Enhanced Energy Absorption with Bioinspired Composite Triply Periodic Minimal Surface Gyroid Lattices Fabricated via Fused Filament Fabrication (FFF)

Abstract

1. Introduction

2. Materials and Methods

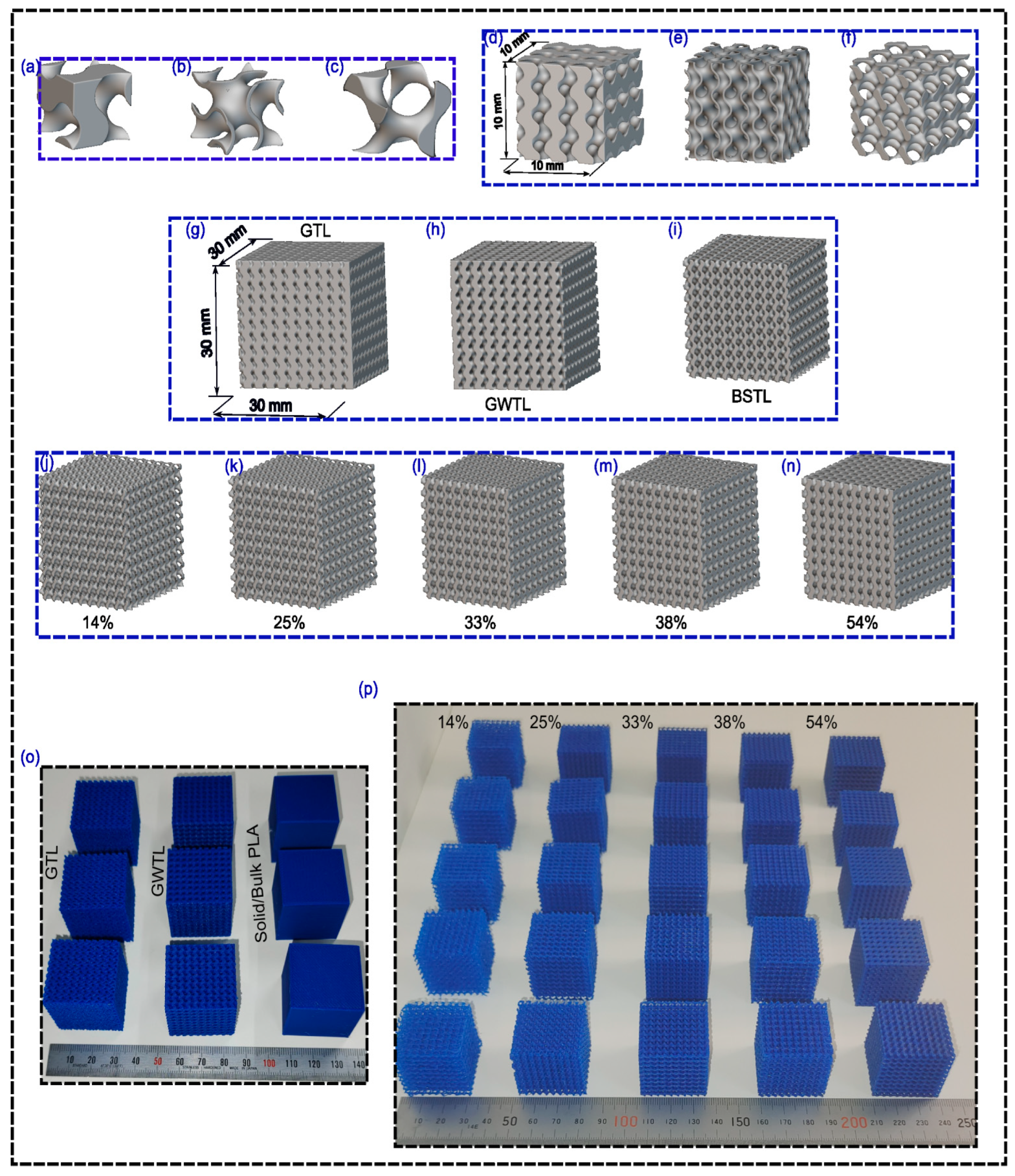

2.1. Lattice 3D CAD Design

2.2. Lattice Additive Manufacturing

2.3. Measurement of Density and Relative Density

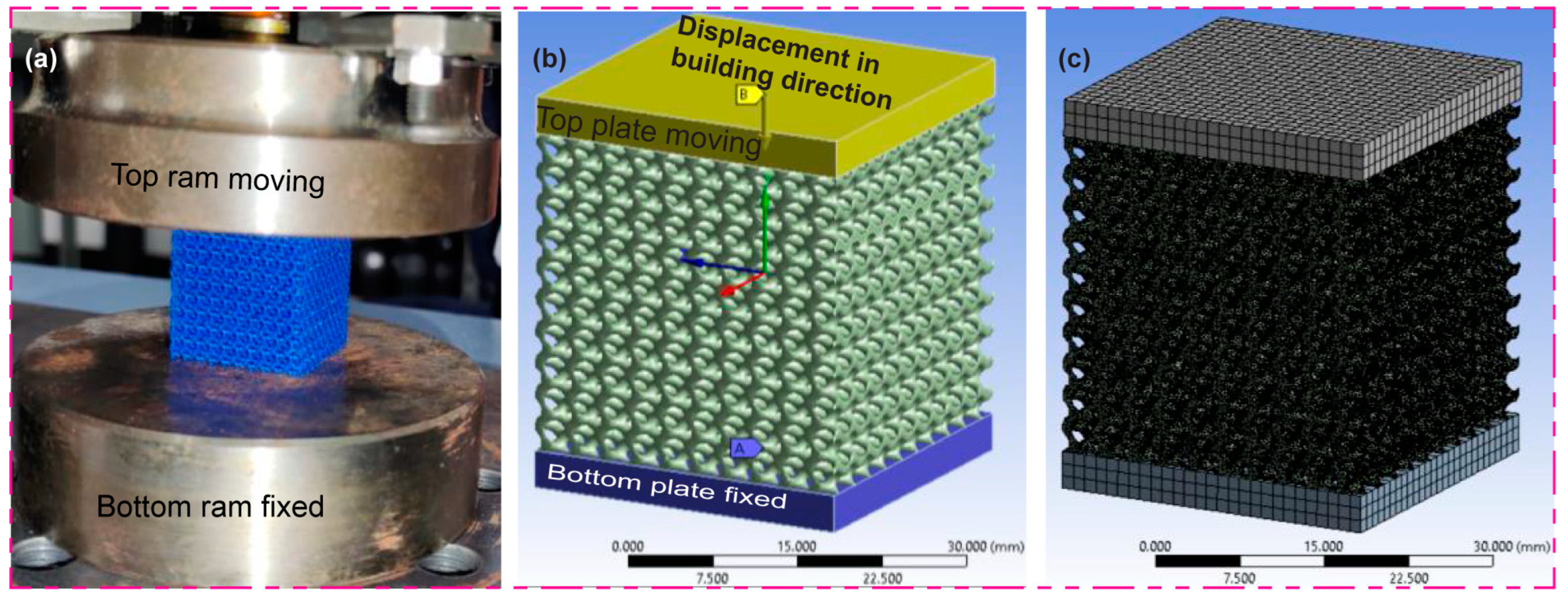

2.4. Mechanical Compression of Lattice

Gibson–Ashby Model

2.5. SEM of Deformed and Undeformed Lattice

2.6. Finite Element Analysis (FEA) of Lattice

2.7. Energy Absorption

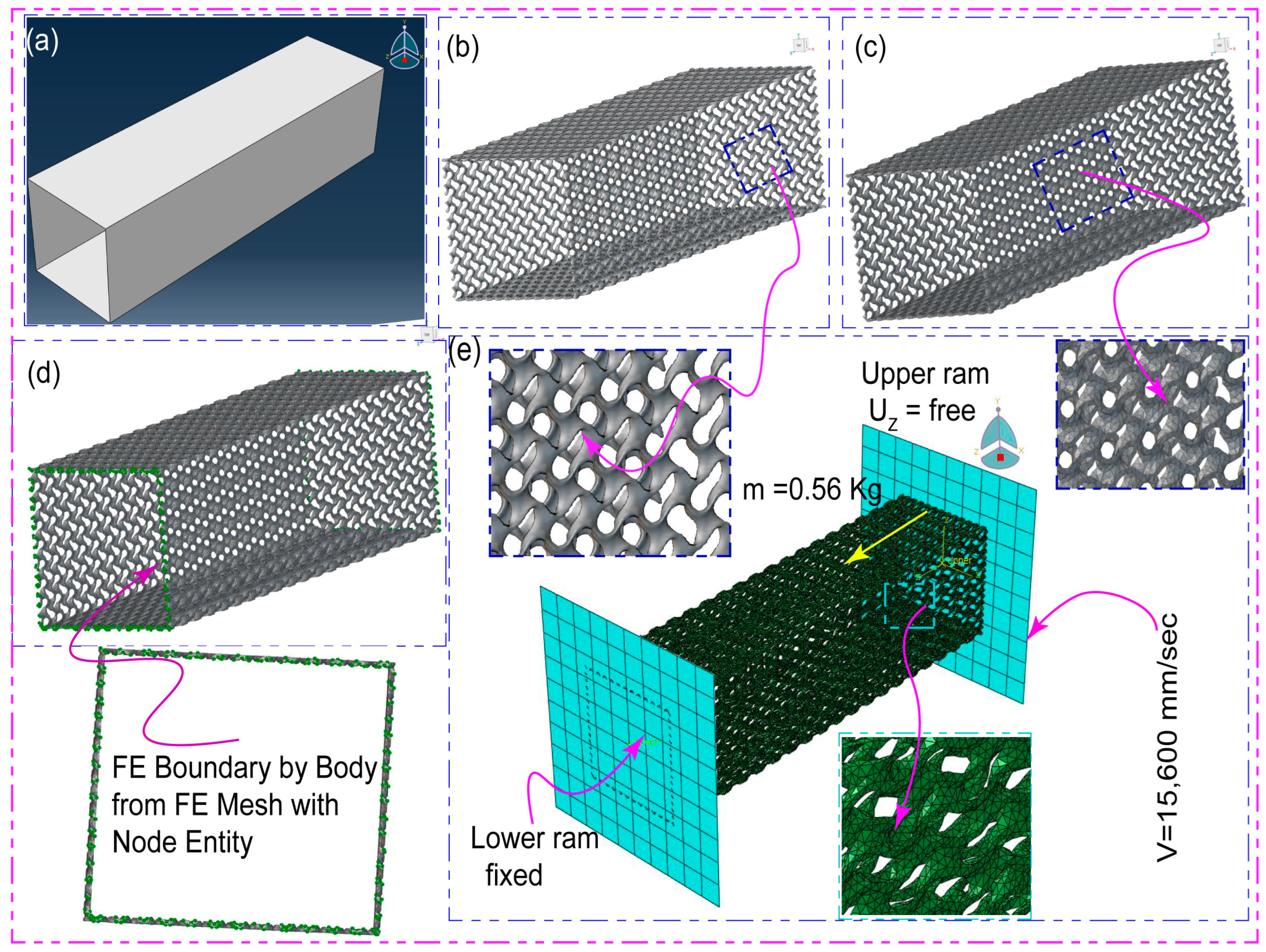

2.8. Case Study on Vehicle Crush Box Energy Absorption

3. Result and Discussion

3.1. Lattice Samples Density and POROSITY Measurement

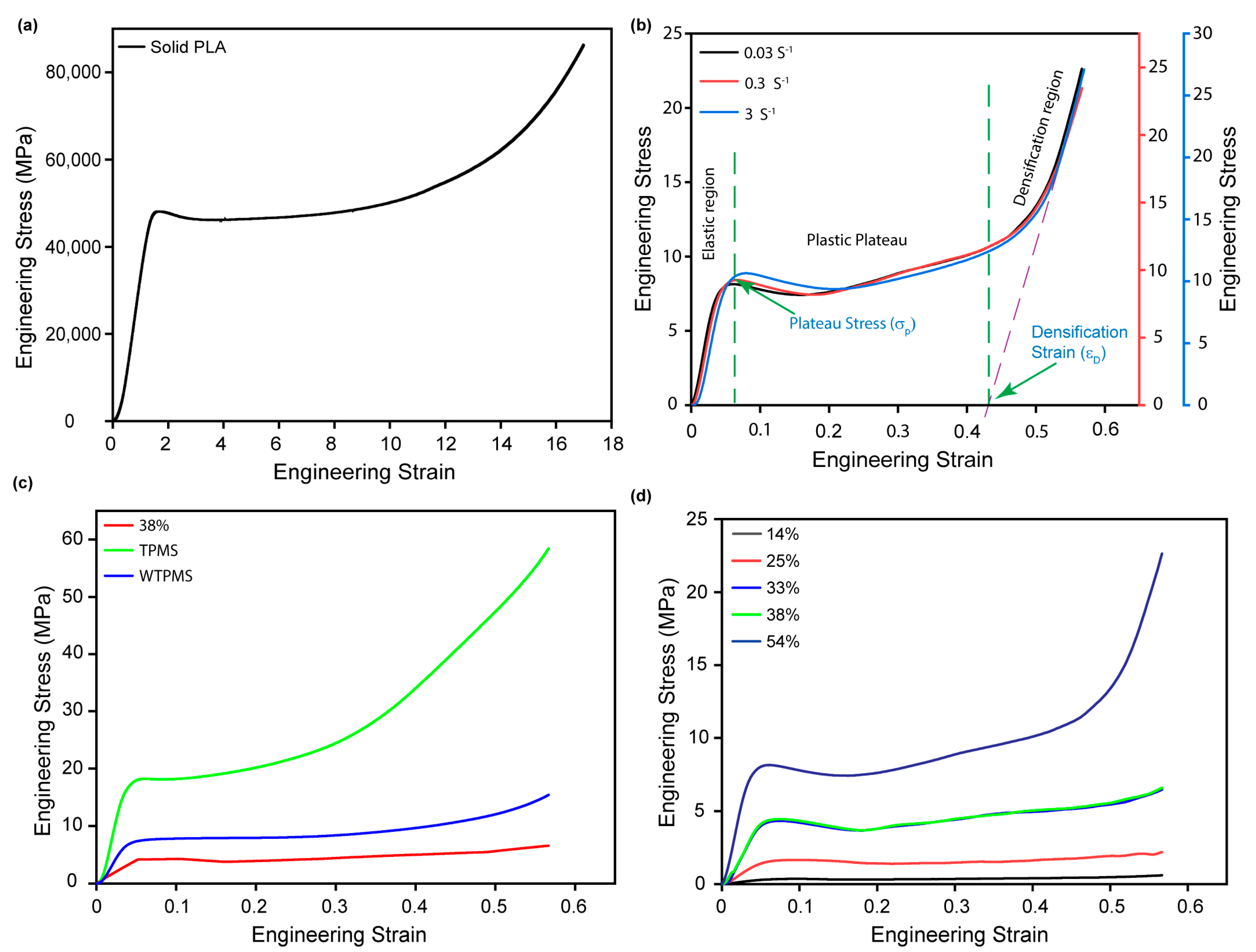

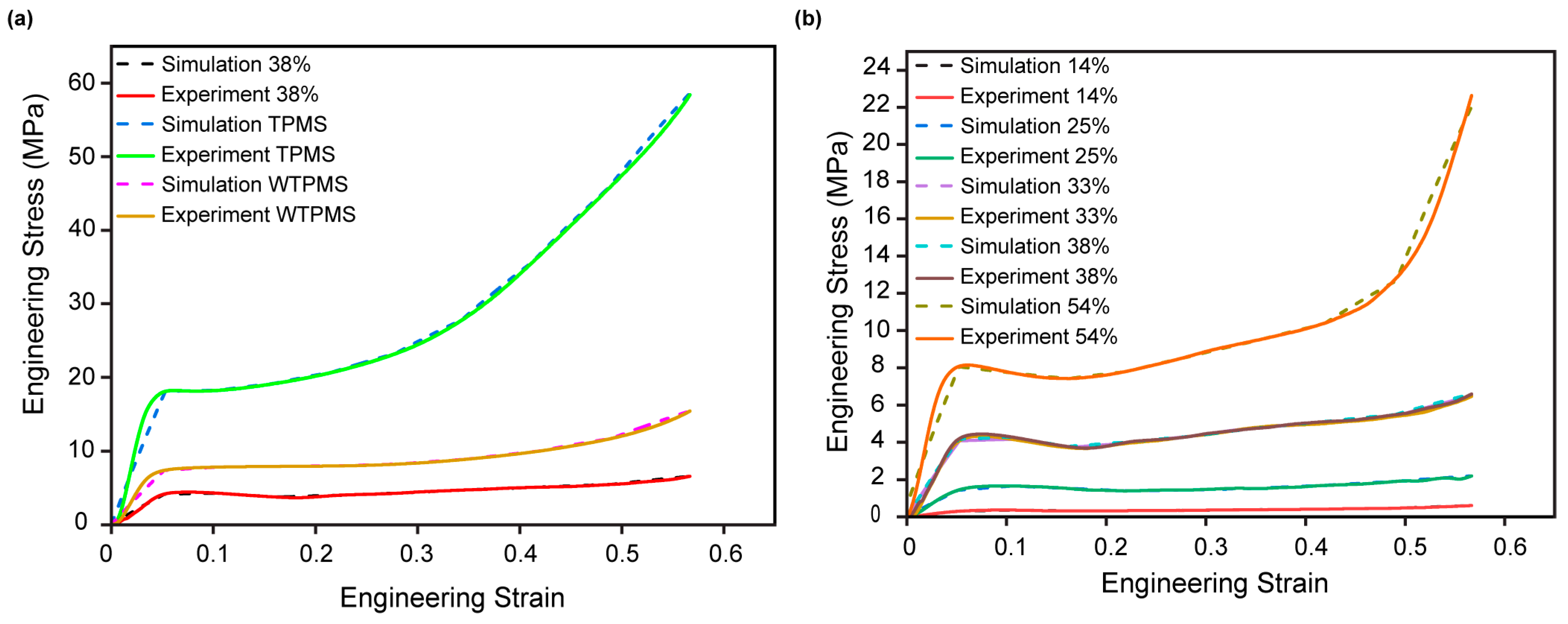

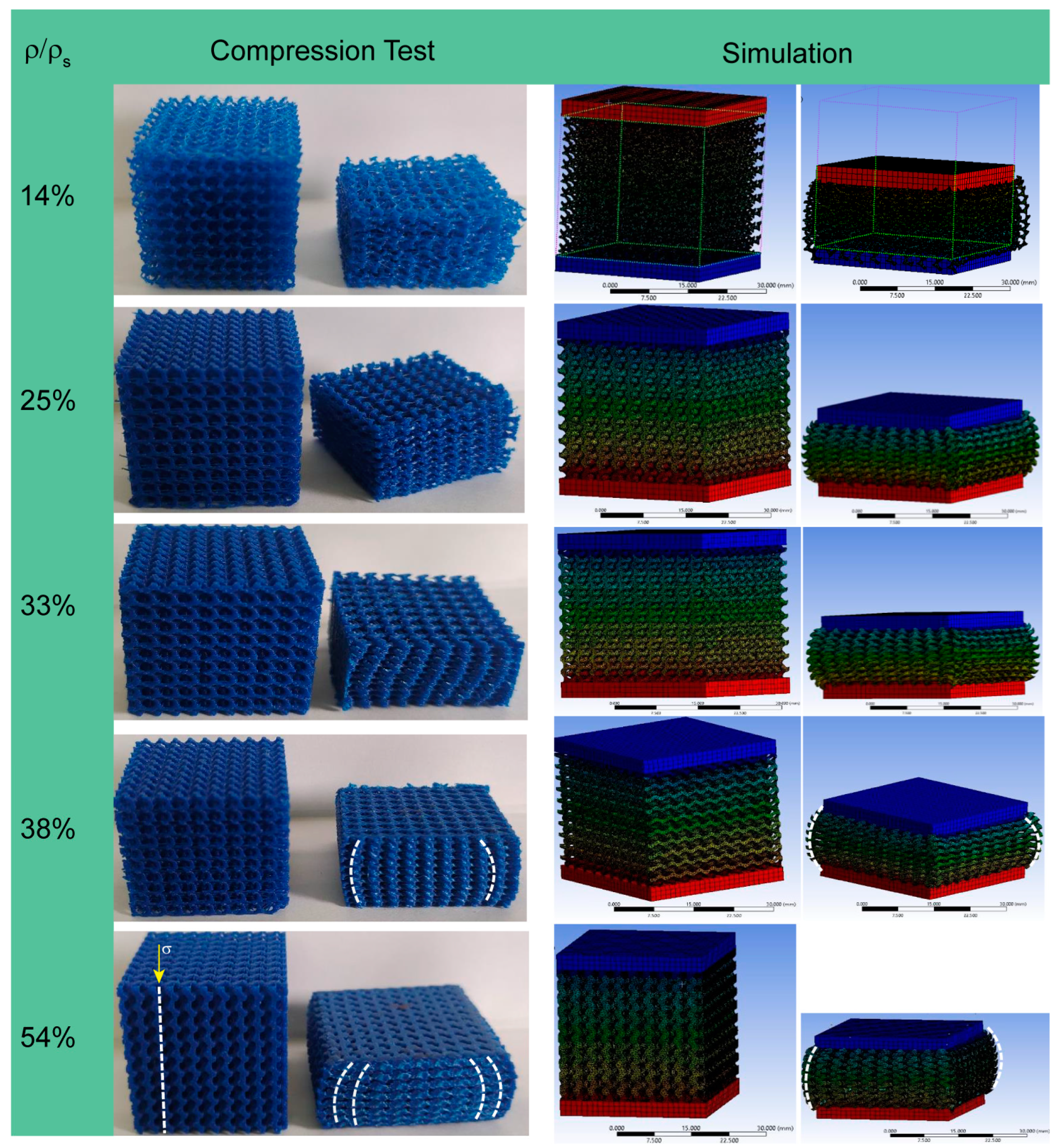

3.2. The Mechanical Properties and Compressive Response

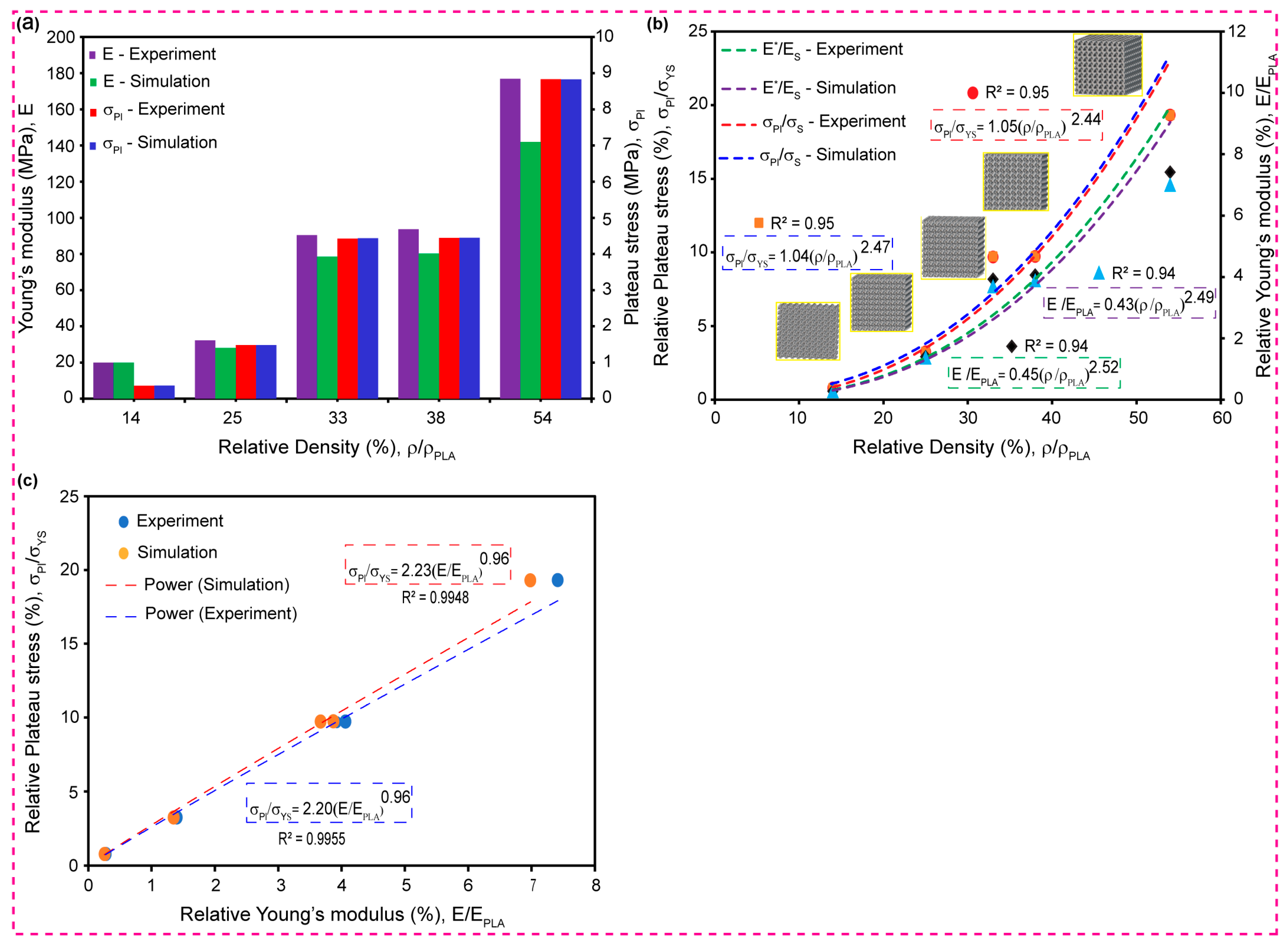

3.3. Plastic Plateau Stress and Young’s Modulus

3.4. Gibson–Ashby Power Fitting Analysis

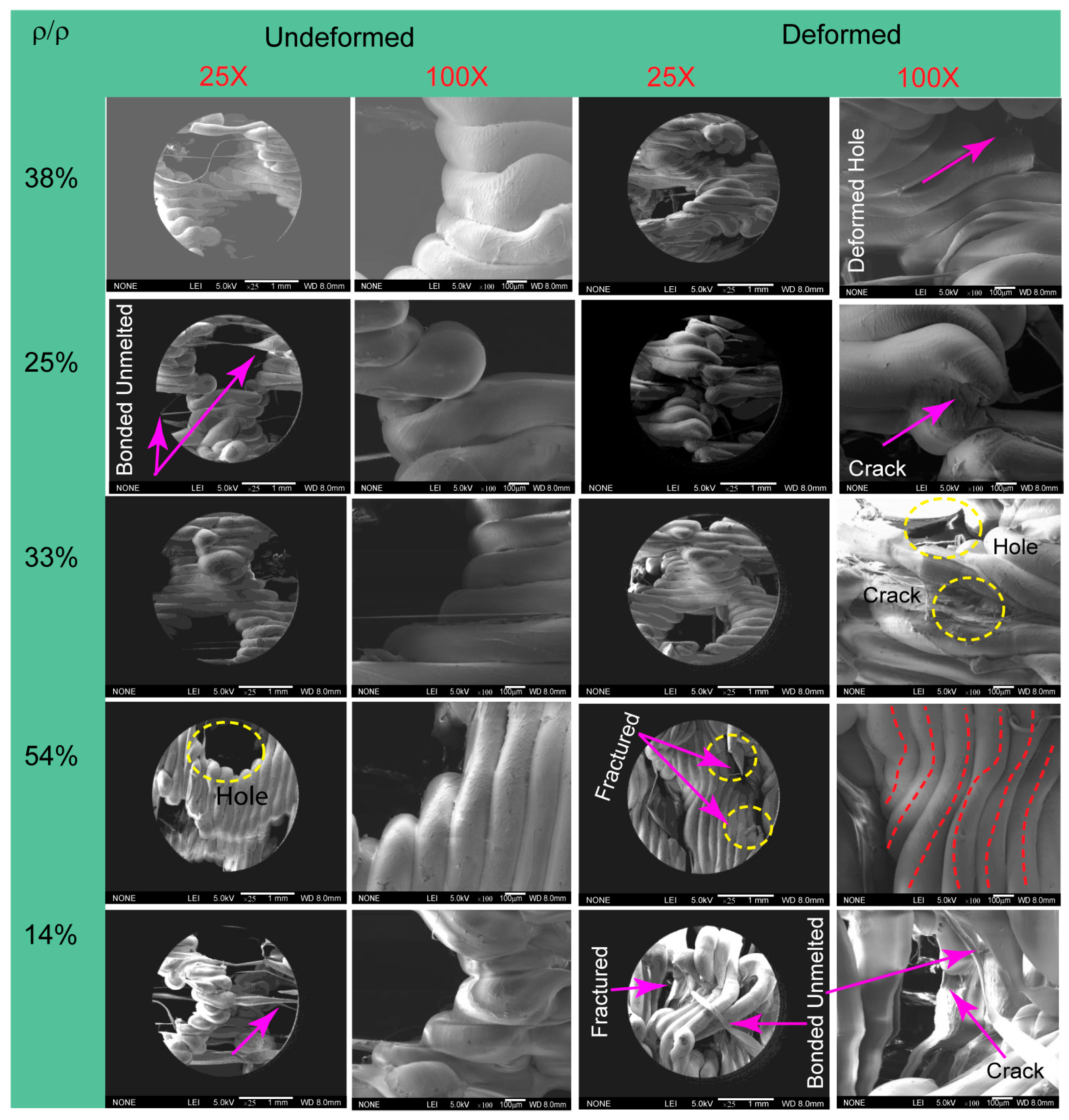

3.5. Microstructure of Undeformed and Deformed Lattice Structure

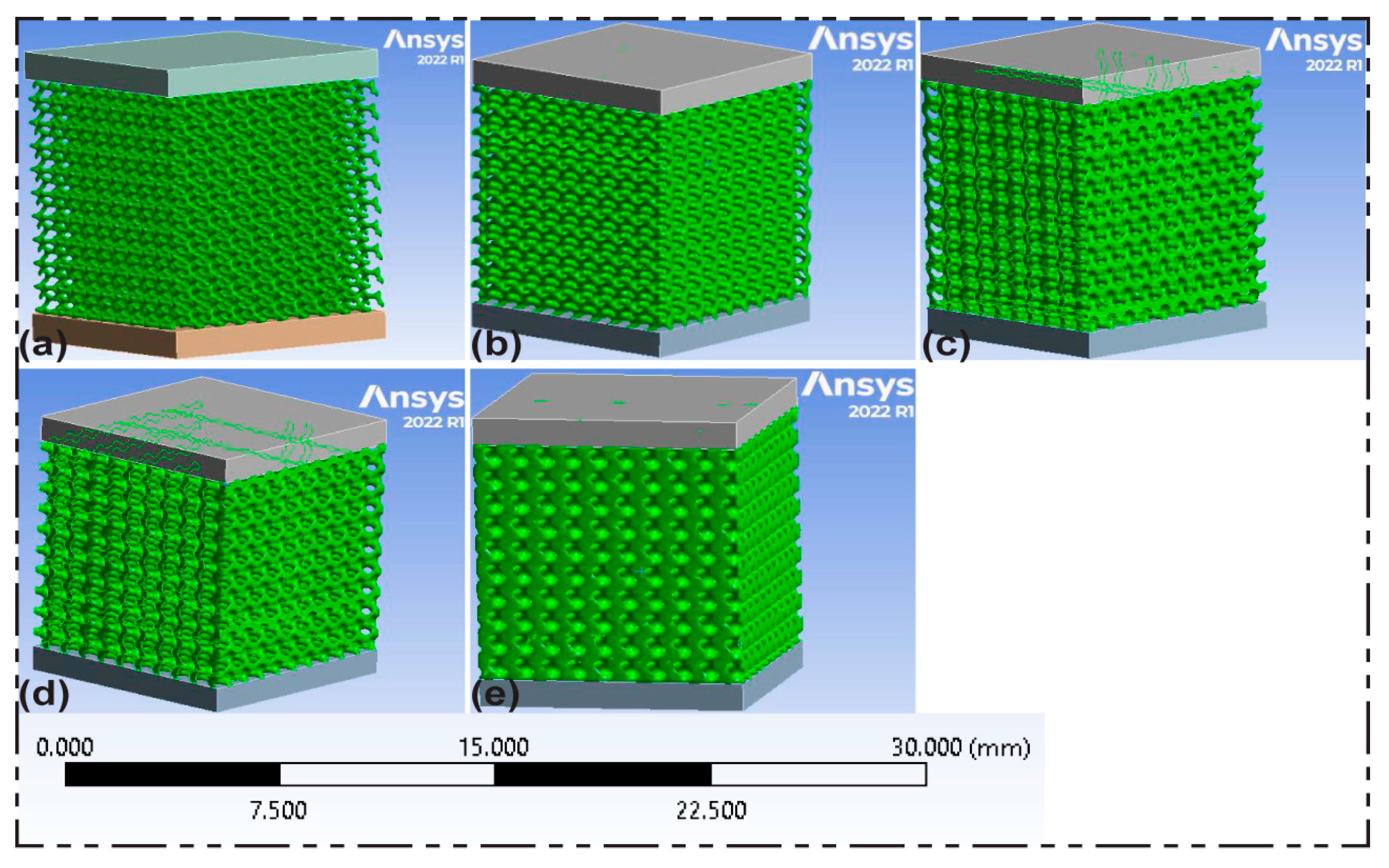

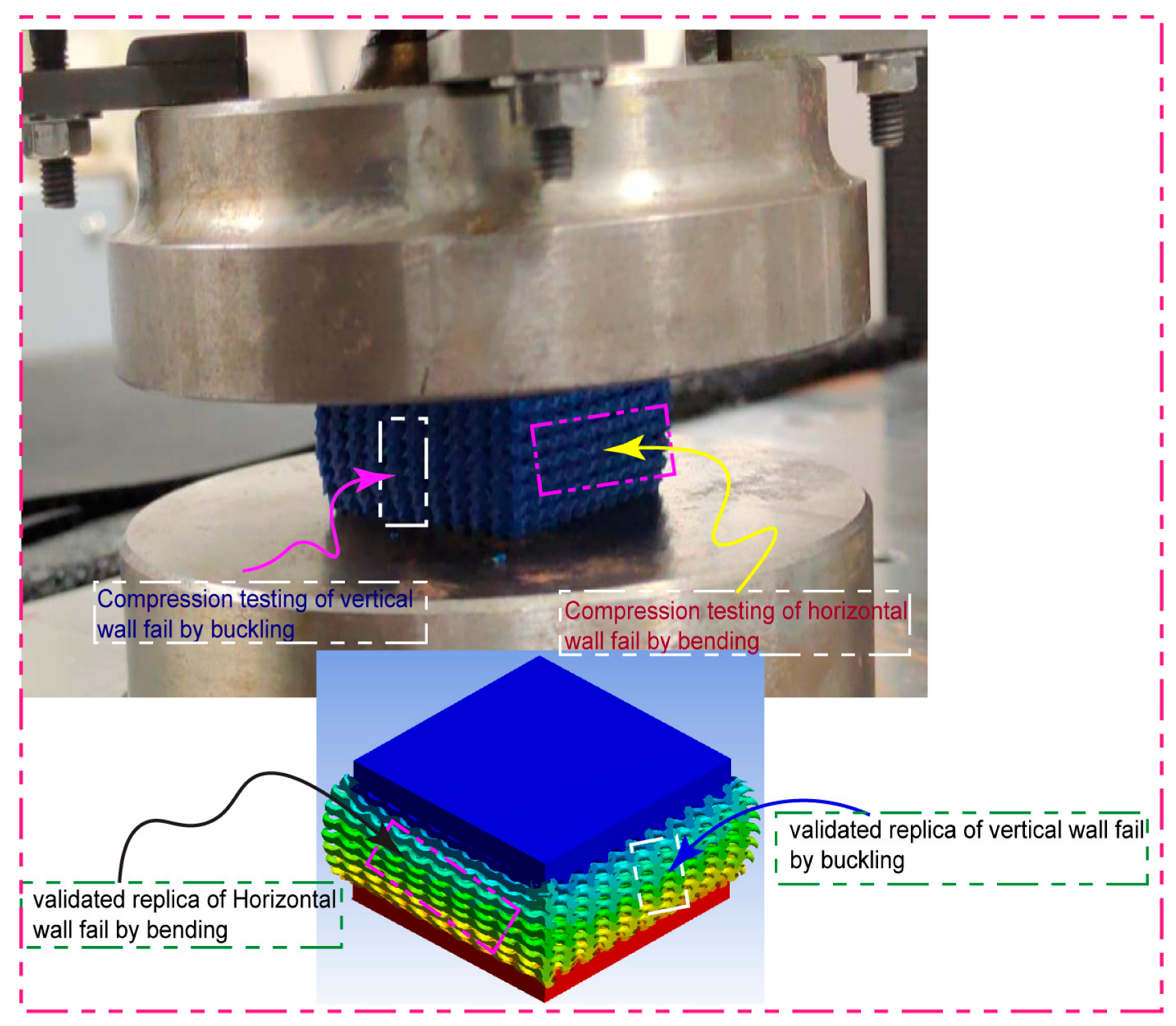

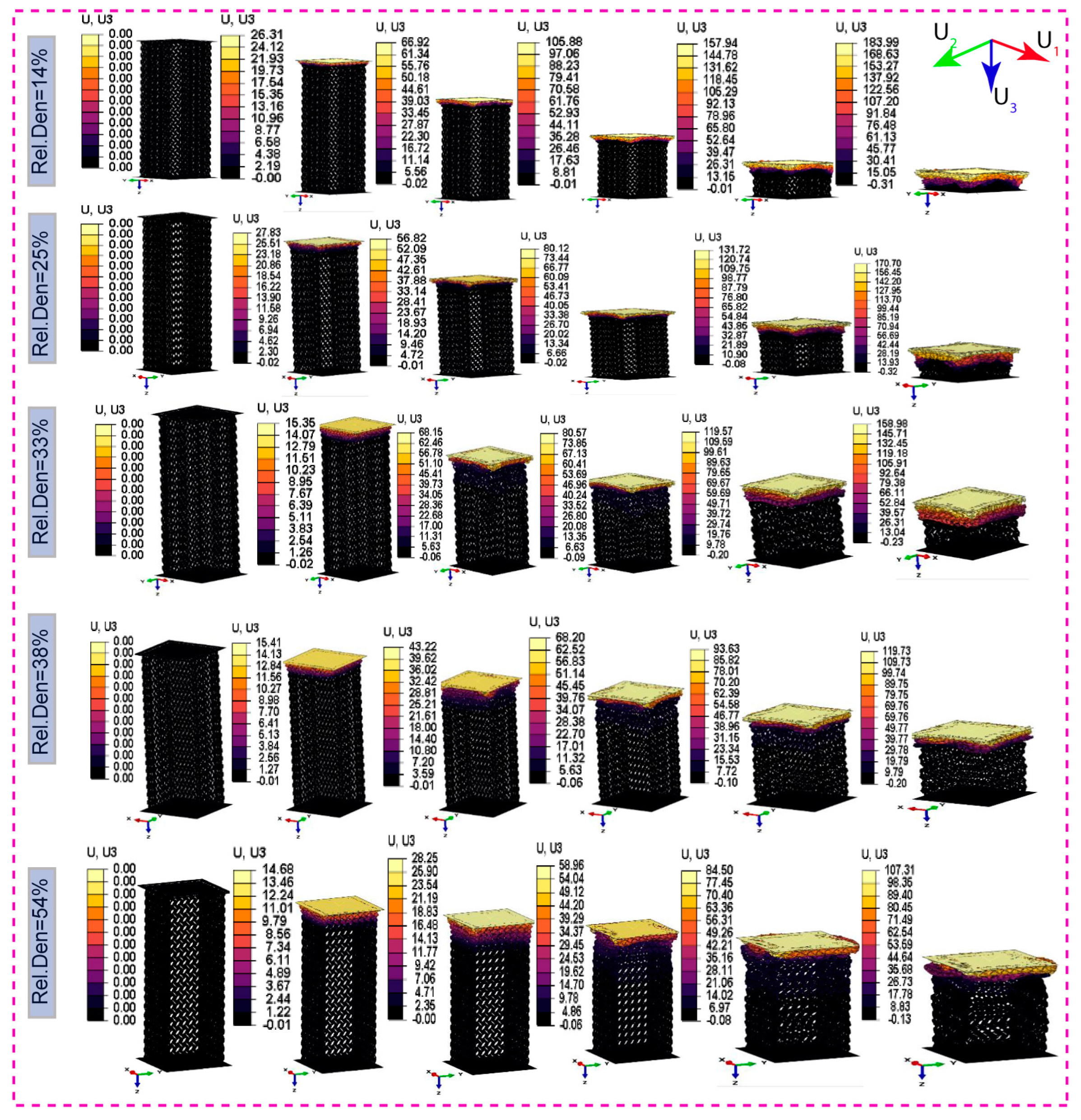

3.6. FEM Simulation of Mechanical Compression and Validation of Stress–Strain Curve

Mesh Convergence STUDY

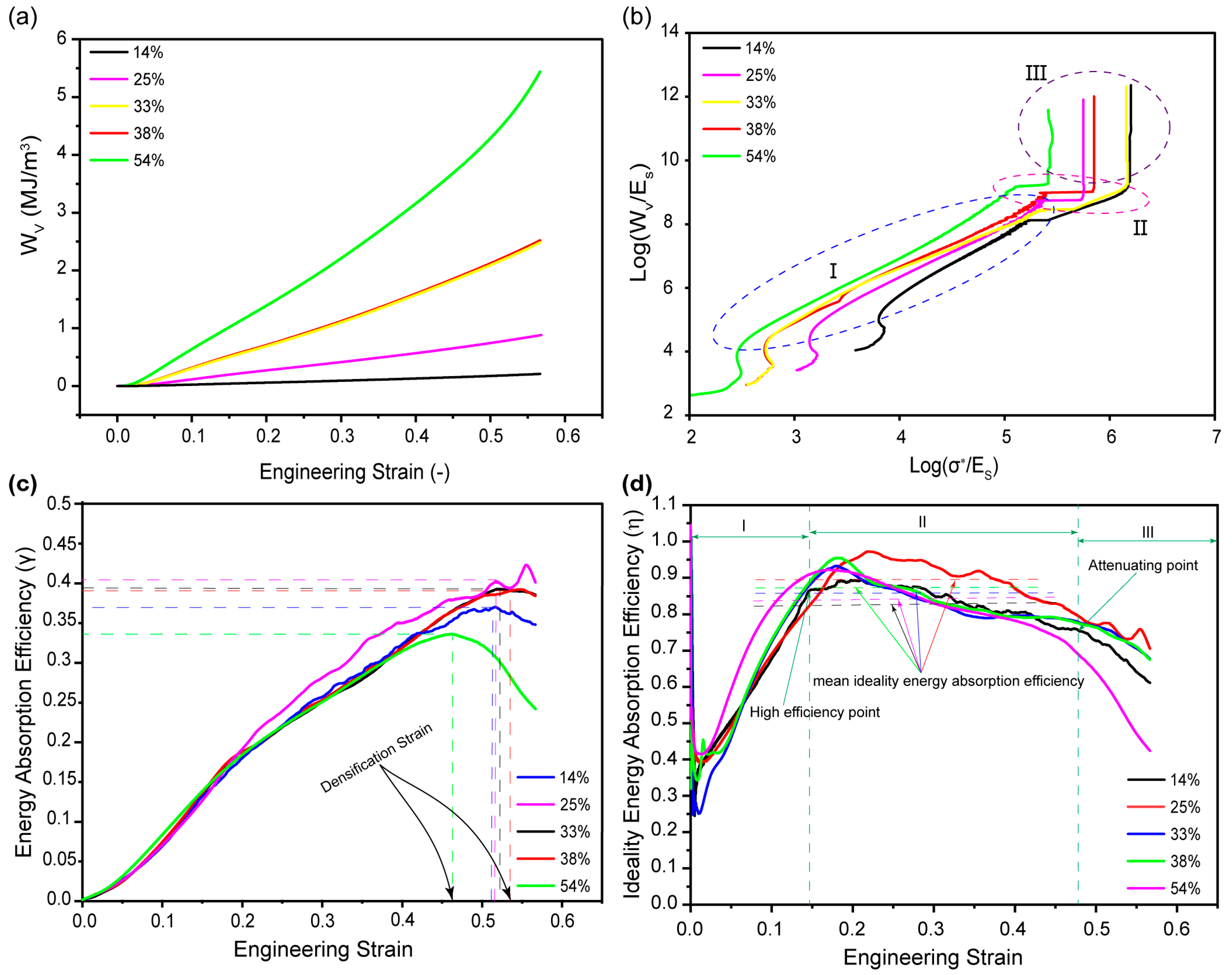

3.7. Energy Absorption

Maximum Energy Absorption and Densification Strain

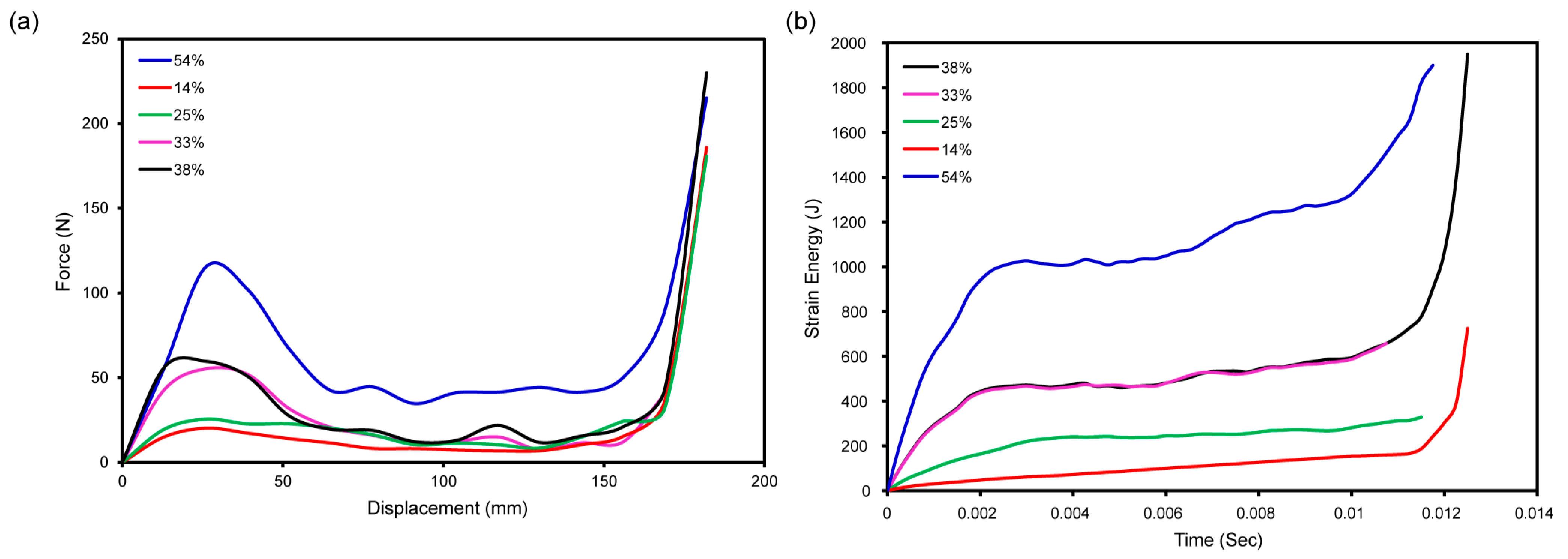

3.8. Case Study on Composite TPMS Gyroid Latticed Crash Box

4. Conclusions

- A newly created composite TPMS gyroid lattice, created by Boolean subtraction, exhibits a deformation mode that is primarily bending, which is consistent with idealized gyroid and ligament-based TPMS behaviors.

- The 54% relative density crash box has a significantly shorter densification phase while having a larger strain energy storage capacity than the 33% and 38% relative density crash boxes, which show ideal energy absorption prior to densification.

- The findings suggest that the composite TPMS gyroid lattice, with its normalized stress and energy absorption, is an excellent model for fabricating foam structures from a class of PLA materials engineered for energy absorption.

- Our findings support the Gibson–Ashby model by confirming the significant influence of relative density on the mechanical properties of composite TPMS gyroid lattices. They also emphasize the importance of tailoring the lattice architecture to optimize energy absorption capabilities.

- A comprehensive force–displacement and strain energy–time analysis elucidates the mechanical behavior of latticed crash boxes when subjected to impact. This analysis has significance for the advancement of design and implementation in high-impact scenarios.

- According to the study, composite TPMS gyroid-latticed crash boxes with lower relative densities outperform in energy absorption and deformability, particularly at 25% density, which provides an optimal balance of displacement capacity and mechanical rigidity, promising improved crashworthiness for automotive safety applications.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bacciaglia, A.; Ceruti, A.; Liverani, A. Structural Analysis of Voxel-Based Lattices Using 1D Approach. 3D Print. Addit. Manuf. 2022, 9, 365–379. [Google Scholar] [CrossRef] [PubMed]

- Pei, E.; Kabir, I.; Breški, T.; Godec, D.; Nordin, A. A Review of Geometric Dimensioning and Tolerancing (GD&T) of Additive Manufacturing and Powder Bed Fusion Lattices. Prog. Addit. Manuf. 2022, 7, 1297–1305. [Google Scholar] [CrossRef]

- McGregor, M.; Patel, S.; McLachlin, S.; Vlasea, M. Data Related to Architectural Bone Parameters and the Relationship to Ti Lattice Design for Powder Bed Fusion Additive Manufacturing. Data Br. 2021, 39, 107633. [Google Scholar] [CrossRef] [PubMed]

- Hussain, S.; Nazir, A.; Waqar, S.; Ali, U.; Gokcekaya, O. Effect of Additive Manufactured Hybrid and Functionally Graded Novel Designed Cellular Lattice Structures on Mechanical and Failure Properties. Int. J. Adv. Manuf. Technol. 2023, 128, 4873–4891. [Google Scholar] [CrossRef]

- Pugliese, R.; Graziosi, S. Biomimetic Scaffolds Using Triply Periodic Minimal Surface-Based Porous Structures for Biomedical Applications. SLAS Technol. 2023, 28, 165–182. [Google Scholar] [CrossRef] [PubMed]

- Shi, K.; Yang, W.; Mei, H.; Yan, Y.; Xu, L.; Cheng, L.; Zhang, L. Characterization and Enhancement of Quasi-Static and Shear Mechanical Properties of 3D Printed Lightweight SiOC Lattices: Effects of Structural Design and Parameters. J. Eur. Ceram. Soc. 2023, 43, 5882–5893. [Google Scholar] [CrossRef]

- Wu, J.; Yin, H.; Yan, Z.; Tian, G.; Ding, Z.; Yuan, X.; Fu, L.; Tian, Z.; Sui, X.; Liu, S. Preparation of Hierarchical Porous Cartilage Composite Scaffolds Loaded with Stromal Cell-Derived Factor-1 Using Low-Temperature Deposition 3D Printing. Chin. J. Tissue Eng. Res. 2023, 27, 4776. [Google Scholar]

- Yang, N.; Wei, H.; Mao, Z. Tuning Surface Curvatures and Young’s Moduli of TPMS-Based Lattices Independent of Volume Fraction. Mater. Des. 2022, 216, 110542. [Google Scholar] [CrossRef]

- Zhang, C.; Zheng, H.; Yang, L.; Li, Y.; Jin, J.; Cao, W.; Yan, C.; Shi, Y. Mechanical Responses of Sheet-Based Gyroid-Type Triply Periodic Minimal Surface Lattice Structures Fabricated Using Selective Laser Melting. Mater. Des. 2022, 214, 110407. [Google Scholar] [CrossRef]

- Du Plessis, A.; Razavi, N.; Benedetti, M.; Murchio, S.; Leary, M.; Watson, M.; Bhate, D.; Berto, F. Properties and Applications of Additively Manufactured Metallic Cellular Materials: A Review. Prog. Mater. Sci. 2022, 125, 100918. [Google Scholar] [CrossRef]

- du Plessis, A.; Broeckhoven, C.; Yadroitsava, I.; Yadroitsev, I.; Hands, C.H.; Kunju, R.; Bhate, D. Beautiful and Functional: A Review of Biomimetic Design in Additive Manufacturing. Addit. Manuf. 2019, 27, 408–427. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Tsongas, K.; Tzetzis, D. Finite Element Analysis of Orthopedic Hip Implant with Functionally Graded Bioinspired Lattice Structures. Biomimetics 2020, 5, 44. [Google Scholar] [CrossRef] [PubMed]

- Pelanconi, M.; Ortona, A. Nature-Inspired, Ultra-Lightweight Structures with Gyroid Cores Produced by Additive Manufacturing and Reinforced by Unidirectional Carbon Fiber Ribs. Materials 2019, 12, 4134. [Google Scholar] [CrossRef]

- Ren, J.; Wang, Y.; Yao, Y.; Wang, Y.; Fei, X.; Qi, P.; Lin, S.; Kaplan, D.L.; Buehler, M.J.; Ling, S. Biological Material Interfaces as Inspiration for Mechanical and Optical Material Designs. Chem. Rev. 2019, 119, 12279–12336. [Google Scholar] [CrossRef] [PubMed]

- Panesar, A.; Abdi, M.; Hickman, D.; Ashcroft, I. Strategies for Functionally Graded Lattice Structures Derived Using Topology Optimisation for Additive Manufacturing. Addit. Manuf. 2018, 19, 81–94. [Google Scholar] [CrossRef]

- Pelanconi, M.; Zavattoni, S.; Cornolti, L.; Puragliesi, R.; Arrivabeni, E.; Ferrari, L.; Gianella, S.; Barbato, M.; Ortona, A. Application of Ceramic Lattice Structures to Design Compact, High Temperature Heat Exchangers: Material and Architecture Selection. Materials 2021, 14, 3225. [Google Scholar] [CrossRef] [PubMed]

- Alizadeh-Osgouei, M.; Li, Y.; Vahid, A.; Ataee, A.; Wen, C. High Strength Porous PLA Gyroid Scaffolds Manufactured via Fused Deposition Modeling for Tissue-Engineering Applications. Smart Mater. Med. 2021, 2, 15–25. [Google Scholar] [CrossRef]

- Bouteldja, A.; Louar, M.A.; Hemmouche, L.; Gilson, L.; Miranda-Vicario, A.; Rabet, L. Experimental Investigation of the Quasi-Static and Dynamic Compressive Behavior of Polymer-Based 3D-Printed Lattice Structures. Int. J. Impact Eng. 2023, 180, 104640. [Google Scholar] [CrossRef]

- Qin, D.; Sang, L.; Zhang, Z.; Lai, S.; Zhao, Y. Compression Performance and Deformation Behavior of 3D-Printed PLA-Based Lattice Structures. Polymers 2022, 14, 1062. [Google Scholar] [CrossRef]

- Coluccia, A.; Jiang, G.; Meyer, G.; De Pasquale, G.; Mittelstedt, C. Nonlinear Static and Dynamic Modeling of Energy Absorption Lattice Structures Behavior. Mech. Adv. Mater. Struct. 2023, 30, 2838–2849. [Google Scholar] [CrossRef]

- Guo, T.; Scimeca, J.-C.; Ivanovski, S.; Verron, E.; Gulati, K. Enhanced Corrosion Resistance and Local Therapy from Nano-Engineered Titanium Dental Implants. Pharmaceutics 2023, 15, 315. [Google Scholar] [CrossRef] [PubMed]

- Intrigila, C.; Nodargi, N.A.; Bisegna, P. The Compressive Response of Additively-Manufactured Hollow Truss Lattices: An Experimental Investigation. Int. J. Adv. Manuf. Technol. 2022, 120, 3529–3541. [Google Scholar] [CrossRef]

- Varma, R.P. Energy Absorption of Multi-Material Cellular Structures. Ph.D. Thesis, Arizona State University, Tempe, AZ, USA, 2021. [Google Scholar]

- Yu, S.; Sun, J.; Bai, J. Investigation of Functionally Graded TPMS Structures Fabricated by Additive Manufacturing. Mater. Des. 2019, 182, 108021. [Google Scholar] [CrossRef]

- Guo, X.; Li, X.; Wang, E.; Fuh, J.Y.H.; Lu, W.F.; Zhai, W. Bioinspired Hierarchical Diamond Triply Periodic Minimal Surface Lattices with High Energy Absorption and Great Damage Tolerance. Addit. Manuf. 2023, 76, 103792. [Google Scholar]

- Mahapatra, I.; Velmurugan, R.; Jayaganthan, R. Enhanced Flexural Performance of Diamond Latticed Triply Periodic Minimal Surface Sandwich Panels. Adv. Eng. Mater. 2023, 2300813. [Google Scholar] [CrossRef]

- Li, F.; Gan, J.; Zhang, L.; Tan, H.; Li, E.; Li, B. Enhancing Impact Resistance of Hybrid Structures Designed with Triply Periodic Minimal Surfaces. Compos. Sci. Technol. 2024, 245, 110365. [Google Scholar] [CrossRef]

- Novak, N.; Al-Ketan, O.; Borovinšek, M.; Krstulović-Opara, L.; Rowshan, R.; Vesenjak, M.; Ren, Z. Development of Novel Hybrid TPMS Cellular Lattices and Their Mechanical Characterisation. J. Mater. Res. Technol. 2021, 15, 1318–1329. [Google Scholar] [CrossRef]

- Nazir, A.; Hussain, S.; Ali, H.M.; Waqar, S. Design and Mechanical Performance of Nature-Inspired Novel Hybrid Triply Periodic Minimal Surface Lattice Structures Fabricated Using Material Extrusion. Mater. Today Commun. 2024, 38, 108349. [Google Scholar] [CrossRef]

- Ingrole, A.; Hao, A.; Liang, R. Design and Modeling of Auxetic and Hybrid Honeycomb Structures for In-Plane Property Enhancement. Mater. Des. 2017, 117, 72–83. [Google Scholar] [CrossRef]

- Lazar, P.J.L.; Subramanian, J.; Natarajan, E.; Markandan, K.; Ramesh, S. Anisotropic Structure-Property Relations of FDM Printed Short Glass Fiber Reinforced Polyamide TPMS Structures under Quasi-Static Compression. J. Mater. Res. Technol. 2023, 24, 9562–9579. [Google Scholar] [CrossRef]

- Miralbes, R.; Higuera, S.; Ranz, D.; Gomez, J.A. Comparative Analysis of Mechanical Properties and Energy Absorption Capabilities of Functionally Graded and Non-Graded Thermoplastic Sheet Gyroid Structures. Mech. Adv. Mater. Struct. 2022, 29, 5142–5155. [Google Scholar] [CrossRef]

- Pasini, C.; Pandini, S.; Ramorino, G.; Sartore, L. Tailoring the Properties of Composite Scaffolds with a 3D-Printed Lattice Core and a Bioactive Hydrogel Shell for Tissue Engineering. J. Mech. Behav. Biomed. Mater. 2024, 150, 106305. [Google Scholar] [CrossRef] [PubMed]

- Sankineni, R.; Ravi Kumar, Y. Evaluation of Energy Absorption Capabilities and Mechanical Properties in FDM Printed PLA TPMS Structures. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 3558–3577. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, X.; Sun, Y.; Yang, J.; Chen, R.; Xiong, Y.; Hou, W.; Bai, L. Design of a Biomimetic Graded TPMS Scaffold with Quantitatively Adjustable Pore Size. Mater. Des. 2022, 218, 110665. [Google Scholar] [CrossRef]

- Borikar, G.P.; Patil, A.R.; Kolekar, S.B. Additively Manufactured Lattice Structures and Materials: Present Progress and Future Scope. Int. J. Precis. Eng. Manuf. 2023, 24, 1–48. [Google Scholar] [CrossRef]

- Li, X.; Yu, X.; Chua, J.W.; Lee, H.P.; Ding, J.; Zhai, W. Microlattice Metamaterials with Simultaneous Superior Acoustic and Mechanical Energy Absorption. Small 2021, 17, 2100336. [Google Scholar] [CrossRef] [PubMed]

- Noronha, J.; Qian, M.; Leary, M.; Kyriakou, E.; Brandt, M. Hollow-Walled Lattice Materials by Additive Manufacturing: Design, Manufacture, Properties, Applications and Challenges. Curr. Opin. Solid State Mater. Sci. 2021, 25, 100940. [Google Scholar] [CrossRef]

- Yang, X.; Ma, W.; Zhang, Z.; Liu, S.; Tang, H. Ultra-High Specific Strength Ti6Al4V Alloy Lattice Material Manufactured via Selective Laser Melting. Mater. Sci. Eng. A 2022, 840, 142956. [Google Scholar] [CrossRef]

- Amaechi, C.V.; Adefuye, E.F.; Kgosiemang, I.M.; Huang, B.; Amaechi, E.C. Scientometric Review for Research Patterns on Additive Manufacturing of Lattice Structures. Materials 2022, 15, 5323. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Pan, Z.; Ding, D.; Rong, Z.; Li, H.; Wu, B. Strut Formation Control and Processing Time Optimization for Wire Arc Additive Manufacturing of Lattice Structures. J. Manuf. Process. 2022, 79, 962–974. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, D.Z.; Li, Z.; Zhang, T.; Zhou, H.; Ren, Z. Design, Mechanical Properties, and Optimization of BCC Lattice Structures with Taper Struts. Compos. Struct. 2022, 295, 115830. [Google Scholar] [CrossRef]

- Bodaghi, M.; Namvar, N.; Yousefi, A.; Teymouri, H.; Demoly, F.; Zolfagharian, A. Metamaterial Boat Fenders with Supreme Shape Recovery and Energy Absorption/Dissipation via FFF 4D Printing. Smart Mater. Struct. 2023, 32, 95028. [Google Scholar] [CrossRef]

- Bouakaz, I.; Drouet, C.; Grossin, D.; Cobraiville, E.; Nolens, G. Hydroxyapatite 3D-Printed Scaffolds with Gyroid-Triply Periodic Minimal Surface Porous Structure: Fabrication and an In Vivo Pilot Study in Sheep. Acta Biomater. 2023, 170, 580–595. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Gao, K.; Yang, J.; Zhang, L. Functionally Graded Porous Structures: Analyses, Performances, and Applications—A Review. Thin-Walled Struct. 2023, 191, 111046. [Google Scholar] [CrossRef]

- Hamzehei, R.; Serjouei, A.; Wu, N.; Zolfagharian, A.; Bodaghi, M. 4D Metamaterials with Zero Poisson’s Ratio, Shape Recovery, and Energy Absorption Features. Adv. Eng. Mater. 2022, 24, 2200656. [Google Scholar] [CrossRef]

- Medvedev, A.E.; Maconachie, T.; Leary, M.; Qian, M.; Brandt, M. Perspectives on Additive Manufacturing for Dynamic Impact Applications. Mater. Des. 2022, 221, 110963. [Google Scholar] [CrossRef]

- Shen, B.; Chen, Y.; Li, C.; Wang, S.; Chen, X. Superconducting Fault Current Limiter (SFCL): Experiment and the Simulation from Finite-Element Method (FEM) to Power/Energy System Software. Energy 2021, 234, 121251. [Google Scholar] [CrossRef]

- David Müzel, S.; Bonhin, E.P.; Guimarães, N.M.; Guidi, E.S. Application of the Finite Element Method in the Analysis of Composite Materials: A Review. Polymers 2020, 12, 818. [Google Scholar] [CrossRef] [PubMed]

- Alemayehu, D.B.; Huang, S.-J.; Koricho, E.G. Experimental and FEM Analysis of Three Carbon Steel Characterization under Quasi-Static Strain Rate for Bumper Beam Application. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2017; Volume 123. [Google Scholar]

- Alemayehu, D.B.; Jeng, Y.R. Three-Dimensional Finite Element Investigation into Effects of Implant Thread Design and Loading Rate on Stress Distribution in Dental Implants and Anisotropic Bone. Materials 2021, 14, 6974. [Google Scholar] [CrossRef]

- Al-Wattar, T.A.A. Developing Equivalent Solid Model for Lattice Cell Structures Using Numerical Approaches. Ph.D. Thesis, Wright State University, Dayton, OH, USA, 2020. [Google Scholar]

- Alemayehu, D.B.; Todoh, M.; Huang, S.-J. Advancing 3D Dental Implant FEA: Incorporating Biomimetic Trabecular Bone with Varied Pore Sizes in Voronoi Lattices. J. Funct. Biomater. 2024, 15, 94. [Google Scholar] [CrossRef]

- Gharehbaghi, H.; Farrokhabadi, A. Experimental, Analytical, and Numerical Studies of the Energy Absorption Capacity of Bi-Material Lattice Structures Based on Quadrilateral Bipyramid Unit Cell. Compos. Struct. 2024, 337, 118042. [Google Scholar] [CrossRef]

- Guo, Z.; Hu, J.; Kong, Z. On Impact Loading of Voronoi Functional Graded Porous Structure. Mater. Today Commun. 2024, 38, 107765. [Google Scholar] [CrossRef]

- NTpology Software. Available online: https://www.ntop.com/ (accessed on 30 January 2024).

- Palmiyanto, M.H.; Surojo, E.; Ariawan, D.; Imaduddin, F. E-Glass/Kenaf Fibre Reinforced Thermoset Composites Fiiled with MCC and Immersion in a Different Fluid. Sci. Rep. 2022, 12, 20332. [Google Scholar] [CrossRef]

- Al, G.; Aydemir, D.; Kaygin, B.; Ayrilmis, N.; Gunduz, G. Preparation and Characterization of Biopolymer Nanocomposites from Cellulose Nanofibrils and Nanoclays. J. Compos. Mater. 2017, 52, 689–700. [Google Scholar] [CrossRef]

- Ervina, J.; Mariatti, M.; Hamdan, S. Mechanical, Electrical and Thermal Properties of Multi-Walled Carbon Nanotubes/Epoxy Composites: Effect of Post-Processing Techniques and Filler Loading. Polym. Bull. 2017, 74, 2513–2533. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Rowshan, R.; Abu Al-Rub, R.K. Topology-Mechanical Property Relationship of 3D Printed Strut, Skeletal, and Sheet Based Periodic Metallic Cellular Materials. Addit. Manuf. 2018, 19, 167–183. [Google Scholar] [CrossRef]

- Cheng, X.Y.; Li, S.J.; Murr, L.E.; Zhang, Z.B.; Hao, Y.L.; Yang, R.; Medina, F.; Wicker, R.B. Compression Deformation Behavior of Ti-6Al-4V Alloy with Cellular Structures Fabricated by Electron Beam Melting. J. Mech. Behav. Biomed. Mater. 2012, 16, 153–162. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Liu, S.Z.; Wu, X.N.; Wang, J.Y.; Han, Y.S.; Zhang, X.C. Mechanical Characteristics of a Novel Rotating Star-Rhombic Auxetic Structure with Multi-Plateau Stages. Thin-Walled Struct. 2023, 191, 111081. [Google Scholar] [CrossRef]

- Wang, N.; Meenashisundaram, G.K.; Chang, S.; Fuh, J.Y.H.; Dheen, S.T.; Senthil Kumar, A. A Comparative Investigation on the Mechanical Properties and Cytotoxicity of Cubic, Octet, and TPMS Gyroid Structures Fabricated by Selective Laser Melting of Stainless Steel 316L. J. Mech. Behav. Biomed. Mater. 2022, 129, 105151. [Google Scholar] [CrossRef]

- Ashby, M.F. The Properties of Foams and Lattices. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 364, 15–30. [Google Scholar] [CrossRef]

- Gibson, L.J. Cellular Solids. Mrs Bull. 2003, 28, 270–274. [Google Scholar] [CrossRef]

- Iantaffi, C.; Bele, E.; McArthur, D.; Lee, P.D.; Leung, C.L.A. Auxetic Response of Additive Manufactured Cubic Chiral Lattices at Large Plastic Strains. Mater. Des. 2023, 233, 112207. [Google Scholar] [CrossRef]

- Kechagias, S.; Oosterbeek, R.N.; Munford, M.J.; Ghouse, S.; Jeffers, J.R.T. Controlling the Mechanical Behaviour of Stochastic Lattice Structures: The Key Role of Nodal Connectivity. Addit. Manuf. 2022, 54, 102730. [Google Scholar] [CrossRef]

- Sahariah, B.J.; Namdeo, A.; Khanikar, P. Composite-Inspired Multilattice Metamaterial Structure: An Auxetic Lattice Design with Improved Strength and Energy Absorption. Mater. Today Commun. 2022, 30, 103159. [Google Scholar] [CrossRef]

- Habib, F.N.; Iovenitti, P.; Masood, S.H.; Nikzad, M. Fabrication of Polymeric Lattice Structures for Optimum Energy Absorption Using Multi Jet Fusion Technology. Mater. Des. 2018, 155, 86–98. [Google Scholar] [CrossRef]

- Miltz, J.; Ramon, O. Energy Absorption Characteristics of Polymeric Foams Used as Cushioning Materials. Polym. Eng. Sci. 1990, 30, 129–133. [Google Scholar] [CrossRef]

- Rahimidehgolan, F.; Altenhof, W. Compressive Behavior and Deformation Mechanisms of Rigid Polymeric Foams: A Review. Compos. Part B Eng. 2023, 253, 110513. [Google Scholar] [CrossRef]

- Maskery, I.; Aboulkhair, N.T.; Aremu, A.O.; Tuck, C.J.; Ashcroft, I.A. Compressive Failure Modes and Energy Absorption in Additively Manufactured Double Gyroid Lattices. Addit. Manuf. 2017, 16, 24–29. [Google Scholar] [CrossRef]

- Toksoy, A.K.; Güden, M. Partial Al Foam Filling of Commercial 1050H14 Al Crash Boxes: The Effect of Box Column Thickness and Foam Relative Density on Energy Absorption. Thin-Walled Struct. 2010, 48, 482–494. [Google Scholar] [CrossRef]

- Simpson, J.; Kazancı, Z. Crushing Investigation of Crash Boxes Filled with Honeycomb and Re-Entrant (Auxetic) Lattices. Thin-Walled Struct. 2020, 150, 106676. [Google Scholar] [CrossRef]

- Ashby, M.F.; Evans, T.; Fleck, N.A.; Hutchinson, J.W.; Wadley, H.N.G.; Gibson, L.J. Metal Foams: A Design Guide; Elsevier: Amsterdam, The Netherlands, 2000; ISBN 0080511465. [Google Scholar]

- Duan, Y.; Zhao, X.; Du, B.; Shi, X.; Zhao, H.; Hou, B.; Li, Y. Quasi-Static Compressive Behavior and Constitutive Model of Graded Foams. Int. J. Mech. Sci. 2020, 177, 105603. [Google Scholar] [CrossRef]

- Maiti, S.K.; Gibson, L.J.; Ashby, M.F. Deformation and Energy Absorption Diagrams for Cellular Solids. Acta Metall. 1984, 32, 1963–1975. [Google Scholar] [CrossRef]

- Haney, C.W.; Siller, H.R. Properties of Hyper-Elastic-Graded Triply Periodic Minimal Surfaces. Polymers 2023, 15, 4475. [Google Scholar] [CrossRef]

- Chen, R.; Wang, S.; Wu, Z.; Jia, Y.; Zhang, W.; Cao, B.; Song, X.; Ma, Q.; Li, C.; Du, J. Compressive Enhancement Gyroid Lattice with Implicit Modeling Implementation and Modified GA Model Property Prediction. Mater. Des. 2023, 232, 112153. [Google Scholar] [CrossRef]

- Vafaeefar, M.; Moerman, K.M.; Vaughan, T.J. Experimental and Computational Analysis of Energy Absorption Characteristics of Three Biomimetic Lattice Structures under Compression. J. Mech. Behav. Biomed. Mater. 2024, 151, 106328. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Liu, F.; Zhou, H.; Zhang, T.; Zhang, D.Z.; Fu, G. Effect of the Direction of the Gradient on the Mechanical Properties and Energy Absorption of Additive Manufactured Ti-6Al-4 V Functionally Graded Lattice Structures. J. Alloys Compd. 2023, 968, 171874. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Tsongas, K.; Tzetzis, D. Mechanical and FEA-Assisted Characterization of Fused Filament Fabricated Triply Periodic Minimal Surface Structures. J. Compos. Sci. 2021, 5, 58. [Google Scholar] [CrossRef]

- Lu, C.; Zhang, C.; Wen, P.; Chen, F. Mechanical Behavior of Al–Si10–Mg Gyroid Surface with Variable Topological Parameters Fabricated via Laser Powder Bed Fusion. J. Mater. Res. Technol. 2021, 15, 5650–5661. [Google Scholar] [CrossRef]

- Abou-Ali, A.M.; Al-Ketan, O.; Lee, D.W.; Rowshan, R.; Abu Al-Rub, R.K. Mechanical Behavior of Polymeric Selective Laser Sintered Ligament and Sheet Based Lattices of Triply Periodic Minimal Surface Architectures. Mater. Des. 2020, 196, 109100. [Google Scholar] [CrossRef]

- Miltz, J.; Gruenbaum, G. Evaluation of Cushioning Properties of Plastic Foams from Compressive Measurements. Polym. Eng. Sci. 1981, 21, 1010–1014. [Google Scholar] [CrossRef]

- Abou-Ali, A.M.; Lee, D.W.; Abu Al-Rub, R.K. On the Effect of Lattice Topology on Mechanical Properties of SLS Additively Manufactured Sheet-, Ligament-, and Strut-Based Polymeric Metamaterials. Polymers 2022, 14, 4583. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Liu, Y.; Babamiri, B.B.; Zhou, Y.; Dargusch, M.; Hazeli, K.; Zhang, M.-X. Enhancing Specific Energy Absorption of Additively Manufactured Titanium Lattice Structures through Simultaneous Manipulation of Architecture and Constituent Material. Addit. Manuf. 2022, 55, 102887. [Google Scholar] [CrossRef]

- Zheng, G.; Zhang, L.; Wang, E.; Yao, R.; Luo, Q.; Li, Q.; Sun, G. Investigation into Multiaxial Mechanical Behaviors of Kelvin and Octet-B Polymeric Closed-Cell Foams. Thin-Walled Struct. 2022, 177, 109405. [Google Scholar] [CrossRef]

| Symbols | Descriptions |

|---|---|

| Density of the gyroid lattice structure, Kg/m3. | |

| Density of the bulk materials from which the gyroid lattice is made, Kg/m3. | |

| Volume fraction, or relative density, of the gyroid lattice; | |

| Young’s modulus of gyroid lattice | |

| Young’s modulus of the bulk materials from which the gyroid lattice is made. | |

| Relative Young’s modulus of the Composite TPMS gyroid lattice, | |

| Plateau Stress of composite TPMS gyroid lattice structure | |

| The yield stress of the bulk materials from which the gyroid lattice is made. | |

| Relative plateau stress of the gyroid lattice | |

| Effective strain of the gyroid lattice structure | |

| Engineering Stress of composite TPMS gyroid lattice structure | |

| p | The porosity of the composite lattice |

| Densification strain of composite TPMS gyroid lattice | |

| MCG | Mass of composite TPMS gyroid lattice, kg |

| WV | Energy absorption per volume of composite TPMS gyroid lattice, MJ/m3. |

| η | Ideal energy absorption efficiency of composite lattice. |

| γ | Efficiency of energy absorption by composite TPMS gyroid lattice. |

| C | Gibson–Ashby constant. |

| n | Gibson–Ashby exponent. |

| Thickness of Sheet TPMS Gyroid (mm) | Thickness of Walled TPMS Gyroid (mm) | Composite TPMS Gyroid (ρ./ρPLA.) |

|---|---|---|

| 0.4 | 1.2 | 14% |

| 0.3 | 1.0 | 25% |

| 0.25 | 0.75 | 33% |

| 0.2 | 0.6 | 38% |

| 0.1 | 0.1 | 54% |

| Printing Parameters | Values |

|---|---|

| Printing speed | 50 mm/s |

| Printing temperature | 205 °C |

| Bed temperature | 65 °C |

| Infill | 100% |

| Extrusion width | 0.48 mm |

| Filament diameter | 1.75 mm |

| Raster angle | 45/−45 |

| Property | Value | Testing Conditions |

|---|---|---|

| Density | 1.2 g/cm3 @ 21.5 °C | ASTM D792-ISO |

| Young’s Modulus | 2636 ± 330 MPa | ASTM D638-ISO 527, Flat (X-Y) |

| Tensile Strength | 46.6 ± 0.9 MPa | ASTM D638-ISO 527, Flat (X-Y) |

| Elongation at Break | 1.90 ± 0.2% | ASTM D638-ISO 527, Flat (X-Y) |

| Levels | Relative Density (%) | Replica |

|---|---|---|

| Solid PLA Cube | - | 3 |

| GTL | - | 3 |

| WGTL | - | 3 |

| CTL14 | 14% | 3 |

| CTL25 | 25% | 3 |

| CTL33 | 33% | 3 |

| CTL38 | 38% | 3 |

| CTL54 | 54% | 3 |

| Lattice Type | Measured Average Weight (g) | Actual Density (g/cm3) | Relative Density (%) | Porosity (%) |

|---|---|---|---|---|

| GTL | 20.38 ± 2.50 × 10−2 | 0.75 ± 1.93 × 10−3 | 61 | 39 |

| WGTL | 13.08 ± 2.40 × 10−3 | 0.48 ± 4.10 × 10−4 | 39 | 61 |

| CTL14 | 4.69 ± 2.38 × 10−3 | 0.17 ± 9.00 ×10−5 | 14 | 86 |

| CTL 25 | 8.37 ± 1.87 × 10−2 | 0.31 ± 6.90 × 10−4 | 25 | 75 |

| CTL 33 | 11.05 ± 2.06 × 10−2 | 0.41 ± 7.60 × 10−4 | 33 | 67 |

| CTL 38 | 12.70 ± 2.10 × 10−2 | 0.47 ± 7.60 × 10−4 | 38 | 62 |

| CTL 54 | 18.08 ± 2.51 × 10−2 | 0.67 ± 9.30 × 10−4 | 54 | 46 |

| Elastic Modulus (MPa) | Plastic Plateau (MPa) | |||||

|---|---|---|---|---|---|---|

| Relative Density | Experiment | Simulation | Error (%) | Experiment | Simulation | Error (%) |

| 14% | 6.34 ± 0.10 | 5.96 ± 0.1 | 6.05 | 0.36 ± 0.10 | 0.36 ± 0.1 | 0.21 |

| 25% | 32.24 ± 0.35 | 30.10 ± 0.35 | 6.64 | 1.48 ± 0.35 | 1.48 ± 0.35 | 0.02 |

| 33% | 90.47 ± 1.08 | 83.62 ± 1.12 | 7.57 | 4.43 ± 1.08 | 4.44 ± 1.12 | 0.35 |

| 38% | 93.66 ± 1.08 | 87.27 ± 1.10 | 6.82 | 4.44 ± 1.08 | 4.45 ± 1.10 | 0.09 |

| 54% | 176.93 ± 3.75 | 163.98 ± 3.55 | 7.32 | 8.83 ± 3.75 | 8.83 ± 3.55 | 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alemayehu, D.B.; Todoh, M. Enhanced Energy Absorption with Bioinspired Composite Triply Periodic Minimal Surface Gyroid Lattices Fabricated via Fused Filament Fabrication (FFF). J. Manuf. Mater. Process. 2024, 8, 86. https://doi.org/10.3390/jmmp8030086

Alemayehu DB, Todoh M. Enhanced Energy Absorption with Bioinspired Composite Triply Periodic Minimal Surface Gyroid Lattices Fabricated via Fused Filament Fabrication (FFF). Journal of Manufacturing and Materials Processing. 2024; 8(3):86. https://doi.org/10.3390/jmmp8030086

Chicago/Turabian StyleAlemayehu, Dawit Bogale, and Masahiro Todoh. 2024. "Enhanced Energy Absorption with Bioinspired Composite Triply Periodic Minimal Surface Gyroid Lattices Fabricated via Fused Filament Fabrication (FFF)" Journal of Manufacturing and Materials Processing 8, no. 3: 86. https://doi.org/10.3390/jmmp8030086

APA StyleAlemayehu, D. B., & Todoh, M. (2024). Enhanced Energy Absorption with Bioinspired Composite Triply Periodic Minimal Surface Gyroid Lattices Fabricated via Fused Filament Fabrication (FFF). Journal of Manufacturing and Materials Processing, 8(3), 86. https://doi.org/10.3390/jmmp8030086