Influence of the Processing Parameters on the Microstructure and Mechanical Properties of 316L Stainless Steel Fabricated by Laser Powder Bed Fusion

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Surface Roughness

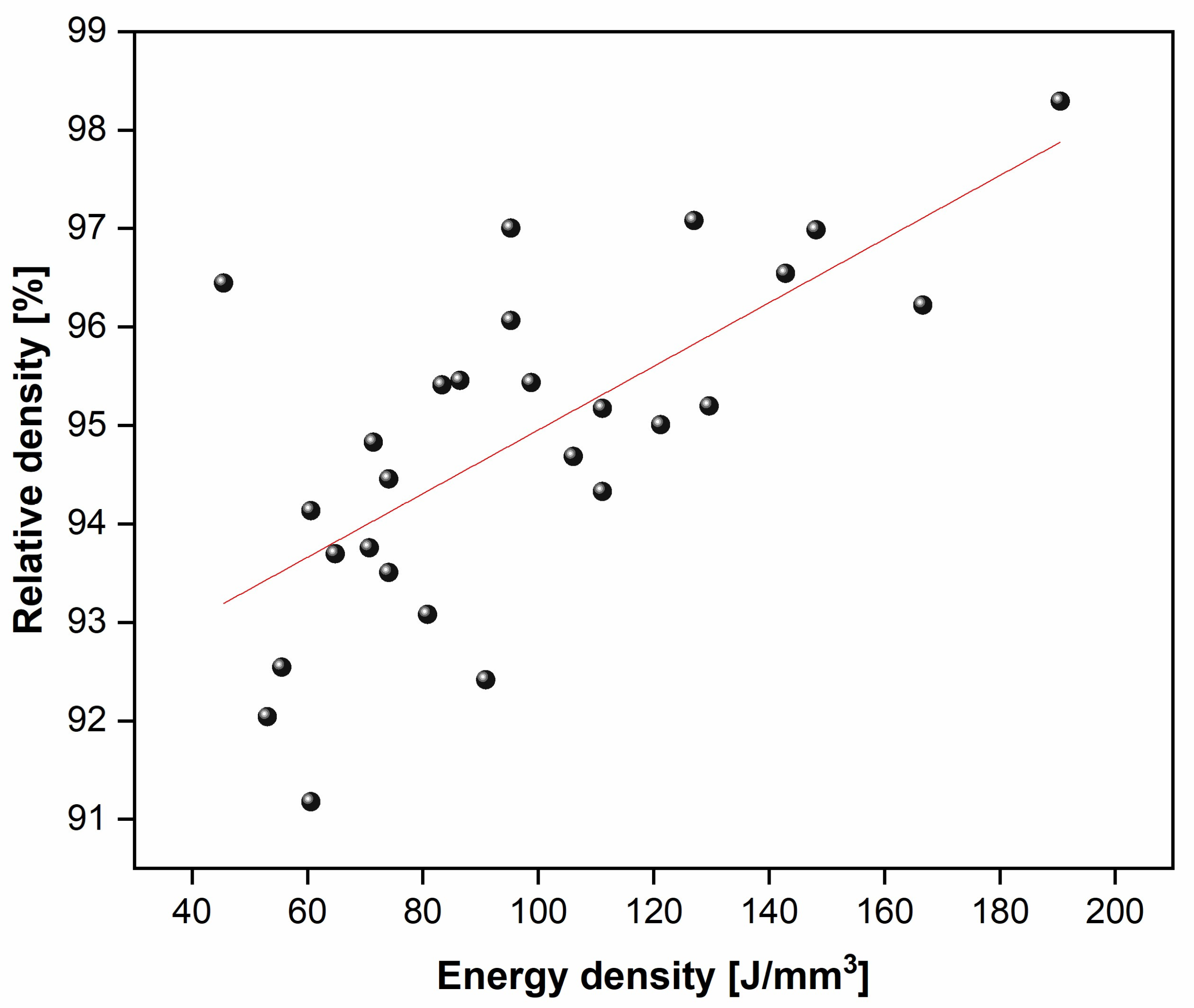

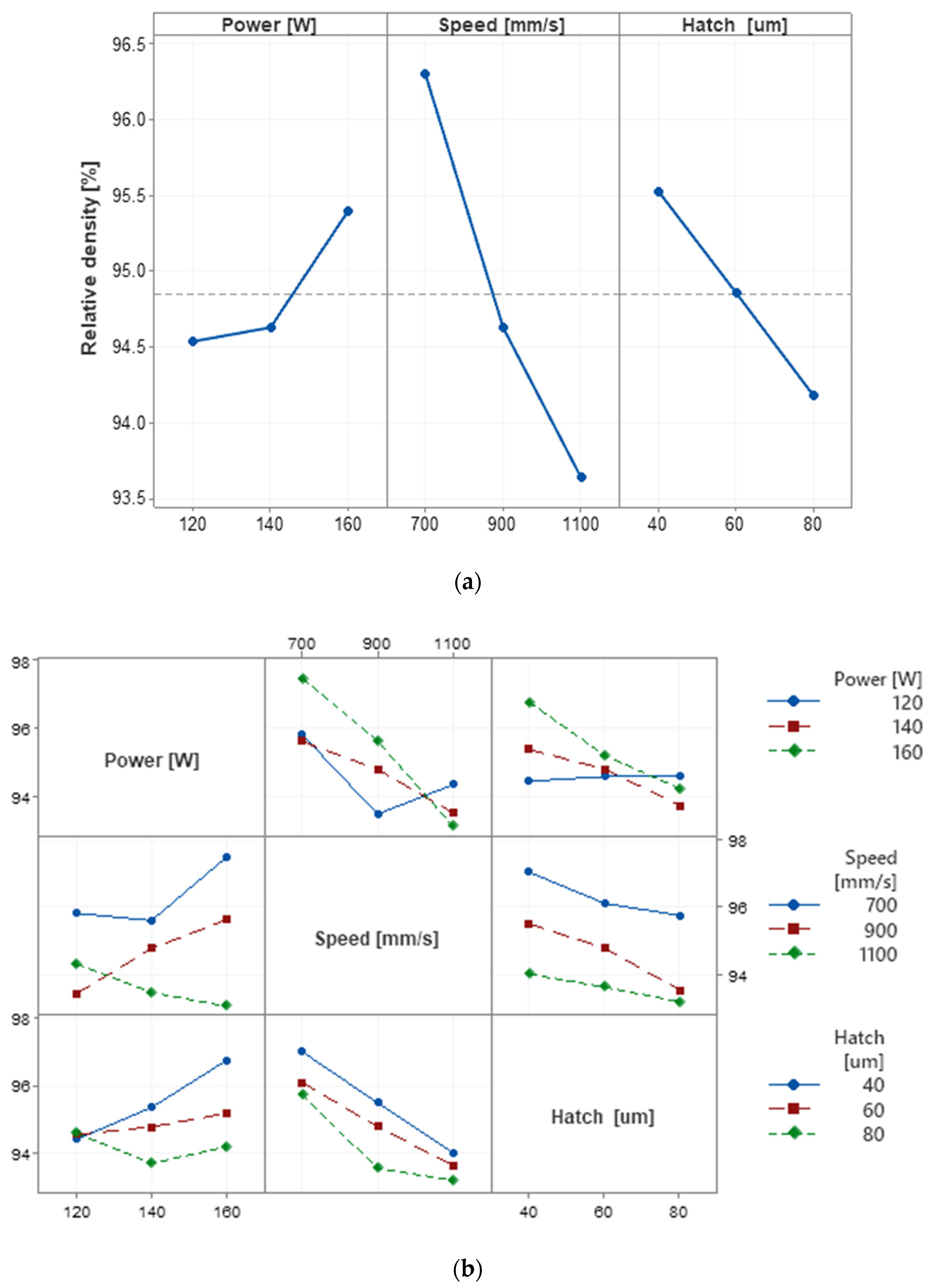

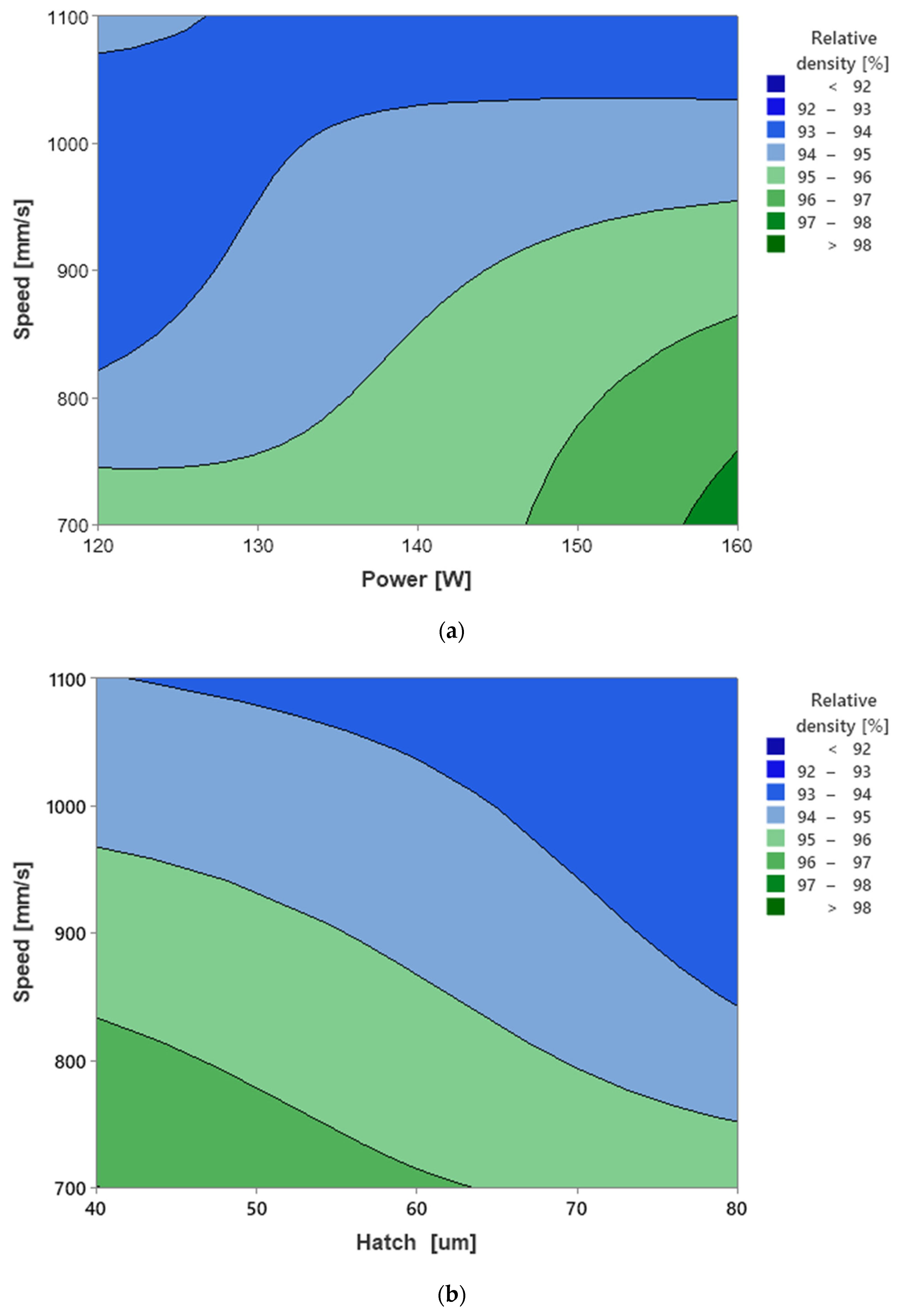

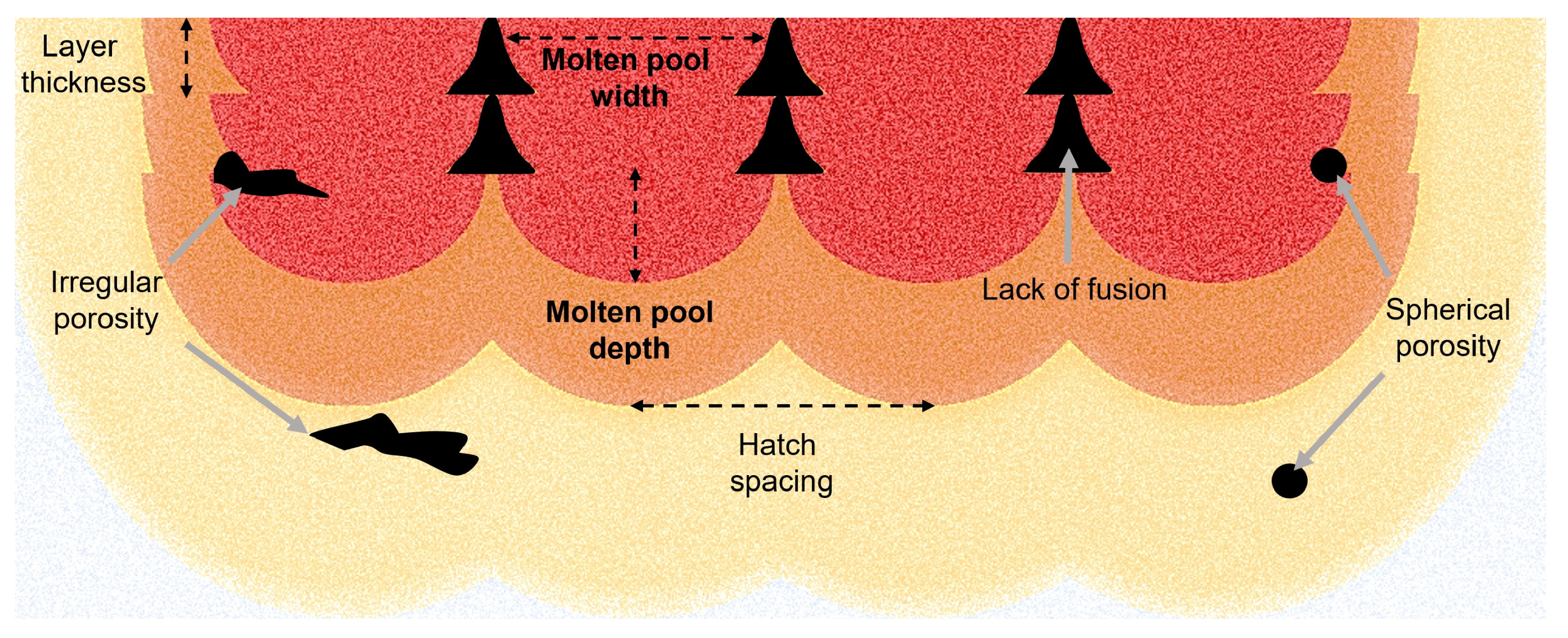

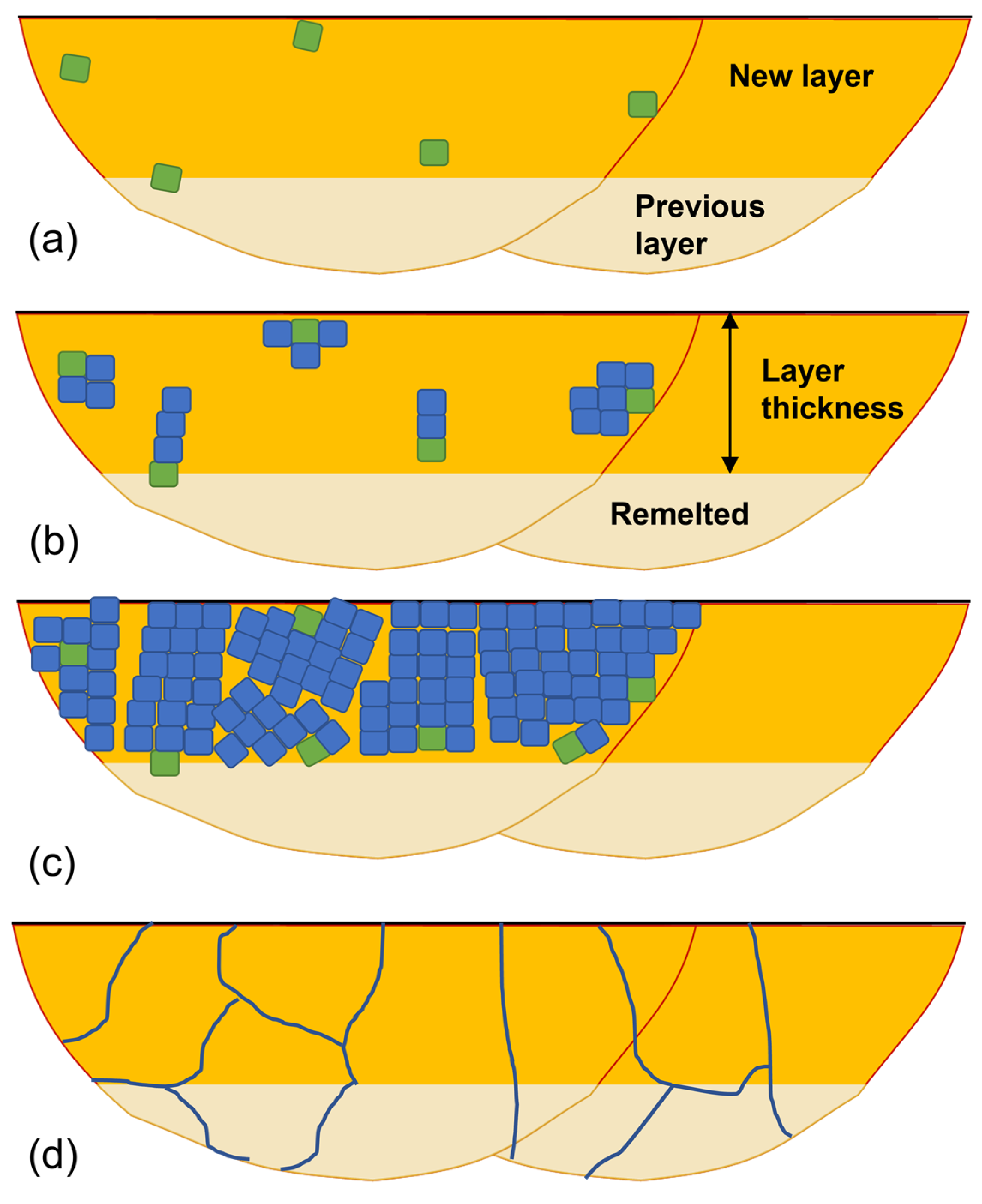

3.2. Relative Density Assessment

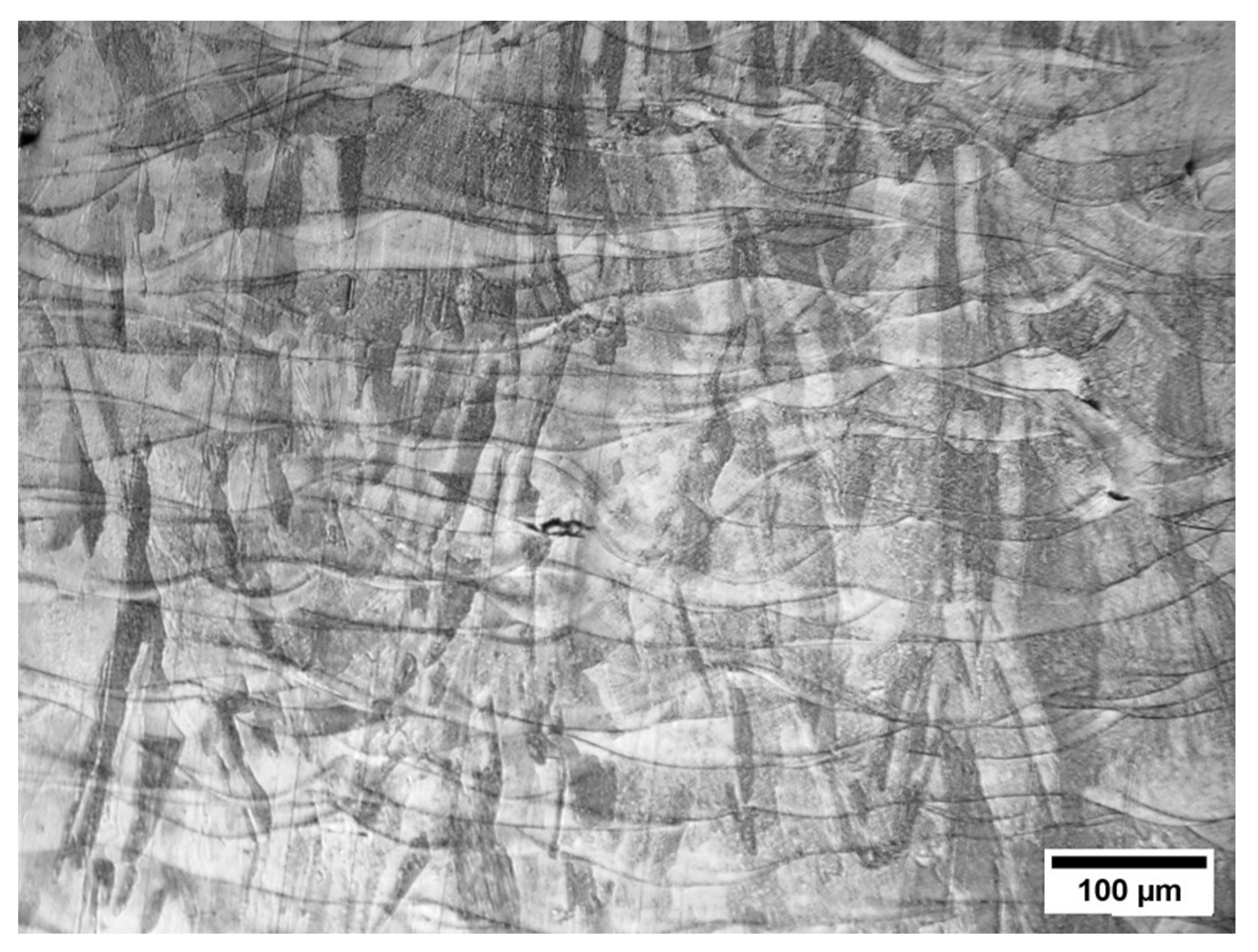

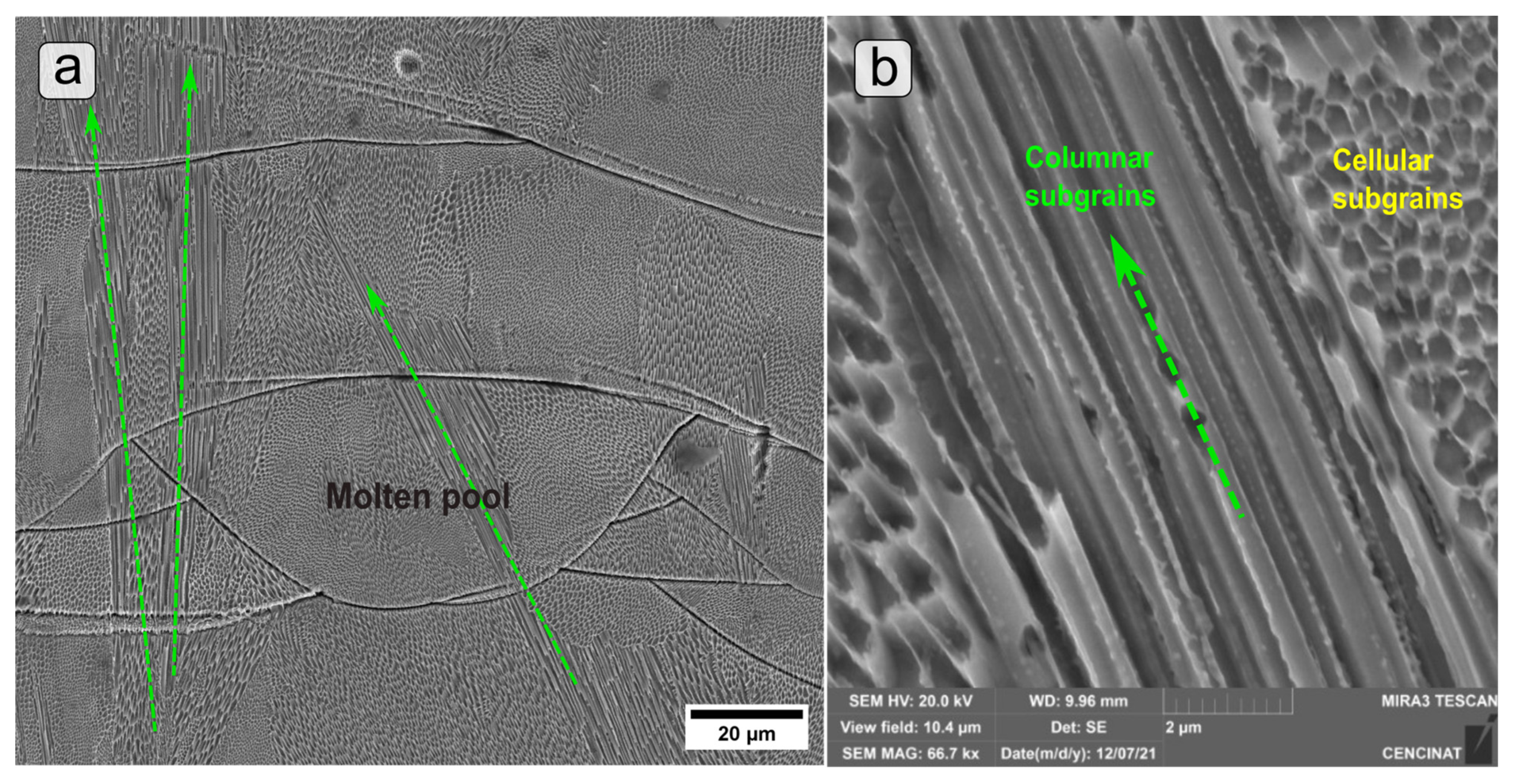

3.3. Microstructure Evaluation

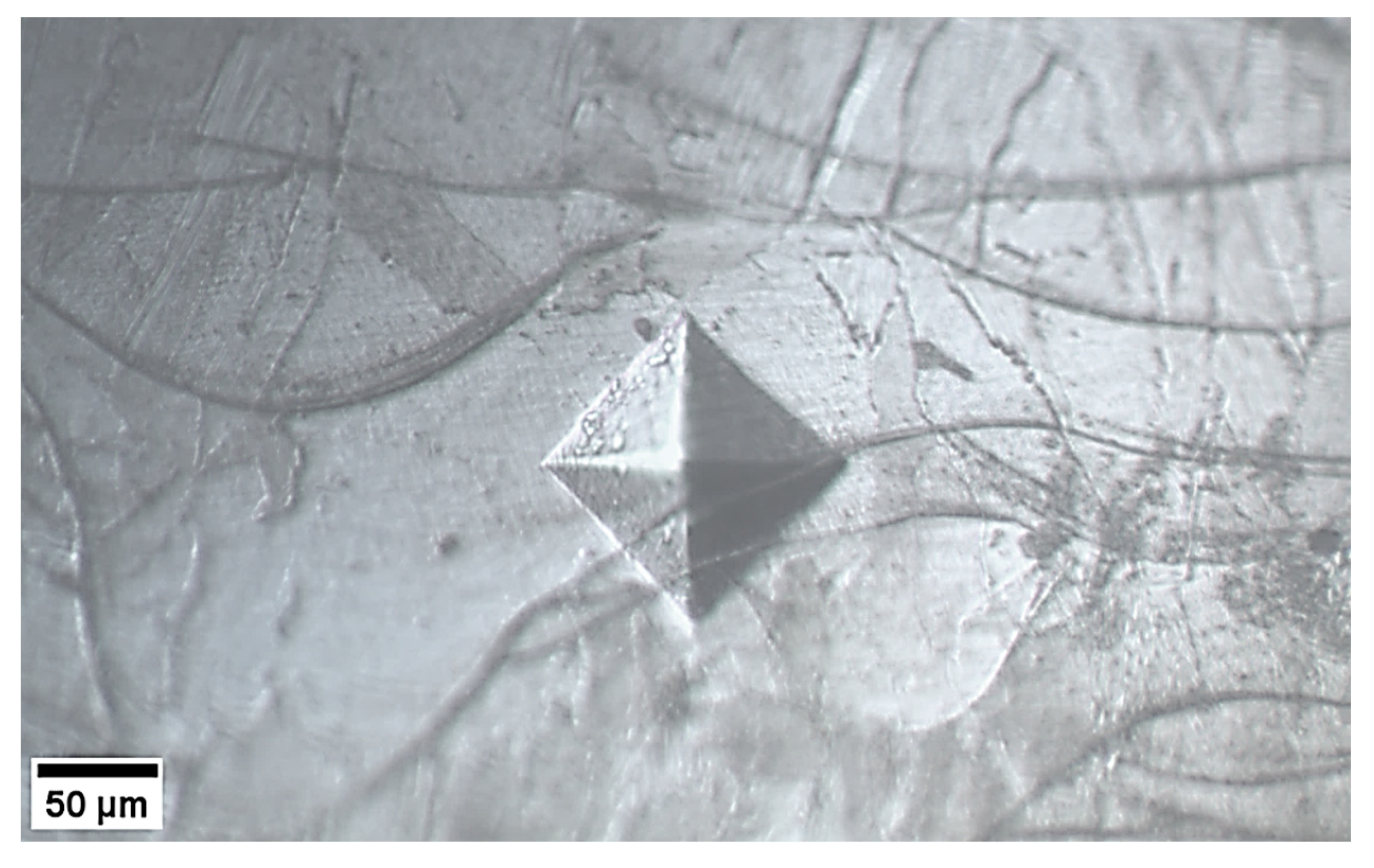

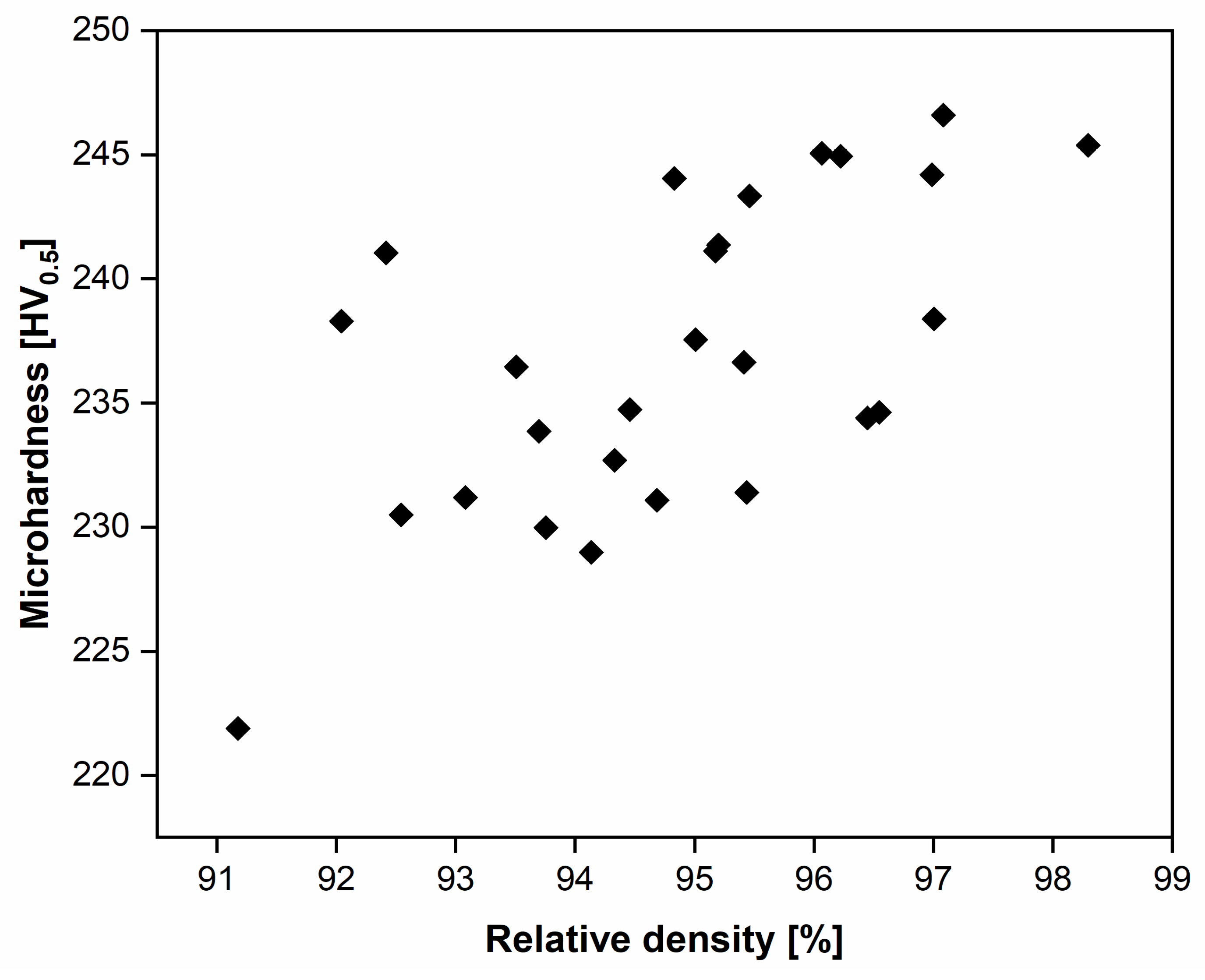

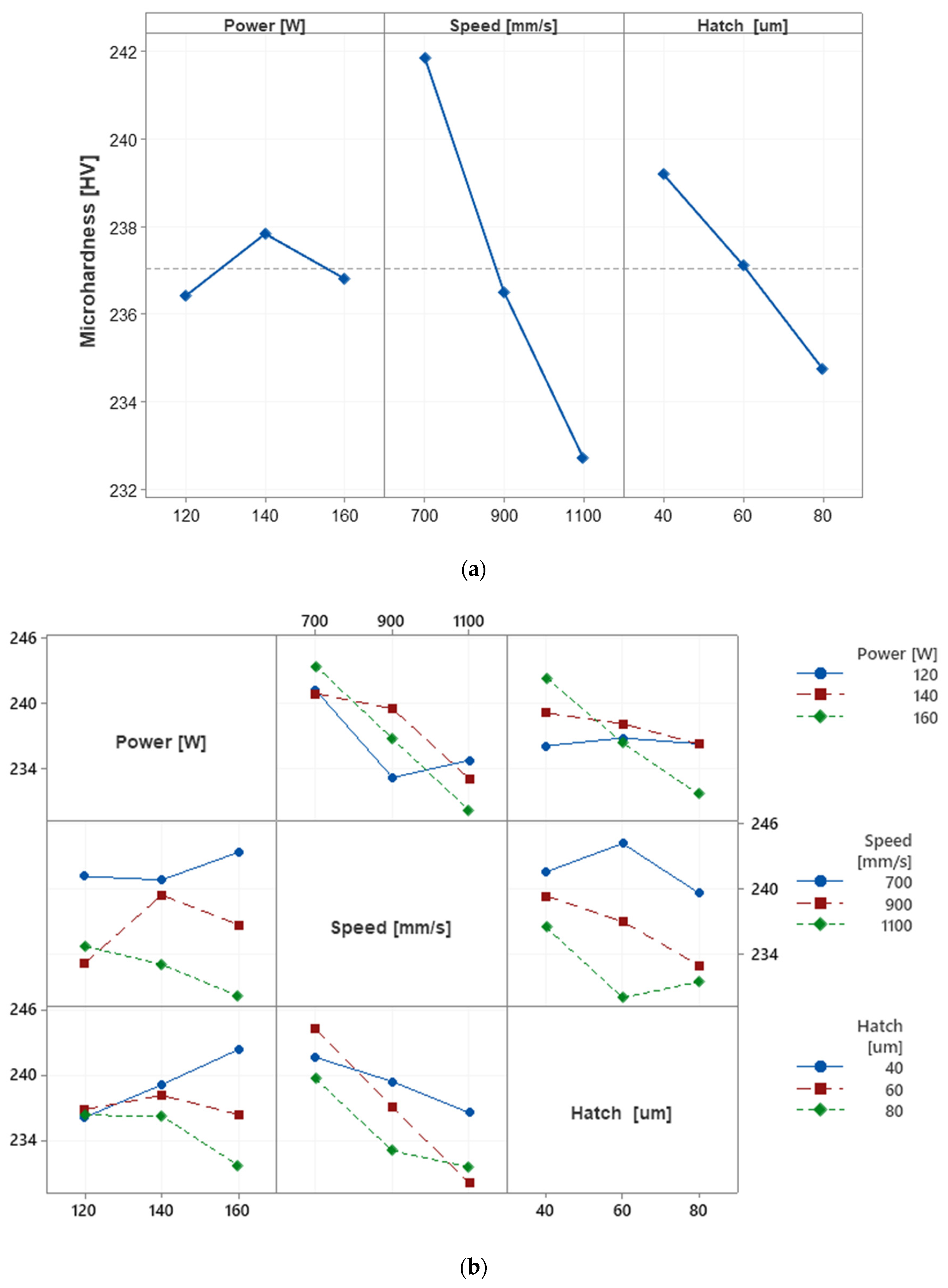

3.4. Microhardness

4. Discussion

5. Conclusions

- It has been found that there is a direct relationship between scanning speed and the porosity level. Enough volumetric energy (125 J/mm3) density must be provided to avoid fusion errors and balling phenomena to obtain pieces with maximum relative density. Within the levels evaluated in the design of experiments, it was found that scanning speed is the most statistically significant factor that affects the relative density and microhardness of the 316L SS processed by LPBF.

- The maximum densification reached was 99.41%, obtained with Archimedes’ principle, equivalent to 99.9% by image correlation, utilizing 180 W of laser power, 700 mm/s of scanning speed, and a hatch spacing of 40 μm. To increase productivity, it is recommended to use a laser power greater than 160 W and a hatch spacing of 60 μm.

- Microstructurally, it was found that the samples are composed of stacked molten pools, one on top of the other, aligned in the build direction; columnar sub-grains can be distinguished within the elongated grains with an extension that sometimes exceeds 300 µm.

- Densification in additive manufacturing processes has reached porosity levels comparable to conventional processes (>99%). Therefore, the laser powder bed fusion technique is suitable for manufacturing mechanical elements.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gong, G.; Ye, J.; Chi, Y.; Zhao, Z.; Wang, Z.; Xia, G.; Du, X.; Tian, H.; Yu, H.; Chen, C. Research status of laser additive manufacturing for metal: A review. J. Mater. Res. Technol. 2021, 15, 855–884. [Google Scholar] [CrossRef]

- Peng, T.; Chen, C. Influence of energy density on energy demand and porosity of 316L stainless steel fabricated by selective laser melting. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 55–62. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Li, N.; Huang, S.; Zhang, G.; Qin, R.; Liu, W.; Xiong, H.; Shi, G.; Blackburn, J. Progress in additive manufacturing on new materials: A review. J. Mater. Sci. Technol. 2019, 35, 242–269. [Google Scholar] [CrossRef]

- Haghdadi, N.; Laleh, M.; Moyle, M.; Primig, S. Additive manufacturing of steels: A review of achievements and challenges. J. Mater. Sci. 2021, 56, 64–107. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; Ramos-Grez, J.A.; Walczak, M.; Sánchez-Sánchez, X.; Guerra, C.; Debut, A.; Haro, E. Microstructure simulation and experimental evaluation of the anisotropy of 316L stainless steel manufactured by laser powder bed fusion. Rapid Prototyp. J. 2023, 29, 425–436. [Google Scholar] [CrossRef]

- La Fé-Perdomo, I.; Ramos-Grez, J.A.; Jeria, I.; Guerra, C.; Barrionuevo, G.O. Comparative analysis and experimental validation of statistical and machine learning-based regressors for modeling the surface roughness and mechanical properties of 316L stainless steel specimens produced by selective laser melting. J. Manuf. Process 2022, 80, 666–682. [Google Scholar] [CrossRef]

- Sharma, S.; Joshi, S.S.; Pantawane, M.V.; Radhakrishnan, M.; Mazumder, S.; Dahotre, N.B. Multiphysics multi-scale computational framework for linking process–structure–property relationships in metal additive manufacturing: A critical review. Int. Mater. Rev. 2023, 68, 943–1009. [Google Scholar] [CrossRef]

- Liu, C.M.; Gao, H.B.; Li, L.Y.; Wang, J.D.; Guo, C.H.; Jiang, F.C. A review on metal additive manufacturing: Modeling and application of numerical simulation for heat and mass transfer and microstructure evolution. China Foundry 2021, 18, 317–334. [Google Scholar] [CrossRef]

- Barrionuevo, G.; Ramos-Grez, J.; Walczak, M.; Betancourt, C. Comparative evaluation of supervised machine learning algorithms in the prediction of the relative density of 316L stainless steel fabricated by selective laser melting. Int. J. Adv. Manuf. Technol. 2021, 113, 419–433. [Google Scholar] [CrossRef]

- Mukherjee, T.; DebRoy, T. Mitigation of lack of fusion defects in powder bed fusion additive manufacturing. J. Manuf. Process 2018, 36, 442–449. [Google Scholar] [CrossRef]

- Kan, W.H.; Chiu, L.N.S.; Lim, C.V.S.; Zhu, Y.; Tian, Y.; Jiang, D.; Huang, A. A critical review on the effects of process-induced porosity on the mechanical properties of alloys fabricated by laser powder bed fusion. J. Mater. Sci. 2022, 57, 9818–9865. [Google Scholar] [CrossRef]

- Wang, D.; Han, H.; Sa, B.; Li, K.; Yan, J.; Zhang, J.; Liu, J.; He, Z.; Wang, N.; Yan, M. A review and a statistical analysis of porosity in metals additively manufactured by laser powder bed fusion. Opto-Electron. Adv. 2022, 5, 210058–210061. [Google Scholar] [CrossRef]

- Sola, A.; Nouri, A. Microstructural porosity in additive manufacturing: The formation and detection of pores in metal parts fabricated by powder bed fusion. J. Adv. Manuf. Process. 2019, 1, e10021. [Google Scholar] [CrossRef]

- Al-Maharma, A.Y.; Patil, S.P.; Markert, B. Effects of porosity on the mechanical properties of additively manufactured components: A critical review. Mater. Res. Express 2020, 7, 122001. [Google Scholar] [CrossRef]

- Alafaghani, A.; Qattawi, A.; Alrawi, B.; Guzman, A. Experimental Optimization of Fused Deposition Modelling Processing Parameters: A Design-for-Manufacturing Approach. Procedia Manuf. 2017, 10, 791–803. [Google Scholar] [CrossRef]

- Gustmann, T.; Neves, A.; Kühn, U.; Gargarella, P.; Kiminami, C.S.; Bolfarini, C.; Eckert, J.; Pauly, S. Influence of processing parameters on the fabrication of a Cu-Al-Ni-Mn shape-memory alloy by selective laser melting. Addit. Manuf. 2016, 11, 23–31. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; Ramos-Grez, J.; Walczak, M.; La Fé-Perdomo, I. Numerical analysis of the effect of processing parameters on the microstructure of stainless steel 316L manufactured by laser-based powder bed fusion. Mater Today Proc. 2021, 59, 93–100. [Google Scholar] [CrossRef]

- Koutiri, I.; Pessard, E.; Peyre, P.; Amlou, O.; De Terris, T. Influence of SLM process parameters on the surface finish, porosity rate and fatigue behavior of as-built Inconel 625 parts. J. Mater. Process Technol. 2018, 255, 536–546. [Google Scholar] [CrossRef]

- AlMangour, B.; Baek, M.S.; Grzesiak, D.; Lee, K.A. Strengthening of stainless steel by titanium carbide addition and grain refinement during selective laser melting. Mater. Sci. Eng. A 2018, 712, 812–818. [Google Scholar] [CrossRef]

- Laleh, M.; Hughes, A.E.; Xu, W.; Gibson, I.; Tan, M.Y. Unexpected erosion-corrosion behaviour of 316L stainless steel produced by selective laser melting. Corros. Sci. 2019, 155, 67–74. [Google Scholar] [CrossRef]

- Lin, K.; Gu, D.; Xi, L.; Yuan, L.; Niu, S.; Lv, P.; Ge, Q. Selective laser melting processing of 316L stainless steel: Effect of microstructural differences along building direction on corrosion behavior. Int. J. Adv. Manuf. Technol. 2019, 104, 2669–2679. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; Walczak, M.; Ramos-grez, J.; Sánchez-sánchez, X. Microhardness and wear resistance in materials manufactured by laser powder bed fusion: Machine learning approach for property prediction. CIRP J. Manuf. Sci. Technol. 2023, 43, 106–114. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Yadroitsava, I.; Plessis, A.D.; MacDonald, E. Fundamentals of Laser Powder Bed Fusion of Metals; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Yan, X.; Gao, S.; Chang, C.; Huang, J.; Khanlari, K.; Dong, D.; Ma, W.; Fenineche, N.; Liao, H.; Liu, M. Effect of building directions on the surface roughness, microstructure, and tribological properties of selective laser melted Inconel 625. J. Mater. Process. Technol. 2021, 288, 116878. [Google Scholar] [CrossRef]

- Salman, O.O.; Brenne, F.; Niendorf, T.; Eckert, J.; Prashanth, K.G.; He, T.; Scudino, S. Impact of the scanning strategy on the mechanical behavior of 316L steel synthesized by selective laser melting. J. Manuf. Process 2019, 45, 255–261. [Google Scholar] [CrossRef]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Zhong, Y. Sub-Grain Structure in Additive Manufactured Stainless Steel 316L. Ph.D. Thesis, Stockolm University, Stockholm, Sweden, 2017. [Google Scholar]

- Zhang, X.; Yocom, C.J.; Mao, B.; Liao, Y. Microstructure evolution during selective laser melting of metallic materials: A review. J. Laser Appl. 2019, 31, 031201. [Google Scholar] [CrossRef]

- Huang, M.; Zhang, Z.; Chen, P. Effect of selective laser melting process parameters on microstructure and mechanical properties of 316L stainless steel helical micro-diameter spring. Int. J. Adv. Manuf. Technol. 2019, 2154, 2117–2131. [Google Scholar] [CrossRef]

- Deng, Y.; Mao, Z.; Yang, N.; Niu, X.; Lu, X. Collaborative optimization of density and surface roughness of 316L stainless steel in selective laser melting. Materials 2020, 13, 1601. [Google Scholar] [CrossRef]

- Larimian, T.; Kannan, M.; Grzesiak, D.; AlMangour, B.; Borkar, T. Effect of energy density and scanning strategy on densification, microstructure and mechanical properties of 316L stainless steel processed via selective laser melting. Mater. Sci. Eng. A 2020, 770, 138455. [Google Scholar] [CrossRef]

- Tucho, W.M.; Lysne, V.H.; Austbø, H.; Sjolyst-Kverneland, A.; Hansen, V. Investigation of effects of process parameters on microstructure and hardness of SLM manufactured SS316L. J. Alloys Compd. 2018, 740, 910–925. [Google Scholar] [CrossRef]

- Ramirez-Cedillo, E.; Uddin, M.J.; Sandoval-Robles, J.A.; Mirshams, R.A.; Ruiz-Huerta, L.; Rodriguez, C.A.; Siller, H.R. Process planning of L-PBF of AISI 316L for improving surface quality and relating part integrity with microstructural characteristics. Surf. Coat. Technol. 2020, 396, 125956. [Google Scholar] [CrossRef]

- Zhang, Z.; Chu, B.; Wang, L.; Lu, Z. Comprehensive effects of placement orientation and scanning angle on mechanical properties and behavior of 316L stainless steel based on the selective laser melting process. J. Alloys Compd. 2019, 791, 166–175. [Google Scholar] [CrossRef]

- Röttger, A.; Geenen, K.; Windmann, M.; Binner, F.; Theisen, W. Comparison of microstructure and mechanical properties of 316L austenitic steel processed by selective laser melting with hot-isostatic pressed and cast material. Mater. Sci. Eng. A 2016, 678, 365–376. [Google Scholar] [CrossRef]

- Liverani, E.; Lutey, A.H.A.; Ascari, A.; Fortunato, A. The effects of hot isostatic pressing (HIP) and solubilization heat treatment on the density, mechanical properties, and microstructure of austenitic stainless steel parts produced by selective laser melting (SLM). Int. J. Adv. Manuf. Technol. 2020, 107, 109–122. [Google Scholar] [CrossRef]

- Sun, Y.; Moroz, A.; Alrbaey, K. Sliding wear characteristics and corrosion behaviour of selective laser melted 316L stainless steel. J. Mater. Eng. Perform. 2014, 23, 518–526. [Google Scholar] [CrossRef]

- Chen, W.; Yin, G.; Feng, Z.; Liao, X. Effect of powder feedstock on microstructure and mechanical properties of the 316L stainless steel fabricated by selective laser melting. Metals 2018, 8, 729. [Google Scholar] [CrossRef]

- Cole, M.E.; Stout, S.D.; Dominguez, V.M.; Agnew, A.M. Pore Extractor 2D: An ImageJ toolkit for quantifying cortical pore morphometry on histological bone images, with application to intraskeletal and regional patterning. Am. J. Biol. Anthropol. 2022, 179, 365–385. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Y.; Bai, Q. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. (Engl. Ed.) 2017, 30, 515–527. [Google Scholar] [CrossRef]

- Shen, X.-J.; Zhang, C.; Yang, Y.-G.; Liu, L. On the microstructure, mechanical properties and wear resistance of an additively manufactured Ti64/metallic glass composite. Mater. Des. 2016, 25, 499–510. [Google Scholar] [CrossRef]

- Shin, W.S.; Son, B.; Song, W.; Sohn, H.; Jang, H.; Kim, Y.J.; Park, C. Heat treatment effect on the microstructure, mechanical properties, and wear behaviors of stainless steel 316L prepared via selective laser melting. Mater. Sci. Eng. A 2021, 806, 140805. [Google Scholar] [CrossRef]

- Kamariah, M.S.I.N.; Harun, W.S.W.; Khalil, N.Z.; Ahmad, F.; Ismail, M.H.; Sharif, S. Effect of heat treatment on mechanical properties and microstructure of selective laser melting 316L stainless steel. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 257. [Google Scholar] [CrossRef]

- Montero-Sistiaga, M.L.; Godino-Martinez, M.; Boschmans, K.; Kruth, J.P.; Van Humbeeck, J.; Vanmeensel, K. Microstructure evolution of 316L produced by HP-SLM (high power selective laser melting). Addit. Manuf. 2018, 23, 402–410. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; Walczak, M.; Ramos-grez, J.; Mendez, P.; Debut, A. Microstructure effect on sliding wear of 316L stainless steel selectively laser melted. Mater. Sci. Technol. (UK) 2024, 02670836231217393. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; La Fé-perdomo, I.; Cáceres-Brito, E.; Navas-Pinto, W. Tensile/Compressive Response of 316L Stainless Steel Fabricated by Additive Manufacturing. Ingenius Rev. De Cienc. Y Tecnol. 2024, 31, 9–18. [Google Scholar] [CrossRef]

- Kovacı, H.; Seçer, Y. Improved tribological performance of AISI 316L stainless steel by a combined surface treatment: Surface texturing by selective laser melting and plasma nitriding. Surf. Coat. Technol. 2020, 400, 126178. [Google Scholar] [CrossRef]

- Chen, H.; Gu, D. Effect of metallurgical defect and phase transition on geometric accuracy and wear resistance of iron-based parts fabricated by selective laser melting. J. Mater. Res. 2016, 31, 1477–1490. [Google Scholar] [CrossRef]

- Yang, Y.; Zhu, Y.; Khonsari, M.M.; Yang, H. Wear anisotropy of selective laser melted 316L stainless steel. Wear 2019, 428, 376–386. [Google Scholar] [CrossRef]

- Bahshwan, M.; Myant, C.W.; Reddyhoff, T.; Pham, M.S. The role of microstructure on wear mechanisms and anisotropy of additively manufactured 316L stainless steel in dry sliding. Mater. Des. 2020, 196, 109076. [Google Scholar] [CrossRef]

- Bahshwan, M.; Gee, M.; Nunn, J.; Myant, C.W.; Reddyhoff, T. In situ observation of anisotropic tribological contact evolution in 316L steel formed by selective laser melting. Wear 2022, 490, 204193. [Google Scholar] [CrossRef]

- Lee, Y.; Nordin, M.; Babu, S.S.; Farson, D.F. Effect of fluid convection on dendrite arm spacing in laser deposition. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2014, 45, 1520–1529. [Google Scholar] [CrossRef]

- Li, X.; Tan, W. Numerical investigation of effects of nucleation mechanisms on grain structure in metal additive manufacturing. Comput. Mater. Sci. 2018, 153, 159–169. [Google Scholar] [CrossRef]

- Cao, Y.; Bai, P.; Liu, F.; Hou, X. Grain growth in IN718 superalloy fabricated by laser additive manufacturing. Mater. Sci. Technol. (UK) 2020, 36, 765–769. [Google Scholar] [CrossRef]

- Fergani, O.; Brotan, V.; Bambach, M.; Pérez-Prado, M.T. Texture evolution in stainless steel processed by selective laser melting and annealing. Mater. Sci. Technol. 2018, 34, 2223–2230. [Google Scholar] [CrossRef]

| Power (W) | Speed (mm/s) | Hatch (μm) | Layer Thickness (μm) | Energy Density (J/mm3) | Machine/ Model | Relative Density (%) | Reference |

|---|---|---|---|---|---|---|---|

| 200 | 750–1000 | 50 | 110 | 35–50 | - | 97.97 | [2] |

| 120–160 | 800–1200 | 60–80 | 20–40 | 32–130 | Concept Laser Mlab200 | 96.6 | [7] |

| 150 | 400–800 | 40 | 80 | 60–120 | Self-developed 500W | 96.82 | [22] |

| 80–100 | 300–1700 | 20 | 40–120 | 20–400 | EP-M100T | 98.77 | [30] |

| 150–300 | 700–1300 | 20 | 60–120 | 36–350 | FS271M | 98.52 | [31] |

| 100 | 111–250 | 50 | 110–120 | 66–400 | SLM 125 | 96.00 | [32] |

| 150–200 | 446–1667 | 30 | 80–140 | 20–180 | SLM 280HL | 98.59 | [33] |

| 125–175 | 180–260 | 40 | 20–60 | 200–1200 | RENISHAW AM 400 | 98.62 | [34] |

| 220 | 960 | 40 | 80 | 70 | BLT S200 | 95.61 | [35] |

| 100 | 400–600 | 30 | 30–150 | 40–280 | REALIZER SLM 100 | 96.50 | [36] |

| 70–130 | 700–1200 | 20 | 60 | 50–150 | MYSINT100 | 96.84 | [37] |

| 175 | 668 | 30 | 120 | 70 | SLM 250 HL | 99.05 | [26] |

| 150 | 125–200 | 50 | 90 | 160–260 | RENISHAW 125 | 96.40 | [38] |

| 200 | 2000 | 30 | 60 | 55 | AFS-M120 | 97.38 | [39] |

| Elements (wt%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Fe | Cr | Ni | Mo | Mn | Si | C | P | S |

| Bal. | 16.5–18 | 10–13 | 2–2.5 | 0–2 | 0–1 | 0–0.03 | 0–0.04 | 0–0.03 |

| Factors | Levels | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| Laser power (W) | 120 | 140 | 160 |

| Scanning speed (mm/s) | 700 | 900 | 1100 |

| Hatch spacing (µm) | 40 | 60 | 80 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Laser Power (W) | 2 | 0.02534 | 0.01267 | 1.22 | 0.317 |

| Scanning speed (mm/s) | 2 | 0.20629 | 0.10315 | 9.91 | 0.001 |

| Hatch spacing (um) | 2 | 0.05160 | 0.02580 | 2.48 | 0.109 |

| Error | 20 | 0.20815 | 0.01041 | ||

| Total | 26 | 0.49138 |

| Glow Discharge Emission Spectrometry (GDOES) | ||||||

| Element (wt%) | ||||||

| Fe | Cr | Ni | Mo | Si | Mn | Co |

| Bal. | 18.9 ± 1.6 | 12.5 ± 0.9 | 2.7 ± 0.2 | 0.9 ± 0.2 | 0.5 ± 0.03 | 0.1 ± 0.01 |

| Energy Dispersive Spectroscopy (EDS) | ||||||

| Element (wt%) | ||||||

| Fe | Cr | Ni | Mo | Si | Mn | Co |

| Bal. | 16.98 | 11.14 | 2.10 | 0.56 | 0.75 | 0.65 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Power (W) | 2 | 9.74 | 4.870 | 0.18 | 0.836 |

| Speed (mm/s) | 2 | 380.51 | 190.257 | 7.06 | 0.005 |

| Hatch (um) | 2 | 89.46 | 44.732 | 1.66 | 0.215 |

| Error | 20 | 538.65 | 26.932 | ||

| Total | 26 | 1018.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barrionuevo, G.O.; Ramos-Grez, J.A.; Sánchez-Sánchez, X.; Zapata-Hidalgo, D.; Mullo, J.L.; Puma-Araujo, S.D. Influence of the Processing Parameters on the Microstructure and Mechanical Properties of 316L Stainless Steel Fabricated by Laser Powder Bed Fusion. J. Manuf. Mater. Process. 2024, 8, 35. https://doi.org/10.3390/jmmp8010035

Barrionuevo GO, Ramos-Grez JA, Sánchez-Sánchez X, Zapata-Hidalgo D, Mullo JL, Puma-Araujo SD. Influence of the Processing Parameters on the Microstructure and Mechanical Properties of 316L Stainless Steel Fabricated by Laser Powder Bed Fusion. Journal of Manufacturing and Materials Processing. 2024; 8(1):35. https://doi.org/10.3390/jmmp8010035

Chicago/Turabian StyleBarrionuevo, Germán Omar, Jorge Andrés Ramos-Grez, Xavier Sánchez-Sánchez, Daniel Zapata-Hidalgo, José Luis Mullo, and Santiago D. Puma-Araujo. 2024. "Influence of the Processing Parameters on the Microstructure and Mechanical Properties of 316L Stainless Steel Fabricated by Laser Powder Bed Fusion" Journal of Manufacturing and Materials Processing 8, no. 1: 35. https://doi.org/10.3390/jmmp8010035

APA StyleBarrionuevo, G. O., Ramos-Grez, J. A., Sánchez-Sánchez, X., Zapata-Hidalgo, D., Mullo, J. L., & Puma-Araujo, S. D. (2024). Influence of the Processing Parameters on the Microstructure and Mechanical Properties of 316L Stainless Steel Fabricated by Laser Powder Bed Fusion. Journal of Manufacturing and Materials Processing, 8(1), 35. https://doi.org/10.3390/jmmp8010035