The Post-Processing of Additive Manufactured Polymeric and Metallic Parts

Abstract

1. Introduction

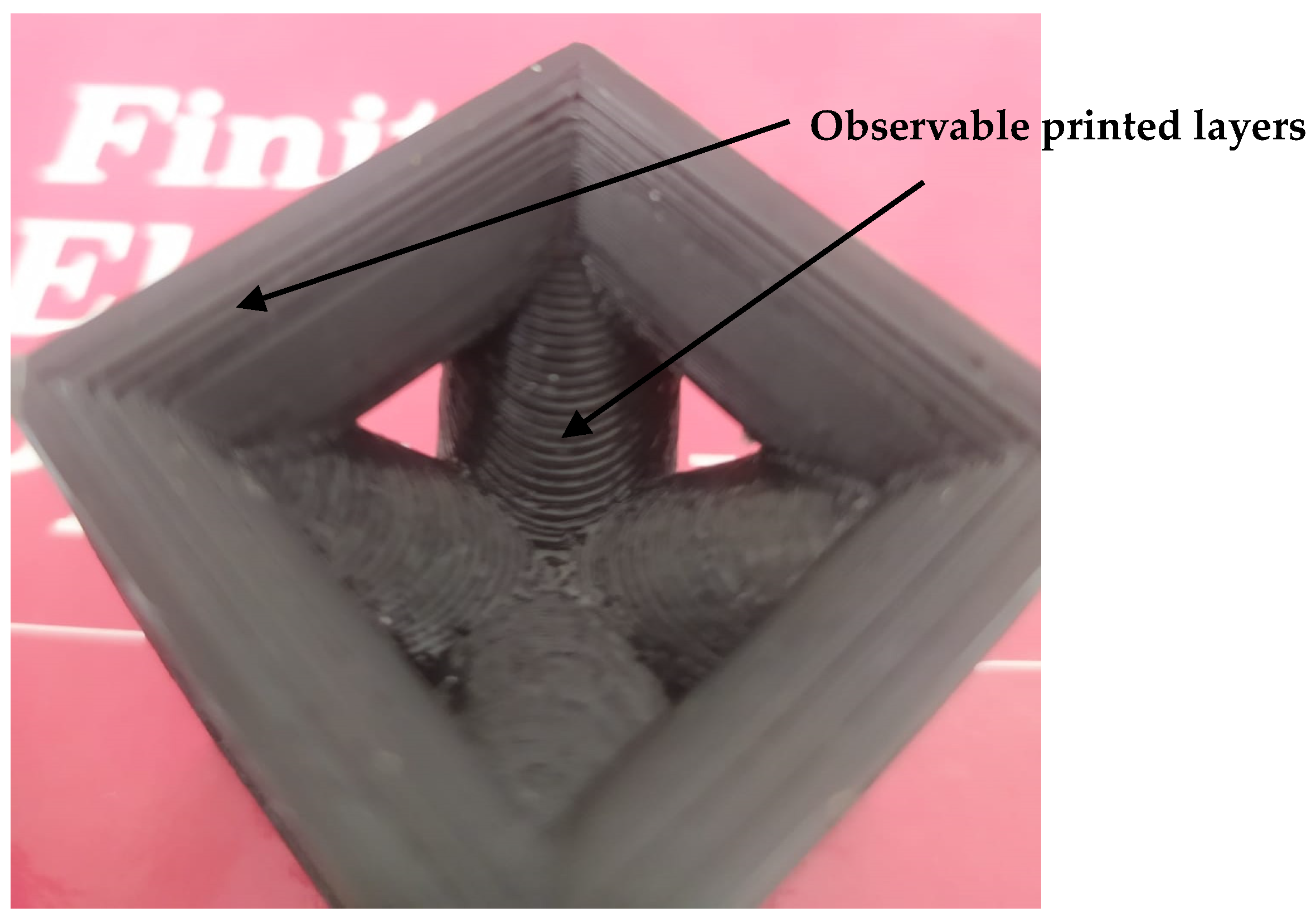

2. Finishing of the Polymer Parts

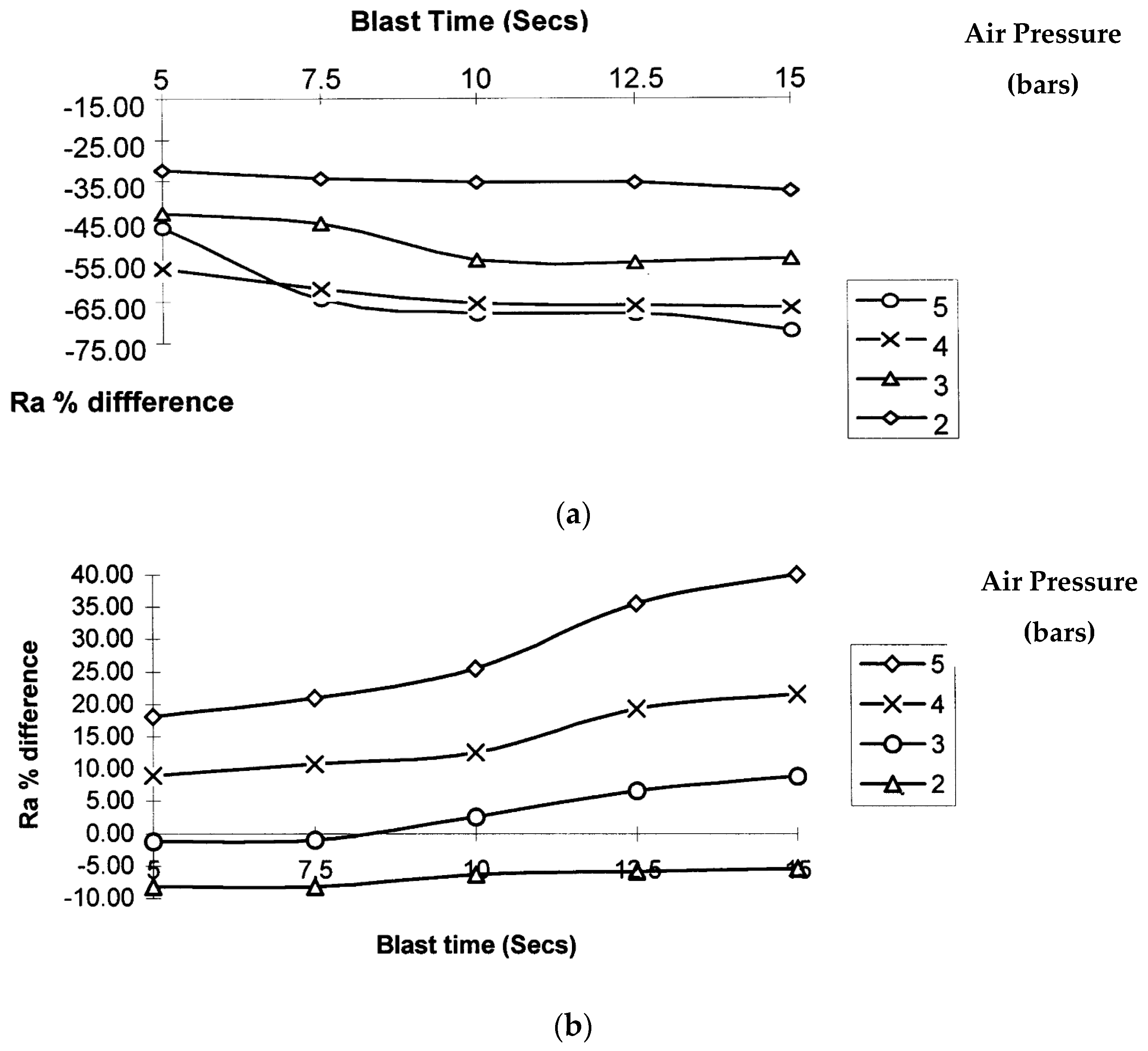

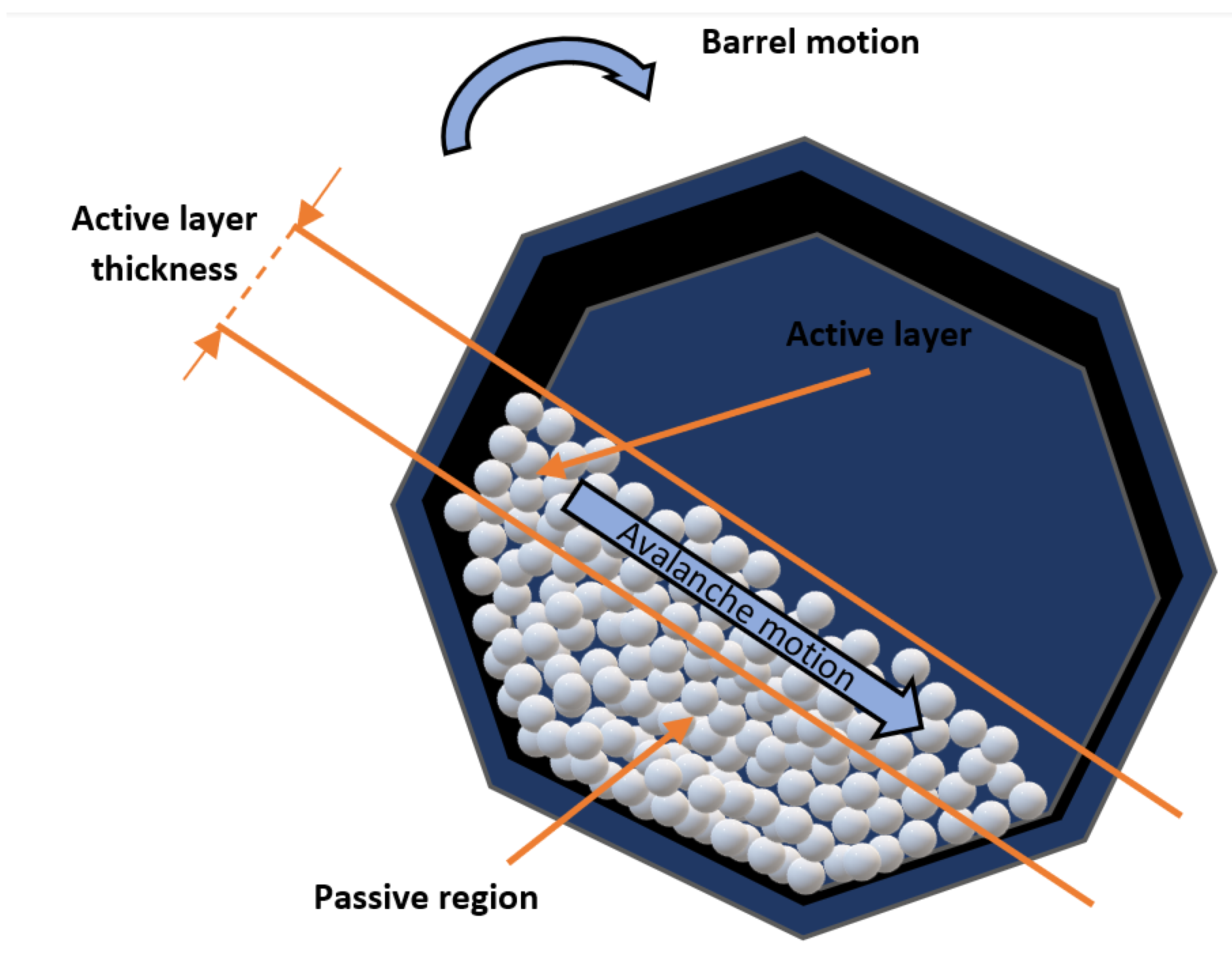

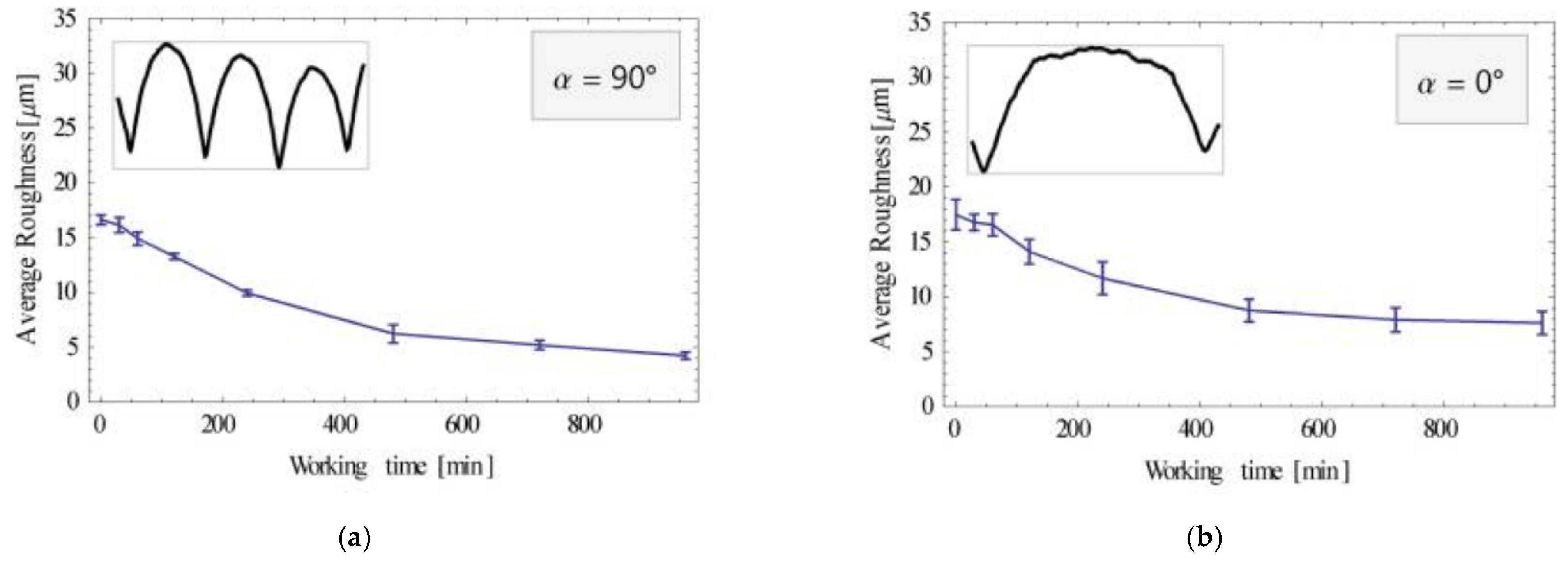

2.1. Mechanical Abrasion

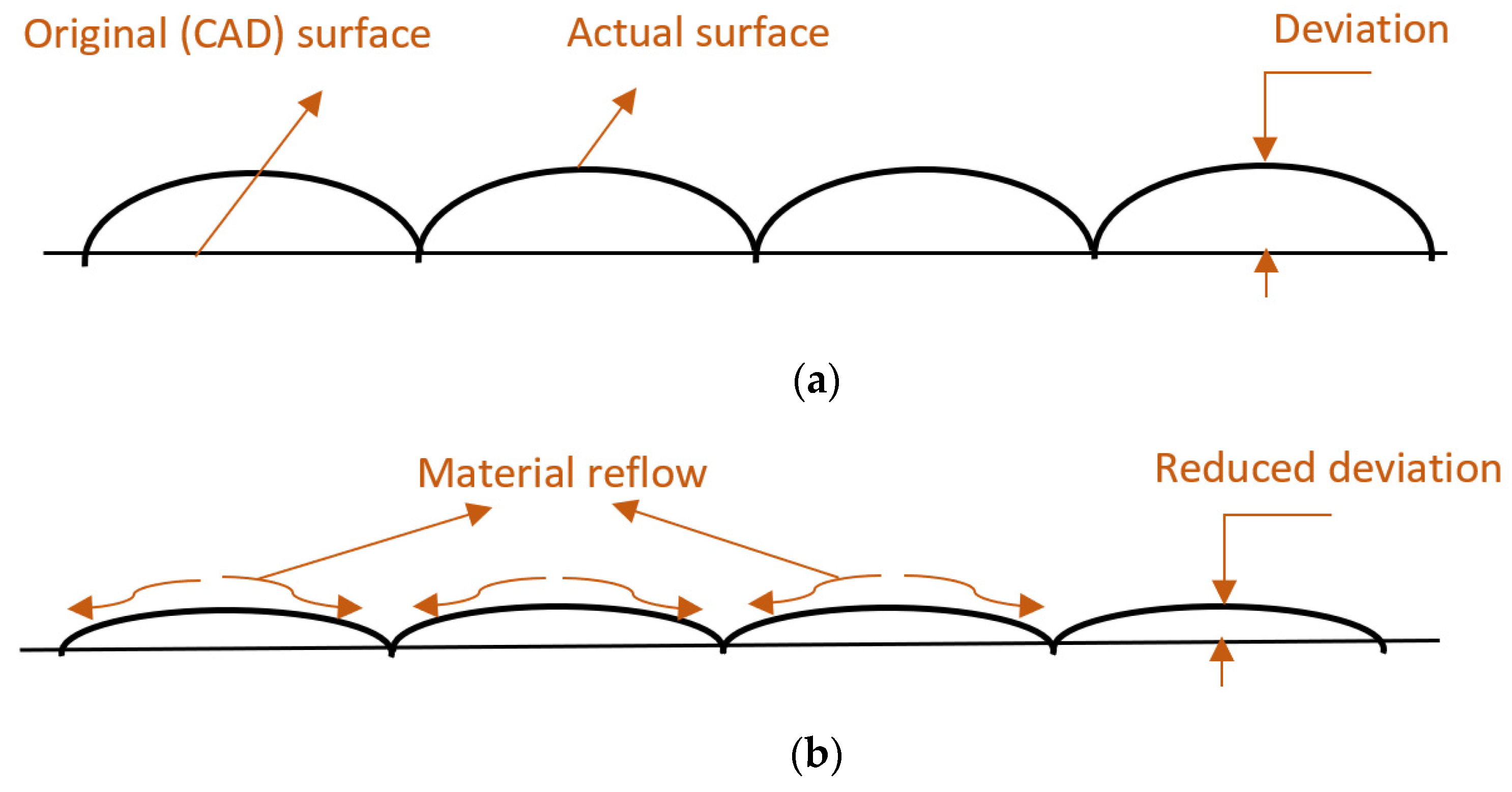

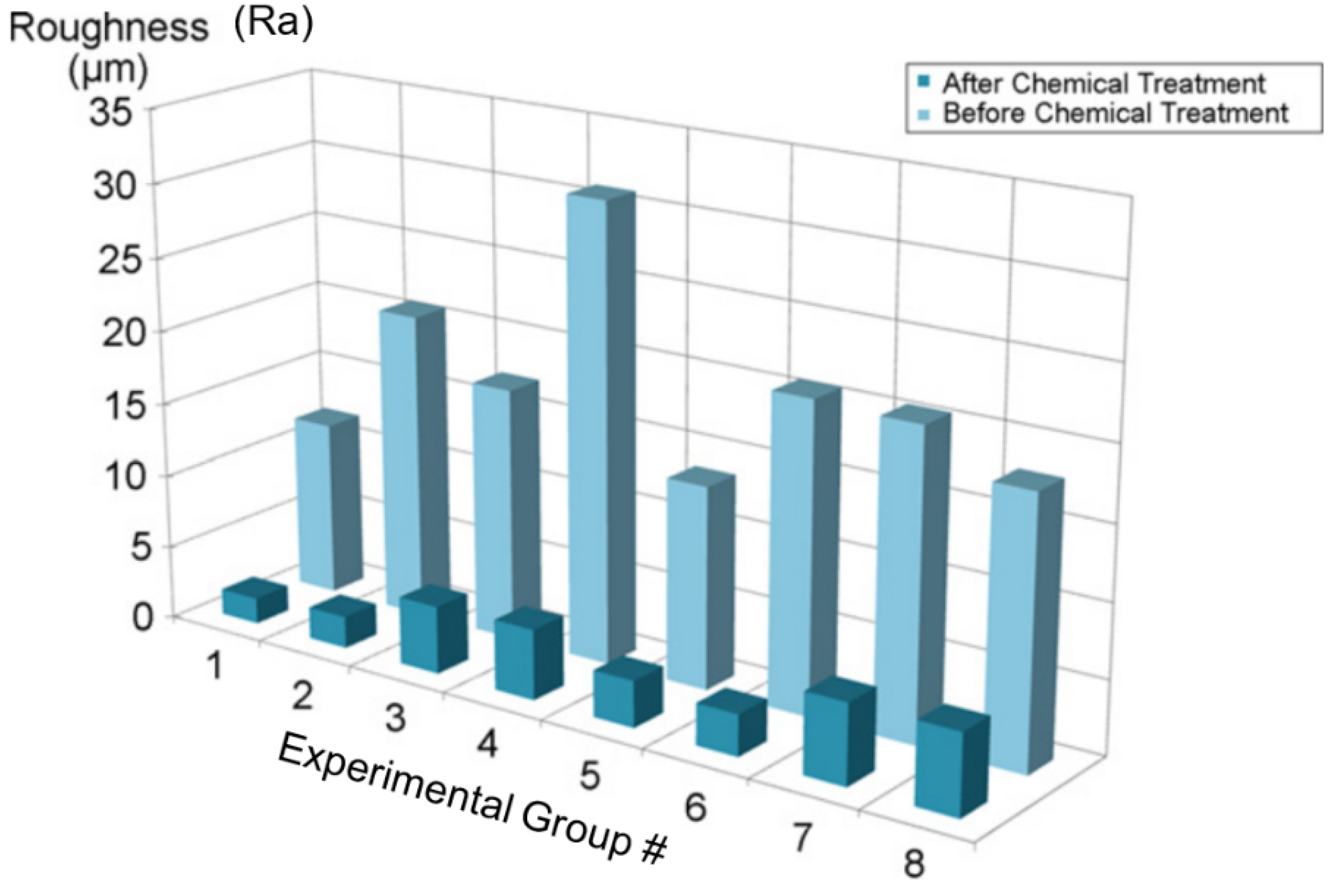

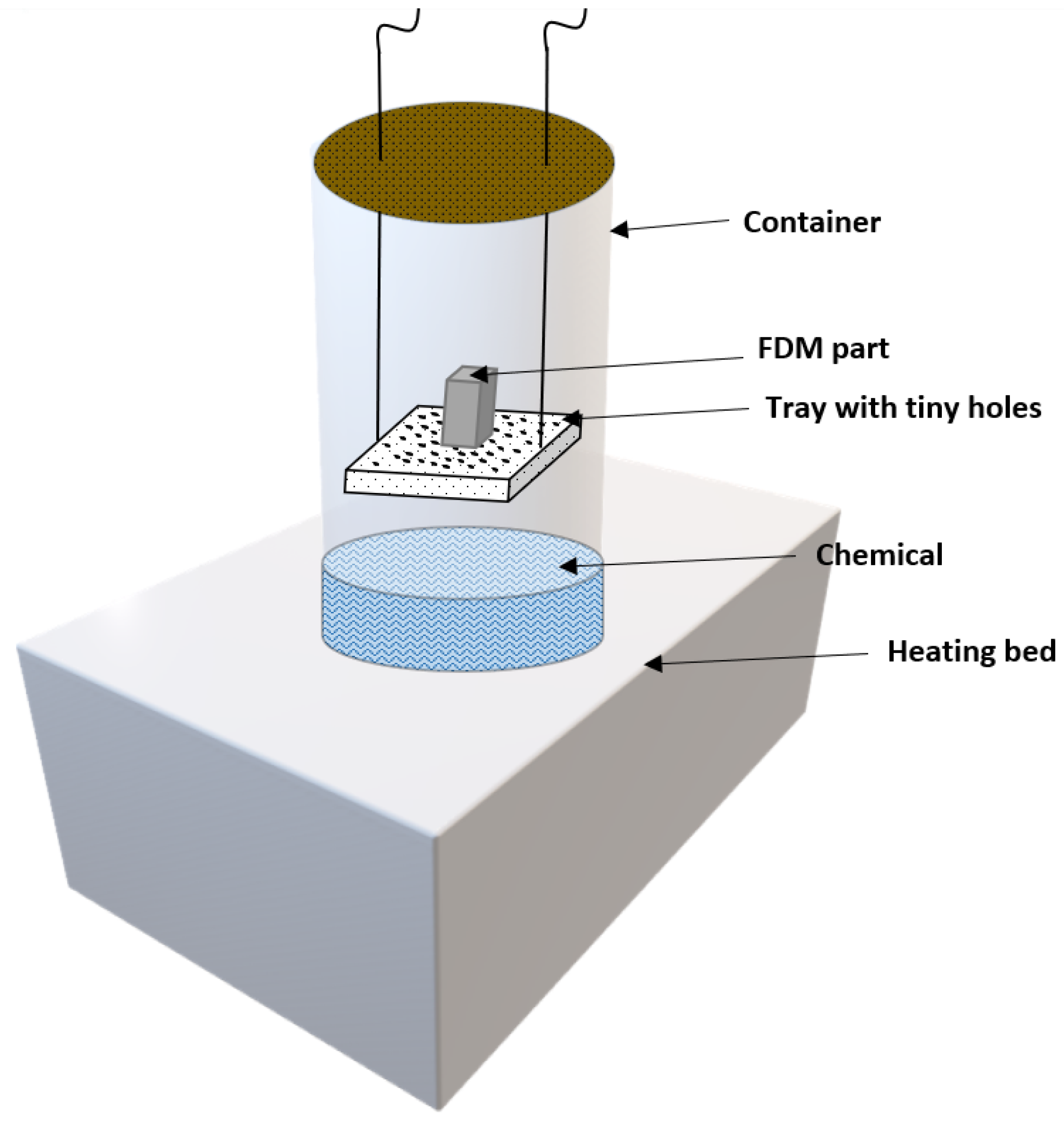

2.2. Chemical Treatment

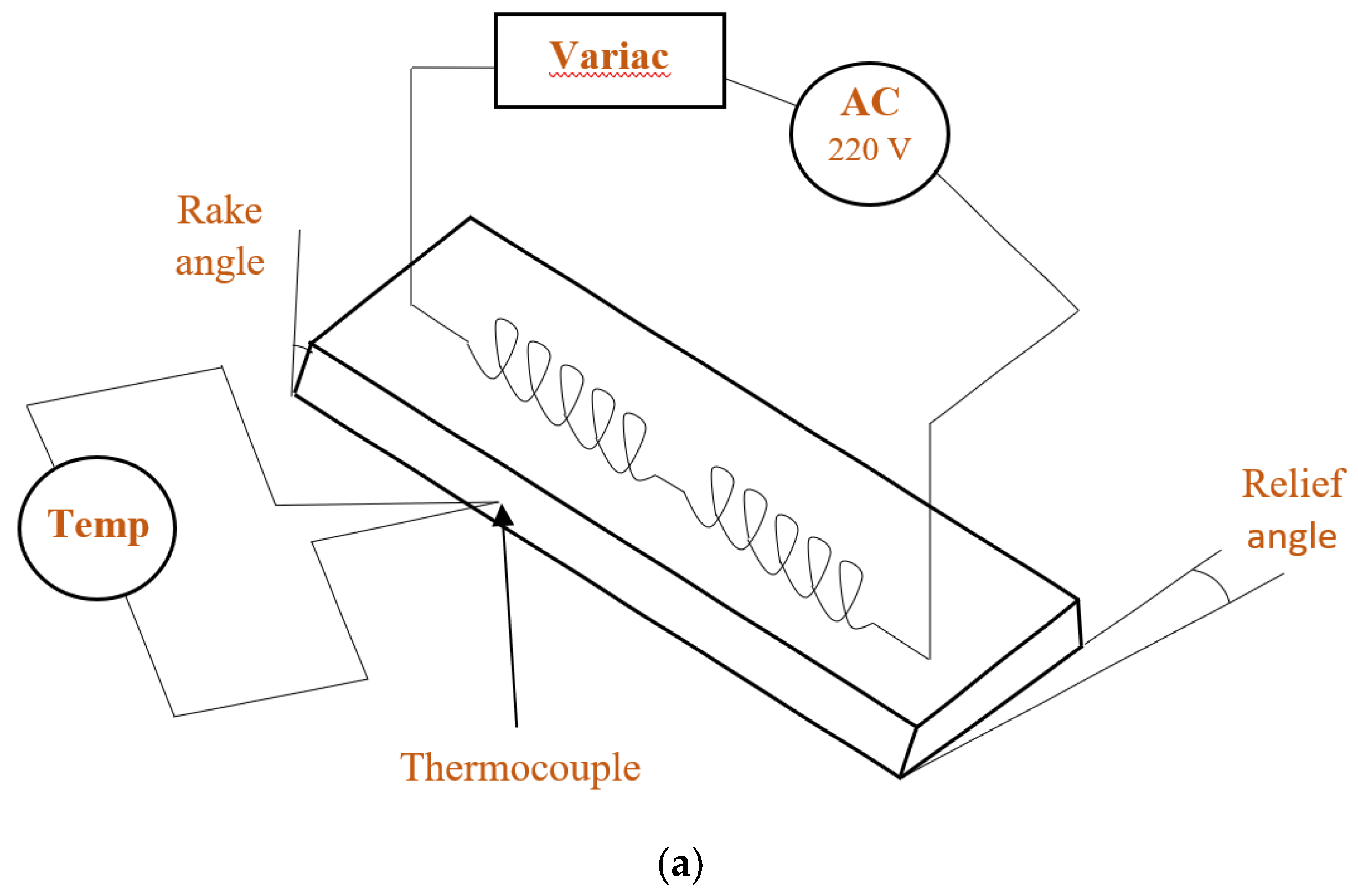

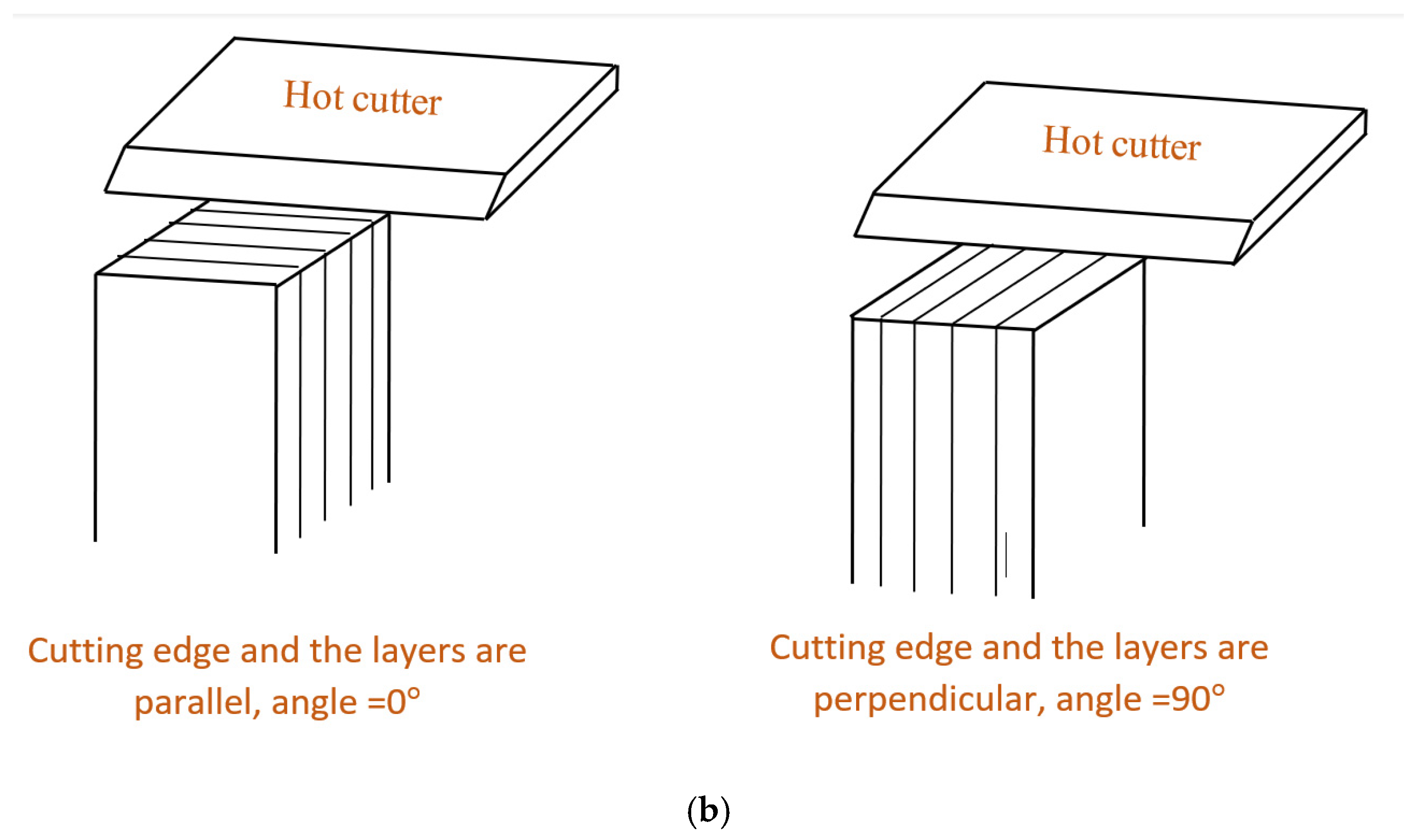

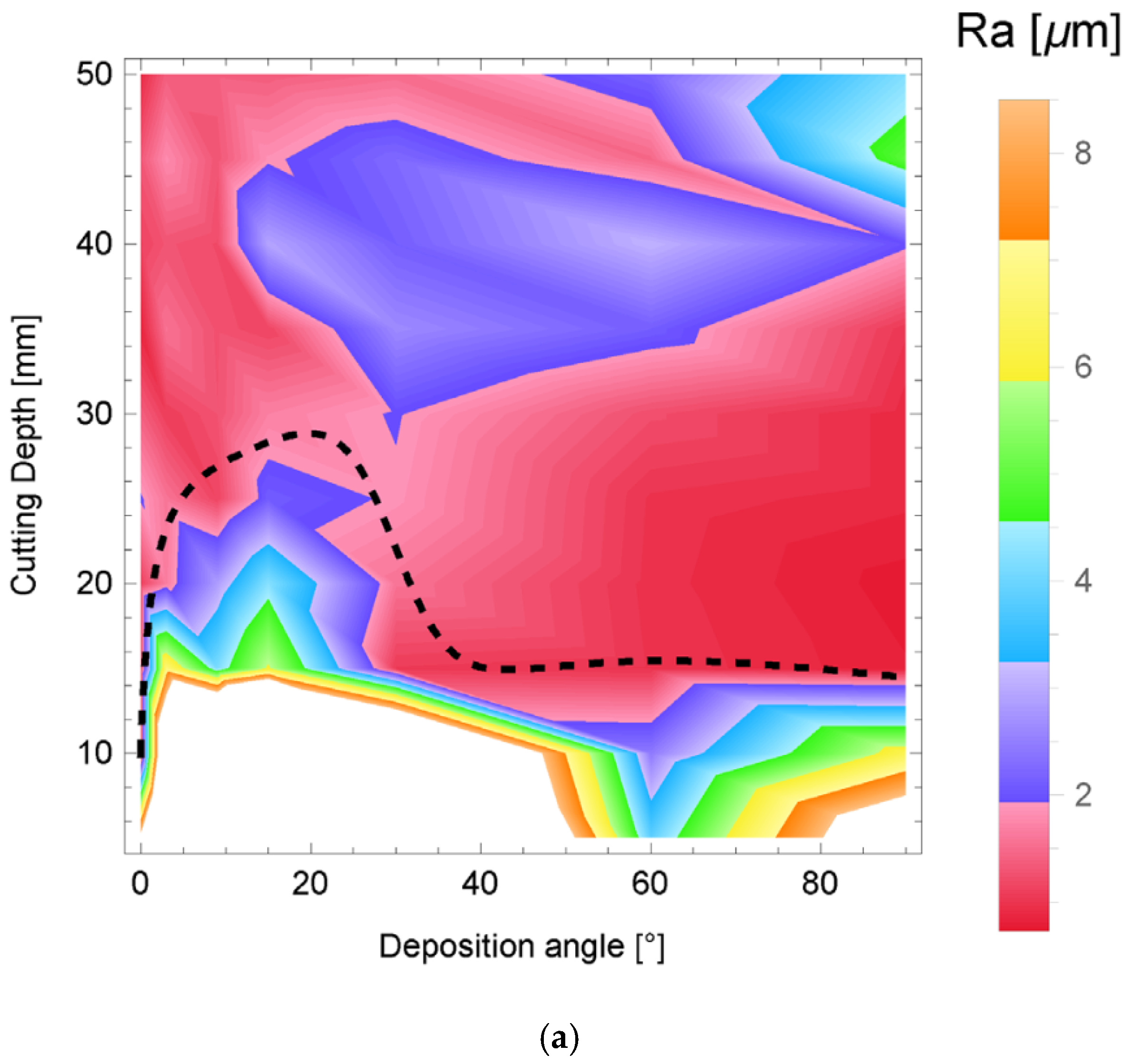

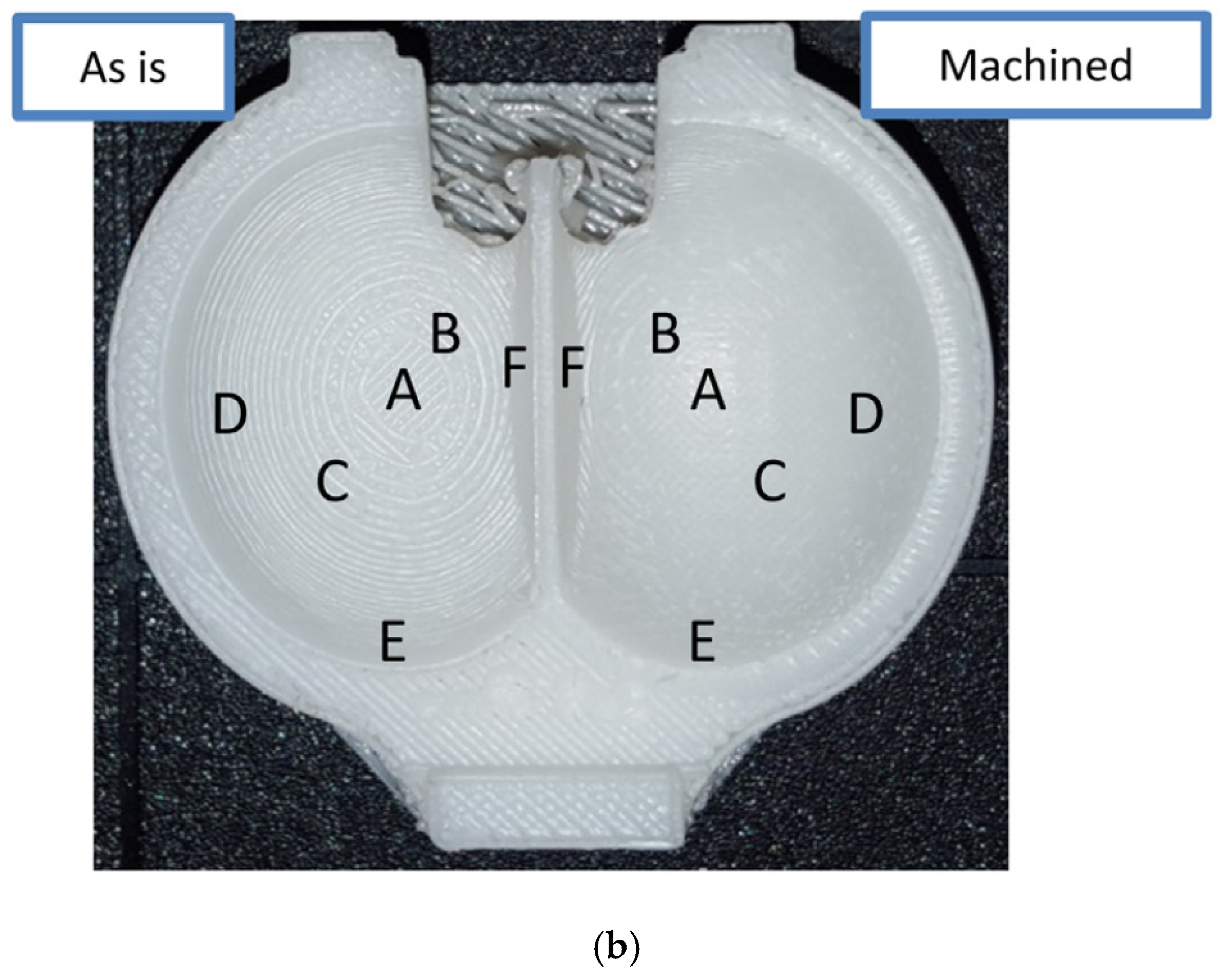

2.3. Post-Machining

2.4. Application of Coatings on Additively Manufactured Parts

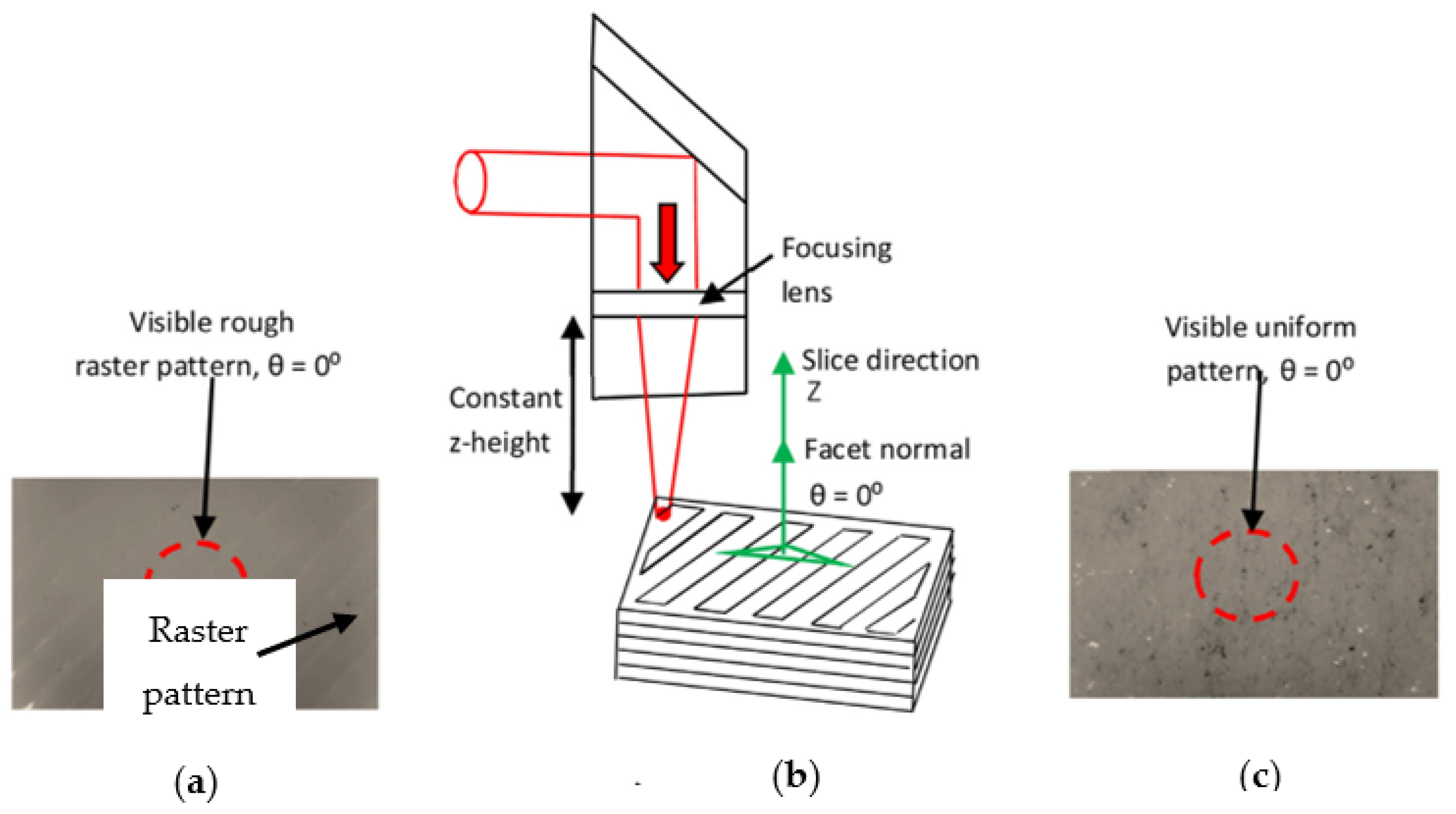

2.5. Laser Finishing of Additively Manufactured Polymer Parts

3. Finishing of the Metal Parts

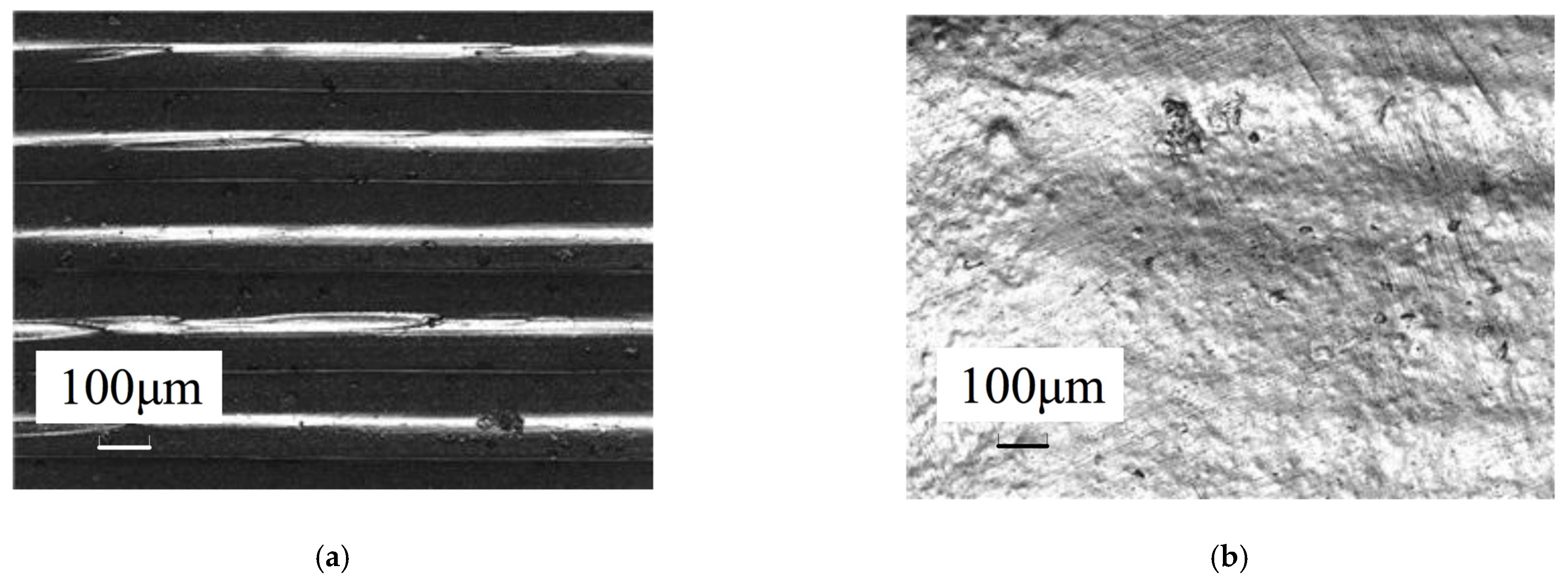

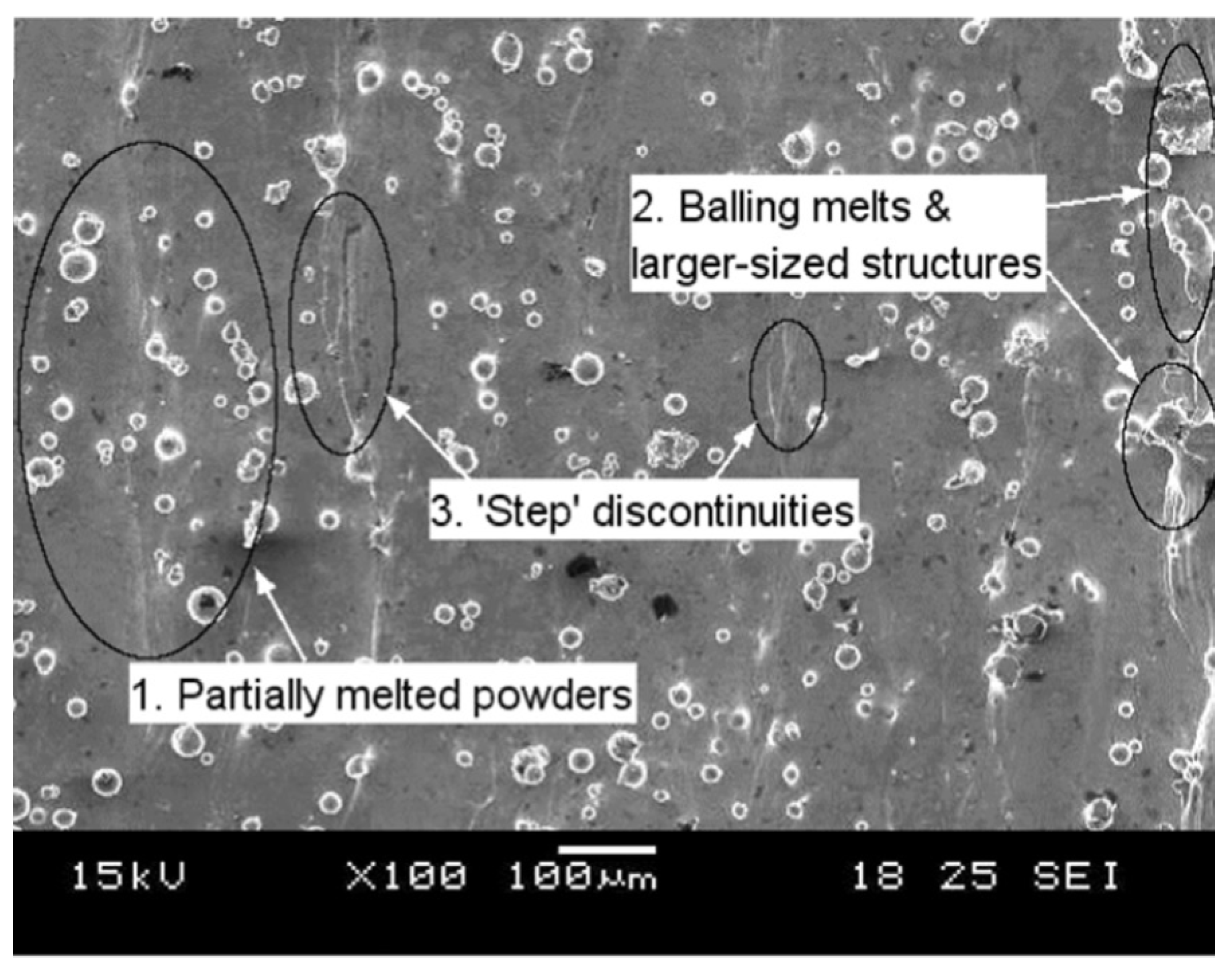

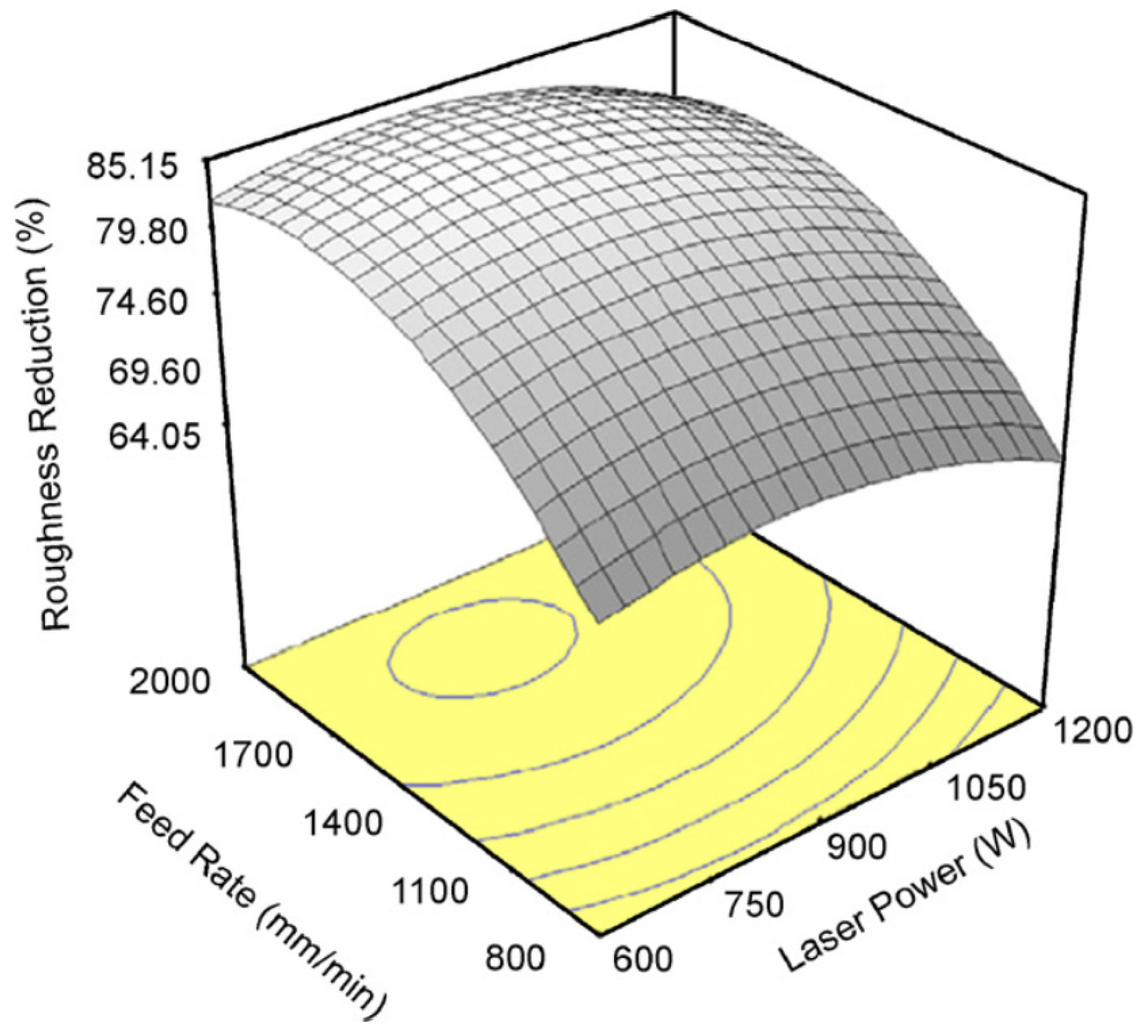

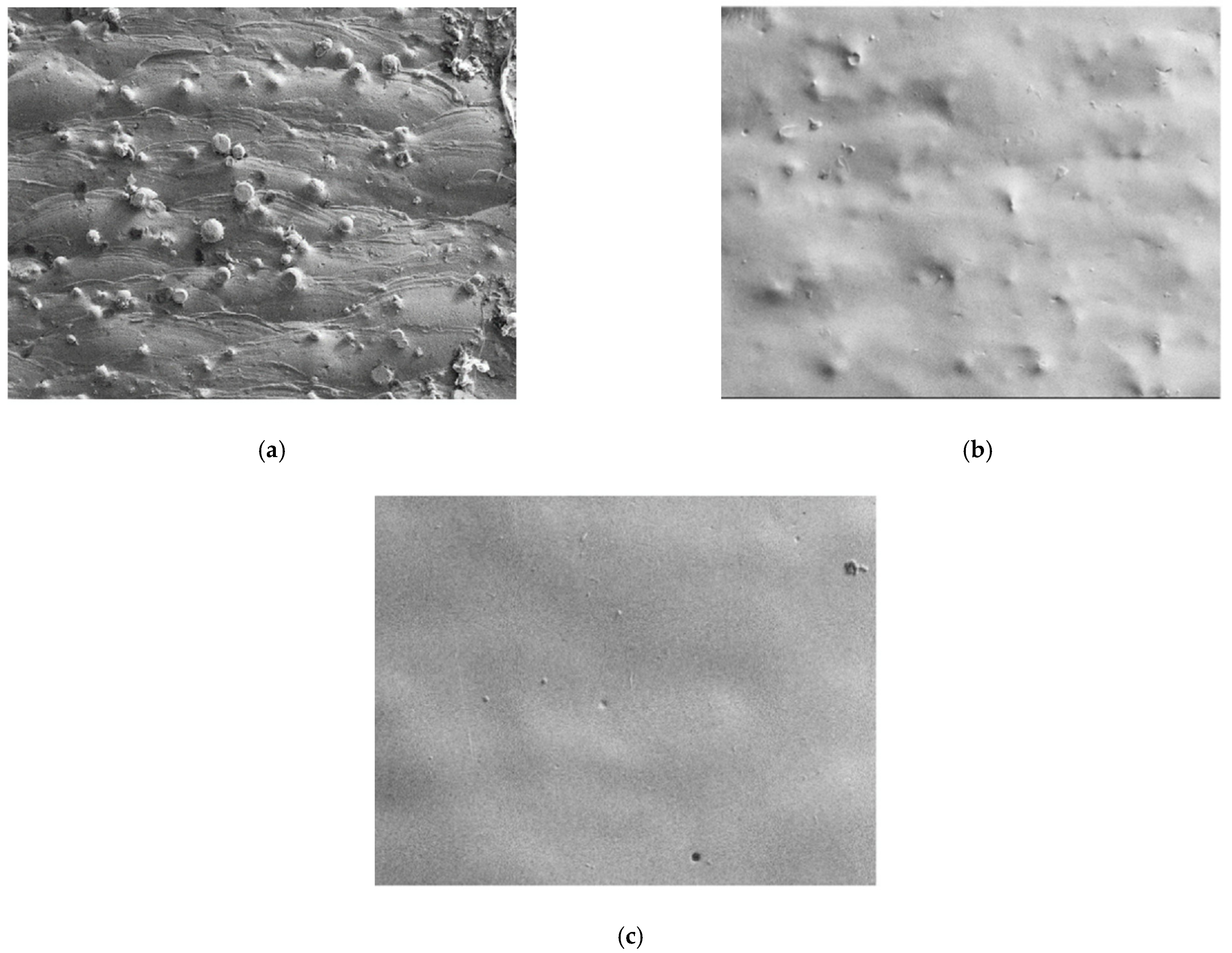

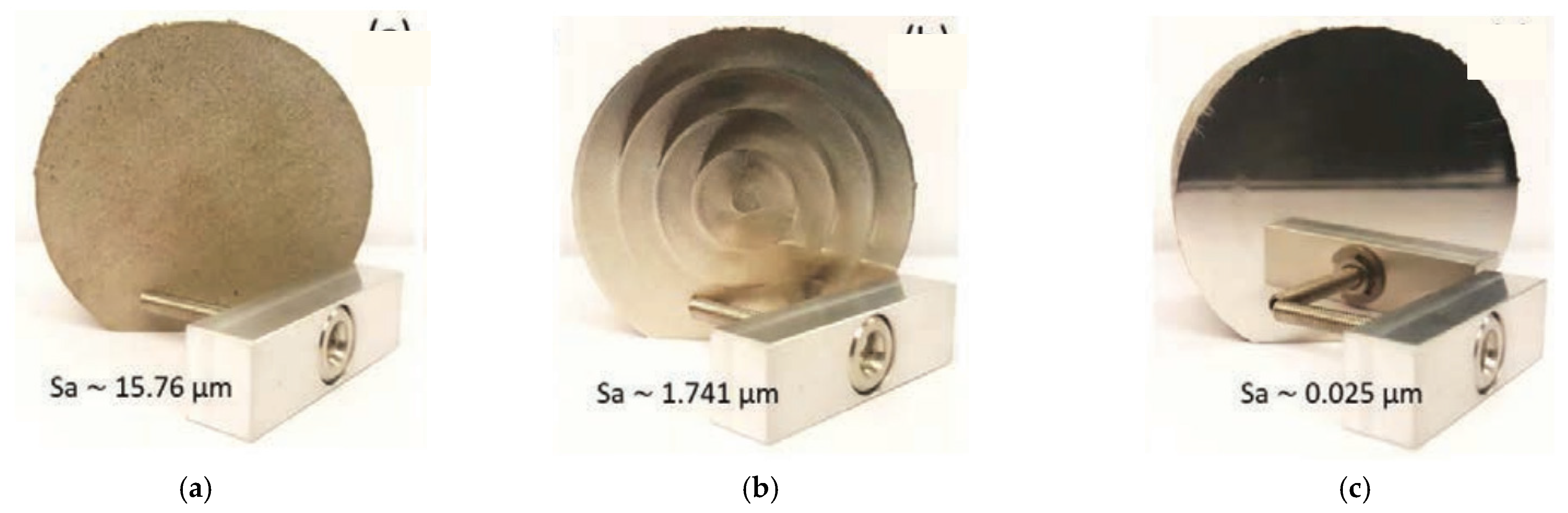

3.1. Laser Polishing of Metal Parts Produced by AM

3.2. Electrochemical and Chemical Machining

3.3. Application of Mechanical Energy to Perform Smoothening of the Part

4. Research Trend and Limitations

4.1. Finishing of the Parts Produced by Polymer Additive Manufacturing

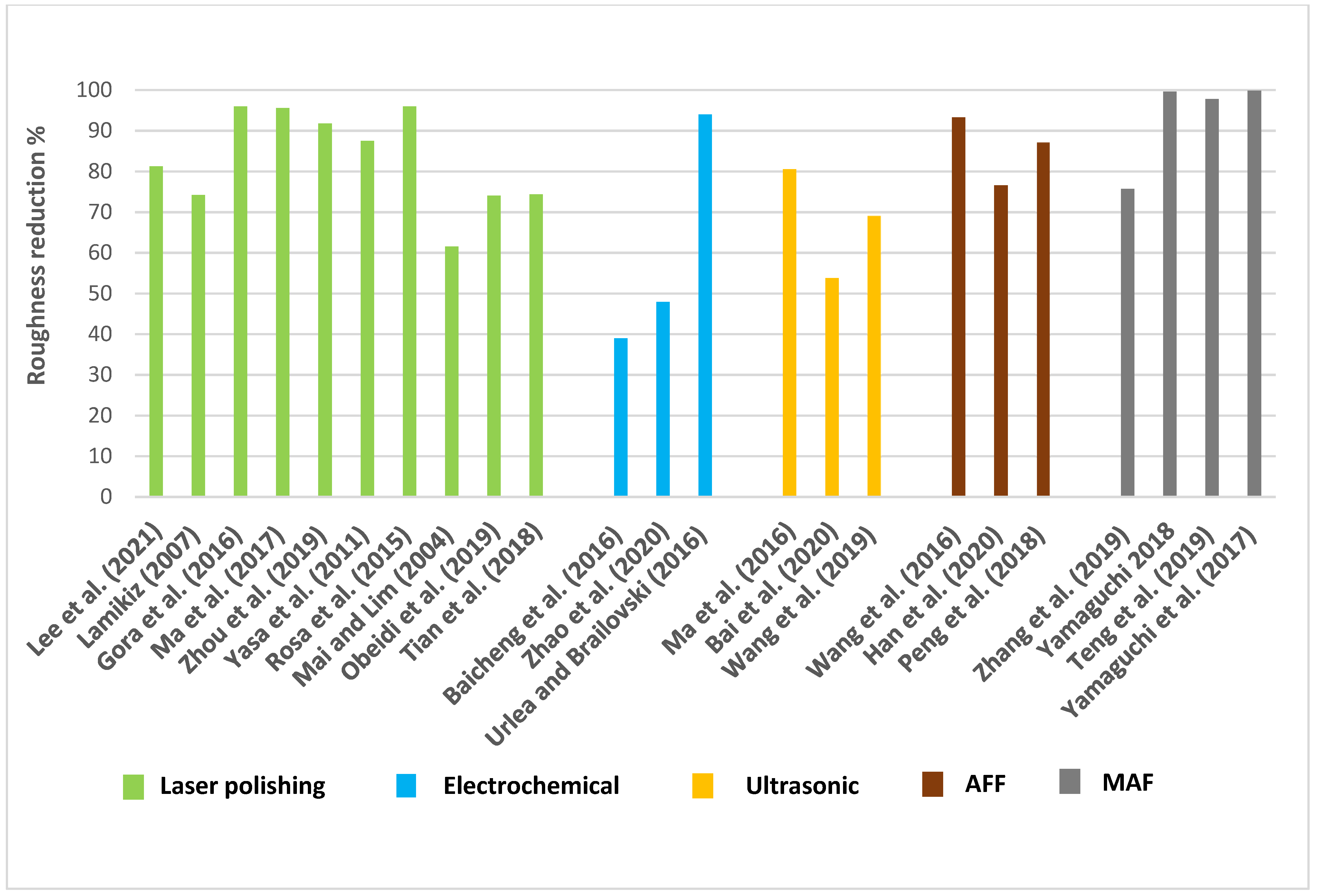

4.2. Finishing of the Metal AM Parts

5. Conclusions

- Chemical finishing for polymers produces a very fine surface finish and can be used to smoothen very complex surfaces. However, the allowances for the finishing should be considered.

- Abrasive finishing methods is the largest group of finishing techniques, and hence very different results can be obtained. Several processes yield an ultra-smooth surface and almost nano-level finishing, but they lack the flexibility of the chemical finishing. Abrasive flow machining seems to be the most successful of the processes considered, in terms of the final roughness and ability to finish complex cavities.

- The application of coatings appears to be a good alternative to finish the patterns for investment casting, but the pattern will enlarge due to applied coating and hence allowances should be considered.

- Finally, laser finishing, although leading to smooth surfaces, needs a careful process control, as excessive energy density might burn the polymer.

- For metals, laser finishing can produce nano-level surface roughness in metal additive manufacturing, but it cannot finish small intricate internal cavities. This process, when applied to metal additive manufactured parts, does not need any capital cost as finishing and can be conducted on the same machine.

- Laser polishing can alter the microstructure of the parts’ subsurface, leading to increased hardness.

- The electrochemical finishing process can also be used to finish metal parts. However, compared to chemical finishing, it cannot finish complex-shaped cavities due to the geometry of the electrode.

- Mechanical abrasion is also the largest group of processes for metal AM parts. Among them, AFF, UCAF, and UNSM are the most flexible and can finish almost any shape.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

List of Acronyms

| Abbreviation | Definition |

| ABS | Acrylonitrile butadiene styrene |

| AFF | Abrasive flow finishing |

| AJ | Abrasive jetting |

| AJM | Abrasive jet machining |

| AM | Additive manufacturing |

| AP | Abrasive particle |

| BEMRF | Ball end magnetorheological finishing |

| CAD | Computer-aided design |

| CIP | Carbonyl iron particle |

| CMP | Chemical mechanical polishing |

| CNC | Computer numerical control |

| DMECP | Dry mechanical–electrochemical polishing |

| DMLS | Direct laser metal sintering |

| EC | Electrochemical |

| ECMP | Electrochemical mechanical polishing |

| EIP | Electrolytic iron particles |

| EMAF | Electrochemical magnetic abrasive finishing |

| FDM | Fused deposition modelling |

| FFF | Fused filament fabrication |

| LF | Laser finishing |

| LSP | Laser shock peening |

| MAFF | Magnetic abrasive flow finishing |

| MFAF | Magnetic field assisted finishing |

| MJP | Magnetorheological jet polishing |

| MR | Magnetorheological |

| MRF | Magnetorheological finishing |

| MRR | Material removal rate |

| PAA | Polyacrylic acid |

| PEGDA | Polyethylene glycol diacrylate |

| PEI | Polyetherimide |

| PLA | Polylactic acid |

| Ra | Linear average roughness |

| Sa | Areal average roughness |

| SLA | Stereolithography |

| SLM | Selective laser melting |

| SLS | Selective laser sintering |

| SP | Shot peening |

| SR | Surface roughness |

| UCAF | Ultrasonic cavitation abrasive finishing |

| UEVAM | Ultrasonic elliptical vibration-assisted machining |

| UNSM | Ultrasonic nanocrystal surface modification |

References

- Kumbhar, N.N.; Mulay, A. Post processing methods used to improve surface finish of products which are manufactured by additive manufacturing technologies: A review. J. Inst. Eng. India Ser. C 2018, 99, 481–487. [Google Scholar] [CrossRef]

- Peng, X.; Kong, L.; Fuh, J.Y.H.; Wang, H. A review of post-processing technologies in additive manufacturing. J. Manuf. Mater. Process. 2021, 5, 38. [Google Scholar] [CrossRef]

- Turner, B.N.; Gold, S.A. A review of melt extrusion additive manufacturing processes: II. Materials, dimensional accuracy, and surface roughness. Rapid Prototyp. J. 2015, 21, 250–261. [Google Scholar] [CrossRef]

- Chan, K.S.; Koike, M.; Mason, R.L.; Okabe, T. Fatigue Life of Titanium Alloys Fabricated by Additive Layer Manufacturing Techniques for Dental Implants. Met. Mater. Trans. A 2012, 44, 1010–1022. [Google Scholar] [CrossRef]

- Gisario, A.; Kazarian, M.; Martina, F.; Mehrpouya, M. Metal additive manufacturing in the commercial aviation industry: A review. J. Manuf. Syst. 2019, 53, 124–149. [Google Scholar] [CrossRef]

- Tan, H.; Fang, Y.; Zhong, C.; Yuan, Z.; Fan, W.; Li, Z.; Chen, J.; Lin, X. Investigation of heating behavior of laser beam on powder stream in directed energy deposition. Surf. Coat. Technol. 2020, 397, 126061. [Google Scholar] [CrossRef]

- Anitha, R.; Arunachalam, S.; Radhakrishnan, P. Critical parameters influencing the quality of prototypes in fused deposition modelling. J. Mater. Process. Technol. 2001, 118, 385–388. [Google Scholar] [CrossRef]

- Li, H.; Wang, T.; Sun, J.; Yu, Z. The adaptive slicing algorithm and its impact on the mechanical property and surface roughness of freeform extrusion parts. Virtual Phys. Prototyp. 2016, 11, 27–39. [Google Scholar] [CrossRef]

- Wang, Z.; Ummethala, R.; Singh, N.; Tang, S.; Suryanarayana, C.; Eckert, J.; Prashanth, K.G. Selective Laser Melting of Aluminum and Its Alloys. Materials 2020, 13, 4564. [Google Scholar] [CrossRef]

- Martínez-Pellitero, S.; Castro, M.; Fernández-Abia, A.I.; González, S.; Cuesta, E. Analysis of influence factors on part quality in micro-SLA technology. Procedia Manuf. 2017, 13, 856–863. [Google Scholar] [CrossRef]

- Fischer, M.; Schöppner, V. Some investigations regarding the surface treatment of Ultem*9085 parts manufactured with fused deposition modeling. In Proceedings of the 2013 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2013. [Google Scholar]

- Tiwary, V.K.; Arunkumar, P.; Deshpande, A.S.; Rangaswamy, N. Surface enhancement of FDM patterns to be used in rapid investment casting for making medical implants. Rapid Prototyp. J. 2019, 25, 904–914. [Google Scholar] [CrossRef]

- Leong, K.F.; Chua, C.K.; Chua, G.S.; Tan, C.H. Abrasive jet deburring of jewellery models built by stereolithography apparatus (SLA). J. Mater. Process. Technol. 1998, 83, 36–47. [Google Scholar] [CrossRef]

- Gajdoš, I.; Spišák, E.; Kaščák, L.; Krasinskyi, V. Surface finish techniques for FDM parts. In Materials Science Forum; Trans Tech Publications: Zurich, Switzerland, 2015; Volume 818, pp. 45–48. [Google Scholar]

- Boschetto, A.; Bottini, L. Roughness prediction in coupled operations of fused deposition modeling and barrel finishing. J. Mater. Process. Technol. 2015, 219, 181–192. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L. Surface improvement of fused deposition modeling parts by barrel finishing. Rapid Prototyp. J. 2015, 21, 686–696. [Google Scholar] [CrossRef]

- Williams, R.E.; Melton, V.L. Abrasive flow finishing of stereolithography prototypes. Rapid Prototyp. J. 1998, 4, 56–67. [Google Scholar] [CrossRef]

- Mali, H.S.; Prajwal, B.; Gupta, D.; Kishan, J. Abrasive flow finishing of FDM printed parts using a sustainable media. Rapid Prototyp. J. 2018, 24, 593–606. [Google Scholar] [CrossRef]

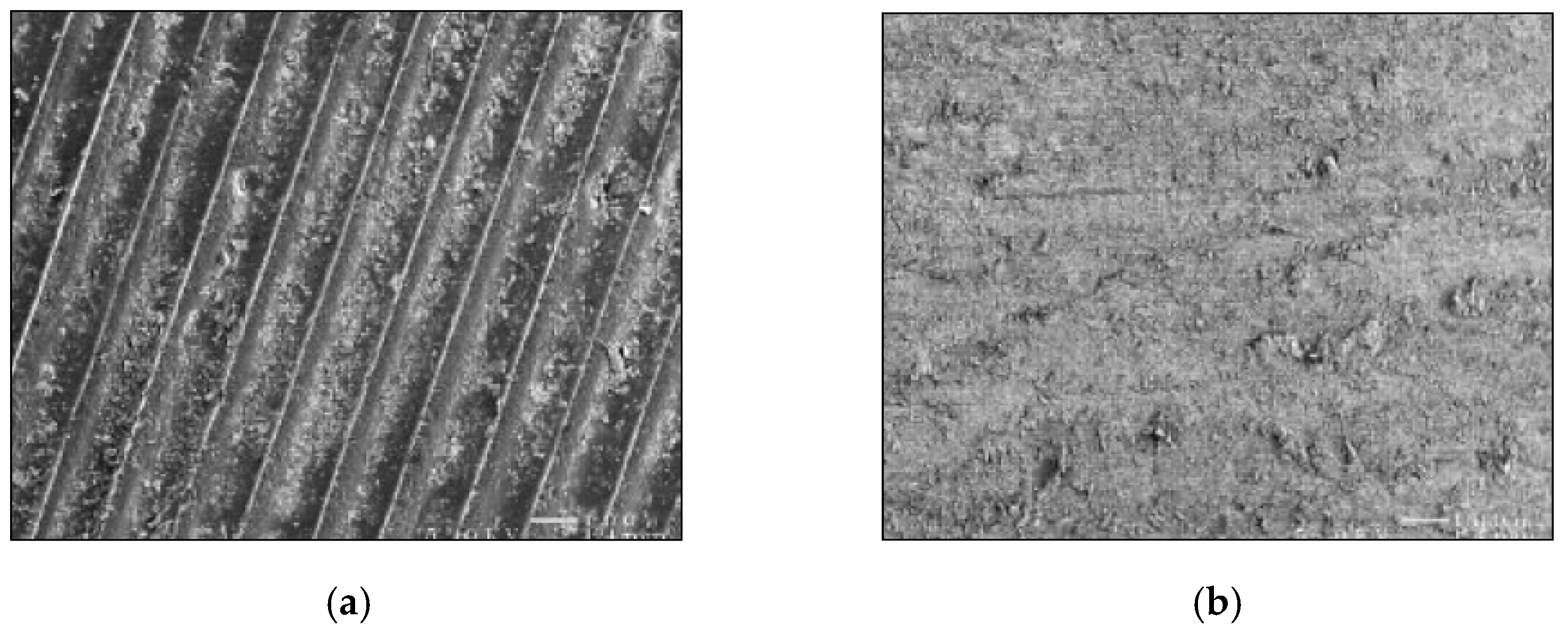

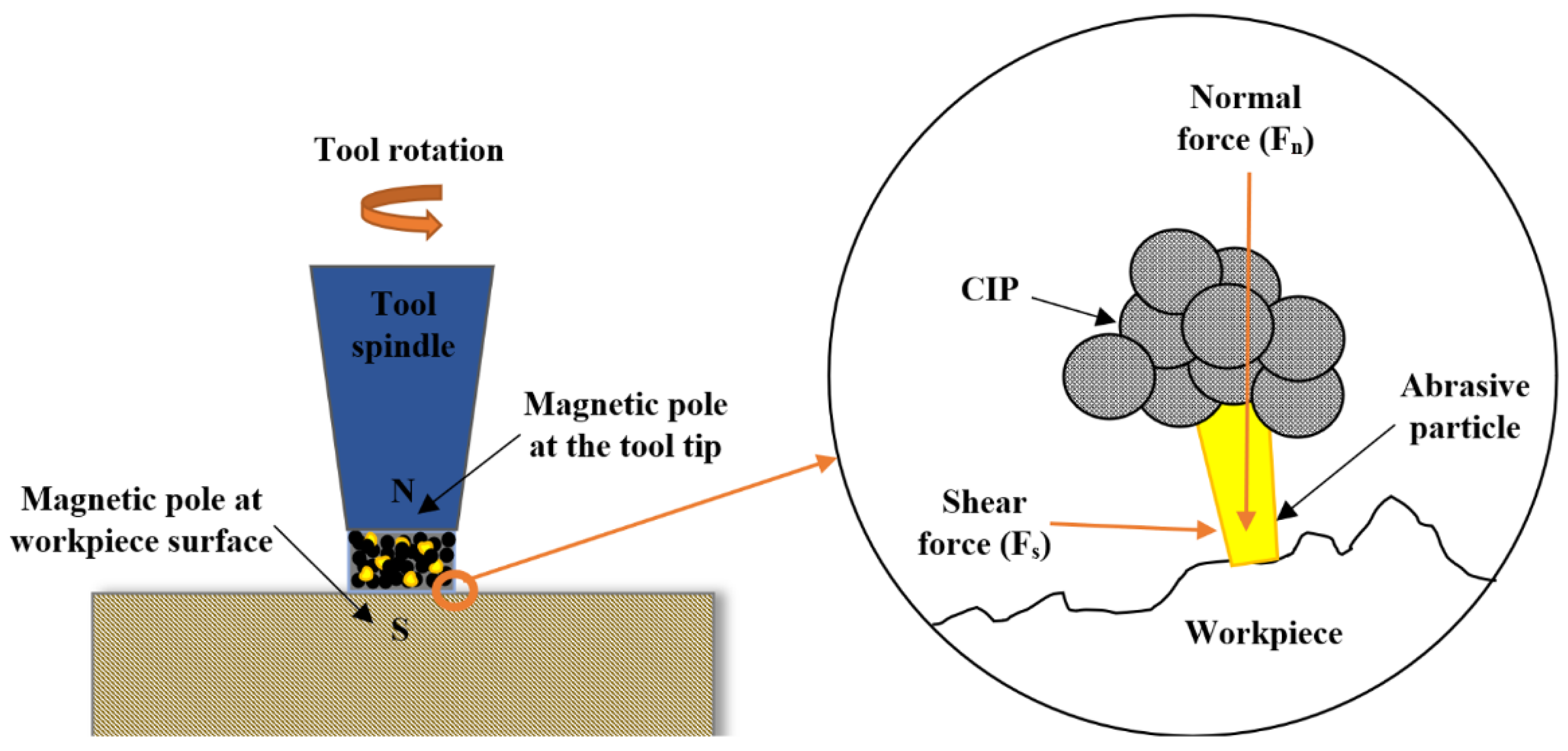

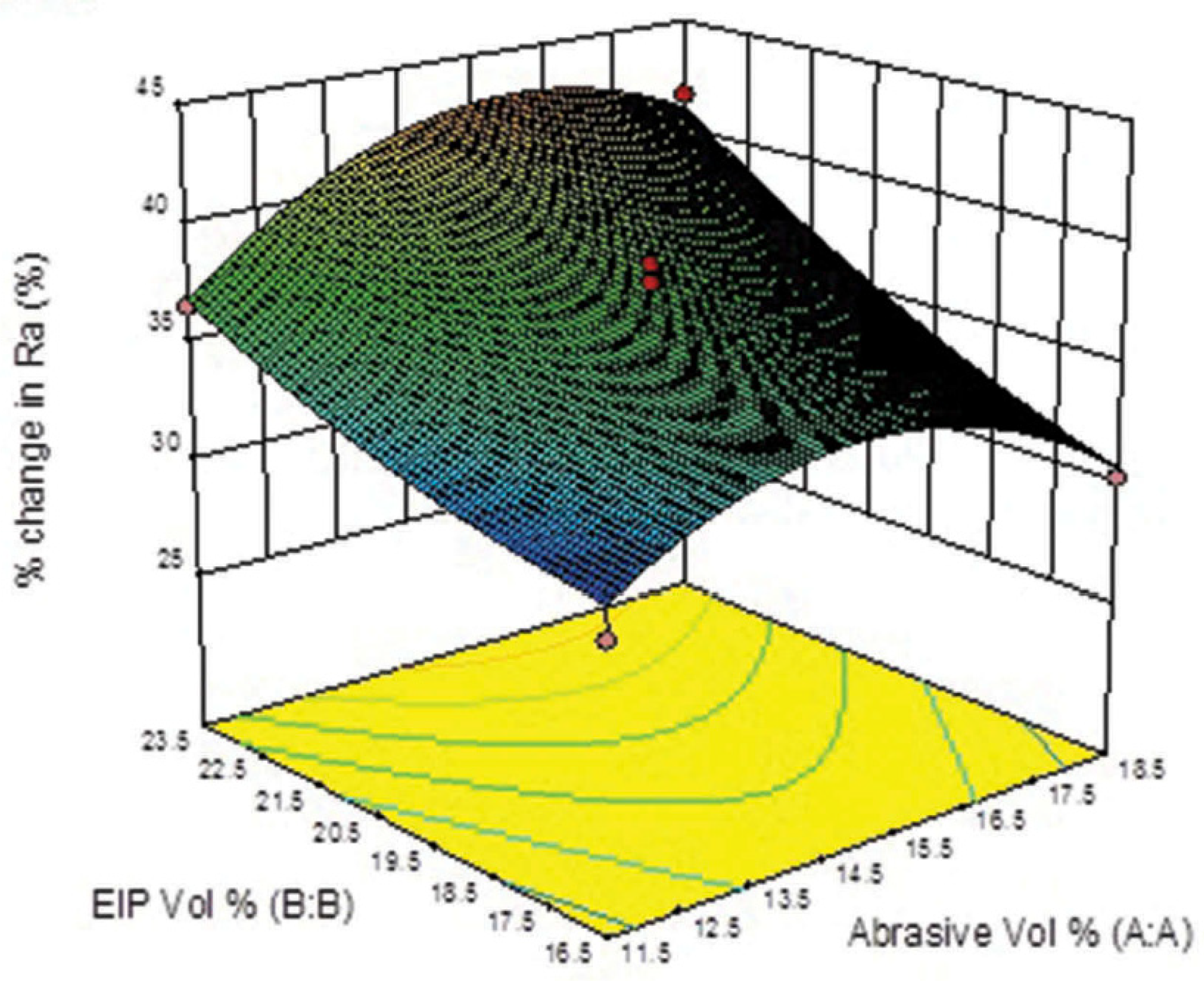

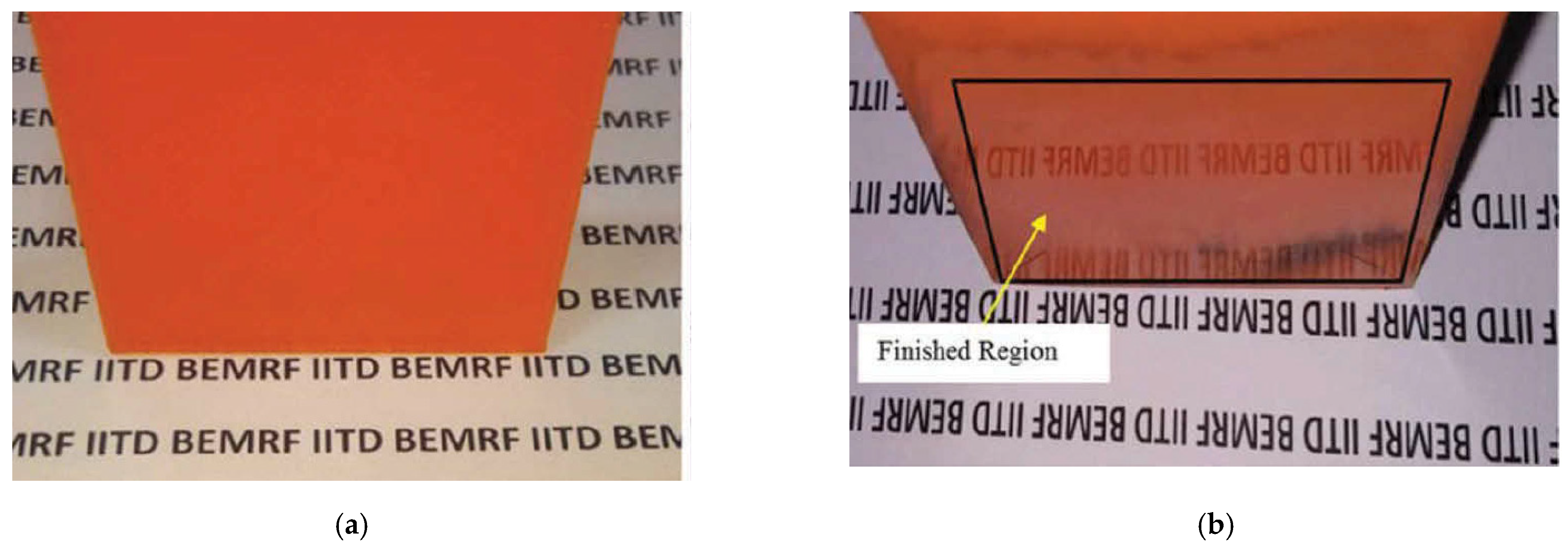

- Kumar, A.; Alam, Z.; Khan, D.A.; Jha, S. Nanofinishing of FDM-fabricated components using ball end magnetorheological finishing process. Mater. Manuf. Process. 2019, 34, 232–242. [Google Scholar] [CrossRef]

- Chohan, J.S.; Singh, R.; Boparai, K.S.; Penna, R.; Fraternali, F. Dimensional accuracy analysis of coupled fused deposition modeling and vapour smoothing operations for biomedical applications. Compos. Part B Eng. 2017, 117, 138–149. [Google Scholar] [CrossRef]

- Galantucci, L.M.; Lavecchia, F.; Percoco, G. Experimental study aiming to enhance the surface finish of fused deposition modeled parts. CIRP Ann. 2009, 58, 189–192. [Google Scholar] [CrossRef]

- Lalehpour, A.; Barari, A. Post processing for fused deposition modeling parts with acetone vapour bath. IFAC-PapersOnLine 2016, 49, 42–48. [Google Scholar] [CrossRef]

- Singh, D.; Singh, R.; Boparai, K.S. Investigations for surface roughness and dimensional accuracy of biomedical implants prepared by combining fused deposition modelling, vapour smoothing and investment casting. Adv. Mater. Process. Technol. 2020, 1–20. [Google Scholar] [CrossRef]

- Jin, Y.; Wan, Y.; Liu, Z. Surface polish of PLA parts in FDM using dichloromethane vapour. MATEC Web Conf. 2017, 95, 05001. [Google Scholar] [CrossRef]

- Valerga, A.P.; Batista, M.; Fernandez-Vidal, S.R.; Gamez, A.J. Impact of chemical post-processing in fused deposition modelling (FDM) on polylactic acid (PLA) surface quality and structure. Polymers 2019, 11, 566. [Google Scholar] [CrossRef]

- Pandey, P.M.; Reddy, N.V.; Dhande, S.G. Improvement of surface finish by staircase machining in fused deposition modeling. J. Mater. Process. Technol. 2003, 132, 323–331. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Veniali, F. Finishing of Fused Deposition Modeling parts by CNC machining. Robot. Comput. Manuf. 2016, 41, 92–101. [Google Scholar] [CrossRef]

- Garg, P.K.; Singh, R.; Ahuja, I. Multi-objective optimization of dimensional accuracy, surface roughness and hardness of hybrid investment cast components. Rapid Prototyp. J. 2017, 23, 845–857. [Google Scholar] [CrossRef]

- Zhou, J.; Lu, Z.; Miao, K.; Ji, Z.; Dong, Y.; Li, D. Quick fabrication of aeronautical complicated structural parts based on stereolithography. Propuls. Power Res. 2015, 4, 63–71. [Google Scholar] [CrossRef]

- Roach, D.J.; Roberts, C.; Wong, J.; Kuang, X.; Kovitz, J.; Zhang, Q.; Spence, T.G.; Qi, H.J. Surface modification of fused filament fabrication (FFF) 3D printed substrates by inkjet printing polyimide for printed electronics. Addit. Manuf. 2020, 36, 101544. [Google Scholar] [CrossRef]

- Dewey, M.P.; Ulutan, D. Development of laser polishing as an auxiliary post-process to improve surface quality in fused deposition modeling parts. In Proceedings of the ASME 2017 12th International Manufacturing Science and Engineering Conference Collocated with the JSME/ASME 2017 6th International Conference on Materials and Processing, Los Angeles, CA, USA, 4–8 June 2017; American Society of Mechanical Engineers, 2017; Volume 50732, p. V002T01A006. [Google Scholar]

- Chen, L.; Zhang, X.; Gan, S. Effects of laser polishing on surface quality and mechanical properties of PLA parts built by fused deposition modeling. J. Appl. Polym. Sci. 2019, 137, 48288. [Google Scholar] [CrossRef]

- Lambiase, F.; Genna, S.; Leone, C. Laser finishing of 3D printed parts produced by material extrusion. Opt. Lasers Eng. 2020, 124, 105801. [Google Scholar] [CrossRef]

- Braun, K.; Willenborg, E.; Schleifenbaum, J.H. Laser polishing as a new post process for 3D-printed polymer parts. Procedia CIRP 2020, 94, 134–138. [Google Scholar] [CrossRef]

- Chai, Y.; Li, R.W.; Perriman, D.M.; Chen, S.; Qin, Q.-H.; Smith, P.N. Laser polishing of thermoplastics fabricated using fused deposition modelling. Int. J. Adv. Manuf. Technol. 2018, 96, 4295–4302. [Google Scholar] [CrossRef]

- Taufik, M.; Jain, P.K. Laser assisted finishing process for improved surface finish of fused deposition modelled parts. J. Manuf. Process. 2017, 30, 161–177. [Google Scholar] [CrossRef]

- Tan, K.L.; Yeo, S.H. Surface modification of additive manufactured components by ultrasonic cavitation abrasive finishing. Wear 2017, 378, 90–95. [Google Scholar] [CrossRef]

- Lee, S.; Ahmadi, Z.; Pegues, J.W.; Mahjouri-Samani, M.; Shamsaei, N. Laser polishing for improving fatigue performance of additive manufactured Ti-6Al-4V parts. Opt. Laser Technol. 2021, 134, 106639. [Google Scholar] [CrossRef]

- Lamikiz, A.; Sánchez, J.; de Lacalle, L.L.; Arana, J. Laser polishing of parts built up by selective laser sintering. Int. Int. J. Mach. Tools Manuf. 2007, 47, 2040–2050. [Google Scholar] [CrossRef]

- Guo, W.; Hua, M.; Tse, P.W.-T.; Mok, A.C.K. Process parameters selection for laser polishing DF2 (AISI O1) by Nd:YAG pulsed laser using orthogonal design. Int. J. Adv. Manuf. Technol. 2012, 59, 1009–1023. [Google Scholar] [CrossRef]

- Gora, W.S.; Tian, Y.; Cabo, A.P.; Ardron, M.; Maier, R.R.J.; Prangnell, P.; Weston, N.J.; Hand, D. Enhancing surface finish of additively manufactured titanium and cobalt chrome elements using laser based finishing. Phys. Procedia 2016, 83, 258–263. [Google Scholar] [CrossRef]

- Ma, C.P.; Guan, Y.C.; Zhou, W. Laser polishing of additive manufactured Ti alloys. Opt. Lasers Eng. 2017, 93, 171–177. [Google Scholar] [CrossRef]

- Zhou, J.; Liao, C.; Shen, H.; Ding, X. Surface and property characterization of laser polished Ti6Al4V. Surf. Coat. Technol. 2019, 380, 125016. [Google Scholar] [CrossRef]

- Tian, Y.; Gora, W.S.; Cabo, A.P.; Parimi, L.L.; Hand, D.P.; Tammas-Williams, S.; Prangnell, P.B. Material interactions in laser polishing powder bed additive manufactured Ti6Al4V components. Addit. Manuf. 2018, 20, 11–22. [Google Scholar] [CrossRef]

- Li, K.; Zhao, Z.; Zhou, H.; Zhou, H.; Jin, J. Numerical analyses of molten pool evolution in laser polishing Ti6Al4V. J. Manuf. Process. 2020, 58, 574–584. [Google Scholar] [CrossRef]

- Yasa, E.; Kruth, J.-P.; Deckers, J. Manufacturing by combining selective laser melting and selective laser erosion/laser re-melting. CIRP Ann. 2011, 60, 263–266. [Google Scholar] [CrossRef]

- Marimuthu, S.; Triantaphyllou, A.; Antar, M.; Wimpenny, D.; Morton, H.; Beard, M. Laser polishing of selective laser melted components. Int. J. Mach. Tools Manuf. 2015, 95, 97–104. [Google Scholar] [CrossRef]

- Richter, B.; Blanke, N.; Werner, C.; Vollertsen, F.; Pfefferkorn, F. Effect of initial surface features on laser polishing of Co-Cr-Mo alloy made by powder-bed fusion. JOM 2019, 71, 912–919. [Google Scholar] [CrossRef]

- Černašėjus, O.; Škamat, J.; Markovič, V.; Višniakov, N.; Indrišiūnas, S. Surface Laser Processing of Additive Manufactured 1.2709 Steel Parts: Preliminary Study. Adv. Mater. Sci. Eng. 2019, 2019, 7029471. [Google Scholar] [CrossRef]

- Rosa, B.; Mognol, P.; Hascoët, J.-Y. Laser polishing of additive laser manufacturing surfaces. J. Laser Appl. 2015, 27, S29102. [Google Scholar] [CrossRef]

- Mai, T.A.; Lim, G.C. Micromelting and its effects on surface topography and properties in laser polishing of stainless steel. J. Laser Appl. 2004, 16, 221–228. [Google Scholar] [CrossRef]

- Chen, L.; Richter, B.; Zhang, X.; Bertsch, K.B.; Thoma, D.J.; Pfefferkorn, F.E. Effect of laser polishing on the microstructure and mechanical properties of stainless steel 316L fabricated by laser powder bed fusion. Mater. Sci. Eng. A 2021, 802, 140579. [Google Scholar] [CrossRef]

- Obeidi, M.A.; McCarthy, E.; O’Connell, B.; Ahad, I.U.; Brabazon, D. Laser polishing of additive manufactured 316L stainless steel synthesized by selective laser melting. Materials 2019, 12, 991. [Google Scholar] [CrossRef]

- Avilés, R.; Albizuri, J.; Lamikiz, A.; Ukar, E.; Avilés, A. Influence of laser polishing on the high cycle fatigue strength of medium carbon AISI 1045 steel. Int. J. Fatigue 2011, 33, 1477–1489. [Google Scholar] [CrossRef]

- Zhou, J.; Han, X.; Li, H.; Liu, S.; Shen, S.; Zhou, X.; Zhang, D. In-Situ Laser Polishing Additive Manufactured AlSi10Mg: Effect of Laser Polishing Strategy on Surface Morphology, Roughness and Microhardness. Materials 2021, 14, 393. [Google Scholar] [CrossRef] [PubMed]

- Temmler, A.; Liu, D.; Preußner, J.; Oeser, S.; Luo, J.; Poprawe, R.; Schleifenbaum, J. Influence of laser polishing on surface roughness and microstructural properties of the remelted surface boundary layer of tool steel H11. Mater. Des. 2020, 192, 108689. [Google Scholar] [CrossRef]

- Lu, J.; Lu, H.; Xu, X.; Yao, J.; Cai, J.; Luo, K. High-performance integrated additive manufacturing with laser shock peening–induced microstructural evolution and improvement in mechanical properties of Ti6Al4V alloy components. Int. J. Mach. Tools Manuf. 2020, 148, 103475. [Google Scholar] [CrossRef]

- Jinoop, A.N.; Subbu, S.K.; Paul, C.P.; Palani, I.A. Post-processing of Laser Additive Manufactured Inconel 718 Using Laser Shock Peening. Int. J. Precis. Eng. Manuf. 2019, 20, 1621–1628. [Google Scholar] [CrossRef]

- Damon, J.; Dietrich, S.; Vollert, F.; Gibmeier, J.; Schulze, V. Process dependent porosity and the influence of shot peening on porosity morphology regarding selective laser melted AlSi10Mg parts. Addit. Manuf. 2018, 20, 77–89. [Google Scholar] [CrossRef]

- Chen, L.; Sun, Y.; Li, L.; Ren, X. Improvement of high temperature oxidation resistance of additively manufactured TiC/Inconel 625 nanocomposites by laser shock peening treatment. Addit. Manuf. 2020, 34, 101276. [Google Scholar] [CrossRef]

- Jiang, Q.; Li, S.; Zhou, C.; Zhang, B.; Zhang, Y. Effects of laser shock peening on the ultra-high cycle fatigue performance of additively manufactured Ti6Al4V alloy. Opt. Laser Technol. 2021, 144, 107391. [Google Scholar] [CrossRef]

- Sagbas, B. Post-Processing Effects on Surface Properties of Direct Metal Laser Sintered AlSi10Mg Parts. Met. Mater. Int. 2020, 26, 143–153. [Google Scholar] [CrossRef]

- Maamoun, A.H.; Elbestawi, M.A.; Veldhuis, S.C. Influence of Shot Peening on AlSi10Mg Parts Fabricated by Additive Manufacturing. J. Manuf. Mater. Process. 2018, 2, 40. [Google Scholar] [CrossRef]

- Uzan, N.E.; Ramati, S.; Shneck, R.; Frage, N.; Yeheskel, O. On the effect of shot-peening on fatigue resistance of AlSi10Mg specimens fabricated by additive manufacturing using selective laser melting (AM-SLM). Addit. Manuf. 2018, 21, 458–464. [Google Scholar] [CrossRef]

- Luo, S.; He, W.; Chen, K.; Nie, X.; Zhou, L.; Li, Y. Regain the fatigue strength of laser additive manufactured Ti alloy via laser shock peening. J. Alloy. Compd. 2018, 750, 626–635. [Google Scholar] [CrossRef]

- Chi, J.; Cai, Z.; Wan, Z.; Zhang, H.; Chen, Z.; Li, L.; Li, Y.; Peng, P.; Guo, W. Effects of heat treatment combined with laser shock peening on wire and arc additive manufactured Ti17 titanium alloy: Microstructures, residual stress and mechanical properties. Surf. Coat. Technol. 2020, 396, 125908. [Google Scholar] [CrossRef]

- Baicheng, Z.; Xiaohua, L.; Jiaming, B.; Junfeng, G.; Pan, W.; Chen-Nan, S.; Muiling, N.; Guojun, Q.; Jun, W. Study of selective laser melting (SLM) Inconel 718 part surface improvement by electrochemical polishing. Mater. Des. 2017, 116, 531–537. [Google Scholar] [CrossRef]

- Zhao, C.; Qu, N.; Tang, X. Removal of adhesive powders from additive-manufactured internal surface via electrochemical machining with flexible cathode. Precis. Eng. 2021, 67, 438–452. [Google Scholar] [CrossRef]

- Urlea, V.; Brailovski, V. Electropolishing and electropolishing-related allowances for powder bed selectively laser-melted Ti-6Al-4V alloy components. J. Mater. Process. Technol. 2017, 242, 1–11. [Google Scholar] [CrossRef]

- Landolt, D. Fundamental aspects of electropolishing. Electrochim. Acta 1987, 32, 1–11. [Google Scholar] [CrossRef]

- Basha, M.M.; Basha, S.M.; Jain, V.K.; Sankar, M.R. State of the art on chemical and electrochemical based finishing processes for additive manufactured features. Addit. Manuf. 2022, 58, 103028. [Google Scholar] [CrossRef]

- Sun, X.; Fu, Y.; Lu, W.; Hang, W. Investigation on the electrochemical assisted magnetic abrasive finishing for a stainless steel of SUS304. Int. J. Adv. Manuf. Technol. 2021, 116, 1509–1522. [Google Scholar] [CrossRef]

- Bai, Y.; Zhao, C.; Yang, J.; Fuh, J.Y.H.; Lu, W.F.; Weng, C.; Wang, H. Dry mechanical-electrochemical polishing of selective laser melted 316L stainless steel. Mater. Des. 2020, 193, 108840. [Google Scholar] [CrossRef]

- An, L.; Wang, D.; Zhu, D. Combined electrochemical and mechanical polishing of interior channels in parts made by additive manufacturing. Addit. Manuf. 2022, 51, 102638. [Google Scholar] [CrossRef]

- Zhao, C.; Qu, N.; Tang, X. Electrochemical mechanical polishing of internal holes created by selective laser melting. J. Manuf. Process. 2021, 64, 1544–1562. [Google Scholar] [CrossRef]

- Tyagi, P.; Goulet, T.; Riso, C.; Stephenson, R.; Chuenprateep, N.; Schlitzer, J.; Benton, C.; Garcia-Moreno, F. Reducing the roughness of internal surface of an additive manufacturing produced 316 steel component by chempolishing and electropolishing. Addit. Manuf. 2019, 25, 32–38. [Google Scholar] [CrossRef]

- Scherillo, F. Chemical surface finishing of AlSi10Mg components made by additive manufacturing. Manuf. Lett. 2019, 19, 5–9. [Google Scholar] [CrossRef]

- Pyka, G.; Kerckhofs, G.; Papantoniou, I.; Speirs, M.; Schrooten, J.; Wevers, M. Surface roughness and morphology customization of additive manufactured open porous Ti6Al4V structures. Materials 2013, 6, 4737–4757. [Google Scholar] [CrossRef]

- Tehrani, A.F.; Imanian, E. A new etchant for the chemical machining of St304. J. Mater. Process. Technol. 2004, 149, 404–408. [Google Scholar] [CrossRef]

- Ivanits’ka, V.G.; Moravec, P.; Franc, J.; Tomashik, V.M.; Tomashik, Z.F.; Masek, K.; Chukhnenko, P.S.; Höschl, P.; Ulrych, J. Chemical Polishing of CdTe and CdZnTe in Iodine–Methanol Etching Solutions. J. Electron. Mater. 2011, 40, 1802–1808. [Google Scholar] [CrossRef]

- Balyakin, A.; Goncharov, E.; Zhuchenko, E. The effect of preprocessing on surface quality in the chemical polishing of parts from titanium alloy produced by SLM. Mater. Today Proc. 2019, 19, 2291–2294. [Google Scholar] [CrossRef]

- Balyakin, A.V.; Shvetcov, A.N.; Zhuchenko, E.I. Chemical polishing of samples obtained by selective laser melting from titanium alloy Ti6Al4V. MATEC Web Conf. 2018, 224, 01031. [Google Scholar] [CrossRef]

- Bezuidenhout, M.; Haar, G.T.; Becker, T.; Rudolph, S.; Damm, O.; Sacks, N. The effect of HF-HNO3 chemical polishing on the surface roughness and fatigue life of laser powder bed fusion produced Ti6Al4V. Mater. Today Commun. 2020, 25, 101396. [Google Scholar] [CrossRef]

- Soro, N.; Saintier, N.; Attar, H.; Dargusch, M.S. Surface and morphological modification of selectively laser melted titanium lattices using a chemical post treatment. Surf. Coat. Technol. 2020, 393, 125794. [Google Scholar] [CrossRef]

- Wysocki, B.; Idaszek, J.; Buhagiar, J.; Szlazak, K.; Brynk, T.; Kurzydlowski, K.; Swieszkowski, W. The influence of chemical polishing of titanium scaffolds on their mechanical strength and in-vitro cell response. Mater. Sci. Eng. C 2019, 95, 428–439. [Google Scholar] [CrossRef] [PubMed]

- Dolimont, A.; Rivière-Lorphèvre, E.; Ducobu, F.; Backaert, S. Impact of chemical polishing on surface roughness and dimensional quality of electron beam melting process (EBM) parts. AIP Conf. Proc. 2018, 1960, 140007. [Google Scholar]

- Dolimont, A.; Demarbaix, A.; Ducobu, F.; Rivière-Lorphèvre, E. Chemical etching as a finishing process for electron beam melting (EBM) parts. AIP Conf. Proc. 2019, 2113, 150020. [Google Scholar]

- Łyczkowska, E.; Szymczyk, P.; Dybała, B.; Chlebus, E. Chemical polishing of scaffolds made of Ti-6Al-7Nb alloy by additive manufacturing. Arch. Civ. Mech. Eng. 2014, 14, 586–594. [Google Scholar] [CrossRef]

- Spitaels, L.; Ducobu, F.; Demarbaix, A.; Rivière-Lorphèvre, E.; Dehombreux, P. Influence of Conventional Machining on Chemical Finishing of Ti6Al4V Electron Beam Melting Parts. Procedia Manuf. 2020, 47, 1036–1042. [Google Scholar] [CrossRef]

- Hou, N.; Wang, M.; Wang, B.; Zheng, Y.; Zhou, S.; Song, C. Fundamental functions of physical and chemical principles in the polishing of titanium alloys: Mechanisms and problems. Int. J. Adv. Manuf. Technol. 2021, 118, 2079–2097. [Google Scholar] [CrossRef]

- Zhang, Z.; Shi, Z.; Du, Y.; Yu, Z.; Guo, L.; Guo, D. A novel approach of chemical mechanical polishing for a titanium alloy using an environment-friendly slurry. Appl. Surf. Sci. 2018, 427, 409–415. [Google Scholar] [CrossRef]

- Hilpert, E.; Hartung, J.; Risse, S.; Eberhardt, R.; Tünnermann, A. Precision manufacturing of a lightweight mirror body made by selective laser melting. Precis. Eng. 2018, 53, 310–317. [Google Scholar] [CrossRef]

- Crane, N.B.; Ni, Q.; Ellis, A.; Hopkinson, N. Impact of chemical finishing on laser-sintered nylon 12 materials. Addit. Manuf. 2017, 13, 149–155. [Google Scholar] [CrossRef]

- Melentiev, R.; Fang, F. Recent advances and challenges of abrasive jet machining. CIRP J. Manuf. Sci. Technol. 2018, 22, 1–20. [Google Scholar] [CrossRef]

- Bagehorn, S.; Wehr, J.; Maier, H.J. Application of mechanical surface finishing processes for roughness reduction and fatigue improvement of additively manufactured Ti-6Al-4V parts. Int. J. Fatigue 2017, 102, 135–142. [Google Scholar] [CrossRef]

- Zhang, J.; Toh, A.Y.X.; Wang, H.; Lu, W.F.; Fuh, J.Y.H. Vibration-assisted conformal polishing of additively manufactured structured surface. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 4154–4164. [Google Scholar] [CrossRef]

- Iquebal, A.S.; El Amri, S.; Shrestha, S.; Wang, Z.; Manogharan, G.P.; Bukkapatnam, S. Longitudinal milling and fine abrasive finishing operations to improve surface integrity of metal am components. Procedia Manuf. 2017, 10, 990–996. [Google Scholar] [CrossRef]

- Bai, Y.; Chaudhari, A.; Wang, H. Investigation on the microstructure and machinability of ASTM A131 steel manufactured by directed energy deposition. J. Mater. Process. Technol. 2020, 276, 116410. [Google Scholar] [CrossRef]

- Lopes, J.G.; Machado, C.M.; Duarte, V.R.; Rodrigues, T.A.; Santos, T.G.; Oliveira, J.P. Effect of milling parameters on HSLA steel parts produced by Wire and Arc Additive Manufacturing (WAAM). J. Manuf. Process. 2020, 59, 739–749. [Google Scholar] [CrossRef]

- Ni, C.; Zhu, L.; Zheng, Z.; Zhang, J.; Yang, Y.; Hong, R.; Bai, Y.; Lu, W.F.; Wang, H. Effects of machining surface and laser beam scanning strategy on machinability of selective laser melted Ti6Al4V alloy in milling. Mater. Des. 2020, 194, 108880. [Google Scholar] [CrossRef]

- Ni, C.; Zhu, L.; Zheng, Z.; Zhang, J.; Yang, Y.; Yang, J.; Bai, Y.; Weng, C.; Lu, W.F.; Wang, H. Effect of material anisotropy on ultra-precision machining of Ti-6Al-4V alloy fabricated by selective laser melting. J. Alloy. Compd. 2020, 848, 156457. [Google Scholar] [CrossRef]

- Ma, C.; Dong, Y.; Ye, C. Improving surface finish of 3D-printed metals by ultrasonic nanocrystal surface modification. Procedia CIRP 2016, 45, 319–322. [Google Scholar] [CrossRef]

- Ma, C.; Andani, M.T.; Qin, H.; Moghaddam, N.S.; Ibrahim, H.; Jahadakbar, A.; Amerinatanzi, A.; Ren, Z.; Zhang, H.; Doll, G.L.; et al. Improving surface finish and wear resistance of additive manufactured nickel-titanium by ultrasonic nano-crystal surface modification. J. Mater. Process. Technol. 2017, 249, 433–440. [Google Scholar] [CrossRef]

- Bai, Y.; Shi, Z.; Lee, Y.J.; Wang, H. Optical surface generation on additively manufactured AlSiMg0.75 alloys with ultrasonic vibration-assisted machining. J. Mater. Process. Technol. 2020, 280, 116597. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, J.; Liew, P.J. Material removal in ultrasonic abrasive polishing of additive manufactured components. Appl. Sci. 2019, 9, 5359. [Google Scholar] [CrossRef]

- Petare, A.C.; Jain, N.K. A critical review of past research and advances in abrasive flow finishing process. Int. J. Adv. Manuf. Technol. 2018, 97, 741–782. [Google Scholar] [CrossRef]

- Sankar, M.R.; Mondal, S.; Ramkumar, J.; Jain, V.K. Experimental investigations and modeling of drill bit-guided abrasive flow finishing (DBG-AFF) process. Int. J. Adv. Manuf. Technol. 2009, 42, 678–688. [Google Scholar] [CrossRef]

- Hashmi, A.W.; Mali, H.S.; Meena, A.; Puerta, A.P.V.; Kunkel, M.E. Surface characteristics improvement methods for metal additively manufactured parts: A review. Adv. Mater. Process. Technol. 2022, 1–40. [Google Scholar] [CrossRef]

- Bouland, C.; Urlea, V.; Beaubier, K.; Samoilenko, M.; Brailovski, V. Abrasive flow machining of laser powder bed-fused parts: Numerical modeling and experimental validation. J. Mater. Process. Technol. 2019, 273, 116262. [Google Scholar] [CrossRef]

- Wang, X.; Li, S.; Fu, Y.; Gao, H. Finishing of additively manufactured metal parts by abrasive flow machining. In Proceedings of the 2016 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2016. [Google Scholar]

- Guo, J.; Song, C.; Fu, Y.; Au, K.H.; Kum, C.W.; Goh, M.H.; Ren, T.; Huang, R.; Sun, C.-N. Internal Surface Quality Enhancement of Selective Laser Melted Inconel 718 by Abrasive Flow Machining. J. Manuf. Sci. Eng. 2020, 142, 101003. [Google Scholar] [CrossRef]

- Han, S.; Salvatore, F.; Rech, J.; Bajolet, J.; Courbon, J. Effect of abrasive flow machining (AFM) finish of selective laser melting (SLM) internal channels on fatigue performance. J. Manuf. Process. 2020, 59, 248–257. [Google Scholar] [CrossRef]

- Peng, C.; Fu, Y.; Wei, H.; Li, S.; Wang, X.; Gao, H. Study on Improvement of Surface Roughness and Induced Residual Stress for Additively Manufactured Metal Parts by Abrasive Flow Machining. Procedia CIRP 2018, 71, 386–389. [Google Scholar] [CrossRef]

- Qian, C.; Fan, Z.; Tian, Y.; Liu, Y.; Han, J.; Wang, J. A review on magnetic abrasive finishing. Int. J. Adv. Manuf. Technol. 2021, 112, 619–634. [Google Scholar] [CrossRef]

- Zhang, J.; Chaudhari, A.; Wang, H. Surface quality and material removal in magnetic abrasive finishing of selective laser melted 316L stainless steel. J. Manuf. Process. 2019, 45, 710–719. [Google Scholar] [CrossRef]

- Wu, P.-Y.; Yamaguchi, H. Material Removal Mechanism of Additively Manufactured Components Finished using Magnetic Abrasive Finishing. Procedia Manuf. 2018, 26, 394–402. [Google Scholar] [CrossRef]

- Teng, X.; Zhang, G.; Zhao, Y.; Cui, Y.; Li, L.; Jiang, L. Study on magnetic abrasive finishing of AlSi10Mg alloy prepared by selective laser melting. Int. J. Adv. Manuf. Technol. 2019, 105, 2513–2521. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Fergani, O.; Wu, P.-Y. Modification using magnetic field-assisted finishing of the surface roughness and residual stress of additively manufactured components. CIRP Ann. 2017, 66, 305–308. [Google Scholar] [CrossRef]

- Guo, J.; Au, K.H.; Sun, C.-N.; Goh, M.H.; Kum, C.W.; Liu, K.; Wei, J.; Suzuki, H.; Kang, R. Novel rotating-vibrating magnetic abrasive polishing method for double-layered internal surface finishing. J. Mater. Process. Technol. 2019, 264, 422–437. [Google Scholar] [CrossRef]

- Mahmood, M.A.; Chioibasu, D.; Ur Rehman, A.; Mihai, S.; Popescu, A.C. Post-Processing Techniques to Enhance the Quality of Metallic Parts Produced by Additive Manufacturing. Metals 2022, 12, 77. [Google Scholar] [CrossRef]

- Zhu, P.; Zhang, G.; Du, J.; Jiang, L.; Zhang, P.; Cui, Y. Removal mechanism of magnetic abrasive finishing on aluminum and magnesium alloys. Int. J. Adv. Manuf. Technol. 2021, 114, 1717–1729. [Google Scholar] [CrossRef]

| Finishing Operation Group | Finishing Operation | Comments | References |

|---|---|---|---|

| Application of mechanical energy | Sand paper finishing | Simple to apply High wear rate Unsuitable for industrial scales | [12] |

| Abrasive jet finishing | Cannot finish intricate parts The translucent surface of the material can become opaque | [13] | |

| Barrel finishing | Long processing times May not be efficient Can finish intricate parts Surface roughness decrease rate can decay over time | [16] | |

| Abrasive flow finishing | Can be time-consuming | [17,18] | |

| Stair-step machining | [26,27] | ||

| Milling | |||

| Magnetic-field-assisted finishing | Magnetorheological finishing | May require primary finishing beforehand to reduce the roughness to 1–2 µm | [19] |

| Chemical finishing | Chemical polishing | Requires the knowledge of the material’s chemical properties May not remove the material evenly Can damage thin and intricate features | [21,22,24,25] |

| Laser polishing | Laser polishing | Does not waste material because it remelts it Can decrease the dimensions by creating negative deviations Highly controllable and can be selectively used for different parts of the workpiece | [31,32,33,34,35,36] |

| Application of coating | Wax coating for FDM | Can be used for investment casting Can lead to dimensional inaccuracy Can compensate for shrinkage | [28,29] |

| Photopolymers for SLA |

| Finishing Operation Group | Finishing Operation | Comments | References |

|---|---|---|---|

| Application of mechanical energy | Post-milling | The tools’ path is restricted so they cannot access intricate details of the parts Waste material May induce undesired deformation The material removal rate can be high | [95,96,97,98,99,100,101] |

| Abrasive jet finishing | Can be applied in a micro and macro scale Can be applied to various shapes, complex surfaces, and geometries Not sensitive to the gap fluctuation between the nozzle and the workpiece The resultant surface roughness and material removal rate are easily controlled Improvement of the surface Slow tool wear without abrupt changes in the process accuracy Abrasives can be recycled More cost-effective compared to polishing, etching, and milling | [94] | |

| Ultrasonic nanocrystal surface modification | [102,103] | ||

| Ultrasonic cavitation abrasive finishing | [37,105] | ||

| Abrasive flow finishing | High initial MRR and decreased MRR with each successive cycle Rounding of the corners might be an issue | [106,107,108,109,110,111,112,113] | |

| Magnetic-field-assisted finishing | Magnetic abrasive finishing | Self-sharpening Good flexibility, stability, and controllability Suitable for regular and complex geometries Suitable for a range of wide materials: resin, ceramics, metals, glass, etc. (mostly for hard materials) The abrasives’ life is short | [72,115,116,121] |

| Electrochemical and chemical finishing | Electrochemical finishing | The post-processing of complex and intricate parts is possible Can be used on any conductive material Does not alter the bulk material properties Pit formation can be an issue | [67,68,69,70,71,72] |

| Chemical finishing | The post-processing of complex and intricate parts is possible The material removal rate might be slow No impact on residual stress Dangerous chemicals Less expensive Repeatable, reproducible results, homogeneous dissolution Can alter mechanical properties due to the change in surface morphology Internal features can be accessed | [76,77,78,79,80,81,82,83,84,85,86,87,88,93] | |

| Laser polishing | Laser polishing | Heat from the laser can cause undesirable tensile residual stresses to appear Does not waste material because it remelts it Similar to laser-based AM technologies, and thus can be integrated with them The initial surface roughness may influence the final surface roughness Can alter the surface microstructure May increase the hardness of the surface material | [38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56] |

| Laser shock peening and shot peening | Can induce compressive stresses in the surface of the workpiece or transform existing tensile stresses to compressive stresses Grain refinement and work hardening in the surface Can improve or degrade the surface Can improve fatigue performance | [2,57,58,59,62,63,64,65,66] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Syrlybayev, D.; Seisekulova, A.; Talamona, D.; Perveen, A. The Post-Processing of Additive Manufactured Polymeric and Metallic Parts. J. Manuf. Mater. Process. 2022, 6, 116. https://doi.org/10.3390/jmmp6050116

Syrlybayev D, Seisekulova A, Talamona D, Perveen A. The Post-Processing of Additive Manufactured Polymeric and Metallic Parts. Journal of Manufacturing and Materials Processing. 2022; 6(5):116. https://doi.org/10.3390/jmmp6050116

Chicago/Turabian StyleSyrlybayev, Daniyar, Aidana Seisekulova, Didier Talamona, and Asma Perveen. 2022. "The Post-Processing of Additive Manufactured Polymeric and Metallic Parts" Journal of Manufacturing and Materials Processing 6, no. 5: 116. https://doi.org/10.3390/jmmp6050116

APA StyleSyrlybayev, D., Seisekulova, A., Talamona, D., & Perveen, A. (2022). The Post-Processing of Additive Manufactured Polymeric and Metallic Parts. Journal of Manufacturing and Materials Processing, 6(5), 116. https://doi.org/10.3390/jmmp6050116