Experimental Characterization of Screw-Extruded Carbon Fibre-Reinforced Polyamide: Design for Aeronautical Mould Preforms with Multiphysics Computational Guidance

Abstract

1. Introduction

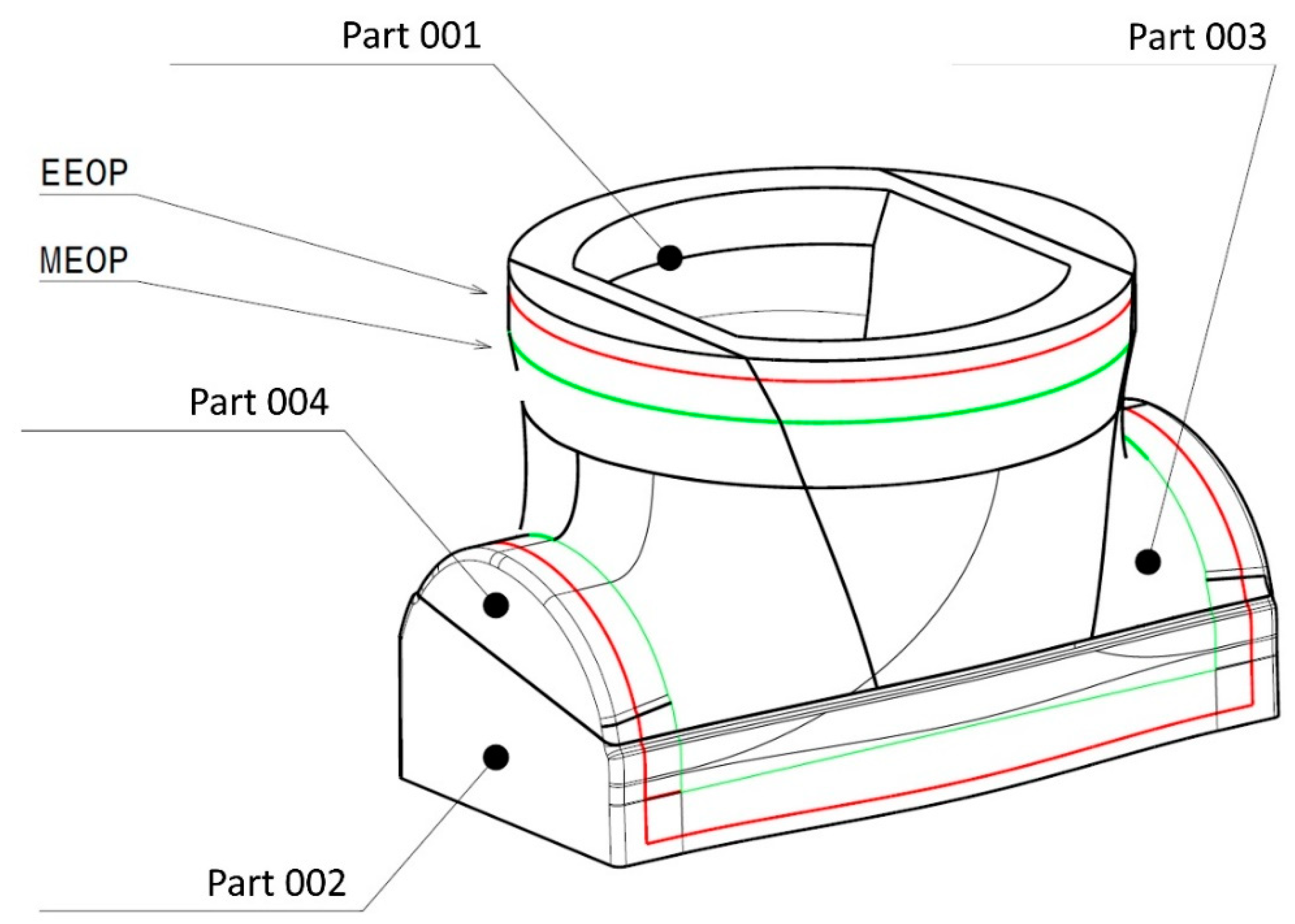

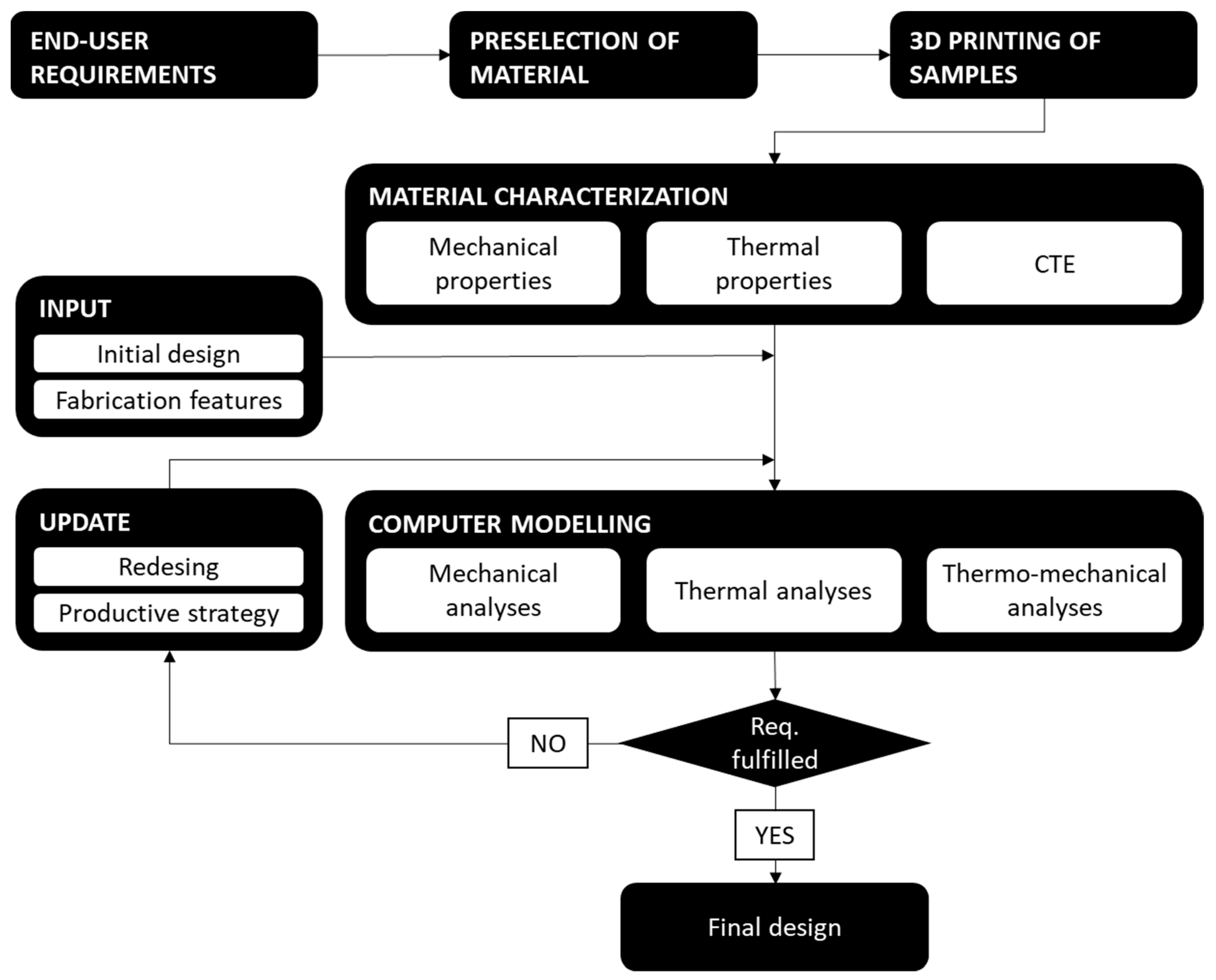

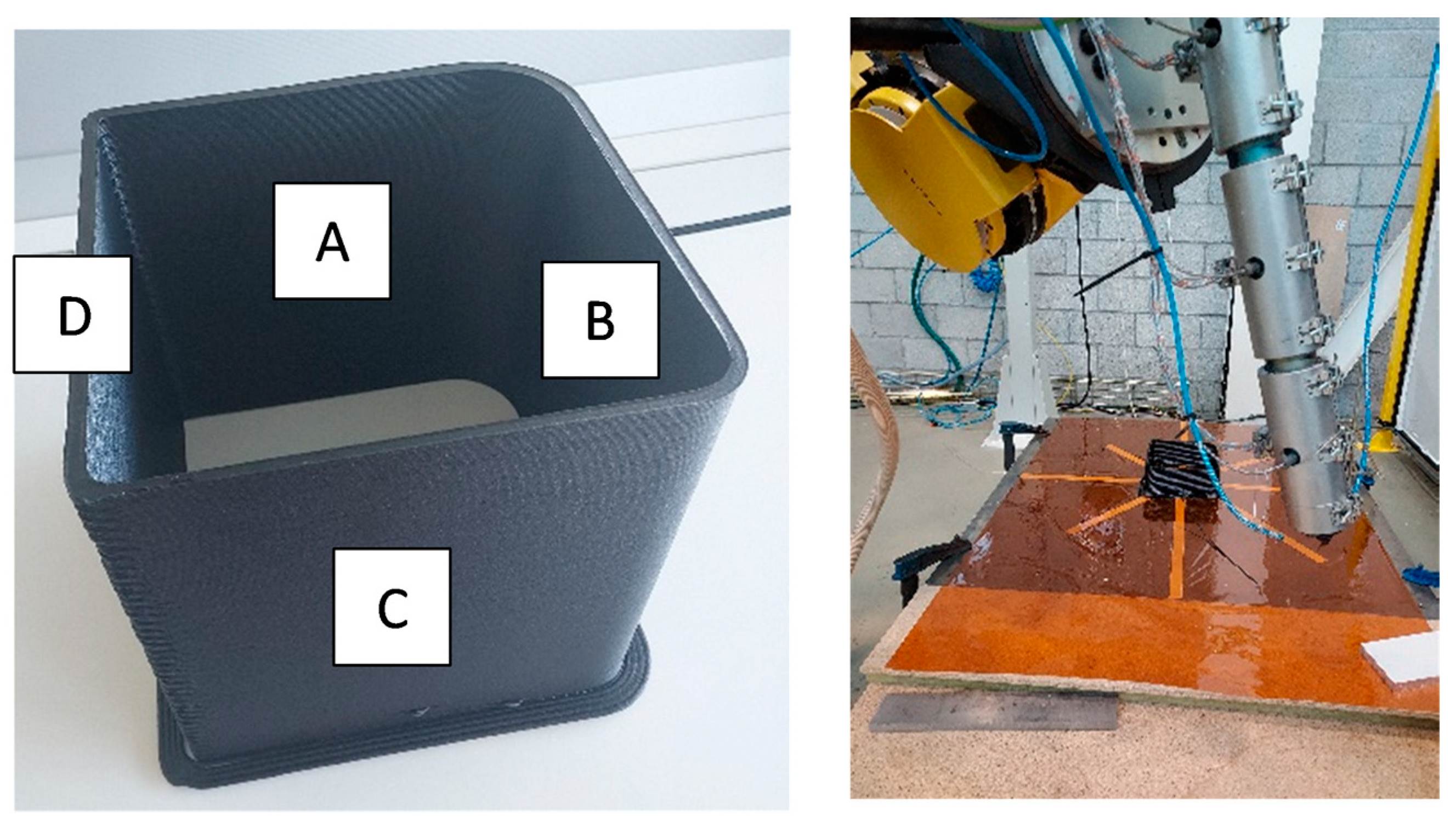

2. Description of the Use Case

3. Methodology

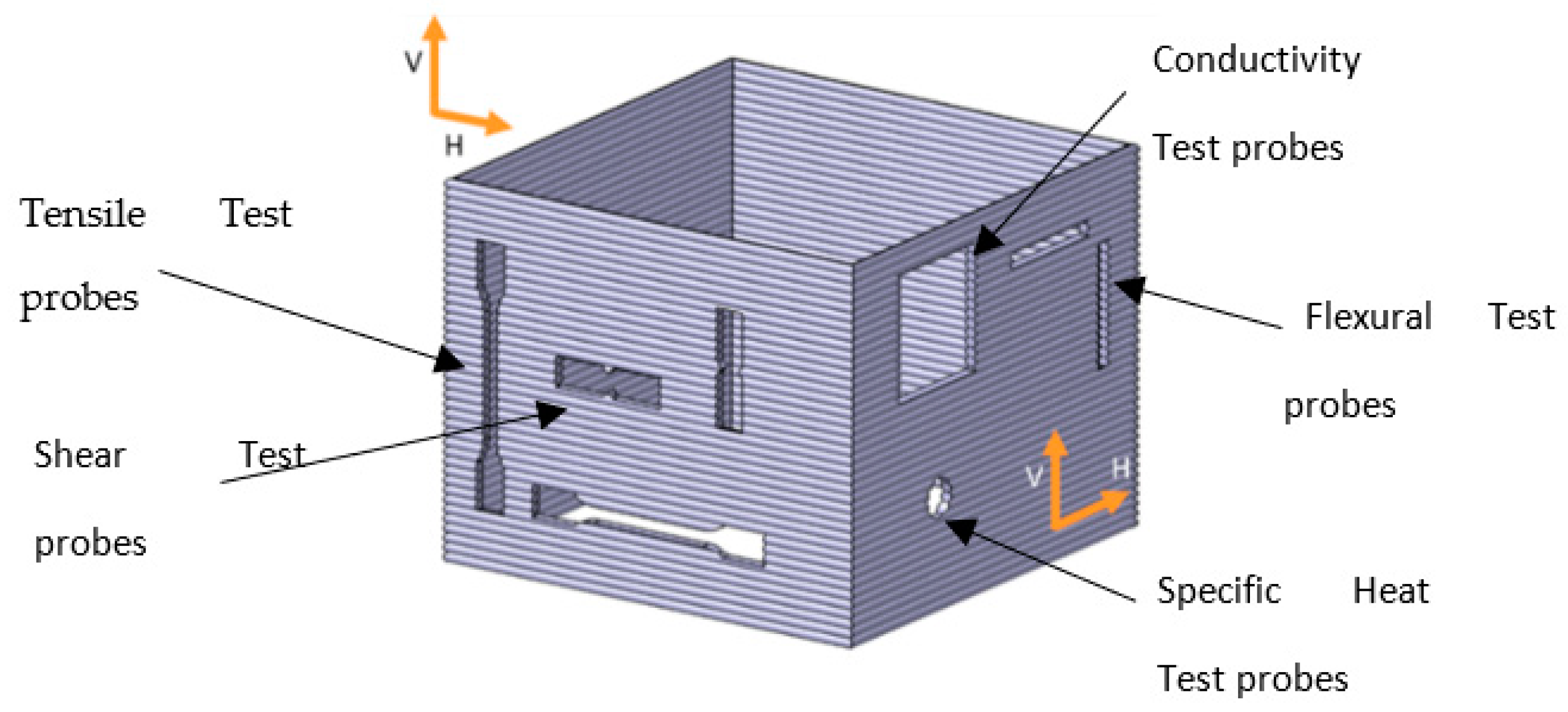

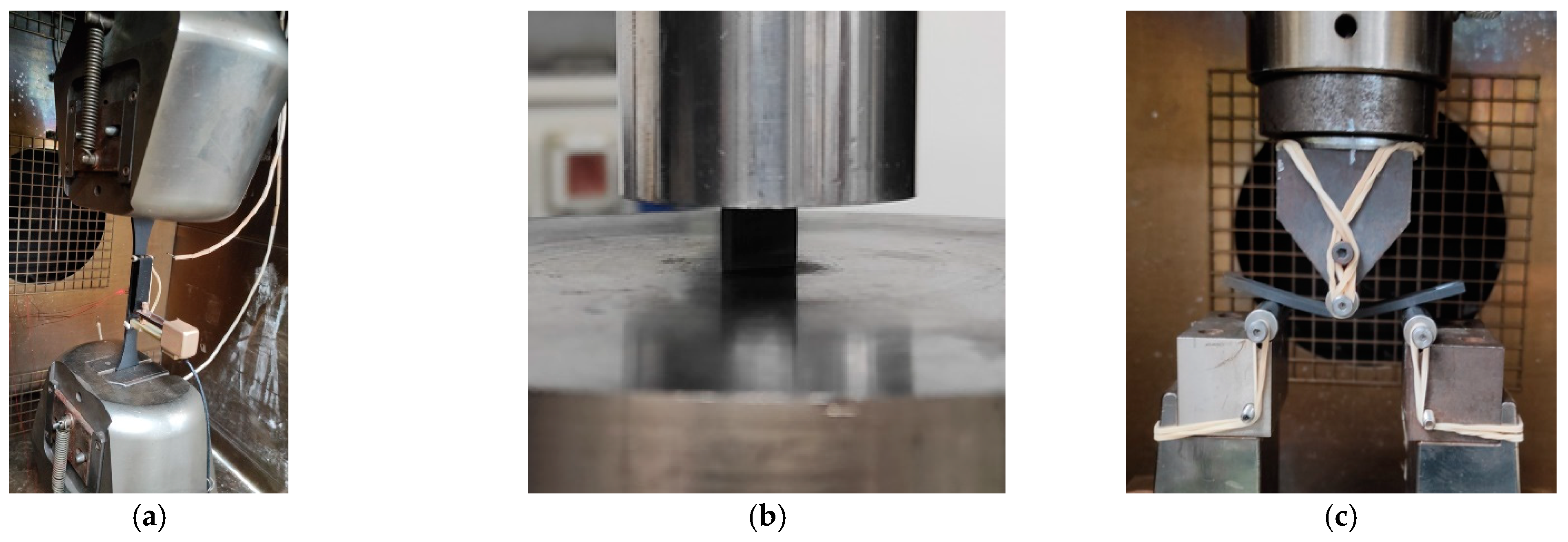

3.1. Material Characterization

| Test | Standard | Obtained Properties | Material Orientation | Temperature [°C] | Number of Samples |

|---|---|---|---|---|---|

| Tensile | ISO 527-1 [53] ISO 527-2 1B Specimens [54] | Tensile Strength Tensile Modulus Nominal Strain at Break | 1 | RT | 3 |

| 80 | 3 | ||||

| 180 | 3 | ||||

| 2 | RT | 3 | |||

| 80 | 3 | ||||

| 180 | 3 | ||||

| Flexural | ISO 14125 3-point test [55] | Flexural Strength Flexural Modulus Flexural Strain at Max Load | 1 | RT | 3 |

| 80 | 3 | ||||

| 180 | 3 | ||||

| 2 | RT | 3 | |||

| 80 | 3 | ||||

| 180 | 3 | ||||

| Compression–Strength | ISO 604 Standard Specimens [56] | Compression Strength Compression Strength (5%) | 1 | RT | 3 |

| 80 | 3 | ||||

| 180 | 3 | ||||

| 2 | RT | 3 | |||

| 80 | 3 | ||||

| 180 | 3 | ||||

| Compression–Modulus | ISO 604 Standard Specimens [56] | Compression Modulus | 1 | RT | 3 |

| 80 | 3 | ||||

| 180 | 3 | ||||

| 2 | RT | 3 | |||

| 80 | 3 | ||||

| 180 | 3 | ||||

| Shear | ASTM D5379 (Iosipescu Fixture) [57] | Ultimate Strength Shear Cord Modulus | 1 | RT | 3 |

| 80 | 3 | ||||

| 180 | 3 | ||||

| 2 | RT | 3 | |||

| 80 | 3 | ||||

| 180 | 3 | ||||

| DMTA | ISO 6721 [58] | CTE | 2 | −25 ÷ 180 | 1 |

| Hot disc | ISO 22007-2.2 [59] | Thermal conductivity Specific heat | 1 | RT | 1 |

| 2 | RT | 2 | |||

| Rugosity | ISO 4287:1997 [52] | Rugosity, Ra | - | RT | 3 |

| Density | UNE-EN ISO 1183-1:2019 [60] | Density | - | RT | 1 |

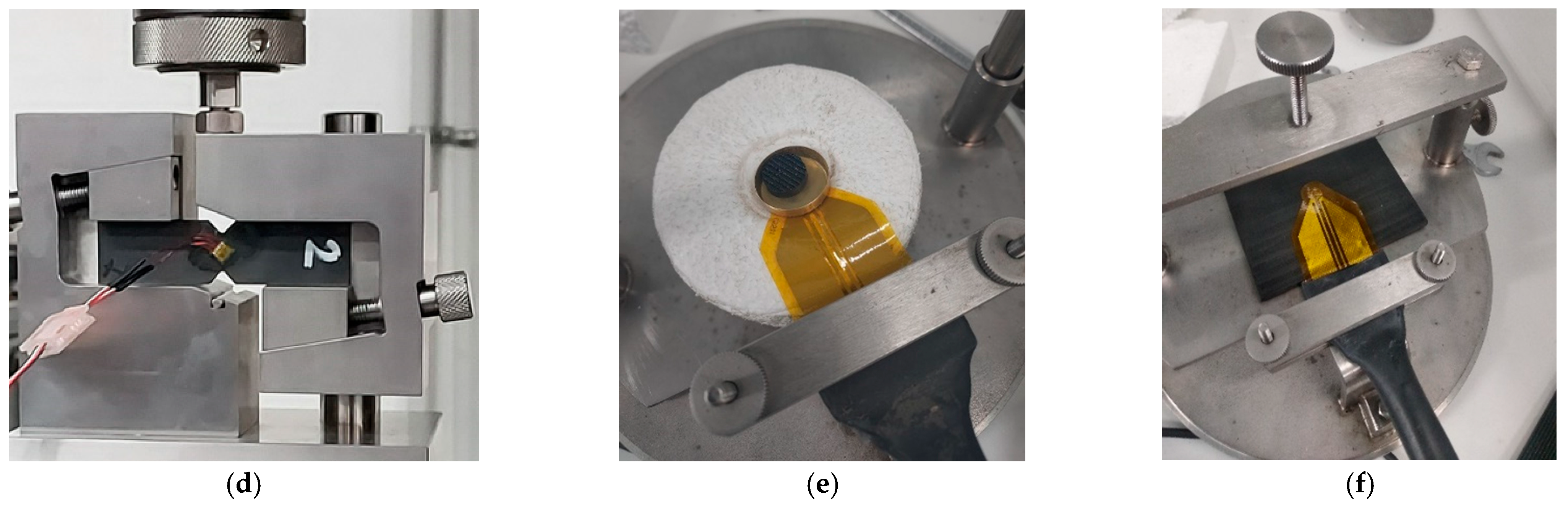

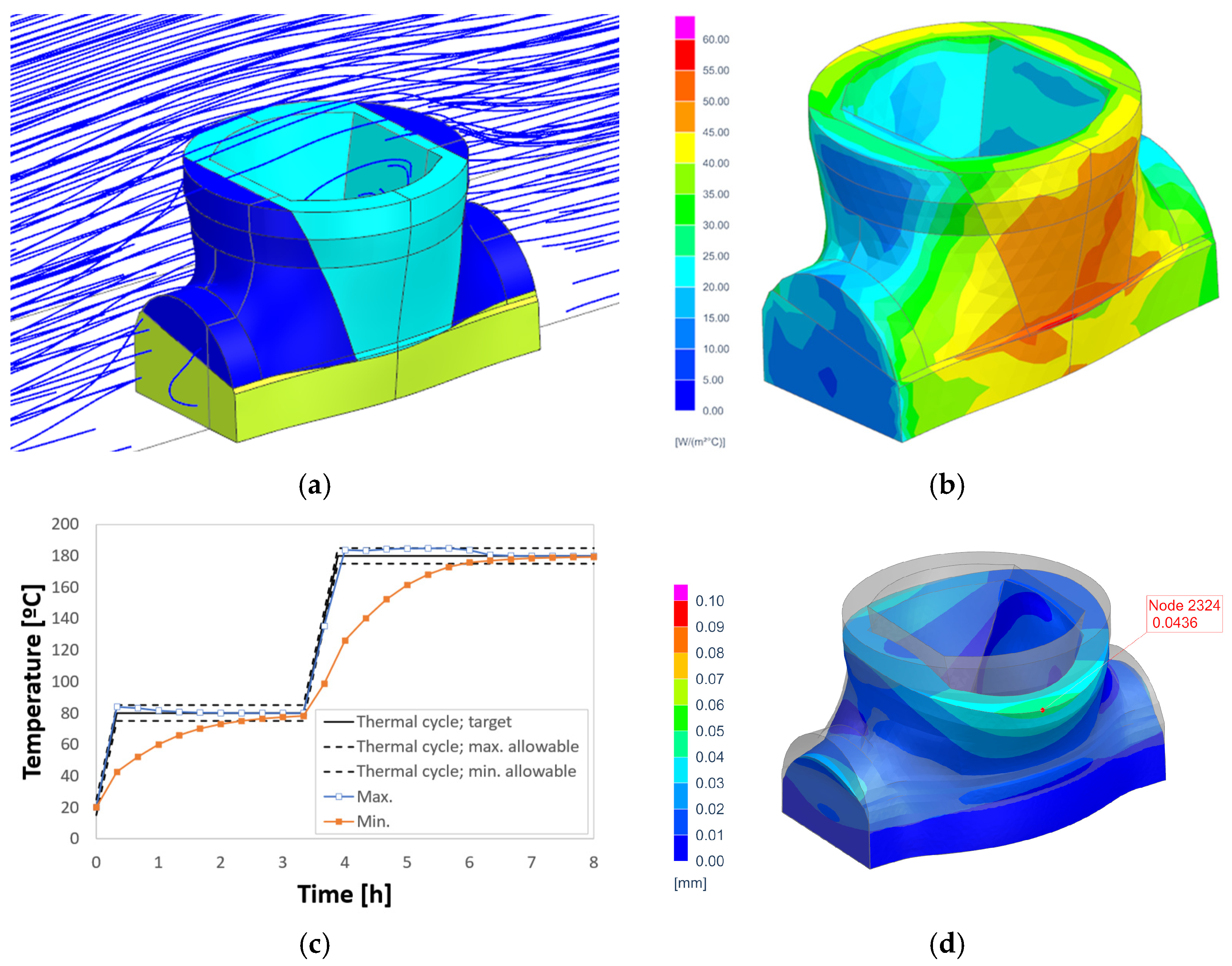

3.2. Preliminary Computer Modelling of the Mould

4. Results and Discussion

4.1. Tensile Moduli and Strength Results

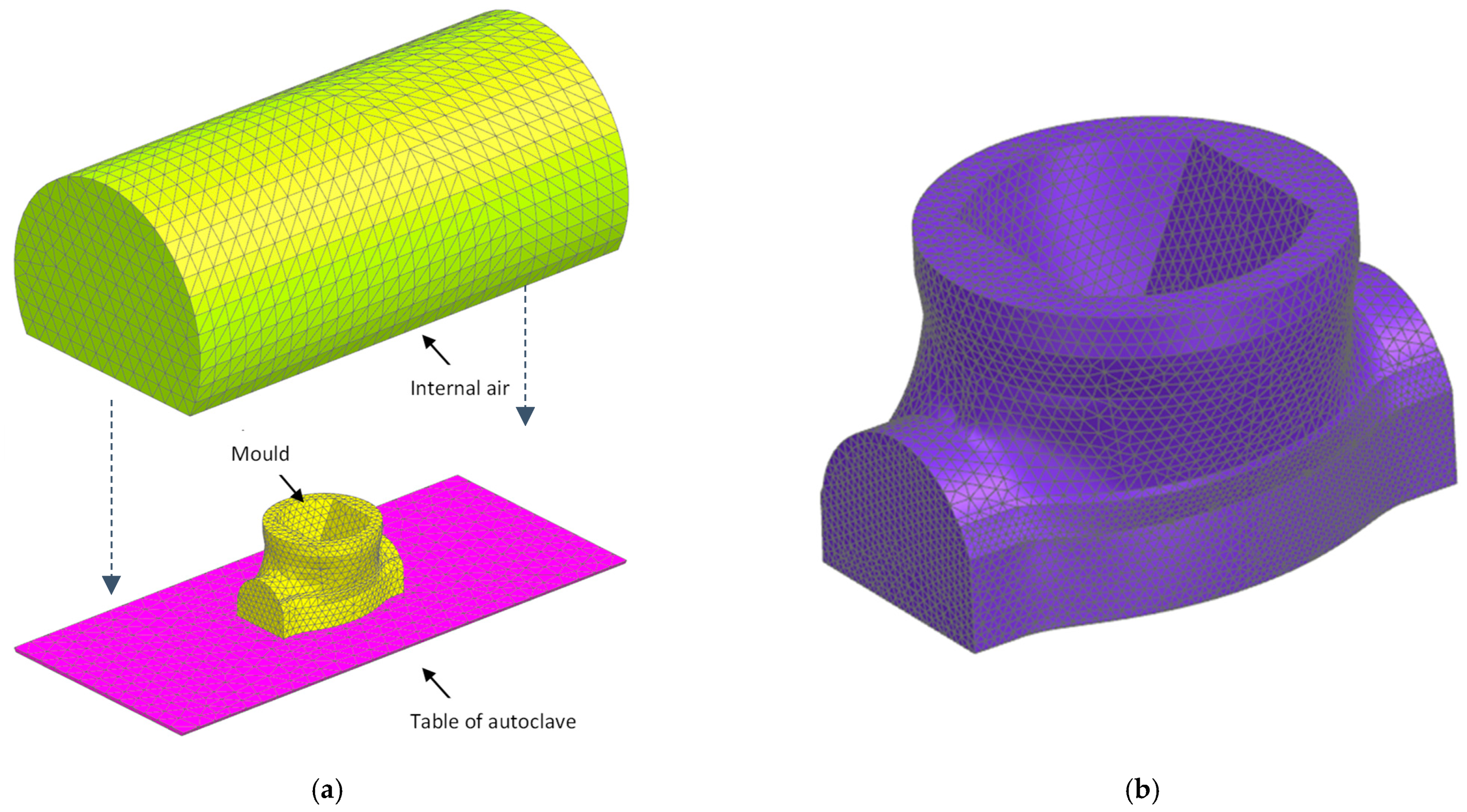

4.2. Bead Height and Width Assessment

4.3. Porosity Evaluation

4.4. Density

4.5. Observed Potential Problems

- Severe CTE mismatch-related problems (critically high tensile states along the mould and/or highly heterogeneous deformations that cannot be compensated in practice) occur under operating conditions when using dissimilar materials (metallic screws/positioners to join the semi-moulds, for instance).

- These problems might also occur in moulds that are entirely made of this material because its CTE is highly orthotropic.

- Temperature-induced deformations along the fibre-perpendicular direction are large, much greater than the maximum deflection required, as a result of the material’s CTE.

- Large displacements are caused in service along the fibre-perpendicular direction, greater than the maximum deflection required, due to the relatively low stiffness of the material at the operating temperature.

- Because of the relatively low thermal diffusivity of the material, the thermal response of the mould is not valid (excessive thermal gradients on the lamination surface) if a light enough mould is not designed.

- The use of dissimilar materials should be avoided.

- It is recommended to follow strategic material deposition, thus printing each layer perpendicularly to the previous one (for example 0/90/0/90/etc.). Such a bidirectional printing strategy results in a mould with homogeneous orthotropic properties. Therefore, the deformations due to the thermal expansion become uniform along each direction, and direction-dependent scale factors can be applied to the original mould geometry to compensate for the large temperature-induced displacements.

- In the case of moulds formed by several semi-moulds, it should be ensured that the printing and stacking directions of every semi-mould matches once the mould is assembled. Positioners made of the same material and placed so that the printing directions match with the ones of the mould should be used to join the semi-moulds.

- From a mechanical point of view, solid moulds should be developed as a general rule. This way, in combination with the printing strategy described in 2, the deformations due to the operating pressure (which are stiffness dependent) become uniform, and direction-dependent scale factors to compensate for the pressure-induced displacements can be applied to the original mould geometry.

- In terms of thermal performance, a thermally light design is required. Moreover, the design must enable similar thermal impedances at ambient temperature and the thermal capacitance should be as uniform as possible along the lamination surfaces to homogenise the temperature contour.

- For the cases in which an entirely solid mould does not allow us to ensure proper thermal behaviour, infill volumes with a particular percentage of material should be designed instead of totally hollow parts. This way, a high enough stiffness can be kept without excessively enlarging the thermal capacitance of the component. The deformations due to the pressure might be uniform enough in these cases. Moreover, the scale factors for compensating for the deformations due to the autoclave process could be applied to result in a proper thermal response.

4.6. Result of the Computer Modelling of the Mould

5. Conclusions and Further Work

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Grankäll, T.; Hallander, P.; Petersson, M.; Åkermo, M. The true shape of composite cure tools. J. Manuf. Process. 2020, 59, 279–286. [Google Scholar] [CrossRef]

- Stewart, R. New mould technologies and tooling materials promise advances for composites. Reinf. Plast. 2010, 54, 30–36. [Google Scholar] [CrossRef]

- Hasan, Z. Chapter 1—Introduction. In Tooling for Composite Aerospace Structures; Hasan, Z., Ed.; Butterworth-Heinemann: Oxford, UK, 2020; pp. 1–19. ISBN 978-0-12-819957-2. [Google Scholar]

- Li, Y.; Xiao, Y.; Yu, L.; Ji, K.; Li, D. A review on the tooling technologies for composites manufacturing of aerospace structures: Materials, structures and processes. Compos. Part A Appl. Sci. Manuf. 2022, 154, 106762. [Google Scholar] [CrossRef]

- Galiana, J. Guías básicas para elección de material de útil de curado en autoclave para fabricar piezas de composite. CFRP vs. INVAR36. In Proceedings of the XII Congreso Nacional de Materiales Compuestos MATCOMP 2017, Donostia-San Sebastian, Spain, 21–23 June 2017; Asociación Española de Materiales Compuestos (AEMAC): Getafe, Spain, 2017. [Google Scholar]

- Adeniran, O.; Cong, W.; Aremu, A. Material design factors in the additive manufacturing of Carbon Fiber Reinforced Plastic Composites: A state-of-the-art review. Adv. Ind. Manuf. Eng. 2022, 5, 100100. [Google Scholar] [CrossRef]

- Garmendia, I.; Vallejo, H.; Osés, U. Composite Mould Design with Multiphysics FEM Computations Guidance. Computation 2023, 11, 41. [Google Scholar] [CrossRef]

- Materials & Processes: Tooling for Composites. Available online: https://www.compositesworld.com/articles/tooling (accessed on 4 August 2023).

- UNE-EN ISO/ASTM 52900:2021; Additive Manufacturing- General Principles- Fundamentals and Vocabulary. UNE-EN (Una Norma Española sobre Norma Europea): Madrid, Spain, 2021.

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Lee, J.-Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Yan, L. Wire and Arc Additive Manufacture (WAAM) Reusable Tooling Investigation. Master’s Thesis, Cranfield University, Cranfield, UK, 2013. [Google Scholar]

- Calignano, F.; Mercurio, V. An overview of the impact of additive manufacturing on supply chain, reshoring, and sustainability. Clean. Logist. Supply Chain 2023, 7, 100103. [Google Scholar] [CrossRef]

- Pignatelli, F.; Percoco, G. An application- and market-oriented review on large format additive manufacturing, focusing on polymer pellet-based 3D printing. Prog. Addit. Manuf. 2022, 7, 1363–1377. [Google Scholar] [CrossRef]

- Bi, X.; Huang, R. 3D printing of natural fiber and composites: A state-of-the-art review. Mater. Des. 2022, 222, 111065. [Google Scholar] [CrossRef]

- Abderrafai, Y.; Diouf-Lewis, A.; Sosa-Rey, F.; Farahani, R.D.; Piccirelli, N.; Lévesque, M.; Therriault, D. Additive manufacturing and characterization of high temperature thermoplastic blends for potential aerospace applications. Compos. Sci. Technol. 2023, 231, 109839. [Google Scholar] [CrossRef]

- Dey, A.; Eagle, I.N.R.; Yodo, N. A review on filament materials for fused filament fabrication. J. Manuf. Mater. Process. 2021, 5, 69. [Google Scholar] [CrossRef]

- Spoerk, M.; Holzer, C.; Gonzalez-Gutierrez, J. Material extrusion-based additive manufacturing of polypropylene: A review on how to improve dimensional inaccuracy and warpage. J. Appl. Polym. Sci. 2020, 137, 48545. [Google Scholar] [CrossRef]

- Saroia, J.; Wang, Y.; Wei, Q.; Lei, M.; Li, X.; Guo, Y.; Zhang, K. A review on 3D printed matrix polymer composites: Its potential and future challenges. Int. J. Adv. Manuf. Technol. 2020, 106, 1695–1721. [Google Scholar] [CrossRef]

- Zhuo, P.; Li, S.; Ashcroft, I.A.; Jones, A.I. Material extrusion additive manufacturing of continuous fibre reinforced polymer matrix composites: A review and outlook. Compos. Part B Eng. 2021, 224, 109143. [Google Scholar] [CrossRef]

- Patel, A.; Taufik, M. Extrusion-Based Technology in Additive Manufacturing: A Comprehensive Review. Arab. J. Sci. Eng. 2022, 225, 111505. [Google Scholar] [CrossRef]

- Hassen, A.A.; Lindahl, J.; Chen, X.; Post, B.; Love, L.; Kunc, V. Additive Manufacturing of Composite Tooling using High Temperature Thermoplastic Materials. In Proceedings of the Society for the Advancement of Material and Process Engineering, Long Beach, CA, USA, 23–26 May 2016; North America Society for the Advancement of Material and Process Engineering (SAMPE): Diamond Bar, CA, USA. [Google Scholar]

- Park, S.J.; Lee, J.E.; Park, J.; Lee, N.K.; Son, Y.; Park, S.H. High-temperature 3D printing of polyetheretherketone products: Perspective on industrial manufacturing applications of super engineering plastics. Mater. Des. 2021, 211, 110163. [Google Scholar] [CrossRef]

- Ajinjeru, C.; Kishore, V.; Liu, P.; Lindahl, J.; Hassen, A.A.; Kunc, V.; Post, B.; Love, L.; Duty, C. Determination of melt processing conditions for high performance amorphous thermoplastics for large format additive manufacturing. Addit. Manuf. 2018, 21, 125–132. [Google Scholar] [CrossRef]

- Oberlercher, H.; Heim, R.; Laux, M.; Berndt, A.; Becker, C.; Amancio-Filho, S.T.; Riemelmoser, F.O. Additive manufacturing of continuous carbon fiber reinforced polyamide 6: The effect of process parameters on the microstructure and mechanical properties. Procedia Struct. Integr. 2021, 34, 111–120. [Google Scholar] [CrossRef]

- Shashikumar, S.; Sreekanth, M.S. The effect of printing parameters on tensile properties of thermoplastics prepared by fused deposition modeling (FDM) based additive manufacturing technique. Mater. Today Proc. 2023, 90, 256–261. [Google Scholar] [CrossRef]

- Chesser, P.; Post, B.; Roschli, A.; Carnal, C.; Lind, R.; Borish, M.; Love, L. Extrusion control for high quality printing on Big Area Additive Manufacturing (BAAM) systems. Addit. Manuf. 2019, 28, 445–455. [Google Scholar] [CrossRef]

- Love, L.J.; Duty, C.E.; Post, B.K.; Lind, R.F.; Lloyd, P.D.; Kunc, V.; Peter, W.H.; Blue, C.A. Breaking Barriers in Polymer Additive Manufacturing. In SAMPE 2015; SAMPE North America: Baltimore, MD, USA, 2015. [Google Scholar]

- Post, B.K.; Richardson, B.; Lind, R.; Love, L.J.; Lloyd, P.; Kunc, V.; Rhyne, B.J.; Roschli, A.; Hannan, J.; Nolet, S.; et al. Big Area Additive Manufacturing application in wind turbine molds. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, SFF 2017, Austin, TX, USA, 7–9 August 2017; pp. 2430–2446. [Google Scholar]

- Roschli, A.; Gaul, K.T.; Boulger, A.M.; Post, B.K.; Chesser, P.C.; Love, L.J.; Blue, F.; Borish, M. Designing for Big Area Additive Manufacturing. Addit. Manuf. 2019, 25, 275–285. [Google Scholar] [CrossRef]

- Sher, D. WHAM, There’s a New “Largest 3D Printer in the World” in Town. Available online: https://www.voxelmatters.com/wham-theres-a-new-largest-composite-3d-printer-in-the-world-in-town/ (accessed on 7 August 2023).

- Thompson, W.; Huelskamp, S.R.; Allessio, T.; Ly, K. Large-Format Additive Manufacturing: Viable for Autoclave Tooling? Available online: https://www.additivemanufacturing.media/articles/large-format-additive-manufacturing-viable-for-autoclave-tooling (accessed on 7 August 2023).

- Chambon, P.; Curran, S.; Huff, S.; Love, L.; Post, B.; Wagner, R.; Jackson, R.; Green, J. Development of a range-extended electric vehicle powertrain for an integrated energy systems research printed utility vehicle. Appl. Energy 2017, 191, 99–110. [Google Scholar] [CrossRef]

- Curran, S.; Chambon, P.; Lind, R.; Love, L.; Wagner, R.; Whitted, S.; Smith, D.; Post, B.; Graves, R.; Blue, C.; et al. Big Area Additive Manufacturing and Hardware-in-the-Loop for Rapid Vehicle Powertrain Prototyping: A Case Study on the Development of a 3-D-Printed Shelby Cobra. In SAE 2016 World Congress and Exhibition; SAE International: Warrendale, PA, USA, 2016. [Google Scholar]

- Moreno Nieto, D.; Casal López, V.; Molina, S.I. Large-format polymeric pellet-based additive manufacturing for the naval industry. Addit. Manuf. 2018, 23, 79–85. [Google Scholar] [CrossRef]

- Post, B.; Chesser, P.; Lind, R.; Sallas, M.; Love, L.J. Feasibility of Using Big Area Additive Manufacturing to Directly Manufacture Boat Molds; Final Report NN-17-1062; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2018.

- Wahlström, N.; Gabrielsson, O. Additive Manufacturing Applications for Wind Turbines. Master of Science Thesis, KTH Industrial Engineering and Management, Stockholm, Sweden, 2017. [Google Scholar]

- Post, B.K.; Richardson, B.; Lloyd, P.; Love, L.J.; Nolet, S.; Hannan, J. Additive Manufacturing of Wind Turbine Molds; CRADA Final Report NFE-16-06051; Oak Ridge National Labnoratory: Oak Ridge, TN, USA, 2017; ISBN 1800553684.

- Silva, M.R.; Pereira, A.M.; Alves, N.; Mateus, G.; Mateus, A.; Malça, C. Development of an additive manufacturing system for the deposition of thermoplastics impregnated with carbon fibers. J. Manuf. Mater. Process. 2019, 3, 35. [Google Scholar] [CrossRef]

- Peng, X.; Zhang, M.; Guo, Z.; Sang, L.; Hou, W. Investigation of processing parameters on tensile performance for FDM-printed carbon fiber reinforced polyamide 6 composites. Compos. Commun. 2020, 22, 100478. [Google Scholar] [CrossRef]

- Zhuo, P.; Li, S.; Ashcroft, I.A.; Jones, A.I. Continuous fibre composite 3D printing with pultruded carbon/PA6 commingled fibres: Processing and mechanical properties. Compos. Sci. Technol. 2022, 221, 109341. [Google Scholar] [CrossRef]

- Li, X.; He, J.; Hu, Z.; Ye, X.; Wang, S.; Zhao, Y.; Wang, B.; Ou, Y.; Zhang, J. High strength carbon-fiber reinforced polyamide 6 composites additively manufactured by screw-based extrusion. Compos. Sci. Technol. 2022, 229, 109707. [Google Scholar] [CrossRef]

- Li, L.; Liu, W.; Sun, L. Mechanical characterization of 3D printed continuous carbon fiber reinforced thermoplastic composites. Compos. Sci. Technol. 2022, 227, 109618. [Google Scholar] [CrossRef]

- Polymaker Technical Data Sheet—PolyMideTM PA6-CF. Available online: https://filament2print.com/es/index.php?controller=attachment&id_attachment=414 (accessed on 13 April 2023).

- Avient Technical Data Sheets. Available online: https://www.avient.com/resources/technical-data-sheets (accessed on 13 April 2023).

- Tagscherer, N.; Bär, A.M.; Zaremba, S.; Drechsler, K. Mechanical Analysis of Parameter Variations in Large-Scale Extrusion Additive Manufacturing of Thermoplastic Composites. J. Manuf. Mater. Process. 2022, 6, 36. [Google Scholar] [CrossRef]

- Al-Maharma, A.Y.; Patil, S.P.; Markert, B. Effects of porosity on the mechanical properties of additively manufactured components: A critical review. Mater. Res. Express 2020, 7, 122001. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Li, D.; Cao, Y.; Zhao, F.; Shi, C. Influence of thermal processing conditions in 3D printing on the crystallinity and mechanical properties of PEEK material. J. Mater. Process. Technol. 2017, 248, 1–7. [Google Scholar] [CrossRef]

- Antolín-Urbaneja, J.C.; Bengoa Ganado, P.; Mateu, A.; Fernández Valares, J.B.; Hernandez Vicente, J.; Bellvert Rios, E.; Vallejo Artola, H.; Alberdi Olaizola, N.; Pacheco Goñi, R.; Luengo Pizarro, A.I. Automated MOLDAM Robotic System for 3D printing: Manufacturing aeronautical mould preforms. In V International Congress on Computer Science, Electronic and Industrail Engineering (CSEI); Universidad Técnica de Ambato, Facultad de Ingeniería en Sistemas, Electrónica e Industrial: Ambato, Ecuador, 2023. [Google Scholar]

- Ly, K.; Thompson, W.; Voorde, D. Evaluating the printability and Mechanical Properties of LFAM Regrind. Available online: https://www.additivemanufacturing.media/articles/evaluating-the-printability-and-mechanical-properties-of-lfam-regrind (accessed on 1 February 2023).

- ISO 4287:1997; Geometrical Product Specifications (GPS). Surface Texture: Profile Method. ISO (International Organization for Standardization): Geneva, Switzerland, 1997.

- ISO 527-1; Plastics—Determination of Tensile Properties—Part 1: General Principles. ISO (International Organization for Standardization): Geneva, Switzerland, 2019.

- ISO 527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO (International Organization for Standardization): Geneva, Switzerland, 2012.

- ISO 14125:1998/Amd 1:2011; Fibre-Reinforced Plastic Composites—Determination of Flexural Properties (Amendment 1). ISO (International Organization for Standardization): Geneva, Switzerland, 2011.

- ISO 604:2022; Plastics—Determination of Compressive Properties. ISO (International Organization for Standardization): Geneva, Switzerland, 2022.

- ASTM D5379/D5379M-19e1; Standard Test Method for Shear Properties of Composite Materials by the V-Notched Beam Method. ASTM International (American Society for Testing and Materials): West Conshohocken, PA, USA, 2021.

- ISO6721-1:2019; Plastics. Determination of Dynamic Mechanical Properties. Part1: General Principles. ISO (International Organization for Standardization): Geneva, Switzerland, 2019.

- ISO 22007-2:2016; Plastics—Determination of Thermal Conductivity and Thermal Diffusivity—Part 2: Transient Plane Heat Source (Hot Disc) Method. ISO (International Organization for Standardization): Geneva, Switzerland, 2016.

- UNE-EN ISO 1183-1:2019; Plastics—Methods for Determining the Density of Non-Cellular Plastics—Part 1: Immersion Method, Liquid Pycnometer Method and Titration Method (ISO 1183-1:2019, Corrected Version 2019-05). UNE-EN (Una Norma Española sobre Norma Europea): Madrid, Spain, 2019.

- UNE-EN ISO 4288:1998; Geometrical Product Specifications (GPS). Surface Texture: Profile Method- Rules and Procedures for the Assessment of Surface Texture. UNE-EN (Una Norma Española sobre Norma Europea): Madrid, Spain, 1998.

- Brinson, H.F.; Brinson, L.C. Time and Temperature Behavior of Polymers. In Polymer Engineering Science and Viscoelasticity: An Introduction; Springer: Boston, MA, USA, 2008; pp. 221–274. ISBN 978-0-387-73861-1. [Google Scholar]

- Valino, A.D.; Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Messman, J.; Advincula, R.C. Advances in 3D printing of thermoplastic polymer composites and nanocomposites. Prog. Polym. Sci. 2019, 98, 101162. [Google Scholar] [CrossRef]

- Park, J.; Zobeiry, N.; Poursartip, A. Tooling materials and their effect on surface thermal gradients. In Proceedings of the International SAMPE Technical Conference, Seattle, WA, USA, 22–26 May 2017; pp. 2554–2568. [Google Scholar]

- ASTM E562-19e1; Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count. ASTM International (American Society for Testing and Materials): West Conshohocken, PA, USA, 2020.

| Product #1 [45] | Product #2 [46] | |

| Material | PolyMideTM PA6/20CF (Supplementary Material S1) | BergamidTM B70 KF20 Black (Supplementary Material S2) |

| Manufacturer | Polymaker (Shangai, China) | Avient Corporation (Barbastro, Spain) |

| Form of material | Filament | Pellet |

| Processing method | FDM | Injection Molding |

| Tensile moduli (X-Y)—GPa | 7.5 | 13.8 |

| Tensile moduli (Z)—GPa | 4.4 | - |

| Tensile strength (X-Y)—MPa | 105 | 220 |

| Tensile strength (Z)—MPa | 68 | - |

| Density—kg/m3 | 1170 | 1210–1250 |

| Parameter | RAMS | AMS I | AMS II (1) | AMSII (2) |

|---|---|---|---|---|

| Extruder Type | 20XD | Pulsar | 20XD | 20XD |

| Nozzle Diameter (mm) | 4 | 3 | 8 | 8 |

| Theoretical Bead Width (mm) | 5 | 3.6 | 8 | 8 |

| Theoretical Bead Height (mm) | 1.5 | 1.5 | 4 | 2 |

| Maximum Mass Flow (kg/h) | 30 | 2.5 | 30 | 30 |

| Extruder Temperature (°C) | ||||

| 1. Feed | 210 | 220 | 190 | 190 |

| 2. Zone 2 (Middle) | 230 | 235 | 200 | 200 |

| 3. Nozzle | 240 | 250 | 235 | 235 |

| Bed Temperature (°C) | RT | 110 | 90 | 90 |

| Barrel Length (mm) | 720 | 300 | 720 | 720 |

| Print Speed (mm/s) | 35 | 35 | 35 | 35 |

| Bead Height and Width | RAMS | AMS I | AMS II (1) | AMSII (2) |

|---|---|---|---|---|

| Theoretical Bead Width (mm) | 5 | 3.6 | 8 | 8 |

| Bead Width Mean, m (mm) | 4.70 | 4.16 | 8.09 | 8.01 |

| Bead Width Deviation (mm) | 0.08 | 0.37 | 0.21 | 0.17 |

| Theoretical Bead Height (mm) | 1.5 | 1.5 | 4 | 2 |

| Bead Height Mean, n (mm) | 1.48 | 1.47 | 3.87 | 1.92 |

| Bead Height Deviation (mm) | 0.04 | 0.15 | 0.07 | 0.15 |

| B. Height Error vs. Theoretical (%) | 1.33 | 2.00 | 3.25 | 4.00 |

| B. Width Error vs. Theoretical (%) | 5.96 | 15.44 | 1.08 | 0.12 |

| Porosity | RAMS | AMS I | AMS II (1) | AMS II (2) |

|---|---|---|---|---|

| (A1) Area #1 (%) | 4.5 | 6.73 | 1.57 | 1.09 |

| (A2) Area #2 (%) | 4.95 | 3.21 | 2.29 | 1.35 |

| (A3) Area #3 (%) | 4.47 | 8.55 | 2.63 | 0.43 |

| (A4) Area #4 (%) | 4.3 | 9.77 | 1.38 | 0.5 |

| (A5) Area #5 (%) | 4.57 | 3.7 | 3.84 | 0.34 |

| Mean Value (%) | 4.6 | 6.4 | 2.3 | 0.7 |

| Standard Deviation | 0.2 | 2.9 | 1 | 0.4 |

| Confidence interval 95% | 0.3 | 3.6 | 1.2 | 0.6 |

| Relative Accuracy (RA %) | 6.6 | 56.3 | 52 | 75.2 |

| Density | RAMS | AMS I | AMS II (1) | AMSII (2) |

|---|---|---|---|---|

| X length (mm) | 30.13 | 30.17 | 30.22 | 30.14 |

| Y width (mm) | 29.98 | 30.15 | 30.07 | 30.09 |

| Z height (mm) | 2.78 | 2.81 | 3.42 | 3.97 |

| Weight (g) | 2.842 | 2.991 | 3.643 | 4.334 |

| Geometrical- ρ (g/cm3) | 1.132 | 1.170 | 1.172 | 1.204 |

| Archimedes- ρ (g/cm3) | 1.12 | 1.17 | 1.2 | 1.19 |

| Potential Problem | Design Strategy |

|---|---|

| Severe problems of CTE mismatch. | Avoid the use of dissimilar materials. Strategically print the semi-moulds and the joining elements to have uniform thermal expansion in each direction. |

| Large temperature-induced displacements. | Accurately determine and apply specific scale factors to compensate for the displacements. |

| Large pressure-induced displacements. | Manufacture solid semi-moulds as a general rule. Accurately determine and apply specific scale factors to compensate for the displacements. |

| Excessive thermal gradients on the lamination surface. | In case of a poor thermal performance, print partially hollow semi-moulds with infill volumes. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antolin-Urbaneja, J.C.; Vallejo Artola, H.; Bellvert Rios, E.; Gayoso Lopez, J.; Hernández Vicente, J.I.; Luengo Pizarro, A.I. Experimental Characterization of Screw-Extruded Carbon Fibre-Reinforced Polyamide: Design for Aeronautical Mould Preforms with Multiphysics Computational Guidance. J. Manuf. Mater. Process. 2024, 8, 34. https://doi.org/10.3390/jmmp8010034

Antolin-Urbaneja JC, Vallejo Artola H, Bellvert Rios E, Gayoso Lopez J, Hernández Vicente JI, Luengo Pizarro AI. Experimental Characterization of Screw-Extruded Carbon Fibre-Reinforced Polyamide: Design for Aeronautical Mould Preforms with Multiphysics Computational Guidance. Journal of Manufacturing and Materials Processing. 2024; 8(1):34. https://doi.org/10.3390/jmmp8010034

Chicago/Turabian StyleAntolin-Urbaneja, Juan Carlos, Haritz Vallejo Artola, Eduard Bellvert Rios, Jorge Gayoso Lopez, Jose Ignacio Hernández Vicente, and Ana Isabel Luengo Pizarro. 2024. "Experimental Characterization of Screw-Extruded Carbon Fibre-Reinforced Polyamide: Design for Aeronautical Mould Preforms with Multiphysics Computational Guidance" Journal of Manufacturing and Materials Processing 8, no. 1: 34. https://doi.org/10.3390/jmmp8010034

APA StyleAntolin-Urbaneja, J. C., Vallejo Artola, H., Bellvert Rios, E., Gayoso Lopez, J., Hernández Vicente, J. I., & Luengo Pizarro, A. I. (2024). Experimental Characterization of Screw-Extruded Carbon Fibre-Reinforced Polyamide: Design for Aeronautical Mould Preforms with Multiphysics Computational Guidance. Journal of Manufacturing and Materials Processing, 8(1), 34. https://doi.org/10.3390/jmmp8010034