Analytical Model of Quantitative Texture Prediction Considering Heat Transfer Based on Single-Phase Material in Laser Powder Bed Fusion

Abstract

1. Introduction

2. Methodology

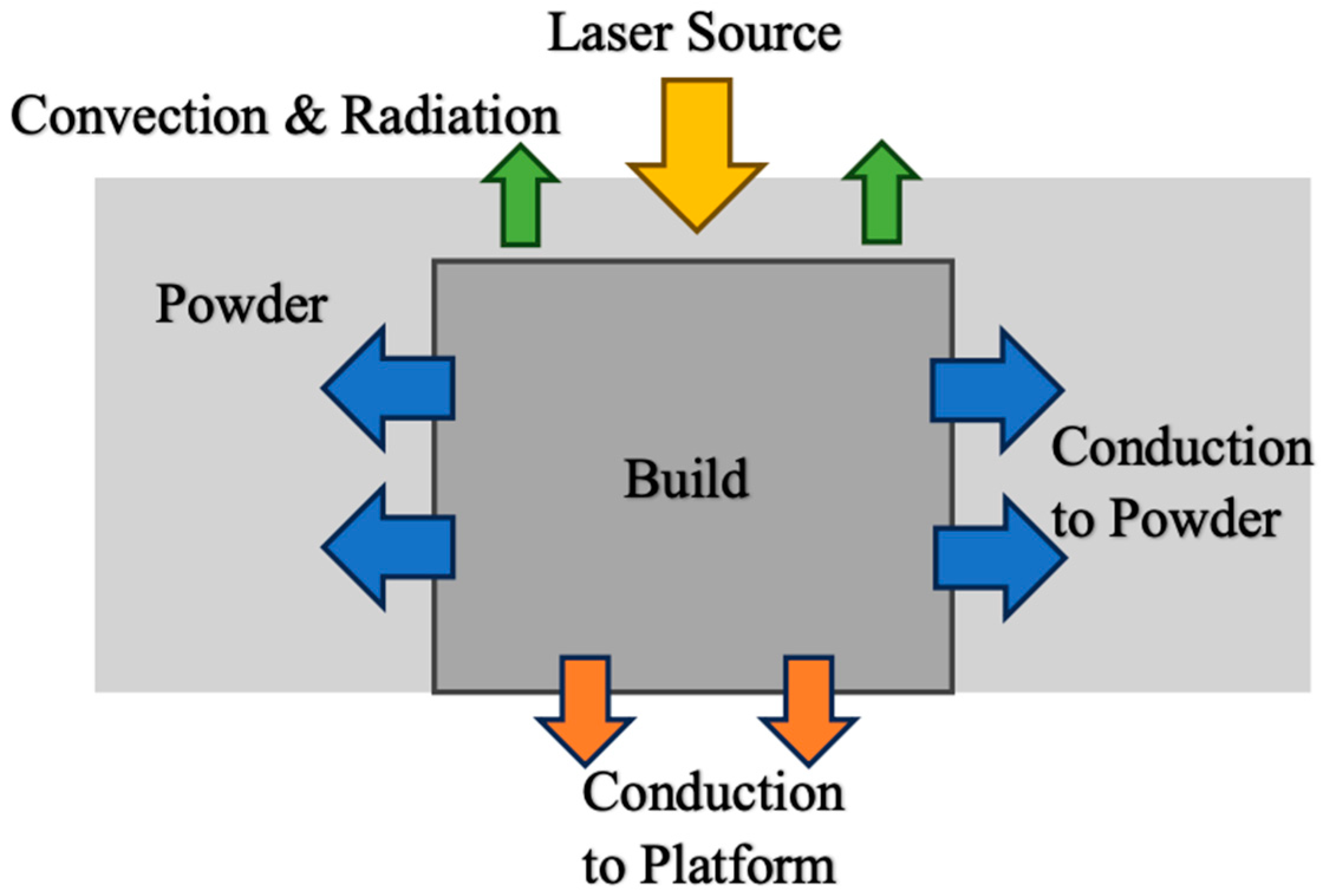

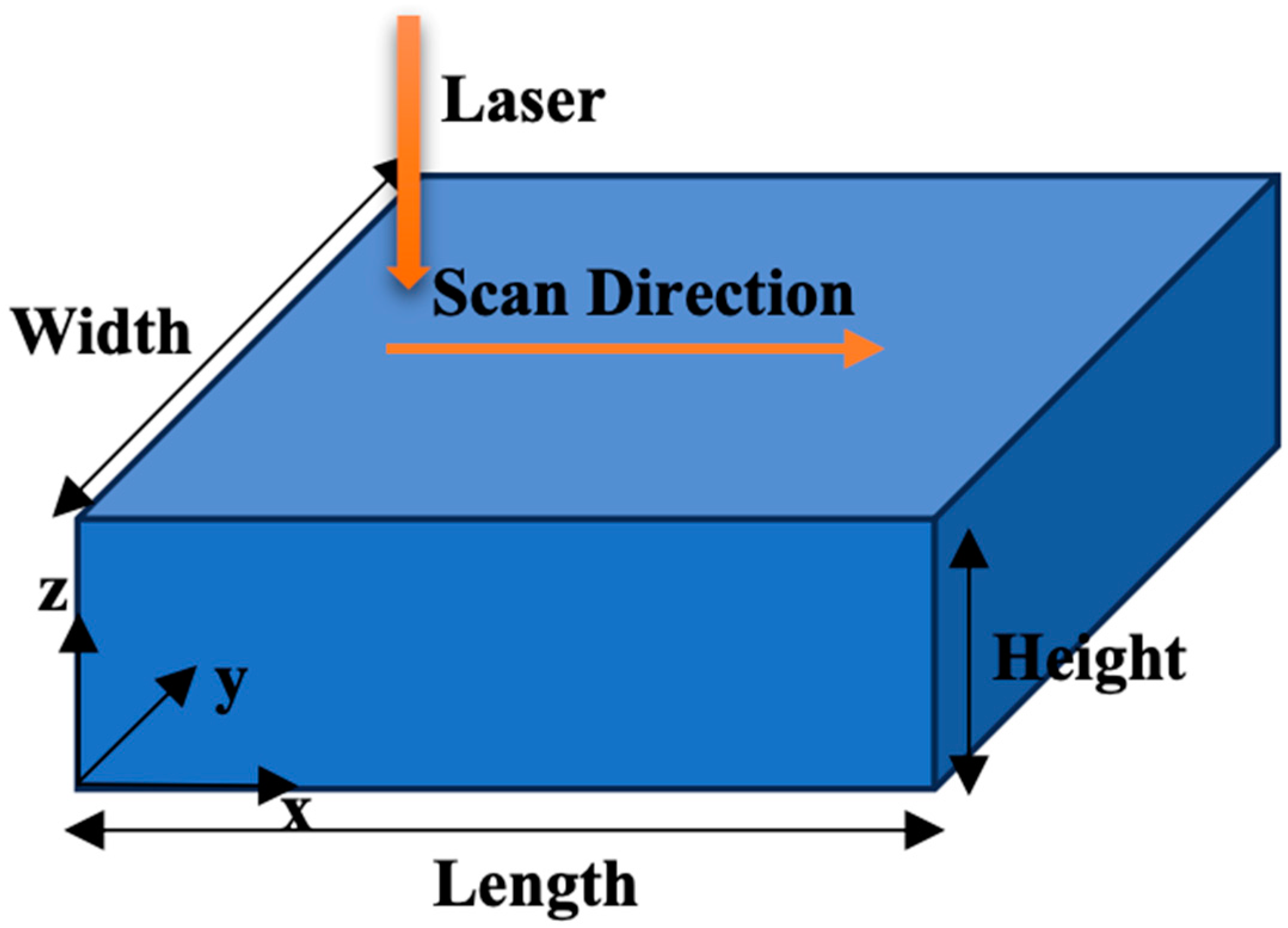

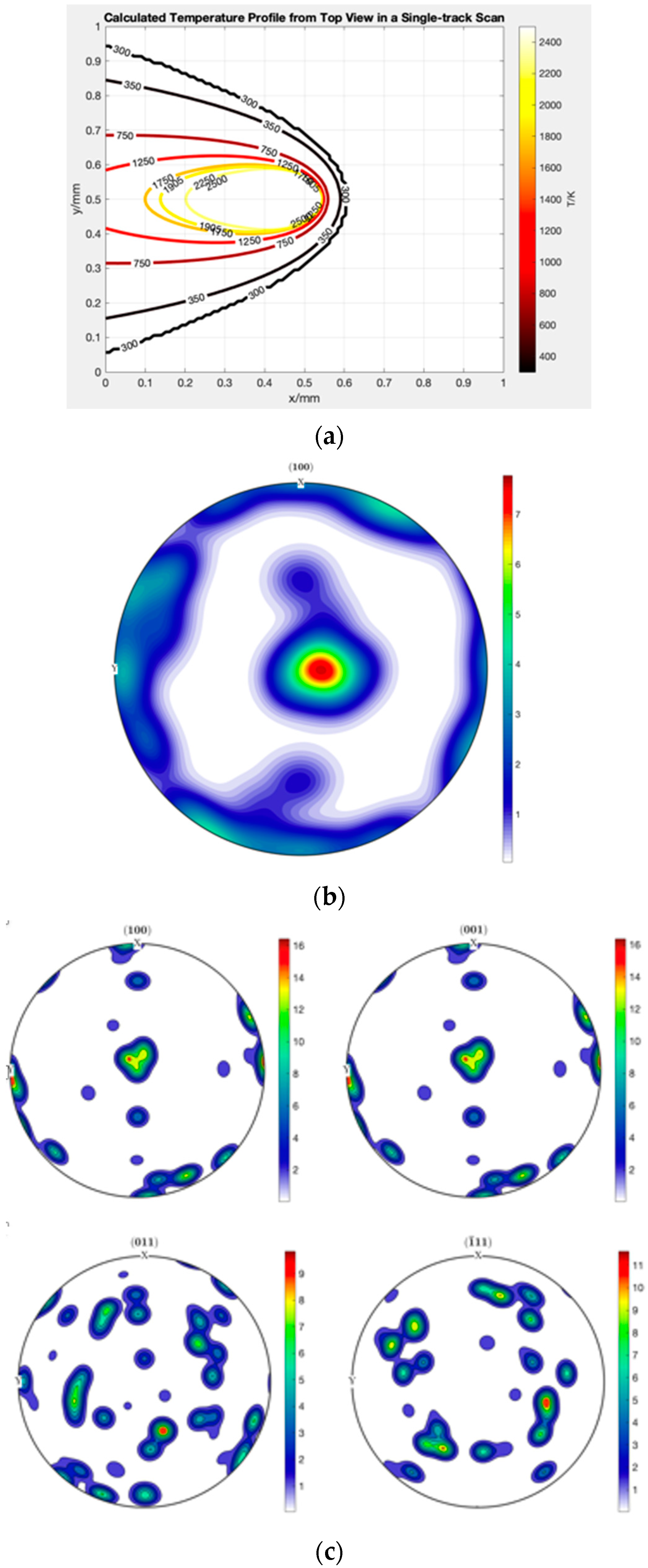

2.1. Thermal Distribution Model and Molten Pool Geometry

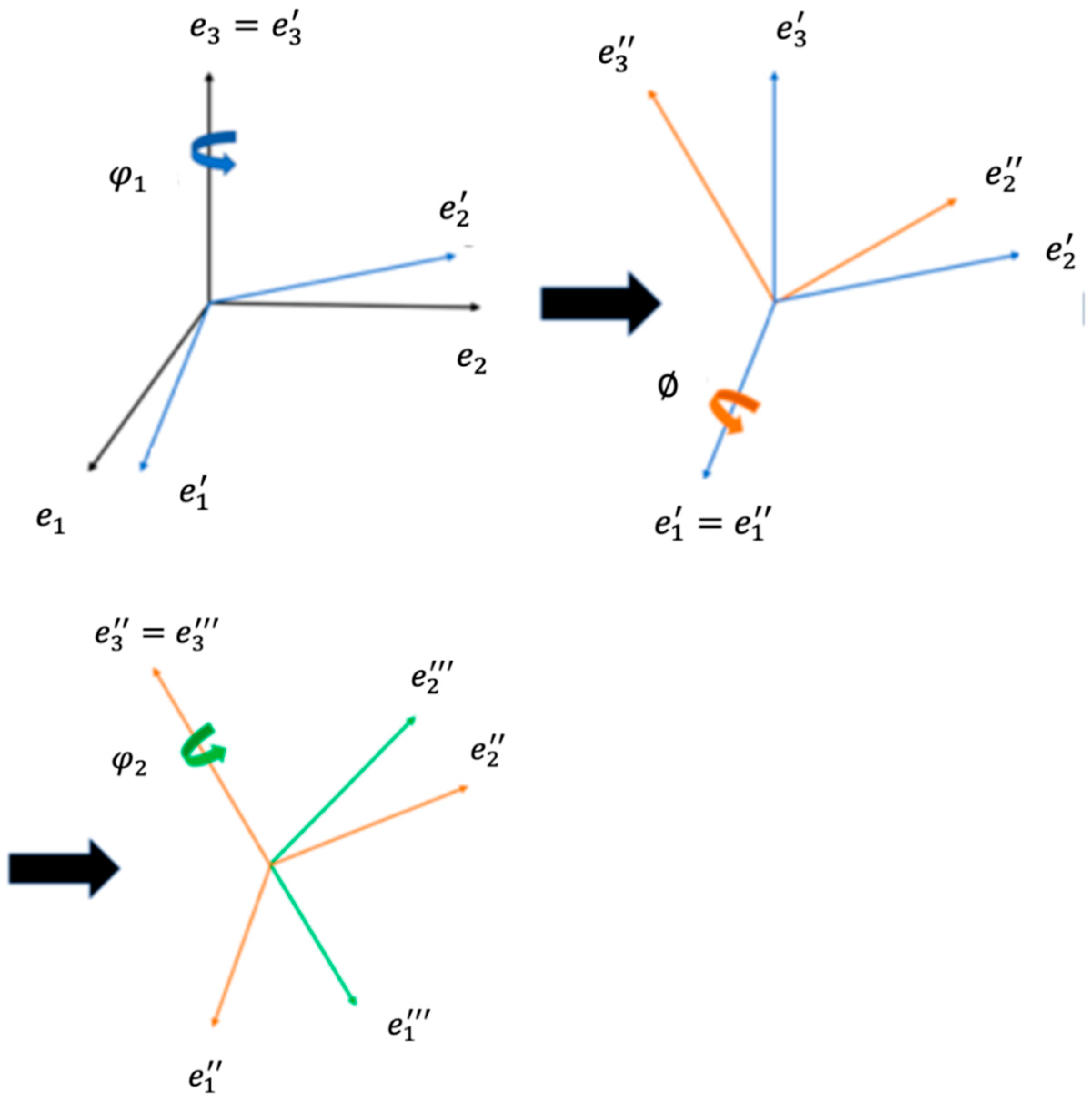

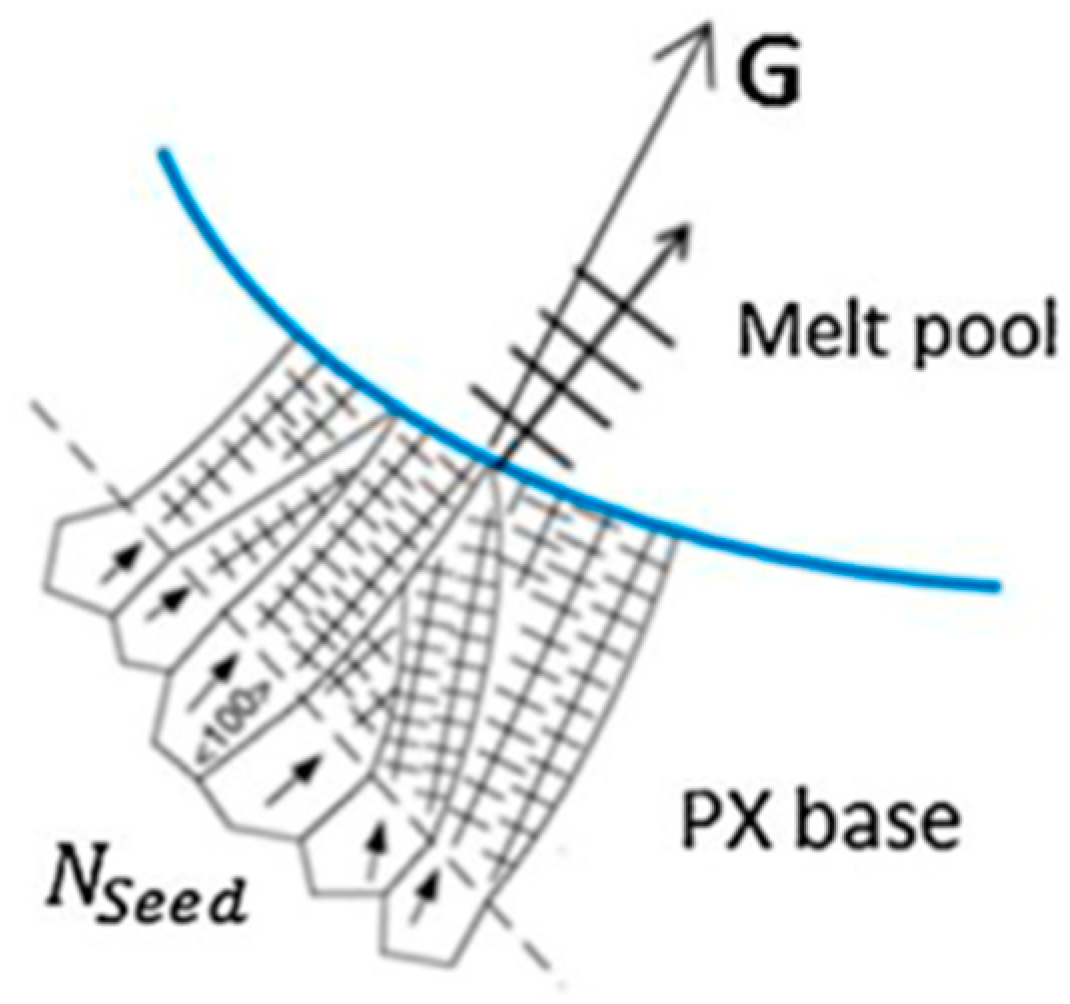

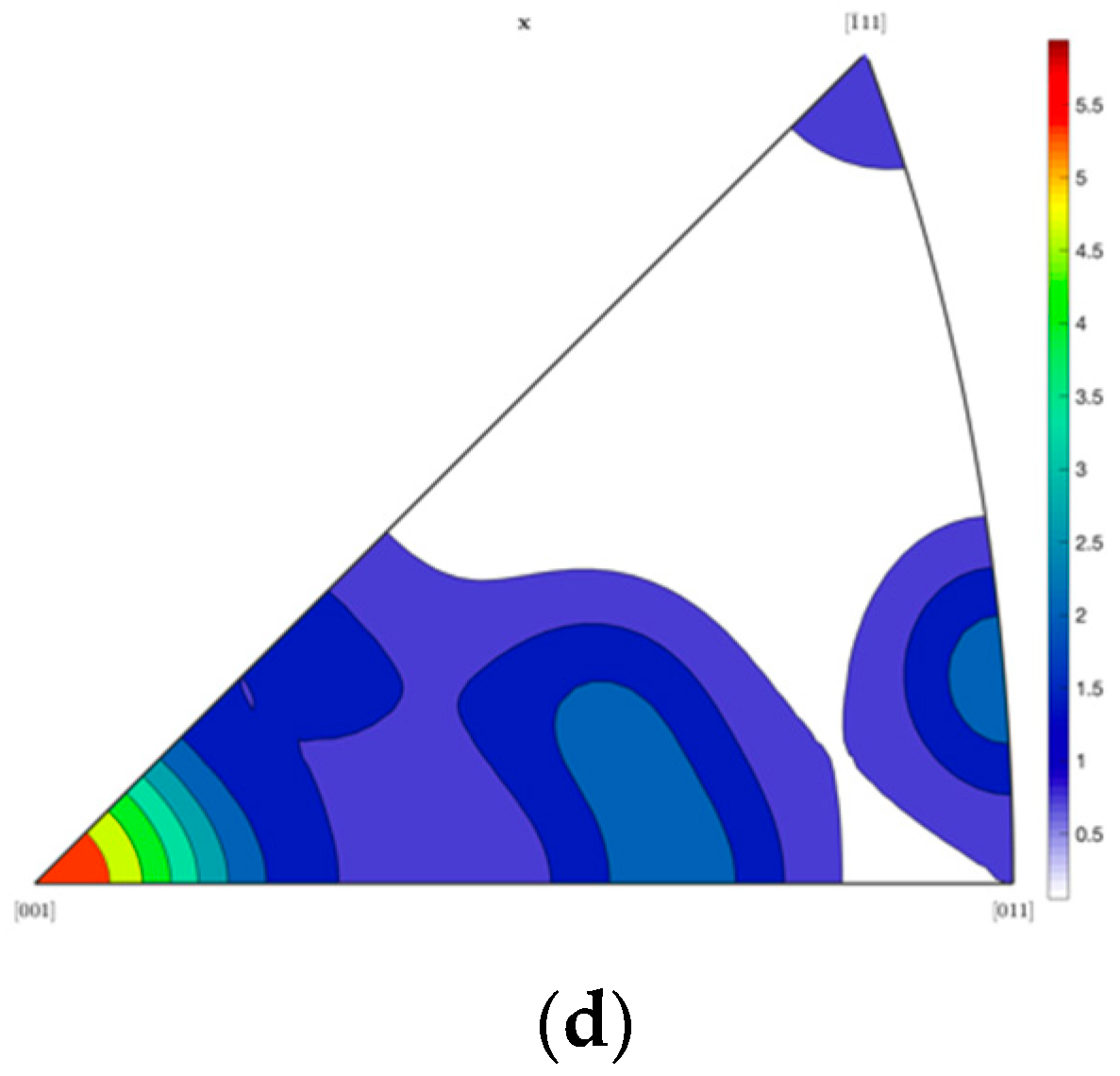

2.2. Single-Phase Texture Model

- Generate/import the random texture of the substrate: randomly generate three Euler angles in the range of [0, 360], [0, 180], and [0, 360] for the , where one can also read files of saved texture (three Euler angles) information.

- Calculate the accurate melt pool border and record the border: x, y, and z locations.

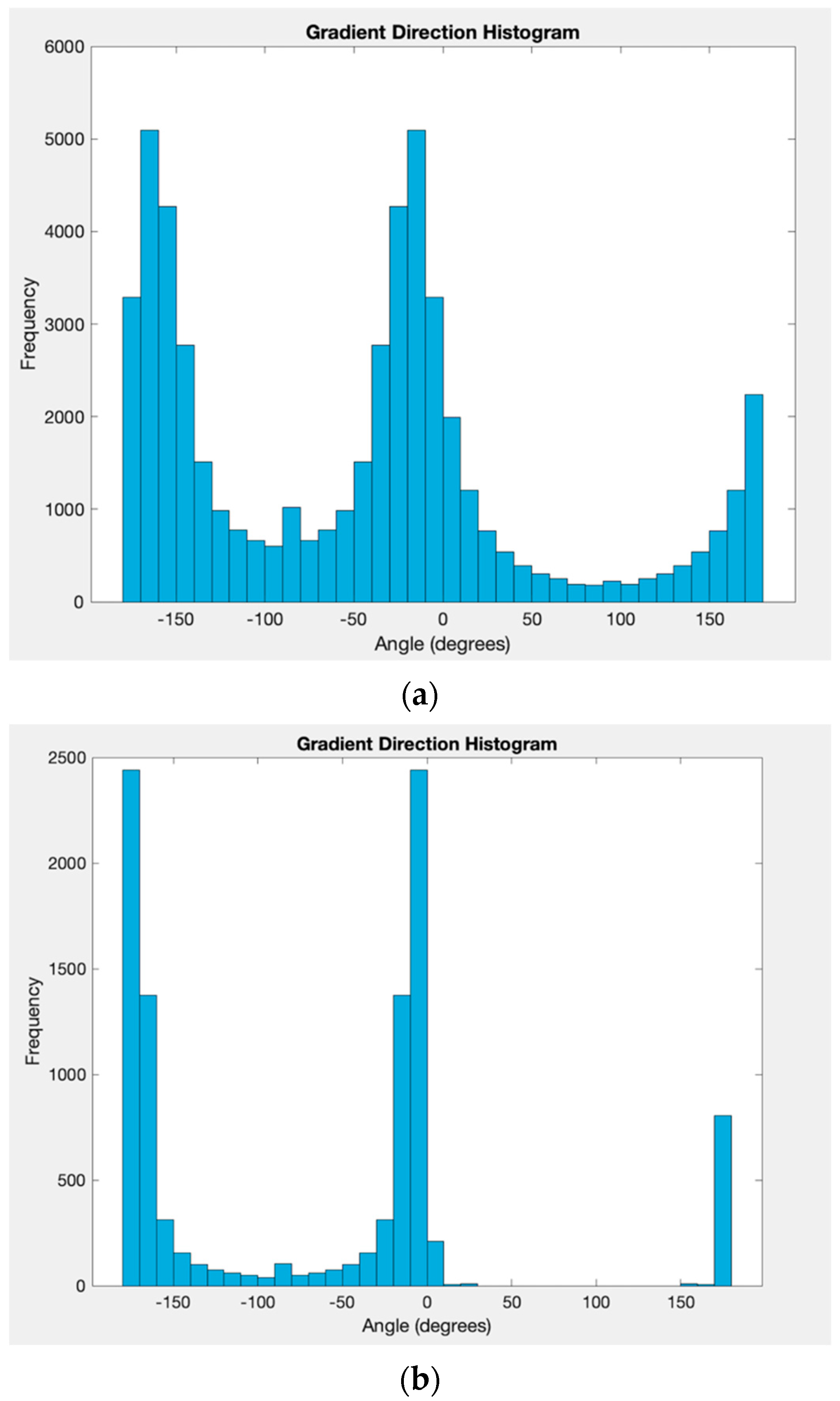

- Calculate the slope values of the melt pool border with a smoothing method of averaging the slope values of several nearby pixels.

- Calculate the angle between the direction of the moving laser source and the growing direction of the solidifying material utilizing the geometric relationship by the smoothing method as well.

- Then, determine the solidification rate using .

- The thermal gradient is obtained using temperature distributions and calculating the average thermal gradient in the z-direction.

- For the texture/Euler angles calculation part, the focus is merely on the molten pool area. Due to the columnar-to-equiaxed transition conditions of ratio with relevant existing transition parameters, the equiaxed and columnar grain areas are determined. If it is an equiaxed grain area, assign it with random Euler angles, and if it is a columnar grain area, select the seed crystal direction with the maximum . Notice here that the border values and internal points values are calculated separately in the selection structure to avoid bugs and cover all of the points in the molten pool accurately.

- Store generated texture data in both EBSD data format (8 variables: 3 Euler angles, X-axis location, Y-axis location, layer, section, and phase (there is only the phase here)) and XRD data format (4 variables: 3 Euler angles and weight).

- Plot pole figures: write the data to CSV files, define file paths, input crystal symmetry, specimen symmetry, etc. Then, use the MTEX toolbox as well as relevant figure plot codes to plot the pole figures.

3. Results and Discussion

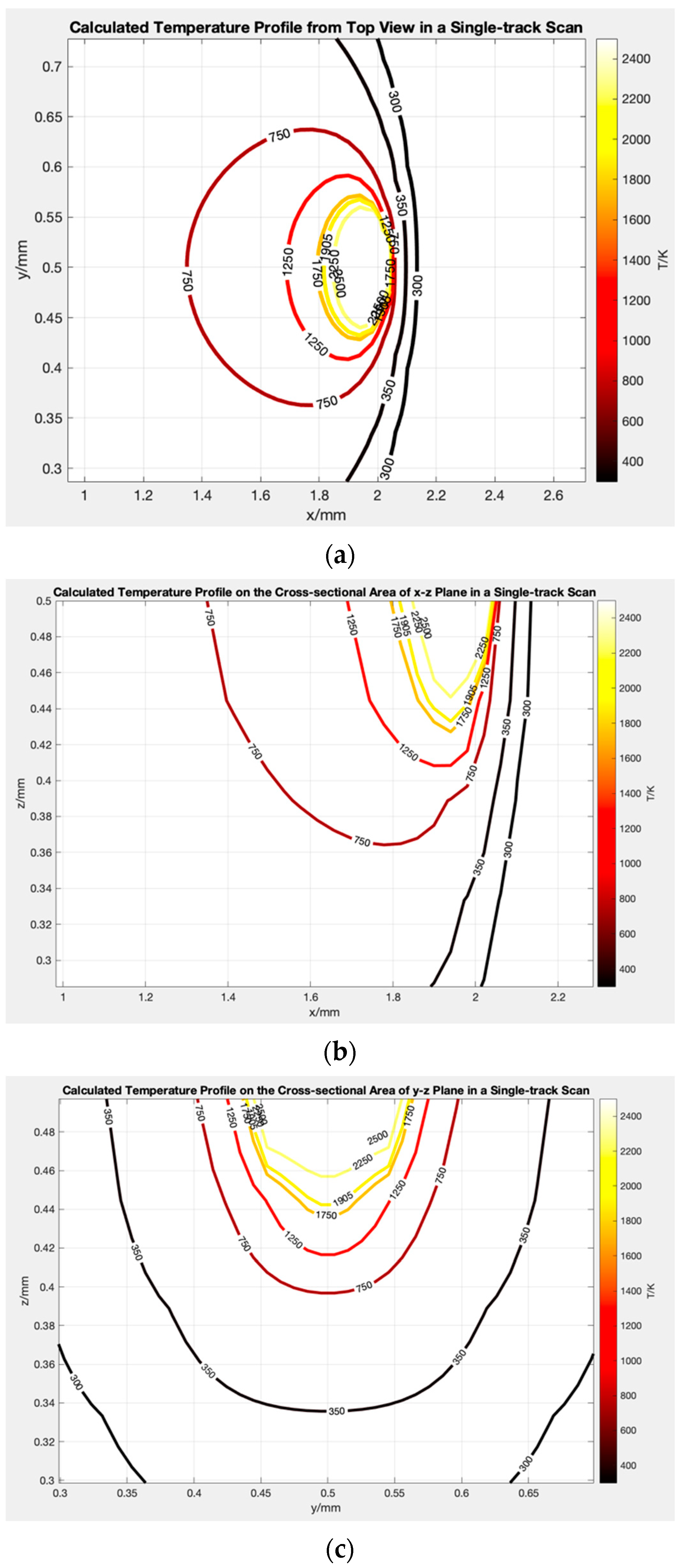

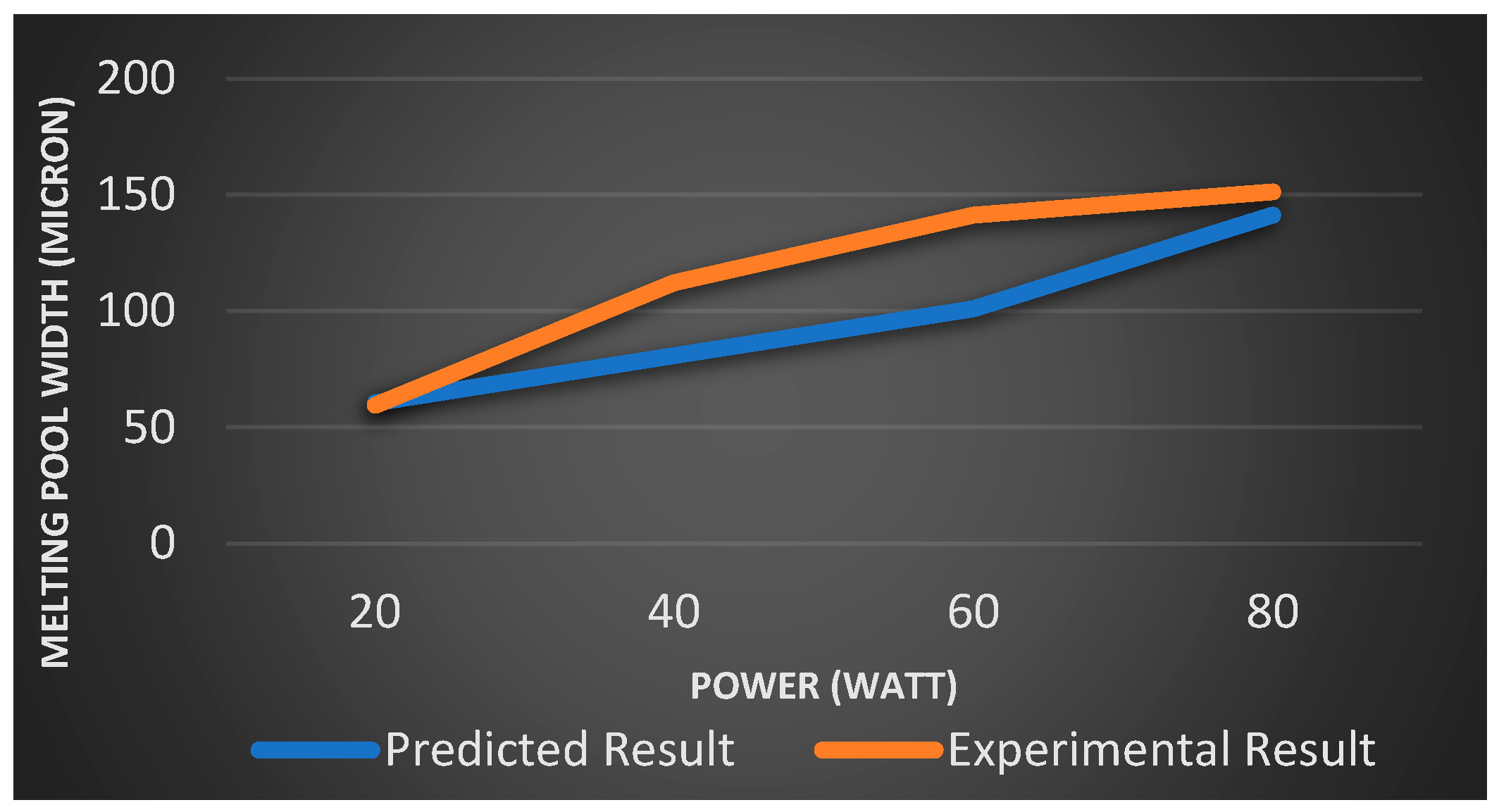

3.1. Thermal Distribution Model and Molten Pool Geometry

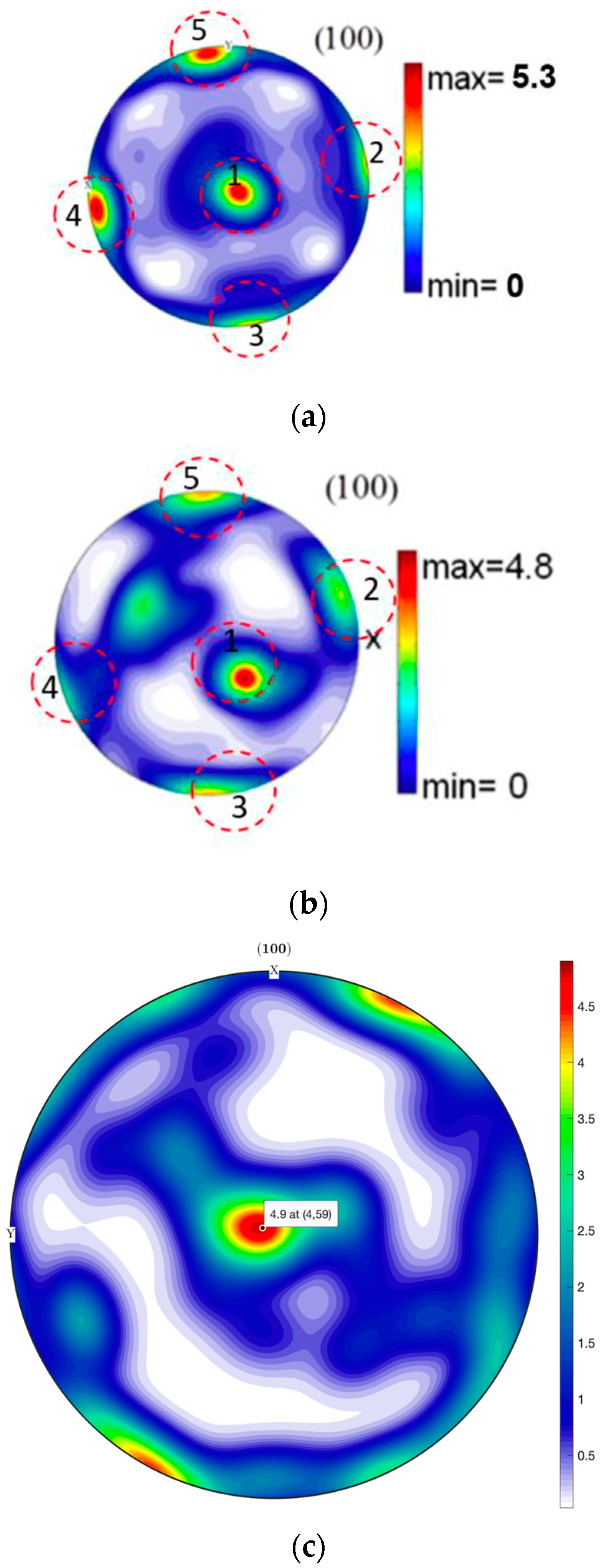

3.2. Single-Phase Texture Model

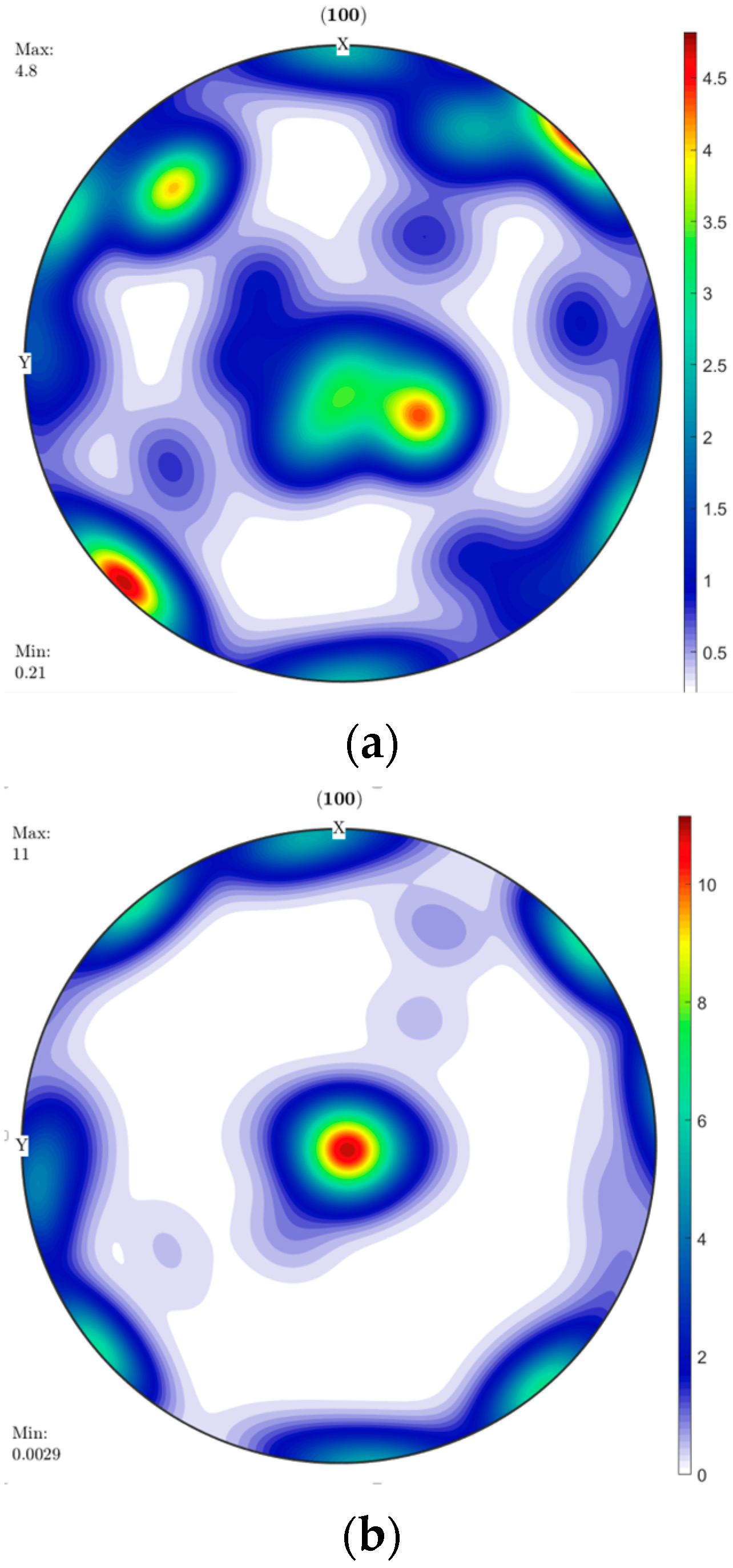

3.3. Discussion about the Influence of Laser Power and Scanning Velocity on Texture

3.4. Scalability of the Part Size of the Thermal Model and Texture Model

3.5. Discussion about Randomly Generated Texture

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- DebRoy, T.; Wei, H.; Zuback, J.; Mukherjee, T.; Elmer, J.; Milewski, J.; Beese, A.M.; Wilson-Heid, A.d.; De, A.; Zhang, W. Additive manufacturing of metallic components–process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Hunt, J.D. Steady state columnar and equiaxed growth of dendrites and eutectic. Mater. Sci. Eng. 1984, 65, 75–83. [Google Scholar] [CrossRef]

- Gockel, J.; Beuth, J.; Taminger, K. Integrated control of solidification microstructure and melt pool dimensions in electron beam wire feed additive manufacturing of Ti-6Al-4 V. Addit. Manuf. 2014, 1–4, 119–126. [Google Scholar] [CrossRef]

- Wei, H.L.; Elmer, J.W.; DebRoy, T. Origin of grain orientation during solidification of an aluminum alloy. Acta Mater. 2016, 115, 123–131. [Google Scholar] [CrossRef]

- Liu, J.; To, A.C. Quantitative texture prediction of epitaxial columnar grains in additive manufacturing using selective laser melting. Addit. Manuf. 2017, 16, 58–64. [Google Scholar] [CrossRef]

- Mahdavi, M. Materials-Affected Manufacturing: Simulation of the Crystallographic Texture, Microstructure, and Inelastic Properties of Additively Manufactured Polycrystalline Materials. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2021. [Google Scholar]

- Wei, S.; Lau, K.B.; Lee, J.J.; Wei, F.; Teh, W.H.; Zhang, B.; Tan, C.C.; Wang, P.; Ramamurty, U. Selective laser melting of Fe–Al alloys with simultaneous gradients in composition and microstructure. Mater. Sci. Eng. A 2021, 821, 141608. [Google Scholar] [CrossRef]

- Zhang, D.; Qiu, D.; Gibson, M.A.; Zheng, Y.; Fraser, H.L.; StJohn, D.H.; Easton, M.A. Additive manufacturing of ultrafine-grained high-strength titanium alloys. Nature 2019, 576, 91–95. [Google Scholar] [CrossRef] [PubMed]

- Ning, J.; Mirkoohi, E.; Dong, Y.; Sievers, D.E.; Garmestani, H.; Liang, S.Y. Analytical modeling of 3D temperature distribution in selective laser melting of Ti-6Al-4V considering part boundary conditions. J. Manuf. Process. 2019, 44, 319–326. [Google Scholar] [CrossRef]

- Carslaw, H.; Jaeger, J. Conduction of Heat in Solids; Oxford Science Publication: Oxford, UK, 1900; Chapter 10. [Google Scholar]

- Bunge, H.-J. Texture Analysis in Materials Science: Mathematical Methods; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Kobryn, P.A.; Semiatin, S.L. Microstructure and texture evolution during solidification processing of Ti–6Al–4 V. J. Mater. Process. Technol. 2003, 135, 330–339. [Google Scholar] [CrossRef]

- Yang, Y.; Knol, M.; Van Keulen, F.; Ayas, C. A semi-analytical thermal modelling approach for selective laser melting. Addit. Manuf. 2018, 21, 284–297. [Google Scholar] [CrossRef]

- Welsch, G.; Boyer, R.; Collings, E. Materials Properties Handbook: Titanium Alloys; ASM International: Tokyo, Japan, 1994. [Google Scholar]

- Yadroitsev, I.; Yadroitsava, I. Evaluation of residual stress in stainless steel 316L and Ti6Al4V samples produced by selective laser melting. Virtual Phys. Prototyp. 2015, 10, 67–76. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Yadroitsev, I.; Bertrand, P.; Smurov, I. Model of radiation and heat transfer in laser-powder interaction zone at selective laser melting. J Heat Transf. 2009, 131, 072101. [Google Scholar] [CrossRef]

- Fu, C.H.; Guo, Y.B. Three-dimensional temperature gradient mechanism in selective laser melting of Ti-6AI-4V. J. Manuf. Sci. Eng. 2014, 136, 061004. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti–6Al–4V. Mater. Sci. Eng. A 2014, 616, 1–11. [Google Scholar] [CrossRef]

| Properties of Material | Value | Unit |

|---|---|---|

| Density () | 4428 | kg/ |

| Bulk Thermal Conductivity () | 5–35 | W/m-K |

| Melting Temperature () | 1655 | |

| Absorption () | 0.818 | 1 |

| Heat Capacity (C) | 500–800 | J/kg-K |

| Powder Thermal Conductivity () | 0.21 | W/m-K |

| Heat Convection Coefficient (h) | 24 | W/-K |

| Radiation Emissivity () | 0.9 | 1 |

| Room Temperature () | 20 | |

| Stefan–Boltzmann Constant () | W/-K | |

| Columnar/equiaxed Transition Coefficient (nn) | 3.2 | 1 |

| Columnar/equiaxed Transition Coefficient (kk) | 1 |

| Test | Laser Power (W) | Scan Velocity V (m/s) |

|---|---|---|

| 1 | 20 | 0.2 |

| 2 | 40 | 0.2 |

| 3 | 60 | 0.2 |

| 4 | 80 | 0.2 |

| Build Parameters | Value |

|---|---|

| Number of Layers | 10 |

| Number of Seeds | 100 |

| Number of Sections | 1000 |

| Number of Grains | 20 |

| Number of Track | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, W.; Wang, W.; Ning, J.; Garmestani, H.; Liang, S.Y. Analytical Model of Quantitative Texture Prediction Considering Heat Transfer Based on Single-Phase Material in Laser Powder Bed Fusion. J. Manuf. Mater. Process. 2024, 8, 70. https://doi.org/10.3390/jmmp8020070

Huang W, Wang W, Ning J, Garmestani H, Liang SY. Analytical Model of Quantitative Texture Prediction Considering Heat Transfer Based on Single-Phase Material in Laser Powder Bed Fusion. Journal of Manufacturing and Materials Processing. 2024; 8(2):70. https://doi.org/10.3390/jmmp8020070

Chicago/Turabian StyleHuang, Wei, Wenjia Wang, Jinqiang Ning, Hamid Garmestani, and Steven Y. Liang. 2024. "Analytical Model of Quantitative Texture Prediction Considering Heat Transfer Based on Single-Phase Material in Laser Powder Bed Fusion" Journal of Manufacturing and Materials Processing 8, no. 2: 70. https://doi.org/10.3390/jmmp8020070

APA StyleHuang, W., Wang, W., Ning, J., Garmestani, H., & Liang, S. Y. (2024). Analytical Model of Quantitative Texture Prediction Considering Heat Transfer Based on Single-Phase Material in Laser Powder Bed Fusion. Journal of Manufacturing and Materials Processing, 8(2), 70. https://doi.org/10.3390/jmmp8020070