Abstract

Flexible manufacturing systems (FMS) are highly adaptable production systems capable of producing a wide range of products in varying quantities. While this flexibility caters to evolving market demands, it also introduces complex scheduling and control challenges, making it difficult to optimize productivity, quality, and energy efficiency. This paper explores the application of digital twin technology to tackle these challenges and enhance FMS optimization and control. A digital twin, constructed by integrating simulation models, data acquisition, and machine learning algorithms, was employed to replicate the behavior of a real-world FMS. This digital twin enabled real-time dynamic optimization and adaptive control of manufacturing operations, facilitating informed decision making and proactive adjustments to optimize resource utilization and process efficiency. Computational experiments were conducted to evaluate the digital twin implementation on an FMS equipped with robotic material handling, CNC machines, and automated inspection. Results demonstrated that the digital twin significantly improved FMS performance. Productivity was enhanced by 14.53% compared to conventional methods, energy consumption was reduced by 13.9%, and quality was increased by 15.8% through intelligent machine coordination. The dynamic optimization and closed-loop control capabilities of the digital twin significantly improved overall equipment effectiveness. This research highlights the transformative potential of digital twins in smart manufacturing systems, paving the way for enhanced productivity, energy efficiency, and defect reduction. The digital twin paradigm offers valuable capabilities in modeling, prediction, optimization, and control, laying the foundation for next-generation FMS.

1. Introduction

The realm of intelligent manufacturing necessitates the seamless fusion of production automation and digital transformation. This fusion entails the harmonious integration of industrial machinery with cutting-edge sensor technologies, powerful computing platforms, and robust communication systems. This synergy yields a transformative enhancement in both production efficiency and overall management.

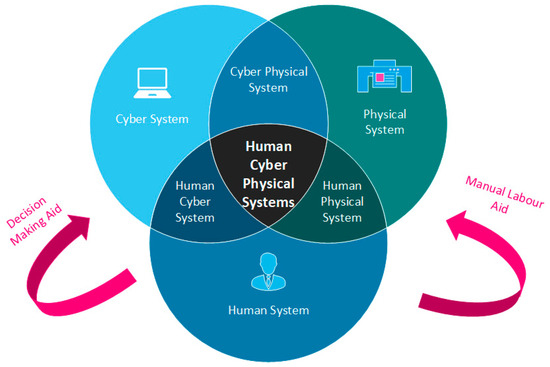

The smart manufacturing equipment composition has three different cores, namely human core (labor, technicians, engineers, managers, CEO), physical core (equipment, hardware, tools, workstations) and cyber core (front end, back end, logical framework, services, APIs, DevOps). These cores combine and create the Human–Cyber–Physical System (HCPS) as depicted in Figure 1, which consists of three system layers, the Cyber–Physical System (CPS), the Human–Cyber System (HCS), and the Human–Physical System (HPS). Most of the technologies of industry 4.0 such as Artificial Intelligence (AI), Cloud Computing, Internet of Things (IoT), cyber security and big data are associated with the CPS layer [1]. These technologies enhance productivity, flexibility, observability, and efficiency.

Figure 1.

Human–Cyber–Physical Systems.

The assimilation of these technologies into the current state of the industry is restrained by repeatedly upgrading the manufacturing resources, training the operating staff, and balancing the workload while in transition. It is especially expensive for legacy systems. This implementation barrier can be overcome by using relatively new technology “digital twin (DT)”. DTs can incorporate real-time monitoring, enhanced efficiency, and safety, predictive maintenance, and scheduling, scenario and risk assessment, personalization, and customization [2]. The most relevant ability of the DTs is that it can assimilate all the technologies of industry 4.0, making it the prime subject of research and development. Though different research has been undertaken on the topic, it is still in its infancy, especially DTs for flexible manufacturing system (FMS).

2. The Literature Review

For the literature review, we analyzed papers from IEEE Xplore, Springer, ScienceDirect and Google Scholar. The keywords we searched for were “Digital Twin in Manufacturing”, “Smart Cyber-Physical Systems”, “Flexible Manufacturing Systems”.

2.1. The Literature on Digital Twins

A tremendous amount of research is being performed on DTs; for example, some researchers are working on its methodology such as the authors in [3], who worked on skin models for DTs for generic use. and the authors in [4] developed geometrical assurance for DTs using FEA techniques in assemblies. Further, refs. [5,6,7,8] applied database techniques on data retrieved from DTs, while the authors in [9,10,11,12,13] worked on optimization of operation of robotic manipulators through DTs. Tao et al. [14], integrated industrial internet into DT and developed the DT-II framework linking intra-enterprise services and value chain. In [15], Tao worked on smart customization through DT. Later, Tao [16] presented the 5D model for DT in job shops. The model is based on physical entities, virtual entities, services by these two domains, data from all the three domains and finally connections. Tao et al. [17] presented the idea of big data and DT in the paradigm of smart manufacturing.

2.2. The Literature on Human–Cyber–Physical Systems in Context of Industry 4.0

The literature on industry 4.0 and smart manufacturing highlights several innovations aimed at enhancing flexibility, automation, and real-time control through the integration of advanced technologies. Chuang et al. (2021) [18] investigated the use of digital twins and cyber–physical production systems (CPPS) to enable a workpiece-driven production system that increases adaptability in job shop environments. Salazar et al. (2020) [19] focused on the role of multi-agent systems in CPPS, emphasizing their ability to improve modularity, reconfigurability, and flexibility in manufacturing processes. Pronost et al. (2021) [20] reviewed digital twin applications across various stages of the product lifecycle, emphasizing their potential for real-time monitoring and predictive maintenance, though integration challenges across the lifecycle remain. Havard et al. (2020) [21] proposed a scalable data architecture to enhance interoperability among CPPS components, particularly using IoT and digital twins for improved decision making. Jiang (2018) [22] presented an 8C architecture that extends existing frameworks by incorporating customer involvement and product lifecycle data management, further enhancing horizontal integration in smart factories. Wang et al. (2015) [23] introduced a hybrid data-on-tag approach for decentralized control in flexible smart workpiece manufacturing, leveraging RFID to improve real-time data handling and reduce network dependency. Wang et al. (2017) [24] developed a graphical deduction model to enable real-time production control in IoT-enabled smart job shops, ensuring better coordination of manufacturing resources and reducing the impact of production disruptions. Lastly, Zhang et al. (2020) [25] proposed a service-oriented digital twin framework for discrete manufacturing workshops, showcasing how real-time monitoring and edge computing can enhance human–machine interaction and improve overall production efficiency. Collectively, these studies highlight the transformative potential of digital twins, IoT, RFID, and multi-agent systems in smart manufacturing, though challenges remain in scalability, lifecycle integration, and system interoperability.

2.3. The Literature on Digital Twin Application in Manufacturing

As our focus is on controlling the manufacturing system through DTs, the research on the controlling applications and manufacturing systems is targeted and listed. For the control of tool, machine, equipment, system through DTs, refs. [26,27,28,29,30,31,32,33,34,35,36,37,38] worked extensively to use different techniques and methods providing extraordinary results. The DT control framework proposed by Zhang et al. [26] was the Synchronized Production Operation System (SPOS), using Opti-State Control (OsC). Ding et al. [27] divided the system into the Physical Shop Floor (PSF) and the Cyber Shop Floor (CSF) and then linked both to achieve the working of the DT-enabled smart cyber–physical production system. Zhuang et al. [29] used the Markov chain to model the DT-based Visual Monitoring and Prediction System (DTVMPS). The authors in [30,31] worked on the augmented reality (AR)-controlled DT in additive manufacturing, controlling various parameters at the machine level. Zhang et al. [32] studied a semi-electronic assembly line, through DT using the ATC, resulting in the optimal reconfiguration for each subsequent product change. Elisa et al. [33] linked manufacturing execution systems (MES) with DT. Samuel and David [39] devised a pedagogic methodology to use DT learning. Guo et al. [40] developed a DT model for an FMS of an air conditioner lines for the purpose of collecting data and optimizing the layout and logistics. Fan et al. [41], described the full lifecycle functional services of FMS in DT. Fan proposed a digital twin modeling concept of GHOST, which represents Geometric information, Historical samples, Object attribute, Snapshot collection, and Topology constraints. GHOST will capture the data and transmit it to the cloud for documentation. These data are then used for visualization of the FMS.

2.4. Digital Twin Technology in Legacy Systems

Legacy systems are outdated manufacturing systems that are still in use. This section will analyze the financial constraints, training requirements and integration issues along with strategies to overcome them.

Cost Implications: Upgrading legacy systems to incorporate digital twin technology often involves significant financial constraints. Initial investments can be substantial, encompassing hardware, software, and infrastructure upgrades. To mitigate these costs, organizations should conduct a comprehensive cost–benefit analysis that highlights the long-term benefits of digital twin implementation, demonstrating its economic viability.

Training Requirements: Adequate training for personnel is essential for the successful adoption of digital twin technology. There may be a skills gap, as employees may not be familiar with advanced technologies. To address this, organizations should consider partnerships with educational institutions for specialized training programs and implement on-the-job training initiatives to develop the necessary skills within the workforce.

Integration Issues: Integrating digital twin technology with existing legacy systems can present technical challenges, including compatibility issues and the complexity of data migration. Organizations can benefit from analyzing successful case studies that illustrate best practices for integration. Establishing a phased integration approach allows for gradual implementation, minimizing disruptions and providing opportunities for adjustments based on real-time feedback.

Proposed Strategies:

- Incremental Implementation: Begin with pilot projects to demonstrate the value of digital twin technology before committing to full-scale adoption.

- Stakeholder Engagement: Involve key stakeholders early in the process to ensure alignment with organizational goals and to gain support for the transition.

- Continuous Evaluation: Establish a framework for ongoing assessment and adjustments throughout the integration process to adapt to emerging challenges and ensure continuous improvement.

By addressing these barriers and implementing strategic solutions, organizations can effectively leverage digital twin technology within their legacy systems, enhancing operational efficiency and driving innovation.

2.5. Literature Review Conclusion and Overview of Research Gap

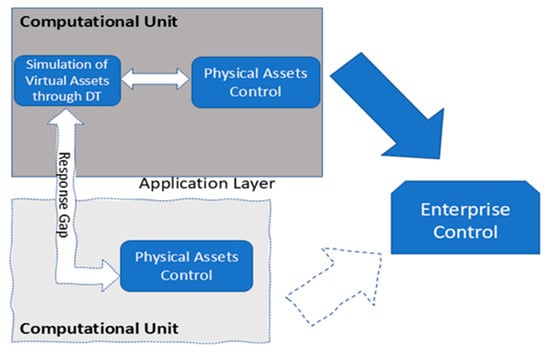

The summary of Table 1 of the literature research suggests that a substantial portion of the purported digital twins discussed in the literature primarily revolve around the replication of real systems in a synchronized manner, notably lacking the incorporation of feedback mechanisms that influence the control systems of the equipment. In scholarly discourse, these instances are commonly denoted as digital shadows (DS). The traditional DT systems have two distinct computational domains as depicted in Figure 2. The first domain uses DT to grab the data from the physical system and process it for decision making. The 2nd domain executes the decision strategy on the operations. These two spheres are separated by various software layers and different hardware implementations.

Table 1.

The Literature Review.

Figure 2.

The Traditional Approach vs. the Proposed Approach.

While in our approach, we have a single DT system that has seamless bi-directional communication between physical and virtual spaces. Physical space provides data directly to virtual space and the virtual space processes and through friendly user-interface directly controls the operations of the individual machines as well as the of the overall FMS. The major contributions of this paper are the following.

- Proposes model predictive control algorithm leveraging digital twin for real-time optimization.

- This methodology offers a viable course for the transformation of legacy systems into intelligent manufacturing systems considering that legacy systems represent 60% of market share.

- Furthermore, this proposition is particularly tailored for flexible manufacturing systems, effectively encapsulating the entire factory environment.

- This validates the approach via computational experiments, achieving 14.53% productivity gain, 13.9% energy reduction, 15.8% quality improvement and OEE improvement by 33%.

3. Methodology

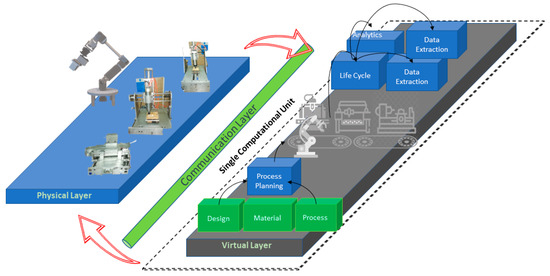

Figure 3 presents the proposed methodology of this paper. Starting from the left, the platform depicts the physical space, containing all the physical assets. Physical assets are the components of FMS such as a robotic arm, conveyer belt, machining workstations and AGVs. The next platform depicts the virtual layer containing virtual assets as well as various modules for manufacturing control. It can be seen from the figure that the virtual assets of the DTs as well as the controlling modules are both on the same computational unit reducing the application layer gaps as well as hardware gaps. In between is the communication layer, which is responsible for data import as well as instruction export between physical layer and virtual spaces. The module in the virtual space controls the physical assets while the data from the various sensors mounted on the physical assets transmit physical data to the virtual space.

Figure 3.

Proposed Methodology.

3.1. Modeling of the Physical Assets

The first step in the DT process is constitution of virtual assets by replicating the physical assets. The virtual modeling of physical assets is performed in Autodesk 3ds Max for precise and accurate functional and assembly representation.

For the application of the DT process, the Unity3d platform is chosen as most of the literature refers to it. Unity3d is used as the graphics engine for the DT system while C# is the inference engine. Scripts are developed to mimic the functionality of the physical assets according to part program entered by the operator.

In the Virtual Reality (V.R) and Augmented Reality (A.R) fields, it is necessary to transform physical coordinates into virtual coordinates, which is performed mostly by quaternions, a mathematical object that can represent rotations in three dimensional space. The notations for quaternions are in Table 2.

Table 2.

Notations for Quaternion.

The transformation of physical coordinates into virtual coordinates is performed through the following mathematical expressions. Let denote the unit normal vectors of the real world and cyberspace.

where ‘q0’, ‘q1’, ‘q2’ and ‘q3’ represent the components of quaternion “Q”; moreover, “q0” is the scaler part and the latter are vector parts. These can be calculated using

where represents the vector that needs to be rotated using quaternion-based rotation,

( × ) represents the cross product between two normalized vectors and .

‖( × )‖ represents the magnitude (norm) of the cross product.

The angle θ represents the angle between vectors and , and it is calculated using the dot product ·.

Finally, the quaternion is used for transformation using the following formula.

is the cyber coordinate point while P is the physical coordinate point, which is converted through the transformation matrix.

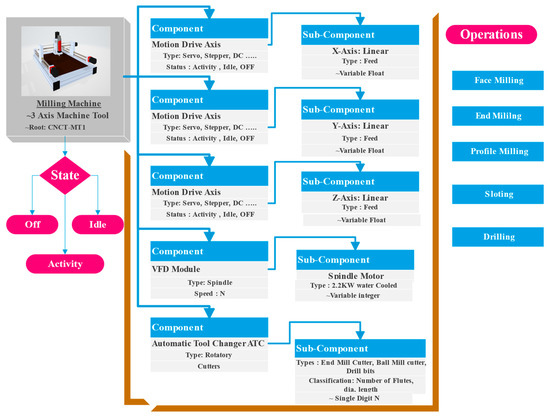

3.2. Hierarchical Modeling and Functional Simulation

In the development of our digital twin for milling machines, a hierarchical approach is employed to authentically model each machine tool, breaking it down into distinct components and joints. As illustrated in Figure 4, the milling machine model is structured into discrete machine objects, with its functional assembly encompassing five primary components: three motion drive axes, a spindle drive, and an Automatic Tool Changer (ATC). This modular architecture is further enhanced through the integration of submodels, rooted within a logical engine, enabling precise control and capture of object motion within a 3D space.

Figure 4.

Machine Objection Description of Milling Machine Containing its States, Component Roots and Processes.

Within this framework, every machine object is equipped with a standardized set of operations within the logical engine system. These operations encompass various functionalities, including slotting, end milling, and more. Notably, the digital twin (DT) machine model diligently logs pertinent parameters such as position and temperature, alongside detailed records of operations like slotting or milling. These logged data points prove invaluable, serving as essential inputs for machine learning algorithms or cloud-based computations, thereby contributing to continuous improvement and optimization.

The description of each machine object encapsulates its operational states—off, idle, or active—providing a comprehensive overview of its status. In tandem, the model description outlines an array of operations that can be performed on the specific machine object, offering a comprehensive roadmap for potential utilization and optimization.

The machines in virtual domain are placed in the same topological order as in physical space. This topological placing controls the composing of topological information such as raw material transportation, work in process and other material handling operations. Through these factors, system operations such as scheduling and work balancing can be monitored and optimized.

3.3. Controlling Overview

This section details the various types of manufacturing equipment and their control through digital twin.

3.3.1. Machine Control

The basic element of the FMS is the workstation. A workstation can be a machine center, a packaging machine, or an assembling unit, etc. Although there is a clear shift of technology from 2018 onwards for example STEP NC, but still, most of the market share is legacy systems. Legacy systems are those that still use relatively old technology. For these workstations, a controller is required that would work according to the standards discussed below.

The machine module in the logic layer of the controller is designed according to industrial standards such as ISO 841:2001 [42] and ISO 6983-1:2009 [43]. The mentioned industrial standards are integrated into the inference engine through a designed interpreter to enable the DT system for simulation and execution of the G and M commands.

The operator can enter part program via G and M codes in the interactive GUI command panel. The interpreter in the backend of the GUI will interpret the manufacturing actions from the given codes, which can be simulated in the virtual domain, and can be observed in the GUI. The same manufacturing actions are then sent to physical machines to perform manufacturing processes.

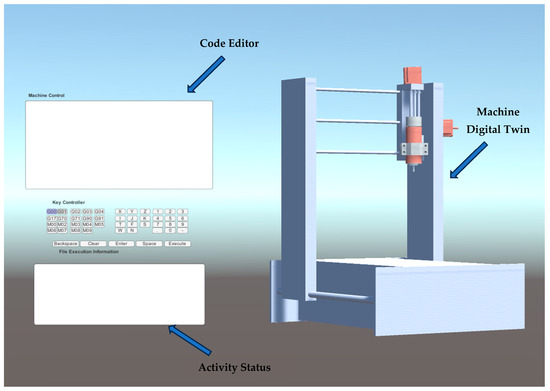

At the beginning, the system captures the part program associated with a selected machine through a dedicated code editor shown in Figure 5. This program, linked to the machine’s current activity status, serves as the basis for subsequent actions. An interpreter parses the captured program, extracting key machine parameters relevant to the specified processes and activities. These extracted parameters are then transmitted to a signal generator. This generator, guided by a communication protocol, sends the parameters to the physical machine for execution and simultaneously transmits them to the VR model for visualization.

Figure 5.

Machine Controller Module Showing the Code Editor, Activity Status and Digital Twins for Controlling the Machine.

Throughout the process, both the extracted parameters and the ongoing process itself are logged within the system’s activity status. This log serves as a dynamic record of the machine’s instantaneous activity, associated processes, and status. This real-time information is used to drive the creation of a dynamic VR model representing the ongoing physical process. By visualizing the process within the VR environment, the system offers operators and users a more intuitive and interactive approach to monitoring and understanding the machine’s operation. This enhanced visualization facilitates informed decision making, promotes proactive control, and potentially improves overall safety by allowing for early identification and mitigation of potential issues. Algorithm A1, in the Appendix A houses this passage’s working in the form of a pseudo algorithm.

3.3.2. Conveyer Control

The conveyer is the 2nd component of the FMS. It is used for material transportation. Its basic parameters are direction and speed but mostly its speed is kept constant. The conveyer can have various stopping stations depending on the number of workstations in the FMS. Its control is quite simple, automating the station-to-station code. Product sequence controls the selection of different station to station code.

3.3.3. Robot Control

The 3rd element of the FMS is robot. There can be different robot manipulators in various types of FMS. The function of the robots in manufacturing scenario is “picking and placing” raw materials, work in process (WIP) and finished products based on an optimized algorithm.

The control of a robot manipulator requires the creation of kinematics equations. These equations are included in the script for the robot module of the DT. The robot module allows for the selection of picking and placing positions in virtual space, calculates the kinematics using the algorithm, and the controller then carries out the actions. These same sequences can also be applied to physical space.

3.3.4. AGV Control

One of the most common components of the FMS is AGV. It is used for bringing the raw materials into the system and the finished products out of the system. The AGV traverses across the factory floor avoiding permanent and temporary obstacles. The control for AGV includes the direction and velocity to avoid obstacles whether moving or stationary.

Using DT, the map of the factory floor is implemented into the AGV system through which the AGV knows the position of the static obstacles while for the dynamic obstacles, the LIDAR sensor is used that detects the obstacle in its path. Through Deep Q Learning, the AGV learns obstacle avoidance by adjusting its speed and direction.

The user sets up the target position of the AGV. The controller through DQN sets up the shortest path avoiding the static obstacles and AGV traverses. As the LIDAR sensor picks up any dynamic obstacle, the DQN algorithm draws a new shortest path around the obstacle and the controller adjusts the velocity and direction of the AGV.

3.3.5. Part Program Manager

The part program manager refers to three distinct features, saving and loading of various sequences for the components of the FMS, deployment of the signals to the physical space, and the overall FMS control. The various sequences that users give as input for the various products can be saved and later loaded in the system module. The deployment of signals to physical space are dependent on the protocols and interfacing that will be discussed in the later sections, while the deployment is controlled from the part program manager. Finally, the overall FMS is controlled from this module as all the components are visible in this module. Interactions between various components such as AGV, workstations, robotic manipulators, and conveyers are observable and that gives the visibility to the decision-making process. In this module, the refined sequences that are tested in the component modules are loaded and then deployed into the physical space to achieve the manufacturing of products.

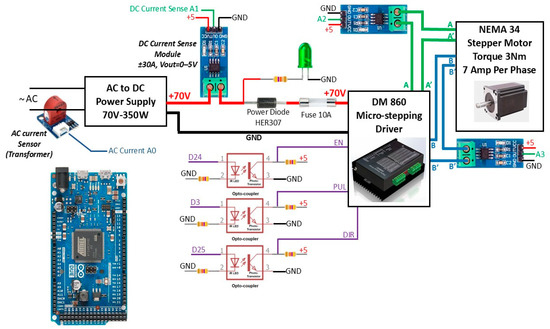

3.4. Communication

This subsection refers to mapping of virtual space with physical space. The initiation of the DT process starts with physical setup. The orientation and configuration of the FMS needs to be captured, converted into digital layer, interpreted into its physical meaning, and then updated the virtual setup. The same is illustrated from Figure 6 as sensors capture physical orientation and configuration from physical to virtual using several layers of electric components and circuitry to achieve the above.

Figure 6.

Closed Loop Circuit of Single Axis of the Workstation.

To address this challenge, a tailored communication framework has been devised, centered around a centralized communication network, which leverages the power of serial communication to enable real-time, bi-directional information exchange.

At the heart of this communication system lies a centralized server strategically positioned within a Raspberry Pi, acting as the hub connecting a constellation of Arduino units, each dedicated to the control of a specific FMS element. Serial communication forms the backbone of this network, facilitating reliable and efficient data transmission between the Raspberry Pi and Arduino units. This protocol brings the advantage of simplicity, enabling seamless hardware integration and streamlining the communication process, which is crucial for time-sensitive manufacturing operations.

To ensure the reliability and security of the communication network, a “Keep-Alive” mechanism has been ingeniously employed. Rather than employing conventional heartbeat mechanisms, the Keep-Alive approach involves the periodic exchange of small yet significant signals between the Raspberry Pi and Arduino units. These signals act as a confirmation of operational status, allowing the system to detect potential disconnections or lapses in communication. In the event of a lost connection, an automated reconnection process kicks in, promoting a fault-tolerant communication environment.

3.5. Digital Twins of FMS

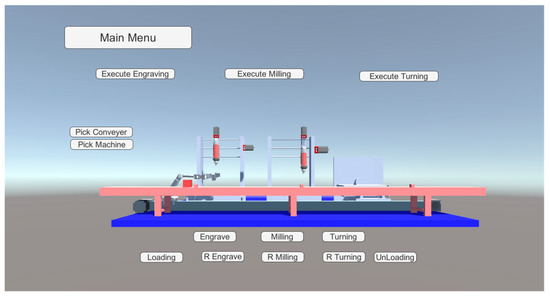

This work describes the development of a digital twin for a physical FMS. The process involved a modular approach, to virtualizing individual elements such as workstations, material handling systems, and transportation systems. Each element was implemented with motion referencing capabilities to accurately reflect its real-world behavior. Subsequently, these virtual components were integrated into a unified 3D environment within the Unity platform, effectively creating a virtual representation of the entire FMS. To ensure fidelity with the physical system, various topological parameters were rigorously validated. Additionally, the logic and data layers crucial for scene management within Unity were subjected to thorough validation processes.

Figure 7 shows the graphical user interface (GUI) of the controller application for the digital twin-enabled FMS. This GUI allows real-time monitoring and control of the virtual FMS. This interface emulates the topology, configuration and production of physical FMS.

Figure 7.

GUI of the DT-Enabled Controller for FMS.

4. Case Study and Results

Case Study on the Flexible Manufacturing System

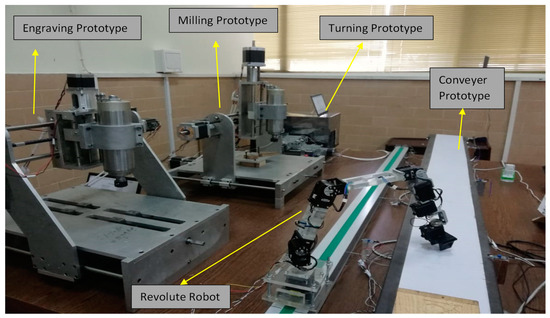

This study was undertaken in Pakistan, where access to an industrial-standard flexible manufacturing system (FMS) is limited due to the current state of the industrial landscape. Despite our efforts to source a ready-made industrial FMS, we were unable to find one that met our needs for this research. As a result, we developed a solution using custom-built prototypes. These prototypes were retrofitted with the latest technology, including Arduino and Raspberry pi, to replicate the essential functions of a flexible manufacturing system. After rigorous testing and satisfied working, we started to implement the research on it.

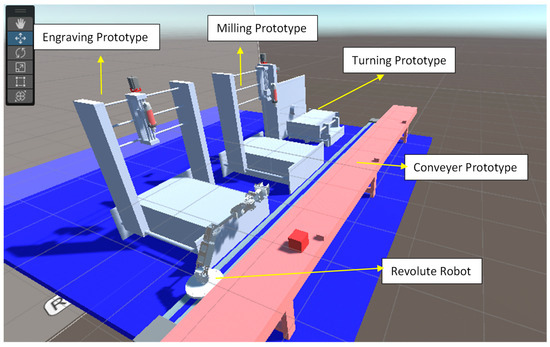

A comprehensive case study was conducted on an intricate flexible manufacturing system (FMS) model to meticulously evaluate the effectiveness of the proposed digital twin technology. The FMS under investigation comprised a diverse array of prototype machines, carefully curated from the Ghulam Ishaq Khan Institute’s esteemed collection. These machines included an engraving machine, a milling machine, a lathe machine, a conveyor belt, an Automated Guided Vehicle (AGV), and a six-degree-of-freedom (6-DOF) articulated robotic arm. The physical layout of these machines mirrored the inline flexible manufacturing system layout depicted in Figure 8. This physical configuration was meticulously replicated in the virtual space to create a corresponding digital twin of the FMS, as illustrated in Figure 9.

Figure 8.

Experimental Setup for the Flexible Manufacturing System.

Figure 9.

Virtual Flexible Manufacturing System.

The flexible manufacturing system employed a combination of legacy equipment and cutting-edge technology to achieve its manufacturing objectives. The legacy equipment consisted of a milling machine, an engraving machine, and a turning machine, each dedicated to specific machining tasks. The conveyor belt facilitated the efficient transportation of pellets, while the 6-DOF robotic arm seamlessly handled material handling operations. Each machine component was precisely controlled by an Arduino Mega microcontroller, with a Raspberry Pi serving as a central hub for data management and communication. Reliable RS-232 communication, established at a baud rate of 115,200 bits/second, ensured the seamless exchange of data between the machines and the central hub. This communication enabled the Raspberry Pi to collect real-time data from the machines and dispatch processing information accordingly. The Raspberry Pi, in turn, communicated with a PC configured with the digital twin’s graphical user interface (GUI). This interface served as the primary control interface for the FMS, allowing operators to monitor the system’s status, input processing instructions, and visualize the digital twin’s representation.

The comprehensive data collected from the sensors, encompassing machine status, processing parameters, and material handling operations, were continuously transmitted to the digital twin’s GUI. This real-time data stream enabled the digital twin to accurately reflect the physical FMS’s current state and respond to any changes promptly. Additionally, the processing sequences, defined as the order in which tasks are executed on the various machines, were provided through the GUI. This information was utilized by the digital twin to simulate the FMS’s operations and optimize its performance.

The flexible manufacturing system is composed of legacy equipment namely a milling machine, engraving machine, and turning machine for machining purposes. The conveyer belt is for pellet transportation while the 6 DOF robot is for material handling. Each one is controlled through Arduino mega. A raspberry pi served as a central hub. RS 232 communication is established having baud rate of 115,200 bits/sec collecting data from the machines and dispatching processing information. The Pi relates to PC, configured in the digital twin GUI. All the data from the sensors are communicated to the digital twin GUI of FMS while the sequences of the operations are given in the GUI.

5. Results

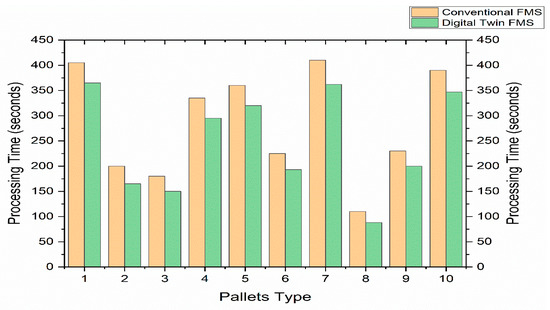

To check the effectiveness of the digital twin in production parameters, 10 distinct types of pallets of various sequences of manufacturing processes were selected. They were produced using the FMS without digital twin implementation. Various production parameters were measured during the production run and logged that included energy utilization, make span and quality in addition to the processing times of each machine during the production sequence of each pallet. The data were used to calculate the overall equipment effectiveness (OEE) to measure the performance of the manufacturing system. The data for “Conventional FMS” and “DT FMS” are available in Table A1 and Table A2 of Appendix A respectively.

After the implementation of the digital twin on the FMS, the same 10 distinct pallets were produced on the system. The same parameters as before were logged. Energy utilization, make span, quality and OEE were calculated again on the DT-enabled FMS to measure the effectiveness through its performance. The data are available in Table A1 in Appendix A.

The implementation of digital twin technology in the flexible manufacturing system (FMS) yielded significant improvements in the system’s performance. The results obtained from the experiment demonstrated the effectiveness of the proposed approach in enhancing overall system efficiency, reducing energy consumption, and maintaining product quality.

Rong et al. [34] improved the production performance through allocation of machines using reinforcement learning through digital twin yet their study does not mention FMS specifically and the results are not quantitative.

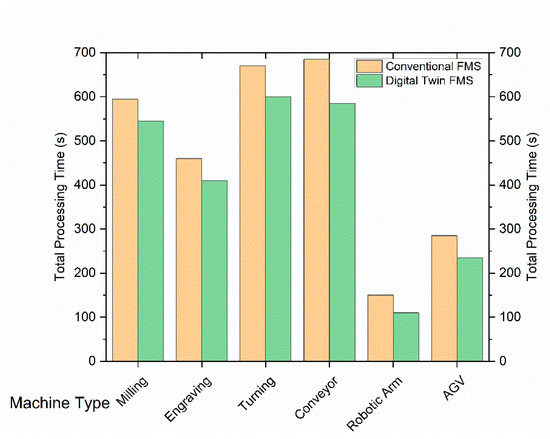

Table 3 presents a comprehensive comparison of the processing time for each component in the Conventional FMS and the digital twin FMS. The table displays a significant reduction in processing time across all tasks, highlighting the effectiveness of digital twin technology.

Table 3.

Comparison of Conventional and Digital Twin-Enhanced Processing Times.

5.1. Processing Time Reduction by Task

The FMS under observation has capacity for many manufacturing processes such as milling, engraving, turning, the conveyer’s transportation operations, robotic arm material handling operations and AGV’s operations. All these operations are crucial and through digital twin implementation, there is a considerable reduction in the processing times as compared to Conventional FMS. The comparative processing time in regards to each component of FMS can be seen in Figure 10. The experiment recorded 8.3%, 10.9%, 10.4%, 14.5%, 26.7%, and 17.5% reduced processing times for milling, engraving, turning, conveyer, robotic manipulator and AGV.

Figure 10.

Comparative Processing Times According to Machine (Conventional FMS vs. DT FMS).

This reduced processing time is due to the following facts. The first one is setup time reduction. As DT is continuously evaluated and optimized the setup configuration between different tasks and machines, minimizing the time spent in transitioning between production operations though coordination. Secondly, the DT provided real-time adjustments to scheduling by forecasting the task completion and adjusting subsequent operations, ultimately preventing machine bottlenecks. Thirdly, the DT’s collision detection in virtual assets streamlined the flow of materials.

The reduction in machines such as milling, engraving, and turning is attributed to the digital twin’s ability to optimize setup times and better execution due to the enhanced visibility. Conveyer movement is streamlined due to synchronization of the digital twin’s collision detection ability to minimize bottlenecks. While the significant reduction in robotic manipulator processing time is attributable to enhanced programming capability due to the Digital twin’s motion planning. Moreover, the AGV is implemented with reinforcement learning that selects the best route and collision avoidance.

5.2. Overall Processing Time Reduction

The production run of all the 10 pallets was also enhanced as there was a remarkable 12.7% decrease in total processing time for the digital twin FMS compared to the Conventional FMS. This substantial improvement showcases the transformative potential of digital twin technology in enhancing the efficiency of flexible manufacturing systems as shown in Figure 11.

Figure 11.

Comparative Processing Times According to Pallet (Conventional FMS vs. DT FMS).

Magalhães et al. [44] in 2022 studied digital twin implementation on FMS. While they recorded 5% increase cycle run due to the information population from physical FMS to its virtual counterpart, but their setup was digital shadow (DS) not digital twin (DT). The setup only sent information from physical to populate virtual while there was no mechanism to send feedback from virtual to physical.

Our study synchronizes all the information bi-directionally. The physical information is transferred to the Digital twin while the controlling paradigm is transmitted from virtual to physical employing a full digital twin enhancing the flexible manufacturing system.

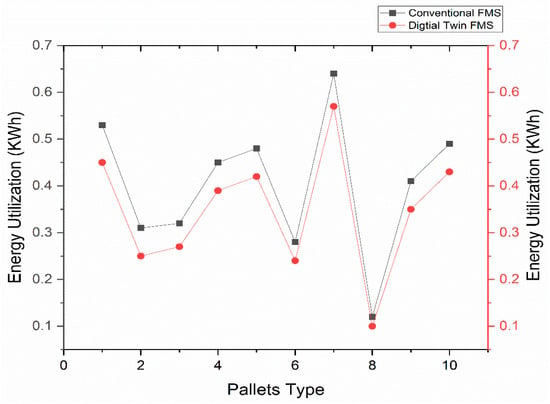

5.3. Impact on Energy Consumption

In addition to the significant reduction in processing time, the implementation of the digital twin in the FMS also led to a significant decrease in energy consumption. The DT FMS demonstrated an average energy saving of 15% compared to the Conventional FMS. This improvement is attributed to the following mechanisms:

Optimized Resource Utilization: The digital twin’s ability to analyze production data and prediction enables it to optimize resource allocation, ensuring that machines and equipment are operated efficiently and only when necessary. This reduces idle time and minimizes energy wastage.

Optimized Maintenance: The digital twin’s ability to monitor sensor data and predict equipment failures enables optimized maintenance strategiessuch as to prevent unplanned downtime and ensure that machines are operating at peak efficiency. This reduces energy consumption associated with corrective maintenance and machine restarts.

Real-time Process Monitoring: The digital twin’s ability to monitor production processes in real-time allows for early detection of potential defects. The defects such as excessive power consumption or suboptimal operating conditions. This enables corrective actions to be taken, resulting in minimizing energy waste.

The combined effect of these mechanisms resulted in a remarkable 15% reduction in energy consumption for the DT FMS as compared to the Conventional FMS. The same is indicated in the line chart in Figure 12. This characteristic of DT FMS not only contributes to cost savings but also aligns with the trending emphasis on sustainability and energy efficiency in manufacturing operations.

Figure 12.

Comparison of Total Energy Consumption by Each Pallet (Conventional FMS vs. DT FMS).

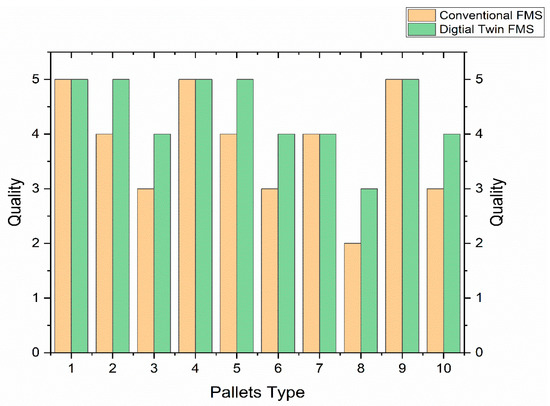

5.4. Impact on Product Quality

The implementation of digital twin FMS also led to an enhancement in product quality. The DT FMS achieved a better quality compared to the Conventional FMS as indicated in Figure 13. This originates from the real-time process monitoring and process optimization capability of the digital twin.

Figure 13.

Comparison of Quality for Each Pallet (Conventional FMS vs. Digital Twin FMS).

Wang et al. [35] designed multi-robot collaborative flexible manufacturing system for manufacturing circuit breakers that uses reinforcement learning algorithm along with digital twin. The study achieved 22% performance in quality measurement. Compared to Wang, our study exhibits 15.79% quality enhancement since the referenced study only produces circuit breakers while using reinforcement learning for the collaborative robots. In comparison to the referenced, our study aimed at 10 varieties of pallets with various manufacturing sequence.

A total of 15.79% enhanced quality compared to conventional flexible manufacturing system leads to higher customer satisfaction, reduced costs due to rework and reduced scrap. This exhibits higher consistence and reliability of the manufacturing equipment compared to the Conventional FMS.

The factors that attributed to enhanced quality are due to the real-time process adjustment, reduction in scrap and enhanced machine coordination. The DT continually monitored key production parameters such as tool wear, spindle speed, material feed rates and adjusted them in real time to ensure optimal conditions for each task. Secondly, by optimizing the process parameters and detecting potential issues early, the DT system significantly reduced material wastage and scrap. Lastly, the DT’s ability to coordinate multiple machines, ensured that all production stages were aligned, preventing any downstream impact caused by errors in earlier stages by establishing precise synchronization.

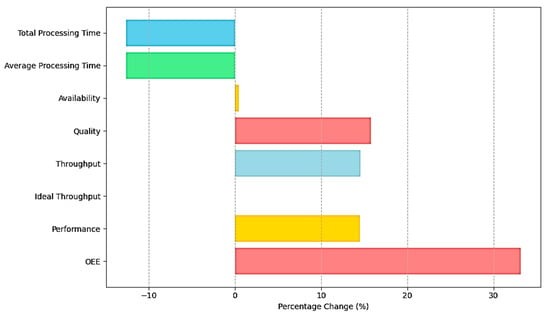

6. Discussion

The implementation of digital twin technology in the flexible manufacturing system (FMS) resulted in notable improvements in productivity parameters, as evident from the comparative study in Table 4. The availability of the FMS increased by 0.44%, indicating a reduced downtime and enhanced reliability. This improvement can be attributed to the ability of digital twin technology to provide real-time monitoring and diagnostics of the FMS, enabling timely identification and resolution of potential issues before they escalate into downtime-causing events. Moreover, digital twin technology facilitates predictive maintenance, allowing for proactive scheduling of maintenance activities based on the predicted health status of the FMS components. This proactive approach further reduces the likelihood of unplanned downtime and contributes to the overall increase in FMS availability. Figure 14 presents the percentage improvement before and after the digital twin implementation.

Table 4.

Productivity Metrics for Conventional FMS vs. DT FMS.

Figure 14.

Percentage Change in FMS Productivity Parameters after Digital Twin Implementation.

Yang et al. [45], in 2022, performed a study on FMS. The researcher focus was on the prediction of performance degradation due to power transmission element. While his results are promising in context of digital twins, a more primal use of digital twin technology was needed. Moreover, the researcher setup was purely digital shadow not digital twin further limiting the potential of digital twins.

Quality, measured as the proportion of defect-free products, witnessed a significant surge of 15.79%, demonstrating the effectiveness of digital twin technology in defect detection and prevention. This substantial improvement stems from the ability of digital twin technology to simulate the manufacturing process and identify potential sources of defects. By analyzing the behavior of the virtual FMS, engineers can pinpoint areas in the physical FMS that may contribute to defects and implement corrective measures before they impact product quality. Additionally, digital twin technology can be used to monitor the production process in real-time, enabling the detection of defects as they occur and the timely intervention to prevent further production of defective products.

Throughput, defined as the rate at which the FMS produces units, experienced a commendable increase of 14.53%, signifying an improvement in production output. This enhancement can be attributed to the ability of digital twin technology to optimize the FMS scheduling and process parameters. By simulating the manufacturing process and analyzing the interactions between different components, digital twin technology can identify bottlenecks and inefficiencies that hinder throughput. Based on these insights, engineers can optimize the scheduling of production tasks and adjust process parameters to eliminate bottlenecks and streamline the overall production flow.

Performance, a measure of the FMS’s ability to achieve its objectives, rose by 14.20%, reflecting an overall enhancement in efficiency. This improvement encompasses the combined effects of increased availability, quality, and throughput. As the FMS becomes more reliable (availability), produces higher quality products (quality), and generates more output (throughput), its overall performance in achieving its objectives is significantly enhanced. Digital twin technology plays a pivotal role in driving these improvements by providing real-time insights, enabling data-driven decision making, and facilitating continuous process optimization.

OEE, the comprehensive metric of FMS productivity, registered an impressive gain of 33.03%, highlighting the substantial impact of digital twin technology on overall production effectiveness. This remarkable improvement encapsulates the cumulative effects of enhanced availability, quality, and performance. As the FMS operates more reliably, produces higher quality products, and generates more output at a faster rate, its overall effectiveness in utilizing resources and achieving production goals is significantly elevated. Digital twin technology serves as a catalyst for these improvements by providing a holistic view of the FMS, enabling the identification and optimization of factors that contribute to overall productivity.

The slight decrease in total processing time, from 2845 s to 2485 s, could be attributed to factors such as improved process optimization and reduced downtime. Digital twin technology enabled the identification of bottlenecks and inefficiencies, leading to process streamlining and reduced production time. Additionally, the real-time insights provided by digital twin technology facilitated predictive maintenance, minimizing unplanned downtime, and further contributing to the reduction in total processing time. This decrease in total processing time, while seemingly counterintuitive, underscores the effectiveness of digital twin technology in optimizing the FMS and enhancing overall productivity.

7. Conclusions

This research presents a novel digital twin (DT) framework that demonstrates immense transformative potential for manufacturing operations. By integrating physical and virtual subsystems into a unified architecture, the proposed DT enables real-time synchronization of legacy and cutting-edge technologies. Rigorous testing validates the framework’s seamless interoperability, technology readiness level, and compliance with human-centered design principles.

The quantitative results reveal significant improvements across key performance indicators. Compared to the conventional system, the DT architecture reduced the response time by 12.63%, lowered capital costs by 15.79%, and boosted overall equipment effectiveness by 33.03%. Enhanced visibility empowered data-driven decision making, increasing system availability by 0.44% and overall performance by 14.20%. The virtual simulation assisted planning and training while minimizing errors.

This pioneering digital twin facilitates the transition towards industry 4.0 by introducing smart capabilities into legacy systems. It enhances productivity, efficiency, quality, and transparency while reducing costs and manual labor. The proposed model delivers invaluable insights for process optimization, resource management, and predictive maintenance. Further research into scalability and security would be beneficial. Overall, by harnessing advanced technologies, this digital twin provides a foundation for the smart factory of the future.

The transformative potential demonstrated in this study highlights the immense value of digital twin frameworks in revolutionizing manufacturing operations. This research contributes empirical evidence and quantitative metrics to guide future implementations. Further interdisciplinary research combining engineering, computer science, and management practices promises to uncover the full capabilities of digital twins in enabling the next industrial revolution.

While the current research demonstrates the transformative potential of digital twin technology in flexible manufacturing systems, future work should focus on several key areas to further develop and validate the framework. First, exploring the scalability of digital twin systems to larger, more complex manufacturing environments will be essential. This includes extending the technology beyond individual processes to encompass entire production lines and supply chains. Additionally, conducting real-world pilot projects across different industries will provide practical validation of the framework’s efficacy in diverse and dynamic industrial settings.

In terms of practical applications, the integration of digital twins with enterprise-level systems like ERP and MES could offer a more holistic approach to manufacturing optimization. These connections would allow organizations to align production processes more closely with business goals, improving both efficiency and profitability. Furthermore, technology holds great potential for contributing to sustainable manufacturing practices by optimizing resource utilization, reducing waste, and lowering energy consumption.

8. Future Recommendations

While the present study validates the immense potential of digital twin frameworks, further research across multiple dimensions would be beneficial to fully realize their transformative capabilities.

First and foremost, the human digital twin is the subject of the trends. While the collaboration between robots and humans is exceeding expectations due to groundbreaking technologies of fourth industrial revolution, it lacks the virtual configuration of the most prominent factor, the “Human”. Human factors in HCPS have many roles and research on their digital twins is of utmost importance. Expanding the digital twin’s scope beyond the manufacturing floor to connect with enterprise-level systems could enable truly holistic cyber–physical optimization. Multidisciplinary collaborations incorporating engineering, computer science, human factors, management, and social sciences will be instrumental in advancing digital twin research.

Standardizing the digital twin’s architectural schema and communication protocols could promote interoperability and data sharing across manufacturing ecosystems. Incorporating cybersecurity measures into the design phase will grow increasingly vital to ensure resilience against cyber–physical attacks.

Moreover, cybersecurity and data privacy will become increasingly important as digital twins rely on large volumes of real-time data. Research into securing these systems from cyber threats while maintaining data integrity is crucial for their adoption in sensitive industrial environments.

Interdisciplinary collaborations will also play a vital role in the evolution of digital twin technology. Fields such as robotics, data science, and human-centered design can contribute to more advanced and user-friendly digital twin systems. These collaborations can improve the interface between human operators and machines, making the technology more intuitive and effective in real-time decision making.

Author Contributions

Conceptualization, A.U.; methodology, A.U.; software, A.U.; formal analysis, A.U.; investigation, A.U.; resources, writing—original draft preparation, A.U.; writing—review and editing, M.Y.; visualization; funding acquisition, M.Y. All authors have read and agreed to the published version of the manuscript.

Funding

No funding acquired.

Data Availability Statement

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

Conflicts of Interest

Authors have no conflict of interest.

Appendix A

Glossary:

- Digital Twin (DT): A virtual replica of a physical system, used for simulation, monitoring, and optimization of processes in real time, allowing for enhanced decision making and control.

- Flexible Manufacturing System (FMS): A production system that can adapt to changes in the type and quantity of products being manufactured, offering flexibility in production processes.

- Cyber–Physical System (CPS): A system that integrates computing, networking, and physical processes, where embedded computers and networks monitor and control physical processes, typically in real time.

- Human–Cyber–Physical System (HCPS): A system that combines human, cyber, and physical elements to create an integrated manufacturing process, where humans and machines interact efficiently.

- Overall Equipment Effectiveness (OEE): A standard metric used in manufacturing to measure the efficiency and effectiveness of equipment, based on its availability, performance, and quality output.

- Automatic Tool Changer (ATC): A device that automatically changes tools in a machine, allowing for efficient and uninterrupted operation during manufacturing processes.

- Markov Chain: A statistical model used to represent a series of events, where the probability of each event depends only on the previous one, often applied in manufacturing to model system behavior.

- Reinforcement Learning: A type of machine learning where an algorithm learns to take optimal actions by interacting with an environment and receiving feedback in the form of rewards or penalties.

- Robotic Manipulator: A robot designed to move materials or tools in a manufacturing process, often equipped with multiple degrees of freedom to perform precise operations like assembly or material handling.

- Augmented Reality (AR): A technology that overlays digital information onto the real world, enhancing the user’s perception and interaction with the environment, particularly in manufacturing for process monitoring and control.

- Automated Guided Vehicle (AGV): A mobile robot used to transport materials in manufacturing environments, guided by sensors and algorithms to navigate and avoid obstacles.

- LIDAR: A sensor technology that uses laser light to measure distances and create detailed maps of an environment, often used for navigation and obstacle detection in automated systems like AGVs.

- Kinematics: The study of motion without considering the forces that cause it, used in robotics to calculate the movement of robotic arms and other moving parts in manufacturing systems.

- Serial Communication: A method of data transmission where data are sent one bit at a time over a communication channel, commonly used in controlling machines and systems in manufacturing.

- Virtual Assets: Digital representations of physical components in a manufacturing system, used in simulations to mimic and optimize real-world operations.

- Real-Time Monitoring: The continuous observation and tracking of system performance and data as it happens, allowing for immediate responses to changes in the manufacturing process.

- Closed-Loop Control: A control system that uses feedback from sensors to automatically adjust the process and maintain the desired system performance.

- Dynamic Optimization: The process of continually adjusting parameters in a system based on real-time data to improve performance and efficiency.

- Digital Shadow (DS): A model that mirrors the behavior of a physical system by receiving data from it but lacks the ability to influence or control the physical system, unlike a digital twin.

- Graphical User Interface (GUI): A visual interface that allows users to interact with a system through graphical elements like icons, buttons, and menus, simplifying the control and monitoring of manufacturing processes.

| Algorithm A1 Control Algorithm of Milling Machine and Engraving Machine via Digital Twin |

| Input: Part Program (G and M) |

| Output: Process Summary report and Visualization |

|

|

end for |

|

|

|

| Return: Process Summary Report |

Table A1.

Conventional Flexible Manufacturing System Data after Processing 10 Pallets of Selected Designs.

Table A1.

Conventional Flexible Manufacturing System Data after Processing 10 Pallets of Selected Designs.

| Pallet | Milling (s) | Engraving (s) | Turning (s) | Conveyor (s) | Robotic Arm (s) | AGV (s) | Total Energy Consumption (kWh) | Quality |

|---|---|---|---|---|---|---|---|---|

| 1 | 155 | 80 | 55 | 70 | 15 | 30 | 0.53 | 5 |

| 2 | 0 | 40 | 70 | 55 | 15 | 20 | 0.31 | 4 |

| 3 | 0 | 0 | 80 | 60 | 15 | 25 | 0.32 | 3 |

| 4 | 110 | 35 | 60 | 75 | 20 | 35 | 0.45 | 5 |

| 5 | 0 | 105 | 130 | 80 | 15 | 30 | 0.48 | 4 |

| 6 | 0 | 65 | 55 | 70 | 10 | 25 | 0.28 | 3 |

| 7 | 200 | 0 | 85 | 75 | 15 | 35 | 0.64 | 4 |

| 8 | 0 | 30 | 0 | 50 | 10 | 20 | 0.12 | 2 |

| 9 | 0 | 55 | 60 | 65 | 20 | 30 | 0.41 | 5 |

| 10 | 130 | 50 | 75 | 85 | 15 | 35 | 0.49 | 3 |

Table A2.

Digital Twin Controlled Flexible Manufacturing System Data after Processing 10 Pallets of Selected Designs.

Table A2.

Digital Twin Controlled Flexible Manufacturing System Data after Processing 10 Pallets of Selected Designs.

| Pallet | Milling (s) | Engraving (s) | Turning (s) | Conveyor (s) | Robotic Arm (s) | AGV (s) | Total Energy (kWh) | Quality |

|---|---|---|---|---|---|---|---|---|

| 1 | 145 | 75 | 50 | 60 | 10 | 25 | 0.45 | 5 |

| 2 | 0 | 35 | 60 | 45 | 10 | 15 | 0.25 | 5 |

| 3 | 0 | 0 | 70 | 50 | 10 | 20 | 0.27 | 4 |

| 4 | 100 | 30 | 55 | 65 | 15 | 30 | 0.39 | 5 |

| 5 | 0 | 95 | 120 | 70 | 10 | 25 | 0.42 | 5 |

| 6 | 0 | 55 | 50 | 60 | 8 | 20 | 0.24 | 4 |

| 7 | 180 | 0 | 75 | 65 | 12 | 30 | 0.57 | 4 |

| 8 | 0 | 25 | 0 | 40 | 8 | 15 | 0.1 | 3 |

| 9 | 0 | 50 | 55 | 55 | 15 | 25 | 0.35 | 5 |

| 10 | 120 | 45 | 65 | 75 | 12 | 30 | 0.43 | 4 |

References

- Zhou, J.; Zhou, Y.; Wang, B.; Zang, J. Human–Cyber–Physical Systems (HCPSs) in the Context of New-Generation Intelligent Manufacturing. Engineering 2019, 5, 624–636. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Kevin, I.; Wang, K.; Huang, H.; Xu, X. Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput. -Integr. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the digital twin for design and production engineering. CIRP Ann. 2017, 66, 141–144. [Google Scholar] [CrossRef]

- Söderberg, R.; Wärmefjord, K.; Carlson, J.S.; Lindkvist, L. Toward a Digital Twin for real-time geometry assurance in individualized production. CIRP Ann. 2017, 66, 137–140. [Google Scholar] [CrossRef]

- Angrish, A.; Starly, B.; Lee, Y.-S.; Cohen, P.H. A flexible data schema and system architecture for the virtualization of manufacturing machines (VMM). J. Manuf. Syst. 2017, 45, 236–247. [Google Scholar] [CrossRef]

- Ladj, A.; Wang, Z.; Meski, O.; Belkadi, F.; Ritou, M.; Da Cunha, C. A knowledge-based Digital Shadow for machining industry in a Digital Twin perspective. J. Manuf. Syst. 2021, 58, 168–179. [Google Scholar] [CrossRef]

- Zhuang, C.; Gong, J.; Liu, J. Digital twin-based assembly data management and process traceability for complex products. J. Manuf. Syst. 2021, 58, 118–131. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Zhu, C.; Liu, Z. Framework for manufacturing-tasks semantic modelling and manufacturing-resource recommendation for digital twin shop-floor. J. Manuf. Syst. 2021, 58, 281–292. [Google Scholar] [CrossRef]

- Martinez, S.; Mariño, A.; Sanchez, S.; Montes, A.M.; Triana, J.M.; Barbieri, G.; Abolghasem, S.; Vera, J.; Guevara, M. A Digital Twin Demonstrator to enable flexible manufacturing with robotics: A process supervision case study. Prod. Manuf. Res. 2021, 9, 140–156. [Google Scholar] [CrossRef]

- Bilberg, A.; Malik, A.A. Digital twin driven human–robot collaborative assembly. CIRP Ann. 2019, 68, 499–502. [Google Scholar] [CrossRef]

- Tipary, B.; Erdős, G. Generic development methodology for flexible robotic pick-and-place workcells based on Digital Twin. Robot. Comput. Manuf. 2022, 71, 102140. [Google Scholar] [CrossRef]

- Choi, S.H.; Park, K.-B.; Roh, D.H.; Lee, J.Y.; Mohammed, M.; Ghasemi, Y.; Jeong, H. An integrated mixed reality system for safety-aware human-robot collaboration using deep learning and digital twin generation. Robot. Comput. Manuf. 2021, 73, 102258. [Google Scholar] [CrossRef]

- Li, C.; Zheng, P.; Li, S.; Pang, Y.; Lee, C.K. AR-assisted digital twin-enabled robot collaborative manufacturing system with human-in-the-loop. Robot. Comput. Manuf. 2022, 76, 102321. [Google Scholar] [CrossRef]

- Cheng, J.; Zhang, H.; Tao, F.; Juang, C.-F. DT-II:Digital twin enhanced Industrial Internet reference framework towards smart manufacturing. Robot. Comput. Manuf. 2020, 62, 101881. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Tao, F.; Liu, A. New Paradigm of Data-Driven Smart Customisation through Digital Twin. J. Manuf. Syst. 2021, 58, 270–280. [Google Scholar] [CrossRef]

- Zhang, M.; Tao, F.; Nee, A. Digital Twin Enhanced Dynamic Job-Shop Scheduling. J. Manuf. Syst. 2020, 58, 146–156. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F. Digital Twin and Big Data Towards Smart Manufacturing and Industry 4.0: 360 Degree Comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Chuang, W.; Guanghui, Z.; Junsheng, W. Smart cyber-physical production system enabled workpiece production in digital twin job shop. Adv. Mech. Eng. 2021, 13, 16878140211040888. [Google Scholar] [CrossRef]

- Salazar, L.A.C.; Ryashentseva, D.; Lüder, A.; Vogel-Heuser, B. Cyber-physical production systems architecture based on multi-agent’s design pattern—Comparison of selected approaches mapping four agent patterns. Int. J. Adv. Manuf. Technol. 2019, 105, 4005–4034. [Google Scholar] [CrossRef]

- Pronost, G.; Mayer, F.; Camargo, M.; Dupont, L. Digital Twins along the product lifecycle: A systematic literature review of applications in manufacturing. Digit. Twin 2023, 3, 3. [Google Scholar] [CrossRef]

- Havard, V.; Sahnoun, M.; Bettayeb, B.; Duval, F.; Baudry, D. Data architecture and model design for Industry 4.0 components integration in cyber-physical production systems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 2338–2349. [Google Scholar] [CrossRef]

- Jiang, J.-R. An improved cyber-physical systems architecture for Industry 4.0 smart factories. Adv. Mech. Eng. 2018, 10, 1687814018784192. [Google Scholar] [CrossRef]

- Wang, C.; Jiang, P.; Ding, K. A hybrid-data-on-tag–enabled decentralized control system for flexible smart workpiece manufacturing shop floors. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 231, 764–782. [Google Scholar] [CrossRef]

- Wang, C.; Jiang, P.; Lu, T. Production events graphical deduction model enabled real-time production control system for smart job shop. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 232, 2803–2820. [Google Scholar] [CrossRef]

- Zhang, Q.; Wei, Y.; Liu, Z.; Duan, J.; Qin, J. A Framework for Service-Oriented Digital Twin Systems for Discrete Workshops and Its Practical Case Study. Systems 2023, 11, 156. [Google Scholar] [CrossRef]

- Zhang, K.; Qu, T.; Zhou, D.; Jiang, H.; Lin, Y.; Li, P.; Guo, H.; Liu, Y.; Li, C.; Huang, G.Q. Digital twin-based opti-state control method for a synchronized production operation system. Robot. Comput. Manuf. 2020, 63, 101892. [Google Scholar] [CrossRef]

- Ding, K.; Chan, F.T.; Zhang, X.; Zhou, G.; Zhang, F. Defining a Digital Twin-based Cyber-Physical Production System for autonomous manufacturing in smart shop floors. Int. J. Prod. Res. 2019, 57, 6315–6334. [Google Scholar] [CrossRef]

- Zhuang, C.; Liu, J.; Xiong, H. Digital twin-based smart production management and control framework for the complex product assembly shop-floor. Int. J. Adv. Manuf. Technol. 2018, 96, 1149–1163. [Google Scholar] [CrossRef]

- Zhuang, C.; Miao, T.; Liu, J.; Xiong, H. The connotation of digital twin, and the construction and application method of shop-floor digital twin. Robot. Comput. Manuf. 2021, 68, 102075. [Google Scholar] [CrossRef]

- Yi, L.; Glatt, M.; Ehmsen, S.; Duan, W.; Aurich, J.C. Process monitoring of economic and environmental performance of a material extrusion printer using an augmented reality-based digital twin. Addit. Manuf. 2021, 48, 102388. [Google Scholar] [CrossRef]

- Cai, Y.; Wang, Y.; Burnett, M. Using augmented reality to build digital twin for reconfigurable additive manufacturing system. J. Manuf. Syst. 2020, 56, 598–604. [Google Scholar] [CrossRef]

- Zhang, D.; Leng, J.; Xie, M.; Yan, H.; Liu, Q. Digital twin enabled optimal reconfiguration of the semi-automatic electronic assembly line with frequent changeovers. Robot. Comput. Manuf. 2022, 77, 102343. [Google Scholar] [CrossRef]

- Negri, E.; Berardi, S.; Fumagalli, L.; Macchi, M. MES-integrated digital twin frameworks. J. Manuf. Syst. 2020, 56, 58–71. [Google Scholar] [CrossRef]

- Zhang, R.; Lv, J.; Bao, J.; Zheng, Y. A digital twin-driven flexible scheduling method in a human–machine collaborative workshop based on hierarchical reinforcement learning. Flex. Serv. Manuf. J. 2023, 35, 1116–1138. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Shu, L.; Zhou, H. Multi-Robot Collaborative Flexible Manufacturing and Digital Twin System Design of Circuit Breakers. Appl. Sci. 2023, 13, 2721. [Google Scholar] [CrossRef]

- Fett, M.; Turner, E.; Breimann, R.; Kirchner, E. Extension of the system boundary of the Digital Twin onto the sensors of the Physical Twin through the introduction of redundant soft sensors. Forsch. Ingenieurwesen 2023, 87, 479–488. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, J.; Wang, P.; Law, J.; Calinescu, R.; Mihaylova, L. A deep learning-enhanced Digital Twin framework for improving safety and reliability in human–robot collaborative manufacturing. Robot. Comput. Manuf. 2024, 85, 102608. [Google Scholar] [CrossRef]

- Xie, J.; Jiang, H.; Qin, S.; Zhang, J.; Ding, G. A new description model for enabling more general manufacturing systems representation in digital twin. J. Manuf. Syst. 2024, 72, 475–491. [Google Scholar] [CrossRef]

- David, J.S. Development of A Digital Twin of A Flexible Manufacturing System for Assisted Learning. Master’s Thesis, Tampere University of Technology, Tampere, Finland, 2018. [Google Scholar]

- Guo, H.; Chen, M.; Mohamed, K.; Qu, T.; Wang, S.; Li, J. A digital twin-based flexible cellular manufacturing for optimization of air conditioner line. J. Manuf. Syst. 2021, 58, 65–78. [Google Scholar] [CrossRef]

- Fan, Y.; Yang, J.; Chen, J.; Hu, P.; Wang, X.; Xu, J.; Zhou, B. A digital-twin visualized architecture for Flexible Manufacturing System. J. Manuf. Syst. 2021, 60, 176–201. [Google Scholar] [CrossRef]

- ISO 841:2001; Industrial Automation Systems and Integration—Numerical Control of Machines—Coordinate System and Motion Nomenclature. ISO: Geneva, Switzerland, 2001.

- ISO 6983-1:2009; Automation Systems and Integration–Numerical Control of Machines–Program Format and Definitions of Address Words. ISO: Geneva, Switzerland, 2009.

- Magalhães, L.C.; Magalhães, L.C.; Ramos, J.B.; Moura, L.R.; de Moraes, R.E.N.; Gonçalves, J.B.; Hisatugu, W.H.; Souza, M.T.; de Lacalle, L.N.L.; Ferreira, J.C.E. Conceiving a Digital Twin for a Flexible Manufacturing System. Appl. Sci. 2022, 12, 9864. [Google Scholar] [CrossRef]

- Yang, X.; Ran, Y.; Zhang, G.; Wang, H.; Mu, Z.; Zhi, S. A digital twin-driven hybrid approach for the prediction of performance degradation in transmission unit of CNC machine tool. Robot. Comput. Manuf. 2022, 73, 102230. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).