Laser Additive Manufacturing of High-Strength Aluminum Alloys: Challenges and Strategies

Abstract

1. Introduction

2. Material Selection Criteria for Metal AM

2.1. Al Alloy Compositions and Properties

2.2. Material Properties Required for Fusion-Based Metal AM

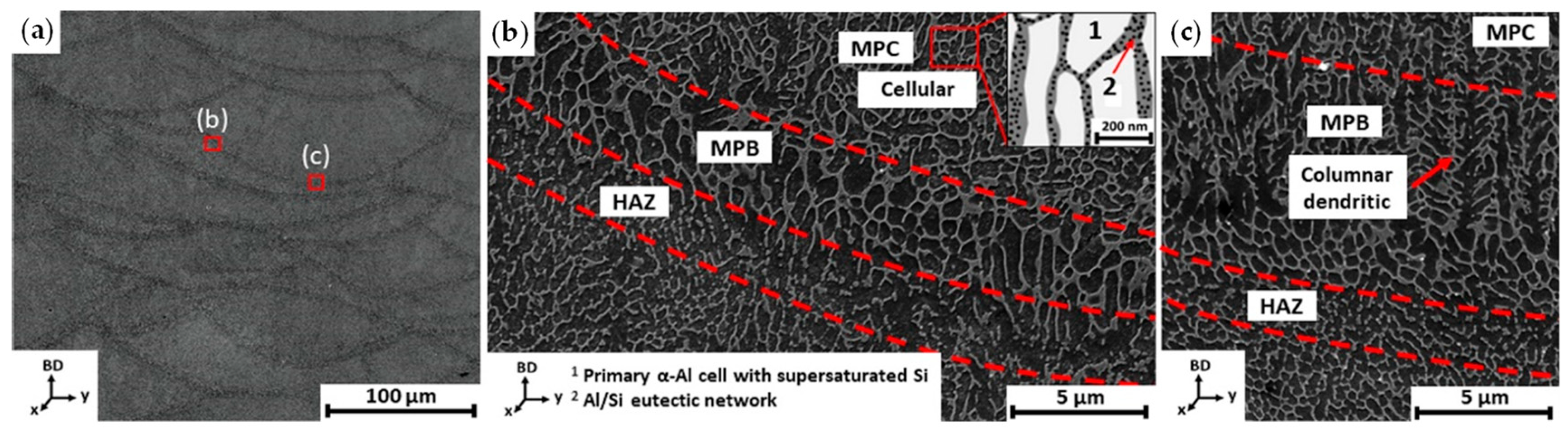

2.2.1. Suitable Al Alloys for Metal AM Processes—Cast Al Alloys

2.2.2. Suitable Al Alloys for Metal AM Processes—6xxx Series Al Alloys

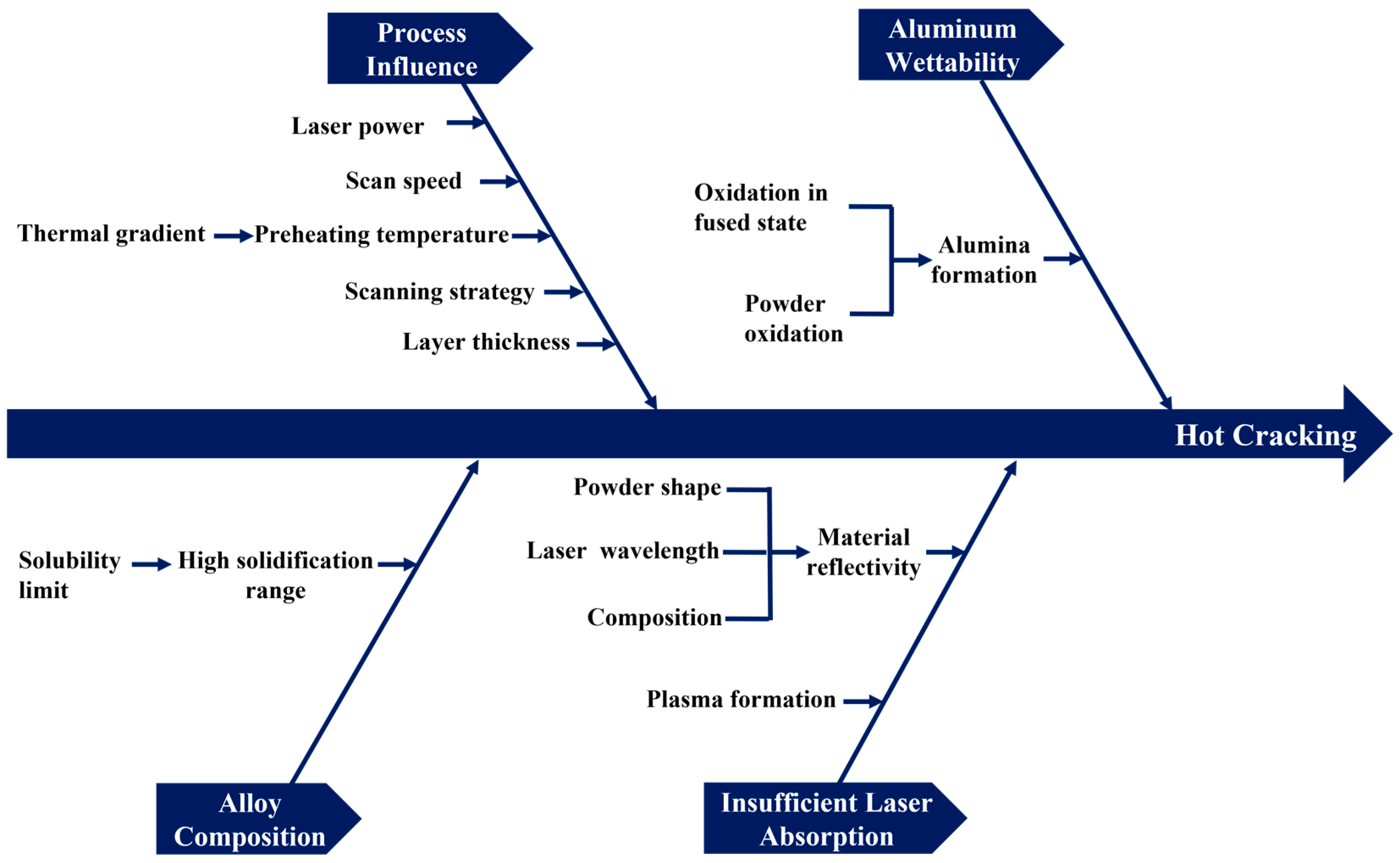

3. Challenges in AM of HS-Al Alloys

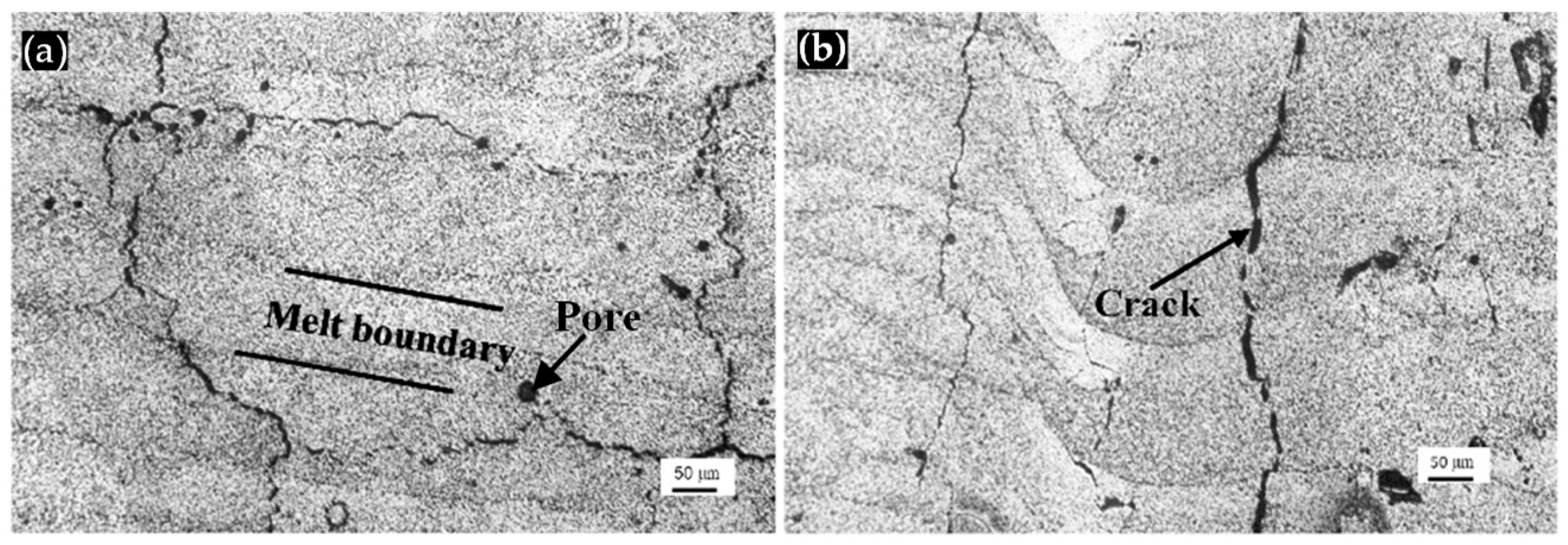

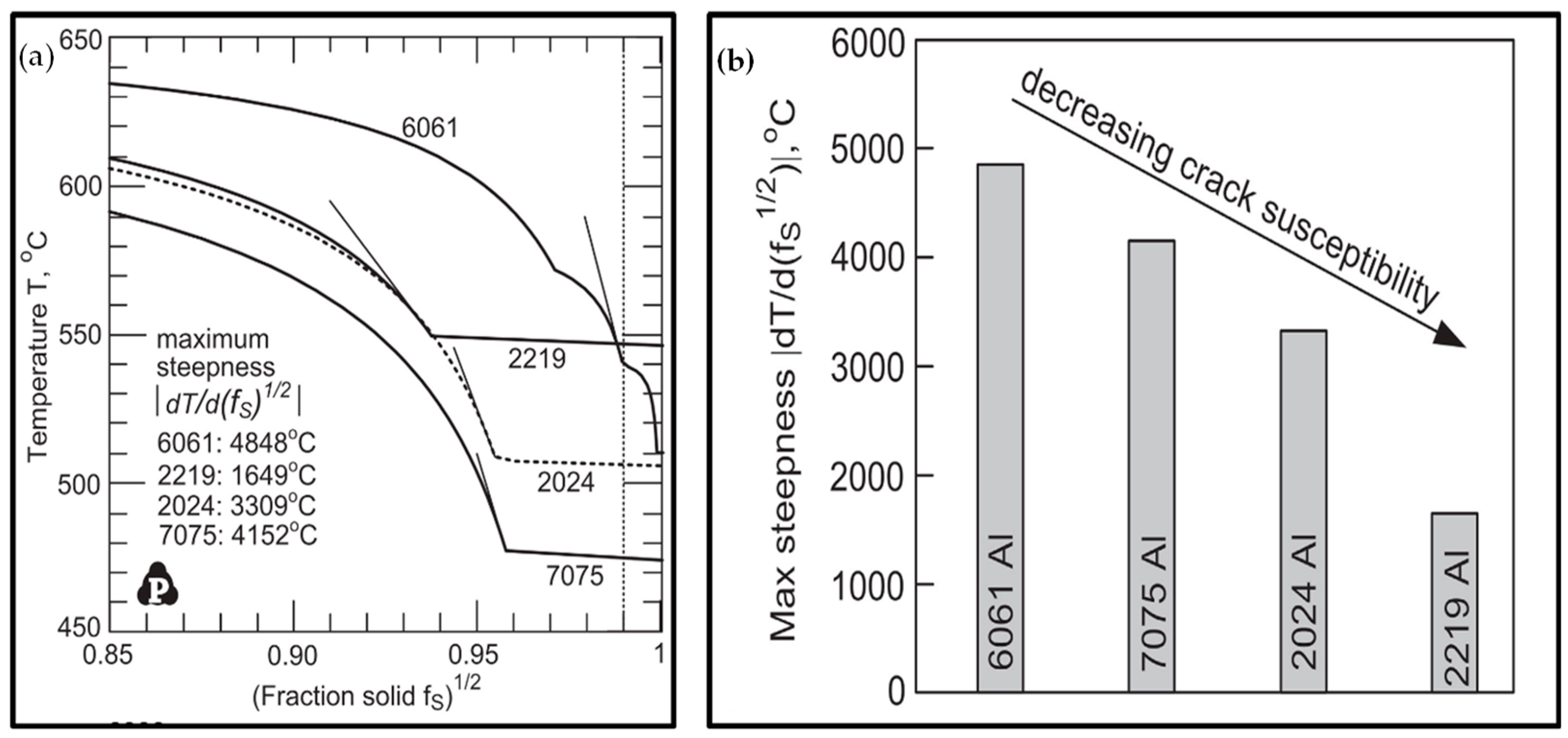

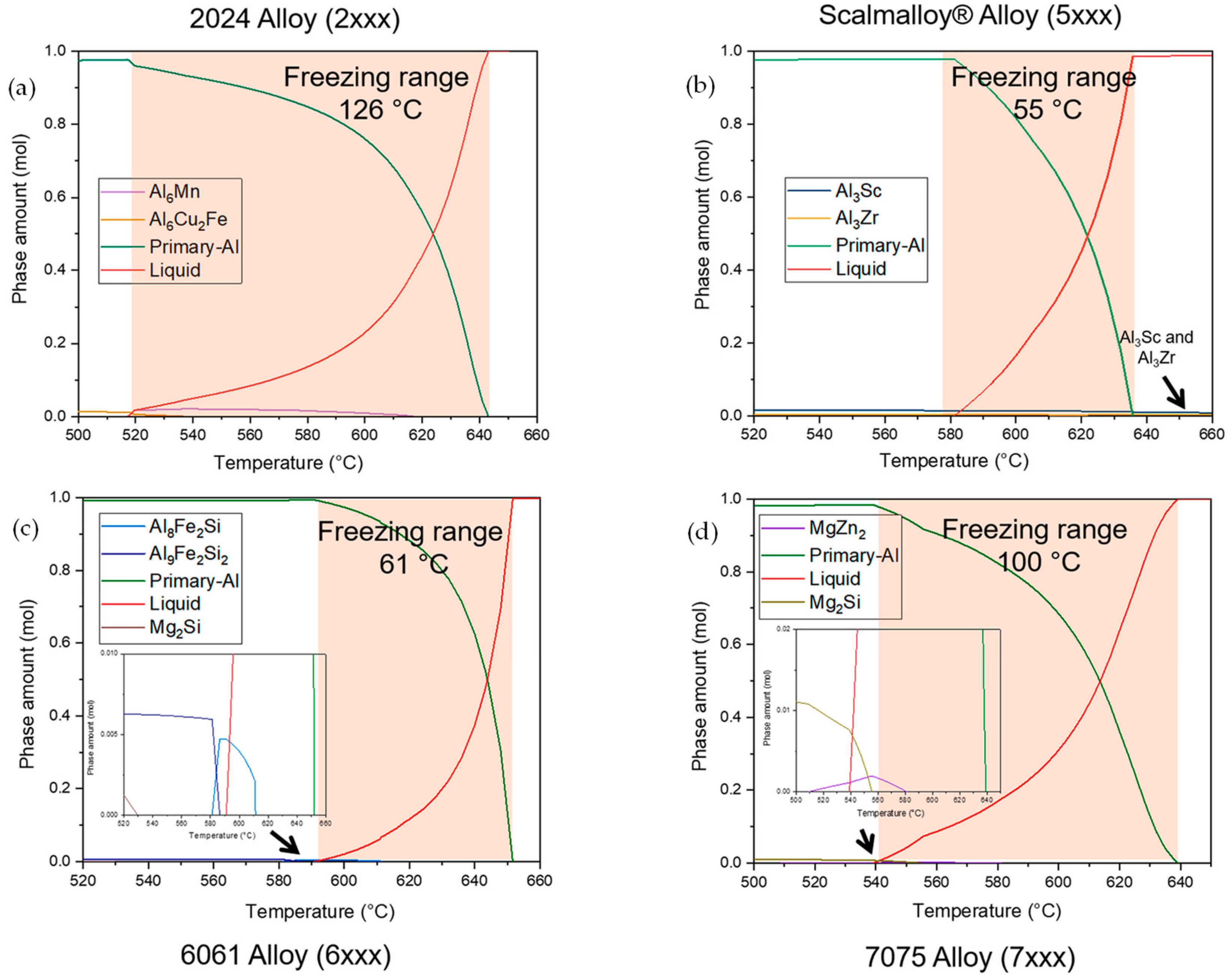

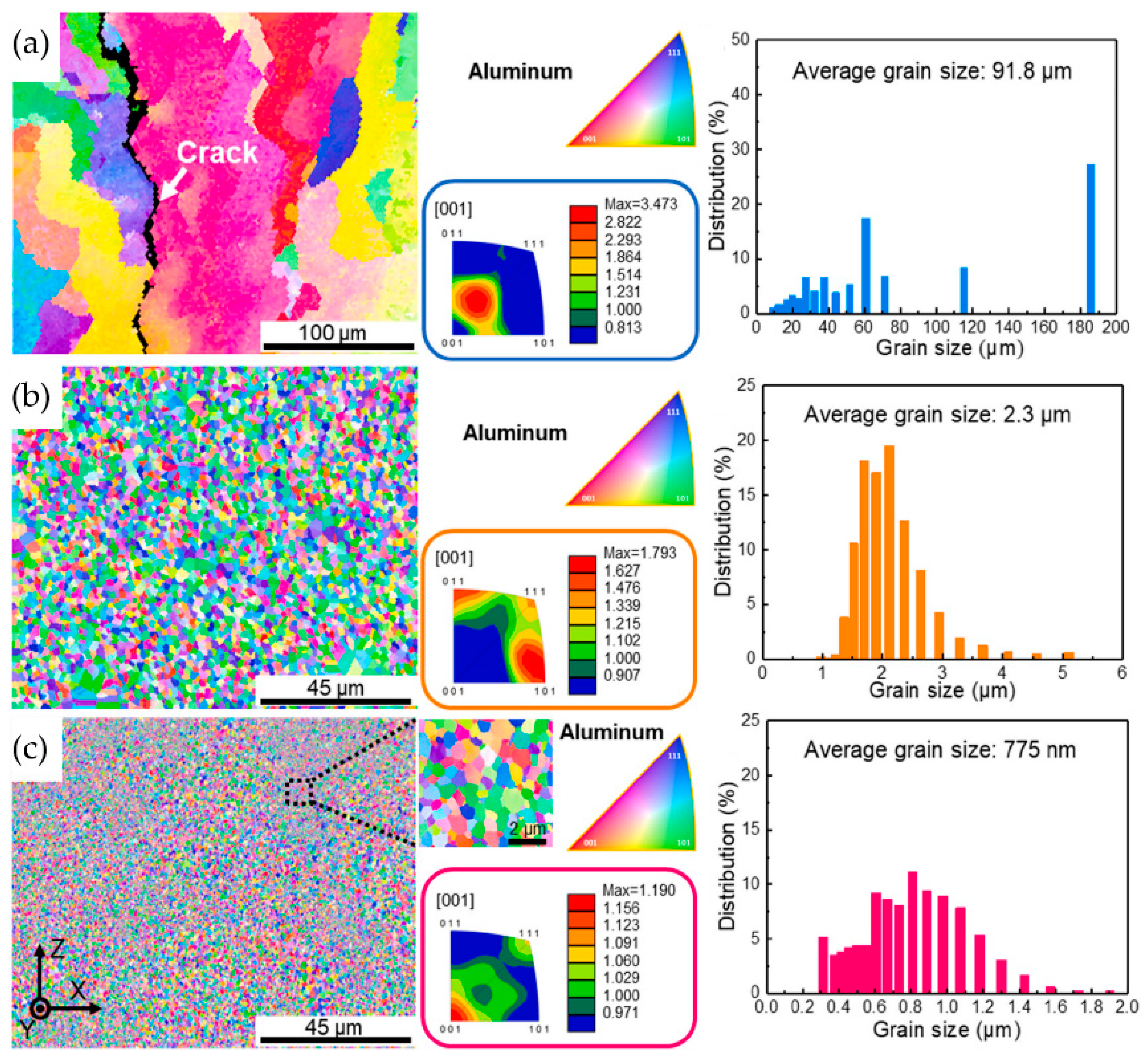

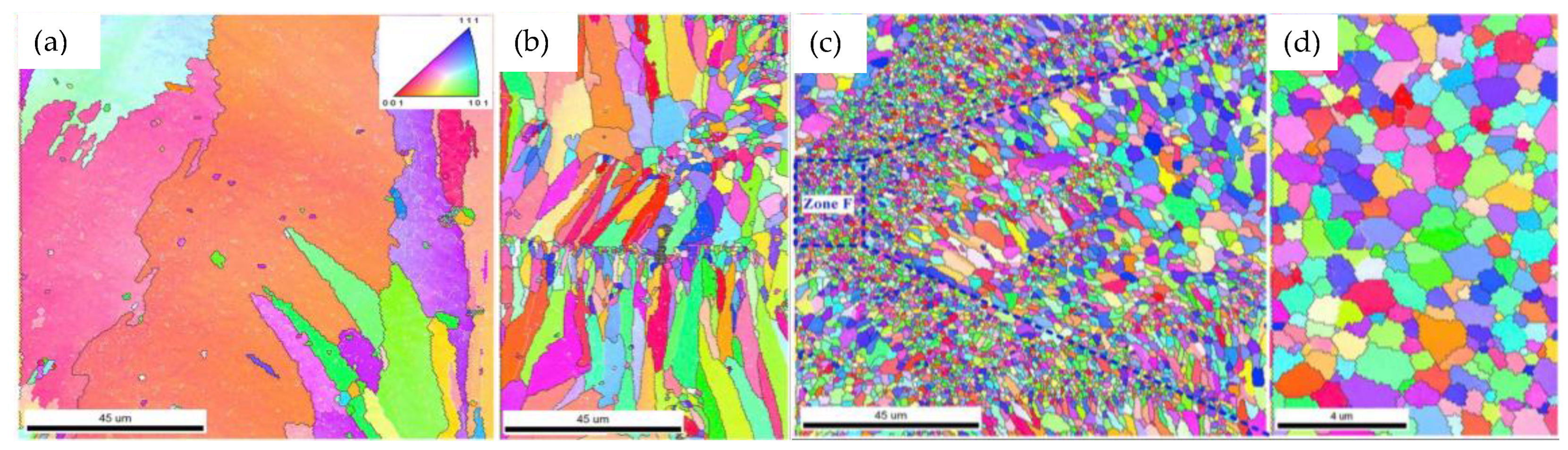

3.1. Cracking

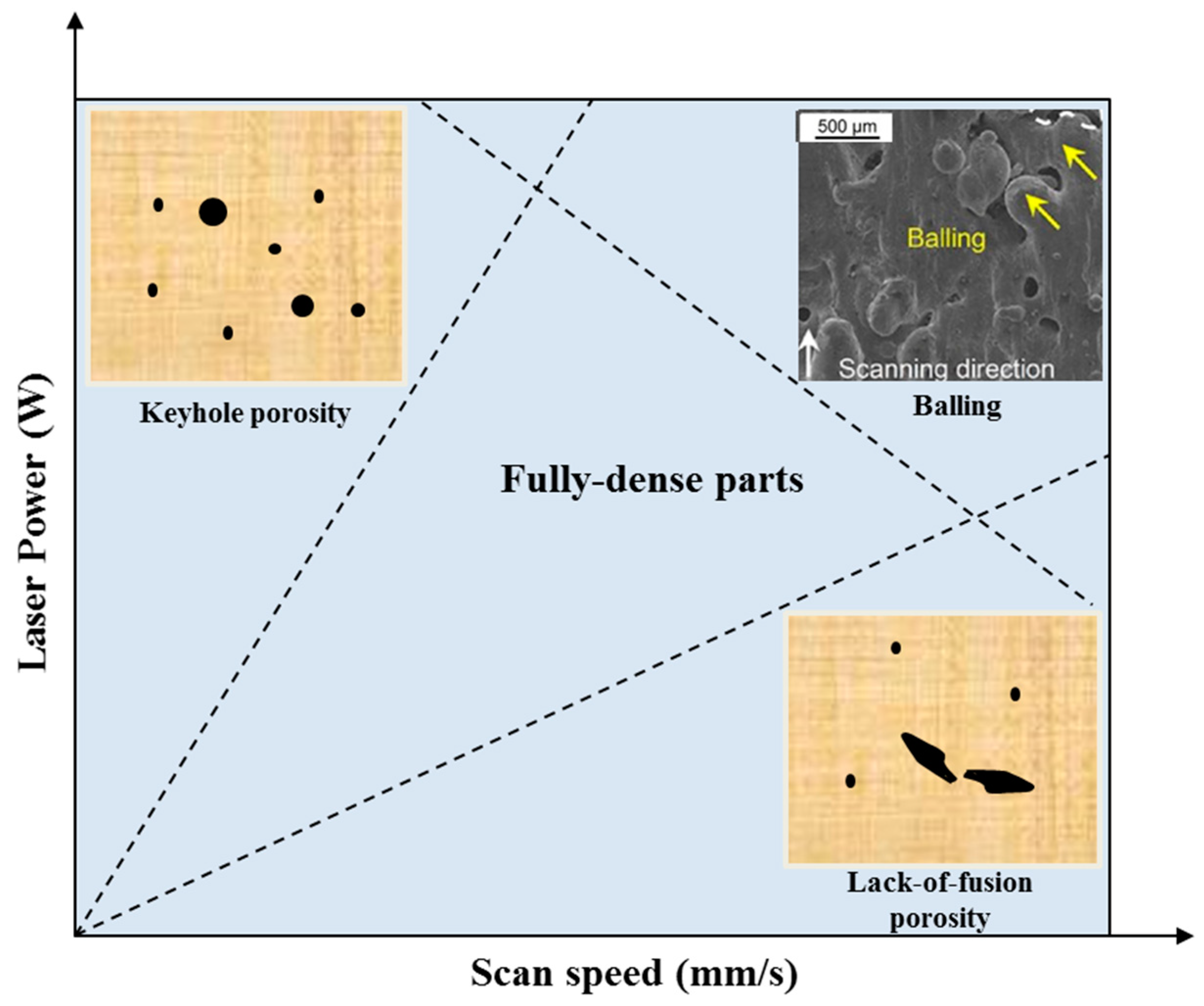

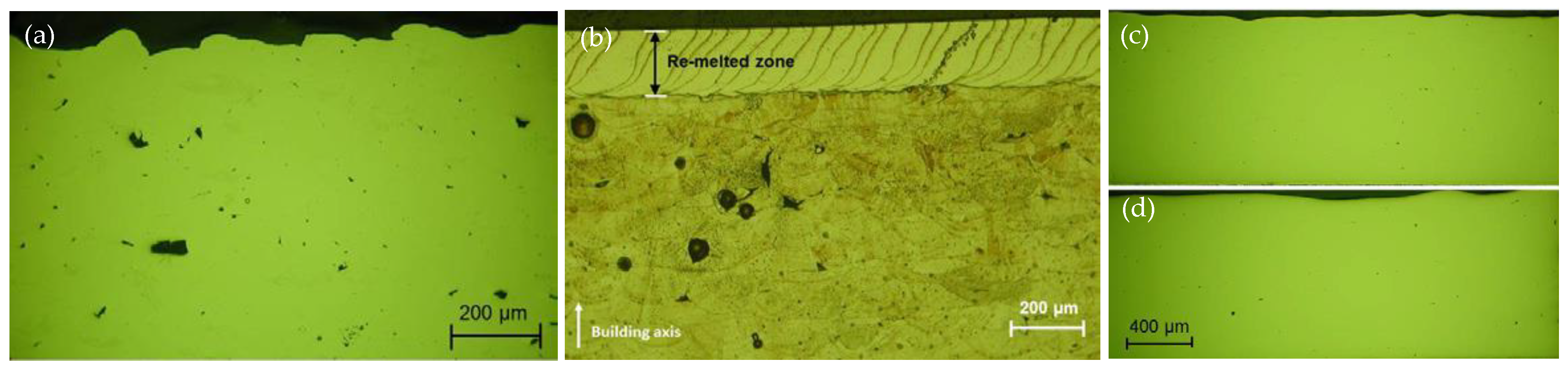

3.2. Porosity

4. Strategies to Improve Printability of HS-Al Alloys—Process Optimization

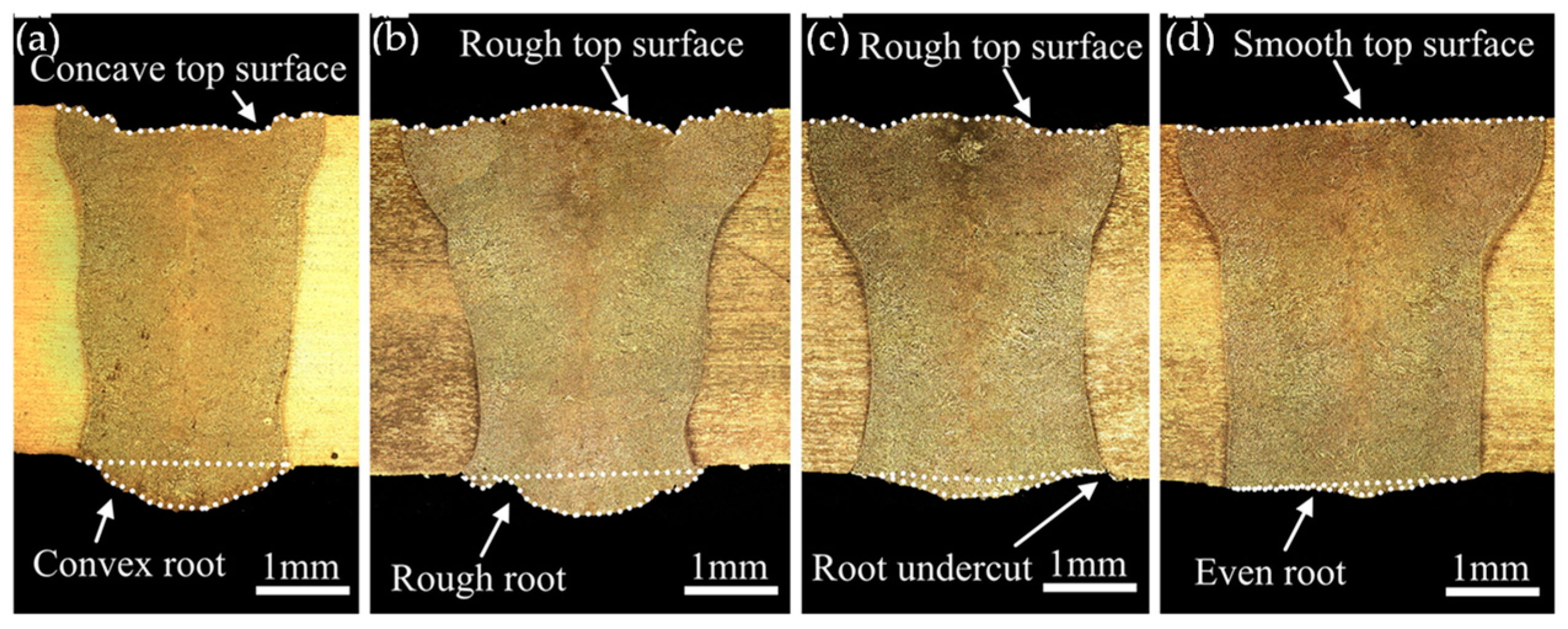

4.1. AM Parameter Optimization

4.1.1. Energy Density

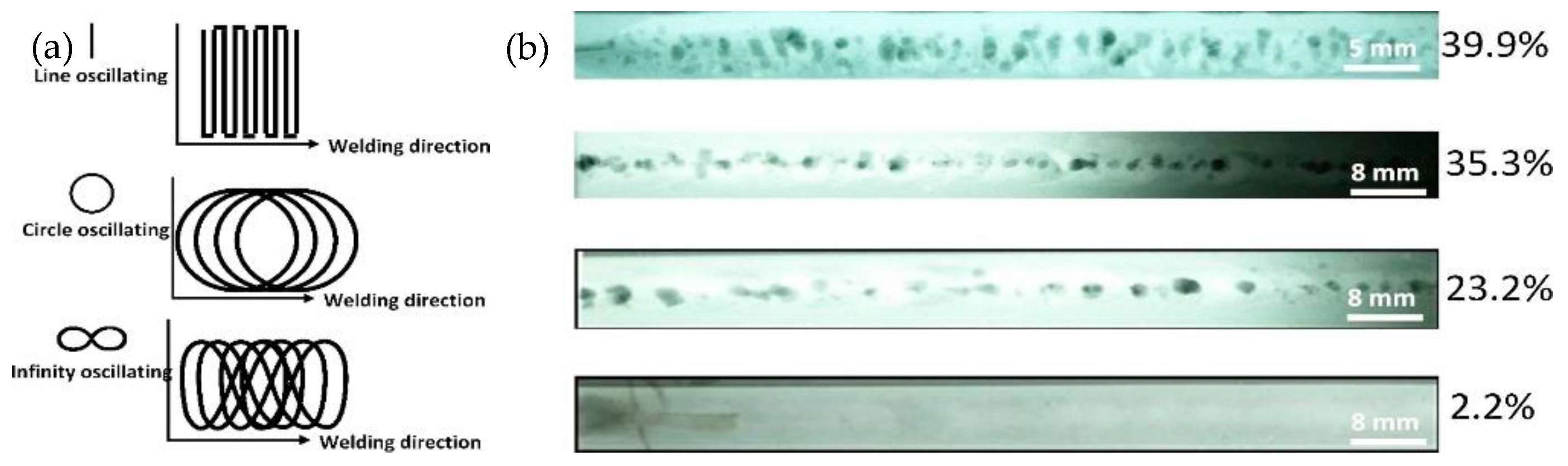

4.1.2. Scanning Strategy

4.2. Hybrid AM Processes

4.3. Post-Processing Treatment

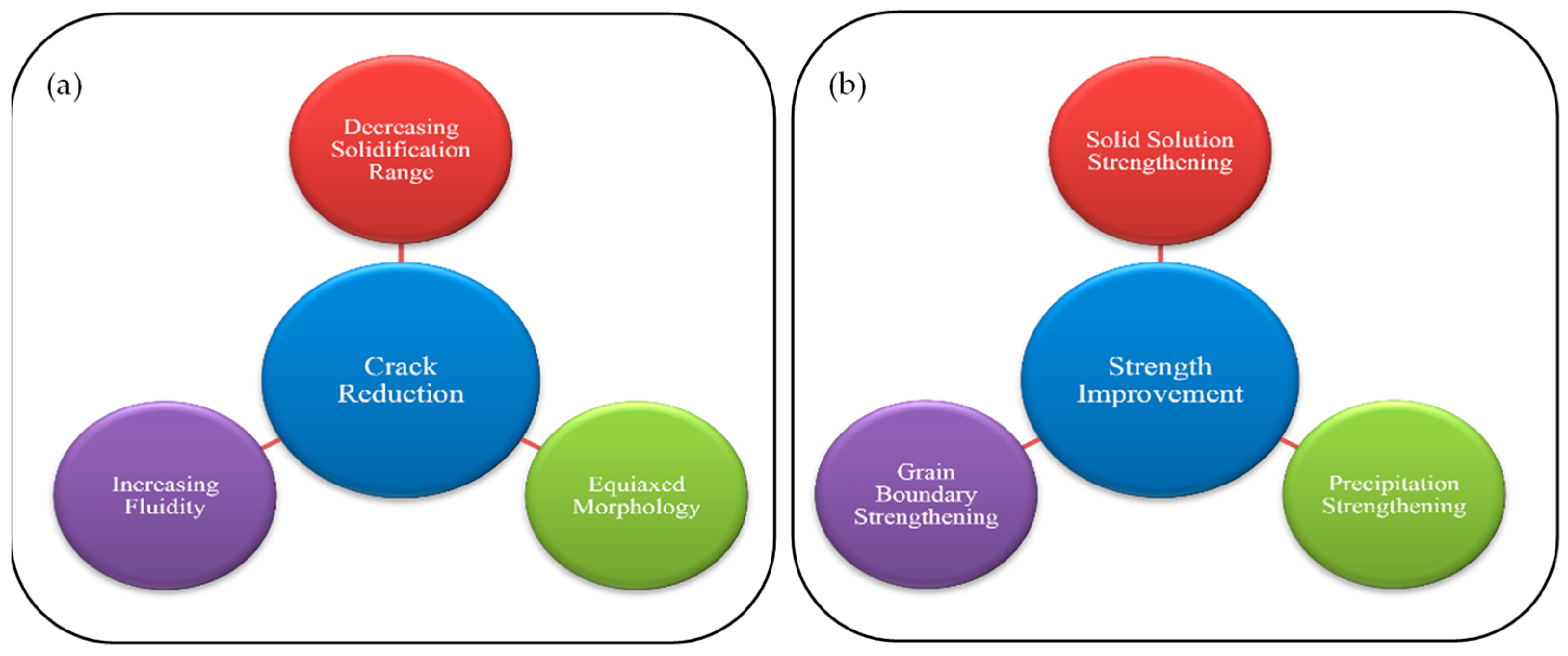

5. Strategies to Improve Printability of HS-Al Alloys—Composition Modification

5.1. Si

5.2. Ti

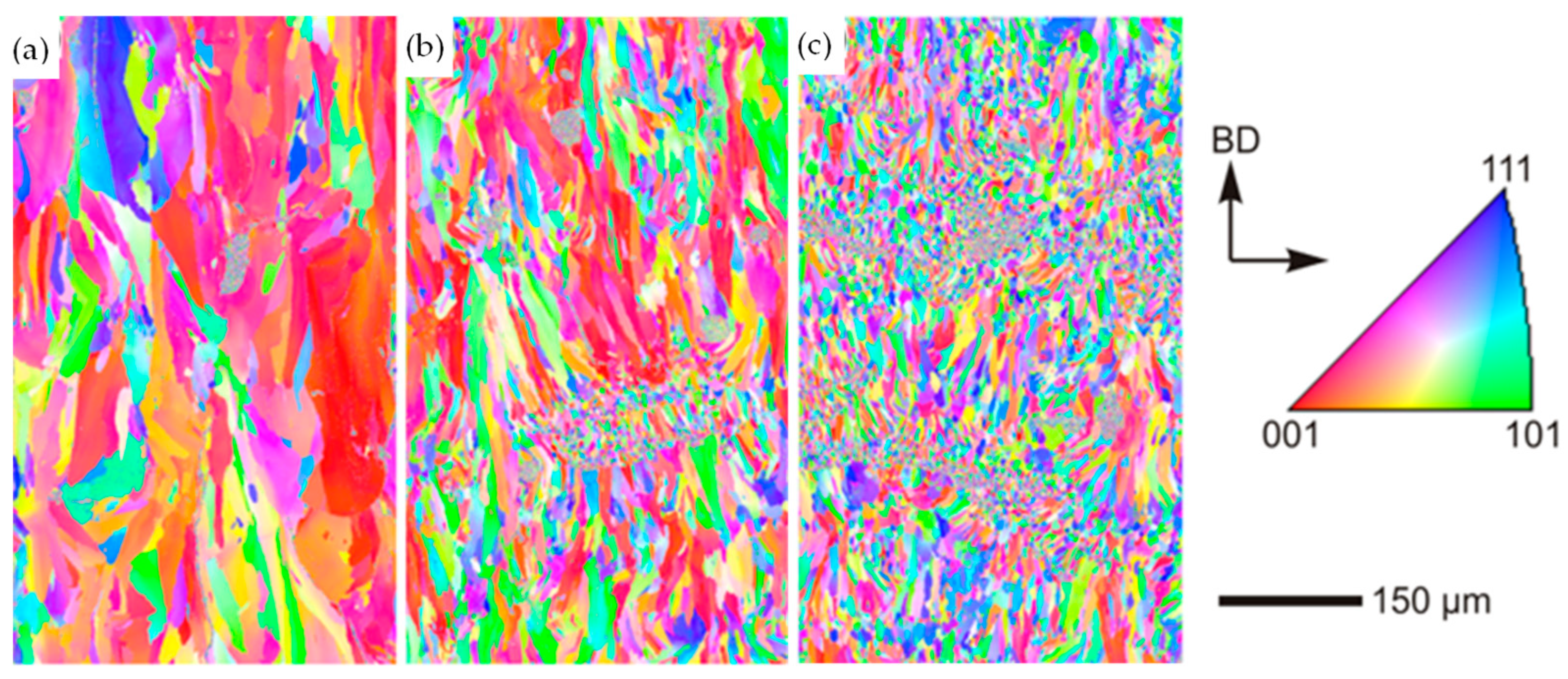

5.3. Zr

5.4. Sc

6. Conclusions

- Metal AM of HS-Al alloys suffers from poor printability that features cracking and porosity due to the extensive solidification range, high thermal conductivity, significant thermal expansion, low absorptivity, poor fluidity, and oxide formation in the melt pool.

- Ideal material candidates for metal AM should have good weldability, castability, and heat treatability; however, these criteria are necessary but insufficient to guarantee good printability.

- Optimizing process conditions through improving AM parameters and incorporating hybrid processes such as preheating, remelting, and laser beam oscillation can reduce porosity significantly but fail to eliminate cracks thoroughly.

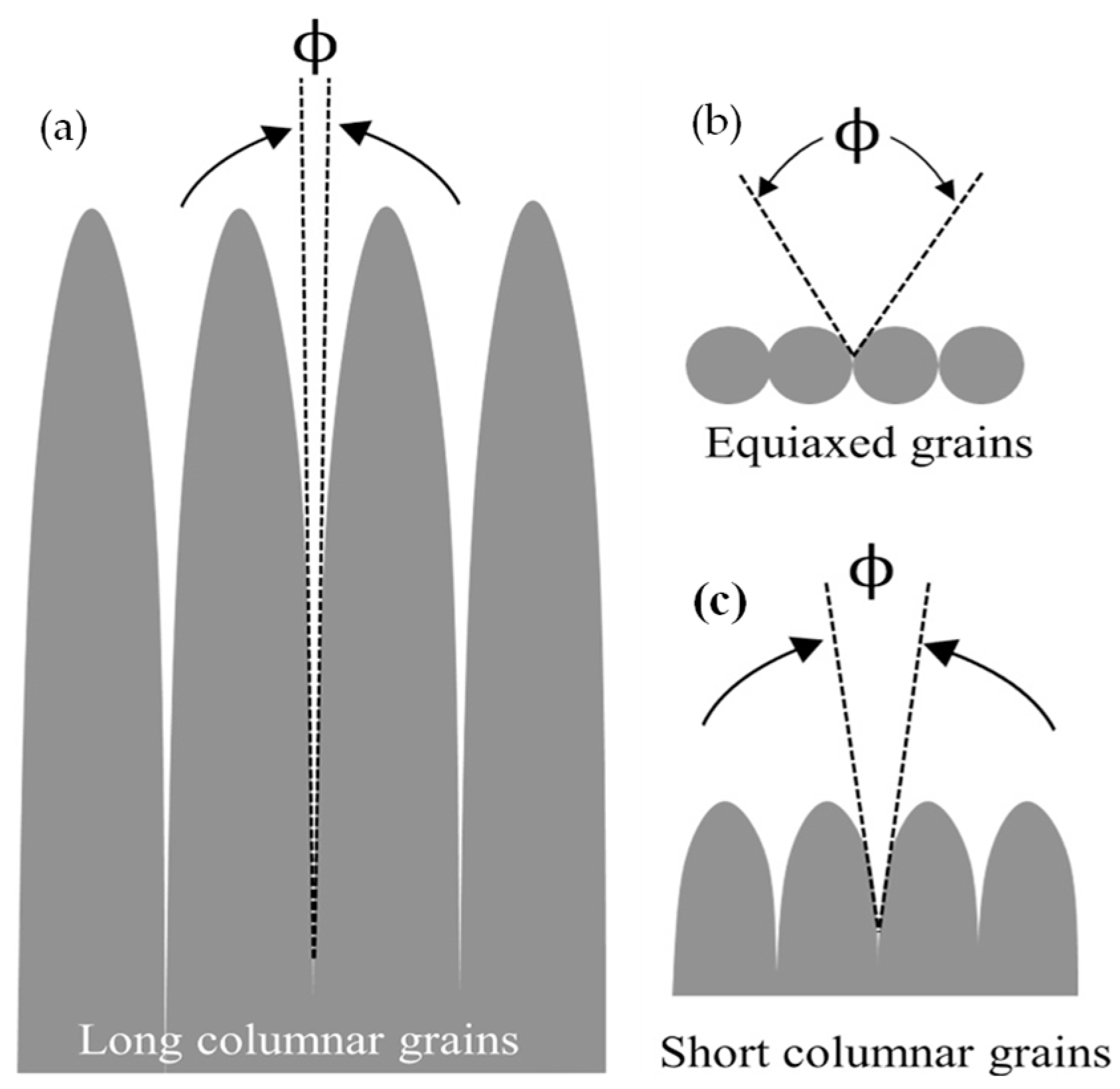

- Composition modification is the most effective strategy to address cracking. Si primarily improves the melt pool fluidity and reduces the solidification range by forming a eutectic mixture. Ti, Zr, Sc, Ta, Er, Nb, and their compounds provide heterogeneous nucleation agents such as Al3Ti, Al3Zr, and Al3Sc, which refine grain structure by transforming columnar grain into equiaxed morphology, suppressing the crack formation and strengthening the Al matrix by forming precipitate reinforcements.

7. Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Das, S.K.; Green, J.A.S.; Kaufman, J.G. The development of recycle-friendly automotive aluminum alloys. JOM 2007, 59, 47–51. [Google Scholar] [CrossRef]

- Mahfoud, M.; Emadi, D. Aluminum recycling-Challenges and opportunities. Proc. Adv. Mater. Res. 2010, 83, 571–578. [Google Scholar] [CrossRef]

- Starke, E.A.; Staley, J.T. Application of modern aluminum alloys to aircraft. Prog. Aerosp. Sci. 1996, 32, 131–172. [Google Scholar] [CrossRef]

- Kermanidis, A.T. Aircraft Aluminum Alloys: Applications and Future Trends. In Revolutionizing Aircraft Materials and Processes; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Nakata, M.; Kitahara, Y.; Haguchi, H. Trends in aluminum alloy casting for aircraft parts. Res. Dev.-Kobe 2005, 55, 87. [Google Scholar]

- Sun, H.T.; Wang, J.; Shen, G.Z.; Hu, P. Application of warm forming aluminum alloy parts for automotive body based on impact. Int. J. Automot. Technol. 2013, 14, 605–610. [Google Scholar] [CrossRef]

- Yang, T.; Liu, T.; Liao, W.; MacDonald, E.; Wei, H.; Zhang, C.; Chen, X.; Zhang, K. Laser powder bed fusion of AlSi10Mg: Influence of energy intensities on spatter and porosity evolution, microstructure and mechanical properties. J. Alloys Compd. 2020, 849, 156300. [Google Scholar] [CrossRef]

- Moghimian, P.; Poirié, T.; Habibnejad-Korayem, M.; Zavala, J.A.; Kroeger, J.; Marion, F.; Larouche, F. Metal powders in additive manufacturing: A review on reusability and recyclability of common titanium, nickel and aluminum alloys. Addit. Manuf. 2021, 43, 102017. [Google Scholar] [CrossRef]

- Yao, X.; Moon, S.K.; Bi, G.; Wei, J. A multi-material part design framework in additive manufacturing. Int. J. Adv. Manuf. Technol. 2018, 99, 2111–2119. [Google Scholar] [CrossRef]

- Leicher, M.; Kamper, S.; Treutler, K.; Wesling, V. Multi-material design in additive manufacturing—Feasibility validation. Weld. World 2020, 64, 1341–1347. [Google Scholar] [CrossRef]

- Haghdadi, N.; Laleh, M.; Moyle, M.; Primig, S. Additive manufacturing of steels: A review of achievements and challenges. J. Mater. Sci. 2021, 56, 64–107. [Google Scholar] [CrossRef]

- Agrawal, R.; Vinodh, S. State of art review on sustainable additive manufacturing. Rapid Prototyp. J. 2019, 25, 1045–1060. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Marattukalam, J.J.; Karlsson, D.; Pacheco, V.; Beran, P.; Wiklund, U.; Jansson, U.; Hjörvarsson, B.; Sahlberg, M. The effect of laser scanning strategies on texture, mechanical properties, and site-specific grain orientation in selective laser melted 316L SS. Mater. Des. 2020, 193, 108852. [Google Scholar] [CrossRef]

- Salman, O.O.; Brenne, F.; Niendorf, T.; Eckert, J.; Prashanth, K.G.; He, T.; Scudino, S. Impact of the scanning strategy on the mechanical behavior of 316L steel synthesized by selective laser melting. J. Manuf. Process. 2019, 45, 255–261. [Google Scholar] [CrossRef]

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in additive manufacturing: A review of their microstructure and properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- Babu, S.S.; Raghavan, N.; Raplee, J.; Foster, S.J.; Frederick, C.; Haines, M.; Dinwiddie, R.; Kirka, M.K.; Plotkowski, A.; Lee, Y.; et al. Additive Manufacturing of Nickel Superalloys: Opportunities for Innovation and Challenges Related to Qualification. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2018, 49, 3764–3780. [Google Scholar] [CrossRef]

- Li, Y.; Liang, X.; Yu, Y.; Wang, D.; Lin, F. Review on Additive Manufacturing of Single-Crystal Nickel-based Superalloys. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100019. [Google Scholar] [CrossRef]

- Liu, S.; Grohol, C.M.; Shin, Y.C. High throughput synthesis of CoCrFeNiTi high entropy alloys via directed energy deposition. J. Alloys Compd. 2022, 916, 165469. [Google Scholar] [CrossRef]

- Klocke, F.; Arntz, K.; Teli, M.; Winands, K.; Wegener, M.; Oliari, S. State-of-the-art Laser Additive Manufacturing for Hot-work Tool Steels. Procedia CIRP 2017, 63, 58–63. [Google Scholar] [CrossRef]

- Mauduit, A.; Pillot, S.; Gransac, H. Study of the suitability of aluminum alloys for additive manufacturing by laser powder-bed fusion. UPB Sci. Bull. Ser. B Chem. Mater. Sci. 2017, 79, 219–238. [Google Scholar]

- Reschetnik, W.; Brüggemann, J.P.; Aydinöz, M.E.; Grydin, O.; Hoyer, K.P.; Kullmer, G.; Richard, H.A. Fatigue crack growth behavior and mechanical properties of additively processed en AW-7075 aluminium alloy. Procedia Struct. Integr. 2016, 2, 3040–3048. [Google Scholar] [CrossRef]

- Brice, C.A.; Tayon, W.A.; Newman, J.A.; Kral, M.V.; Bishop, C.; Sokolova, A. Effect of compositional changes on microstructure in additively manufactured aluminum alloy 2139. Mater. Charact. 2018, 143, 50–58. [Google Scholar] [CrossRef]

- Brice, C.; Shenoy, R.; Kral, M.; Buchannan, K. Precipitation behavior of aluminum alloy 2139 fabricated using additive manufacturing. Mater. Sci. Eng. A 2015, 648, 9–14. [Google Scholar] [CrossRef]

- Kimura, T.; Nakamoto, T. Microstructures and mechanical properties of A356 (AlSi7Mg0.3) aluminum alloy fabricated by selective laser melting. Mater. Des. 2016, 89, 1294–1301. [Google Scholar] [CrossRef]

- Bradford, R.L.; Cao, L.; Klosterman, D.; Herman, F.; Forman, L.; Browning, C. A metal–metal powder formulation approach for laser additive manufacturing of difficult-to-print high-strength aluminum alloys. Mater. Lett. 2021, 300, 130113. [Google Scholar] [CrossRef]

- McDonald, S.D.; Nogita, K.; Dahle, A.K. Eutectic nucleation in Al-Si alloys. Acta Mater. 2004, 52, 4273–4280. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Rooy, E.L. Introduction to Aluminum and Aluminum Alloys. In Properties and Selection: Nonferrous Alloys and Special-Purpose Materials; ASM International: Almere, The Netherlands, 2018. [Google Scholar]

- Kaufmann, N.; Imran, M.; Wischeropp, T.M.; Emmelmann, C.; Siddique, S.; Walther, F. Influence of process parameters on the quality of aluminium alloy en AW 7075 using Selective Laser Melting (SLM). Phys. Procedia 2016, 83, 918–926. [Google Scholar] [CrossRef]

- Pekok, M.A.; Setchi, R.; Ryan, M.; Han, Q.; Gu, D. Effect of process parameters on the microstructure and mechanical properties of AA2024 fabricated using selective laser melting. Int. J. Adv. Manuf. Technol. 2021, 112, 175–192. [Google Scholar] [CrossRef]

- Oko, O.E.; Mbakaan, C.; Barki, E. Experimental investigation of the effect of processing parameters on densification, microstructure and hardness of selective laser melted 7075 aluminium alloy. Mater. Res. Express 2020, 7, 036512. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Xue, Y.F.; Elbestawi, M.A.; Veldhuis, S.C. Effect of selective laser melting process parameters on the quality of al alloy parts: Powder characterization, density, surface roughness, and dimensional accuracy. Materials 2018, 11, 2343. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Zhu, H.; Qi, T.; Hu, Z.; Zeng, X. Selective laser melting of high strength Al-Cu-Mg alloys: Processing, microstructure and mechanical properties. Mater. Sci. Eng. A 2016, 656, 47–54. [Google Scholar] [CrossRef]

- Giganto, S.; Zapico, P.; Castro-Sastre, M.Á.; Martínez-Pellitero, S.; Leo, P.; Perulli, P. Influence of the scanning strategy parameters upon the quality of the SLM parts. Proc. Procedia Manuf. 2019, 41, 698–705. [Google Scholar] [CrossRef]

- Koutny, D.; Palousek, D.; Pantelejev, L.; Hoeller, C.; Pichler, R.; Tesicky, L.; Kaiser, J. Influence of scanning strategies on processing of aluminum alloy EN AW 2618 using selective laser melting. Materials 2018, 11, 298. [Google Scholar] [CrossRef] [PubMed]

- Yasa, E.; Kruth, J.P. Microstructural investigation of selective laser melting 316 L stainless steel parts exposed to laser re-melting. Procedia Eng. 2011, 19, 389–395. [Google Scholar] [CrossRef]

- Uddin, S.Z.; Murr, L.E.; Terrazas, C.A.; Morton, P.; Roberson, D.A.; Wicker, R.B. Processing and characterization of crack-free aluminum 6061 using high-temperature heating in laser powder bed fusion additive manufacturing. Addit. Manuf. 2018, 22, 405–415. [Google Scholar] [CrossRef]

- Wu, D.; Liu, D.; Niu, F.; Miao, Q.; Zhao, K.; Tang, B.; Bi, G.; Ma, G. Al–Cu alloy fabricated by novel laser-tungsten inert gas hybrid additive manufacturing. Addit. Manuf. 2020, 32, 100954. [Google Scholar] [CrossRef]

- Liu, D.; Wu, D.; Wang, R.; Shi, J.; Niu, F.; Ma, G. Formation mechanism of Al-Zn-Mg-Cu alloy fabricated by laser-arc hybrid additive manufacturing: Microstructure evaluation and mechanical properties. Addit. Manuf. 2022, 50, 102554. [Google Scholar] [CrossRef]

- Skalicky, P.; Koutny, D.; Pantelejev, L.; Palousek, D. Processing of Aluminum Alloy En Aw 7075 Using Selective Laser Melting: Initial Study. In Proceedings of the 58th International Conference of Machine Design Departments (ICMD 2017), Prague, Czech Republic, 6–8 September 2017. [Google Scholar]

- Roberts, C.E.; Bourell, D.; Watt, T.; Cohen, J. A novel processing approach for additive manufacturing of commercial aluminum alloys. Phys. Procedia 2016, 83, 909–917. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, X.; Kang, N.; Wang, Z.; Wang, Q.; Liu, Y.; Huang, W. Laser powder bed fusion of Zr-modified Al–Cu–Mg alloy: Crack-inhibiting, grain refinement, and mechanical properties. Mater. Sci. Eng. A 2022, 838, 142618. [Google Scholar] [CrossRef]

- Mehta, A.; Zhou, L.; Huynh, T.; Park, S.; Hyer, H.; Song, S.; Bai, Y.; Imholte, D.D.; Woolstenhulme, N.E.; Wachs, D.M.; et al. Additive manufacturing and mechanical properties of the dense and crack free Zr-modified aluminum alloy 6061 fabricated by the laser-powder bed fusion. Addit. Manuf. 2021, 41, 101966. [Google Scholar] [CrossRef]

- Tian, S.; Li, J.; Zhang, J.; Wulabieke, Z.; Lv, D. Effect of Zr and Sc on microstructure and properties of 7136 aluminum alloy. J. Mater. Res. Technol. 2019, 8, 4130–4140. [Google Scholar] [CrossRef]

- Yang, K.V.; Shi, Y.; Palm, F.; Wu, X.; Rometsch, P. Columnar to equiaxed transition in Al-Mg(-Sc)-Zr alloys produced by selective laser melting. Scr. Mater. 2018, 145, 113–117. [Google Scholar] [CrossRef]

- Zhou, S.Y.; Su, Y.; Wang, H.; Enz, J.; Ebel, T.; Yan, M. Selective laser melting additive manufacturing of 7xxx series Al-Zn-Mg-Cu alloy: Cracking elimination by co-incorporation of Si and TiB2. Addit. Manuf. 2020, 36, 101458. [Google Scholar] [CrossRef]

- Montero Sistiaga, M.L.; Mertens, R.; Vrancken, B.; Wang, X.; Van Hooreweder, B.; Kruth, J.P.; Van Humbeeck, J. Changing the alloy composition of Al7075 for better processability by selective laser melting. J. Mater. Process. Technol. 2016, 238, 437–445. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Y.; Zhou, Z.; Zhan, Q. Enhanced strength and ductility in Al-Zn-Mg-Cu alloys fabricated by laser powder bed fusion using a synergistic grain-refining strategy. J. Mater. Sci. Technol. 2022, 124, 41–52. [Google Scholar] [CrossRef]

- Tan, Q.; Zhang, J.; Sun, Q.; Fan, Z.; Li, G.; Yin, Y.; Liu, Y.; Zhang, M.X. Inoculation treatment of an additively manufactured 2024 aluminium alloy with titanium nanoparticles. Acta Mater. 2020, 196, 1–16. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.; Mayer, J.; Mone, R.; Stonkevitch, E.; Miller, J.; O’Masta, M.R.; Schaedler, T.; Hundley, J.; Callahan, P.; et al. Grain refinement mechanisms in additively manufactured nano-functionalized aluminum. Acta Mater. 2020, 200, 1022–1037. [Google Scholar] [CrossRef]

- Guo, Y.; Wei, W.; Shi, W.; Zhang, B.; Zhou, X.; Wen, S.; Wu, X.; Gao, K.; Rong, L.; Huang, H.; et al. Effect of Er and Zr additions and aging treatment on grain refinement of aluminum alloy fabricated by laser powder bed fusion. J. Alloys Compd. 2022, 912, 165237. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Chen, X.; Qiu, C. Complete columnar-to-equiaxed transition and significant grain refinement in an aluminium alloy by adding Nb particles through laser powder bed fusion. Addit. Manuf. 2022, 51, 102615. [Google Scholar] [CrossRef]

- Xinwei, L.; Shi, S.; Shuang, H.; Xiaogang, H.; Qiang, Z.; Hongxing, L.; Wenwu, L.; Yusheng, S.; Hui, D. Microstructure, solidification behavior and mechanical properties of Al-Si-Mg-Ti/TiC fabricated by selective laser melting. Addit. Manuf. 2020, 34, 101326. [Google Scholar] [CrossRef]

- Xi, L.; Guo, S.; Gu, D.; Guo, M.; Lin, K. Microstructure development, tribological property and underlying mechanism of laser additive manufactured submicro-TiB2 reinforced Al-based composites. J. Alloys Compd. 2020, 819, 152980. [Google Scholar] [CrossRef]

- Wen, X.; Wang, Q.; Mu, Q.; Kang, N.; Sui, S.; Yang, H.; Lin, X.; Huang, W. Laser solid forming additive manufacturing TiB2 reinforced 2024Al composite: Microstructure and mechanical properties. Mater. Sci. Eng. A 2019, 745, 319–325. [Google Scholar] [CrossRef]

- Zhou, L.; Hyer, H.; Thapliyal, S.; Mishra, R.S.; McWilliams, B.; Cho, K.; Sohn, Y. Process-Dependent Composition, Microstructure, and Printability of Al-Zn-Mg and Al-Zn-Mg-Sc-Zr Alloys Manufactured by Laser Powder Bed Fusion. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2020, 51, 3215–3227. [Google Scholar] [CrossRef]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Galy, C.; Le Guen, E.; Lacoste, E.; Arvieu, C. Main defects observed in aluminum alloy parts produced by SLM: From causes to consequences. Addit. Manuf. 2018, 22, 165–175. [Google Scholar] [CrossRef]

- Aversa, A.; Marchese, G.; Saboori, A.; Bassini, E.; Manfredi, D.; Biamino, S.; Ugues, D.; Fino, P.; Lombardi, M. New aluminum alloys specifically designed for laser powder bed fusion: A review. Materials 2019, 12, 1007. [Google Scholar] [CrossRef]

- Kotadia, H.R.; Gibbons, G.; Das, A.; Howes, P.D. A review of Laser Powder Bed Fusion Additive Manufacturing of aluminium alloys: Microstructure and properties. Addit. Manuf. 2021, 46, 102155. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Yardley, V.A.; Shi, Z.; Lin, J. Challenges in additive manufacturing of high-strength aluminium alloys and current developments in hybrid additive manufacturing. Int. J. Light. Mater. Manuf. 2021, 4, 246–261. [Google Scholar] [CrossRef]

- Asnafi, N. Metal additive manufacturing—State of the art 2020. Metals 2021, 11, 867. [Google Scholar] [CrossRef]

- Davis, J.R. Aluminum and Aluminum Alloys, ASM Specialty Handbook; ASM International: Almere, The Netherlands, 1993. [Google Scholar]

- Luo, A.A. Recent advances in light metals and manufacturing for automotive applications. CIM J. 2021, 13, 79–87. [Google Scholar] [CrossRef]

- Boillat, R.; Isanaka, S.P.; Liou, F. The effect of nanostructures in aluminum alloys processed using additive manufacturing on microstructural evolution and mechanical performance behavior. Crystals 2021, 11, 524. [Google Scholar] [CrossRef]

- Nie, J.F.; Muddle, B.C. Microstructural design of high-strength aluminum alloys. J. Phase Equilibria 1998, 217, 1251–1256. [Google Scholar] [CrossRef]

- Zhang, X.; Deng, Y.; Zhang, Y. Development of high strength aluminum alloys and processing techniques for the materials. Jinshu Xuebao/Acta Metall. Sin. 2015, 51, 257–271. [Google Scholar] [CrossRef]

- METAL Supermarkets 7 Things to Consider When Choosing an Aluminum Grade. 2015. Available online: https://www.metalsupermarkets.com/7-things-consider-choosing-aluminum-grade/ (accessed on 19 January 2020).

- Oliveira, J.P.; LaLonde, A.D.; Ma, J. Processing parameters in laser powder bed fusion metal additive manufacturing. Mater. Des. 2020, 193, 108762. [Google Scholar] [CrossRef]

- Mosallanejad, M.H.; Niroumand, B.; Aversa, A.; Saboori, A. In-Situ alloying in laser-based additive manufacturing processes: A critical review. J. Alloys Compd. 2021, 872, 159567. [Google Scholar] [CrossRef]

- Dass, A.; Moridi, A. State of the art in directed energy deposition: From additive manufacturing to materials design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef]

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive manufacturing processes: Selective laser melting, electron beam melting and binder jetting-selection guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef]

- Campbell, I.; Bourell, D.; Gibson, I. Additive manufacturing: Rapid prototyping comes of age. Rapid Prototyp. J. 2012, 18, 255–258. [Google Scholar] [CrossRef]

- Xia, C.; Pan, Z.; Polden, J.; Li, H.; Xu, Y.; Chen, S.; Zhang, Y. A review on wire arc additive manufacturing: Monitoring, control and a framework of automated system. J. Manuf. Syst. 2020, 57, 31–45. [Google Scholar] [CrossRef]

- Panwisawas, C.; Tang, Y.T.; Reed, R.C. Metal 3D printing as a disruptive technology for superalloys. Nat. Commun. 2020, 11, 2327. [Google Scholar] [CrossRef]

- Qiu, C.; Kindi, M.A.; Aladawi, A.S.; Hatmi, I. Al a comprehensive study on microstructure and tensile behaviour of a selectively laser melted stainless steel. Sci. Rep. 2018, 8, 7785. [Google Scholar] [CrossRef]

- Sun, Z.; Tan, X.; Tor, S.B.; Yeong, W.Y. Selective laser melting of stainless steel 316L with low porosity and high build rates. Mater. Des. 2016, 104, 197–204. [Google Scholar] [CrossRef]

- Vikram, R.J.; Murty, B.S.; Fabijanic, D.; Suwas, S. Insights into micro-mechanical response and texture of the additively manufactured eutectic high entropy alloy AlCoCrFeNi2.1. J. Alloys Compd. 2020, 827, 154034. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Javidani, M.; Arreguin-Zavala, J.; Danovitch, J.; Tian, Y.; Brochu, M. Additive Manufacturing of AlSi10Mg Alloy Using Direct Energy Deposition: Microstructure and Hardness Characterization. J. Therm. Spray Technol. 2017, 26, 587–597. [Google Scholar] [CrossRef]

- Wang, M.; Song, B.; Wei, Q.; Zhang, Y.; Shi, Y. Effects of annealing on the microstructure and mechanical properties of selective laser melted AlSi7Mg alloy. Mater. Sci. Eng. A 2019, 739, 463–472. [Google Scholar] [CrossRef]

- Rao, J.H.; Zhang, Y.; Zhang, K.; Huang, A.; Davies, C.H.J.; Wu, X. Multiple precipitation pathways in an Al-7Si-0.6Mg alloy fabricated by selective laser melting. Scr. Mater. 2019, 160, 66–69. [Google Scholar] [CrossRef]

- Leary, M.; Mazur, M.; Elambasseril, J.; McMillan, M.; Chirent, T.; Sun, Y.; Qian, M.; Easton, M.; Brandt, M. Selective laser melting (SLM) of AlSi12Mg lattice structures. Mater. Des. 2016, 98, 344–357. [Google Scholar] [CrossRef]

- Louvis, E.; Fox, P.; Sutcliffe, C.J. Selective laser melting of aluminium components. J. Mater. Process. Technol. 2011, 211, 275–284. [Google Scholar] [CrossRef]

- Buchbinder, D.; Meiners, W.; Wissenbach, K.; Müller-Lohmeier, K.; Brandl, E.; Skrynecki, N. Rapid Manufacturing of Aluminium Parts for Serial Production Via Selective Laser Melting (SLM); International Conference on Rapid Manufacturing: Loughborough, UK, 2008. [Google Scholar]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.; Yan, C.; Shi, Y. Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture mechanism. Mater. Sci. Eng. A 2016, 663, 116–125. [Google Scholar] [CrossRef]

- Asgari, H.; Baxter, C.; Hosseinkhani, K.; Mohammadi, M. On microstructure and mechanical properties of additively manufactured AlSi10Mg_200C using recycled powder. Mater. Sci. Eng. A 2017, 707, 148–158. [Google Scholar] [CrossRef]

- Ansari, P.; Salamci, M.U. On the selective laser melting based additive manufacturing of AlSi10Mg: The process parameter investigation through multiphysics simulation and experimental validation. J. Alloys Compd. 2022, 890, 161873. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Pakkanen, J.; Aversa, A.; Ambrosio, E.P.; Lombardi, M.; Fino, P.; Manfredi, D. On the selective laser melting (SLM) of the AlSi10Mg alloy: Process, microstructure, and mechanical properties. Materials 2017, 10, 76. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Van Humbeeck, J.; Kruth, J.P. Mechanical Properties of AlSi10Mg Produced by Selective Laser Melting. Phys. Procedia 2012, 39, 439–446. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. The microstructure and mechanical properties of selectively laser melted AlSi10Mg: The effect of a conventional T6-like heat treatment. Mater. Sci. Eng. A 2016, 667, 139–146. [Google Scholar] [CrossRef]

- Wang, X.J.; Zhang, L.C.; Fang, M.H.; Sercombe, T.B. The effect of atmosphere on the structure and properties of a selective laser melted Al-12Si alloy. Mater. Sci. Eng. A 2014, 597, 370–375. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.Q.; Wang, W.; Attallah, M.M.; Loretto, M.H. Microstructure and strength of selectively laser melted AlSi10Mg. Acta Mater. 2016, 117, 311–320. [Google Scholar] [CrossRef]

- Van Cauwenbergh, P.; Samaee, V.; Thijs, L.; Nejezchlebová, J.; Sedlák, P.; Iveković, A.; Schryvers, D.; Van Hooreweder, B.; Vanmeensel, K. Unravelling the multi-scale structure–property relationship of laser powder bed fusion processed and heat-treated AlSi10Mg. Sci. Rep. 2021, 11, 6423. [Google Scholar] [CrossRef]

- Kaufman, J.G. Properties of Aluminum Alloys: Tensile Creep and Fatigue Data at High and Low Temperatures; ASM International: Almere, The Netherlands, 1999. [Google Scholar]

- Lumley, R.N. Technical Data Sheets for Heat-Treated Aluminum High-Pressure Die Castings. Die Cast. Eng. 2008, 32, 1–36. [Google Scholar]

- ASM International Handbook Committee. Properties and Selection: Nonferrous Alloys and Special-Purpose Materials; ASM International: Almere, The Netherlands, 1990. [Google Scholar]

- Wang, L.; Gao, M.; Zhang, C.; Zeng, X. Effect of beam oscillating pattern on weld characterization of laser welding of AA6061-T6 aluminum alloy. Mater. Des. 2016, 108, 707–717. [Google Scholar] [CrossRef]

- Fulcher, B.A.; Leigh, D.K.; Watt, T.J. Comparison of ALSI10MG and AL 6061 processed through DMLS. In Proceedings of the 25th Annual International Solid Freeform Fabrication Symposium: An Additive Manufacturing Conference, Austin, TX, USA, 4–6 August 2014; SFF. 2014. [Google Scholar]

- Cicalǎ, E.; Duffet, G.; Andrzejewski, H.; Grevey, D.; Ignat, S. Hot cracking in Al-Mg-Si alloy laser welding-Operating parameters and their effects. Mater. Sci. Eng. A 2005, 395, 1–9. [Google Scholar] [CrossRef]

- Loh, L.E.; Liu, Z.H.; Zhang, D.Q.; Mapar, M.; Sing, S.L.; Chua, C.K.; Yeong, W.Y. Selective Laser Melting of aluminium alloy using a uniform beam profile. Virtual Phys. Prototyp. 2014, 9, 11–16. [Google Scholar] [CrossRef]

- Ding, Y.; Muñiz-Lerma, J.A.; Trask, M.; Chou, S.; Walker, A.; Brochu, M. Microstructure and mechanical property considerations in additive manufacturing of aluminum alloys. MRS Bull. 2016, 41, 745–751. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Nie, X.; Qi, T.; Hu, Z.; Zeng, X. Fabrication and heat treatment of high strength Al-Cu-Mg alloy processed using selective laser melting. Laser 3D Manuf. III 2016, 9738, 97380X. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Ghaini, F.M.; Sheikhi, M.; Torkamany, M.J.; Sabbaghzadeh, J. The relation between liquation and solidification cracks in pulsed laser welding of 2024 aluminium alloy. Mater. Sci. Eng. A 2009, 519, 167–171. [Google Scholar] [CrossRef]

- Pellini, W.S. Strain theory of hot tearing. Foundry 1952, 80, 125–133. [Google Scholar]

- Soysal, T.; Kou, S. A simple test for assessing solidification cracking susceptibility and checking validity of susceptibility prediction. Acta Mater. 2018, 143, 181–197. [Google Scholar] [CrossRef]

- Xu, R.; Li, R.; Yuan, T.; Niu, P.; Wang, M.; Lin, Z. Microstructure, metallurgical defects and hardness of Al–Cu–Mg–Li–Zr alloy additively manufactured by selective laser melting. J. Alloys Compd. 2020, 835, 155372. [Google Scholar] [CrossRef]

- Liu, S.; Hong, K.M.; Shin, Y.C. A novel 3D cellular automata-phase field model for computationally efficient dendrite evolution during bulk solidification. Comput. Mater. Sci. 2021, 192, 110405. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Prediction of 3D microstructure and phase distributions of Ti6Al4V built by the directed energy deposition process via combined multi-physics models. Addit. Manuf. 2020, 34, 101234. [Google Scholar] [CrossRef]

- Katgerman, D.L.; Eskin, D.G. In search of the prediction of hot cracking in aluminium alloys. In Hot Cracking Phenomena in Welds II; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Fischer, P.; Karapatis, N.; Romano, V.; Glardon, R.; Weber, H.P. A model for the interaction of near-infrared laser pulses with metal powders in selective laser sintering. Appl. Phys. A Mater. Sci. Process. 2002, 74, 467–474. [Google Scholar] [CrossRef]

- Li, Y.; Gu, D.; Zhang, H.; Xi, L. Effect of Trace Addition of Ceramic on Microstructure Development and Mechanical Properties of Selective Laser Melted AlSi10Mg Alloy. Chin. J. Mech. Eng. 2020, 33, 33. [Google Scholar] [CrossRef]

- Yang, K.V.; Rometsch, P.; Jarvis, T.; Rao, J.; Cao, S.; Davies, C.; Wu, X. Porosity formation mechanisms and fatigue response in Al-Si-Mg alloys made by selective laser melting. Mater. Sci. Eng. A 2018, 712, 166–174. [Google Scholar] [CrossRef]

- Weingarten, C.; Buchbinder, D.; Pirch, N.; Meiners, W.; Wissenbach, K.; Poprawe, R. Formation and reduction of hydrogen porosity during selective laser melting of AlSi10Mg. J. Mater. Process. Technol. 2015, 221, 112–120. [Google Scholar] [CrossRef]

- Dai, D.; Gu, D. Effect of metal vaporization behavior on keyhole-mode surface morphology of selective laser melted composites using different protective atmospheres. Appl. Surf. Sci. 2015, 355, 310–319. [Google Scholar] [CrossRef]

- Bayoumy, D.; Schliephake, D.; Dietrich, S.; Wu, X.H.; Zhu, Y.M.; Huang, A.J. Intensive processing optimization for achieving strong and ductile Al-Mn-Mg-Sc-Zr alloy produced by selective laser melting. Mater. Des. 2021, 198, 109317. [Google Scholar] [CrossRef]

- Nie, X.; Zhang, H.; Zhu, H.; Hu, Z.; Zeng, X. The effect of processing parameter on zirconium modified Al-Cu-Mg alloys fabricated by selective laser melting. In Proceedings of the Solid Freeform Fabrication 2018: Proceedings of the 29th Annual International, Solid Freeform Fabrication Symposiu—An Additive Manufacturing Conference; Austin, TX, USA, 13–15 August 2018, pp. 1246–1252.

- Maamoun, A.H.; Xue, Y.F.; Elbestawi, M.A.; Veldhuis, S.C. The effect of selective laser melting process parameters on the microstructure and mechanical properties of Al6061 and AlSi10Mg alloys. Materials 2018, 12, 12. [Google Scholar] [CrossRef]

- Qbau, N.; Nam, N.D.; Ca, N.X.; Hien, N.T. The crack healing effect of scandium in aluminum alloys during laser additive manufacturing. J. Manuf. Process. 2020, 50, 241–246. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, S.; Gan, Y.; Huang, T.; Yang, C.; Junjie, L.; Lin, J. Study on the microstructure, mechanical property and residual stress of SLM Inconel-718 alloy manufactured by differing island scanning strategy. Opt. Laser Technol. 2015, 75, 197–206. [Google Scholar] [CrossRef]

- Chen, C.; Yin, J.; Zhu, H.; Xiao, Z.; Zhang, L.; Zeng, X. Effect of overlap rate and pattern on residual stress in selective laser melting. Int. J. Mach. Tools Manuf. 2019, 145, 103433. [Google Scholar] [CrossRef]

- Sealy, M.P.; Madireddy, G.; Williams, R.E.; Rao, P.; Toursangsaraki, M. Hybrid processes in additive manufacturing. J. Manuf. Sci. Eng. Trans. ASME 2018, 140, 060801. [Google Scholar] [CrossRef]

- Wang, Z.; Oliveira, J.P.; Zeng, Z.; Bu, X.; Peng, B.; Shao, X. Laser beam oscillating welding of 5A06 aluminum alloys: Microstructure, porosity and mechanical properties. Opt. Laser Technol. 2019, 111, 58–65. [Google Scholar] [CrossRef]

- Yu, W.; Sing, S.L.; Chua, C.K.; Tian, X. Influence of re-melting on surface roughness and porosity of AlSi10Mg parts fabricated by selective laser melting. J. Alloys Compd. 2019, 792, 574–581. [Google Scholar] [CrossRef]

- Han, Q.; Jiao, Y. Effect of heat treatment and laser surface remelting on AlSi10Mg alloy fabricated by selective laser melting. Int. J. Adv. Manuf. Technol. 2019, 102, 3315–3324. [Google Scholar] [CrossRef]

- Schmidt, J.; Scholz, R.; Riegel, H. Laser polishing of aluminum by remelting with high energy pulses. Materwiss. Werksttech. 2015, 46, 686–691. [Google Scholar] [CrossRef]

- Damon, J.; Dietrich, S.; Vollert, F.; Gibmeier, J.; Schulze, V. Process dependent porosity and the influence of shot peening on porosity morphology regarding selective laser melted AlSi10Mg parts. Addit. Manuf. 2018, 20, 458–464. [Google Scholar] [CrossRef]

- Teng, X.; Zhang, G.; Zhao, Y.; Cui, Y.; Li, L.; Jiang, L. Study on magnetic abrasive finishing of AlSi10Mg alloy prepared by selective laser melting. Int. J. Adv. Manuf. Technol. 2019, 105, 2513–2521. [Google Scholar] [CrossRef]

- Mahmood, M.A.; Chioibasu, D.; Rehman, A.U.; Mihai, S.; Popescu, A.C. Post-Processing Techniques to Enhance the Quality of Metallic Parts Produced by Additive Manufacturing. Metals 2022, 12, 77. [Google Scholar] [CrossRef]

- Peng, X.; Kong, L.; Fuh, J.Y.H.; Wang, H. A review of post-processing technologies in additive manufacturing. J. Manuf. Mater. Process. 2021, 5, 38. [Google Scholar] [CrossRef]

- Shiyas, K.A.; Ramanujam, R. A review on post processing techniques of additively manufactured metal parts for improving the material properties. Mater. Today Proc. 2021, 46, 1429–1436. [Google Scholar] [CrossRef]

- Ye, C.; Zhang, C.; Zhao, J.; Dong, Y. Effects of Post-processing on the Surface Finish, Porosity, Residual Stresses, and Fatigue Performance of Additive Manufactured Metals: A Review. J. Mater. Eng. Perform. 2021, 30, 6407–6425. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.F.; Sun, J.; Yu, X.L.; Shi, Y.; Zhu, X.G.; Cheng, L.Y.; Liang, H.H.; Yan, B.; Guo, L.J. Enhancement in mechanical properties of selectively laser-melted AlSi10Mg aluminum alloys by T6-like heat treatment. Mater. Sci. Eng. A 2018, 734, 299–310. [Google Scholar] [CrossRef]

- Schuster, M.; De Luca, A.; Widmer, R.; Maeder, X.; Leinenbach, C. Processability, microstructure and precipitation of a Zr-modified 2618 aluminium alloy fabricated by laser powder bed fusion. J. Alloys Compd. 2022, 913, 165346. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Elbestawi, M.; Dosbaeva, G.K.; Veldhuis, S.C. Thermal post-processing of AlSi10Mg parts produced by Selective Laser Melting using recycled powder. Addit. Manuf. 2018, 21, 234–247. [Google Scholar] [CrossRef]

- Otani, Y.; Sasaki, S. Effects of the addition of silicon to 7075 aluminum alloy on microstructure, mechanical properties, and selective laser melting processability. Mater. Sci. Eng. A 2020, 777, 139079. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, J.; Song, B.; Zhang, L.; Han, C.; Cai, C.; Zhou, K.; Shi, Y. A novel crack-free Ti-modified Al-Cu-Mg alloy designed for selective laser melting. Addit. Manuf. 2021, 38, 101829. [Google Scholar] [CrossRef]

- Li, X.; Li, G.; Zhang, M.X.; Zhu, Q. Novel approach to additively manufacture high-strength Al alloys by laser powder bed fusion through addition of hybrid grain refiners. Addit. Manuf. 2021, 48, 102400. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, X.; Kang, N.; Wang, Z.; Liu, Y.; Huang, W. Influence of post-heat treatment on the microstructure and mechanical properties of Al-Cu-Mg-Zr alloy manufactured by selective laser melting. J. Mater. Sci. Technol. 2022, 111, 35–48. [Google Scholar] [CrossRef]

- Nie, X.; Zhang, H.; Zhu, H.; Hu, Z.; Ke, L.; Zeng, X. Effect of Zr content on formability, microstructure and mechanical properties of selective laser melted Zr modified Al-4.24Cu-1.97Mg-0.56Mn alloys. J. Alloys Compd. 2018, 764, 977–986. [Google Scholar] [CrossRef]

- Zhou, L.; Pan, H.; Hyer, H.; Park, S.; Bai, Y.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure and tensile property of a novel AlZnMgScZr alloy additively manufactured by gas atomization and laser powder bed fusion. Scr. Mater. 2019, 158, 24–28. [Google Scholar] [CrossRef]

- Koutny, D.; Skulina, D.; Pantělejev, L.; Paloušek, D.; Lenczowski, B.; Palm, F.; Nick, A. Processing of Al-Sc aluminum alloy using SLM technology. Procedia CIRP 2018, 74, 44–48. [Google Scholar] [CrossRef]

- Qi, T.; Zhu, H.; Zeng, X.; Yin, J. Effect of Si content on the cracking behavior of selective laser melted Al7050. Rapid Prototyp. J. 2019, 25, 1592–1600. [Google Scholar] [CrossRef]

- John, E. Hatch Aluminum: Properties and Physical Metallurgy; ASM International: Almere, The Netherlands, 1984. [Google Scholar]

- Gäumann, M.; Trivedi, R.; Kurz, W. Nucleation ahead of the advancing interface in directional solidification. Mater. Sci. Eng. A 1997, 226, 763–769. [Google Scholar] [CrossRef]

- Men, H.; Fan, Z. Effects of solute content on grain refinement in an isothermal melt. Acta Mater. 2011, 59, 2704–2712. [Google Scholar] [CrossRef]

- Zedalis, M.; Fine, M.E. Lattice parameter variation of Al3 (Ti, V, Zr, Hf) in Al-2 AT.% (Ti, V, Zr, Hf) alloys. Scr. Metall. 1983, 17, 1247–1251. [Google Scholar] [CrossRef]

- Wang, P.; Gammer, C.; Brenne, F.; Niendorf, T.; Eckert, J.; Scudino, S. A heat treatable TiB2/Al-3.5Cu-1.5Mg-1Si composite fabricated by selective laser melting: Microstructure, heat treatment and mechanical properties. Compos. Part B Eng. 2018, 147, 162–168. [Google Scholar] [CrossRef]

- Zhang, J.; Yuan, W.; Song, B.; Yin, S.; Wang, X.; Wei, Q.; Shi, Y. Towards understanding metallurgical defect formation of selective laser melted wrought aluminum alloys. Adv. Powder Mater. 2022, 1, 100035. [Google Scholar] [CrossRef]

- Nicholls, R.J.; Ni, N.; Lozano-Perez, S.; London, A.; McComb, D.W.; Nellist, P.D.; Grovenor, C.R.M.; Pickard, C.J.; Yates, J.R. Crystal structure of the ZrO phase at zirconium/zirconium oxide interfaces. Adv. Eng. Mater. 2015, 17, 211–215. [Google Scholar] [CrossRef]

- Opprecht, M.; Garandet, J.P.; Roux, G.; Flament, C.; Soulier, M. A solution to the hot cracking problem for aluminium alloys manufactured by laser beam melting. Acta Mater. 2020, 197, 40–53. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef] [PubMed]

- Zakharov, V.V. Effect of scandium on the structure and properties of aluminum alloys. Met. Sci. Heat Treat. 2003, 45, 246–253. [Google Scholar] [CrossRef]

- Bi, J.; Lei, Z.; Chen, Y.; Chen, X.; Tian, Z.; Liang, J.; Zhang, X.; Qin, X. Microstructure and mechanical properties of a novel Sc and Zr modified 7075 aluminum alloy prepared by selective laser melting. Mater. Sci. Eng. A 2019, 768, 138478. [Google Scholar] [CrossRef]

- Wang, P.; Yang, Y.; Moghaddam, N.S. Process modeling in laser powder bed fusion towards defect detection and quality control via machine learning: The state-of-the-art and research challenges. J. Manuf. Process. 2022, 73, 961–984. [Google Scholar] [CrossRef]

- Fu, Y.; Downey, A.R.J.; Yuan, L.; Zhang, T.; Pratt, A.; Balogun, Y. Machine learning algorithms for defect detection in metal laser-based additive manufacturing: A review. J. Manuf. Process. 2022, 75, 693–710. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; Ramos-Grez, J.A.; Walczak, M.; Betancourt, C.A. Comparative evaluation of supervised machine learning algorithms in the prediction of the relative density of 316L stainless steel fabricated by selective laser melting. Int. J. Adv. Manuf. Technol. 2021, 113, 419–433. [Google Scholar] [CrossRef]

- Aoyagi, K.; Wang, H.; Sudo, H.; Chiba, A. Simple method to construct process maps for additive manufacturing using a support vector machine. Addit. Manuf. 2019, 27, 353–362. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, H.; Paul, M.J.; He, P.; Peng, Z.; Gludovatz, B.; Kruzic, J.J.; Wang, C.H.; Li, X. Machine-learning assisted laser powder bed fusion process optimization for AlSi10Mg: New microstructure description indices and fracture mechanisms. Acta Mater. 2020, 201, 316–328. [Google Scholar] [CrossRef]

- Paulson, N.H.; Gould, B.; Wolff, S.J.; Stan, M.; Greco, A.C. Correlations between thermal history and keyhole porosity in laser powder bed fusion. Addit. Manuf. 2020, 34, 101213. [Google Scholar] [CrossRef]

- Muhammad, W.; Brahme, A.P.; Ibragimova, O.; Kang, J.; Inal, K. A machine learning framework to predict local strain distribution and the evolution of plastic anisotropy & fracture in additively manufactured alloys. Int. J. Plast. 2021, 136, 102867. [Google Scholar] [CrossRef]

- Fang, L.; Cheng, L.; Glerum, J.A.; Bennett, J.; Cao, J.; Wagner, G.J. Data-driven analysis of process, structure, and properties of additively manufactured Inconel 718 thin walls. NPJ Comput. Mater. 2022, 8, 126. [Google Scholar] [CrossRef]

| Density, g/cm3 | Cost, $/lb. | Applications | Limitations | |

|---|---|---|---|---|

| Steel | 7.75–8.05 | 0.35–0.42 | The main body and chassis structural materials | High density, low strength-to-mass ratio |

| Al | 2.7 | 1.6 | Engine blocks, transmission casings, wheels, vehicle hoods, fenders (exterior components) | Lower strength than high-strength steels |

| Mg | 1.74 | 2.7 | Steering wheels, seat structures, instrument panels (interior components) | Low creep resistance, galvanic corrosion |

| Ti | 4.51 | 30 | Connecting rods, valves, camshafts, exhaust systems | High cost |

| Grade | Alloy # | Weldability | Castability | Heat-Treatability | Strength |

|---|---|---|---|---|---|

| Cast Al | AlSi10Mg | Excellent | Good | Yes | Medium |

| AlSi7Mg | Excellent | Excellent | Yes | Medium | |

| 1xxx | 1100 | Excellent | Good | No | Low |

| 2xxx | 2011 | Poor | Excellent | Yes | High |

| 2024 | Poor | Good | Yes | High | |

| 2618 | Poor | Good | Yes | High | |

| 3xxx | 3003 | Excellent | Good | No | Medium |

| 4xxx | 4043 | Excellent | Good | No | Medium |

| 5xxx | 5052 | Good | Fair | No | Medium |

| 6xxx | 6061 | Good | Good | Yes | Medium |

| 6063 | Good | Fair | Yes | Medium | |

| 7xxx | 7075 | Poor | Fair | Yes | High |

| 8xxx | 8090 | Fair | Fair | No | High |

| Al Alloys | AM Methods | Conditions | References |

|---|---|---|---|

| AlSi10Mg | LPBF, DED | As printed | [80,81] |

| AlSi7Mg | LPBF | As printed | [82] |

| Al7Si0.6Mg | LPBF | As printed | [83] |

| AlSi12Mg | LPBF | As printed | [84] |

| AA6061 | Hybrid AM | Powder-bed preheating | [38] |

| AA2219 | Hybrid AM | Single track | [39] |

| AA7075 | Hybrid AM | Singletrack | [40] |

| Manufacturing Condition | YS, MPa | UTS, MPa | εbreak, % | Reference |

|---|---|---|---|---|

| As-built LPBF AlSi10Mg | 322.17 ± 8.1 | 434.25 ± 10.7 | 5.3 ± 0.22 | [87] |

| As-built LPBF AlSi10Mg after 450 °C solution for 2 h | 196.58 ± 3.6 | 282.36 ± 6.1 | 13.4 ± 0.51 | [87] |

| As-built LPBF AlSi10Mg after 500 °C solution for 2 h | 126.00 ± 2.1 | 213.75 ± 4.6 | 23.5 ± 0.81 | [87] |

| As-built LPBF AlSi10Mg after 550 °C solution for 2 h | 90.52 ± 1.6 | 168.11 ± 2.4 | 23.7 ± 0.84 | [87] |

| High-pressure die casting | 175 | 300–350 | 3–5 | [96] |

| High-pressure die casting after T6 aging heat treatment | - | 330–365 | 3–5 | [97] |

| Wrought AA6061-O | 55 | 124 | 30 | [98] |

| Wrought AA6061 after T6 treatment | 276 | 310 | 12 | [98] |

| Manufacturing Condition | YS, MPa | UTS, MPa | εbreak, % | Reference |

|---|---|---|---|---|

| Heated powder bed-LPBF-built AA6061 | 70.5 | 137 | 13 | [38] |

| Heated powder bed-LPBF-built AA6061-T6 | 286 | 313 | 4.45 | |

| Wrought AA6061-O | 55 | 124 | 30 | |

| Wrought AA6061 after T6 treatment | 276 | 310 | 12 |

| Alloying Element | Alloy Series | Manufacturing Condition | YS (MPa) | UTS (MPa) | Elongation (%) | References |

|---|---|---|---|---|---|---|

| 5 wt.% Si | 7075 | As printed | 360 | 537 | 9.7 | [138] |

| 50 wt.% AlSi10Mg | 6061 | As printed | 219.25 | 353.01 | 7.3 | [26] |

| 4wt.% Si + 2 wt.% TiB2 | 7xxx | As printed | 361 | 445 | 2.9 | [47] |

| 4wt.% Si + 2 wt.% TiB2 | 7xxx | T6-heat treated | 453 | 541 | 5.3 | [47] |

| 1.5 wt.% Ti | 2xxx | As printed | 293 | 426 | 9.1 | [139] |

| 1.82 wt.% Ti | 7xxx | As printed | - | 427 | 3.9 | [140] |

| 2 wt.% Ti/TiN | 7xxx | As printed | - | 540–550 | 10 | [140] |

| 4 wt.% Ti/TiN | 7xxx | As printed | - | 595–613 | 8.8 | [140] |

| 6 wt.% Ti/TiN | 7xxx | As printed | - | 390–402 | 13.6 | [140] |

| 2 wt.% Ti/TiC | 6xxx | As printed | - | 562 | 8.8 | [54] |

| 3 wt.% TiB2 | 2xxx | As printed | 163 | 284 | 18.7 | [56] |

| 1.3 wt.%Zr | 2xxx | As printed | 376 | 441 | 14.1 | [141] |

| 1.3 wt.%Zr | 2xxx | STA | 402 | 483 | 6.9 | [141] |

| 1.3 wt.%Zr | 2xxx | DA | 435 | 445 | 7.5 | [141] |

| 1.3 wt.% Zr | 2xxx | As printed | 376 ± 7 | 441 ± 7 | 14.1 ± 1.6 | [43] |

| 1.3 wt.% Zr | 2xxx | T6-heat treated | 402 ± 9 | 483 ± | 6.9 ± 1.8 | [43] |

| 1 wt.% Zr | 6xxx | As printed | 210 | 268 | 26.5 | [44] |

| 1 wt.% Zr | 6xxx | T6- heat treated | 300 | 327 | 14 | [44] |

| 0.5 wt.% Zr | 2xxx | As printed | 293 | 448 | 11.8 | [142] |

| 2 wt.% Zr | 2xxx | As printed | 464.06 ± 2.04 | 493.3 ± 10.45 | 4.76 ± | [142] |

| 1 wt.% (Sc + Zr) | 7xxx | As printed | 283 | 385 | 18.4 | [143] |

| 1 wt.% (Sc + Zr) | 7xxx | T6-heat treated | 418.3 | 435.7 | 11.1 | [143] |

| 0.15 wt.% Sc | 6xxx | As printed | 300 | 350 | 31 | [121] |

| 1.1 wt.% Sc +0.42 wt.% Zr | Scalmalloy | As printed | 306 | 334 | 12.2 | [144] |

| Wrought | 2024 | T6-heat treated | 393 | 476 | 10 | [34] |

| Wrought | 6061 | T6-heat treated | 276 | 310 | 12 | [98] |

| Wrought | 7075 | T6-heat treated | 480–505 | 560–572 | 8–11 | [98] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dixit, S.; Liu, S. Laser Additive Manufacturing of High-Strength Aluminum Alloys: Challenges and Strategies. J. Manuf. Mater. Process. 2022, 6, 156. https://doi.org/10.3390/jmmp6060156

Dixit S, Liu S. Laser Additive Manufacturing of High-Strength Aluminum Alloys: Challenges and Strategies. Journal of Manufacturing and Materials Processing. 2022; 6(6):156. https://doi.org/10.3390/jmmp6060156

Chicago/Turabian StyleDixit, Som, and Shunyu Liu. 2022. "Laser Additive Manufacturing of High-Strength Aluminum Alloys: Challenges and Strategies" Journal of Manufacturing and Materials Processing 6, no. 6: 156. https://doi.org/10.3390/jmmp6060156

APA StyleDixit, S., & Liu, S. (2022). Laser Additive Manufacturing of High-Strength Aluminum Alloys: Challenges and Strategies. Journal of Manufacturing and Materials Processing, 6(6), 156. https://doi.org/10.3390/jmmp6060156