Impact of Green Ceramic Hybrid Machining (GCHM) on Reliability and Repeatability of the Properties of Sintered Yttrium-Tetragonal Zirconia Polycrystal Parts

Abstract

:1. Introduction

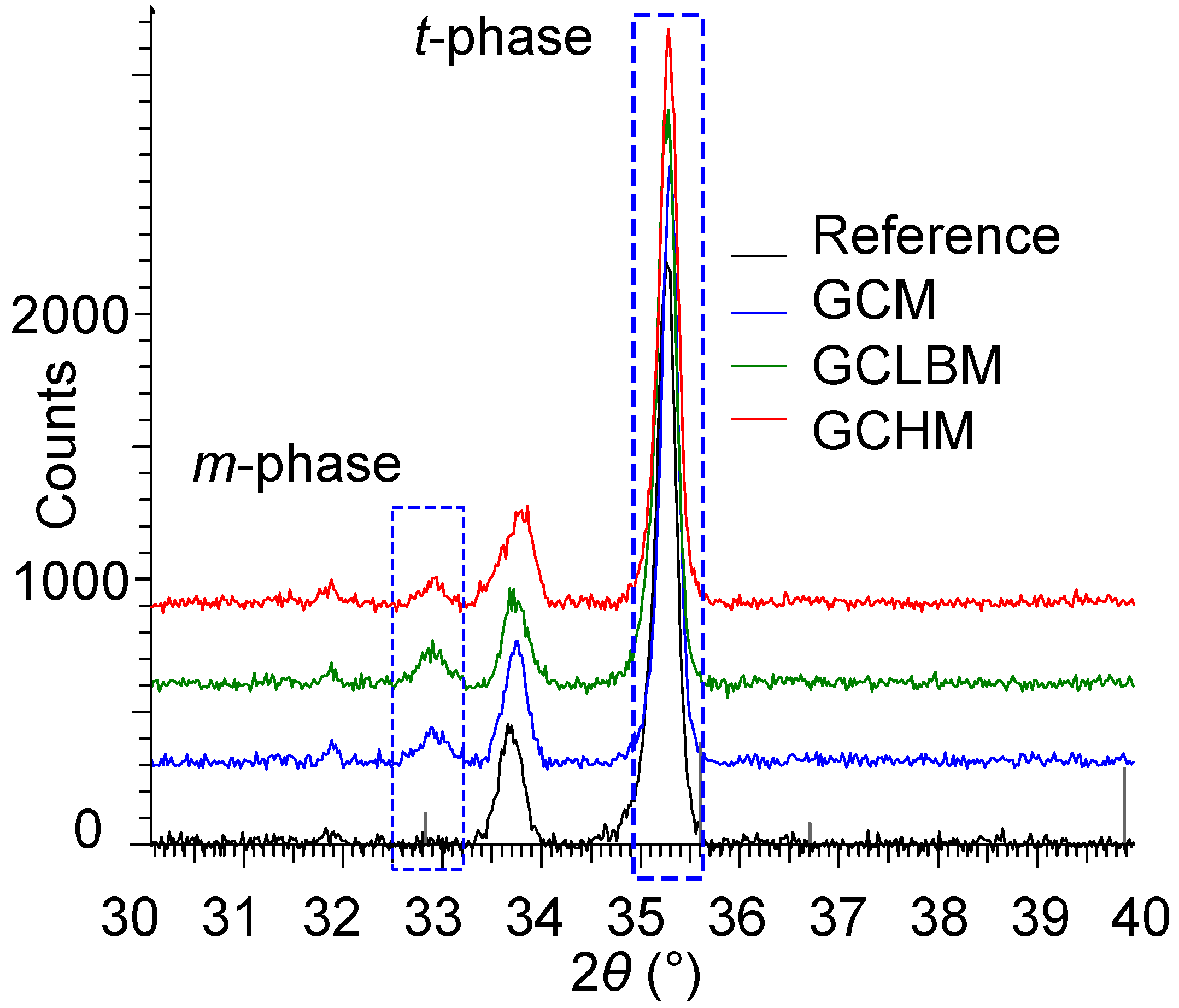

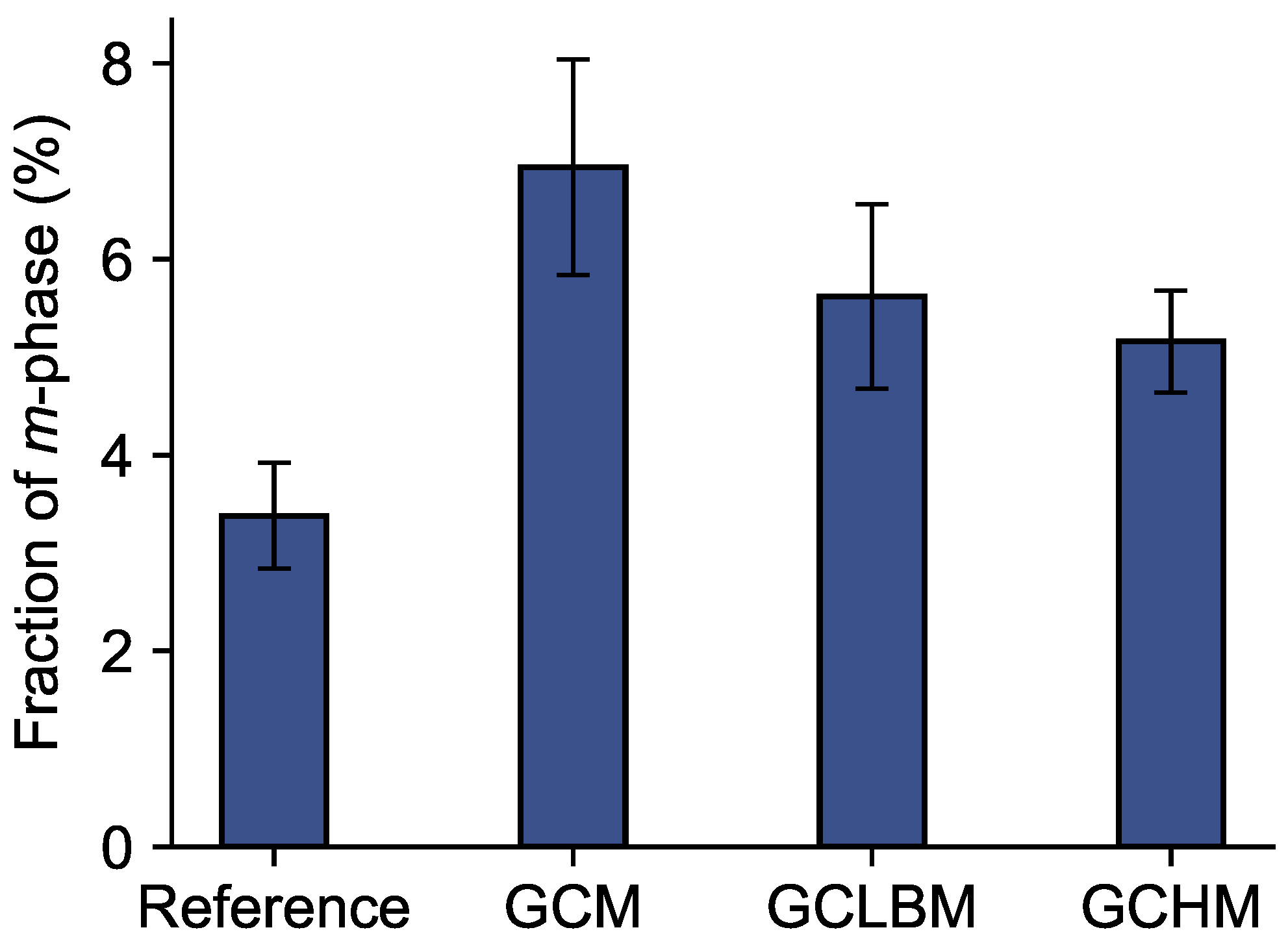

- Compressive residual stresses can be induced as a consequence of plastic deformation and, thus, of the transformation [12]. A large transformation depth leads to a degradation of mechanical properties due to the presence of deep cracks that overcome the benefits of the transformation [13]. A low fraction of m-phase is, therefore, recommended [12].

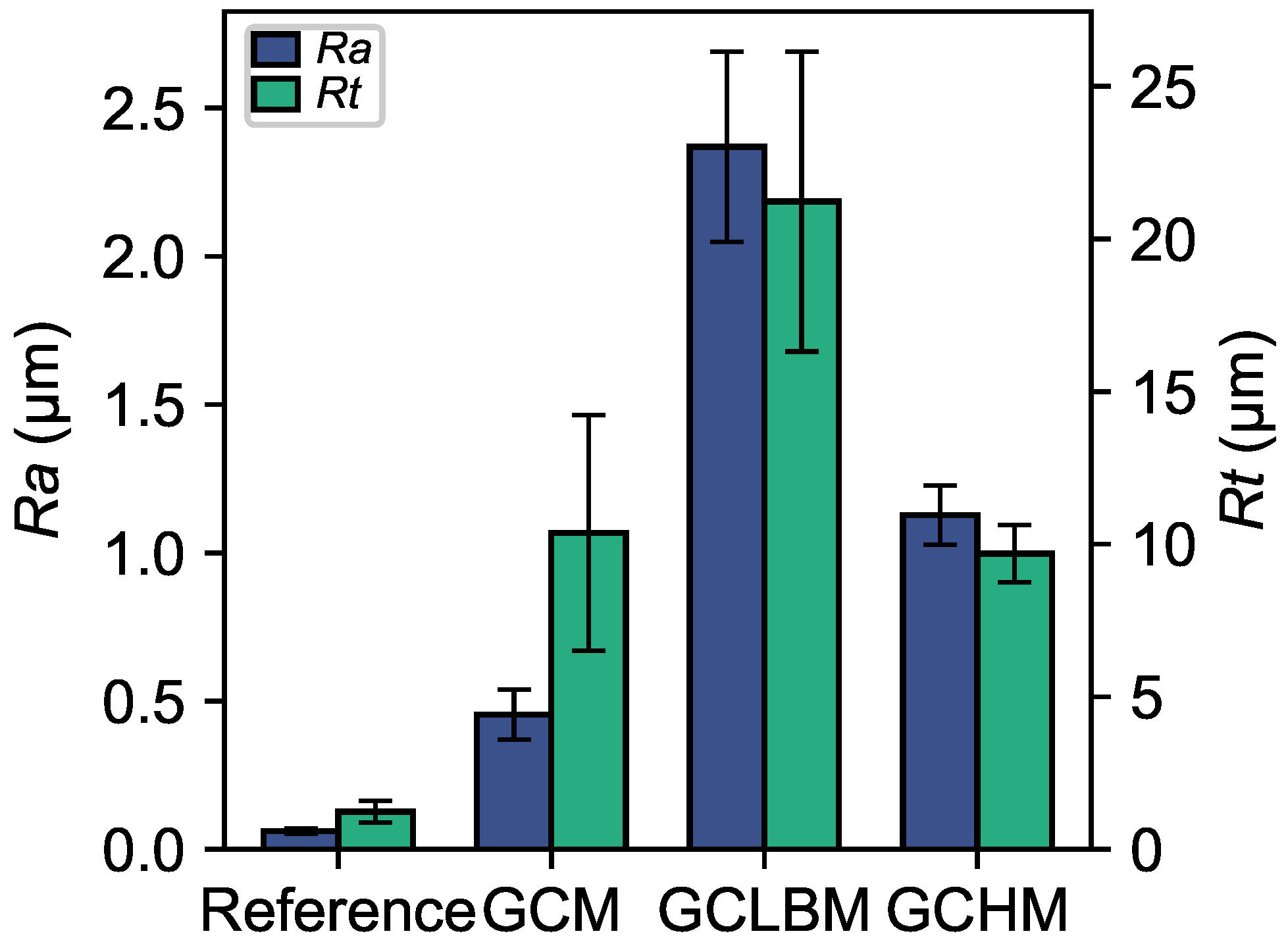

- Surface defects (such as micro-cracks ranging from 50 to 200 [11]) can be generated, introducing stress concentrations that decrease the flexural strength. A correlation between surface roughness and flexural strength was observed after grinding; the main influencing factor is the number of surface defects that increases with the surface roughness. This explains the higher flexural strength after grinding than after milling [13,14]. Milling at the pre-sintered stage allows to benefit from a ductile behaviour of Y-TZP that contributes to reducing surface defects [15].

2. Materials and Methods

2.1. Material

- All the blanks are sintered in the same conditions in a furnace following this sequence:

- Room temperature to 250 at a rate of 1 /min;

- 250 for 2 ;

- 250 to 750 at a rate of 1 /min;

- 750 for 2 ;

- 750 to 1430 at a rate of 3 /min;

- 1430 for 2 ;

- 1430 to room temperature at a rate of 5 /min.

- All surfaces except the machined ones are polished with SiC of meshes 220#, 500#, 800#, 1200#, 2400#, and 4000#, then on a felt with 3–6 diamond paste (for 4–5 min for each step).

2.2. Measurements

2.3. Failure Analysis

- : the flexural strength of a sample from the batch, computed by with F the peak force at fracture, l the distance between the centres of the inner and outer support rollers, and b and h the width and the thickness of the sample, respectively ( if ).

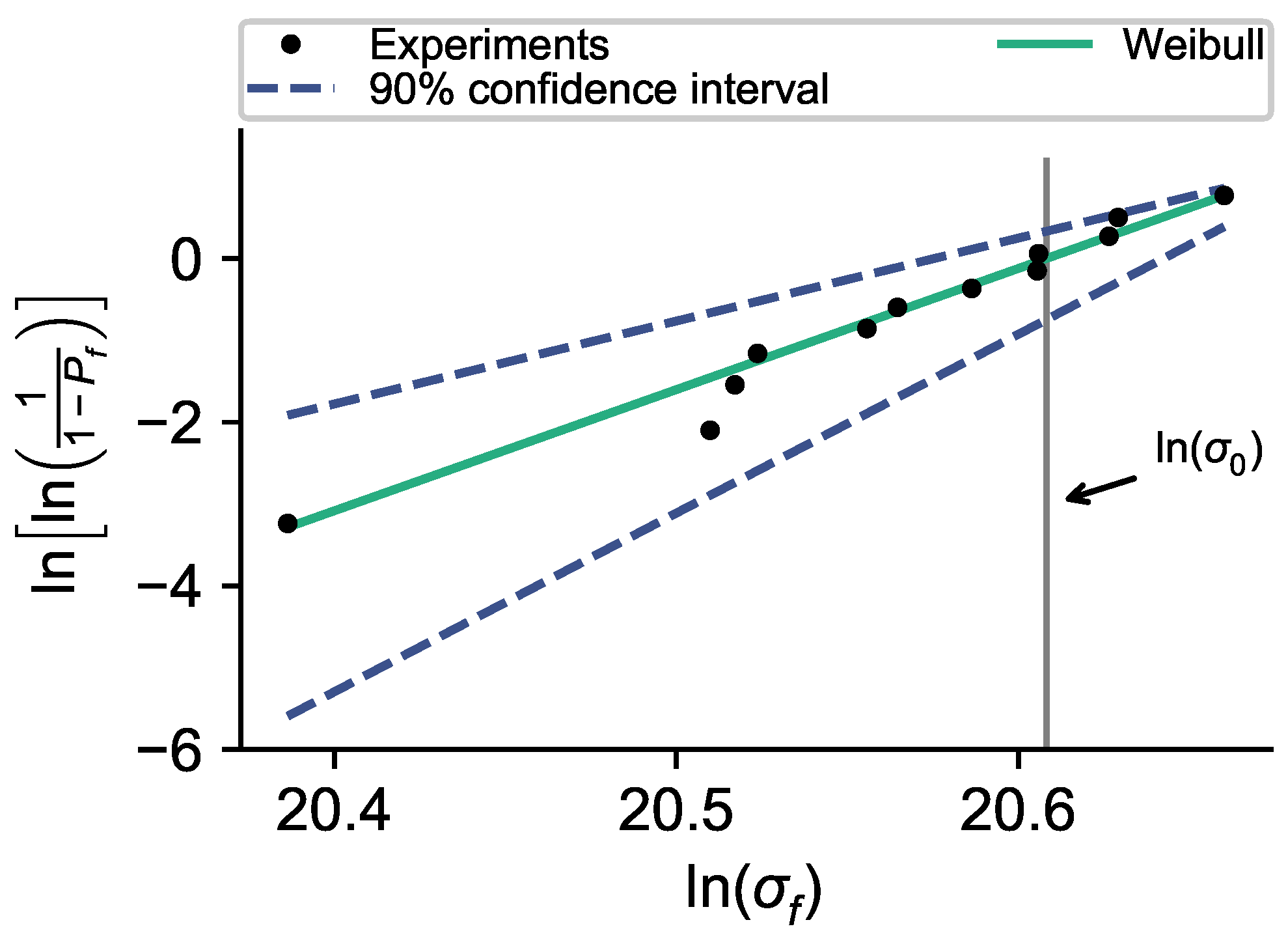

- : the Weibull characteristic strength of the batch, it is a normalising factor and represents the strength of the sample with a probability of failure of 63.2%.

- k: the Weibull modulus, it is an image of the defects distribution (cracks, voids) inside the material and represents the dispersion of the values (the higher k, the smaller the dispersion and the safer the material) [2]. Weibull modulus values are usually 10 or less for brittle materials such as ceramic materials (values for ductile metals are from 10 to 200) [33].

3. Results

3.1. Surface Roughness

3.2. Phase Destabilisation

3.3. Flexural Strength

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Özel, T.; Biermann, D.; Enomoto, T.; Mativenga, P. Structured and Textured Cutting Tool Surfaces for Machining Applications. CIRP Ann. 2021, 70, 495–518. [Google Scholar] [CrossRef]

- Ferraris, E.; Vleugels, J.; Guo, Y.; Bourell, D.; Kruth, J.P.; Lauwers, B. Shaping of Engineering Ceramics by Electro, Chemical and Physical Processes. CIRP Ann. 2016, 65, 761–784. [Google Scholar] [CrossRef]

- Axinte, D.; Guo, Y.; Liao, Z.; Shih, A.J.; M’Saoubi, R.; Sugita, N. Machining of Biocompatible Materials—Recent Advances. CIRP Ann. 2019, 68, 629–652. [Google Scholar] [CrossRef]

- Kuebler, J.; Blugan, G. Failure Analysis of Zirconia Ceramic Watch Bracelet Components. Eng. Fail. Anal. 2011, 18, 625–632. [Google Scholar] [CrossRef]

- Bilal, A.; Jahan, M.P.; Talamona, D.; Perveen, A. Electro-Discharge Machining of Ceramics: A Review. Micromachines 2019, 10, 10. [Google Scholar] [CrossRef] [Green Version]

- Hannink, R.H.J.; Kelly, P.M.; Muddle, B.C. Transformation Toughening in Zirconia-Containing Ceramics. J. Am. Ceram. Soc. 2000, 83, 461–487. [Google Scholar] [CrossRef]

- Pereira, G.K.R.; Amaral, M.; Simoneti, R.; Rocha, G.C.; Cesar, P.F.; Valandro, L.F. Effect of Grinding with Diamond-Disc and -Bur on the Mechanical Behavior of a Y-TZP Ceramic. J. Mech. Behav. Biomed. Mater. 2014, 37, 133–140. [Google Scholar] [CrossRef]

- Ferrage, L.; Bertrand, G.; Lenormand, P.; Grossin, D.; Ben-Nissan, B. A Review of the Additive Manufacturing (3DP) of Bioceramics: Alumina, Zirconia (PSZ) and Hydroxyapatite. J. Aust. Ceram. Soc. 2017, 53, 11–20. [Google Scholar] [CrossRef] [Green Version]

- Liang, Y.; Dutta, S.P. Application Trend in Advanced Ceramic Technologies. Technovation 2001, 21, 61–65. [Google Scholar] [CrossRef]

- ISO 13356:2008; Implants for Surgery—Ceramic Materials Based on Yttria-Stabilized Tetragonal Zirconia (Y-TZP). International Organization for Standardization: Geneva, Switzerland, 2008.

- Demarbaix, A.; Mulliez, M.; Rivière-Lorphèvre, E.; Spitaels, L.; Duterte, C.; Preux, N.; Petit, F.; Ducobu, F. Green Ceramic Machining: Determination of the Recommended Feed Rate for Y-TZP Milling. J. Compos. Sci. 2021, 5, 231. [Google Scholar] [CrossRef]

- Cui, J.; Gong, Z.; Lv, M.; Rao, P. Determination of Fracture Toughness of Y-TZP Ceramics. Ceram. Int. 2017, 43, 16319–16322. [Google Scholar] [CrossRef]

- Song, J.Y.; Park, S.W.; Lee, K.; Yun, K.D.; Lim, H.P. Fracture Strength and Microstructure of Y-TZP Zirconia after Different Surface Treatments. J. Prosthet. Dent. 2013, 110, 274–280. [Google Scholar] [CrossRef]

- Zucuni, C.P.; Guilardi, L.F.; Fraga, S.; May, L.G.; Pereira, G.K.R.; Valandro, L.F. CAD/CAM Machining Vs Pre-Sintering in-Lab Fabrication Techniques of Y-TZP Ceramic Specimens: Effects on Their Mechanical Fatigue Behavior. J. Mech. Behav. Biomed. Mater. 2017, 71, 201–208. [Google Scholar] [CrossRef] [PubMed]

- Demarbaix, A.; Rivière-Lorphèvre, E.; Ducobu, F.; Filippi, E.; Petit, F.; Preux, N. Behaviour of Pre-Sintered Y-TZP during Machining Operations: Determination of Recommended Cutting Parameters. J. Manuf. Process. 2018, 32, 85–92. [Google Scholar] [CrossRef]

- Jarosz, K.; Ukar, E.; Krödel, A.; Özel, T. Laser Ablation and Processing of Polycrystalline Cubic Boron Nitride Cutting Tool Material. Int. J. Adv. Manuf. Technol. 2022, 118, 785–800. [Google Scholar] [CrossRef]

- Roitero, E.; Lasserre, F.; Roa, J.J.; Anglada, M.; Mücklich, F.; Jiménez-Piqué, E. Nanosecond-Laser Patterning of 3Y-TZP: Damage and Microstructural Changes. J. Eur. Ceram. Soc. 2017, 37, 4876–4887. [Google Scholar] [CrossRef]

- Yang, L.; Deng, Z.; He, B.; Özel, T. An Experimental Investigation on Laser Surface Texturing of AISI D2 Tool Steel Using Nanosecond Fiber Laser. Lasers Manuf. Mater. Process. 2021, 8, 140–156. [Google Scholar] [CrossRef]

- Samant, A.N.; Dahotre, N.B. Laser Machining of Structural Ceramics—A Review. J. Eur. Ceram. Soc. 2009, 29, 969–993. [Google Scholar] [CrossRef]

- Petit, F.; Lardot, V.; Ott, C.; Juste, E.; Cambier, F. Ceramic Particle Mixture, and Method for Manufacturing Ceramic Parts from Such a Mixture. U.S. Patent US9115034, 25 August 2015. [Google Scholar]

- Carter, C.B.; Norton, M.G. Ceramic Materials: Science and Engineering, 2nd ed.; Springer: New York, NY, USA, 2013. [Google Scholar] [CrossRef]

- Demarbaix, A.; Ducobu, F.; Preux, N.; Petit, F.; Rivière-Lorphèvre, E. Green Ceramic Machining: Influence of the Cutting Speed and the Binder Percentage on the Y-TZP Behavior. J. Manuf. Mater. Process. 2020, 4, 50. [Google Scholar] [CrossRef]

- Ducobu, F.; Rivière-Lorphèvre, E.; Demarbaix, A.; Lauwers, B. Prediction of Local Sintering in Laser Beam Machining of Green Y-TZP Ceramic. CIRP Ann.—Manuf. Technol. 2020, 69, 225–228. [Google Scholar] [CrossRef]

- Demarbaix, A.; Ducobu, F.; Juste, E.; Petit, F.; Duterte, C.; Rivière-Lorphèvre, E. Experimental Investigation on Green Ceramic Machining with Nanosecond Laser Source. J. Manuf. Process. 2021, 61, 245–253. [Google Scholar] [CrossRef]

- Xia, H.; Zhao, G.; Mao, P.; Hao, X.; Li, L.; He, N. Improved Machinability of TiB2–TiC Ceramic Composites via Laser-Induced Oxidation Assisted Micro-Milling. Ceram. Int. 2021, 47, 11514–11525. [Google Scholar] [CrossRef]

- Hao, X.; Xu, W.; Chen, M.; Wang, C.; Han, J.; Li, L.; He, N. Laser Hybridizing with Micro-Milling for Fabrication of High Aspect Ratio Micro-Groove on Oxygen-Free Copper. Precis. Eng. 2021, 70, 15–25. [Google Scholar] [CrossRef]

- Demarbaix, A.; Ducobu, F.; Preux, N.; Petit, F.; Rivière-Lorphèvre, E. Binder Influence on Green Ceramic Machining by Means of Milling and Laser Machining. Procedia CIRP 2021, 101, 206–209. [Google Scholar] [CrossRef]

- EN 843-1; Advanced Technical Ceramics—Mechanical Properties of Monolithic Ceramics at Room Temperature—Part 1 Determination of Flexural Strength. European Comittee for Standardization: Brussels, Belgium, 2004.

- EN 843-5; Advanced Technical Ceramics—Mechanical Properties of Monolithic Ceramics at Room Temperature—Part 5: Statistical Analysis. European Comittee for Standardization: Brussels, Belgium, 2006.

- Pereira, G.K.R.; Fraga, S.; Montagner, A.F.; Soares, F.Z.M.; Kleverlaan, C.J.; Valandro, L.F. The Effect of Grinding on the Mechanical Behavior of Y-TZP Ceramics: A Systematic Review and Meta-Analyses. J. Mech. Behav. Biomed. Mater. 2016, 63, 417–442. [Google Scholar] [CrossRef]

- Lughi, V.; Sergo, V. Low Temperature Degradation -Aging- of Zirconia: A Critical Review of the Relevant Aspects in Dentistry. Dent. Mater. 2010, 26, 807–820. [Google Scholar] [CrossRef]

- ISO 4288:1996; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Rules and Procedures for the Assessment of Surface Texture. International Organization for Standardization: Geneva, Switzerland, 1996.

- Ono, K. A Simple Estimation Method of Weibull Modulus and Verification with Strength Data. Appl. Sci. 2019, 9, 1575. [Google Scholar] [CrossRef] [Green Version]

| Surface Condition | Parameter | Length (mm) | Width, b (mm) | Thickness, h (mm) |

|---|---|---|---|---|

| All | Dimensional range | ≥45 | 4.0 ± 0.2 | 3.0 ± 0.2 |

| Machined | Parallelism tolerance | – | ±0.02 | ±0.02 |

| As-fired | Parallelism tolerance | – | ±0.10 | ±0.10 |

| GCM [22] | GCLBM [23] | |

|---|---|---|

| Depth of cut (mm) | 0.7 | 0.027 |

| Feed rate /Scan speed (mm/min) | 1350 | 30,000 |

| Tool/Beam diameter (mm) | 3 | 0.05 |

| Cutting speed (m/min) | 133 | – |

| Material removal rate (mm3/min) | 2835 | 40.5 |

| Repetition rate (kHz) | – | 78 |

| Power (%) | – | 85 |

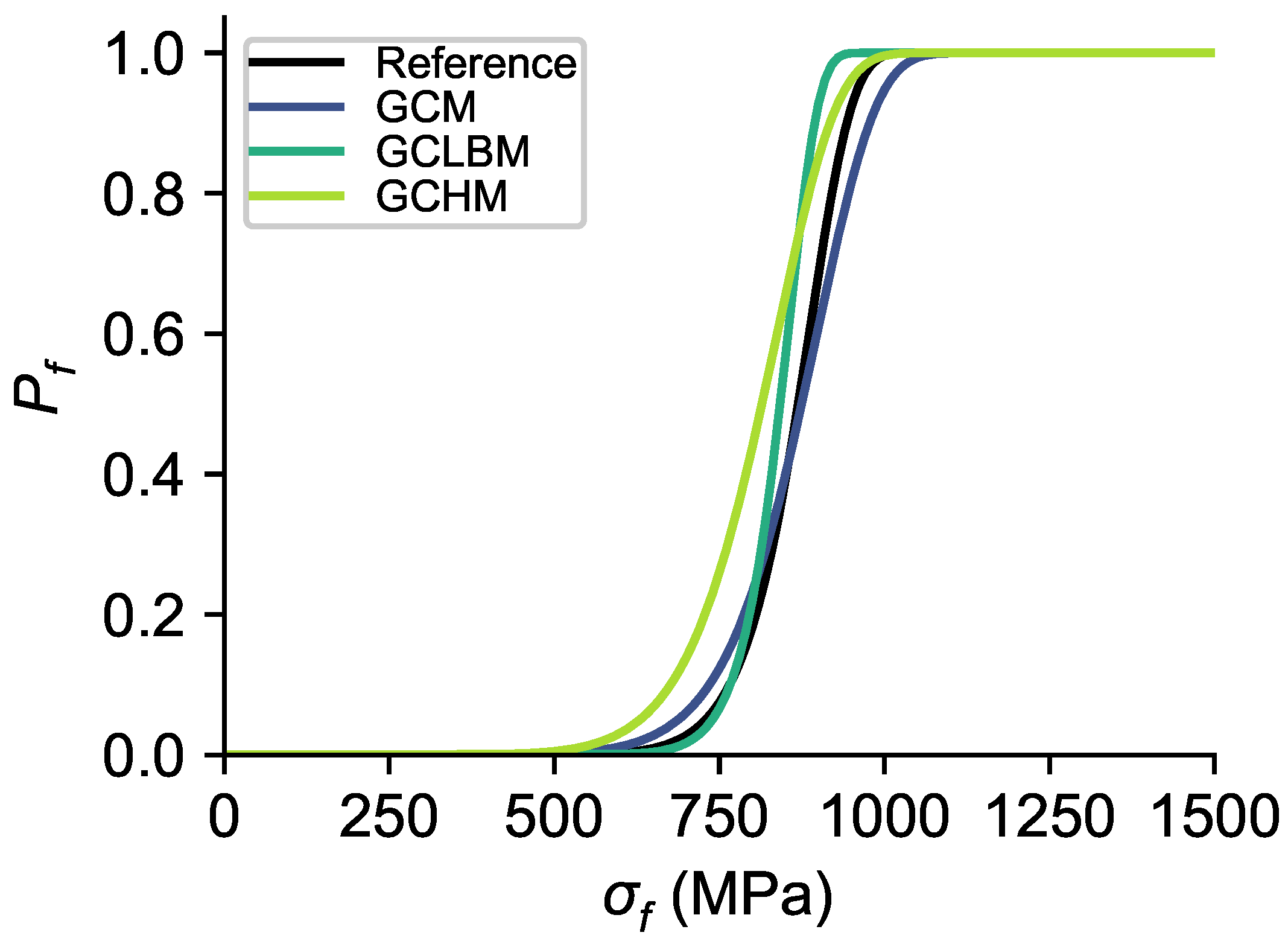

| Process | k | (MPa) |

|---|---|---|

| Reference | 15 | 891 |

| GCM | 11 | 905 |

| GCLBM | 20 | 858 |

| GCHM | 10 | 845 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ducobu, F.; Demarbaix, A.; Rivière-Lorphèvre, E.; Spitaels, L.; Petit, F.; Preux, N.; Duterte, C.; Mulliez, M.; Lauwers, B. Impact of Green Ceramic Hybrid Machining (GCHM) on Reliability and Repeatability of the Properties of Sintered Yttrium-Tetragonal Zirconia Polycrystal Parts. J. Manuf. Mater. Process. 2023, 7, 118. https://doi.org/10.3390/jmmp7030118

Ducobu F, Demarbaix A, Rivière-Lorphèvre E, Spitaels L, Petit F, Preux N, Duterte C, Mulliez M, Lauwers B. Impact of Green Ceramic Hybrid Machining (GCHM) on Reliability and Repeatability of the Properties of Sintered Yttrium-Tetragonal Zirconia Polycrystal Parts. Journal of Manufacturing and Materials Processing. 2023; 7(3):118. https://doi.org/10.3390/jmmp7030118

Chicago/Turabian StyleDucobu, François, Anthonin Demarbaix, Edouard Rivière-Lorphèvre, Laurent Spitaels, Fabrice Petit, Nicolas Preux, Charles Duterte, Marylou Mulliez, and Bert Lauwers. 2023. "Impact of Green Ceramic Hybrid Machining (GCHM) on Reliability and Repeatability of the Properties of Sintered Yttrium-Tetragonal Zirconia Polycrystal Parts" Journal of Manufacturing and Materials Processing 7, no. 3: 118. https://doi.org/10.3390/jmmp7030118

APA StyleDucobu, F., Demarbaix, A., Rivière-Lorphèvre, E., Spitaels, L., Petit, F., Preux, N., Duterte, C., Mulliez, M., & Lauwers, B. (2023). Impact of Green Ceramic Hybrid Machining (GCHM) on Reliability and Repeatability of the Properties of Sintered Yttrium-Tetragonal Zirconia Polycrystal Parts. Journal of Manufacturing and Materials Processing, 7(3), 118. https://doi.org/10.3390/jmmp7030118