Artificial Intelligence and Machine Learning in Cold Spray Additive Manufacturing: A Systematic Literature Review

Abstract

1. Introduction

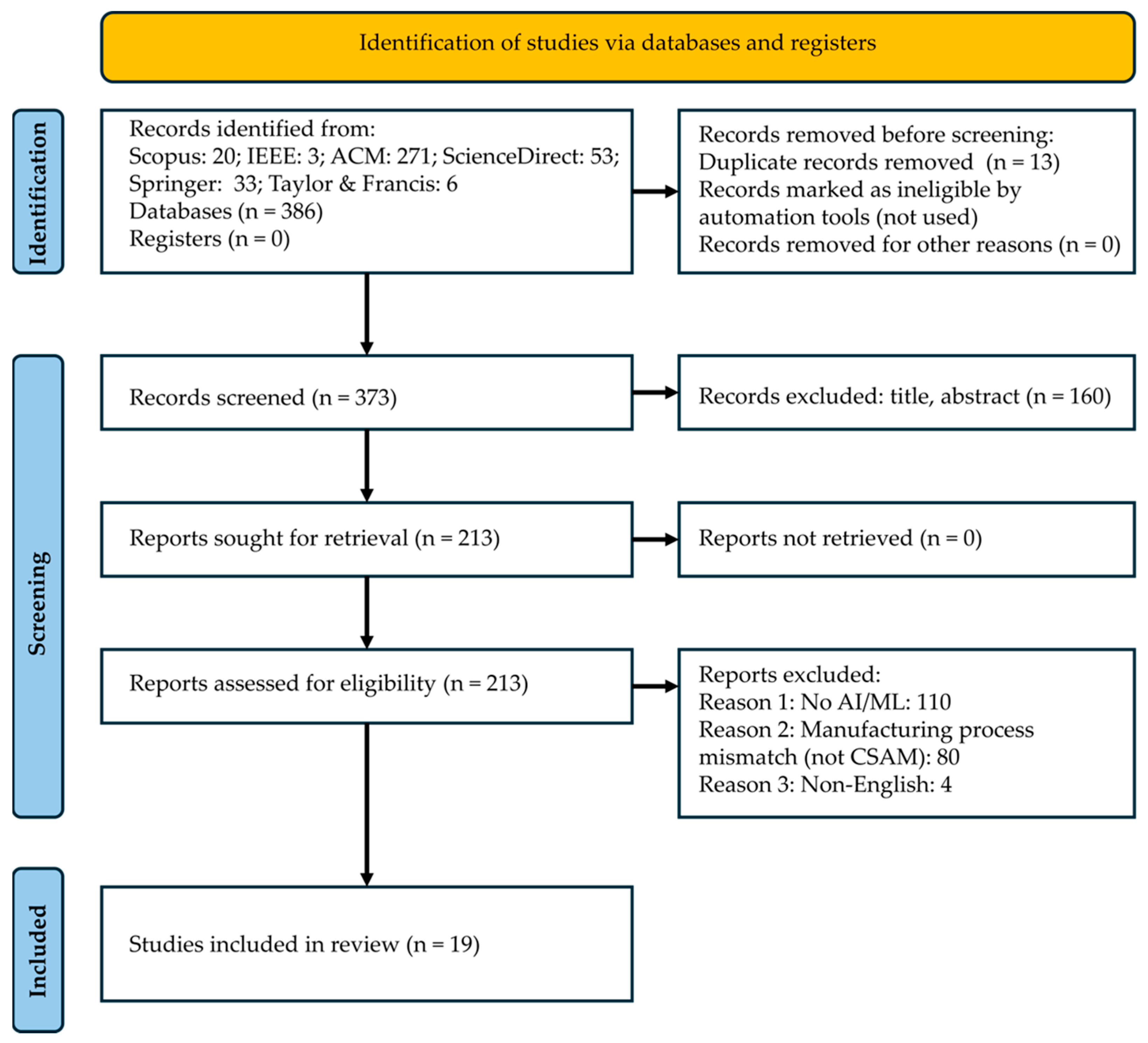

2. Research Methodology

2.1. Step 1: Potential Research Questions

- RQ1: What types of CSAM problems are currently being addressed with AI/ML?

- RQ2: Which AI/ML models are used for the identified CSAM problems?

- RQ3: What benefits, limitations, and open challenges are reported when applying AI/ML to CSAM?

2.2. Step 2: Keywords Identification

2.3. Step 3: Resources for Searching

2.4. Step 4: Inclusion and Exclusion Criteria

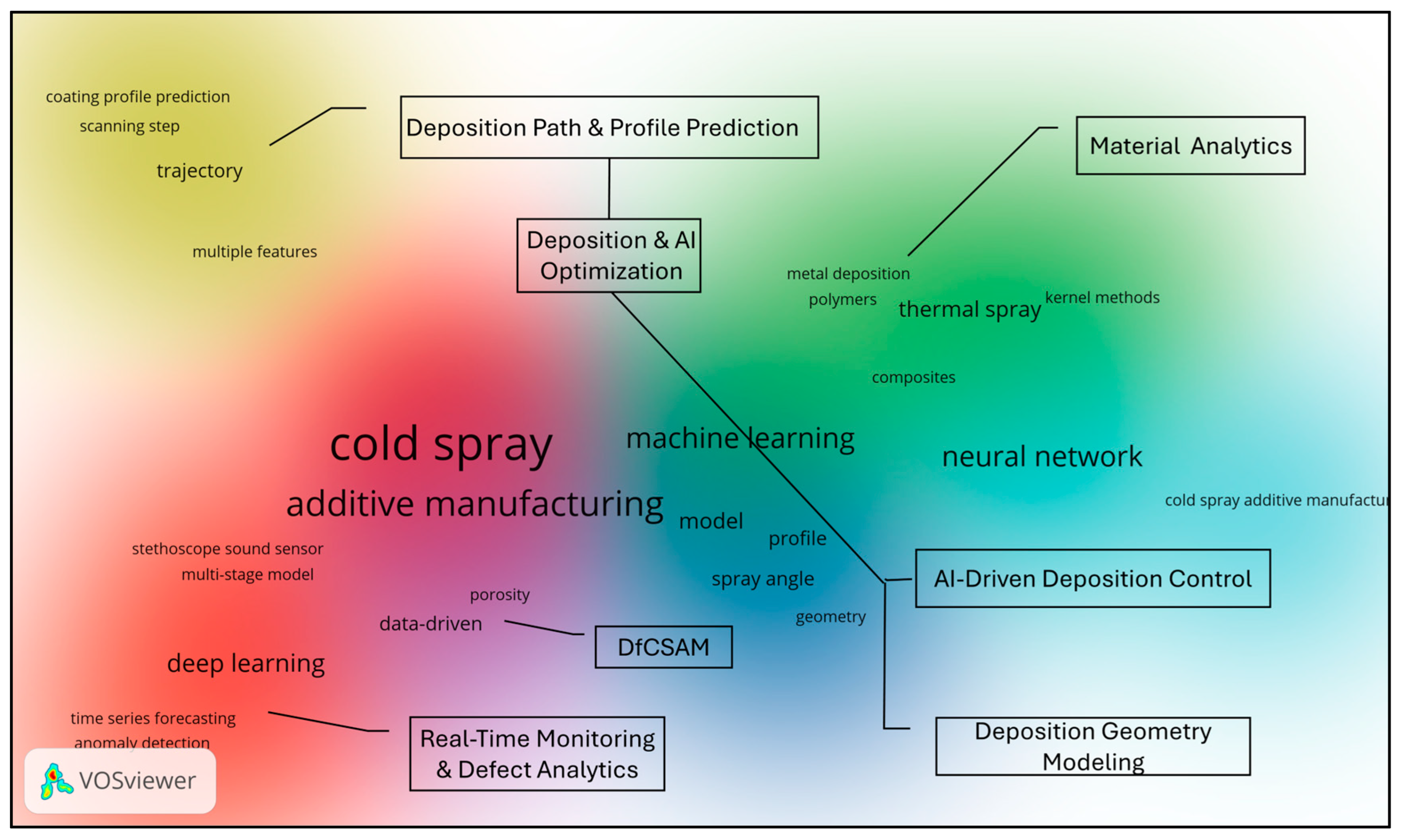

2.5. Step 5: Selecting Studies and Analysing Keyword Co-Occurrence

- State clearly defined CSAM problems.

- Justify why an AI/ML approach was suitable.

- Demonstrate that the proposed method was evaluated or validated.

2.6. Data Synthesis: A Priori Plan, Feasibility of Pooling, and Overview of Observed Patterns

2.7. Bias Risk

2.8. Certainty of Evidence Approach

3. Classification of the Selected Literature

4. AI/ML Applications for CSAM

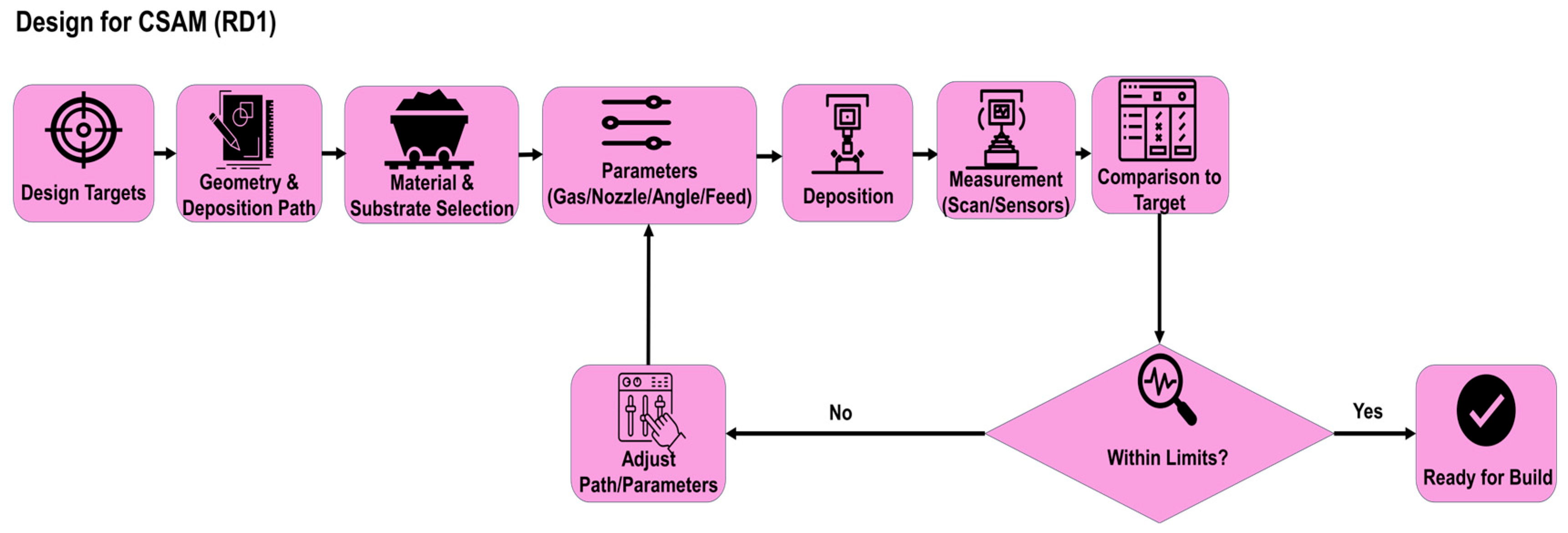

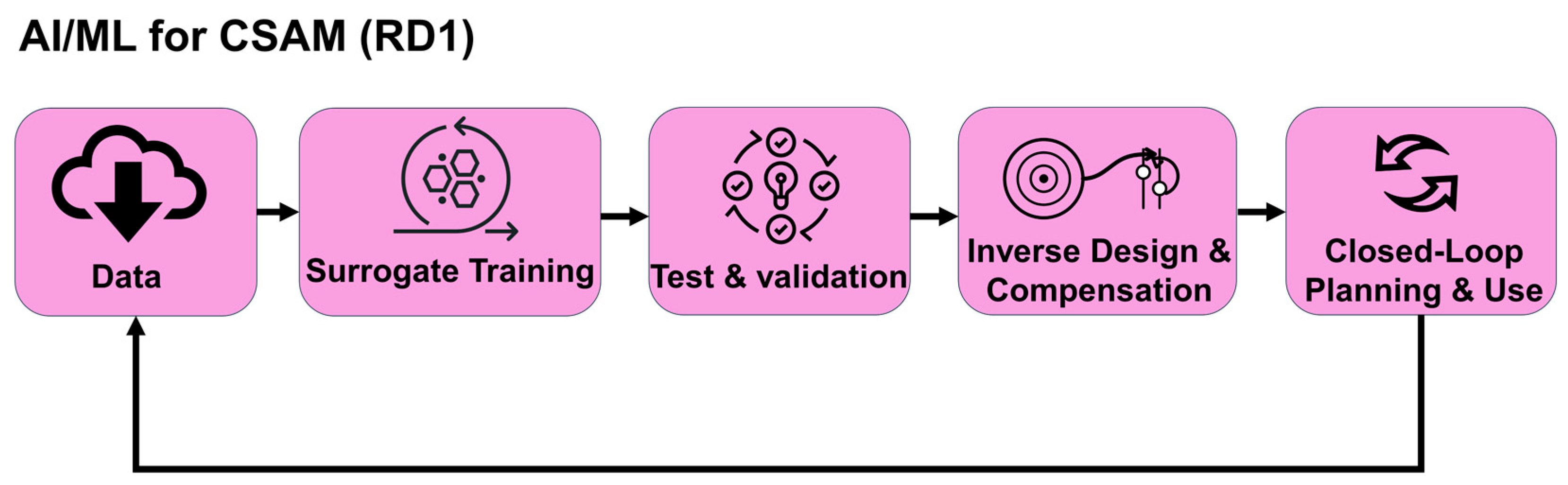

4.1. Design for CSAM (RD1)

4.1.1. Part Design and Deposition Strategy

4.1.2. Design Optimisation

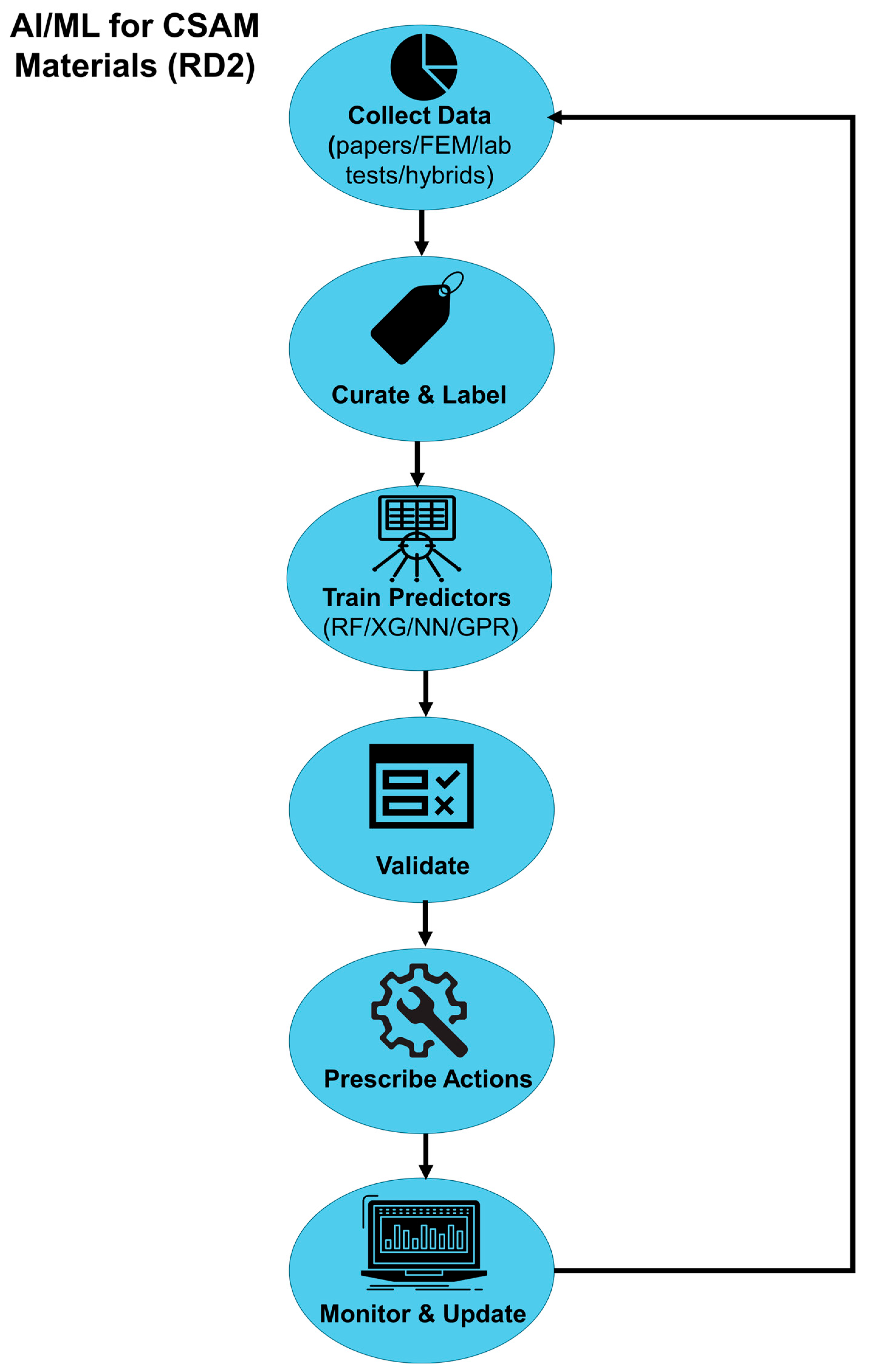

4.2. Material Analytics and Characterisation for CSAM (RD2)

4.2.1. From Material Analytics in AM to Quality Assurance

4.2.2. CSAM: Solid-State Process, Properties, and Characterisation Challenges

4.2.3. Materials, Techniques, and Property Performance Relationships in CSAM

4.2.4. Data-Driven and Physics-Informed Analytics for CSAM: Porosity Prediction and Surrogate Modelling

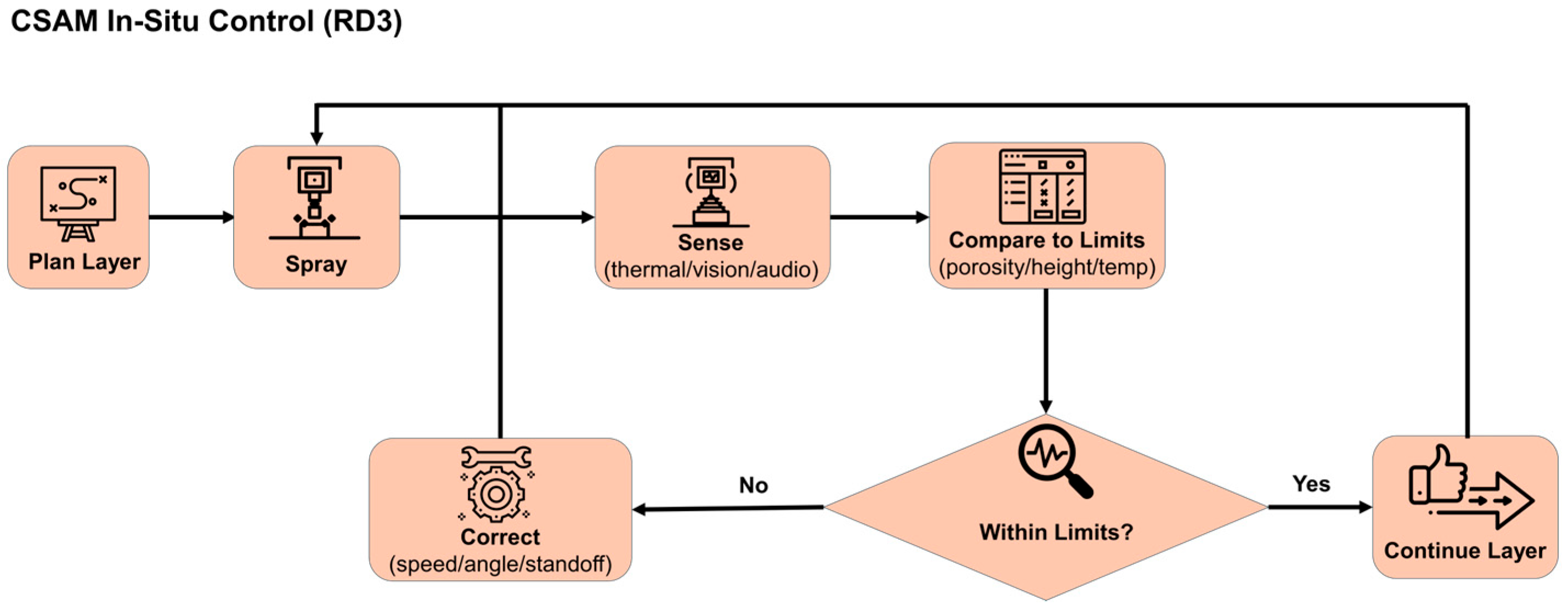

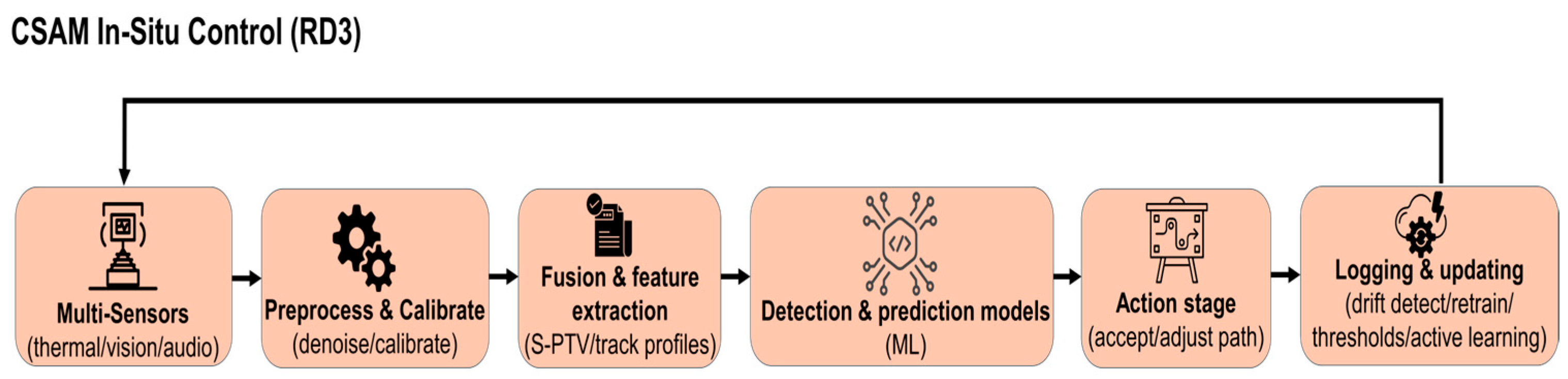

4.3. In Situ Control and Monitoring in CSAM (RD3)

4.3.1. Modelling Approaches: CFD, Surrogates, and AI/ML Integration

4.3.2. In Situ Monitoring and First Steps Toward Closed-Loop Control

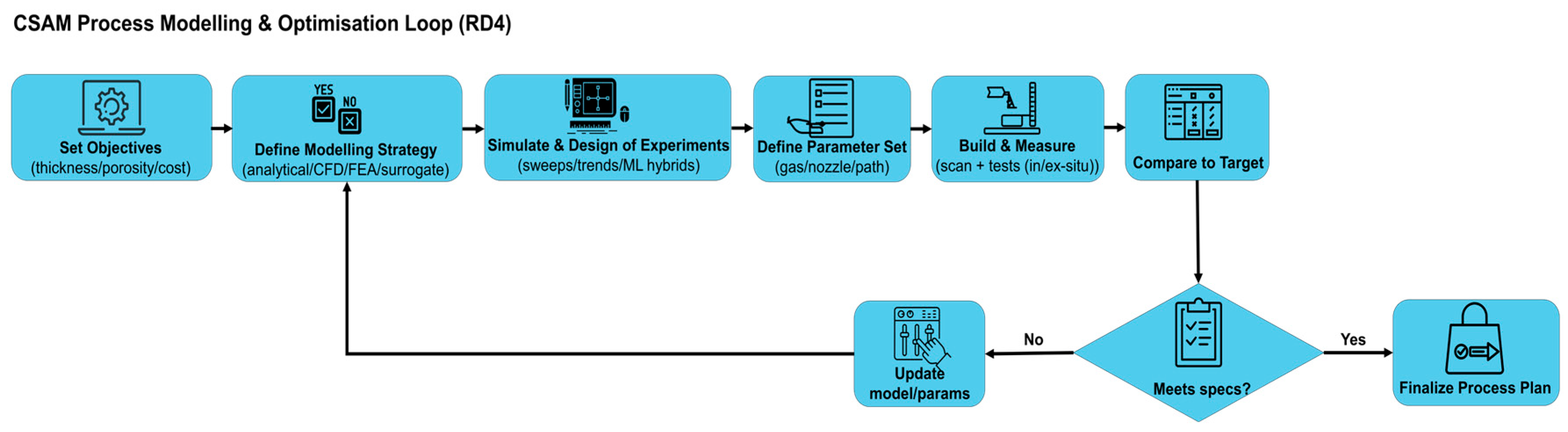

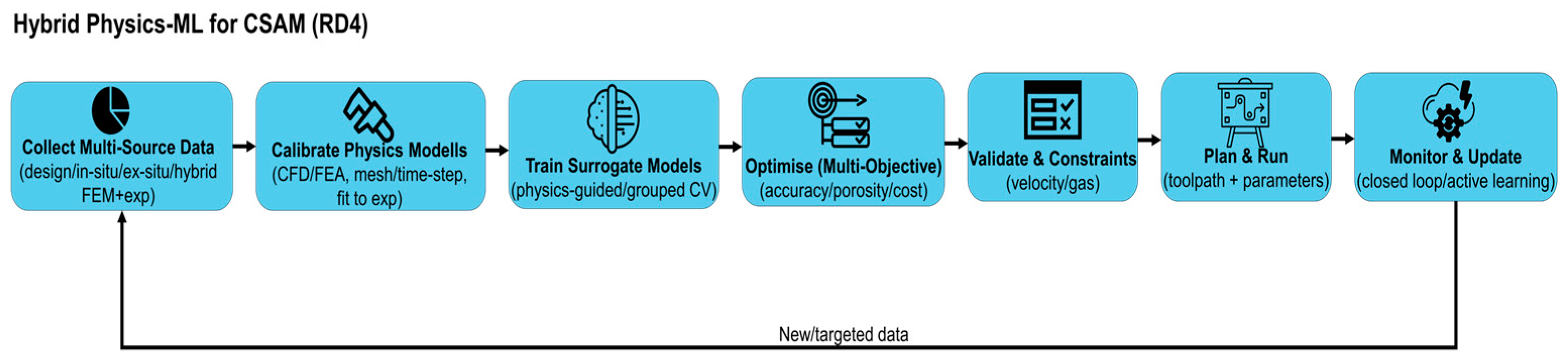

4.4. Process Modelling and Optimisation (RD4)

4.4.1. From Model-Driven Understanding to Optimisation in AM

4.4.2. Modelling and Optimisation for CSAM

4.4.3. Synthesis of Findings on Modelling and Optimisation Approaches for CSAM

4.4.4. Numerical Analysis: Physics-Based Simulations and Reduced-Order Modelling for CSAM

5. Challenges and Opportunities

5.1. Data

5.1.1. Limited Data vs. Big Data

5.1.2. Bias, Measurement Inconsistencies, and Data-Leakage Risks

5.1.3. A Unified Protocol for Data Collection and Database Construction

5.1.4. Data Pre-Processing and Feature Extraction

5.1.5. Cloud-Edge Synergy

5.1.6. Transfer Learning

5.2. ML Models

5.2.1. Interpretability

5.2.2. Overfitting vs. Underfitting

5.2.3. Physics-Based vs. Data-Driven ML Modelling

5.3. Multiscale Spatiotemporal Modelling and Control

5.3.1. Sensing System

5.3.2. Process–Structure–Properties–Performance (PSPP) Relationships

5.4. ML/AI for CSAM Sustainability

6. Answers to the Research Questions

7. Future Work

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AM | Additive manufacturing |

| ABS | Acrylonitrile butadiene–styrene |

| ANN | Artificial neural network |

| AI | Artificial Intelligence |

| BPNN | Backpropagation neural network |

| CFRP | Carbon Fibre–Reinforced Polymer |

| CNN | Convolutional Neural Network |

| CLIAO | Closed-loop image-aided optimisation |

| CGS | Cold Gas Spraying |

| CSAM | Cold Spray Additive Manufacturing |

| CP | Compensation paths |

| CFD | Computational fluid dynamics |

| r | Correlation coefficient |

| CEL | Coupled Eulerian–Lagrangian |

| CV | Cross-validation |

| CS | Cold Spray |

| DS | Dataset |

| DL | Deep learning |

| DNN | Deep neural network |

| DE | Deposition efficiency |

| DOE | Design of Experiments |

| EAM | Embedded Atom Method |

| EBSD | Electron Backscatter Diffraction |

| EGO | Efficient global optimisation |

| FP | Filling paths |

| FEA | Finite Element Analysis |

| FEM | Finite Element Method |

| GMM | Gaussian Mixture Model |

| GPR | Gaussian Process Regression |

| GA | Genetic algorithm(s) |

| v | Gun traverse speed |

| IG | Integrated Gradients |

| IIoT | Industrial Internet of Things |

| IPP | Input process parameter |

| LGBM | Light Gradient-Boosting Machine |

| LP | Linking paths |

| LPCS | Low-Pressure Cold Spray |

| LR | Linear Regression |

| LSTMs | Long Short-Term Memories |

| MAE | Mean Absolute Error |

| MAPE | Mean Absolute Percentage Error |

| MD | Molecular dynamics |

| ML | Machine Learning |

| MSE | Mean Squared Error |

| MK | Metal Knitting |

| MLP | Multilayer perceptron |

| NN | Neural network(s) |

| NDT | Non-destructive testing |

| OM | Optical microscopy |

| PCC | Pearson correlation coefficient |

| PA66 | Polyamide-66 |

| PEEK | Polyether ether ketone |

| PSO | Particle swarm optimisation |

| RANS | Reynolds-Averaged Navier–Stokes |

| RF | Random Forest |

| RRT | Rapidly Exploring Random Tree |

| rpm | Revolutions per minute |

| RMSE | Root Mean Square Error |

| RNNs | Recurrent Neural Networks |

| RSM | Response Surface Methodology |

| RUS | Resonant Ultrasound Spectroscopy |

| SDP | Spray Deposit Profile |

| SEM | Scanning Electron Microscopy |

| SHAP | SHapley Additive exPlanations |

| S-PTV | Sizing Particle Tracking Velocimetry |

| STL | Stereolithography |

| SOD SSIM | Standoff Distance Structural Similarity Index Measure |

| SM | Support Material |

| SVM | Support vector machine |

| SVR | Support Vector Regression |

| 2D | Two-dimensional |

| 3D | Three-dimensional |

| TST | Thermal Spray Toolkit |

| TNN | Trilayer neural network |

| UQ | Uncertainty quantification |

| WNN | Wide Neural Network |

| XGB | XGBoost |

Appendix A

References

- BS EN ISO/ASTM 52900:2021; Additive Manufacturing. General Principles. Fundamentals and Vocabulary. British Standards Institute: London, UK, 2022.

- Kafle, A.; Silwal, R.; Koirala, B.; Zhu, W. Advancements in Cold Spray Additive Manufacturing: Process, Materials, Optimization, Applications, and Challenges. Materials 2024, 17, 5431. [Google Scholar] [CrossRef] [PubMed]

- Vaz, R.F.; Garfias, A.; Albaladejo, V.; Sanchez, J.; Cano, I.G. A Review of Advances in Cold Spray Additive Manufacturing. Coatings 2023, 13, 267. [Google Scholar] [CrossRef]

- Roshith, P. An Exhaustive Examination of the Contemporary Technology, Impediments, and Forthcoming Hurdles Regarding Environmentally Sound Cold Spray Additive Manufacturing: A Review. Can. Metall. Q. 2025, 1–43. [Google Scholar] [CrossRef]

- Wu, H.; Xie, X.; Liu, M.; Chen, C.; Liao, H.; Zhang, Y.; Deng, S. A New Approach to Simulate Coating Thickness in Cold Spray. Surf. Coat. Technol. 2020, 382, 125151. [Google Scholar] [CrossRef]

- Martínez-Flores, M.; Cervantes-Cabello, J.J.; Barba-Pingarrón, A. Low-Pressure Cold Spray Deposition Window Derived from a One-Dimensional Analytical Model. Coatings 2023, 13, 1015. [Google Scholar] [CrossRef]

- Kamaraj, A.; Zhou, W.; Song, X. Computational Fluid Dynamics Simulation of Cold Spray Process for Particle Velocity Investigation; Springer: Singapore, 2022; pp. 244–248. ISBN 978-981-16-5762-7. [Google Scholar]

- Singh, P.; Singh, S.; Singh, H. Flow Visualization and Parameter Suitability in Cold Spray Titanium Deposition: A CFD Approach; Advances in Transdisciplinary Engineering; IOS Press BV: Schiedam, The Netherlands, 2023; Volume 44, pp. 43–49. [Google Scholar]

- Kindermann, P.; Wunderer, M.; Strasser, M.; Lehmann, M.; Ünsal, I.; Schlick, G.; Seidel, C.; Volk, W. Key Factors Influencing the Gas and Nozzle Outlet Temperature in Cold Spray. In Proceedings of the Euro Powder Metallurgy 2024 Congress & Exhibition, Malmö, Sweden, 29 September–2 October 2024. [Google Scholar]

- Cavaliere, P. Cold Spray Coating Technology for Metallic Components Repairing; Springer: Cham, Switzerland, 2015; pp. 175–184. [Google Scholar]

- Yin, S.; Lupoi, R. Manufacturing Parameters for Cold Spray Additive Manufacturing; Springer: Cham, Switzerland, 2021; pp. 53–67. ISBN 978-3-030-73366-7. [Google Scholar]

- Perna, A.S.; Carrino, L.; Gatta, R.D.; Viscusi, A. Cold Sprayed Metallic Coatings on Fibre-Reinforced Composites: A Machine Learning Approach for the Optimization of the Process. Key Eng. Mater. 2022, 926, 122–131. [Google Scholar] [CrossRef]

- Ikeuchi, D.; Vargas-Uscategui, A.; Wu, X.; King, P.C. Data-Driven Overlapping-Track Profile Modeling in Cold Spray Additive Manufacturing. J. Therm. Spray Technol. 2024, 33, 530–539. [Google Scholar] [CrossRef]

- Falco, R.; Jalayer, M.; Bagherifard, S. Enhanced Geometrical Control in Cold Spray Additive Manufacturing through Deep Neural Network Predictive Models. Virtual Phys. Prototyp. 2025, 20, e2472388. [Google Scholar] [CrossRef]

- Mehmood, A.; Zunaid, M.; Madan, A.K. Multi-Objective Optimization and Performance Improvement of CD Nozzle Design Parameters for Cold Spray Coating Process Using RSM, ANN and GA. Mater. Today Commun. 2024, 40, 109446. [Google Scholar] [CrossRef]

- Roy, S.; Ravi, K. A Machine Learning Based Approach for Cold Spray Deposition Porosity Prediction from Processing Parameters. In Proceedings of the ITSC2022, Macau, China, 8–12 October 2022. [Google Scholar]

- Li, W.; Wu, H.; Huang, F.; Liao, H.; Deng, S. Revolutionizing Repair and Production: An Integrated Modular Cold Spray Additive Manufacturing System. J. Therm. Spray Technol. 2025, 34, 531–549. [Google Scholar] [CrossRef]

- Arkhipov, I.; Kokal, U.; Özdemir, O. Aeroacoustic Process Monitoring and Anomaly Detection in Cold Spray Additive Manufacturing. J. Therm. Spray Technol. 2025, 34, 97–119. [Google Scholar] [CrossRef]

- Bokade, R.; Müftü, S.; Özdemir, O.Ç.; Jin, X. Thermal Imaging Based Non-Destructive Testing for Fault Detection in Cold Spray Additive Manufacturing. J. Manuf. Process 2025, 134, 1057–1068. [Google Scholar] [CrossRef]

- Eberle, M.; Pinches, S.; Osborne, M.; Qin, K.; Ang, A. Analysis of Data Generation and Preparation for Porosity Prediction in Cold Spray Using Machine Learning. J. Therm. Spray Technol. 2024, 33, 1270–1291. [Google Scholar] [CrossRef]

- Perna, A.S.; Carrino, L.; Citarella, A.A.; De MARCO, F.; Di Biasi, L.; Tortora, G.; Viscusi, A. A Machine Learning Approach for Adhesion Forecasting of Cold-Sprayed Coatings on Polymer-Based Substrates. Mater. Res. Proc. 2023, 28, 57–64. [Google Scholar]

- Savangouder, R.V.; Patra, J.C.; Palanisamy, S. A Machine Learning Technique for Prediction of Cold Spray Additive Manufacturing Input Process Parameters to Achieve a Desired Spray Deposit Profile. IEEE Trans. Ind. Inf. 2024, 20, 12275–12283. [Google Scholar] [CrossRef]

- Ikeuchi, D.; Vargas-Uscategui, A.; Wu, X.; King, P.C. Neural Network Modelling of Track Profile in Cold Spray Additive Manufacturing. Materials 2019, 12, 2827. [Google Scholar] [CrossRef]

- Liu, M.; Wu, H.; Yu, Z.; Liao, H.; Deng, S. Description and Prediction of Multi-Layer Profile in Cold Spray Using Artificial Neural Networks. J. Therm. Spray Technol. 2021, 30, 1453–1463. [Google Scholar] [CrossRef]

- Chandra, M.; Vimal, K.E.K.; Rajak, S. In Situ Process Monitoring and Control in Metal Additive Manufacturing. In Additive Manufacturing: Advanced Materials and Design Techniques; CRC Press: Boca Raton, FL, USA, 2023; pp. 57–75. ISBN 9781000835014. [Google Scholar]

- Koivuluoto, H.; Larjo, J.; Marini, D.; Pulci, G.; Marra, F. Cold-Sprayed Al6061 Coatings: Online Spray Monitoring and Influence of Process Parameters on Coating Properties. Coatings 2020, 10, 348. [Google Scholar] [CrossRef]

- MacDonald, D.; Rahmati, S.; Jodoin, B.; Birtch, W. An Economical Approach to Cold Spray Using In-Line Nitrogen–Helium Blending. J. Therm. Spray Technol. 2019, 28, 161–173. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Xiao, Y.; Watson, M. Guidance on Conducting a Systematic Literature Review. J. Plan. Educ. Res. 2019, 39, 93–112. [Google Scholar] [CrossRef]

- van Eck, N.J.; Waltman, L. Software Survey: VOSviewer, a Computer Program for Bibliometric Mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef]

- Waltman, L.; van Eck, N.J.; Noyons, E.C.M. A Unified Approach to Mapping and Clustering of Bibliometric Networks. J. Inf. 2010, 4, 629–635. [Google Scholar] [CrossRef]

- Su, H.N.; Lee, P.C. Mapping Knowledge Structure by Keyword Co-Occurrence: A First Look at Journal Papers in Technology Foresight. Scientometrics 2010, 85, 65–79. [Google Scholar] [CrossRef]

- Moons, K.G.M.; Wolff, R.F.; Riley, R.D.; Whiting, P.F.; Westwood, M.; Collins, G.S.; Reitsma, J.B.; Kleijnen, J.; Mallett, S. PROBAST: A Tool to Assess Risk of Bias and Applicability of Prediction Model Studies: Explanation and Elaboration. Ann. Intern. Med. 2019, 170, W1–W33. [Google Scholar] [CrossRef]

- Lee, J.; Akin, S.; Sim, Y.; Lee, H.; Kim, E.; Nam, J.; Song, K.; Jun, M.B.G. A Stethoscope-Guided Interpretable Deep Learning Framework for Powder Flow Diagnosis in Cold Spray Additive Manufacturing. Manuf. Lett. 2024, 41, 1515–1525. [Google Scholar] [CrossRef]

- Perna, A.S.; Carrino, L.; Auriemma Citarella, A.; DE MARCO, F.; Di Biasi, L.; Tortora, G.; Viscusi, A. Artificial Intelligence Approaches for Enhanced Coating Performance. Mater. Res. Proc. 2024, 41, 300–307. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, H.; Liu, G.-R. Deep convolutional neural network aided optimization for cold spray 3D simulation based on molecular dynamics. J. Intell.Manuf. 2020, 32, 1009–1023. [Google Scholar] [CrossRef]

- Ikeuchi, D.; Vargas-Uscategui, A.; Wu, X.; King, P.C. Data-Efficient Neural Network for Track Profile Modelling in Cold Spray Additive Manufacturing. Appl. Sci. 2021, 11, 1654. [Google Scholar] [CrossRef]

- Buescher, J.; Zajaczkowski, J.; Blecking, C.; Baumann, I.; Mohle, R.; Wagstyl, D.; Rademacher, H.G.; Tillmann, W.; Deuse, J. Leveraging Trustworthy AI and IIoT for Cost-Efficient Multimodal Quality Control in Metallurgic Additive Manufacturing. In Proceedings of the 2024 IEEE International Conference on Technology, Informatics, Management, Engineering and Environment, TIME-E 2024, Bali, Indonesia, 7–9 August 2024; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2024; pp. 24–31. [Google Scholar]

- Sharma, D.; Boruah, D.; Bakir, A.A.; Ameen, A.; Paul, S.; Sharma, D.; Boruah, D.; Alperen Bakir, A.; Ameen, A.; Paul, S. Machine Learning-Based Predictions of Porosity during Cold Spray Machine Learning-Based Predictions of Porosity during Cold Spray Deposition of High Entropy Alloy Coatings. Coatings 2024, 14, 404. [Google Scholar] [CrossRef]

- Li, W.; Yao, Y.; Wu, H.; Liao, H.; Costil, S.; Deng, S. Spray Trajectory Planning for Complex Structural Components in Robotized Cold Spray Additive Manufacturing. J. Therm. Spray Technol. 2024, 33, 71–87. [Google Scholar] [CrossRef]

- Cai, Z.; Deng, S.; Liao, H.; Zeng, C.; Montavon, G. The Effect of Spray Distance and Scanning Step on the Coating Thickness Uniformity in Cold Spray Process. J. Therm. Spray Technol. 2014, 23, 354–362. [Google Scholar] [CrossRef]

- Su, C.; Wang, Y.; Che, H.; Yue, S.; Huang, X. Cold Spray—A Solid-State Additive Manufacturing Technology. IOP Conf. Ser. Mater. Sci. Eng. 2024, 1310, 012044. [Google Scholar] [CrossRef]

- Ren, B.; Song, J. Peridynamic Simulation of Particles Impact and Interfacial Bonding in Cold Spray Process. J. Therm. Spray Technol. 2022, 31, 1827–1843. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Mohamed, S.; Li, W.; Rija Nirina, R.; Liao, H.; Deng, S. Toolpath Planning for Cold Spray Additive Manufacturing; Springer: Singapore, 2022; pp. 240–243. ISBN 978-981-16-5762-7. [Google Scholar]

- Wu, H.; Li, W.; Lewke, M.; Deng, S.; List, A.; Gärtner, F.; Klassen, T. 3D Volume Construction Methodology for Cold Spray Additive Manufacturing. Addit. Manuf. 2024, 92, 104407. [Google Scholar] [CrossRef]

- Vandadi, M.; Klenam, D.; Rahbar, N.; Soboyejo, W. Advances in the Structural Integrity of Cold Sprayed Alloys—A Critical Review of Process Models and Mechanical Properties; Elsevier: Amsterdam, The Netherlands, 2023; pp. 2–37. ISBN 9780128035818. [Google Scholar]

- Kondas, J.; Guagliano, M.; Bagherifard, S.; Singh, R.; Cizek, J.; Lukac, F.; Konopik, P.; Rzepa, S. Importance of Feedstock Powder Selection for Mechanical Properties Improvement of Cold Spray Additively Manufactured Ti6Al4V Deposits. Addit. Manuf. Lett. 2024, 9, 100199. [Google Scholar] [CrossRef]

- Abubakar, A.A.; Arif, A.F.M.; Al-Athel, K.S.; Akhtar, S.S.; Ankah, N.; Sorour, A.A. Optimizing Cold Spraying Parameters of Metallic Coatings Deposited Onto Polymer Substrate. In Proceedings of the ASME 2024 International Mechanical Engineering Congress and Exposition, Portland, OR, USA, 17–21 November 2024. [Google Scholar] [CrossRef]

- Sova, A.; Doubenskaia, M.; Trofimov, E.; Samodurova, M.; Ulianitsky, V.; Smurov, I. Cold Spray of Metal Powder Mixtures: Achievements, Issues and Perspectives. Trans. Indian. Inst. Met. 2021, 74, 559–570. [Google Scholar] [CrossRef]

- Schwenger, M.S.; Kaminskyj, M.S.; Haas, F.M.; Stanzione, J.F. Mixed-Material Feedstocks for Cold Spray Additive Manufacturing of Metal–Polymer Composites. J. Therm. Spray Technol. 2024, 33, 619–628. [Google Scholar] [CrossRef]

- Della Gatta, R.; Perna, A.S.; Viscusi, A.; Pasquino, G.; Astarita, A. Cold Spray Deposition of Metallic Coatings on Polymers: A Review. J. Mater. Sci. 2022, 57, 27–57. [Google Scholar] [CrossRef]

- Melentiev, R.; Yu, N.; Lubineau, G. Polymer Metallization via Cold Spray Additive Manufacturing: A Review of Process Control, Coating Qualities, and Prospective Applications. Addit. Manuf. 2021, 48, 102459. [Google Scholar] [CrossRef]

- Verdi, D.; Merino-Millán, D.; Salazar, A. Metallisation of Additive Manufactured Polyamide 12 by Low Pressure Cold Spray. Surf. Coat. Technol. 2024, 479, 130484. [Google Scholar] [CrossRef]

- Liao, T.Y.; Biesiekierski, A.; Berndt, C.C.; King, P.C.; Ivanova, E.P.; Thissen, H.; Kingshott, P. Multifunctional Cold Spray Coatings for Biological and Biomedical Applications: A Review. Prog. Surf. Sci. 2022, 97, 100654. [Google Scholar] [CrossRef]

- Noorakma, A.C.W.; Zuhailawati, H.; Aishvarya, V.; Dhindaw, B.K. Hydroxyapatite-Coated Magnesium-Based Biodegradable Alloy: Cold Spray Deposition and Simulated Body Fluid Studies. J. Mater. Eng. Perform. 2013, 22, 2997–3004. [Google Scholar] [CrossRef]

- Wu, D.; Xu, Y.; Li, W.; Yang, Y.; Liu, K.; Wan, W.; Qi, Z. Process Optimisation of Cold Spray Additive Manufacturing of FeCoNiCrMn High-Entropy Alloy. Sci. Technol. Weld. Join. 2023, 28, 540–547. [Google Scholar] [CrossRef]

- Zhang, Z.; Meng, T.L.; Lee, C.J.J.; Wei, F.; Ba, T.; Zhang, Z.Q.; Pan, J. Experimental and Numerical Study of Al2219 Powders Deposition on Al2219-T6 Substrate by Cold Spray: Effects of Spray Angle, Traverse Speed, and Standoff Distance. Materials 2023, 16, 5240. [Google Scholar] [CrossRef]

- Muhammad Umer, H.; Zia, U.; Masud, J.; Zakir, J. Numerical Analysis and Parametric Study of Modified and Benchmark Optimized Cold Spray Designs. In AIAA SCITECH 2023 Forum, Online, 23–27 January 2023; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2023. [Google Scholar]

- Adebiyi, D.I.; Popoola, A.P.; Botef, I. Experimental Verification of Statistically Optimized Parameters for Low-Pressure Cold Spray Coating of Titanium. Metals 2016, 6, 135. [Google Scholar] [CrossRef]

- Hamrani, A.; Medarametla, A.; John, D.; Agarwal, A. Machine-Learning-Driven Optimization of Cold Spray Process Parameters: Robust Inverse Analysis for Higher Deposition Efficiency. Coatings 2025, 15, 12. [Google Scholar] [CrossRef]

- Hu, W.J.; Shorinov, O. Optimization of Technological Parameters for Cold Spraying Using the Response Surface Method. J. Eng. Sci. 2024, 11, F1–F8. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Q. Study on Processing Parameters of Cold Spray Al Coating on Magnesium Alloy. In Proceedings of the 2015 International Conference on Materials, Environmental and Biological Engineering, Guilin, China, 28–30 March 2015. [Google Scholar]

- Singhal, C.; Murtaza, Q. Numerical Optimization of Cold Gas Dynamic Spray Process Parameters through Response Surface Methodology. Adv. Mater. Process.Technol. 2024, 1–18. [Google Scholar] [CrossRef]

- Poza, P.; Garrido-Maneiro, M.Á. Cold-Sprayed Coatings: Microstructure, Mechanical Properties, and Wear Behaviour. Prog. Mater. Sci. 2022, 123, 100839. [Google Scholar] [CrossRef]

- Tan, K.; Markovych, S.; Hu, W.; Shorinov, O.; Wang, Y. Review of manufacturing and repair of aircraft and engine parts based on cold spraying technology and additive manufacturing technology. Aerosp. Tech. Technol. 2020, 3, 53–70. [Google Scholar] [CrossRef]

- Affi, J.; Okazaki, H.; Yamada, M.; Fukumoto, M. Fabrication of Aluminum Coating onto CFRP Substrate by Cold Spray. Mater. Trans. 2011, 52, 1759–1763. [Google Scholar] [CrossRef]

- Al-Mangour, B.; Mongrain, R.; Irissou, E.; Yue, S. Improving the Strength and Corrosion Resistance of 316L Stainless Steel for Biomedical Applications Using Cold Spray. Surf. Coat. Technol. 2013, 216, 297–307. [Google Scholar] [CrossRef]

- Choudhuri, A.; Mohanty, P.S.; Karthikeyan, J. Bio-Ceramic Composite Coatings by Cold Spray Technology. In Proceedings of the International Thermal Spray Conference, Las Vegas, NV, USA, 4–7 May 2009; pp. 391–396. [Google Scholar]

- Tregenza, O.; Hutasoit, N.; Khalik, M.A.; Palanisamy, S.; Hulston, C. An Application of Cold Spray Additive Manufacturing for Thermoelectric Generator Thermal Interfacing. Int. J. Heat. Mass. Transf. 2024, 220, 124996. [Google Scholar] [CrossRef]

- Lewke, M.; Wu, H.; List, A.; Gärtner, F.; Klassen, T.; Fay, A. Automated Path and Trajectory Planning for Automated Repair of Damaged Components by Cold Spray. Therm. Spray 2023, 84536, 436–442. [Google Scholar] [CrossRef]

- Vo, P.; Martin, M. Layer-by-Layer Buildup Strategy for Cold Spray Additive Manufacturing. In Proceedings of the ITSC2017, Yokohama, Japan, 16–19 October 2017. [Google Scholar]

- Li, W.; Wu, H.; Shi, Z.; Liao, H.; Costil, S.; Deng, S. Towards a General Cold Spray Additive Manufacturing Framework for Fabricating Complex Structural Components. In Proceedings of the ITSC 2023, Québec City, QC, Canada, 22–25 May 2023. [Google Scholar]

- Garfias, A.; Vaz, R.; Albaladejo-Fuentes, V.; Sánchez, J.; Cano, I.G. Geometry and Microstructure Control of Remanufactured Metallic Parts by Cold Spray Additive Manufacturing. Materials 2023, 16, 4735. [Google Scholar] [CrossRef]

- Váz, R.F.; Canales, H.; Sanchez, J.; Ocaña, U.; Albaladejo, V.; Cano, I.G. Metal Knitting: A Method to Control Morphology and Properties in Cold Spray Additive Manufacturing. In Proceedings of the ITSC2022, Vienna, Austria, 4–6 May 2022. [Google Scholar]

- Rayhan, M.M.; Hamrani, A.; Sarker, M.S.A.; Agarwal, A.; McDaniel, D. A Physics-Guided Parameter Estimation Framework for Cold Spray Additive Manufacturing Simulation. Coatings 2025, 15, 364. [Google Scholar] [CrossRef]

- Xames, M.D.; Torsha, F.K.; Sarwar, F. A Systematic Literature Review on Recent Trends of Machine Learning Applications in Additive Manufacturing. J. Intell. Manuf. 2023, 34, 2529–2555. [Google Scholar] [CrossRef]

- Gutiérrez de Frutos, J.; List, A.; Nielsen, S.; Gärtner, F.; Klassen, T. Nozzle Geometry Evaluation for Cold Spray Applications by Using 3D-CFD Calculations. J. Therm. Spray Technol. 2025, 34, 570–586. [Google Scholar] [CrossRef]

- Zou, Y. Cold Spray Additive Manufacturing: Microstructure Evolution and Bonding Features. Acc. Mater. Res. 2021, 2, 1071–1081. [Google Scholar] [CrossRef]

- Bagherifard, S.; Heydari Astaraee, A.; Locati, M.; Nawaz, A.; Monti, S.; Kondás, J.; Singh, R.; Guagliano, M. Design and Analysis of Additive Manufacturedbimodal Structures Obtained by Cold Spray Deposition. Addit. Manuf. 2020, 33, 101131. [Google Scholar] [CrossRef]

- Bagherifard, S.; Monti, S.; Zuccoli, M.V.; Riccio, M.; Kondás, J.; Guagliano, M. Cold Spray Deposition for Additive Manufacturing of Freeform Structural Components Compared to Selective Laser Melting. Mater. Sci. Eng. A 2018, 721, 339–350. [Google Scholar] [CrossRef]

- Yin, S.; Yan, X.; Jenkins, R.; Chen, C.; Kazasidis, M.; Liu, M.; Kuang, M.; Lupoi, R. Hybrid Additive Manufacture of 316L Stainless Steel with Cold Spray and Selective Laser Melting: Microstructure and Mechanical Properties. J. Mater. Process. Technol. 2019, 273, 116248. [Google Scholar] [CrossRef]

- Champagne Jr, V.; Nardi, A.; Cote, D. Materials Characterization of Advanced Cold-Spray Aluminum Alloys. Int. J. Powder Metall. 2015, 51, 37–47. [Google Scholar]

- Ghasemi, M.; Seifi, A.; Kateb, M.; Gudmundsson, J.T.; Brault, P.; Marashi, P. Probing Trade-off between Critical Size and Velocity in Cold-Pray: An Atomistic Simulation. J. Vac. Sci. Technol. A 2024, 42, 3968. [Google Scholar] [CrossRef]

- Tsaknopoulos, K.; Grubbs, J.; Siopis, M.; Nardi, A.; Cote, D. Microstructure and Mechanical Property Evaluation of Aluminum F357 Powder for Cold Spray Applications. J. Therm. Spray Technol. 2021, 30, 643–654. [Google Scholar] [CrossRef]

- Vaz, R.F.; Avila, J.A.; Barriobero-Vila, P.; Muñoz, J.A.; Albaladejo, V.; Cano, I.G. Heat Treatment Effect on Microstructural Evolution of Cold Spray Additive Manufacturing Ti6Al4V. J. Mater. Sci. 2025, 60, 5558–5576. [Google Scholar] [CrossRef]

- Ren, Y.; Tariq, N.u.H.; Liu, H.; Zhao, L.; Cui, X.; Shen, Y.; Wang, J.; Xiong, T. Study of Microstructural and Mechanical Anisotropy of 7075 Al Deposits Fabricated by Cold Spray Additive Manufacturing. Mater Des 2021, 212, 110271. [Google Scholar] [CrossRef]

- Munagala, V.N.V.; Akinyi, V.; Vo, P.; Chromik, R.R. Influence of Powder Morphology and Microstructure on the Cold Spray and Mechanical Properties of Ti6Al4V Coatings. J. Therm. Spray Technol. 2018, 27, 827–842. [Google Scholar] [CrossRef]

- Sabard, A.; Hussain, T. Inter-particle bonding in cold spray deposition of a gas-atomised and a solution heat-treated Al 6061 powder. J. Mater.Sci. 2019, 54, 12061–12078. [Google Scholar] [CrossRef]

- Yin, S.; Jenkins, R.; Yan, X.; Lupoi, R. Microstructure and Mechanical Anisotropy of Additively Manufactured Cold Spray Copper Deposits. Mater. Sci. Eng. A 2018, 734, 67–76. [Google Scholar] [CrossRef]

- Cheng, J.; Huang, J.; Li, H.; Zhang, K.; Lan, H.; Xin, H.; Huang, R. Microstructure and Tensile Properties of Cu-Ti Composites Deposited by Cold Spray Additive Manufacturing. Materials 2025, 18, 2787. [Google Scholar] [CrossRef]

- Janovská, M.; Sedlák, P.; Ševčík, M.; Cizek, J.; Kondas, J.; Singh, R.; Čupera, J.; Seiner, H. Magnetoelastic Softening in Cold-Sprayed Polycrystalline Nickel Studied by Resonant Ultrasound Spectroscopy. J. Acoust. Soc. Am. 2025, 158, 732–742. [Google Scholar] [CrossRef]

- Suo, X.; Guo, X.; Li, W.; Planche, M.P.; Bolot, R.; Liao, H.; Coddet, C. Preparation and Characterization of Magnesium Coating Deposited by Cold Spraying. J. Mater. Process. Technol. 2012, 212, 100–105. [Google Scholar] [CrossRef]

- Moridi, A.; Hassani-Gangaraj, S.M.; Guagliano, M.; Dao, M. Cold Spray Coating: Review of Material Systems and Future Perspectives. Surf. Eng. 2014, 30, 369–395. [Google Scholar] [CrossRef]

- Malamousi, K.; Delibasis, K.; Allcock, B.; Kamnis, S. Digital Transformation of Thermal and Cold Spray Processes with Emphasis on Machine Learning. Surf. Coat. Technol. 2022, 433, 128138. [Google Scholar] [CrossRef]

- Kvvssn, V.; Butt, M.M.; Laieghi, H.; Uddin, Z.; Salamci, E.; Kim, D.B.; Kizil, H. Recent Progress in Additive Manufacturing of 7XXX Aluminum Alloys. Int. J. Adv. Manuf. Technol. 2025, 137, 4353–4399. [Google Scholar] [CrossRef]

- Mondal, S.; Shubhra Goswami, S. Machine Learning Techniques for Quality Assurance in Additive Manufacturing Processes. Int. J. AI Mater. Des. 2024, 1, 21–40. [Google Scholar] [CrossRef]

- Stránský, O.; Tarant, I.; Beránek, L.; Holešovský, F.; Pathak, S.; Brajer, J.; Mocek, T.; Denk, O. Machine Learning Approach towards Laser Powder Bed Fusion Manufactured AlSi10Mg Thin Tubes in Laser Shock Peening. Surf. Eng. 2024, 40, 66–72. [Google Scholar] [CrossRef]

- Sousa, B.C.; Gleason, M.A.; Haddad, B.; Champagne, V.K.; Nardi, A.T.; Cote, D.L. Nanomechanical Characterization for Cold Spray: From Feedstock to Consolidated Material Properties. Metals 2020, 10, 1195. [Google Scholar] [CrossRef]

- Menon, V.; Aranas, C.; Saha, G. Cold Spray Additive Manufacturing of Copper-Based Materials: Review and Future Directions. Mater. Sci. Addit. Manuf. 2022, 1, 12. [Google Scholar] [CrossRef]

- Sun, W.; Tan, A.W.Y.; Wu, K.; Yin, S.; Yang, X.; Marinescu, I.; Liu, E. Post-Process Treatments on Supersonic Cold Sprayed Coatings: A Review. Coatings 2020, 10, 123. [Google Scholar] [CrossRef]

- Koivuluoto, H.; Matikainen, V.; Larjo, J.; Vuoristo, P. Novel Online Diagnostic Analysis for In-Flight Particle Properties in Cold Spraying. J. Therm. Spray Technol. 2018, 27, 423–432. [Google Scholar] [CrossRef]

- Fatoba, O.S.; Jen, T.C. Acoustic-Based In-Situ Monitoring of Additive Manufacturing Fabrication: A Review. In Proceedings of the 2023 14th International Conference on Mechanical and Intelligent Manufacturing Technologies, ICMIMT 2023, Cape town, South Africa, 26–28 May 2023; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2023; pp. 250–256. [Google Scholar]

- Chen, B.; Zha, J.; Cai, Z.; Wu, M. Predictive Modelling of Surface Roughness in Precision Grinding Based on Hybrid Algorithm. CIRP J. Manuf. Sci. Technol. 2025, 59, 1–17. [Google Scholar] [CrossRef]

- Shi, C.; Chen, B.; Shi, Y.; Zha, J. Surface Roughness Prediction of Bearing Ring Precision Grinding Based on Feature Extraction. Appl. Sci. 2025, 15, 6027. [Google Scholar] [CrossRef]

- Duan, J.; Cao, G.; Ma, G.; Yu, Z.; Shao, C. Research on On-Line Monitoring of Grinding Wheel Wear Based on Multi-Sensor Fusion. Sensors 2024, 24, 5888. [Google Scholar] [CrossRef]

- Cooper, C.; Zhang, J.; Ragai, I.; Gao, R.X. Multi-Sensor Fusion and Machine Learning-Driven Sequence-to-Sequence Translation for Interpretable Process Signature Prediction in Machining. J. Manuf. Syst. 2024, 75, 288–298. [Google Scholar] [CrossRef]

- Julien, S.E.; Hanson, N.; Lynch, J.; Boese, S.; Roberts, K.; Padir, T.; Ozdemir, O.C.; Müftü, S. In Situ Measurement of Track Shape in Cold Spray Deposits. J. Therm. Spray Technol. 2024, 33, 2189–2208. [Google Scholar] [CrossRef]

- Shorinov, O.; Polyvianyi, S.; Dolmatov, A. Calculation of Velocity and Temperature of Nickel Powder Particles in a Supersonic Nozzle During Low-Pressure Cold Spraying. In Proceedings of the Integrated Computer Technologies in Mechanical Engineering—2022; Nechyporuk, M., Pavlikov, V., Kritskiy, D., Eds.; Springer Nature Switzerland: Cham, Switzerland, 2023; pp. 346–356. [Google Scholar]

- Alonso, L.; Garrido-Maneiro, M.A.; Poza, P. A Study of the Parameters Affecting the Particle Velocity in Cold-Spray: Theoretical Results and Comparison with Experimental Data. Addit. Manuf. 2023, 67, 103479. [Google Scholar] [CrossRef]

- Singhal, C.; Murtaza, Q. Numerical Study Using Nano-Particles by Varying the Expansion Ratio and Height of Cold Spray Nozzle to Predict Deposition Efficiency. In Proceedings of the ITSC 2018, Orlando, FL, USA, 7–10 May 2018. [Google Scholar]

- Hu, W.; Shorinov, O. Optimization of Particle Acceleration Parameters of Special Cold Spray Nozzles via Neural Network and Genetic Algorithm. Aerosp. Tech. Technol. 2024, 64–70. [Google Scholar] [CrossRef]

- Zhu, W.; Li, H.; Shen, S.; Wang, Y.; Hou, Y.; Zhang, Y.; Chen, L. In-Situ Monitoring Additive Manufacturing Process with AI Edge Computing. Opt. Laser Technol. 2024, 171, 110423. [Google Scholar] [CrossRef]

- Xu, R.; Huang, S.; Song, Z.; Gao, Y.; Wu, J. A Deep Mixed-Effects Modeling Approach for Real-Time Monitoring of Metal Additive Manufacturing Process. IISE Trans. 2024, 56, 945–959. [Google Scholar] [CrossRef]

- Guessasma, S.; Montavon, G.; Coddet, C. On the Implementation of Neural Network Concept to Optimize Thermal Spray Deposition Process. MRS Online Proc. Libr. 2011, 700, 82. [Google Scholar] [CrossRef]

- Schmitt, R.; Doeren, J.; Bobzin, F.; Lugscheider, E.; Ernst, F. Implementation of Neural Networks into Modern Process Control Equipment. Therm. Spray 2006, 83669, 965–970. [Google Scholar] [CrossRef]

- Hartz-Behrend, K.; Kirner, S.; Schein, J.; Jonke, D.P.; Englhart, M. Control of Wire Arc Spraying Using Artificial Neural Networks for the Production of Thin-Walled Moulds for Carbon Fiber Reinforced Plastics. In Proceedings of the International Thermal Spray Conference, Houston, TX, USA, 21–24 May 2012; Volume 83720, pp. 436–441. [Google Scholar]

- Fassl, L.; Nabavi, M.; Schwenk, A. Gain Insight About Thermal Spray Processes Using Artificial Intelligence and Big Data Analysis. In Proceedings of the ITSC 2022, Vienna, Austria, 4–6 May 2022; Volume 84369, pp. 369–376. [Google Scholar] [CrossRef]

- Page, T.D.; Yang, S.; Zhao, Y.F. Automated Candidate Detection for Additive Manufacturing: A Framework Proposal. In Proceedings of the Design Society: International Conference on Engineering Design, Delft, The Netherlands, 4–8 August 2019; Cambridge University Press: Cambridge, UK, 2019; pp. 679–688. [Google Scholar]

- Zhang, Y.; Dong, G.; Yang, S.; Zhao, Y.F. Machine Learning Assisted Prediction of the Manufacturability of Laser-Based Powder Bed Fusion Process. In Proceedings of the ASME 2019 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Anaheim, CA, USA, 18–21 August 2019. [Google Scholar]

- Vanerio, D.; Guagliano, M.; Bagherifard, S. Emerging Trends in Large Format Additive Manufacturing Processes and Hybrid Techniques. Prog. Addit.Manuf. 2024, 10, 1945–1972. [Google Scholar] [CrossRef]

- Bagherifard, S.; Kondas, J.; Monti, S.; Cizek, J.; Perego, F.; Kovarik, O.; Lukac, F.; Gaertner, F.; Guagliano, M. Tailoring Cold Spray Additive Manufacturing of Steel 316 L for Static and Cyclic Load-Bearing Applications. Mater. Des. 2021, 203, 109575. [Google Scholar] [CrossRef]

- Oyinbo, S.T.; Jen, T.C. A Comparative Review on Cold Gas Dynamic Spraying Processes and Technologies. Manuf. Rev. 2019, 6, 25. [Google Scholar] [CrossRef]

- Falco, R.; Bagherifard, S. Cold Spray Additive Manufacturing: A Review of Shape Control Challenges and Solutions. J. Therm. Spray Technol. 2025, 34, 1023–1041. [Google Scholar] [CrossRef]

- Wu, H.; List, A.; Gärtner, F.; Klassen, T.; Deng, S. Methods for 3D Volume Building in Cold Spray Additive Manufacturing. In Proceedings of the ITSC 2023, Québec City, QC, Canada, 22–25 May 2023. [Google Scholar]

- Yunzhen, Y. Intelligent Process Modeling of Robotic Plasma Spraying Based on Multi-Layer Artificial Neural Network. Trans. China Weld. Inst. 2009, 30, 41–44. [Google Scholar]

- Kanta, A.F.; Montavon, G.; Planche, M.P.; Coddet, C. Prospect for Plasma Spray Process On-Line Control Via Artificial Intelligence (Neural Networks and Fuzzy Logic). In Proceedings of the ITSC 2006, Toronto, ON, Canada, 17–20 September 2006. [Google Scholar]

- Guessasma, S.; Montavon, G.; Gougeon, P.; Coddet, C. On the Neural Network Concept to Describe the Thermal Spray Deposition Process: Correlation Between In-Flight Particles Characteristics and Processing Parameters. In Proceedings of the ITSC 2002, Essen, Germany, 4–6 March 2002. [Google Scholar]

- Li, W.; Yao, Y.; Wu, H.; Deng, S.; Liao, H.; Costil, S. Development of Robotized Spraying Trajectory of Multi-Featured Parts in Cold Spray Additive Manufacturing System. In Proceedings of the ITSC 2022, Vienna, Austria, 4–6 May 2022. [Google Scholar]

- Li, W.; Cao, C.; Wang, G.; Wang, F.; Xu, Y.; Yang, X. ‘Cold Spray +’ as a New Hybrid Additive Manufacturing Technology: A Literature Review. Sci. Technol. Weld. Join. 2019, 24, 420–445. [Google Scholar] [CrossRef]

- Estalaki, S.M.; Lough, C.S.; Landers, R.G.; Kinzel, E.C.; Luo, T. Predicting Defects in Laser Powder Bed Fusion Using In-Situ Thermal Imaging Data and Machine Learning. Addit. Manuf. 2022, 58, 103008. [Google Scholar] [CrossRef]

- Butt, J.; Mohaghegh, V. Combining Digital Twin and Machine Learning for the Fused Filament Fabrication Process. Metals 2023, 13, 24. [Google Scholar] [CrossRef]

- Sani, A.R.; Zolfagharian, A.; Kouzani, A.Z. Artificial Intelligence-Augmented Additive Manufacturing: Insights on Closed-Loop 3D Printing. Adv. Intell. Syst. 2024, 6, 2400102. [Google Scholar] [CrossRef]

- Jiang, J. A Survey of Machine Learning in Additive Manufacturing Technologies. Int. J. Comput. Integr. Manuf. 2023, 36, 1258–1280. [Google Scholar] [CrossRef]

| Inclusion Criteria | Exclusion Criteria |

|---|---|

| All English-language publications AI/ML applied to CSAM | No AI/ML Manufacturing process mismatch |

| All years included | Non-English works |

| No access limitations |

| Cluster | Keywords Samples | Research Domain |

|---|---|---|

| Cluster 1 (purple) | additive manufacturing, toolpath optimisation, porosity, data driven | DfCSAM (RD1) |

| Cluster 2 (green) | cantor alloy, composites, polymers, metal deposition, thermal spray, gradient boosting | Material Analytics (RD2) |

| Cluster 3 (Red) | anomaly detection, powder-flow monitoring, thermal imaging, multi-stage model, deep learning, time-series forecasting | Real-Time Monitoring & Defect Analytics (RD3) |

| Cluster 4 (dark blue + yellow + light blue) | multi-layer profile, coating-profile prediction, spray distance, geometry/overlap, gaussian process, neural network | Deposition & AI Optimisation (RD4) |

| Keyword | RD (Cluster) | Occurrences | Total Link Strength |

|---|---|---|---|

| cold spray | RD3 | 11 | 51 |

| additive manufacturing | RD1 | 7 | 35 |

| machine learning | RD2 | 5 | 26 |

| neural network | RD4 | 5 | 25 |

| deep learning | RD3 | 4 | 14 |

| model | RD4 | 3 | 19 |

| thermal spray | RD2 | 3 | 12 |

| profile | RD4 | 2 | 14 |

| spray angle | RD4 | 2 | 14 |

| trajectory | RD4 | 2 | 9 |

| data-driven | RD1 | 2 | 7 |

| data-efficient | RD4 | 1 | 9 |

| geometry | RD4 | 1 | 9 |

| limited data | RD4 | 1 | 9 |

| multi-stage model | RD3 | 1 | 5 |

| Reference | Participants and Data Source | Predictors | Outcome | Analysis and Validation | Overall Risk of Bias | |

|---|---|---|---|---|---|---|

| 1 | [21] | Unclear: Mixed FEM + experimental with small FEM pool (~50 impacts); experimental share not numerically specified. | Low: Inputs clearly defined/consistent across sources; no cross-paper aggregation. | Unclear: Outcome measured (SEM), but experimental reporting incomplete. | Unclear: Overfitting flagged for GPR. | Unclear |

| 2 | [16] | Unclear: 227 literature-derived cases with mixed sources. | High: Predictor definitions may vary across sources (7 inputs from many papers). | High: Porosity measured by different methods across papers. | Unclear: Validation details sparse; some algorithms underperform markedly. | High |

| 3 | [34] | Unclear: Purpose-built dataset, but only 4 lab states. | Unclear: potential leakage from segmentation with a single 80/20 split. | Unclear: Fault labels clear but not linked to deposition metrics. | Unclear: 80/20 internal split only; small Number; potential leakage/overfitting. | Unclear |

| 4 | [22] | Unclear: Reuses a single prior experimental dataset ([23]); limited coverage. | Low: Predictors from a single source reduce heterogeneity. | Unclear: Inverse-problem setup; sparse detail on outcome fidelity | Unclear: Forward model driven; inverse accuracy constrained by forward MLP. | Unclear |

| 5 | [20] | Unclear: 35-paper literature dataset with many missing values (84% complete). | High: Mixed-source predictors with imputation choices add bias risk. | High: Porosity from differing measurement techniques and operator bias. | Unclear: Many models; performance depends on handling; external generalisation limited. | High |

| 6 | [35] | Unclear—Mixed FEM/experimental; absolute sizes not stated. | Low—Study-defined predictors; materials fixed. | Low—Outcomes consistently measured within study | Unclear—Overfitting on penetration; GA tuned architecture only. | Unclear |

| 7 | [36] | Unclear: Pure MD-generated data. | Low: Predictors defined within simulation. | Unclear: Flattening ratio is geometric proxy; no adhesion outcomes. | Unclear: Optimisers compared but no physical validation. | Unclear |

| 8 | [12] | High: Very small dataset (~56; single material pair). | Low: Study-defined predictors, Single derived predictor (impact velocity). | Low: Outcomes measured consistently within study. | Unclear: Simple internal split; poor fit for flattening. | High |

| 9 | [19] | Unclear: 37 sprays; Controlled runs/material; limited size. | Low: Thermal time-series defined within study. | Low: Anomaly labels tied to thermal trends within study. | Unclear: Clear train/validation/test. | Unclear |

| 10 | [13] | Unclear: All-experimental overlaps (48 overlap profiles + references); single material setup. | Low: Study-defined geometric predictors including surface prior. | Low: Profile outcomes consistently measured. | Low: Strong comparative baselines; large improvement; clear test split. | Unclear |

| 11 | [37] | Unclear: Small training/test with some virtual data. | Low: Predictors defined within study. | Unclear: Virtual data may be biased; single-track only. | Unclear: reliance on virtual augmentation; varied spray/nozzle setups untested; model trained offline | Unclear |

| 12 | [24] | Low: ~330 multi-layer samples (flat/curved). | Unclear: High-dimensional inputs and sample-level splits could leak context; reporting insufficient to exclude it. | Low: Outcome definition clear and consistent. | Low: Train/validation/test split; strong RMSE/R2; acknowledges overfit risks. | Unclear |

| 13 | [14] | Unclear: Large, simulated set with limited experimental confirmation. | Low: Study-defined inputs. | Unclear: Simulation-dominant outcomes; edge-case errors noted. | Unclear: Good within-sim metrics; edge degradation; external validity unclears. | Unclear |

| 14 | [38] | Unclear: DoE within one setup; range not fully explained. | Unclear: Multimodal (optical/ Infrared) + process sensors well specified. | Low: Labels from lab tests. | Unclear: 5-fold Cross-Validation; very high F1/Acc; drift not yet handled. | Unclear |

| 15 | [39] | High: Very small mixed literature/experimental set (n = 35), with 80/20 split. | High: Mixed sources and limited features increase bias/leakage risk. | Unclear: Porosity target with limited detail. | Unclear: Multiple complex models on tiny sample number; overfitting risk high. | High |

| 16 | [23] | High: Small single-material dataset (48 tracks). | Low: Study-defined predictors. | Unclear: Accuracy degrades at off-normal angles; sensitivity suggests instability. | Unclear: No extra data splitting was performed; the train/test set was small, and the model’s accuracy went down at angles. | High |

| 17 | [17] | High: No unified quantitative dataset shared. | Unclear: Predictors referenced conceptually; not specified for a usable model. | Unclear: No quantitative outcomes reported. | High: Conceptual; no validation metrics/splits. | High |

| 18 | [40] | Unclear: Planning framework with limited experimental checks. | Low: Inputs from CAD/simulation defined within study. | Unclear: Outcomes are geometric errors; limited detail on measurement repeatability. | Unclear: Demonstrations only. | Unclear |

| 19 | [41] | High: Small single-material dataset; narrow process range. | Low: Distance/step predictors measured directly. | Low: Thickness measured consistently. | Unclear: Limited validation/reporting; narrow conditions. | High |

| Outcome Domain | Certainty | Downgrades Applied (with Reasons) |

|---|---|---|

| Geometry/profile prediction (RD4) | Moderate | Evidence For 9 studies ([12]; [21]; [35]; [23]; [37]; [13]; [24]; [14]; [41]) shows, Risk of bias: downgraded (3/9 High; 6/9 Unclear; small single-site datasets; mixed FEM/experimental). Imprecision: downgraded (limited scope; very few external or repeated tests). Consistency: not downgraded (results point in the same direction; low errors reported). Indirectness: not downgraded (tasks directly match CSAM geometry; limited use of simulations). |

| Porosity prediction (RD2/RD3) | Low | Evidence from 3 studies ([16]; [20]; [39]) shows, risk of bias: downgraded (3/3 High; mixed sources from the literature; inconsistent measurements; missing data and estimations). Consistency: downgraded (model results change depending on dataset setup). Imprecision: downgraded (small test samples; little reporting of uncertainty). Indirectness: not downgraded (focus matches porosity; variation fits under bias/inconsistency issues). |

| Monitoring/anomaly or defect detection (RD3) | Moderate | Evidence from 3 studies ([34]; [38]; [19]) shows, risk of bias: downgraded (0/3 High but 3/3 Unclear; single setup/material; potential split leakage). Imprecision: downgraded (no external validation across sites; small sample size). Consistency: not downgraded (accuracy within each study was consistently high). Indirectness: not downgraded (tasks directly relate to monitoring). |

| Inverse design/optimisation (RD1/RD4) | Low | Evidence from 4 studies ([36]; [22]; [40]; [17]) shows, Indirectness: downgraded (simulation-only or rule-based planning; relies on surrogate forward models; limited experimental verification). Imprecision: downgraded (few, small demonstrations; limited quantitative validation). Risk of bias: downgraded (1/4 High; 3/4 Unclear; single setup/material; dependent on earlier models). Consistency: downgraded (different methods/metrics make comparisons hard). |

| References | Research Domain | ML/AI Models | Data Type | Research Target | Material | Data Volume | Open Challenges | Final Performance /Accuracy | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | [21] | RD2/RD4 | Linear Regression (LR), Gaussian Process Regression (GPR), Neural Networks (NN); trained on FEM and mixed (FEM + experimental) datasets | Train: 70% FEM (2-D explicit, 50 impacts per material pair) + 30% experimental; Test: 100% experimental | Forecasting particle flattening ratio and penetration depth to improve coating adhesion from impact velocity, powder Yp, substrate Ys | Powders: Cu, Al, 316 L steel Substrates: PEEK and ABS (unreinforced and long-carbon-fibre-reinforced) | 50 simulated impacts (FEM); experimental share not numerically specified (30% of mixed-training set + full test set) | No real-time process control or adaptive ML strategies GPR showed inconsistency in flattening accuracy (possible overfitting). Generalisation to other substrate types not tested FEM-only data lacks some microstructural realism Optimal ratio of FEM-to-experimental data for training is still unresolved. | Flattening (normalised): RMSE 4.7387, MAE 2.0051, R2 0.34—Data: FEM—Model: GPR; Penetration (%): RMSE 1.45, MAE 0.7654, R2 0.73—Data: FEM—Model: GPR; Flattening (normalized): RMSE 1.8327, MAE 1.4462, R2 0.90—Data: Mixed (30% experimental + FEM), Test: experimental-only—Model: LR; Penetration (%): RMSE 0.5842, MAE 0.4130, R2 0.96—Data: Mixed (30% experimental + FEM), Test: experimental-only—Model: NN. |

| 2 | [16] | RD3 | Linear Regression (LR), Decision Tree Regression (DT), Random Forest Regression (RF), Extreme Gradient Boosting (XGBRegressor), LightGBM Regressor (LGBMRegressor) | 227 literature-derived cases; 7 input variables (gas γ, gas T, gas P, standoff, powder D50, powder ρ, substrate ρ) | Prediction of coating porosity from spray/material parameters | Generic metal/alloy cold spray powders; exact materials not detailed | 227 labelled cases for training + 10 unseen test sets | Dataset aggregated from the literature, hence measurement inconsistency (porosity via different methods). No in situ data or process feedback. Limited to static prediction (no dynamic control or monitoring). Some algorithms (e.g., linear regression) underperform (R2 = 0.27, MAE = 5.06) | Porosity (%): Best model Decision Tree—R2 0.75, MAE 2.93; Worst Linear Regression—R2 0.27, MAE 5.06; Trends: higher gas pressure and temperature reduce porosity, whereas larger particle size increases porosity. |

| 3 | [34] | RD3 | Convolutional Autoencoder (CAE) unsupervised anomaly detector + Convolutional Neural Network (CNN) classifier with Integrated Gradients (IG) explainability | Internal stethoscope sensor sound (48 kHz) from powder-feeder vibrations; external microphone baseline sensors under 4 CS conditions (normal + 3 anomalies) for comparison | Real-time detection and classification of powder-flow faults (no-powder flow, feeder clogging, no-gas flow) during LPCS | Tin (Sn) powder, (10–45 µm, d50 ≈ 17 µm), sprayed on aluminium plate in low-pressure CSAM setup | 30 s signals × 4 states, segmented into 1 s frames; 80/20 split for train/validation; total ≈ 240 Log-Mel spectra per class | No direct link yet to quantitative flow rate or deposition efficiency. Evaluation limited to 3 specific anomalies under fixed test settings. Interpretation via IG is qualitative and not calibrated to deposition metrics. | Powder-flow fault classification: Anomaly detection (s-CAE) 96.7%, (m-CAE) 90.8%; CNN classification test accuracy 95% (stethoscope input); best class (“no gas”) precision/recall 100%. |

| 4 | [22] | RD1/RD4 | Hybrid Particle Swarm Optimisation—Multilayer Perceptron (PSO-MLP) (Forward MLP learns SDP → PSO inverse model predicts IPPs) | Experimental SDP data from [23]: 67-point SDP samples with θ (spray angle), v (traverse speed), SOD (stand-off distance); no synthetic data | Inverse prediction of spray angle (α), nozzle traverse speed (v), and standoff distance (d) to reproduce a user-defined SDP (single-track) | Not explicitly specified—generic metallic CSAM powders | DS1: 36 SDPs × 67 pts = 2412 data points (train/validation/test split); DS2: 12 SDPs × 67 pts = 804 data points | Accuracy of inverse model limited by forward-model MLP. Large error for standoff distance d, posed inverse problem: many-to-one mapping of SDP to IPPs. Need larger and more diverse datasets. | Track profile height (forward model): MAE 0.0086–0.0131 mm (DS2); Inverse prediction of (angle, speed, standoff): MAE 0.0591—Optimiser: PSO-MLP; Runtime ≈ 2.7 s. |

| 5 | [20] | RD2/RD4 | Random Forest (RF), Extreme Gradient Boosting (XGB), Categorical Boosting (CatB) | Literature-derived dataset: 35 papers, 242 porosity labels, 14 parameters; 84% completeness | Predict percentage porosity of cold-sprayed deposits | metallic powders (e.g., CP Ti, Ti-6Al-4V, copper, 304/316 SS) and matching substrates | 242 porosity measurements, 14 process parameters (gas temp, pressure, angle, standoff, feeder rate, etc.) from 35 papers (84% complete) | The literature-derived data introduce “a higher level of uncertainty regarding its accuracy and quality” and many missing values. Porosity measurements obtained by two techniques (image analysis ≈ 90%, Archimedes ≈ 10%) prone to operator bias. | Porosity (%): Random Forest test RMSE 0.79% (train 2.77%); CatBoost RMSE 1.34–1.78%; 12 models achieved ≤2% RMSE; Most influential: gas temperature, gas pressure, particle size. |

| 6 | [35] | RD2/RD4 | Genetic-algorithm (GA)–designed Deep Learning: Wide Neural Network (WNN) for flattening; Tri-layer Neural Network (TNN) for penetration; compared to LR/ANN baselines | Train: 30% experimental + 70% FEM, powders Cu/Al/Steel/Ti on ABS/PEEK/PA66; Test: 100% experimental | Predict particle flattening and penetration to improve coating quality | Powders: Cu, Al, Steel, Ti; Substrates: ABS, PEEK, PA66 | Training: 30% experimental/70% FEM; second training set FEM-only; test set experimental-only (absolute size not stated) | GA optimised architecture, not hyperparameters—structure-focused. TNN showed high variance on unseen data (overfitting on penetration prediction)—poor generalisation. Need for multi-output regression for simultaneous flattening + penetration—to avoid separate models DL model interpretation and explainability not addressed—remains a black box. Further generalization to new material combinations untested—trained on known sets only. | Flattening (normalised): RMSE 0.73, MAE 0.51, R2 0.92—Model: GA-designed Wide NN—Test: experimental-only; Penetration (%): RMSE 2.57, MAE 1.46, R2 0.60—Model: Tri-layer NN (variance on unseen data). |

| 7 | [36] | RD4 | Back-Propagation Neural Network (BPNN)—surrogate/meta-model Optimisers: Particle Swarm Optimisation (PSO), Differential Evolution (DE), Efficient Global Optimisation (EGO + Kriging surrogate) | Synthetic, simulation-generated data: MD snapshots (images) processed to a numerical flattening ratio + the input process variables (velocity, radius, angle) | Maximise deposition quality (flattening ratio µ) by tuning particle velocity, size and impact angle | Copper (Cu) particle on Cu substrate (FCC lattice) | 1000 MD samples for BPNN training + 1000 for testing. Optimisation runs: 20 initial EGO samples; 20 particles in each PSO/DE run | MD-based optimisation is time-consuming. Trade-off between efficiency vs. accuracy when choosing optimisation method (EGO is described as the most efficient, but not always the most accurate also, PSO and DE give better solutions, but are more computationally expensive). µ is scalar geometric metric; no stress/damage or adhesion outputs. Shows BPNN works better with PSO/DE, not EGO. | Optimisation of flattening (μ): Best classic PSO objective c = 0.15084 (μ ≈ 6.6) at v = 1200 m/s, r = 16.145 Å, θ = 0.7°; BPNN surrogate cut heuristic optimisation cost by ~50% vs. direct PSO/DE. |

| 8 | [12] | RD2/RD4 | Univariate Linear Regression (LR); Theory-Guided Machine Learning (TGML) | Mixed dataset: 50% experimental (SEM-based flattening/penetration) + 50% FEM simulations (ABAQUS); impact velocity estimated using analytical physics-based model | Predict single-particle penetration depth and flattening ratio from impact velocity to optimise coating quality | Cu particles on PEEK (fibre-reinforced composite) substrate | 56 total samples → 40 simulated + 16 experimental Split ≈ 70%/30% ⇒ near to 50 train/16 test (authors note “Fifty training examples were fed to the model”) | Univariate model unable to capture nonlinear or coupled effects. Low accuracy for flattening predictions (suggests need for cubic/multivariate models). Impact velocity estimation based on theoretical formula, not real sensor data. Lacks generalisation to other materials (only Cu–PEEK studied). Manual feature selection and gradient descent convergence issues limit scalability. | Penetration (normalised): RMSE 0.2713, Correlation 0.95; Flattening (normalized): RMSE 1.0206, Correlation 0.83—Univariate linear regression on mixed (exp + FEM) data. |

| 9 | [19] | RD3 | ThermoAnoNet—unsupervised deep-learning time-series forecaster built on N-BEATS; baselines: Recurrent Neural Network (RNN) and Temporal Convolutional Network (TCN) | 50 fps FLIR A655sc IR image sequences (640 × 480 px) converted to averaged substrate-temperature time series | Detect anomalies (e.g., feed rate changes) in CS by comparing forecasted vs. observed substrate temperature trends | Cu-159-3 copper powder sprayed on Cu plate; N2 carrier gas | 37 total sprays (22 for training, 5 for validations, 10 for testing); layer wise mean temp trend extracted and filtered; input: 200 steps; output: 300 step forecasts | Lower sensitivity to small feed rate changes (2 → 4 rpm) Lack of generalisation to complex geometries or obscured views Real-time inference limited to sub-layer detection granularity. Thermal-only modality; requires multi-sensor fusion for robustness. No feedback integration or active process control. | Thermal-trend anomaly monitoring: Accuracy 0.90, F1 0.94 (test); Mean detection delay 0.27–0.54 layers; Spray-class accuracy 1.00 for large feed-rate shifts (drops to 0.60 for small 2 → 4 rpm change). |

| 10 | [13] | RD4 | Surface-aware Gaussian Process Regression (GPR) with explicit Gaussian-superposing mean; baseline purely data-driven GPR | 48 overlapping-track profiles (exp.); 21 single-track profiles for surface reference; inputs: traverse speed, standoff, polar angle, surface type | Predict the overlapping-track profile shape to improve geometric control and toolpath planning in CSAM | Powder and substrate: ASTM grade-2 Ti | 48 overlapping-track profiles + 21 single-track profiles → 48 × 151 ≈ 7248 geometry samples (plus 3171 single-track points) | Focused only on 2-track overlaps (no multi-track/layer generalisation). Limited to fixed powder/gas setup (single gas temp/pressure). No feedback loop or adaptive control. GPR surrogate depends on quality of initial mean function. Current results based on 2D cross-sections, not 3D prediction. | Overlapping-track profile: MSE 0.0002183, R2 0.9988, MAPE 0.57%, Max APE 6.91%—Surface-aware GPR outperformed data-only GPR. |

| 11 | [37] | RD4 | Data-assisted Artificial Neural Network (DANN) (feed-forward ANN with Bayesian-regularised back-prop) + Gaussian function with quadratic regression coefficients (hybrid) | Experimental process parameters (spray-angle, traverse-speed, standoff); 3-D laser-scanned track-profile geometry; virtual Gaussian-generated samples—all numerical | Predict full single-track geometry to improve geometric control | CP-Ti (grade-2) powder (15–45 µm), N2 carrier gas | Training: 36 physical tracks × 67 points = 2412 + 804 virtual points; Test: 12 tracks × 67 = 804 | Limited to single-track profiles only; no overlap/layer modelling. Virtual data generated from simplified Gaussian model may bias ANN. Applicability to curved paths, varied spray/nozzle setups untested. Model trained offline; no in situ update or closed-loop feedback. | Single-track profile: MAPE 1.23%, Max APE 5.75%, R2 0.9988, MSE 1.03 × 10−4—Data-efficient ANN + Gaussian hybrid beat pure ANN. |

| 12 | [24] | RD4 | Feed-forward Artificial Neural Network (ANN) (2 hidden layers, 86 + 54; SCG training) | 330 real-time scanned multi-layer profiles (flat + curved substrates) collected from 50 CS runs: 3 process variables + substrate profile as inputs | Predict complete multi-layer deposition profiles from CSAM parameters (SOD, traverse speed, cycles) and previous surface morphology | Cu powder (D50 ≈ 26 µm); Al substrate; 10-layer max, SOD = 20–40 mm, v = 20–100 mm/s | 330 profile samples × 206 points (70% train/15% validation/15% test) | Limited to 2D profiles (no 3D volume prediction). ANN performance is sensitive to substrate irregularity and noise. No physical features (e.g., temp/velocity) integrated. No coupling with real-time sensor feedback or path planning yet. ANN may overfit due to large input size (209 features) and limited process space. | Multi-layer profile (flat + curved): RMSE 0.02209, R2 0.9957—2-hidden-layer ANN robust to noisy substrate geometry. |

| 13 | [14] | RD1/RD4 | Deep Neural Networks (DNNs) for 2D and 3D shape prediction trained on physics-based analytical simulations; compared with Transformers, CNNs, LSTMs, Gaussian Mixture Model (GMM), XGBoost | Simulated single-track shapes generated with a physics-based analytical model, plus a smaller set of experimental cross-sections for validation | Predicting single-track cross-sections and full 3-D deposit geometry; using these predictions inside an adaptive slicing and tool-path framework to inimize waviness/overspray. | Ti-6Al-4V powder (AP&C) | 2400 simulated linear tracks (each 30 mm long) (full-factorial DoE on 4 input variables: scanning speed, spray angle, standoff distance). | Lower accuracy at the domain edges; difficulty capturing profile asymmetry at high spray angles; need to handle curved substrates and shadowing in future work. | Shape prediction: 2D DNN—Relative L2 error 0.59%, MSE 8.06 × 10−5, R2 0.999 (simulated); 3D DNN—Relative L2 error 2.62%; Experimental validation: MSE ≈ 9.4 × 10−3, R2 0.981, MAPE 16%. |

| 14 | [38] | RD3 | 2D Convolutional Neural Networks (CNNs) for multimodal defect detection; Grad-CAM used for interpretability; F1 score evaluation under 5-fold CV | IDS optical cam, FLIR A70 thermal cam, N2 gas T/P/flow; ring and side lights; edge-cloud IIoT | Detect oxidation, porosity, and geometric defects in each sprayed layer using multimodal image inputs; enable in situ defect classification and real-time monitoring | CuZn30 (copper-zinc alloy); sprayed via CGS; process gas: N2 | DoE-based experiments: 3 × 3 matrix of temp (300–800 °C) × pressure (2.5–4.5 MPa); images + process sensor data per layer; labels from expert + lab tests | Model does not yet handle process drift (e.g., changing material batches or conditions). Data is labelled by experts—still semi-automated and subjective. Grad-CAM explanations are qualitative, not linked to quantitative domain thresholds. | In situ defect classification: F1 0.999 (ring-light oxidation), 0.998 (side-light porosity/shape); Accuracy 1.00; Grad-CAM highlights are consistent with defects. |

| 15 | [39] | RD3/RD4 | Linear Regression (LR), Decision Tree (DT), Random Forest (RF), Gradient Boosting (GBOOST), XGBoost, Support Vector Regression (linear, polynomial, RBF), Artificial Neural Network (ANN) | 35 samples: 22 from literature, 13 from experiment (Cantor alloy CS on steel) | Predict porosity (%) in CS-deposited High Entropy Alloy coatings using material + process parameters | Fe(20)Cr20Mn20Ni20Co20 (Cantor HEA) | 35 total samples; 80/20 train-test split; 5 input features; test band analysis + SHAP-based feature ranking | ANN underperformed due to low data volume. Features like traverse speed, spray spacing not included despite influence. | Porosity in HEA coatings (%): Best Support Vector Regression (linear)—RMSE 2.07, PCC 0.85; Linear Regression—RMSE 2.06, PCC 0.83; Several models show 1–3 outliers within 40% prediction band. |

| 16 | [23] | RD1/RD4 | Multilayer-perceptron Artificial Neural Network (Bayesian-regularised back-prop) | Experimental parameters (spray angle, traverse speed, standoff distance) + measured single-track profiles | Predict full single-track geometry from angle, speed, standoff | Grade-2 (commercial-purity) Ti powder | 36 training + 12 test samples (48 tracks); each track represented by 67 polar-length outputs, no simulation data | Model lacks robustness in regions of high geometric variation; ANN requires more data-efficient approaches and improved real-time acquisitions; Model sensitivity limited by small input vector (3 parameters only) vs. large output space (67 neurons); Accuracy degraded at off-normal spray angles (e.g., 48°) diverse data | Single-track profile: MAE 0.05782 mm, MAPE 8.34%, MSE 0.009454, R2 0.9493—MLP (Bayesian regularisation). |

| 17 | [17] | RD1/RD3/RD4 | Artificial Neural Network (ANN)-based geometry predictors; Convolution-based shape predictor; discusses broader Deep Learning and Reinforcement Learning (RL) for optimisation | Hybrid system combining 3D scan data, reverse engineering, numerical simulation (MATLAB), in situ sensor feedback, and rule-based optimisation (porosity, hardness, roughness) → structured numeric and profile data | Develop an integrated hardware–software CSAM platform that couple’s path-planning, shape prediction, real-time monitoring and subtractive finishing to fabricate complex, precise parts | Cu (pure copper), Al (aluminium) demonstrator parts; system intended for “a wide variety of materials” | Complex digital models from structured light scanning and simulation-based shape evolution (no unified raw dataset shared) | pretreatment and post-treatment modules still not fully integrated; need better inter-module data exchange and quantitative validation | None reported; paper is conceptual (no numerical accuracy metrics). |

| 18 | [40] | RD1/RD4 | Hierarchical clustering (unsupervised ML) + Optimised Rapidly Exploring Random Tree (RRT) for path-planning | 3D CAD models (STL mesh of 122,774 triangles); MATLAB-based simulation; Experimental validation with physical spraying on aluminium substrate; no training set | Generate layer-wise filling (FP), compensation (CP), and linking (LP) trajectories for multi-featured CSAM parts, avoiding over-deposition and ensuring shape fidelity | 1050 A Al substrate + commercial Al powder (29 µm); extra demo with Cu powder | Example model: 122,774 triangular facets (slice points generated for every layer) | No ML model trained from data: intelligent planning but not learning-based LP generation is path-optimised but still deterministic. Low resolution at small features (e.g., fingertips) due to nozzle size limits. Spray angle constraints and hardware limitations restrict path variety. Trajectory is fixed after planning; does not adapt to in-process changes. Cannot yet generalise to full curved or non-uniform layer build features. | Dimensional accuracy: Height error 0.8–1.2 mm (5.7–7.4%); Surface flatness ≤ 1.4 mm; Wall straightness 32.8 µm; Uniform layer thickness ≈ 1.25 mm. |

| 19 | [41] | RD4 | Gaussian curve-fitting regression embedded in Thermal Spray Toolkit | Experimental thickness profiles captured by CMM; simulated Gaussian curves | Optimise spray-distance and scanning-step to maximise coating uniformity and generate robot trajectories | Al 5056 powder (40 µm) on Al substrate | 4 spray distances × 5 profiles × ≈30 points ≈ 600 profile points; scanning-step sweep 2–8 mm | Measurement and experimental noise can cause deviations between simulated and actual coating thickness scanning steps exceeding one standard deviation (near to 3 mm) lead to significant loss of surface flatness, reducing coating uniformity. Absence of defined robust parameter ranges makes it harder to ensure consistent quality across different setups. Results are based only on a constant spray angle (90°) and a single material (Al 5056), limiting generalisation to other conditions. | Thickness/profile fit: R2 98.92%; Absolute error ≤ 0.09 mm across cases; Gaussian regression matched CMM profiles closely. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Afsharnia, H.; Butt, J. Artificial Intelligence and Machine Learning in Cold Spray Additive Manufacturing: A Systematic Literature Review. J. Manuf. Mater. Process. 2025, 9, 334. https://doi.org/10.3390/jmmp9100334

Afsharnia H, Butt J. Artificial Intelligence and Machine Learning in Cold Spray Additive Manufacturing: A Systematic Literature Review. Journal of Manufacturing and Materials Processing. 2025; 9(10):334. https://doi.org/10.3390/jmmp9100334

Chicago/Turabian StyleAfsharnia, Habib, and Javaid Butt. 2025. "Artificial Intelligence and Machine Learning in Cold Spray Additive Manufacturing: A Systematic Literature Review" Journal of Manufacturing and Materials Processing 9, no. 10: 334. https://doi.org/10.3390/jmmp9100334

APA StyleAfsharnia, H., & Butt, J. (2025). Artificial Intelligence and Machine Learning in Cold Spray Additive Manufacturing: A Systematic Literature Review. Journal of Manufacturing and Materials Processing, 9(10), 334. https://doi.org/10.3390/jmmp9100334