Material Behavior around the FSW/FSP Tool Described by Molecular Dynamics

Abstract

1. Introduction

2. Considerations about FSW/FSP Multiscale Modelling

2.1. Temperature

2.2. Advancing and Rotating Speeds—Weld Pitch

2.3. Tool Size and Geometry

3. Molecular Dynamics Simulations

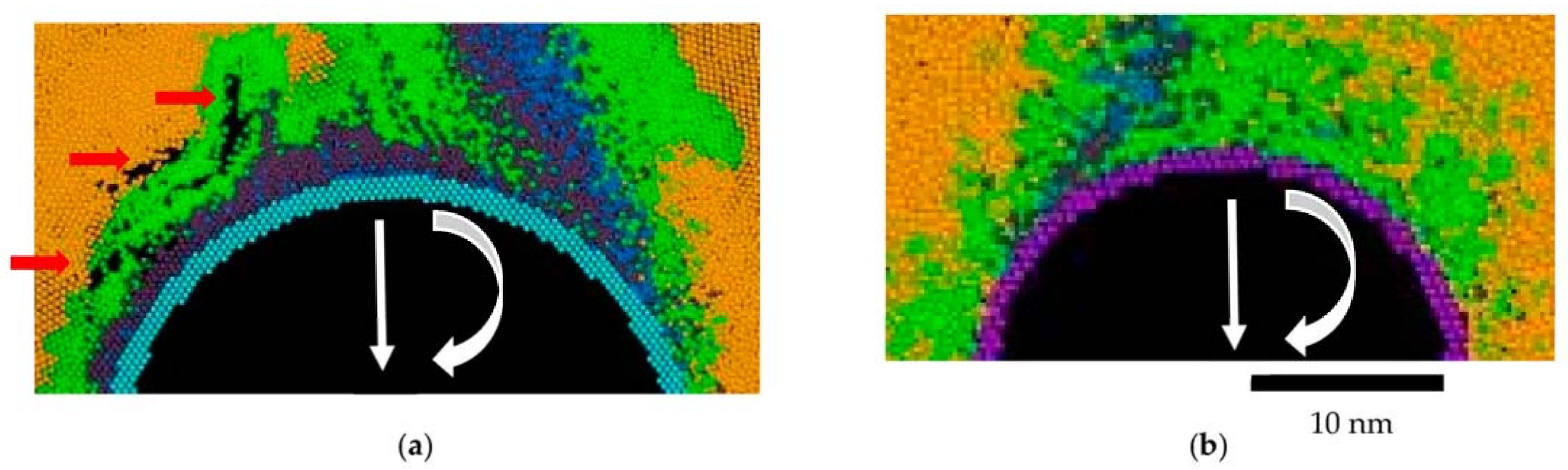

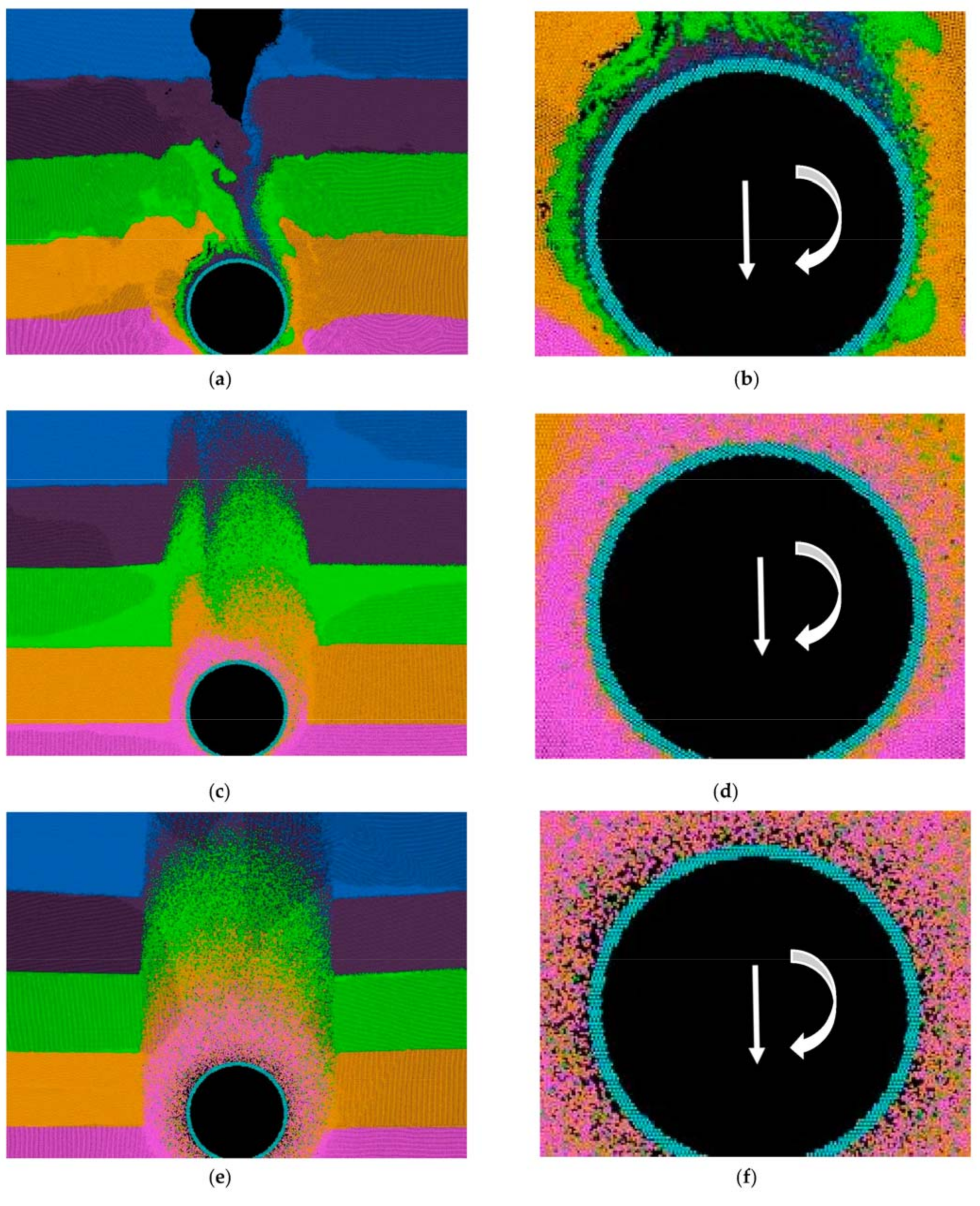

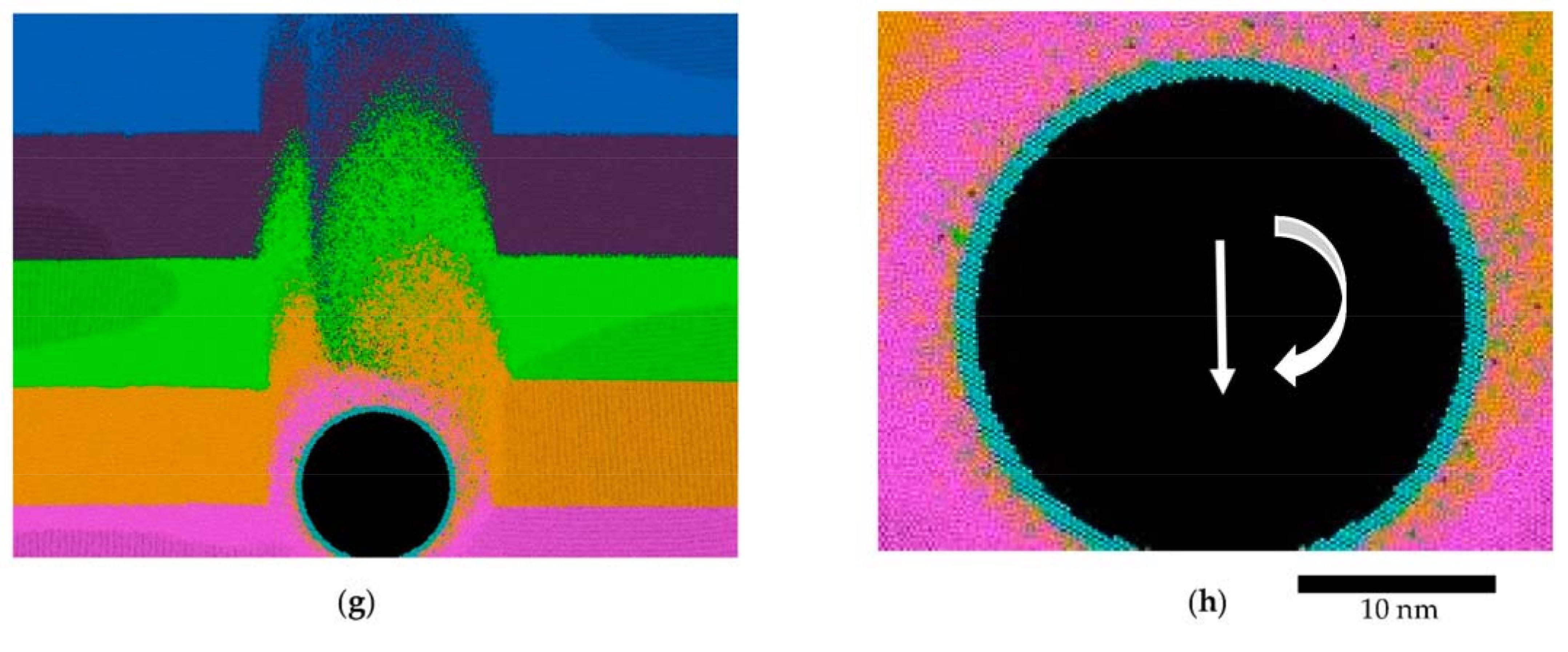

3.1. Material Flow

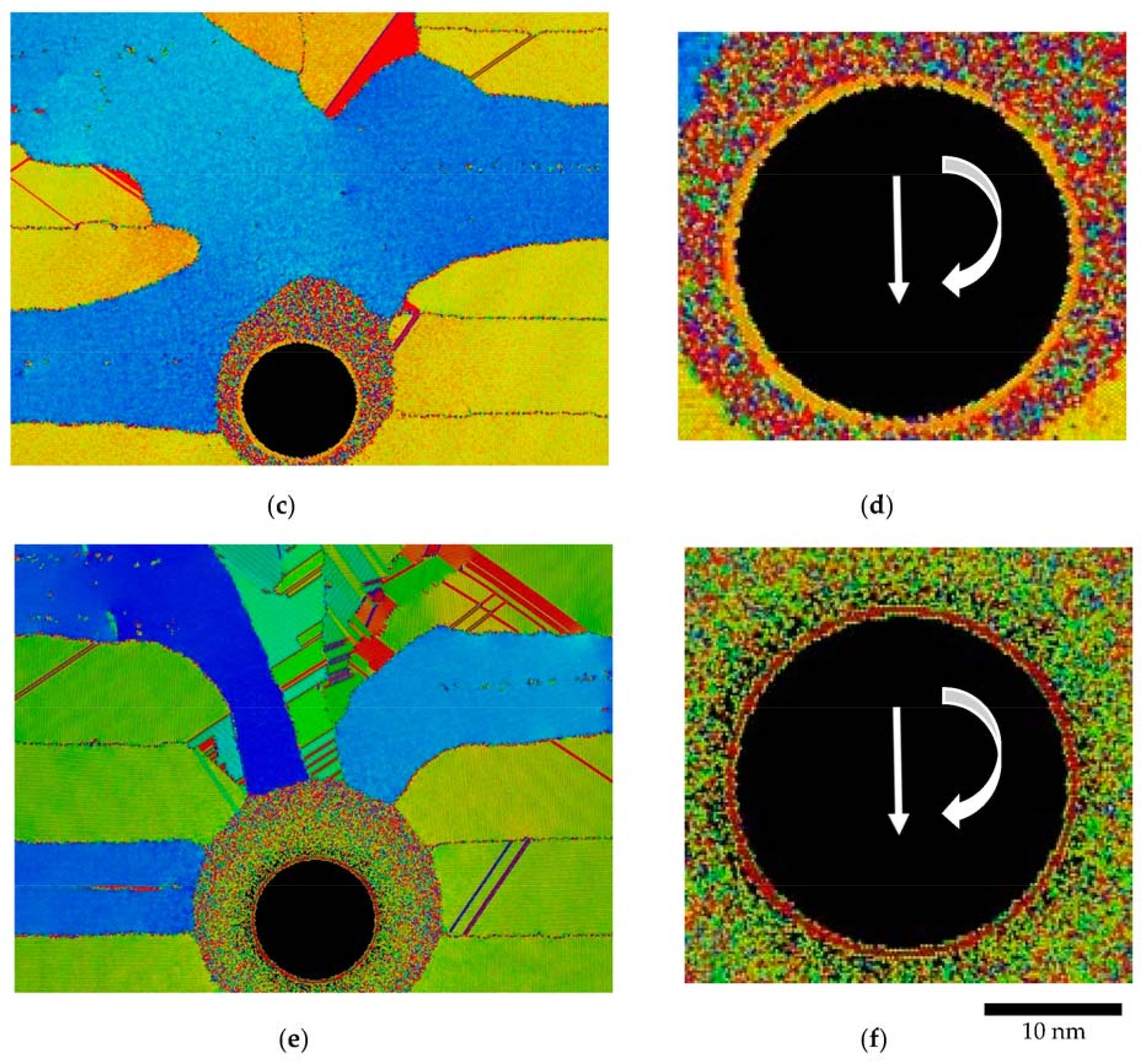

3.2. Microstructure

| Author | Technique | w (rpm) | v (mm/s) | Pin Radius (mm) | v/wr (mm/rev) | Atoms | Tmelt (K) | Tmax (K) | TmaxMD (K) |

|---|---|---|---|---|---|---|---|---|---|

| [12] | FEM | 6.00 × 102 | 3.30 × 100 | 3.50 × 100 | 9.4 × 10−2 | 300 k | 660 | 645 | |

| “ | “ | 6.00 × 102 | 6.60 × 100 | 3.50 × 100 | 1.9 × 10−1 | “ | 660 | 609 | |

| “ | “ | 1.20 × 102 | 6.60 × 100 | 3.50 × 100 | 9.4 × 10−1 | “ | 660 | 480 | |

| “ | “ | 7.98 × 101 | 9.90 × 100 | 3.50 × 100 | 2.1 × 100 | “ | 660 | 445 | |

| “ | “ | 1.20 × 103 | 6.60 × 100 | 3.50 × 100 | 9.4 × 10−2 | “ | 660 | 686 | |

| [21] | MD | 6.00 × 1010 | 5.00 × 104 | 1.80 × 10−6 | 2.8 × 101 | 85 k | 1000 | 721 | |

| “ | “ | 6.00 × 1010 | 1.00 × 105 | 1.80 × 10−6 | 5.6 × 101 | “ | 1000 | 677 | |

| [22] | “ | 6.00 × 1010 | 5.00 × 104 | 2.45 × 10−6 | 2.0 × 102 | 75 k | 660 | 597 | |

| [37] | Experimental | 2.00 × 103 | 6.70 × 100 | 2.00 × 100 | 1.0 × 10−1 | --- | 660 | 679 | |

| [38] | “ | 1.20 × 103 | 3.00 × 100 | 2.00 × 100 | 7.5 × 10−2 | --- | 660 | 666 | |

| [39] | “ | 4.50 × 102 | 8.30 × 10−2 | 3.25 × 100 | 3.4 × 10−3 | --- | 660 | 853 | |

| [40] | “ | 6.00 × 102 | 1.33 × 101 | 2.00 × 100 | 6.7 × 10−1 | --- | 1000 | 660 | |

| [41] | “ | 1.20 × 103 | 3.30 × 101 | 2.50 × 100 | 6.6 × 10−3 | --- | 660 | 687 | |

| This work | MD | 6.00 × 1010 | 1.00 × 105 | 1.20 × 10−5 | 8.3 × 100 | 678 k | 660 | 744 | |

| “ | “ | 6.00 × 1011 | 1.00 × 105 | 5.00 × 10−6 | 2.0 × 101 | 27 k | 660 | 996 | |

| “ | “ | 6.00 × 1010 | 1.00 × 104 | 1.20 × 10−5 | 8.3 × 10−1 | 678 k/1.27 M | 660 | 938 | |

| “ | “ | 6.00 × 1011 | 1.00 × 104 | 1.20 × 10−5 | 8.3 × 10−2 | 678 k | 660 | 1600 | |

| “ | “ | 6.00 × 1010 | 1.00 × 105 | 5.00 × 10−6 | 2.0 × 101 | “ (550 K) | 660 | 935 | 935 |

| “ | “ | 6.00 × 1010 | 1.00 × 105 | 5.00 × 10−6 | 2.0 × 101 | “ (400 K) | 660 | 807 | 807 |

4. Discussion

5. Conclusions

- The molecular dynamics simulation technique adequately describes a material’s plastic flow during the FSW/FSP process if the pin size is large enough, i.e., >10 nm in aluminum;

- The number of atoms in the system must be proportional to the pin diameter, as the system dimensions are around 4 times that of the pin diameter, to avoid edge effects and allow an adequate description of the material flow;

- The advancing and rotating speeds must be normalized by the pin radius to obtain weld-pitch values equivalent to the heat input and temperatures typical of real processes;

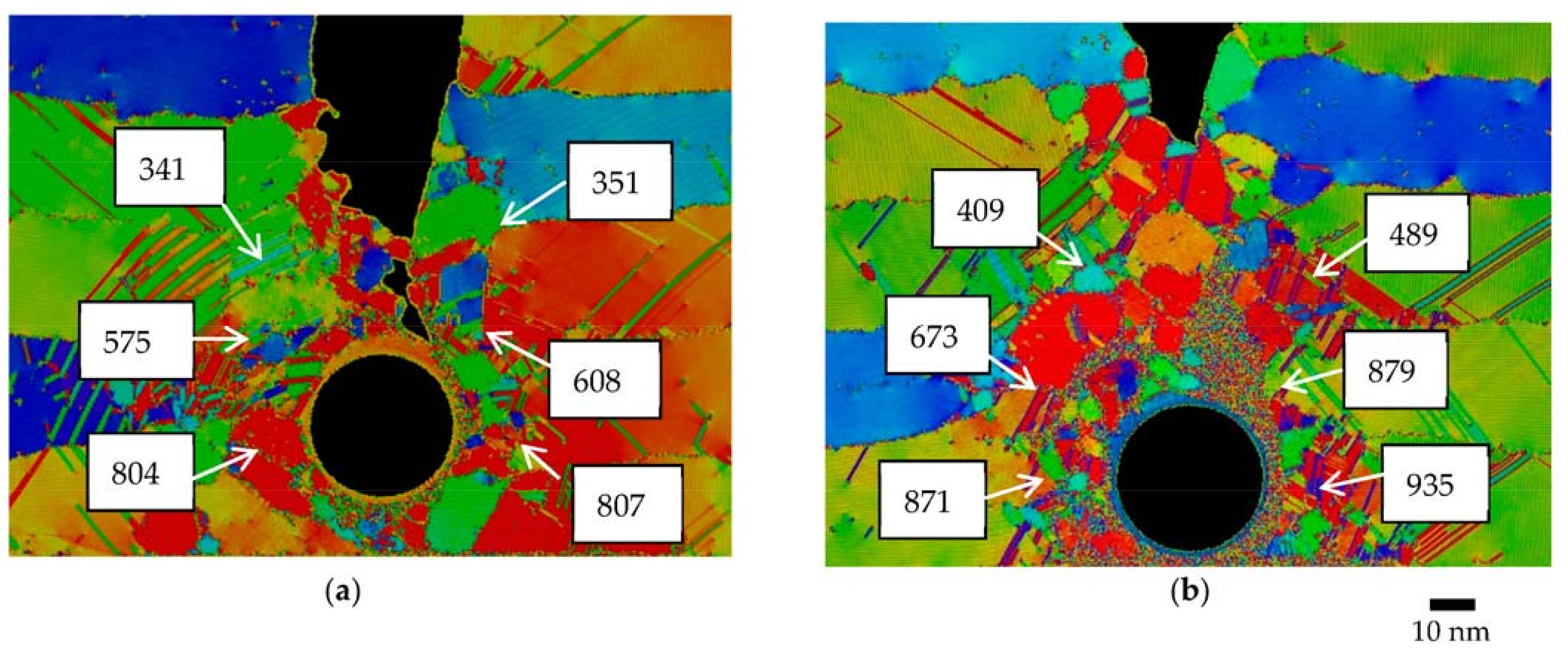

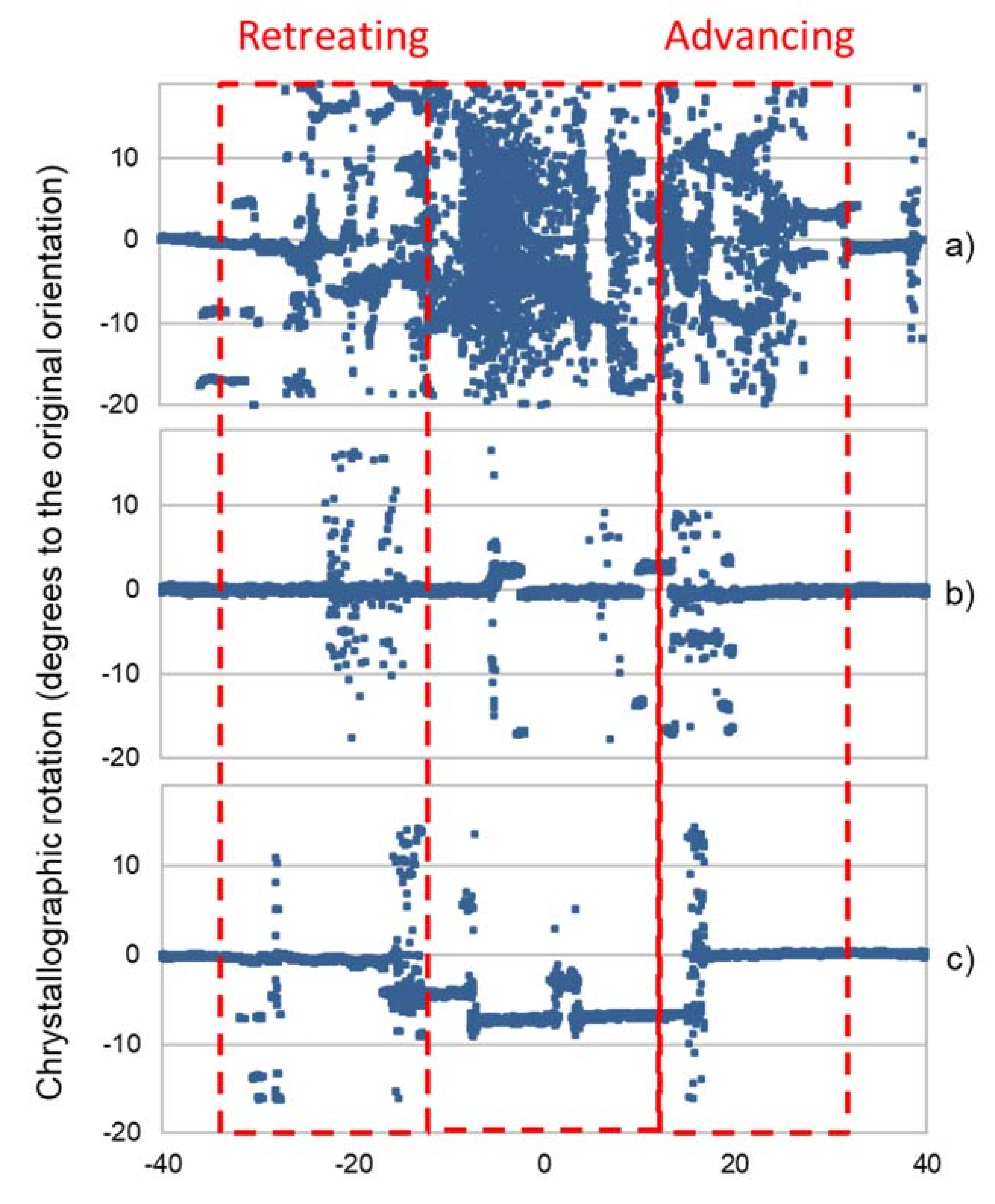

- The typical microstructural zones of the FSW/FSP materials and their crystallographic characteristics, namely grain size, texture, and lattice parameter (equivalent to residual stress), are well-correlated to the temperatures around the pin as calculated by MD simulations.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Global Friction Stir Welding Machine Market, Forecast to 2026. Available online: www.fiormarkets.com (accessed on 1 September 2022).

- Xu, S.; Deng, X. Two-Dimensional Finite Element Simulation of Material Flow in the Friction Stir Welding Process. J. Manuf. Proc. 2004, 2, 125–133. [Google Scholar]

- Santiago, D.H.; Lombera, G.; Urquiza, S.; Cassanelli, A.; de Vedia, L.A. Influence of Welding Parameters and Post-weld Aging on Tensile Properties and Fracture Location of AA2139-T351 Friction-stir-welded Joints. Process. Mat. Res. 2004, 7, 569–574. [Google Scholar] [CrossRef]

- Colegrove, P.; Shercliff, H. CFD modelling of friction stir welding of thick plate 7449 aluminium alloy. Sci. Tech. Weld. Join 2006, 11, 429–441. [Google Scholar] [CrossRef]

- Derazkola, H.; Eyvazian, A.; Simchi, A. Modeling and experimental validation of material flow during FSW of polycarbonate. Mater. Today Commun. 2020, 22, 100796. [Google Scholar] [CrossRef]

- Mendes, N.; Loureiro, A.; Martins, C.; Neto, P.; Pires, J.N. Effect of friction stir welding parameters on morpholo-gy and strength of acrylonitrile butadiene styrene plate welds. Mater. Des. 2014, 58, 457–464. [Google Scholar] [CrossRef]

- Fernández, R.; González-Doncel, G.; Garcés, G.; Bruno, G. Fractional brownian motion of dislocations during creep deformation of metals. Mat. Sci. Eng. A 2020, 776, 139036. [Google Scholar] [CrossRef]

- Fernández, R.; Bokuchava, G.; Toda-Caraballo, I.; Bruno, G.; Turchenko, V.; Gorshkova, Y.; González-Doncel, G. Analysis of the Combined Strengthening Effect of Solute Atoms and Precipitates on Creep of Aluminum Alloys. Adv. Eng. Mater. 2020, 22, 1901355. [Google Scholar] [CrossRef]

- Kobelev, V. Some basic solutions for nonlinear creep. Int. J. Sol. Struct. 2014, 51, 3372–3381. [Google Scholar] [CrossRef]

- Dialami, N.; Chiumenti, M.; Cervera, M.; Segatori, A.; Osikowicz, W. Enhanced friction model for Friction Stir Welding (FSW) analysis: Simulation and experimental validation. Int. J. Mech. Sci. 2017, 133, 555–567. [Google Scholar] [CrossRef]

- Dialami, N.; Chiumenti, M.; Cervera, M.; de Saracibar, C.A. An apropos kinematic framework for the numerical modeling of friction stir welding. Comp. Struct 2013, 117, 48–57. [Google Scholar] [CrossRef]

- Dialami, N.; Cervera, M.; Chiumenti, M. A Solids Defect Formation and Material Flow in Friction Stir Welding. Eur. J. Mech. 2020, 80, 103912. [Google Scholar] [CrossRef]

- Dialami, N.; Cervera, M.; Chiumenti, M.; Segatori, A.; Osikowicz, W. Experimental validation of an FSW model with an enhanced friction law: Application to a threaded cylindrical pin tool. Metals 2017, 7, 1–14. [Google Scholar] [CrossRef]

- Meyghani, B.; Awang, M.; Wu, C.S. Finite element modeling of friction stir welding (FSW) on a complex curved plate. J. Adv. Join. Process. 2020, 1, 100007. [Google Scholar] [CrossRef]

- Reynolds, A.P. Join Visualization of Material Flow in Autogenous Friction Stir Welds. Sci. Tech. Weld. 2000, 5, 120–124. [Google Scholar] [CrossRef]

- Iqbal, M.P.; Tripathi, A.; Jain, R.; Mahto, R.P.; Pal, S.K.; Mandal, P. Numerical modelling of microstructure in friction stir welding of aluminium alloys. Int. J. Mech. Sci. 2020, 185, 105882. [Google Scholar] [CrossRef]

- Xiao, S.; Hu, R.; Li, Z.; Attarian, S.; Bjork, K.-M.; Lendasse, A. A machine-learning-enhanced hierarchical multiscale method for bridging from molecular dynamics to continua. Neural Comput. Appl. 2020, 32, 14359–14373. [Google Scholar] [CrossRef]

- Anand, P.P.G. Chattopadhyay, Computational Design of Microstructure. In Computational Approaches to Materials Design: Theoretical and Practical Aspects; Datta, S., Paulo Davim, J., Eds.; IGI Global: Hershey, PA, USA, 2016; pp. 61–100. [Google Scholar]

- Allen, M.P.; Tildesley, D.J. Computer Simulation of Liquids; Oxford University Press: Oxford, UK, 1989. [Google Scholar]

- Kwon, S.; Kim, H.; Pei, X.; Ko, H.; Park, H.; Bennewitz, R.; Caron, A. Effect of cooling rate on the structure and nanotribology of Ag–Cu nano-eutectic alloys. J Mater. Sci. 2019, 54, 9168–9184. [Google Scholar] [CrossRef]

- Dmitriev, A.I.; Kolubaev, E.A.; Nikonov, A.Y.; Rubstob, V.E.; Psakhie, S.G. Study patterns of microstructure formation during friction stir welding. In Proceedings of the Proc. XLII Int. Summer School–Conference APM (2014), St. Petersburg, Russia, 30 June–5 July 2014; pp. 10–16. [Google Scholar]

- Konovalenko, I.; Dmitriev, A.; Psakhie, S.; Kolubaev, E. Molecular dynamics simulation of welding and joining processes: An overview. Key Eng. Mat. 2016, 683, 626–631. [Google Scholar] [CrossRef]

- Yongchang, L.; Cemal, B. A multiscale modeling technique for bridging molecular dynamics with finite element method. J. Comp. Phys. 2013, 253, 64–85. [Google Scholar]

- Zhou, M. Series A: Mathematical, Physical and Engineering Sciences. Proc. Roy. Soc. Lon. 2003, 459, 2347–2392. [Google Scholar] [CrossRef]

- Goel, S.; Luo, X.; Agrawal, A.; Reuben, R. Diamond machining of silicon: A review of advances in molecular dynamics simulation. Int. J. Mach. Tools Manuf. 2015, 88, 131–164. [Google Scholar] [CrossRef]

- Jain, A.; McGaughey, A.J.H. Thermal transport by phonons and electrons in aluminum, silver, and gold from first principles. Phys. Rev. B 2016, 93, 081206. [Google Scholar] [CrossRef]

- Long, T.; Tang, W.; Reynolds, A.P. Join Process response parameter relationships in aluminium alloy friction stir welds. Sci. Tech. Weld. 2007, 12, 311–317. [Google Scholar] [CrossRef]

- Yan, J.; Sutton, M.A.; Reynolds, A.P. Process–structure–property relationships for nugget and heat affected zone regions of AA2524–T351 friction stir welds. Sci. Tech. Weld. Join. 2005, 10, 725–736. [Google Scholar] [CrossRef]

- Acharya, U.; Roy, B.S.; Saha, S.C. Torque and force perspectives on particle size and its effect on mechanical property of friction stir welded AA6092/17.5SiCp-T6 composite joints. J. Manuf. Proc. 2019, 38, 113–121. [Google Scholar] [CrossRef]

- Simar, A.; Lecomte-Beckers, J.; Pardoen, T.; Meester, B.D. Effect of boundary conditions and heat source distribution on temperature distribution in friction stir welding. Sci. Tech. Weld. Join. 2006, 11, 170–177. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comp. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model. Sim. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Mendelev, M.; Kramer, M.; Becker, C.; Asta, M. Analysis of semi-empirical interatomic potentials appropriate for simulation of crystalline and liquid Al and Cu. Phil. Mag. 2008, 88, 1723–1750. [Google Scholar] [CrossRef]

- Finnis, M.W.; Sinclair, J.E. A simple empirical N-body potential for transition metals. Philos. Mag. A 1984, 50, 45–55. [Google Scholar] [CrossRef]

- Rasti, J. Study of the welding parameters effect on the tunnel void area during friction stir welding of 1060 aluminum alloy. Int. J. Adv. Manuf. Technol. 2018, 97, 2221–2230. [Google Scholar] [CrossRef]

- Ohsaki, S.; Hono, K.; Hidaka, H.; Takaki, S. Characterization of nanocrystalline ferrite produced by mechanical milling of pearlitic steel. Scr. Mater. 2005, 52, 271–276. [Google Scholar] [CrossRef]

- Laska, A.; Szkodo, M. Manufacturing Parameters, Materials, and Welds Properties of Butt Friction Stir Welded Joints–Overview. Materials 2020, 13, 4940. [Google Scholar] [CrossRef]

- Barbini, A.; Carstensen, J.; dos Santos, J.F. Influence of a non-rotating shoulder on heat generation, microstructure and mechanical properties of dissimilar AA2024/AA7050 FSW joints. J. Mater. Sci. Technol. 2018, 34, 119–127. [Google Scholar] [CrossRef]

- Colligan, K. Material Flow Behavior during Friction Stir Welding of Aluminum. Weld. J. 1999, 78, 229–237. [Google Scholar]

- Tamadon, A.; Pons, D.J.; Clucas, D. Structural Anatomy of Tunnel Void Defect in Bobbin Friction Stir Welding, Elucidated by the Analogue Modelling. Appl. Syst. Innov. 2020, 3, 2–15. [Google Scholar] [CrossRef]

- Ji, S.D.; Meng, X.C.; Liu, J.G.; Zhang, L.G.; Gao, S.S. Formation and mechanical properties of stationary shoulder friction stir welded 6005A-T6 aluminum alloy. Mater. Des. 2014, 62, 113–117. [Google Scholar] [CrossRef]

- Fernández, R.; Ibáñez, J.; Cioffi, F.; Verdera, D.; González-Doncel, G. Friction stir welding of 25%SiC/2124Al composite with optimal mechanical properties and minimal tool wear. Sci. Tech. Weld. Join. 2017, 22, 526–535. [Google Scholar] [CrossRef]

- Ouyang, J.; Kovacevic, R. Material Flow and Microstructure in the Friction Stir Butt Welds of the Same and Dissimilar Aluminum Alloys. J. Mat. Eng. Perf. 2002, 11, 51–63. [Google Scholar] [CrossRef]

- Guerra, M.; Schmidt, C.; McClure, J.; Murr, L.; Nunes, A. Flow patterns during friction stir welding. Mat. Char. 2003, 49, 95–101. [Google Scholar] [CrossRef]

- Schmidt, H.; Dickerson, T.; Hattel, J. Material flow in butt friction stir welds in AA2024-T3. Acta Mater. 2006, 54, 1199–1209. [Google Scholar] [CrossRef]

- Nandan, R.; Roy, G.; Lienert, T.; Debroy, T. Three-dimensional heat and material flow during friction stir welding of mild steel. Acta Mater. 2007, 55, 883–895. [Google Scholar] [CrossRef]

- Lorrain, O.; Favier, V.; Zahrouni, H.; Lawrjaniec, D. Understanding the material flow path of friction stir welding process using unthreaded tools. J. Mat. Proc. Tech. 2010, 210. [Google Scholar] [CrossRef]

- Mironov, S.; Sato, Y.; Kokawa, H. Applications of EBSD to Microstructural Control in Friction Stir Welding/Processing. In Electron Backscatter Diffraction in Materials Science; Schwartz, A., Kumar, M., Adams, B., Field, D., Eds.; Springer: Boston, MA, USA, 2009. [Google Scholar] [CrossRef]

- Chen, M.; Ma, E.; Hemker, K.; Sheng, H.; Wang, Y.; Cheng, X. Deformation Twinning in Nanocrystalline Aluminum. Science 2003, 300, 1275–1277. [Google Scholar] [CrossRef] [PubMed]

- Sun, R.; Li, L.; Zhu, Y.; Guo, W.; Peng, P.; Cong, B.; Sun, J.; Che, Z.; Li, B.; Guo, C.; et al. Microstructure, residual stress and tensile properties control of wire-arc additive manufactured 2319 aluminum alloy with laser shock peening. J. Alloys Comp. 2018, 747, 255–265. [Google Scholar] [CrossRef]

- Moradi, M.; Aval, H.; Jamaati, R.; Amirkhanlou, S.; Ji, S. Microstructure and texture evolution of friction stir welded dissimilar aluminum alloys: AA2024 and AA6061. J. Man. Proc. 2018, 32, 1–10. [Google Scholar] [CrossRef]

- Hoyos, E.; Montoya, Y.; Fernández, R.; González-Doncel, G. Approach to plastic deformation and strain rate in FSW process. Weld. World 2021, 65, 1519–1530. [Google Scholar] [CrossRef]

- Takayama, Y.; Akutsu, Y.; Choshiro, N.; Kato, H.; Watanabe, H. Temperature Measurement During Friction Stir Welding of Dissimilar Aluminum Alloys. The Japan Institute of Light Metals. In In Proceedings of the 12th International Conference on Aluminium Alloys, Yokohama, Japan, 5–9 September 2010; pp. 1829–1834. [Google Scholar]

- Mehta, M.; Arora, A.; DeTarasankar, A.; Debroy, T. Tool Geometry for Friction Stir Welding—Optimum Shoulder Diameter. Met. Mat. Trans. A 2011, 42, 2716–2722. [Google Scholar] [CrossRef]

- Siddiqui, M.A.; Jafri, S.; Alam, S. Validation of Maximum Temperature during Friction Stir Welding of Butt Joint of Aluminium Alloy by using HyperWorks. Mat. Sci. Int. J. Eng. Res. Technol. 2015, 4, 817–821. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medina, B.; Fernández, R. Material Behavior around the FSW/FSP Tool Described by Molecular Dynamics. J. Manuf. Mater. Process. 2023, 7, 13. https://doi.org/10.3390/jmmp7010013

Medina B, Fernández R. Material Behavior around the FSW/FSP Tool Described by Molecular Dynamics. Journal of Manufacturing and Materials Processing. 2023; 7(1):13. https://doi.org/10.3390/jmmp7010013

Chicago/Turabian StyleMedina, Bentejui, and Ricardo Fernández. 2023. "Material Behavior around the FSW/FSP Tool Described by Molecular Dynamics" Journal of Manufacturing and Materials Processing 7, no. 1: 13. https://doi.org/10.3390/jmmp7010013

APA StyleMedina, B., & Fernández, R. (2023). Material Behavior around the FSW/FSP Tool Described by Molecular Dynamics. Journal of Manufacturing and Materials Processing, 7(1), 13. https://doi.org/10.3390/jmmp7010013