Abstract

Due to its unique benefits over conventional subtractive manufacturing, additive manufacturing methods continue to attract interest in both academia and industry. One such method is called Cold Spray Additive Manufacturing (CSAM), a solid-state coating deposition technology to manufacture repair metallic components using a gas jet and powder particles. CSAM offers low heat input, stable phases, suitability for heat-sensitive substrates, and high deposition rates. However, persistent challenges include porosity control, geometric accuracy near edges and concavities, anisotropy, and cost sensitivities linked to gas selection and nozzle wear. Interdisciplinary research across manufacturing science, materials characterisation, robotics, control, artificial intelligence (AI), and machine learning (ML) is deployed to overcome these issues. ML supports quality prediction, inverse parameter design, in situ monitoring, and surrogate models that couple process physics with data. To demonstrate the impact of AI and ML on CSAM, this study presents a systematic literature review to identify, evaluate, and analyse published studies in this domain. The most relevant studies in the literature are analysed using keyword co-occurrence and clustering. Four themes were identified: design for CSAM, material analytics, real-time monitoring and defect analytics, and deposition and AI-enabled optimisation. Based on this synthesis, core challenges are identified as small and varied datasets, transfer and identifiability limits, and fragmented sensing. Main opportunities are outlined as physics-based surrogates, active learning, uncertainty-aware inversion, and cloud-edge control for reliable and adaptable ML use in CSAM. By systematically mapping the current landscape, this work provides a critical roadmap for researchers to target the most significant challenges and opportunities in applying AI/ML to industrialise CSAM.

1. Introduction

Design in additive manufacturing (AM) has evolved into physics-aware, co-designed workflows that couple digital design, process physics, and data-driven control. This builds on international standards that define AM’s layer-wise nature and its implications for tolerances, planning, and verification [1,2,3,4]. However, AM is a multidisciplinary field, combining mechanics, materials science, fluid and thermal physics, electronics, robotics, and computer science; therefore, quality depends on linked process conditions, parameters, and feedstock quality [2,5,6,7,8].

One such AM method that is receiving immense attention due to its benefits is called Cold Spray Additive Manufacturing (CSAM). It is a solid-state deposition technology that accelerates powders to supersonic velocities in heated gas and consolidates them by severe plastic deformation, oxide fracture, and mechanical interlocking without melting. Using de Laval or constant-diameter nozzles (CD) and gases such as N2 and He (or blends), CSAM achieves dense deposits, phase retention, and compatibility with temperature-sensitive substrates [2,9]. Porosity control, geometric accuracy near edges and concavities, helium cost exposure, and nozzle wear remain limiting features [2,3,10]. Because CSAM is a continuous jetting process, dimensional control depends on path planning, spray angle, stand-off, traverse speed, and jet-footprint overlap. Bonding further requires exceeding material-dependent critical velocities that link feedstock state to nozzle gas conditions [5,6,11]. CSAM is multi-physics and multi-scale. Nozzle flow and particle acceleration set in-flight states; impact plasticity forms solid surfaces; track and layer build-up depend on kinematics and overlap. Final parts show porosity and residual stress. Physics-based models, computational fluid dynamics (CFD) for gas–particle flow and nozzle design, finite-element analysis for impact, analytical deposition maps, and geometric growth solvers, provide useful insights but are slow to compute and have only been tested in limited cases. This restricts wide use, reverse design, or real-time control [5,6,7,12].

Artificial intelligence (AI) and machine learning (ML) help address these gaps. Surrogate models speed up track/layer prediction and support parameter design as well as nozzle optimisation. Design filters estimate porosity or quality, vision and signal tools enable in-process defect detection, and physics-guided solvers combine analytical and CFD knowledge with flexible corrections [13,14,15,16]. Recent works show robot-mounted laser profilometry for layer-wise detect-and-correct, aero-acoustics for nozzle and feed anomalies, and thermal forecasting for feed-rate changes, pointing toward closed-loop control [17,18,19]. Most ML analysis for CSAM relies on small, varied datasets from single machines or mined from the literature. Random data splits overestimate accuracy and reduce generalisability. More robust evaluation is needed, using grouped or forward-looking splits, propagating uncertainty from reported ranges, and combining training across simulations and experiments [16,20,21]. Model transfer also breaks down under changes in methods, sensor, or material. Identifiability limits appear in inverse design (e.g., low sensitivity to stand-off), and purely data-driven one-shot predictors fail under new conditions or geometries [22,23,24]. Sensing is still fragmented, where thermal, sizing–particle tracking velocimetry (S-PTV), sound, and laser-scanning data are rarely combined into fast feedback systems [2,25,26].

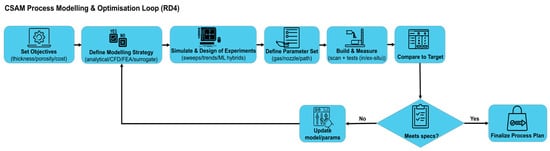

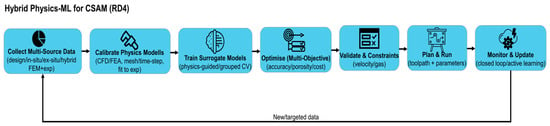

To organise the landscape and provide a holistic overview of AI and ML on CSAM, a systematic literature review has been conducted in this study using structured searches and keyword clustering. ML and AI for CSAM are grouped into four main research domains: (RD1) design (printability, path planning, inverse mapping, nozzle optimisation); (RD2) material analysis (linking process to structure and properties); (RD3) real-time monitoring and defect detection (thermal, optical, sound, and geometric sensing); and (RD4) deposition modelling and AI-based optimisation (surrogates, inverse design, and workflow integration). Across these areas, four key strategies are highlighted: combined physics-and-data surrogates improved with targeted experiments; active learning to cover difficult regions; uncertainty-aware search that respects feasibility; and keep heavy CFD and FEA offline while using light predictors at the tool level [13,14,17].

This review also draws out implications for industrial use and sustainability. Costs and environmental impacts come from gas heating and helium use, wear of consumables, and wasted material from errors and porosity. ML supports improvements in all areas: CFD-based optimisation to reach required speeds at lower temperatures; cost-effective gas mixing; design filters that reduce failed builds; predictive geometry and porosity control that cut rework; and monitoring systems that detect wear and drift early [15,17,20,27]. A key missing element is an integrated, fast, and uncertainty-aware closed-loop system that combines sensing with robotic control, particularly for complex geometries. The research methodology for this systematic literature review has been described in Section 2, following by classification and discussion of the research domains in Section 3 and Section 4, respectively. Section 5 highlights the challenges and opportunities for AI/ML in CSAM, whereas Section 6 provides answers to the research questions. The conclusions of this work are outlined in Section 8.

2. Research Methodology

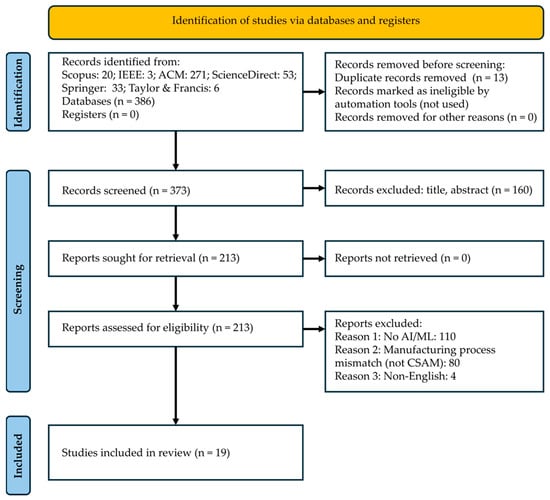

An extensive systematic literature review combined with text-mining analysis was undertaken to identify, evaluate, and synthesise studies in which artificial intelligence or machine learning techniques have been applied to cold-spray additive manufacturing up to April 2025, using the PRISMA-2020 guidelines [28]. The overall process adopted is summarised in Figure 1. Identification and evaluation of relevant publications followed the systematic-review procedure outlined by [29], which involves formulating guiding research questions, collecting potentially relevant studies, and critically selecting and evaluating the collected literature. Each primary study was examined against predetermined inclusion and exclusion criteria (Table 1).

Figure 1.

PRISMA 2020 flow diagram.

Table 1.

Inclusion and exclusion criteria.

For the final set of accepted papers, keyword co-occurrence and clustering analysis were performed using VOSviewer version 1.6.20, according to the VOSviewer method proposed by [30,31]. This bibliometric step provides a clear overview of the main research topics and directions in the application of AI and ML to CSAM.

2.1. Step 1: Potential Research Questions

Here are three high-level research questions that capture the core themes in the literature:

- RQ1: What types of CSAM problems are currently being addressed with AI/ML?

- RQ2: Which AI/ML models are used for the identified CSAM problems?

- RQ3: What benefits, limitations, and open challenges are reported when applying AI/ML to CSAM?

2.2. Step 2: Keywords Identification

To conduct the systematic literature review, keywords were selected carefully to identify studies at the intersection of cold spray additive manufacturing and machine learning (using Boolean operators: “AND”, “OR”).

[(“cold spray additive manufacturing” OR “cold spray 3D printing”) AND (“artificial intelligence” OR “machine learning” OR “supervised learning” OR “semi-supervised learning” OR “unsupervised learning” OR “reinforcement learning” OR “deep learning” OR “neural networks”)].

2.3. Step 3: Resources for Searching

Databases used for identifying the relevant papers include Scopus, IEEE Xplore, ACM Digital Library, ScienceDirect, SpringerLink, and Taylor & Francis Online. Together, these platforms provide the most extensive and reliable sources to cover the subject of this review, offering major collections of peer-reviewed journal articles, books, conference proceedings, and other scholarly publications. The search covered publications from 2014 to 2025 in all the aforementioned databases (last search: 30 April 2025). No study registers or literature sources were searched. The review protocol was not formally registered in any external registry.

2.4. Step 4: Inclusion and Exclusion Criteria

Table 1 summarises the inclusion and exclusion criteria guiding the article-selection process. Publications were first screened using their titles, abstracts, and keyword lists; those remaining were then evaluated in full-text form to confirm inclusion.

2.5. Step 5: Selecting Studies and Analysing Keyword Co-Occurrence

The systematic literature review was conducted in four stages, following the PRISMA 2020 guidelines [28]. First, an initial Boolean keyword search identified 386 candidate papers. Before screening, 3 duplicate records were removed. In the second stage, titles, abstracts and keywords of 383 records were screened against the exclusion criteria, leading to the removal of 160 records and 223 reports being sought for retrieval (reports not retrieved, n = 0). In the third stage, 223 full texts were assessed for eligibility. At this stage, a study had to

- State clearly defined CSAM problems.

- Justify why an AI/ML approach was suitable.

- Demonstrate that the proposed method was evaluated or validated.

Applying these criteria resulted in the exclusion of 204 reports (No AI/ML = 120; manufacturing process mismatch non-CSAM = 80; non-English = 4). In the fourth and final stage, 19 primary studies met all requirements and were included for synthesis. The above process is summarised in the PRISMA flow diagram (Figure 1).

Analysing how specific keywords appear together in the literature offers a practical way to highlight the main themes in a research field [32]. A keyword co-occurrence matrix C = [] was constructed, where is the number of documents in which keywords and co-occur and = 0. is the total number of documents containing keyword . Following VOSviewer, pairwise similarity () was computed using association strength:

This normalisation corrects marginal frequencies and is the default in VOSviewer [30]. Two-dimensional coordinates = () ∈ were obtained using the VOS mapping technique by minimising a weighted sum of squared distances,

subject to the scale-fixing constraint that the average inter-item distance equals 1:

These steps correspond to VOSviewer’s similarity to mapping pipeline [30].

For clustering, links weights were taken as = with node degrees = and total link weight m = . Items were assigned to cluster labels ∈ {1, …, K} by maximising the weighted, resolution-parameterized modularity used in the unified VOS framework:

Here = 1 if items i and j are in the same cluster and 0 otherwise; is a pairwise weight; γ is the resolution parameter controlling typical cluster size; and K is the number of clusters. This objective is equivalent to minimising the unified energy with clustering distances, and it reduces to modularity when = 1 and = 1 [31].

The are continuous map coordinates from (2) and (3) (used for visualisation), whereas are discrete cluster labels from (4). They are produced by related but distinct optimisations; in plots, items are positioned at and coloured by . There is no direct algebraic mapping from to [30,31]. VOSviewer was used to generate keyword maps and clusters [30].

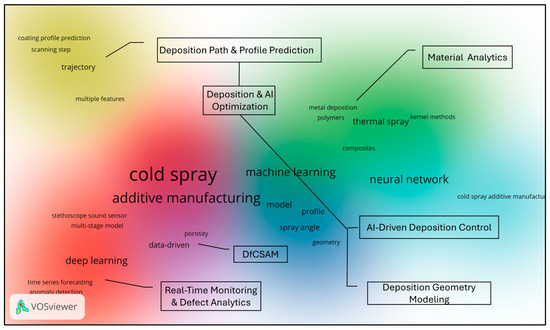

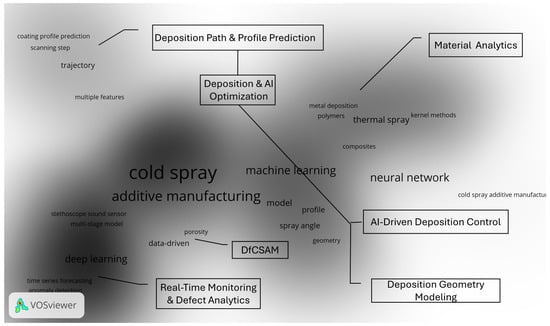

Figure 2 shows the keyword co-occurrence map obtained from the 19 papers that met the inclusion criteria. This is a label-only VOSviewer view (without showing links). The size of each keyword shows how often it appears and is usually linked to its total connections. The colours represent VOSviewer clusters (groups of related keywords), and the distance between labels shows how closely they are related (closer labels co-occur more often). VOSviewer settings: minimum keyword occurrences = 1; normalisation = Association Strength; clustering resolution = 1.00; minimum cluster size = 4; layout (default) = Attraction 2, Repulsion 0. In the VOSviewer layout, physical distance reflects how frequently two terms co-occur; therefore, the closeness of nodes and groups indicates how strongly the keywords are related. Moreover, a grey scale keyword co-occurrence map with description has been provided in the Appendix A.

Figure 2.

The clustering analysis of the proposed article selection.

Six colour-coded clusters emerge, indicating the main research focus areas within the field of AI/ML that connect with CSAM. As the VOSviewer output, physical distance in the map reflects how frequently two terms appear together, the closeness of each group shows how related the keywords are together. The red cluster includes phrases such as anomaly detection, powder-flow monitoring, thermal imaging and deep learning and therefore represents Monitoring & Defect Analytics; the green cluster collects materials terms (Cantor alloy, thermal spray, composites, gradient boosting), pointing to Material Analytics; a dark-blue cluster built around layer, profile, and Gaussian process reflects Deposition Geometry Modelling; the yellow cluster, contains spray distance, coating-profile prediction and related path-planning terms and is labelled Deposition Path & Profile Prediction; the purple cluster groups design-stage concepts such as additive manufacturing, tool-path optimisation and porosity, defining Design-for-CSAM (DfCSAM); finally, a light-blue cluster centred on neural network and AI-driven deposition control rounds out the map.

Although six clusters appear visually, the findings are reported in four research domains aligned with the CSAM workflow. Applying the ≥50% content rule, dark blue, yellow, and light blue clusters all map to RD4 (Deposition & AI Optimisation, reported together under RD4). The remaining clusters map to RD1 DfCSAM (purple), RD2 Material Analytics (green), and RD3 Real-Time Monitoring & Defect Analytics (Red). This organisation matches the clustered keywords to the CSAM phases from design through in-process control to deposition optimisation, as summarised in Table 2.

Table 2.

Clustering of selected publishing outcomes.

Keyword statistics supporting these thematic patterns are presented in Table 3. “Cold spray” appears eleven times and has the highest total link strength (51), confirming this cluster (RD3) is a key research area. Across the 75 important keywords, RD 4 (geometry and AI-focused) shows the most prominence, as it includes 28 occurrences (almost 37% of the sample) and a total link strength of 155. Example items include “neural network” (5 occurrences, 25 links), “model” (3 occurrences, 19 links), and the paired geometry descriptors “profile” and “spray angle” (each 2 occurrences, 14 links). Even single occurrence terms such as “data-efficient,” “geometry,” “limited data,” and “trajectory” have link strengths of 9, showing ongoing interest in predictive models that work with less data.

Table 3.

The keywords clustering co-occurrence.

In contrast, the design focused RD 1 cluster contains 11 keyword mentions “additive manufacturing” and “data-driven” and an aggregate link strength of 49, while the materials analytics RD 2 cluster has 14 hits “machine learning” and “thermal spray” with a combined strength of 62. Because the table lists only the top terms, these figures represent lower than actual totals; nevertheless, they indicate that current research gives more attention to in-process monitoring (RD 3) and Deposition & AI Optimisation (RD 4), whereas the systematic integration of AI/ML into design part (RD 1) and alloy development (RD 2) remains comparatively under explored.

2.6. Data Synthesis: A Priori Plan, Feasibility of Pooling, and Overview of Observed Patterns

At the planning stage, it was decided that a quantitative meta-analysis would only be performed if studies looked at similar outcomes, used comparable measures on similar scales, and reported uncertainty (or enough data to calculate it). Otherwise, a structured summary would be provided, organised by research area, data source, sensing, and algorithm type, with collection of study details and reported performance results.

After collecting the data, meta-analysis was not carried out because of major differences in research focus, tasks, and outcomes as well as variations in measures and scales with frequent lack of uncertainty estimates, differences in data sources and measurement methods, and variation in validation approaches and sample sizes. These factors prevented calculating a meaningful overall effect. The planned structured summary was therefore followed.

In terms of overall findings, performance depended heavily on context: results within the same setup were usually better than across different setups; imaging-based monitoring often showed good accuracy within the tested ranges; porosity-focused models were less consistent and more sensitive to how the dataset was built; and inverse-design studies often used forward models with limited outside validation. No claims are made about specific methods or algorithms beyond this neutral summary.

2.7. Bias Risk

Risk of bias was evaluated with the PROBAST tool [33], which reviews prediction-model studies across four domains and assigns Low, High, or Unclear judgments at both domain and study level. The first domain (participants and data source) examines dataset suitability and origin, including size and coverage of the explored process space, completeness or missing data, and whether different literature sources were combined. The second (predictors) assesses how input variables were defined and measured and whether any preprocessing, segmentation, or feature construction could introduce information leakage. The third (outcome) reviews the clarity and consistency of outcome definition and measurement and matches the stated modelling goal. The fourth (analysis and validation) evaluates sample size in relation to model complexity; separation of tuning from evaluation; carefulness of internal split design; presence or absence of external or temporal testing; handling of missing data; and clarity of performance reporting, including calibration where applicable. PROBAST rules were followed: overall risk of bias is High if any domain is High; overall is Low only if all four domains are Low; otherwise overall is Unclear. Inter-rater agreement was measured using percent agreement before resolving disagreements: title/abstract screening, 86% agreement; full-text eligibility, 83% agreement; risk-of-bias ratings, 84% agreement. Disagreements were resolved through discussion, and no automation tools were used. Across 19 studies, overall risk of bias was High in 7; the remaining studies did not meet criteria for Low risk across all domains and were therefore judged Unclear overall. Common concerns included limited or mixed datasets (especially literature-based), reliance on internal splits without external or temporal testing, barriers to reproducibility, measurement inconsistency, and potential context leakage when segmenting or combining data. Per-study domain-level judgments and justifications are presented below in Table 4.

Table 4.

Risk of bias (PROBAST) per-study judgments and justifications.

2.8. Certainty of Evidence Approach

Certainty (confidence) in the body of evidence for each outcome was graded qualitatively (High, Moderate, Low, Very Low) using four criteria: risk of bias, assessed with the PROBAST tool at study and domain level; consistency of findings across studies; imprecision (sample size, uncertainty/variance reporting, and presence of external or temporal validation); and indirectness (applicability of data, tasks, and outcomes to CSAM). Ratings were downgraded when serious concerns were identified in any criteria. Across the 19 included studies, PROBAST overall risk of bias was ‘High’ in 7 and ‘Unclear’ in 12, which drove risk-of-bias downgrades at the outcome level. Considering all four criteria, certainty was ‘Moderate’ for geometry/profile prediction and monitoring and anomaly detection (consistent within-study performance but limited by small, single-site datasets and scarce external validation), and ‘Low’ for porosity prediction and inverse design and optimisation (high risk of bias from mixed literature-derived data, inconsistent measurement and metrics, limited or simulation-only validation, and small test samples). Outcome-level justifications and contributing studies are detailed in Table 5.

Table 5.

Certainty of evidence.

3. Classification of the Selected Literature

This section summarises the 19 CSAM papers after screening (Table 6) and allocates them to the four research directions (RD) identified earlier: design for CSAM (DfCSAM, RD 1), material analytics (RD 2), real-time Monitoring & Defect Analytics (RD 3), and Deposition & AI Optimisation (RD 4).

Table 6.

Research domain classification and data extraction.

Terms associated with RD 4 (e.g., neural network, model, profile, spray angle) appear 28 times and accumulate the highest aggregate link strength (155), while RD 3 keywords (e.g., cold spray, deep learning, anomaly detection) register 22 occurrences and 94 link points. Together, RD 3 and RD 4 include almost two-thirds of all important keywords, showing the field’s focus on parameter optimisation and in-process quality assurance. By contrast, design-oriented RD 1 and materials-focused RD 2 contribute only 11 and 14 keyword mentions, with much lower link strengths (49 and 62), highlighting clear research gaps in part-level design methodology and alloy development.

The paper-level distribution matches this keyword pattern. Sixteen of the nineteen studies (≈79%) target RD 4 objectives such as predicting layer geometry, coating thickness or deposition trajectory, whereas six papers (≈32%) focus on RD 3 tasks centred on defect detection, thermal imaging or anomaly forecasting. Only five studies (≈26%) explicitly address design issues (RD 1) and four (≈21%) concentrate on material analytics (RD 2). Because several papers cover multiple categories, these shares exceed 100%, but the trend is clear: recent CSAM research prioritises real-time monitoring and data-driven process optimisation, while systematic integration of ML into design guidelines and alloy discovery remains at an early stage.

With respect to algorithms, neural-network-based models are the most common, where fifteen papers use basic feed-forward neural networks, convolutional neural networks or related deep-learning variants, reflecting their flexibility for both prediction and classification. Advanced deep models (Convolutional Neural Networks (CNNs), autoencoders, Long Short-Term Memories (LSTMs)) already appear in about a quarter of the studies, while older methods like support vector machines and regressors are used in only one paper, and Gaussian process regression in two. A small but growing number of studies combine data-driven learning with physics-based knowledge using physics-informed ML, offering a clearer option compared to fully data-driven models.

In practical terms, these findings indicate that the strong methods used in RD 3 and RD 4 are deep-learning-based surrogates and anomaly detectors, which could be used earlier in the process. Combining data from different sources, and hybrid physics and ML methods developed for monitoring may help fill the clear gaps in design for CSAM (RD 1) and material analytics (RD 2). The data was extracted from the identified publications and independently verified by the authors for accuracy and consistency. Any discrepancies were resolved through discussion until a consensus was reached. Outcomes of interest were study-reported performance metrics (e.g., coefficient of determination (R2), root mean squared error (RMSE), mean absolute error (MAE), mean absolute percentage error (MAPE), F1 score (F1)). Additional items extracted included reference, research domain, ML/AI model, data type, research target, material, data volume, and reported open challenges (Table 6). Where necessary, metric names were standardised to common definitions (e.g., root mean squared error (RMSE) vs. mean squared error (MSE)); otherwise, results are presented as originally reported. Considering the studies that used different tasks, datasets, and metrics, results were combined narratively; no merging of results into a single combined number or sensitivity analysis was performed.

4. AI/ML Applications for CSAM

In this section, recent applications of artificial intelligence and machine learning in Cold Spray Additive Manufacturing are categorised into four core research directions, building on a systematic literature review and keyword clustering analysis. The domains include: (RD1) Design for CSAM, which focuses on data-driven design frameworks and inverse modelling to achieve desired deposition profiles; (RD2) Material Analytics & Characterization, focusing on porosity prediction, microstructure–property links, and hybrid simulation plus experiment surrogates for adhesion and flattening; (RD3) Real-Time Monitoring & Defect Analytics, which applies AI/ML for anomaly detection, process state classification, and in situ quality control using sensor and image data; and (RD4) Deposition Modelling & AI Optimisation, where physics-guided surrogates and solver-in-the-loop networks accelerate geometry prediction and inverse search, and CFD-assisted optimisation improves nozzle and recipe performance. This work addresses three critical aspects: evaluation using grouped and prospective data splits to avoid context leakage, parameter identifiability (e.g., stand-off distance), and uncertainty-aware methods with cloud-edge deployment for reliable, low-latency control. The four research domains are discussed below.

4.1. Design for CSAM (RD1)

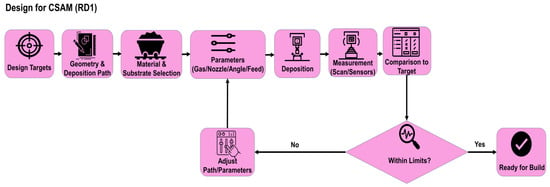

Design in additive manufacturing has progressed from early layer-wise prototyping of simple geometries to a mature engineering discipline that couples digital design, process physics and data-driven control to deliver structural, functional, and multi-material components with predictable performance. International standards such as ISO/ASTM 52900:2021 have advanced AM development by establishing standardised terminology and process categories. These standards define AM as layer-by-layer material joining from 3D model data and explicitly address geometric tolerances, process planning, and verification requirements [1]. From an engineering design standpoint, AM’s unique advantages (design freedom, shorter lead times) are limited by constraints that are process-specific: melt pool dynamics and thermal gradients in fusion-based methods; flow of liquid resin, speed, and process of hardening in photopolymerization; and impact of particles on the surface and how they compact together in solid-state methods. Accordingly, design for AM has shifted from shape-first modelling to physics-based workflows in which deposition strategies, parameter ranges and post-processing are co-designed with geometry to achieve desired microstructures and mechanical properties, minimising residual stresses and ensuring dimensional accuracy at scale [1,2,3,4]. The core insight is that in advanced AM, design cannot be separated from process physics and control, and geometry alone is an insufficient specification for performance. This insight is demonstrated with a design-for-CSAM loop in Figure 3.

Figure 3.

Design-for-CSAM loop.

4.1.1. Part Design and Deposition Strategy

Cold spray additive manufacturing narrows this landscape to a solid-state deposition route in which powders (roughly 1–100 μm) are accelerated to supersonic velocities (roughly 300–1200 m/s) in pressurised carrier gases and directed through special supersonic nozzles onto a surface. Bonding is achieved via severe plastic deformation, oxide fracture, and mechanical interlocking rather than melting; thereby, preserving feedstock phase constitution and avoiding heat-affected zones [2,8,42]. Successful deposition occurs only when particle speed exceeds a material dependent critical velocity. This threshold increases with decreasing particle size, increasing surface oxide thickness, and increasing hardness, making it a principal design constraint that couples material state to nozzle flow and gas selection. Critical velocity is the key factor in CSAM, and it must be adjusted together with nozzle shape, gas settings, and particle shape to obtain good bonding while avoiding damage to the surface [2,11,43]. Because cold spray is a continuous jetting process, dimensional control depends on path planning and scanning strategy. Toolpaths must integrate jet footprint models, robot kinematics, and access constraints more stringently than in other AM modalities to avoid over or under build, especially near edges and concavities. Recent 3D volume construction and toolpath frameworks explicitly embed cold-spray characteristics to improve geometric accuracy in repair and freeform builds, confirming that algorithmic planning is a first-order design variable in CSAM [44,45].

Material selection for CSAM includes pure metals, alloys, and metal-matrix composites, with feedstock morphology, size distribution, and microstructure shaping deposition efficiency and the mechanical properties of the components [2,46,47]. Spherical and irregular particles exhibit distinct penetration depths and substrate interactions under otherwise similar conditions, and surface condition, especially oxide coverage modulates effective critical velocity and interfacial bonding [2,8,48]. Multi-material CSAM, including simultaneous powder mixing and metal polymer blends, enables tailored property combinations and, in some cases, synergistic responses that exceed linear mixing rules due to interpenetrating microstructures and load-transfer mechanisms [49,50]. Substrate compatibility is unusually broad because the process temperature is below melting. Metals can be deposited on temperature-sensitive substrates, including engineering polymers and CFRPs (Carbon Fibre-Reinforced Polymer), facilitating metal coating and functional modifications without thermal degradation [51,52,53,54,55]. This low-temperature range is deliberately advantageous, as it allows bonding to polymers and composites that fusion-based AM cannot process, while maintaining bioactive or unstable phases in functional coatings.

Process parameters in CSAM are numerous and interdependent. Gas type, temperature, and pressure set the acceleration field. Helium can be necessary for dense deposits of hard or challenging alloys due to its superior sound speed and thermal properties, although it comes at a higher cost [11,56]. Standoff distance, spray angle, and traverse speed control the variation in impact conditions across the surface. Experiments on Al2219–T6 show that spray angle and traverse speed have stronger effects than standoff distance on thickness and properties, highlighting the impact of directional impact and residence time in jet-footprint development [57]. Nozzle exit diameter, divergence angle, and internal contour interacts with gas heating and mass flow to determine particle velocity distributions and gas temperature at the outlet. Recent 3D-CFD and parametric studies map these dependencies to better align design targets with attainable jet conditions [7,9,57,58]. Because these controls interact nonlinearly, multi-parameter optimisation methods such as response surface methodology (RSM), artificial neural networks (ANNs), and hybrid Artificial Neural Network-Genetic Algorithm (ANN–GA) schemes, are becoming increasingly popular to reduce time and costly trial-and-error [15,59,60,61,62,63].

Industrial applications mirror these strengths of CSAM. In aerospace, CSAM is widely used for repair and remanufacture of aluminium and titanium-based components, restoring geometry and function while preserving underlying microstructure; thus, offering a cost-effective solution for high-value parts with minimum heat input [10,64,65]. For lightning-strike protection, aluminium cold spray coatings on CFRP fuselages can provide surface conductivity and avoid laminate damage when applied over a suitably designed plasma-sprayed aluminium interlayer, which improves bonding and prevents erosion of the composite substrate [66]. In biomedical applications, cold spray is employed to produce wear and corrosion resistant coatings, as well as bioactive ceramics and Ti–hydroxyapatite composites that retain the feedstock phase composition and promote bone integration [54,55,67,68]. Emerging areas include thermoelectric device interfacing and even aspects of solid-state battery manufacturing where low-temperature metallisation is essential [46,69]. Across these claims, CSAM’s key distinction is not only its low heat input but its controllable solid-state plastic deformation at impact, which can be leveraged to retain material properties, preserve phases, and enable compatibility with a wide range of substrates [2,42,64].

Despite these advantages, limitations remain. Porosity control and uniform thickness over complex topologies are challenging as jet flow tends to become uneven near edges and separates over sharp features. Many reports note that producing morphologically precise features is particularly problematic in areas with tight curves or deep concavity [2,3,4]. Geometric complexity also increases sensitivity to fixture orientation, robot path discretisation, and overspray, while economics are impacted by high-pressure systems, helium usage, and nozzle wear, which collectively constrain wider adoption [2,10]. At present, the main barrier to CSAM’s industrial scaling is not fundamental feasibility but achieving reliable, uncertainty-aware control of geometry and porosity in complex builds, along with managing the operational costs of advanced gas-nozzle systems.

4.1.2. Design Optimisation

Within this context, design strategies specific to CSAM increasingly integrate adaptive path planning, deposition order, and post-processing to mitigate geometric and residual stress constraints. Automated scan-to-path frameworks that integrate 3D scanning, defect characterisation, and adaptive trajectory generation have been shown to reduce post-processing and improve deposit conformity in repair settings, highlighting workflow integration as a key vector of design maturity [45,70]. Layer-by-layer build up strategies that explicitly address interlayer bonding and stability improve control over wall straightness and topology in freeform components, provided process ranges maintain impact energies above critical thresholds without destroying substrate integrity [71,72]. Shape-aware deposition methods such as “Metal Knitting (MK)” also show how trajectory design can act as a control tool to reduce anisotropy and shape error [73,74]. MK follows continuous circular nozzle paths at fixed angles < 90°, enable straighter walls and thicker, well-bonded deposits with finer geometric control. Although these factors initially elevate porosity and reduce adhesion due to reduced normal impact, these effects can be mitigated by post heat treatments.

Annealing of copper and aluminium deposits relieves residual stresses, reduces microstructural defects, and significantly enhances cohesion and adhesion. Wear resistance approaching bulk material has been reported after appropriate thermal treatments, confirming the utility of post-processing as a design variable [73]. Complementing these strategies, physics-guided parameter estimation frameworks formalise links from operational variables such as spray angle, traverse speed, powder feed rate, standoff distance, nozzle exit diameter and divergence angle, to deposit profiles through analytical gas dynamics, particle ballistics and impact mechanics. Sensitivity analysis emphasises the dominant roles of nozzle geometry, feed rate, and critical velocity, with standoff distance reducing height via velocity loss [75]. Together, these results support a design approach in which deposition strategy, parameter selection, and post-processing are optimised using models that expose sensitivities and identifiability limits.

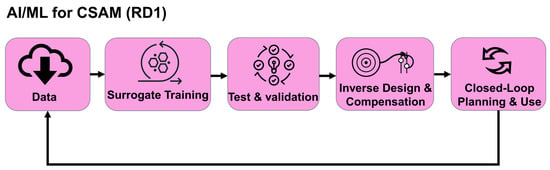

Turning to the application of artificial intelligence and machine learning in CSAM, the state-of-the-art spans forward surrogates for track and layer shape prediction, surrogate-based inverse design of parameters, and workflow integration for scan-to-path planning and overspray management. Figure 4 shows the minimal AI and ML pipeline used for CSAM design and compensation.

Figure 4.

AI/ML pipeline used for CSAM design.

At the design stage, ML supports printability assessment, tolerance analysis, path planning, track-profile prediction, and inverse parameter mapping, as well as nozzle optimisation, often in combination with rapid convolution-based or Gaussian deposition approximations to reduce experimental cost [2,37,76]. Early data-driven forward models predict single-track shapes directly from spray angle, traverse speed, and standoff distance. For example, a compact multilayer perceptron (MLP) with Bayesian regularisation achieved roughly R2 = 0.95 and 0.06 mm mean absolute height error on held-out tracks, outperforming a Gaussian baseline particularly at edges, though accuracy degraded for strongly off-normal angles due to sparse training coverage [23]. The critical limitation here is data coverage rather than model class, indicating that active learning and design-of-experiments (DOE) expansion are likely to deliver larger gains than deeper architectures. To mitigate data scarcity, synthetic datasets generated from validated analytical models have been used to train two-dimensional (2D) and three-dimensional (3D) deep surrogates, yielding sub-percent relative errors in simulation and millisecond inference. When embedded into adaptive slicing with zigzag planning and edge-compensation, these surrogates ran more than 250× faster and met flatness targets while limiting overspray on test geometries [14]. The approach is compelling for interactive design, but accuracy declines at high spray angles and domain edges reflect biases and limits of the underlying analytical solver. Integration with real data remains necessary to close the domain gap.

Inverse design efforts frame CSAM parameter selection as optimisation over fast forward surrogates. A representative study couples a small MLP trained on 36 single-track profiles with a particle swarm optimiser to retrieve impact angle, particle velocity, and standoff distance that reproduce a target geometry. The method returned low profile error within seconds and achieved a near perfect correlation on held-out tracks, but the tiny dataset, narrow material or process coverage, and low-capacity network raise external validity concerns, and standoff distance emerged as weakly identifiable, consistent with physical insensitivity and signalling potential non-uniqueness of solutions [22]. Search-on-surrogate is efficient and practical, but it carries the biases of the surrogate model and cannot guarantee global optimisation without uncertainty quantification or feasibility constraints. Addressing non-identifiability explicitly is essential in production. Beyond tracks, end-to-end workflow integrations now combine reverse-engineering scans, mesh-based deposition simulators using cylindrical jet models, and automatic tool–path generators in unified software components. These reduce handoffs and enable pre-spray verification of layer height evolution, detouring around features to avoid overspray and demonstrating that clean multi-feature can build-up to almost 145 × 95 mm in copper [17]. The principal contribution is integration rather than novel physics, and accuracy is currently limited by simplified jet models and uncertainty bounds. Online corrections are needed to assure robustness across geometries and environmental variation. A related design stage toolkit improves uniform-layer slicing, adds edge compensation, and plans transfers via RRT (Rapidly Exploring Random Tree) to avoid existing deposits, eliminating stray material on multi-feature builds, including a 2.3 kg “hand” made from copper. However, uniform-layer assumptions struggle near steep gradients, and concave contours remain challenging without learned deposition fields [40].

Parallel ML threads address parameter optimisation and nozzle design. RSM, ANN, and hybrid ANN–GA have been applied to optimise nozzle parameters, gas heating, and traverse strategies for deposition efficiency and porosity control. Inverse, theory-guided learning has also been used to set process conditions for difficult alloys and fibre-reinforced composites, with helium often required to suppress porosity in high-entropy and hard systems [12,15,56,60]. Nozzle-geometry optimisation via 3D-CFD improves particle-velocity distributions and identifies dominant geometric controls. However, further work is needed on non-adiabatic effects and environmental interactions to strengthen robustness near the substrate and in free-jet regions [9,58,77]. Across these studies, four risks emerge: dataset sparsity, domain shift when training on synthetic data, lack of uncertainty quantification, and parameter non-identifiability in inverse settings.

Synthesising these findings, a coherent trajectory for AI/ML-enabled CSAM design emerges. First, hybrid physics and data surrogates grounding learning in analytical or CFD models but corrected with targeted experiments, can reduce bias while retaining speed [14,77]. Second, active learning and DOE are needed to fill coverage holes at off-normal angles and near boundaries, where both forward and inverse accuracy degrade [14,23]. Third, uncertainty-aware inverse search with feasibility constraints can address non-identifiability, and produce parameter sets with quantified confidence, suitable for shop-floor deployment [22]. Fourth, closed-loop planning, integrating in situ scanning to correct drift and update paths online should be built upon scan-to-path frameworks to harden workflows against environmental and system variation [17,56]. These four pillars (hybrid surrogates, active data, uncertainty-aware inversion, and closed-loop planning) are the differentiators most likely to move CSAM from lab-grade demonstrations to robust industrial practice. In parallel, design must continue to treat critical velocity, nozzle–gas–particle coupling, and path strategy as interdependent variables, while leveraging CSAM’s key advantage (solid-state impact bonding) and to functionalize temperature-sensitive substrates and preserve phases otherwise destroyed by fusion methods. This would allow the design phase to be framed as a multi-scale optimisation challenge (spanning geometric, thermo-fluidic, and microstructural levels), which can then be addressed through an increasingly integrated combination of physics-based models, data-driven surrogates, and autonomous planning.

4.2. Material Analytics and Characterisation for CSAM (RD2)

4.2.1. From Material Analytics in AM to Quality Assurance

Material analytics and characterisation in CSAM focus on linking process conditions with resulting microstructure, porosity, residual stresses, and mechanical performance. These methods establish the evidence base needed to validate design strategies and to guide optimisation of deposition parameters, heat treatments, and post-processing [78,79,80]. In metallic AM, this progression is marked by a shift from monolithic, isotropic design assumptions to designs that explicitly account for anisotropy and the characteristics of inter-track and inter-layer interfaces, whether in fusion routes (e.g., SLM) or solid-state routes (e.g., cold spray), with hybrid process chains leveraging the strengths of each process to meet structural requirements [80,81]. In this framing, DfAM is inseparable from metrology and materials characterisation, since the credibility of any design claim depends on reproducible links between processing parameters, local morphology, phases, and the resulting mechanical response, including failure modes [78,82]. For solid-state deposition, where bonding is driven by high-velocity impacts and severe plastic deformation rather than melting, geometric intent must be balanced with impact mechanics, critical velocity, particle-size thresholds, and post-deposition thermal history, all which shape defect populations (e.g., porosity). Therefore, design should not merely be treated as a geometry creation process, but as a coupled optimisation across feedstock state, trajectory planning, energy delivery, and heat treatment, underpinned by characterisation workflows that can detect anisotropy, residual stress, and bonding quality with sufficient fidelity to inform iterations.

4.2.2. CSAM: Solid-State Process, Properties, and Characterisation Challenges

As defined, CSAM is a solid-state process; in which particles accelerated by a propellant gas impact a substrate and consolidate via mechanical interlocking and metallurgical bonding under severe plastic deformation, enabling dense metallic builds at comparatively low temperatures, with reduced oxidation compared with fusion processes. Bonding requires exceeding a material-dependent critical velocity and size, which are material dependent and interact with particle morphology and oxide state. Atomistic and continuum studies underline trade-offs between critical size and velocity that directly shape process ranges and trajectory design [83]. Post-deposition heat treatment (HT) mediates recovery, recrystallization, and grain growth, often improving inter-particle bonding and ductility while relaxing work-hardening-driven hardness [78,84,85].

Design for CSAM is constrained by anisotropy across multiple scales, from splat and track interfaces to full layer stacks, influenced by impact angle, scan strategy, and local heat buildup. Empirical studies show that cross-hatching can mitigate anisotropy compared with simple bidirectional passes [86]. Porosity and insufficient inter-particle cohesion remain dominant defect modes, with mitigation through parameter optimisation and HT, yet persistent pores frequently originate during deposition from imperfect inter-particle contact and cannot be fully eliminated post-facto, underscoring the importance of precise primary process control [73,85,87]. Residual stresses are typically compressive, reflecting peening-like plasticity, but their quantification at component scale remains challenging, demanding careful selection and calibration of measurement methods.

4.2.3. Materials, Techniques, and Property Performance Relationships in CSAM

CSAM research is dominated by aluminium alloys, including Al6061 (gas-atomized vs. solution-treated), Al F357 (effects of powder heat treatment), Al7075 (deposit anisotropy), and advanced Al grades characterised for CSAM-specific applications [84,86,88]. Copper and its alloys are frequent subjects for anisotropy studies and composite development (e.g., Cu–Ti), while Inconel 718 freeform builds demonstrate structural potential and pure Ni has been probed via resonant ultrasound spectroscopy for magneto elastic behaviour. Mg coatings extend the palette and illustrate process versatility [80,89,90,91,92]. Collectively, these studies converge on the central design focus of CSAM for maximising impact-driven bonding and densification without incurring damage, while orchestrating scan strategies and HT to fine-tune anisotropy and residual stress toward target performance.

In CSAM, checking and analysing the material is central to quality control because it shows how process settings affect the microstructure and final properties. Most studies still rely on familiar tools like optical microscopy (OM), scanning electron microscopy (SEM), and microhardness testing. These methods are easy to use and provide quick results, but they depend heavily on the operator and the sample chosen, which makes it harder to automate or compare results between different studies [73,93,94]. Electron backscatter diffraction (EBSD) adds another layer by mapping crystal orientation and phases, which is especially useful for assessing heat treatments. Still, its accuracy depends on fine details such as step size, pattern clarity, and surface preparation. If these are not well controlled, the resolution drops, and predictive models based on the microstructure can fail, exposing a significant weakness for data-driven workflows.

Porosity is the main factor behind strength loss and crack initiation in CSAM. It is most often measured through 2D cross-section image analysis, while X-ray micro-CT is used when full 3D detail and non-destructive inspection are required. The method chosen has a real impact on measurement accuracy and on how process ranges are interpreted [2,73,95]. Heat treatment can reduce porosity, but defects caused by poor splat or inter-layer bonding during deposition often remain. This means HT should be considered as a secondary densification step rather than a primary solution. Hardness is typically assessed by micro or nano indentation, which reveals gradients linked to local work hardening and recovery. In metal-matrix composites (MMCs), however, interactions with the reinforcing phases can affect results, making it difficult to compare hardness across different materials [73,93].

Mechanical performance in CSAM is usually evaluated through tensile testing, often conducted in multiple directions to capture anisotropy, and complemented by fracture and fatigue assessments. In many cases, as-sprayed deposits need post processing to approach the mechanical response of materials behaviour, consistent with the microstructural findings noted earlier [4,73,95]. Standard adhesion tests, such as ASTM C633 (tensile adhesion test, TAT), are suitable for coating-type geometries but do not reflect the bulk nature of CSAM, where stress states and failure mechanisms differ significantly. This mismatch highlights the need for alternative specimen designs that better capture adhesion and bonding behaviours [73]. Residual stresses are typically compressive and are commonly measured using incremental hole drilling in line with ASTM E837-20. Other methods present trade-offs: thin-coating curvature (Stoney-type) approaches fail to scale to bulk builds; X-ray diffraction provides only near-surface stress information; and neutron diffraction, while capable of probing stresses deep within the material, is resource-intensive and limited to crystalline systems.

Alongside the standard techniques, newer analytical methods are being explored. Resonant ultrasound spectroscopy (RUS) has been deployed to extract elastic properties and magneto-elastic softening in cold-sprayed Ni, illustrating non-destructive paths to correlate stress state and bonding, although with calibration needs and material constraints [91]. Fractography remains central for clarifying failure modes and to diagnose interface weaknesses [87,90]. Meanwhile, machine-learning (ML) and computer-vision (CV) tools are beginning to deliver objective microstructure classification, defect detection, and property prediction, including similarity metrics for micrographs (e.g., Structural Similarity Index Measure; SSIM). However, barriers remain, such as limited high-quality labelled datasets (especially for rare defects), computational costs, challenges in integrating with industrial workflows, and a persistent interpretability gap for safety-critical decisions [2,62,87,96,97]. Integrating robust experimental measurement with ML-assisted analysis will be practical to mitigating anisotropy, optimising process monitoring, and improving strength, ductility, and durability in CSAM components, provided data and evaluation protocols are rigorous.

Within this evidence base, the materials investigated, and the associated characterisation methods together form a coherent picture. Aluminium alloys are most common: Al6061 appears repeatedly in atomized and heat-treated powder conditions, Al F357 is used for powder HT effects on microstructure and mechanical properties, and Al7075 is used to examine anisotropy in deposits. Beyond these, advanced Al alloys have been systematically characterised for CSAM [82,84,88,89]. Ti-6Al-4V is the second most-studied CSAM alloy owing to its aerospace relevance. Studies link powder morphology to coating properties, detail heat-treatment-driven microstructural progress and demonstrate hybrid CSAM–SLM routes that broaden the process design space [81,85,87]. Copper and its alloys support anisotropy analyses and composite development. For example, Cu–Ti composites achieving almost 15% elongation after 400 °C HT while maintaining tensile strength above 270 MPa, a combination that illustrates the ductility gains available via HT without catastrophic strength loss [90]. Inconel 718 free-standing components have reached tensile strengths close to 338 MPa after optimisation, demonstrating the potential for structural applications, while pure Ni has served as a platform for resonant ultrasound spectroscopy (RUS)-based elasticity and stress interrogation. Coatings of magnesium and other light alloys demonstrate the extension of CSAM to more reactive systems [80,91,92].

SEM is for particle morphology, cross-sections, and fracture surfaces. Energy dispersive spectroscopy (EDS) augments elemental interpretation, while X-ray diffraction (XRD) supports phase and crystallographic analysis. EBSD offers grain structure, orientation and bonding features, and optical microscopy is still widely used for general microstructural features such as dendrite size [80,84,87,89]. Nanoindentation has emerged as a flexible method applicable to both feedstock and consolidated material. Vickers microhardness is consistently deployed, tensile testing quantifies strength and ductility, fatigue tests explore durability, and fractography remains essential for diagnosing failure mechanisms [80,87,89,90,98]. Key microstructural concepts include severe plastic deformation at particle interfaces and localised solid-state bonding. Heat treatment generally promotes recrystallization (sometimes accompanied by grain growth, depending on material), improving bonding and ductility. Anisotropy remains a recurrent feature, with equiaxed particle footprints in the XY plane, contrasting with lens-like cross-sections in XZ/YZ planes. Cross-hatching scan strategies have been shown to reduce these anisotropic effects compared with simple bidirectional scans [80,84,89,92]. Defects in CSAM are often linked to porosity and weak bonding between particles. Annealing can reduce porosity up to approximately 30% in specific settings, while irregular powder morphology has sometimes produced lower porosity than spherical powders, opposite to trends in fusion-based AM, reflecting the nature of CSAM [73,87]. Process property relations are now sufficiently consistent to inform parameter linkage. For example, higher propellant gas temperatures (almost 800 °C) improve particle deformation and bonding but remain material-specific and sensitive to feedstock and trajectory choices [90].

This study demonstrates strengths such as broad coverage across metallic systems, the use of multiple methods (microscopy, diffraction, indentation, and mechanical testing), and an increasing consistency between experimental observations and mechanistic or atomistic models [83]. Limitations include frequent single-material and single-parameter studies that limit generalisation, challenging quantification of residual stresses, and in some cases small sample sizes in various reports [3,91]. From an application perspective, the evidence indicates that CSAM can be used for structural parts when supported by careful process optimisation and heat treatment. Hybrid approaches offer pathways to geometric complexity with microstructural control and functionally graded properties. Future directions include multi-material and hybrid builds, advanced non-destructive evaluation, and physics-based analytics that can translate microstructure to reliable property predictions.

4.2.4. Data-Driven and Physics-Informed Analytics for CSAM: Porosity Prediction and Surrogate Modelling

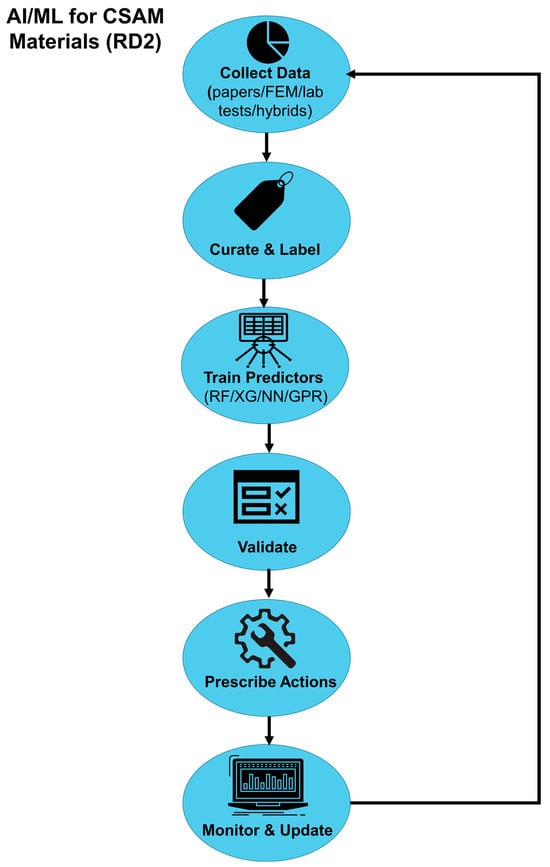

On porosity, ref. [20] assembled a “mega-dataset” by mining approximately 35 papers to extract a few hundred porosity labels with around 14 process and material features, emphasising single-powder cases for completeness. Measurement diversity across CSAM studies is useful, but differences in testing protocols, imaging methods, and porosity definitions introduce noise and cross-study variation that weaken model reliability. The study utilised tree aggregate models (RF, XG, and CatBoost), which are robust to missing distributional roughness. These models can handle absent values but cannot correct systematic bias or inconsistent scaling across sources, which must instead be addressed during dataset curation. After feature selection, imputation, and 10-fold cross-validation (CV), several models keep average errors within around 0–2% porosity on a held-out split, and the best RF reaches RMSE around 0.8%, notably better than common image-analysis repeatability. However, random data splits can sometimes inflate performance via information leakage from the same paper (known as same-paper context leakage), and the authors also note that using grouped CV (e.g., leave-one-paper-out) is a more reliable and fairer test of generalisability. Moreover, the reported uncertainties in gas temperature and pressure (about 100 °C and around 1 MPa) should be properly included and propagated (e.g., via Monte-Carlo simulations or interval predictions) rather than treated as exact single values. Despite these limitations, the work delivers a fast, millisecond-scale porosity predictor and a carefully prepared ML workflow that is well-suited for screening and process condition exploration, provided that grouped CV, feature-importance stability analysis, and prospective validation on new laboratory data are performed before deployment. The key insight is that data evaluation design on model choice, and that uncertainty quantification is necessary to map predictions onto process decisions [20]. In this context, Figure 5 shows the minimal AI/ML pipeline, referencing porosity, adhesion, and stress analytics.

Figure 5.

AI/ML pipeline for CSAM materials.

For physics-informed surrogates targeting particle flattening and penetration, models for micro-features linked to adhesion have been developed and trained on hybrid datasets with approximately 70% FEM impacts and around 30% SEM measured experiments across metals (Cu, Al, steel, and Ti) and polymers (PEEK, ABS, PA66) [12,21,35]. Hybridization reduces data collection cost, but combination of simulation and experimentation can cause biased mappings unless treated explicitly via multi accuracy or domain-adaptation strategies [21,35]. Their models use minimal input, impact velocity, and yield strengths of powder and substrate, which capture first-order mechanics. However, they leave out other particle characteristics (size, shape, temperature, oxide condition, and impact angle), limiting predictive accuracy. On FEM-only data, GPR achieved the lowest test errors, especially for penetration, reflecting smooth relationships in simulation space. However, when both simulated and experimental data were combined, a small (Moderately complex) model neural network performed better than GPR for predicting penetration, while linear regression slightly outperformed the others for flattening. This outcome suggests that the flattening behaviour may depend on only a few key variables (i.e., has limited effective dimensionality), or that the remaining differences between simulation and experiment (residual simulator biases) can be well captured by a simple linear model. Ref. [35] study evolves compact deep networks via genetic algorithms: a WNN for flattening reaches around 0.73% RMSE with approximately R2 = 0.92, while a TNN for penetration performed poorly (RMSE ≈ 2.6%, R2 ≈ 0.60) consistent with penetration’s greater nonlinearity and sensitivity to missing descriptors. The authors argue that DL surrogates can replace many FEM runs and enable rapid exploration of new material pairs. As with porosity, safety-critical adoption requires calibrated uncertainty and error budgets defined relative to adhesion thresholds, along with grouped-CV by material and substrate family and validation tests on unseen powders and substrates. The critical insight here is that input sufficiency and evaluation protocols, not just model architecture, determine practical utility, and that multi-output, physics-constrained models with active learning to target high-value experiments are likely to deliver larger gains than simply increasing network complexity.

Synthesis indicates that well-prepared large datasets can power fast porosity prediction and that hybrid simulation plus experiment surrogates can estimate adhesion features, but the main risks are domain shift (simulation-to-experiment), inconsistent labels from mined papers, missing physical descriptors (size, temperature, oxide state, angle), and bias evaluation from random splits. For CSAM designers and process engineers, a pragmatic path forward is clear. First, adopt grouped cross-validation and prospective validation (e.g., leave-one-paper-out, lab, material) to test transfer. Second, use multi-accuracy physics-guided learning to bridge FEM–experiment gaps. Third, expand descriptors with particle morphology, thermal state, oxide condition, and impact angle. Lastly, implement calibrated uncertainty to ensure that predictions map to porosity and adhesion thresholds and associated decision policies [20,21,35]. In parallel, robust, standardised measurement pipelines, covering porosity imaging, EBSD step size, pattern quality, and residual stress calibration are essential to reduce label noise and ensure that ML-based analytics are transferable across labs and material systems [2,3,94,97].

4.3. In Situ Control and Monitoring in CSAM (RD3)

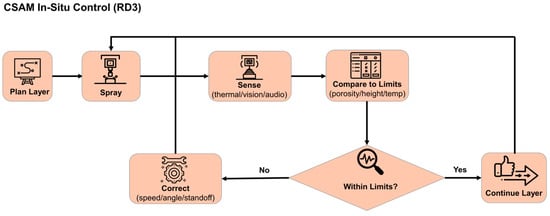

The move toward adaptive and self-aware AM has placed in situ sensing, monitoring, and control at the centre of contemporary research and industrial adoption. Historically, AM quality assurance relied on post-process inspection. However, the demand for higher build rates, certification of critical parts, and reduced material waste has shifted focus to real-time observation and intervention during the build itself. Across different AM processes, the core objectives are consistent, i.e., maintain process stability, detect and prevent defects as they form, and ensure repeatability through feedback loops that connect sensors to models and control [76,96]. The sensors include thermal, optical (vision), and acoustic, while the algorithms range from rule-based diagnostics to ML-based estimation and optimisation. The key insight is that sensing alone is insufficient and the real benefit comes when measurements are combined with models and used to trigger timely and stable control actions. Such a workflow with basic in situ monitoring, decision, and action steps is shown in Figure 6.

Figure 6.

In situ control loop for CSAM.

This integration remains uneven across AM processes and is often limited by data quality, complexity of models, and the challenges of system integration. However, as CSAM moves from coatings toward bulk builds, in situ control and monitoring become crucial for stabilising a process dominated by high momentum particle jets, impact bonding, and constantly changing surface geometry [2,99]. Compared with melt-based AM, CSAM’s solid-state nature removes melt-pool signatures but introduces process-specific challenges, such as measurement in harsh, particle-laden flows, deposition efficiency that depends on particle trajectories, heat accumulation tied to geometry and path, nozzle wear, and tight requirements for nozzle standoff and traverse speed to achieve uniform layers [2,9,100]. These features limit direct transfer of sensing and control strategies from thermal spray or laser powder-bed fusion. They also highlight the need for robust, high-signal-to-noise sensors, fast data reduction, and low-latency control methods adapted to supersonic flow and impact mechanics.

CSAM monitoring and control remain early-stage, with advances in multi-modal sensing (thermal, optical, acoustic, geometric), CFD-based modelling with empirical surrogates, and emerging AI/ML decision systems. The key challenge and opportunity lie in integrating these three components [2,25]. Thermal sensing is the most established approach. Infrared pyrometers and thermal cameras provide real-time surface temperature data. However, their calibration is complicated by emissivity sensitivity and by changes in surface conditions, especially over complex geometries and under varying oxidation states [100]. Optical diagnostics, notably the HiWatch HR platform, use sizing-particle tracking velocimetry (S-PTV) to measure in-flight particle velocities, trajectories, and size distributions and to produce 2D velocity scan maps that operators can use for process monitoring [26,101]. These systems provide detailed insight into jet quality but face harsh environment constraints such as particle occlusion, limited measurement volumes, and fouling of observation windows.

In practice, airborne acoustic sounds in CSAM are generated within a supersonic jet environment where turbulent mixing noise, shock-associated noise, and screech can mask weaker process cues. Nozzle wear and geometry shift further alter the sound pattern and direction, making exact monitoring hard and pushing the need for more advanced metrology and feature engineering. Recent CSAM work shows that low-frequency (0–20 kHz) microphones can still notice changes in nozzle gas pressure/temperature, powder feed rate, and nozzle wear via power-spectrum analysis, and that sliding-window derivatives of power in the time domain show slow (e.g., throat wear) versus sudden (e.g., delamination) problems, while being fairly unaffected by microphone position once power is balanced. To handle noise and overlapping sources more widely in AM, reviews highlight background-noise removal and strong feature picking to separate process-important signals from time-changing environmental effects [102].

To strengthen reliability, other machining processes (especially milling and turning) also fuse acoustic emission (AE) with vibration/force signals (and process settings) for quality prediction. In precision grinding, mixed deep models that use both sound emission and vibration signals (plus process settings) reach very high accuracy for surface-roughness (SR) prediction. For example, a DBO-optimised 1D-CNN-LSTM showed R2 ≈ 0.991, with MAE ≈ 0.005, RMSE ≈ 0.0067, and MAPE ≈ 4.9%, while an SVR model using multi-domain features from CEEMDAN and PCA merging reached R2 ≈ 0.995 with MAE ≈ 0.002 and RMSE ≈ 0.005; both clearly gain from adding grinding settings alongside sensor signals [103,104]. Multi-sensor combination also improves tool/state classification. For example, combining AE, force, and acceleration for grinding-wheel wear recognition resulted in over 92% accuracy with a better SVM [105]. Beyond prediction, explainable ML helps show what the combined models learn. In machining, a sequence-to-sequence fusion network linked acoustics and vibrations to machining-power signals with only 2.5% error (vs. 5.6% from acoustics alone and 8.2% from vibration alone), and Integrated Gradients showed which time regions/signals most shaped the predictions [106].

Similarly in AM, XAI (Grad-CAM on a 1D-CNN) highlighted frequency bands (≈5–6.5 kHz; ≈10–12.5 kHz) that correlate with laser motion and printing position in LPBF while yielding strong classification rates, demonstrating how physically meaningful spectral regions can be surfaced from acoustic data [105]. Taken together, these results indicate a clear opportunity for CSAM to combine aeroacoustics with complementary sensors (e.g., vibration, force, thermal) and adopt interpretable AI to ensure that anomaly flags and quality predictions can be linked back to specific, physically plausible frequency-time patterns, improving both reliability and insight.

Moreover, geometric sensing has advanced through laser profilometry. A custom nozzle-tracking system used in situ track-shape evolution across the spray duration, providing real-time insight into the deposition efficiency, layer stability, and demonstrating that skewed Gaussian functions represent track profiles better than symmetric alternatives [107]. Other systems, such as a Keyence LJ-X8000 (Keyence, Japan) mounted on the robot for pre-spray scans and per-layer captures, detecting under-build or heat accumulation and triggering path adjustments or pauses as needed, demonstrate a practical closed-loop system even without ML, with strong potential for future uncertainty handling and predictive control [17].

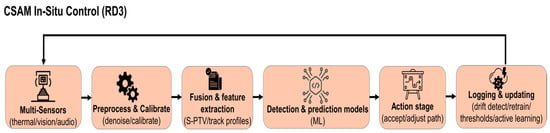

At the system level, integrated low-cost Industrial Internet of Things (IIoT) setups that stream optical and thermal images along with N2 temperature, pressure, flow, and robot triggers, have been demonstrated for layer-wise quality assurance. Lighting setups are tailored (side lighting for porosity and geometry and ring lighting for oxidation), and downstream CNNs deliver very high F1 scores near 0.998–0.999 on internal splits, including 100% accuracy on a CuZn30 test set [38]. While cost-efficiency and open-source tooling are impressive, such high metrics invite caution about data leakage or overly easy test conditions. Long-term stability, lighting stability, and retraining schedules must be validated for production deployment. To reduce fragmentation across sensing modalities, Figure 7 presents a simple multi-sensor fusion action pipeline for CSAM.

Figure 7.

Monitoring and AI pipeline for CSAM.

4.3.1. Modelling Approaches: CFD, Surrogates, and AI/ML Integration

Computational fluid dynamics (CFD) remains the dominant mechanistic route for understanding gas dynamics and particle motion in CSAM. Two-dimensional axisymmetric models, often based on one-dimensional isentropic gas-flow relations with Lagrangian particle tracking, can predict particle acceleration, temperature histories, and exit velocity distributions and show within 5–10% agreement with experimental measurements [6,7,15,61,63,108,109,110].

Empirical approaches, especially Response Surface Methodology (RSM) with Central Composite Designs remain prevalent and often deliver quadratic regressions with R2 > 0.96 for parameter screens and trade-off studies [61,63]. Fast, one-dimensional analytical models can describe deposition ranges as functions of pressure, temperature, particle size, and standoff. Recent work introduced clear metrics, maximum ideal particle velocity (γ), acceleration capacity (β), and free-jet deceleration (α), to compare process regimes and nozzle designs efficiently [6]. For geometry, coating-thickness simulators exhibit reliable accuracy on curved surfaces and skewed-Gaussian track models outperform symmetric fits [5,107].

AI/ML usage is expanding in both modelling and monitoring. Gaussian Process Regression with physics-informed mean functions that include prior knowledge about surface geometry (geometric priors) improve overlapping-track profile prediction by blending these geometry-based assumptions and flexible residual learning [13]. Combination of Latin Hypercube Sampling, neural networks, and genetic algorithms achieve particle velocity optimisation with almost 4% error, underscoring the efficiency of hybrid design-of-experiments plus machine learning [111]. Edge-deployed computer vision advances, combining visual transformer-based video super-resolution with fully convolutional networks, report 96.34% accuracy for multi-object extraction at near 118.83 ms inference times, showing that feasibility of real-time, high-resolution perception at the toolhead is feasible [112]. In broader AM, deep mixed-effects frameworks that integrate neural networks with random-effects terms have improved real-time thermal monitoring and anomaly detection, a transferable concept for CSAM where nozzle, powder, and path introduce layered variability [113].

Beyond modelling, pre-run recipe predictors for cold spray porosity and quality have matured. On a 35-sample Cantor-alloy dataset (22 literature + 13 new records, with five preset descriptors: gas type, gas pressure/temperature, powder type, standoff), linear-kernel SVM and ordinary squares outperform deeper learners (PCC ≈ 0.85 and 0.83; RMSE ≈ 2.1% porosity), and SHAP analyses prioritise gas and powder type, then temperature and standoff. However, the small, mixed dataset invites heterogeneity and overfitting risks, making leave-one-paper-out validation more appropriate than random cross-validation for deployment claims [39]. On a larger 227-record literature dataset covering 35 studies and seven descriptors, decision trees achieved R2 ≈ 0.75 (MAE ≈ 2.9%) on ten unseen cases, whereas linear regression lagged (R2 ≈ 0.27). It should be noted that testing on only ten cases is statistically weak, and label noise and inconsistent protocols limit achievable accuracy [16]. These models are millisecond-fast and can help filter out risky parameter settings before a run, but they are not substitutes for in situ sensing and should also provide calibrated uncertainty to avoid false “go and no-go” outcomes.

4.3.2. In Situ Monitoring and First Steps Toward Closed-Loop Control

Signal and vision-based irregularity detection illustrates the feasibility of layer-wise fault detection and response. By attaching a stethoscope on the powder hopper to capture clean internal vibrations, one study converted audio to log-mel spectrograms and used an autoencoder for anomaly detection, followed by a CNN to classify “no powder,” “clogging,” and “no gas.” On short blind tests, recall reached 100% with near 97% accuracy for the stethoscope signal, while an external microphone recalls only near 34%, showing the clear SNR advantage of mechanically coupled sensing [34]. Integrated-gradient attributions highlighted important frequency bands at 600–1600 Hz, offering interpretability, but portability across guns, powders, and rigs and lifecycle issues (mounting, calibration, clog-detection delay) remain to be proven.

Thermal forecasting via ThermoAnoNet uses a single FLIR A655sc (50 fps) and educes each frame to average substrate temperature. An N-BEATS forecaster trained with Bayesian-tuned thresholds, detects mid-build feed-rate jumps with near 96% accuracy (F1 ≈ 0.97) on validation and near 90% (F1 ≈ 0.94) on eleven blind tests, typically within almost 0.3 layer; performance degrades for subtle 2–4 rpm changes (recall ≈ 0.60) [19]. Temporal-forecast thresholds performed better than RNN, Temporal Convolutional Networks (TCN) and statistical baselines in F1 and detection delay without early alarms, but emissivity calibration, lens contamination, and camera placement remain critical for robustness.

Most importantly, closing the loop has been demonstrated in practice, with robot-mounted laser profilometry enabling pre-layer scans and per-layer checks. When heat build-up or under-build is detected, trajectories are adjusted or paused in real time, and data feeds back for process and path optimisation [17]. Even without ML, this architecture delivers layer-wise sensing and immediate corrections. Moreover, adding uncertainty thresholds and learned predictors could reduce false stops and give more accurate corrections.

Decades of work in thermal spray show that nonlinear links between parameters, in-flight particle states, and deposit responses are learnable and controllable. Early neural networks mapped these relationships [114], later embedded in process-control equipment for adaptive responses [115], and eventually produced repeatable builds (e.g., thin-walled moulds) in wire-arc spraying [116]. More recently, big-data frameworks have supported quality monitoring and laid pathways to adaptive control, contingent on standardised, high-quality data pipelines [117]. In CSAM, automated path and trajectory planning for repairs show the link between sensing and decision-making for in-process optimisation, though long-term robustness under drift, wear, and environmental variation remain underreported [70].