Ultrasonic Welding of Additively Manufactured PEEK and Carbon-Fiber-Reinforced PEEK with Integrated Energy Directors

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Design and Fabrication

2.2. Ultrasonic Welding Equipment

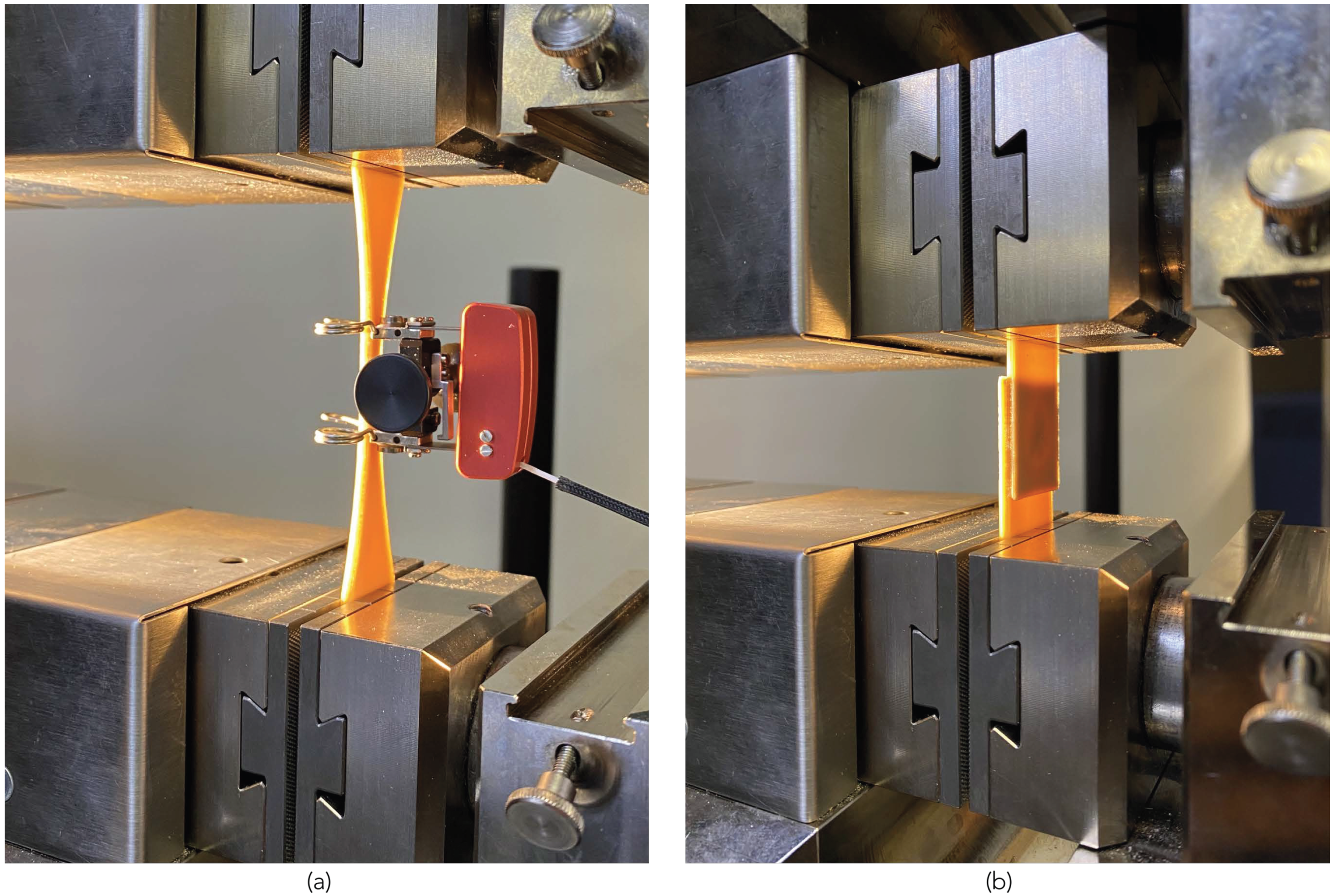

2.3. Mechanical Characterization

2.4. Fracture Surface Analysis

3. Results and Discussion

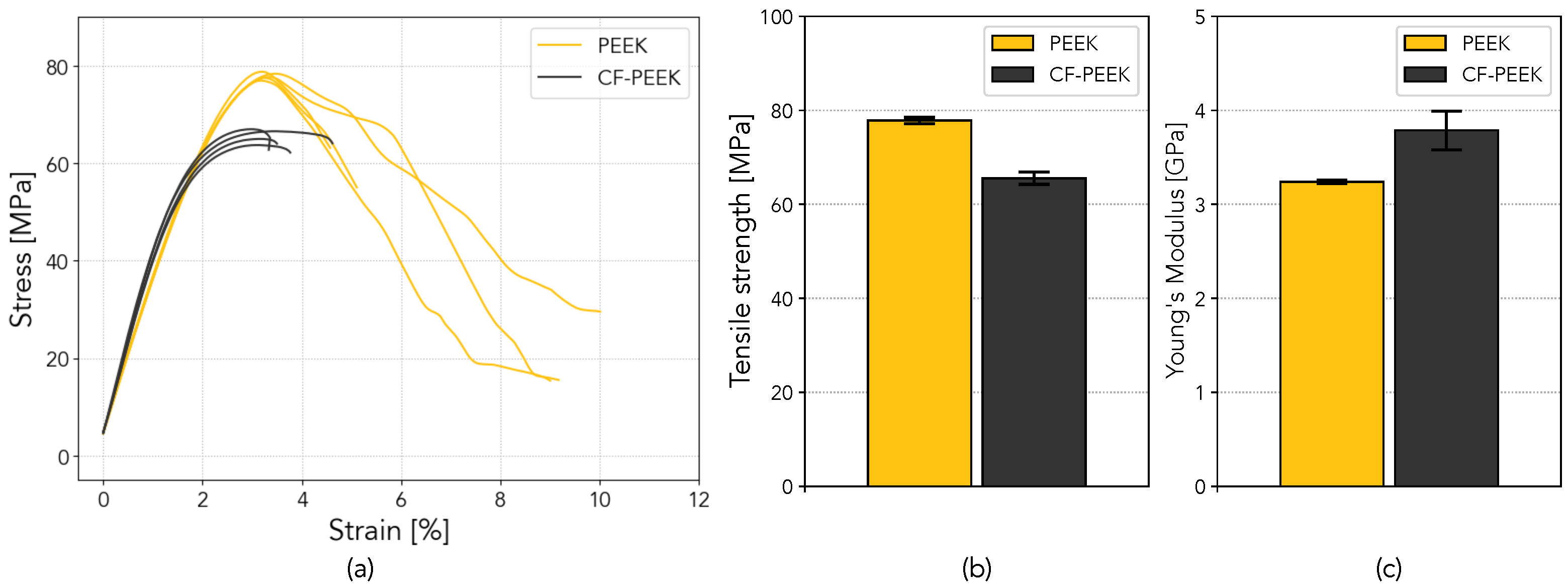

3.1. Monotonic Tests

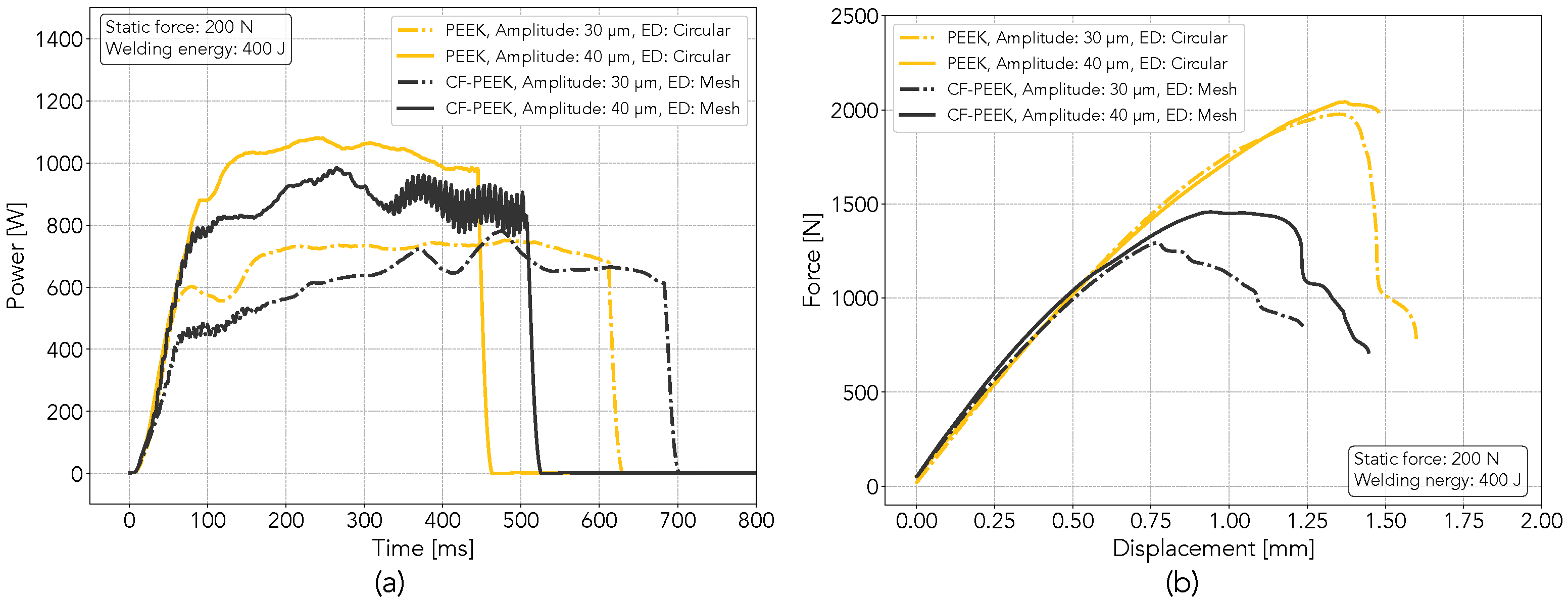

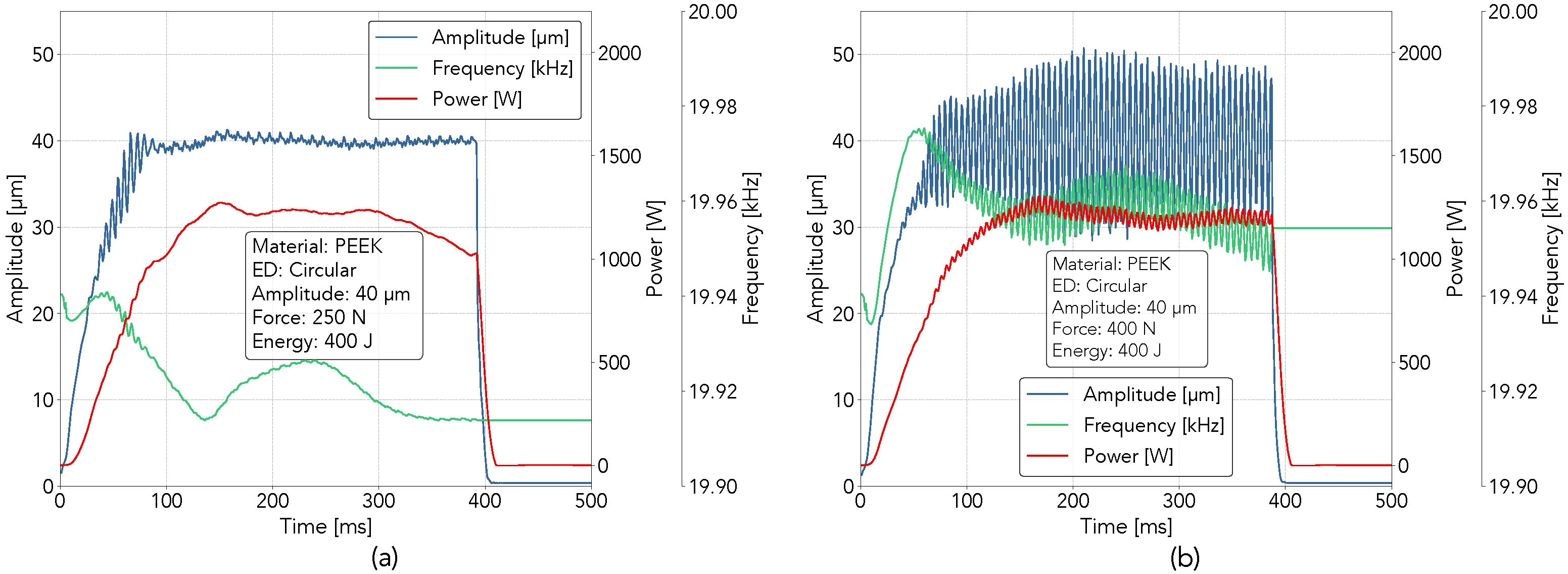

3.2. Ultrasonic Welding Parameter Optimization

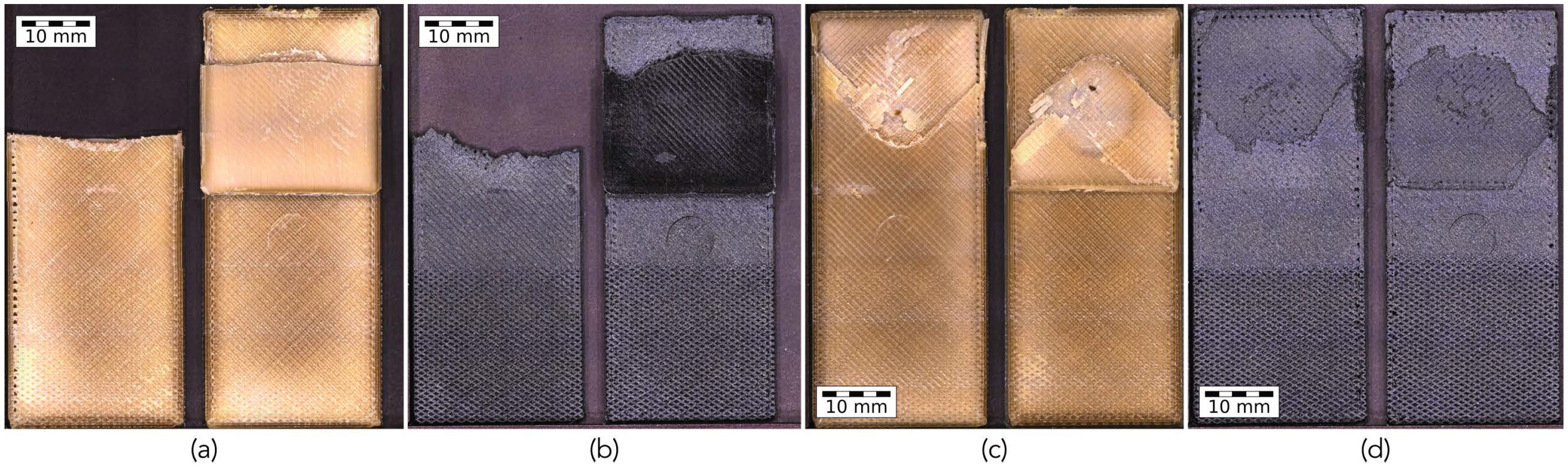

3.3. Lap-Shear Strength Tests

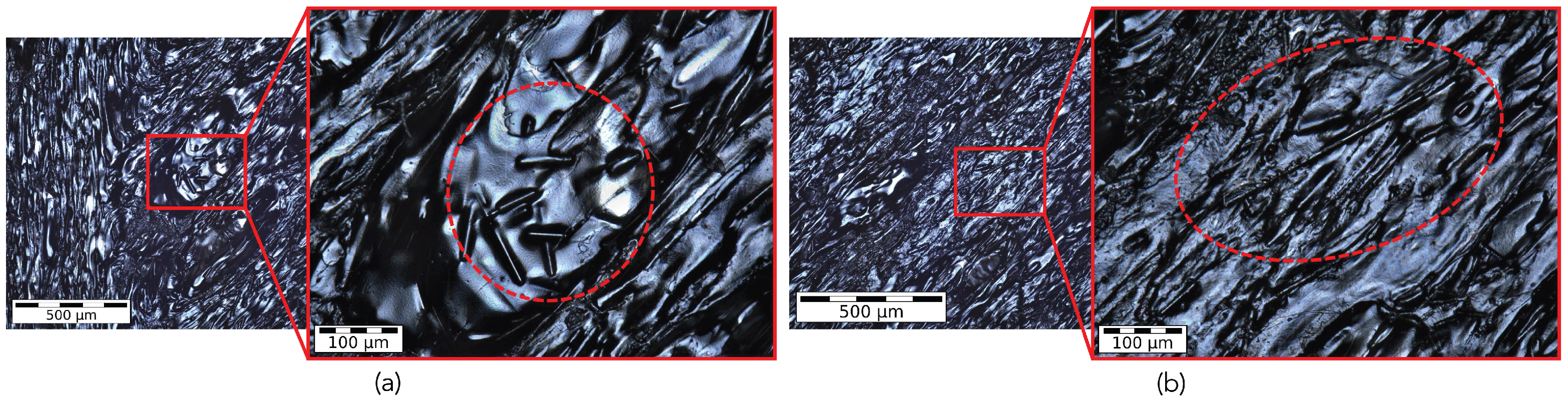

3.4. Microscopy and Failure Behavior

4. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Additive manufacturing |

| CF-PEEK | Carbon-fiber-reinforced polyether ether ketone |

| ED | Energy director |

| FFF | Fused filament fabrication |

| LSS | Lap-shear strength |

| PAEK | Polyarylether ether ketone |

| PEEK | Polyether ether ketone |

| PEI | Polyetherimide |

| USW | Ultrasonic welding |

References

- Dey, A.; Nanjin, I.; Eagle, R.; Yodo, N. A Review on Filament Materials for Fused Filament Fabrication. J. Manuf. Mater. Process. 2021, 5, 69. [Google Scholar] [CrossRef]

- Algarni, M.; Ghazali, S. Comparative study of the sensitivity of PLA, ABS, PEEK, and PETG’s mechanical properties to FDM printing process parameters. Crystals 2021, 11, 995. [Google Scholar] [CrossRef]

- El Magri, A.; Vanaei, S.; Vaudreuil, S. An overview on the influence of process parameters through the characteristic of 3D-printed PEEK and PEI parts. High Perform. Polym. 2021, 33, 862–880. [Google Scholar] [CrossRef]

- Zanjanijam, A.R.; Major, I.; Lyons, J.G.; Lafont, U.; Devine, D.M. Fused filament fabrication of PEEK: A review of process-structure-property relationships. Polymers 2020, 12, 1665. [Google Scholar] [CrossRef]

- Arif, M.F.; Alhashmi, H.; Varadarajan, K.M.; Koo, J.H.; Hart, A.J.; Kumar, S. Multifunctional performance of carbon nanotubes and graphene nanoplatelets reinforced PEEK composites enabled via FFF additive manufacturing. Compos. Part Eng. 2020, 184, 107625. [Google Scholar] [CrossRef]

- Palacios-Ibáñez, B.; Relinque, J.J.; Moreno-Sánchez, D.; de León, A.S.; Delgado, F.J.; Escobar-Galindo, R.; Molina, S.I. Synthesis and Characterisation of ASA-PEEK Composites for Fused Filament Fabrication. Polymers 2022, 14, 496. [Google Scholar] [CrossRef]

- Hartig, S.; Hildebrandt, L.; Fette, M.; Meyer, T.; Musienko, E.; Redlich, T.; Wulfsberg, J. Process parameter determination for small recycling plants for the production of filament for FFF printing using the Taguchi method. Prog. Addit. Manuf. 2021, 7, 87–97. [Google Scholar] [CrossRef]

- Reis, J.P.; de Moura, M.; Samborski, S. Thermoplastic composites and their promising applications in joining and repair composites structures: A review. Materials 2020, 13, 5832. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.; Farina, I. On the 3D printing of recycled ABS, PLA and HIPS thermoplastics for structural applications. Psu Res. Rev. 2018, 2, 115–137. [Google Scholar] [CrossRef]

- Zandi, M.D.; Jerez-Mesa, R.; Lluma-Fuentes, J.; Jorba-Peiro, J.; Travieso-Rodriguez, J.A. Study of the manufacturing process effects of fused filament fabrication and injection molding on tensile properties of composite PLA-wood parts. Int. J. Adv. Manuf. Technol. 2020, 108, 1725–1735. [Google Scholar] [CrossRef]

- Becker, M.; Kuball, A.; Ghavimi, A.; Adam, B.; Busch, R.; Gallino, I.; Balle, F. Solid State Joining of a Cold Rolled Zr-Based Bulk Metallic Glass to a Wrought Aluminum Alloy by Power Ultrasonics. Materials 2022, 15, 7673. [Google Scholar] [CrossRef] [PubMed]

- Becker, M.; Balle, F. Multi-spot ultrasonic welding of aluminum to steel sheets: Process and fracture analysis. Metals 2021, 11, 779. [Google Scholar] [CrossRef]

- Liesegang, M.; Arweiler, S.; Beck, T.; Balle, F. Orbital ultrasonic welding of ti-fittings to cfrp-tubes. J. Manuf. Mater. Process. 2021, 5, 30. [Google Scholar] [CrossRef]

- Staab, F.; Balle, F. Fatigue and fracture of ultrasonically welded aluminum alloys to carbon fiber reinforced thermoplastics. Fatigue Fract. Eng. Mater. Struct. 2021, 45, 607–616. [Google Scholar] [CrossRef]

- Staab, F.; Balle, F. Ultrasonic torsion welding of ageing-resistant Al/CFRP joints: Properties, microstructure and joint formation. Ultrasonics 2019, 93, 139–144. [Google Scholar] [CrossRef]

- Li, W.; Frederick, H.; Palardy, G. Multifunctional films for thermoplastic composite joints: Ultrasonic welding and damage detection under tension loading. Compos. Part Appl. Sci. Manuf. 2021, 141, 106221. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Fai, L.K.; Barsotti, R.J. Investigation on ultrasonic welding attributes of novel carbon/Elium® composites. Materials 2020, 13, 1117. [Google Scholar] [CrossRef]

- Wang, K.; Shriver, D.; Li, Y.; Banu, M.; Hu, S.J.; Xiao, G.; Arinez, J.; Fan, H.T. Characterization of weld attributes in ultrasonic welding of short carbon fiber reinforced thermoplastic composites. J. Manuf. Process. 2017, 29, 124–132. [Google Scholar] [CrossRef]

- Korycki, A.; Garnier, C.; Bonmatin, M.; Laurent, E.; Chabert, F. Assembling of Carbon Fibre/PEEK Composites: Comparison of Ultrasonic, Induction, and Transmission Laser Welding. Materials 2022, 15, 6365. [Google Scholar] [CrossRef]

- Villegas, I.F. Ultrasonic Welding of Thermoplastic Composites. Front. Mater. 2019, 6, 291. [Google Scholar] [CrossRef]

- Benatar, A. Ultrasonic welding of plastics and polymeric composites. In Power Ultrasonics: Applications of High-Intensity Ultrasound; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; Chapter 12; pp. 295–312. [Google Scholar] [CrossRef]

- Tsiangou, E.; Teixeira de Freitas, S.; Villegas, I.F.; Benedictus, R. Ultrasonic welding of epoxy- to polyetheretherketone- based composites: Investigation on the material of the energy director and the thickness of the coupling layer. J. Compos. Mater. 2020, 54, 3081–3098. [Google Scholar] [CrossRef]

- Tao, W.; Su, X.; Wang, H.; Zhang, Z.; Li, H.; Chen, J. Influence mechanism of welding time and energy director to the thermoplastic composite joints by ultrasonic welding. J. Manuf. Process. 2019, 37, 196–202. [Google Scholar] [CrossRef]

- Chuah, Y.K.; Chien, L.H.; Chang, B.C.; Liu, S.J. Effects of the shape of the energy director on far-field ultrasonic welding of thermoplastics. Polym. Eng. Sci. 2000, 40, 157–167. [Google Scholar] [CrossRef]

- Palardy, G.; Villegas, I.F. On the effect of flat energy directors thickness on heat generation during ultrasonic welding of thermoplastic composites. Compos. Interfaces 2017, 24, 203–214. [Google Scholar] [CrossRef]

- Wu, W.; Wang, H.; Wang, J.; Liu, Q.; Zhang, Z.; Li, K.; Gong, Y.; Zhao, J.; Ren, L.; Li, G. Hybrid Additive Manufacturing of Fused Filament Fabrication and Ultrasonic Consolidation. Polymers 2022, 14, 2385. [Google Scholar] [CrossRef]

- Tofangchi, A.; Han, P.; Izquierdo, J.; Iyengar, A.; Hsu, K. Effect of ultrasonic vibration on interlayer adhesion in Fused Filament Fabrication 3D printed ABS. Polymers 2019, 11, 315. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Zhao, J.; Jiang, J.; Jiang, H.; Wu, W.; Tang, M. Ultrasonic strengthening improves tensile mechanical performance of fused deposition modeling 3D printing. Int. J. Adv. Manuf. Technol. 2018, 96, 2747–2755. [Google Scholar] [CrossRef]

| Nozzle temperature | 390 |

| Build-plate temperature | 135 |

| Build-chamber temperature | 60 |

| Filament drying/storage temperature | 70 |

| Nozzle diameter | mm |

| Layer thickness | mm |

| Print speed | 30 mm/ |

| Sample volume-fill | 100% |

| Number of shells | 2 |

| Welding energy | 300, 400, 500 |

| Static welding force | 250 |

| Amplitude of US-oscillation | 40 |

| Hold-time | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khatri, B.; Roth, M.F.; Balle, F. Ultrasonic Welding of Additively Manufactured PEEK and Carbon-Fiber-Reinforced PEEK with Integrated Energy Directors. J. Manuf. Mater. Process. 2023, 7, 2. https://doi.org/10.3390/jmmp7010002

Khatri B, Roth MF, Balle F. Ultrasonic Welding of Additively Manufactured PEEK and Carbon-Fiber-Reinforced PEEK with Integrated Energy Directors. Journal of Manufacturing and Materials Processing. 2023; 7(1):2. https://doi.org/10.3390/jmmp7010002

Chicago/Turabian StyleKhatri, Bilal, Manuel Francis Roth, and Frank Balle. 2023. "Ultrasonic Welding of Additively Manufactured PEEK and Carbon-Fiber-Reinforced PEEK with Integrated Energy Directors" Journal of Manufacturing and Materials Processing 7, no. 1: 2. https://doi.org/10.3390/jmmp7010002

APA StyleKhatri, B., Roth, M. F., & Balle, F. (2023). Ultrasonic Welding of Additively Manufactured PEEK and Carbon-Fiber-Reinforced PEEK with Integrated Energy Directors. Journal of Manufacturing and Materials Processing, 7(1), 2. https://doi.org/10.3390/jmmp7010002