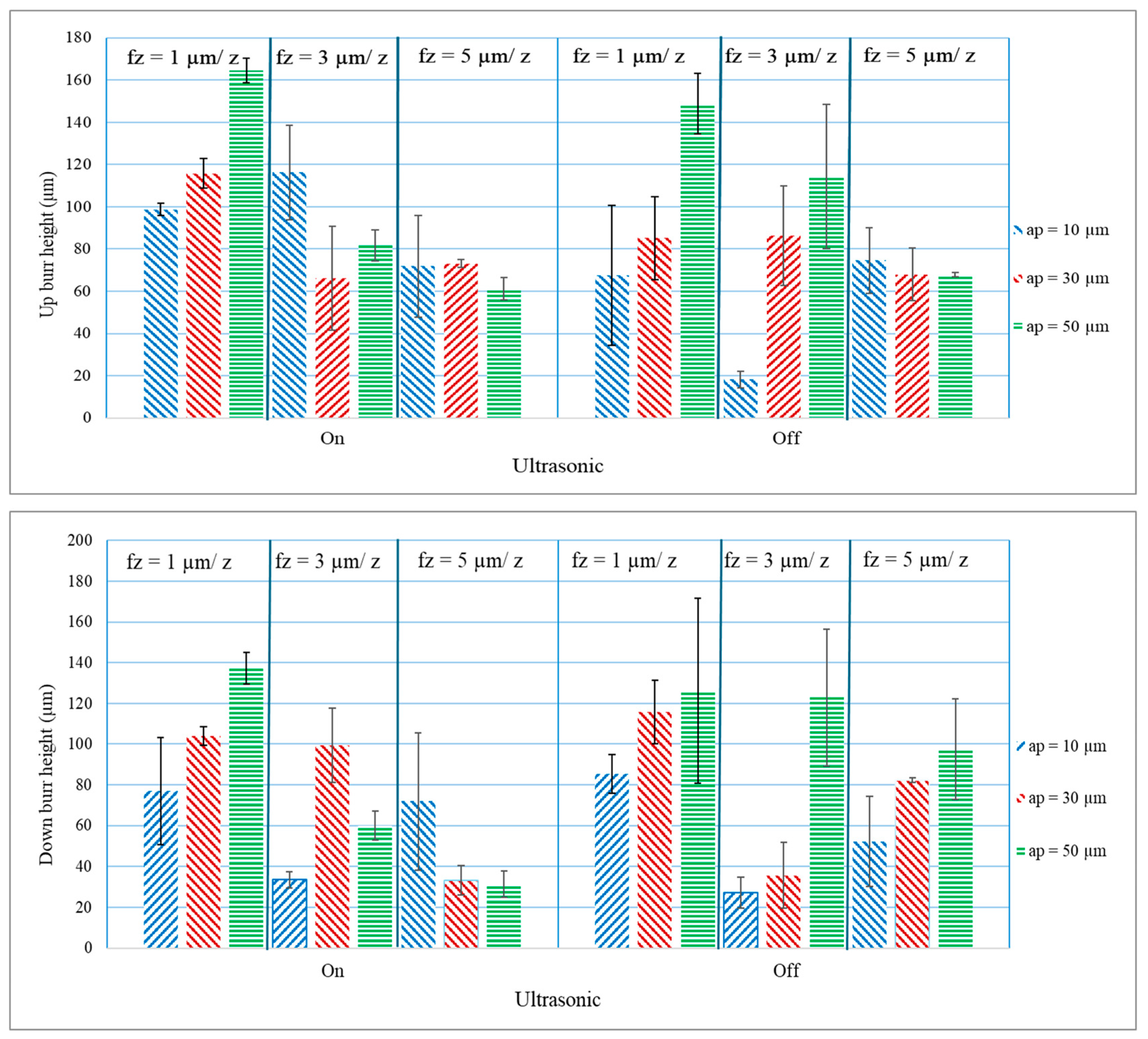

3.2.2. Parameters Affecting Burr Size

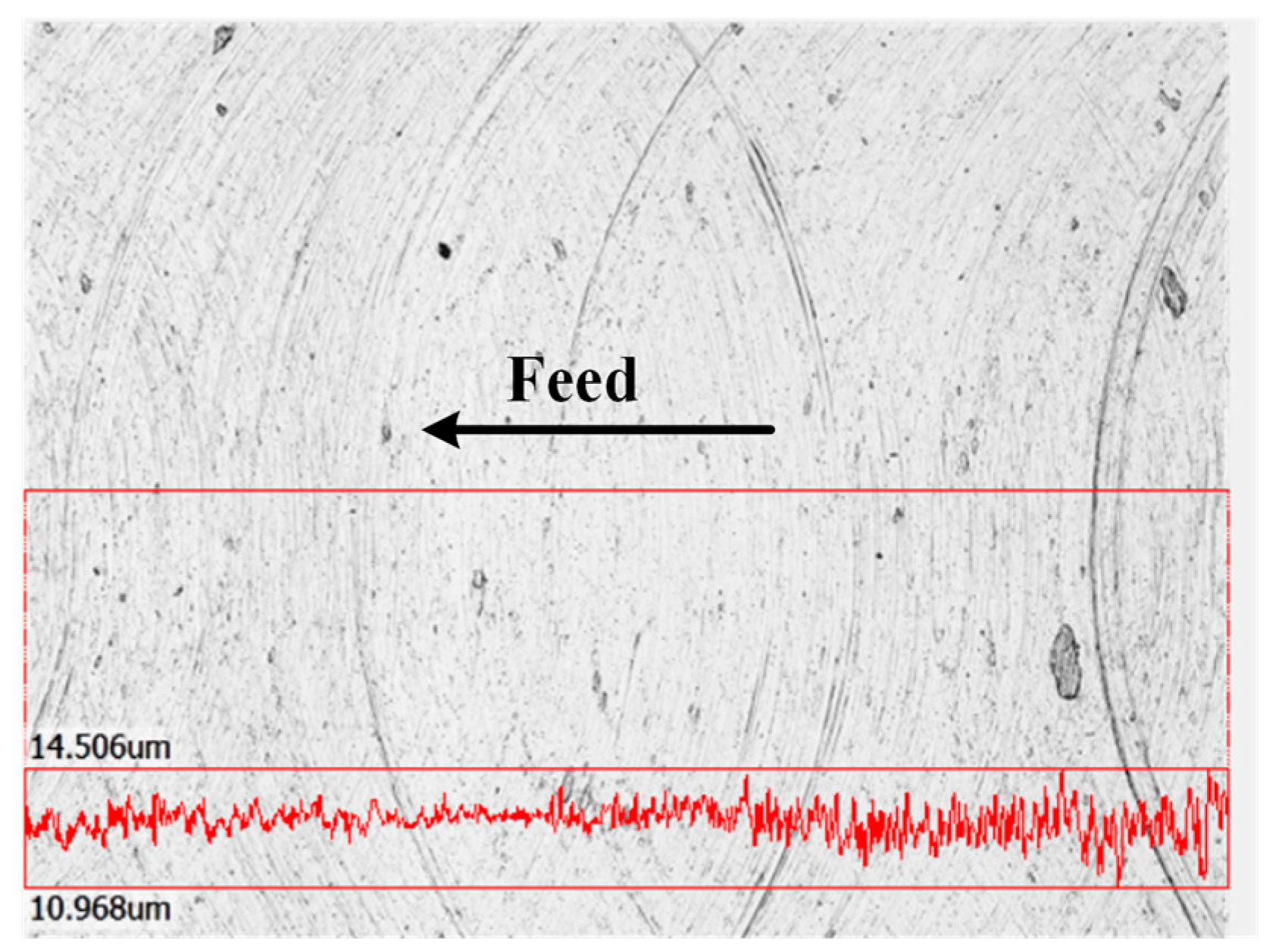

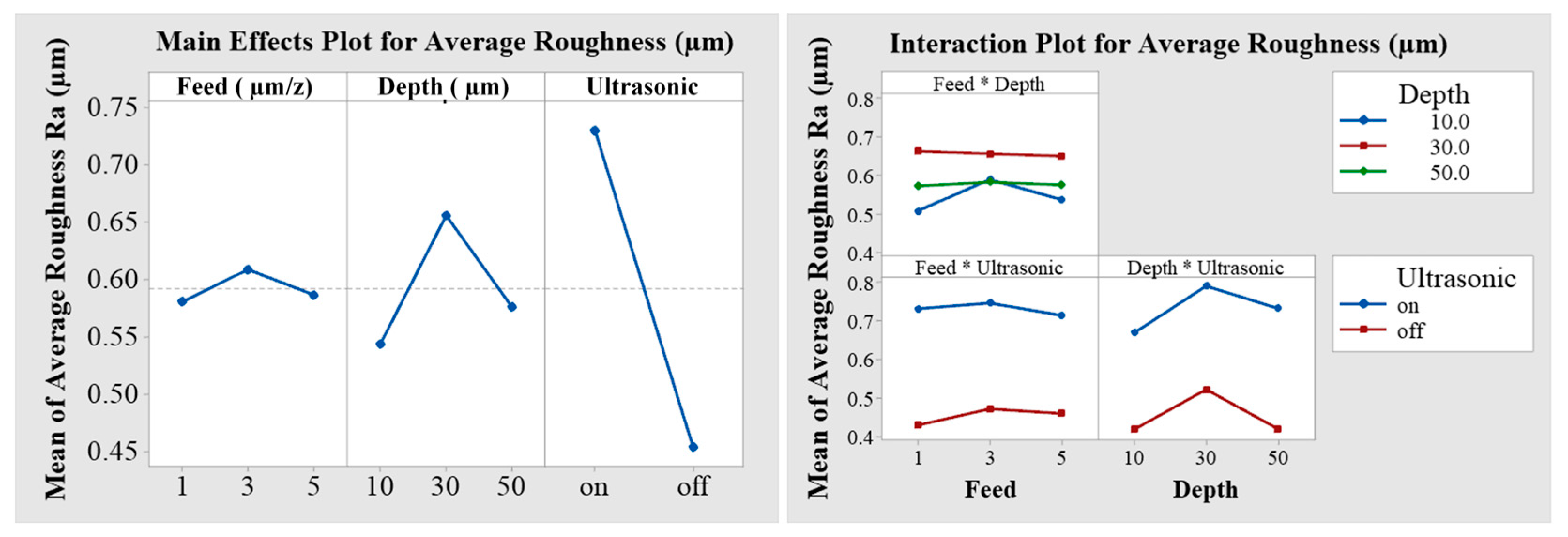

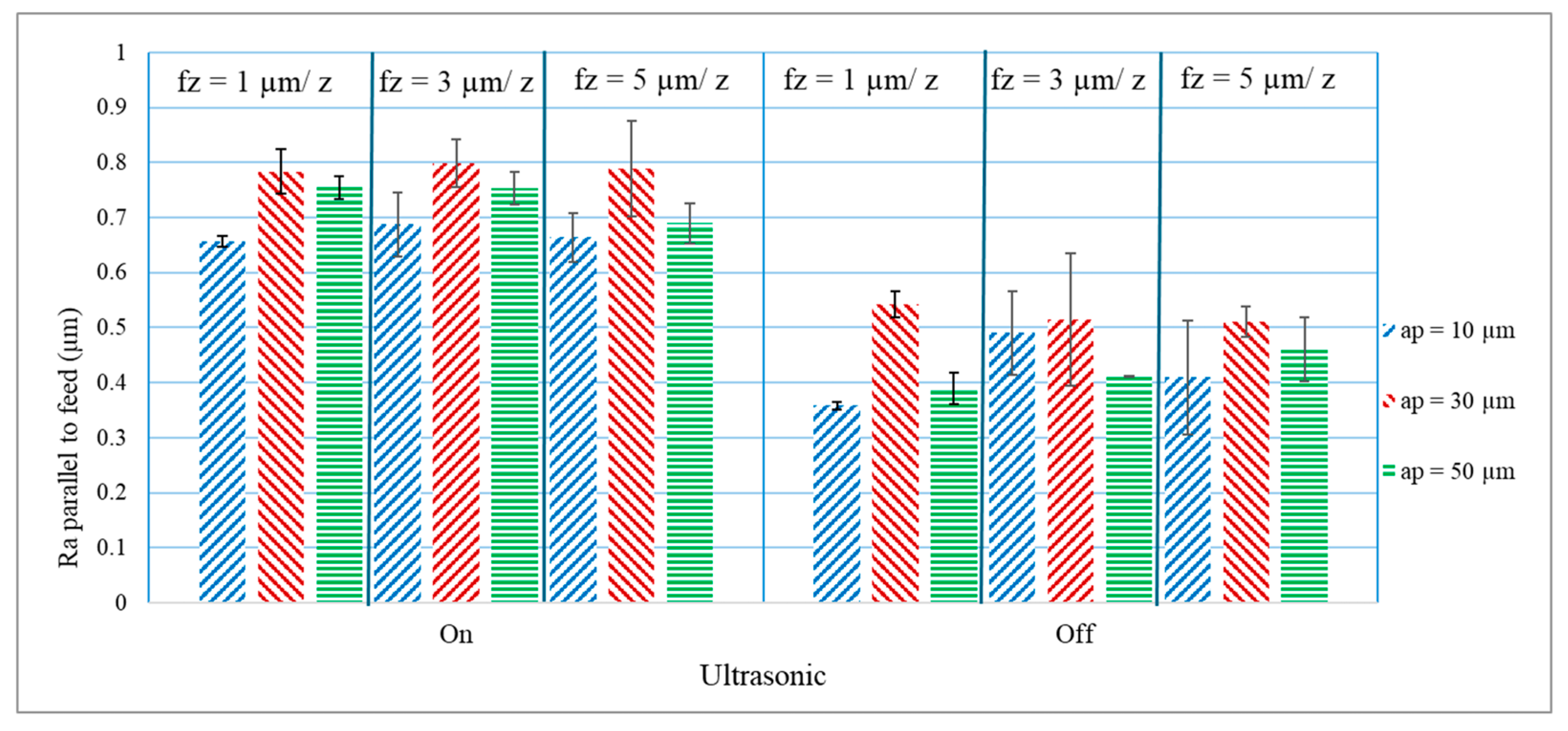

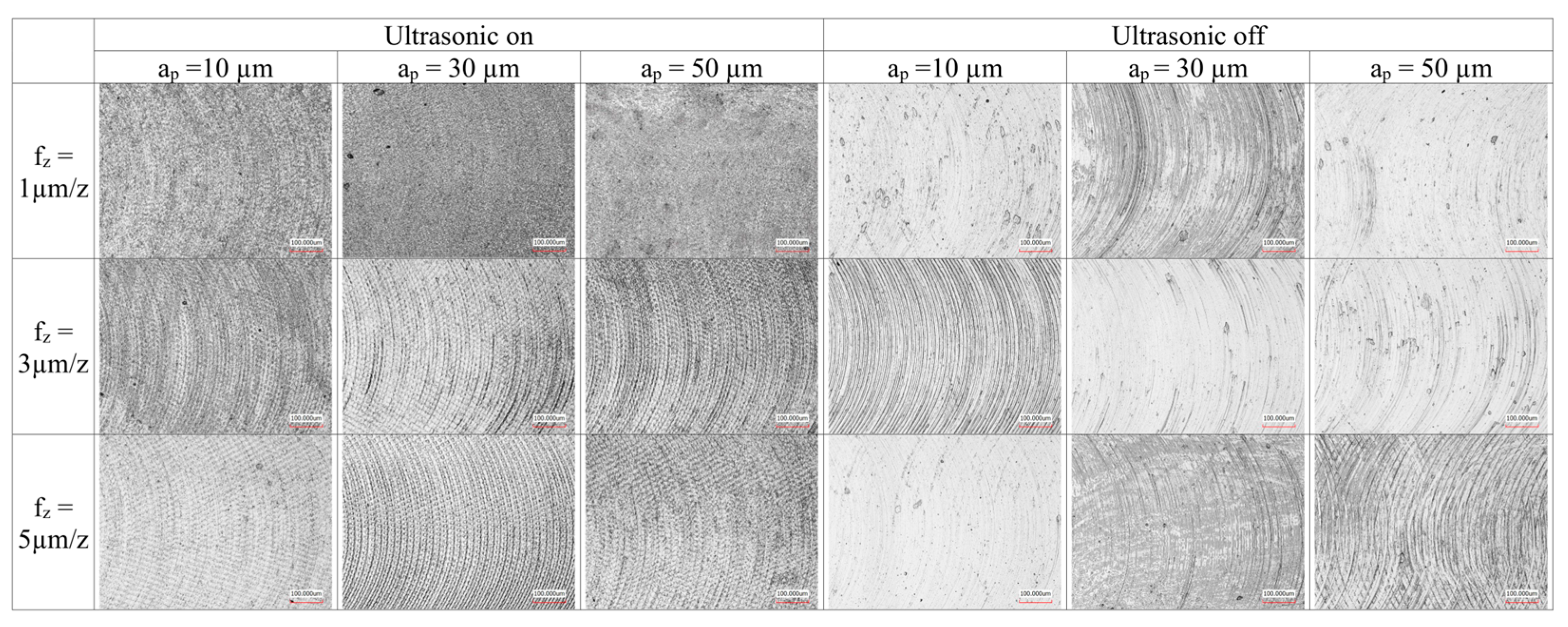

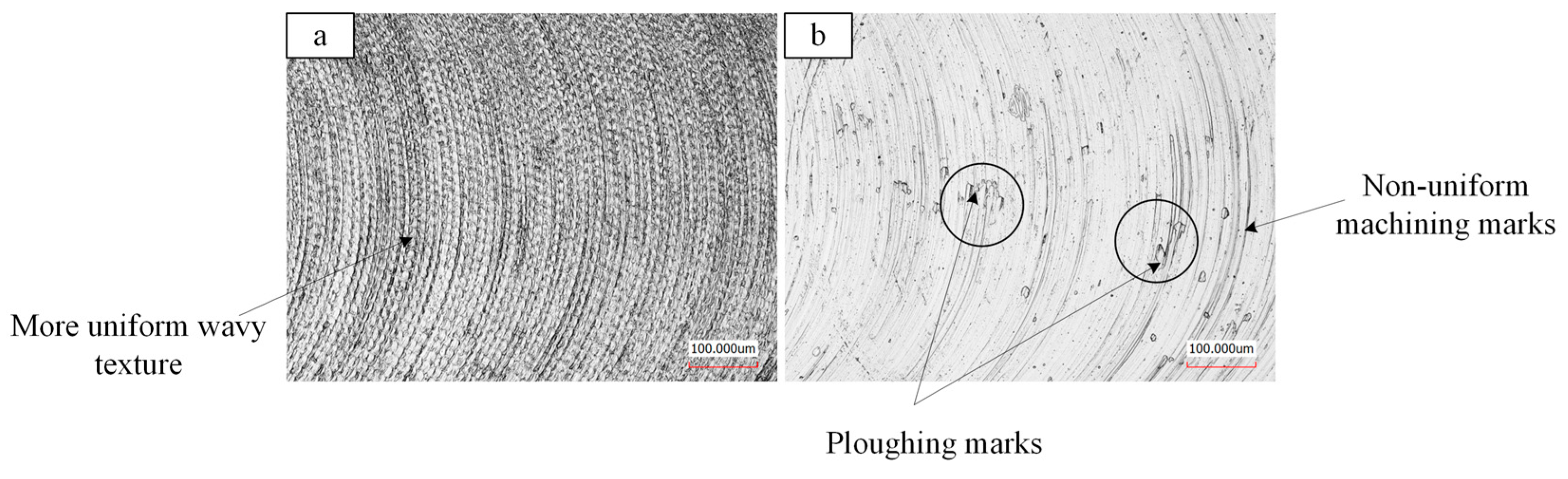

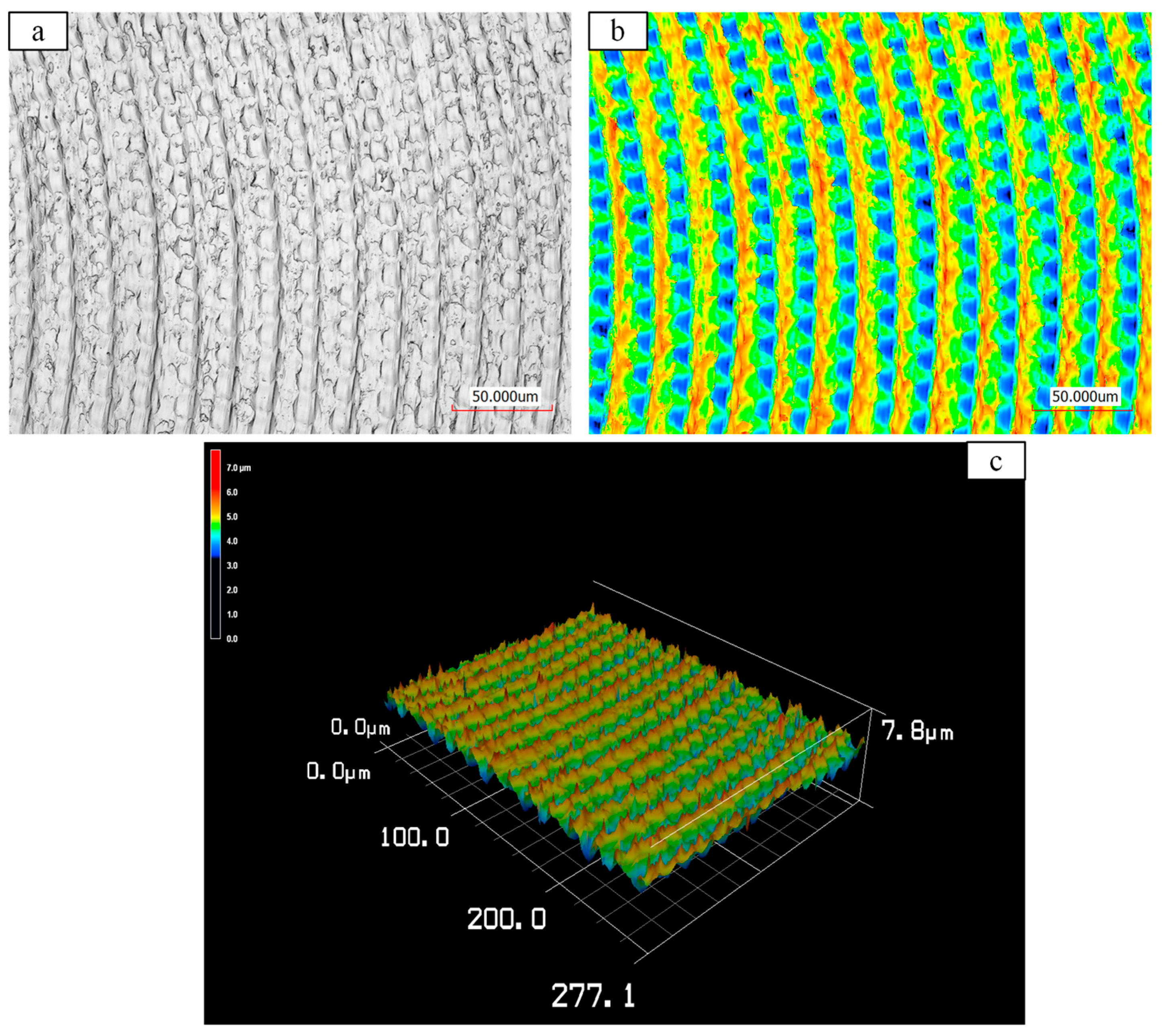

3.3. Surface Texture

4. Conclusions

- The results demonstrated that ultrasonic vibration reduced cutting forces significantly by 20.09% through intermittent cutting effects and decreased tool wear by improving chip evacuation. However, it increased surface roughness due to the formation of micro-dimples, which could benefit tribological applications. The ultrasonic vibrations have no significant effect on burr formation; however, it slightly increased the value of the minimum undeformed chip thickness (hmin).

- The increase in feed-per-tooth significantly increased the cutting forces and BUE formation due to the increase in the chip area. However, the role of fz in controlling burr formation was clear; the results suggest that hmin is reached when fz approaches to re, which was approximately 71% re in the current study.

- Regarding the increase in the axial depth-of-cut, the cutting forces are significantly increased and is an effective factor in increasing burr formation. For the surface roughness, Ra increased first with the increase of ap and then decreased. This study recommends the use of ap = 10 µm.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LIGA | Lithography–Electroplating, and Molding |

| UCT | Uncut Chip Thickness |

| FEM | Finite-Element Method |

| DLC | Diamond-like Coating |

| BUE | Built-up Edge |

| MQL | Minimum Quantity Lubrication |

| ANOVA | Analysis of Variance |

| WEDM | Wire Electrical Discharge Machining |

| LTUAM | Longitudinal Torsional Ultrasonic-assisted Milling |

| UVAM | Ultrasonic Vibration-assisted Milling |

References

- Balázs, B.Z.; Geier, N.; Takács, M.; Davim, J.P. A Review on Micro-Milling: Recent Advances and Future Trends. Int. J. Adv. Manuf. Technol. 2021, 112, 655–684. [Google Scholar] [CrossRef]

- Roushan, A.; Rao, U.S.; Sahoo, P.; Patra, K. Performance Study of Uncoated and AlTiN-Coated Tungsten Carbide Tools in Micromilling of Ti6Al4V Using Nano-MQL. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 63. [Google Scholar] [CrossRef]

- Uriarte, L.; Herrero, A.; Zatarain, M.; Santiso, G.; Lopéz de Lacalle, L.N.; Lamikiz, A.; Albizuri, J. Error Budget and Stiffness Chain Assessment in a Micromilling Machine Equipped with Tools Less than 0.3 mm in Diameter. Precis. Eng. 2007, 31, 1–12. [Google Scholar] [CrossRef]

- Saha, S.; Sravan Kumar, A.; Deb, S.; Bandyopadhyay, P.P. An Investigation on the Top Burr Formation during Minimum Quantity Lubrication (MQL) Assisted Micromilling of Copper. Mater. Today Proc. 2019, 26, 1809–1814. [Google Scholar] [CrossRef]

- O’Toole, L.; Kang, C.W.; Fang, F.Z. Precision Micro-Milling Process: State of the Art. Adv. Manuf. 2021, 9, 173–205. [Google Scholar] [CrossRef] [PubMed]

- De Oliveira, F.B.; Rodrigues, A.R.; Coelho, R.T.; De Souza, A.F. Size Effect and Minimum Chip Thickness in Micromilling. Int. J. Mach. Tools Manuf. 2015, 89, 39–54. [Google Scholar] [CrossRef]

- Srinivas, M.S.; Sangeeth, P.; Venkaiah, N.; Sankar, M. RState of the Art on Tool Wear Characterization in Micro-Milling. Mater. Today Proc. 2023, 80, 355–363. [Google Scholar] [CrossRef]

- Wang, J.; Gong, Y.; Abba, G.; Antoine, J.F.; Shi, J. Chip Formation Analysis in Micromilling Operation. Int. J. Adv. Manuf. Technol. 2009, 45, 430–447. [Google Scholar] [CrossRef]

- Li, K.M.; Chou, S.Y. Experimental Evaluation of Minimum Quantity Lubrication in near Micro-Milling. J. Mater. Process Technol. 2010, 210, 2163–2170. [Google Scholar] [CrossRef]

- Kumar, M.; Bajpai, V. Investigation of Top Burr Formation in Micromilling for Surface Quality Improvement. J. Mater. Eng. Perform. 2023, 32, 2139–2150. [Google Scholar] [CrossRef]

- Silva, L.C.; da Silva, M.B. Investigation of Burr Formation and Tool Wear in Micromilling Operation of Duplex Stainless Steel. Precis. Eng. 2019, 60, 178–188. [Google Scholar] [CrossRef]

- Yadav, R.; Chakladar, N.D.; Paul, S. Modelling and Experimental Validation of Burr Control in Micro Milling of Metals. Mater. Today Commun. 2023, 35, 106205. [Google Scholar] [CrossRef]

- de Oliveira, D.; Gomes, M.C.; de Oliveira, G.V.; dos Santos, A.G.; da Silva, M.B. Experimental and Computational Contribution to Chip Geometry Evaluation When Micromilling Inconel 718. Wear 2021, 476, 203658. [Google Scholar] [CrossRef]

- Kumar, K.; Zindani, D.; Kumari, N.; Davim, J.P. Micro and Nano Machining of Engineering Materials: Recent Developments; Springer: Berlin/Heidelberg, Germany, 2019; ISBN 978-3-319-99899-2. [Google Scholar]

- Kiswanto, G.; Mandala, A.; Azmi, M.; Ko, T.J. The Effects of Cutting Parameters to the Surface Roughness in Low Speed Machining of Micro-Milling of Titanium Alloy Ti-6Al-4V. IOP Conf. Ser. Mater. Sci. Eng. 2019, 654, 012013. [Google Scholar] [CrossRef]

- Kim, D.H.; Lee, P.; Kim, J.S.; Moon, H.; Lee, S.W. Experimental Study on Micro End-Milling Process of Ti-6AL-4V Using Nanofluid Minimum Quantity Lubrication (MQL). In Volume 1: Materials; Micro and Nano Technologies; Properties, Applications and Systems; Sustainable Manufacturing, Proceedings of the ASME 2014 International Manufacturing Science and Engineering Conference collocated with the JSME 2014 International Conference on Materials and Processing and the 42nd North American Manufacturing Research Conference, Detroit, MI, USA, 9–13 June 2014; American Society of Mechanical Engineers: New York, NY, USA, 2014; pp. 1–7. [Google Scholar]

- Lv, B.; Lin, B.; Zhang, J.; Liu, C.; Wang, L.; Sui, T. Micro- and Nano-Scale Spindle Perpendicularity Modulation Method to Enhance the Quality of Milled Surfaces. Int. J. Extrem. Manuf. 2024, 6, 065101. [Google Scholar] [CrossRef]

- Ziberov, M.; de Oliveira, D.; da Silva, M.B.; Hung, W.N.P. Wear of TiAlN and DLC Coated Microtools in Micromilling of Ti-6Al-4V Alloy. J. Manuf. Process 2020, 56, 337–349. [Google Scholar] [CrossRef]

- Roushan, A.; Srinivas Rao, U.; Patra, K.; Sahoo, P. Multi-Characteristics Optimization in Micro-Milling of Ti6Al4V Alloy. J. Phys. Conf. Ser. 2021, 1950, 012046. [Google Scholar] [CrossRef]

- Aslantas, K.; Alatrushi, L.K.H.; Bedir, F.; Kaynak, Y.; Yılmaz, N. An Experimental Analysis of Minimum Chip Thickness in Micro-Milling of Two Different Titanium Alloys. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 234, 1486–1498. [Google Scholar] [CrossRef]

- Zhang, Y.; Bai, Q.; Wang, P. 3D Surface Topography Analysis and Functionality-Related Performance of the Machined Surface in Slot Micro-Milling Titanium Alloy Ti6Al4V. Int. J. Adv. Manuf. Technol. 2023, 127, 1609–1629. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, N.; Bian, R.; He, N.; Li, Z.; Li, L. Investigations on Burr Formation Mechanisms in Micro Milling of High-Aspect-Ratio Titanium Alloy Ti-6al-4 v Structures. Int. J. Mech. Sci. 2020, 185, 105884. [Google Scholar] [CrossRef]

- Wang, P.; Bai, Q.; Cheng, K.; Zhao, L.; Ding, H.; Zhang, Y. Machinability Analysis of Micro-Milling Thin-Walled Ti-6Al-4V Micro Parts under Dry, Lubrication, and Chatter Mitigation Conditions. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2023, 238, 335–346. [Google Scholar] [CrossRef]

- Hassanpour, H.; Sadeghi, M.H.; Rezaei, H.; Rasti, A. Experimental Study of Cutting Force, Microhardness, Surface Roughness, and Burr Size on Micromilling of Ti6Al4V in Minimum Quantity Lubrication. Mater. Manuf. Process. 2016, 31, 1654–1662. [Google Scholar] [CrossRef]

- Zamani, M.; Farahnakian, M.; Elhami, S. Employment of Ultrasonic Assisted Turning in the Fabrication of Microtextures to Improve the Surface Adhesion of the Titanium Implant. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 1983–1991. [Google Scholar] [CrossRef]

- Zhu, L.; Ni, C.; Yang, Z.; Liu, C. Investigations of Micro-Textured Surface Generation Mechanism and Tribological Properties in Ultrasonic Vibration-Assisted Milling of Ti–6Al–4V. Precis. Eng. 2019, 57, 229–243. [Google Scholar] [CrossRef]

- Pape, F.; Poll, G. Frictional Properties o Freshwater Fish Skin. In Proceedings of the 3rd African Conference in Tribology (ACT 2020), Dakar, Senegal, 13–15 April 2022. [Google Scholar]

- Pape, F.; Dong, S.; Poll, G. Fluid-Structure Interaction Coupling for Elastohydrodynamic Lubricated Micro Structured Contacts. In Proceedings of the Eleventh International Conference on Engineering Computational Technology, Mallorca, Spain, 23–25 August 2020; pp. 8–10. [Google Scholar]

- Kelley, J.; Poll, G.; Pape, F. Investigation of the Possible Applications for Microtextured Rolling Bearings. Front. Manuf. Technol. 2022, 2, 1012343. [Google Scholar] [CrossRef]

- Celaya, A.; De Lacalle, L.N.L.; Campa, F.J.; Lamikiz, A. Ultrasonic Assisted Turning of Mild Steels. Int. J. Mater. Prod. Technol. 2010, 37, 60–70. [Google Scholar] [CrossRef]

- Verma, G.C.; Pandey, P.M.; Dixit, U.S. Modeling of Static Machining Force in Axial Ultrasonic-Vibration Assisted Milling Considering Acoustic Softening. Int. J. Mech. Sci. 2018, 136, 1–16. [Google Scholar] [CrossRef]

- Yuan, Z.; Fang, B.; Zhang, Y.; Wang, F. Effect of Cutting Parameters on Chips and Burrs Formation with Traditional Micromilling and Ultrasonic Vibration Assisted Micromilling. Int. J. Adv. Manuf. Technol. 2022, 119, 2615–2628. [Google Scholar] [CrossRef]

- Yuan, Z.; Fang, B.; Dong, Y.; Ding, H.; Zhang, Y. Study on Surface Texture and Corrosion Resistance of Ultrasonic Vibration-Assisted Micromilling Inconel718. Int. J. Adv. Manuf. Technol. 2022, 121, 601–618. [Google Scholar] [CrossRef]

- Fang, B.; Yuan, Z.; Li, D.; Gao, L. Effect of Ultrasonic Vibration on Finished Quality in Ultrasonic Vibration Assisted Micromilling of Inconel718. Chin. J. Aeronaut. 2021, 34, 209–219. [Google Scholar] [CrossRef]

- Greco, S.; Klauer, K.; Kirsch, B.; Aurich, J.C. Vibration-Assisted Micro Milling of AISI 316L Produced by Laser-Based Powder Bed Fusion. J. Manuf. Process 2021, 71, 298–305. [Google Scholar] [CrossRef]

- Xu, L.H.; Na, H.B.; Han, G.C. Machinablity Improvement with Ultrasonic Vibration–Assisted Micro-Milling. Adv. Mech. Eng. 2018, 10, 1687814018812531. [Google Scholar] [CrossRef]

- Lian, H.; Guo, Z.; Huang, Z.; Tang, Y.; Song, J. Experimental Research of Al6061 on Ultrasonic Vibration Assisted Micro-Milling. Procedia CIRP 2013, 6, 561–564. [Google Scholar] [CrossRef]

- Feng, X.; Dong, Z.; Li, B.; Peng, H. Finite Element Simulation and Experimental Analysis of Axial Ultrasonic Vibration-Assisted Micro-Milling of 316L Stainless Steel. Int. J. Adv. Manuf. Technol. 2024, 133, 4365–4383. [Google Scholar] [CrossRef]

- Ullah, S.; Khan, M.A.; Umeed, M.; Juraev, N.; Ijaz Khan, M. Finite Element Simulation Investigation on Ultrasonic Vibration Assisted Micro Milling of AISI 410 Grade MSS. Int. J. Interact. Des. Manuf. 2024. [Google Scholar] [CrossRef]

- Zhang, Y.; Yuan, Z.; Fang, B.; Gao, L.; Chen, Z.; Su, G. Study on the Mechanism of Burr Formation by Simulation and Experiment in Ultrasonic Vibration-Assisted Micromilling. Micromachines 2023, 14, 625. [Google Scholar] [CrossRef]

- Satpute, V.; Huo, D.; Hedley, J.; Dale, C. A Comprehensive Experimental Investigation into Vibration-Assisted Micro-Milling of Monocrystalline Silicon. J. Manuf. Process 2024, 131, 12–26. [Google Scholar] [CrossRef]

- Li, K.M.; Wang, S.L. Effect of Tool Wear in Ultrasonic Vibration-Assisted Micro-Milling. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 847–855. [Google Scholar] [CrossRef]

- Mahmat, A.; Agar, S.; Tosun, N. Ultrasonic-Assisted High-Speed Micro-Milling of Ti6Al4V. J. Braz. Soc. Mech. Sci. Eng. 2025, 47, 46. [Google Scholar] [CrossRef]

- Liu, X.F.; Wang, W.H.; Jiang, R.S.; Xiong, Y.F.; Lin, K.Y. Tool Wear Mechanisms in Axial Ultrasonic Vibration Assisted Milling In-Situ TiB2/7050Al Metal Matrix Composites. Adv. Manuf. 2020, 8, 252–264. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, B.; Zhao, C. Effect of Ultrasonic Vibration-Assisted Face Milling on the Surface Microstructure and Tribological Properties. J. Vibroeng. 2022, 24, 1–17. [Google Scholar] [CrossRef]

- Mansour, M.M.; Maher, I.; Nassef, M.G.A.; El-Hofy, H.; Yan, J.; Khairaldien, W.M. Statistical Modeling and Optimization of Ultrasonic Vibration Assisted End Grinding of Alumina Ceramics. Int. J. Interact. Des. Manuf. 2025, 19, 7283–7301. [Google Scholar] [CrossRef]

- Nath, C.; Rahman, M. Effect of Machining Parameters in Ultrasonic Vibration Cutting. Int. J. Mach. Tools Manuf. 2008, 48, 965–974. [Google Scholar] [CrossRef]

- Guo, S.; Du, W.; Jiang, Q.; Dong, Z.; Zhang, B. Surface Integrity of Ultrasonically-Assisted Milled Ti6Al4V Alloy Manufactured by Selective Laser Melting. Chin. J. Mech. Eng. (Engl. Ed.) 2021, 34, 67. [Google Scholar] [CrossRef]

- Ibrahim, M.R.; Rahim, Z.; Rahim, E.; Tobi, L.; Cheng, K.; Ding, H. An Experimental Investigation of Cutting Temperature and Tool Wear in 2 Dimensional Ultrasonic Vibrations Assisted Micro-Milling. In Proceedings of the MATEC Web of Conferences, Shanghai, China, 21–23 October 2016; EDP Sciences: Les Ulis, France, 2017; Volume 95. [Google Scholar]

- Feng, Y.; Hsu, F.C.; Lu, Y.T.; Lin, Y.F.; Lin, C.T.; Lin, C.F.; Lu, Y.C.; Liang, S.Y. Temperature Prediction of Ultrasonic Vibration-Assisted Milling. Ultrasonics 2020, 108, 106212. [Google Scholar] [CrossRef] [PubMed]

- Rauf, A.; Khan, M.A.; Jaffery, S.H.I.; Butt, S.I. Effects of Machining Parameters, Ultrasonic Vibrations and Cooling Conditions on Cutting Forces and Tool Wear in Meso Scale Ultrasonic Vibrations Assisted End-Milling (UVAEM) of Ti–6Al–4V under Dry, Flooded, MQL and Cryogenic Environments—A Statistical Analysis. J. Mater. Res. Technol. 2024, 30, 8287–8303. [Google Scholar] [CrossRef]

- Zhao, P.; Lin, B.; Zhou, J.; Lv, B.; Li, J.; Zhang, J.; Wang, L.; Sui, T. Review of Grinding Temperature Theory and Measurement for the Needs of the Times: Promoting the Development of Advanced Manufacturing. J. Mater. Process. Technol. 2025, 337, 118744. [Google Scholar] [CrossRef]

- Su, Y.; Li, L. An Investigation of Cutting Performance and Action Mechanism in Ultrasonic Vibration-Assisted Milling of Ti6al4v Using a Pcd Tool. Micromachines 2021, 12, 1319. [Google Scholar] [CrossRef]

- Rinck, P.M.; Gueray, A.; Zaeh, M.F. Modeling of Cutting Forces in 1-D and 2-D Ultrasonic Vibration-Assisted Milling of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2022, 119, 1807–1819. [Google Scholar] [CrossRef]

- Aurich, J.C.; Dornfeld, D.; Arrazola, P.J.; Franke, V.; Leitz, L.; Min, S. Burrs-Analysis, Control and Removal. CIRP Ann. Manuf. Technol. 2009, 58, 519–542. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, X.; He, L.; Jiang, F.; Shen, J.; Zhu, L. Comparative Study on Micro-Milling Machinability of Titanium Alloys Prepared by Different Processes: Forging Process, Additive Manufacturing Process and Heat-Treatment Process. Precis. Eng. 2024, 88, 164–176. [Google Scholar] [CrossRef]

- Wu, X.; Du, M.; Shen, J.; Jiang, F.; Li, Y.; Liu, L. Experimental Research on the Top Burr Formation in Micro Milling. Int. J. Adv. Manuf. Technol. 2021, 117, 3477–3486. [Google Scholar] [CrossRef]

- Yabo, Z.; Qingshun, B.; Yangyang, S.; Donghai, L. Burr Formation Mechanism and Machining Parameter Effect in Slot Micro-Milling Titanium Alloy Ti6Al4V. Int. J. Adv. Manuf. Technol. 2022, 123, 2073–2086. [Google Scholar] [CrossRef]

- de Oliveira, D.; Ziberov, M.; de Paiva, R.L.; da Silva, M.B. An Experimental Evaluation of Cutting Parameters Influence on the Surface Integrity and Tool Wear Mechanisms on the Dry Micromilling of Austenitic Alloy Inconel 718. Wear 2025, 571, 205789. [Google Scholar] [CrossRef]

- Zheng, K.; Liao, W.; Dong, Q.; Sun, L. Friction and Wear on Titanium Alloy Surface Machined by Ultrasonic Vibration-Assisted Milling. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 411. [Google Scholar] [CrossRef]

- Shen, X.; Zhang, J. Studies on Friction and Wear Properties of Surface Produced by Ultrasonic Vibration-Assisted Milling. Int. J. Adv. Manuf. Technol. 2013, 67, 349–356. [Google Scholar] [CrossRef]

- Xia, Z.; Gao, G.; Wang, Y.; Zhang, M.; Jia, F.; Shan, C. Surface Micro-Texture and Tribological Properties in Longitudinal-Torsional Ultrasonic-Assisted Milling Ti2AlNb. Int. J. Adv. Manuf. Technol. 2023, 126, 1919–1935. [Google Scholar] [CrossRef]

- Ermis, M.; Antmen, E.; Hasirci, V. Micro and Nanofabrication Methods to Control Cell-Substrate Interactions and Cell Behavior: A Review from the Tissue Engineering Perspective. Bioact. Mater. 2018, 3, 355–369. [Google Scholar] [CrossRef]

- Chen, X.; Zhai, W.; Dong, S.; Zheng, K.; Xu, R.; Wang, J.; Liu, X.; Lu, W. Investigations on Torsional Fretting Wear Properties of CuAlNi Processed by Ultrasonic Vibration-Assisted Milling. Tribol. Int. 2020, 146, 106238. [Google Scholar] [CrossRef]

- Xing, D.; Zhang, J.; Shen, X.; Zhao, Y.; Wang, T. Tribological Properties of Ultrasonic Vibration Assisted Milling Aluminium Alloy Surfaces. Procedia CIRP 2013, 6, 539–544. [Google Scholar] [CrossRef]

- Lotfi, M.; Sajjady, S.A.; Amini, S. Wettability Analysis of Titanium Alloy in 3D Elliptical Ultrasonic Assisted Turning. Int. J. Lightweight Mater. Manuf. 2019, 2, 235–240. [Google Scholar] [CrossRef]

| Author | Workpiece | Vibration Direction | Measured Responses | Effect of Vibration Assistance |

|---|---|---|---|---|

| Li (2013) [42] | SKD61 (AISI H13) | Axial | - Tool wear - Surface roughness - Burr height | 1. Tool wear reduced at low cutting speed only. 2. Surface roughness was reduced. 3. A 2.18% reduction in down milling burrs, which increased to 80% reduction by using MQL. |

| Lian (2013) [37] | Al6061 | Vertical (to workpiece) | - Surface roughness | 1. Ultrasonic assistance reduced surface roughness. 2. The optimum value was at amplitude 11 µm. |

| Xu (2018) [36] | Titanium alloy TC4 and Aluminum alloy 6061T6 | Feed direction | - Cutting forces - Surface morphology - Dimensional accuracy | 1. Ultrasonic vibrations reduced the size-effect point in terms of feed rate. 2. The vibrations can effectively reduce the milling force by 12% and 17%, respectively, for aluminum alloy 6061T6 and titanium alloy TC4. 3. Ultrasonic µ improved the dimensional accuracy and reduced the surface defects due to the lower forces. |

| FANG (2021) [34] | Inconel 718 | Feed direction | - Cutting force - Burr formation - Surface morphology - BUE | 1. The effect of ultrasonic assistance on burr submission was clear at fz 5 µm/z. 2. Ultrasonic assistance suppresses BUE formation. 3. Cutting forces are reduced by 7.6%, 11.5%, and 1.3%, in x, y, and z directions, respectively. |

| Yuan (2022) [32] | Inconel 718 | Feed direction | - Chip size - Burr size and morphology | 1. Ultrasonic assistance can significantly reduce chip size and burr. 2. Under the conditions of low n, large ƒz, and large amplitude, the burr suppression is more obvious. |

| Yuan (2022) [33] | Inconel 718 | Feed direction | - Cutting force - Tool wear - Surface quality - Corrosion surface | Ultrasonic assistance produces excellent surface with excellent corrosion resistance. |

| Zhang (2023) [40] | Inconel 718 | Feed direction | - Burr formation | 1. Ultrasonic assistance reduces burr formation, especially at higher amplitude. 2. Ultrasonic vibrations can reduce the size effect at small fz which will reduce the burr formation. |

| Feng (2024) [38] | AISI 316L | Vertical (to workpiece) | - Cutting force - Surface roughness and morphology - Tool wear - (cutting forces, cutting temperature, chip formation by simulation) | 1. Ultrasonic assistance reduced the cutting temperature. 2. Chip size was lower than conventional micro-milling. 3. Surface morphology and surface roughness were improved. 4. Ultrasonic reduced the cutting force in x and y directions. |

| Ullah (2024) [39] | AISI 410 | Feed direction | - Cutting forces - Cutting temperature - Tool wear - Burr formation and chip formation (by simulation) | The increase in ultrasonic amplitude reduced the resultant force, cutting temperature, tool wear, and burr. |

| Mahmat (2024) [43] | Ti6Al4V | Vertical (to workpiece) | - Cutting force - Cutting temperature - Surface roughness - Tool life | 1. The implementation of ultrasonic assistance causes a reduction in the cutting force, cutting temperature, surface roughness, and prolonged tool life. 2. The increase in frequency to 30 kHz can reduce cutting force and surface roughness. However, the tool life was reduced and cutting temperature increased. |

| Satpute (2024) [41] | Monocrystalline silicone | Feed, 2D axial-feed, 2D cross feed-feed | - Surface roughness - Tool wear | 1. Average roughness reduction 144.26% and 106.61% can be achieved with high-frequency 1D or 2D ultrasonic-assisted micro-milling. 2. Both 1D and 2D ultrasonic vibrations reduced the tool wear compared to conventional micro-milling. |

| Element | Ti | Al | V | Mn | Fe | W | Pd | Nb |

| wt.% | 89.7 | 6.17 | 3.7333 | 0.17133 | 0.15 | 0.08263 | 0.0328 | 0.03177 |

| Element | Si | Cr | Sn | Ru | Cu | Mo | Ni | Zr |

| wt.% | 0.028567 | 0.018033 | 0.0145 | 0.013433 | 0.006533 | 0.004 | 0.001 | 0.001 |

| No. | Feed-per-Tooth (fz) | Axial Depth-of-Cut (ap) | Ultrasonic Vibrations |

|---|---|---|---|

| 1 | 1 | 10 | on |

| 2 | 1 | 10 | off |

| 3 | 1 | 30 | on |

| 4 | 1 | 30 | off |

| 5 | 1 | 50 | on |

| 6 | 1 | 50 | off |

| 7 | 3 | 10 | on |

| 8 | 3 | 10 | off |

| 9 | 3 | 30 | on |

| 10 | 3 | 30 | off |

| 11 | 3 | 50 | on |

| 12 | 3 | 50 | off |

| 13 | 5 | 10 | on |

| 14 | 5 | 10 | off |

| 15 | 5 | 30 | on |

| 16 | 5 | 30 | off |

| 17 | 5 | 50 | on |

| 18 | 5 | 50 | off |

| Source | Resultant Force | Up Burr Height | Up Burr Width | Down Burr Height | Down Burr Width | Ra |

|---|---|---|---|---|---|---|

| Feed-per-tooth | 0.000 | 0.019 | 0.089 | 0.018 | 0.453 | 0.808 |

| Axial depth of cut | 0.007 | 0.101 | 0.446 | 0.097 | 0.022 | 0.064 |

| Ultrasonic vibrations | 0.021 | 0.281 | 0.970 | 0.429 | 0.702 | 0.000 |

| Feed * Depth | 0.277 | 0.255 | 0.919 | 0.642 | 0.352 | 0.947 |

| Feed * Ultrasonic | 0.147 | 0.645 | 0.692 | 0.545 | 0.044 | 0.872 |

| Depth * Ultrasonic | 0.185 | 0.231 | 0.178 | 0.343 | 0.438 | 0.787 |

| Feed * Depth * Ultrasonic | 0.063 | 0.305 | 0.174 | 0.290 | 0.116 | 0.896 |

| Source | Resultant Force | Up Burr Height | Up Burr Width | Down Burr Height | Down Burr Width | Ra |

|---|---|---|---|---|---|---|

| Feed-per-tooth | 29.29% | 20.09% | 14.63% | 22.19% | 3.20% | 0.52% |

| Axial depth of cut | 15.20% | 10.53% | 4.47% | 11.69% | 18.33% | 7.76% |

| Ultrasonic vibrations | 7.31% | 2.49% | 0.00% | 1.43% | 0.29% | 66.91% |

| Feed * Depth | 6.32% | 11.80% | 2.41% | 5.60% | 9.12% | 0.86% |

| Feed * Ultrasonic | 4.86% | 1.82% | 1.98% | 2.76% | 14.42% | 0.33% |

| Depth * Ultrasonic | 4.22% | 6.42% | 10.04% | 4.99% | 3.33% | 0.59% |

| Feed * Depth * Ultrasonic | 12.34% | 10.54% | 18.93% | 11.85% | 16.59% | 1.29% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wadee, A.; Nassef, M.G.A.; Pape, F.; Maher, I. Enhancing Micro-Milling Performance of Ti6Al4V: An Experimental Analysis of Ultrasonic Vibration Effects on Forces, Surface Topography, and Burr Formation. J. Manuf. Mater. Process. 2025, 9, 356. https://doi.org/10.3390/jmmp9110356

Wadee A, Nassef MGA, Pape F, Maher I. Enhancing Micro-Milling Performance of Ti6Al4V: An Experimental Analysis of Ultrasonic Vibration Effects on Forces, Surface Topography, and Burr Formation. Journal of Manufacturing and Materials Processing. 2025; 9(11):356. https://doi.org/10.3390/jmmp9110356

Chicago/Turabian StyleWadee, Asmaa, Mohamed G. A. Nassef, Florian Pape, and Ibrahem Maher. 2025. "Enhancing Micro-Milling Performance of Ti6Al4V: An Experimental Analysis of Ultrasonic Vibration Effects on Forces, Surface Topography, and Burr Formation" Journal of Manufacturing and Materials Processing 9, no. 11: 356. https://doi.org/10.3390/jmmp9110356

APA StyleWadee, A., Nassef, M. G. A., Pape, F., & Maher, I. (2025). Enhancing Micro-Milling Performance of Ti6Al4V: An Experimental Analysis of Ultrasonic Vibration Effects on Forces, Surface Topography, and Burr Formation. Journal of Manufacturing and Materials Processing, 9(11), 356. https://doi.org/10.3390/jmmp9110356