Heat Dissipation Plays Critical Role for Longevity of Polymer-Based 3D-Printed Inserts for Plastics Injection Moulding †

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

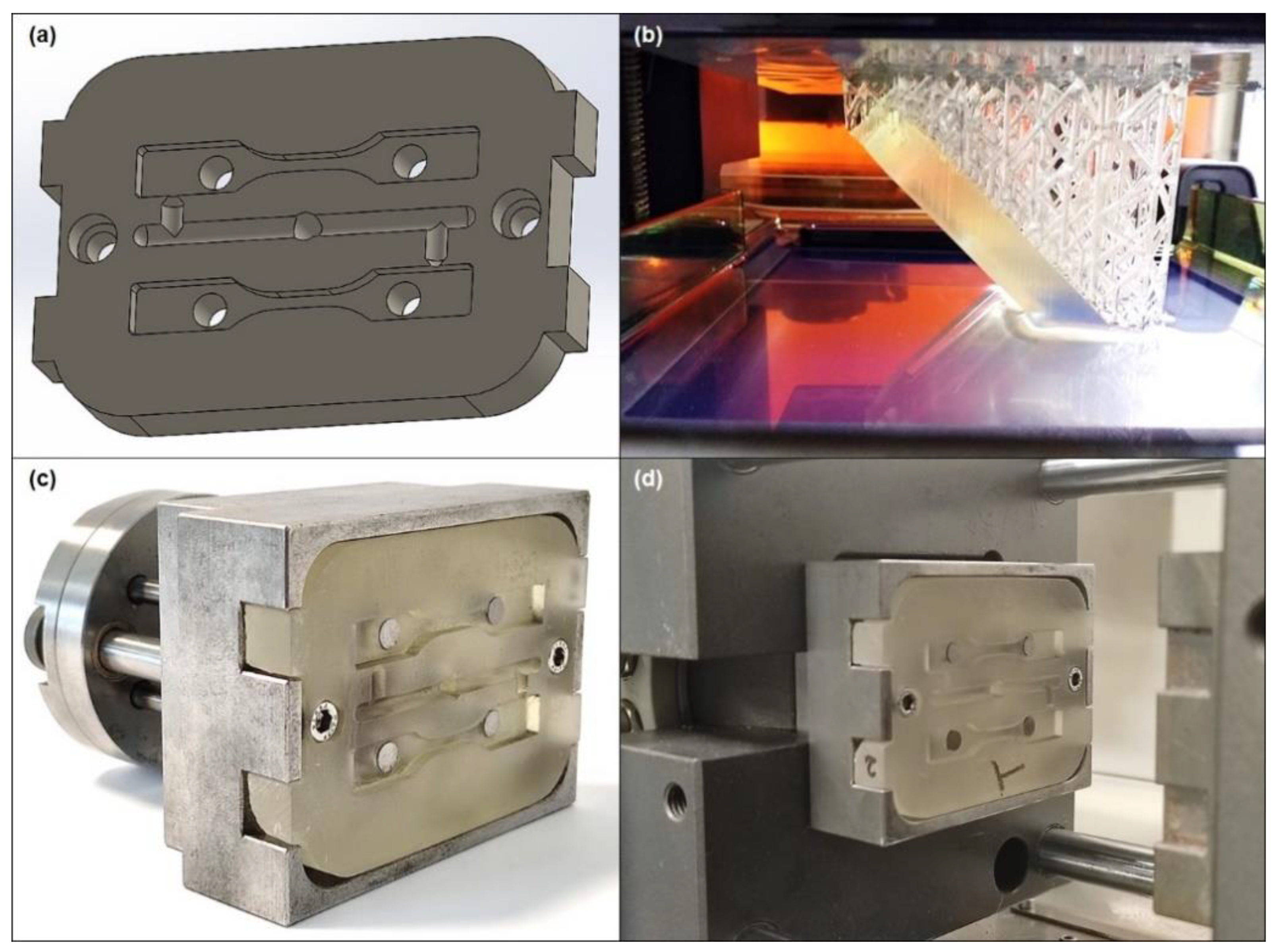

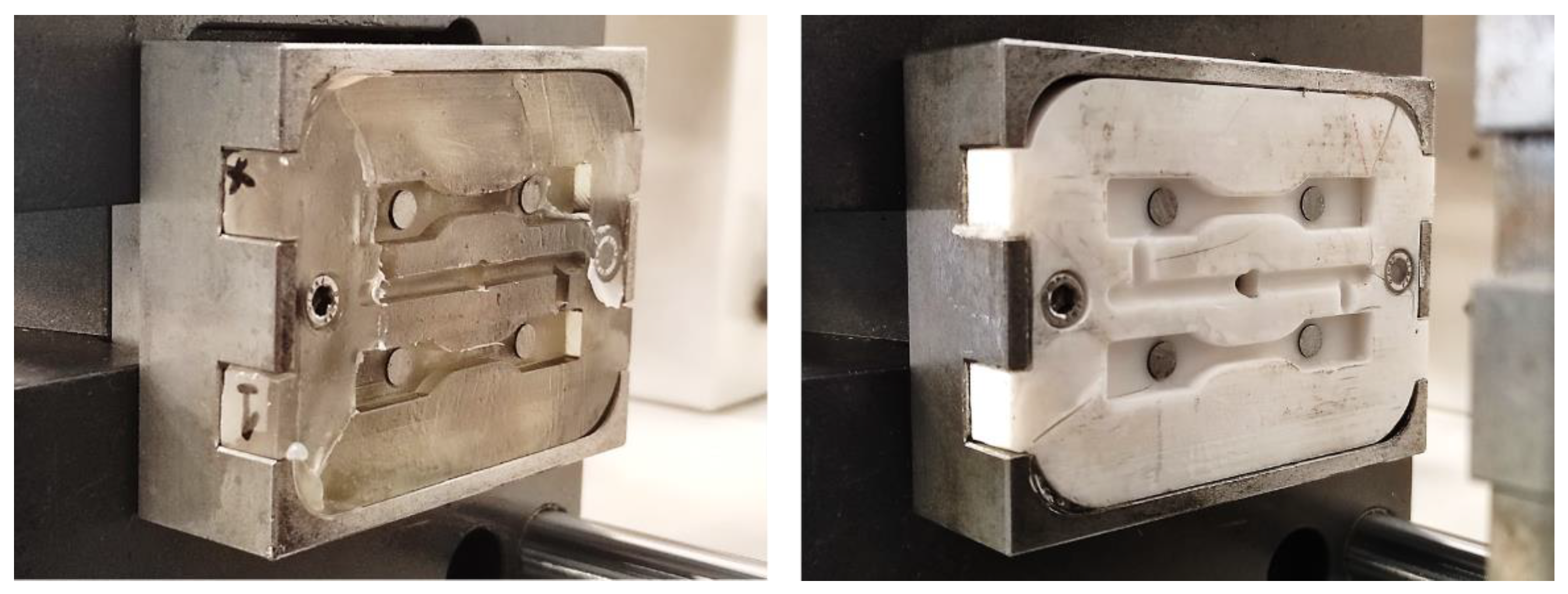

2.2. Fabrication of Mould Inserts

2.3. Injection Moulding

2.4. Mould Insert Materials Characterisation

2.5. Differential Scanning Calorimetry

2.6. Tensile Testing

2.7. Dimensional Stability

2.8. Statistical Analyses

3. Results and Discussion

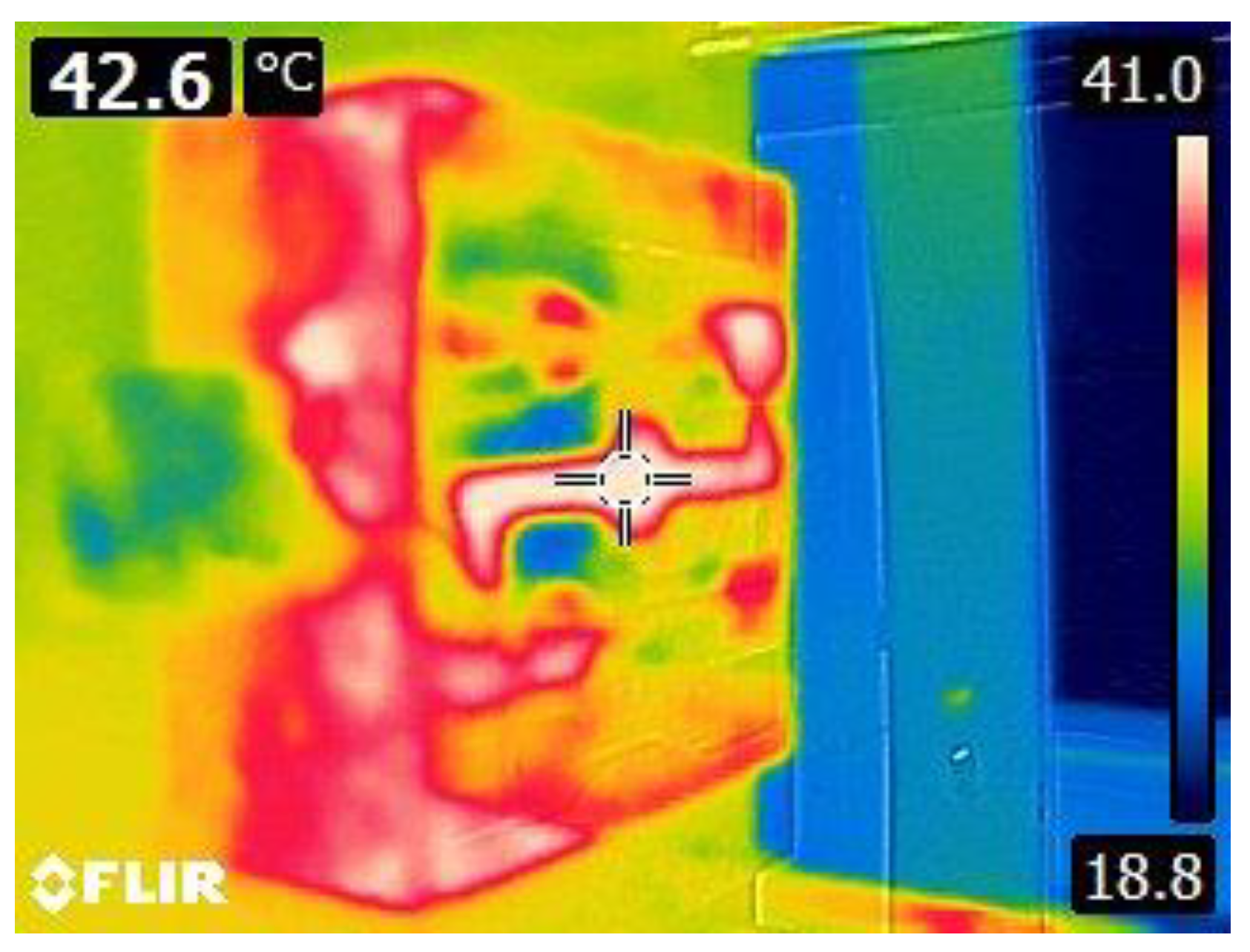

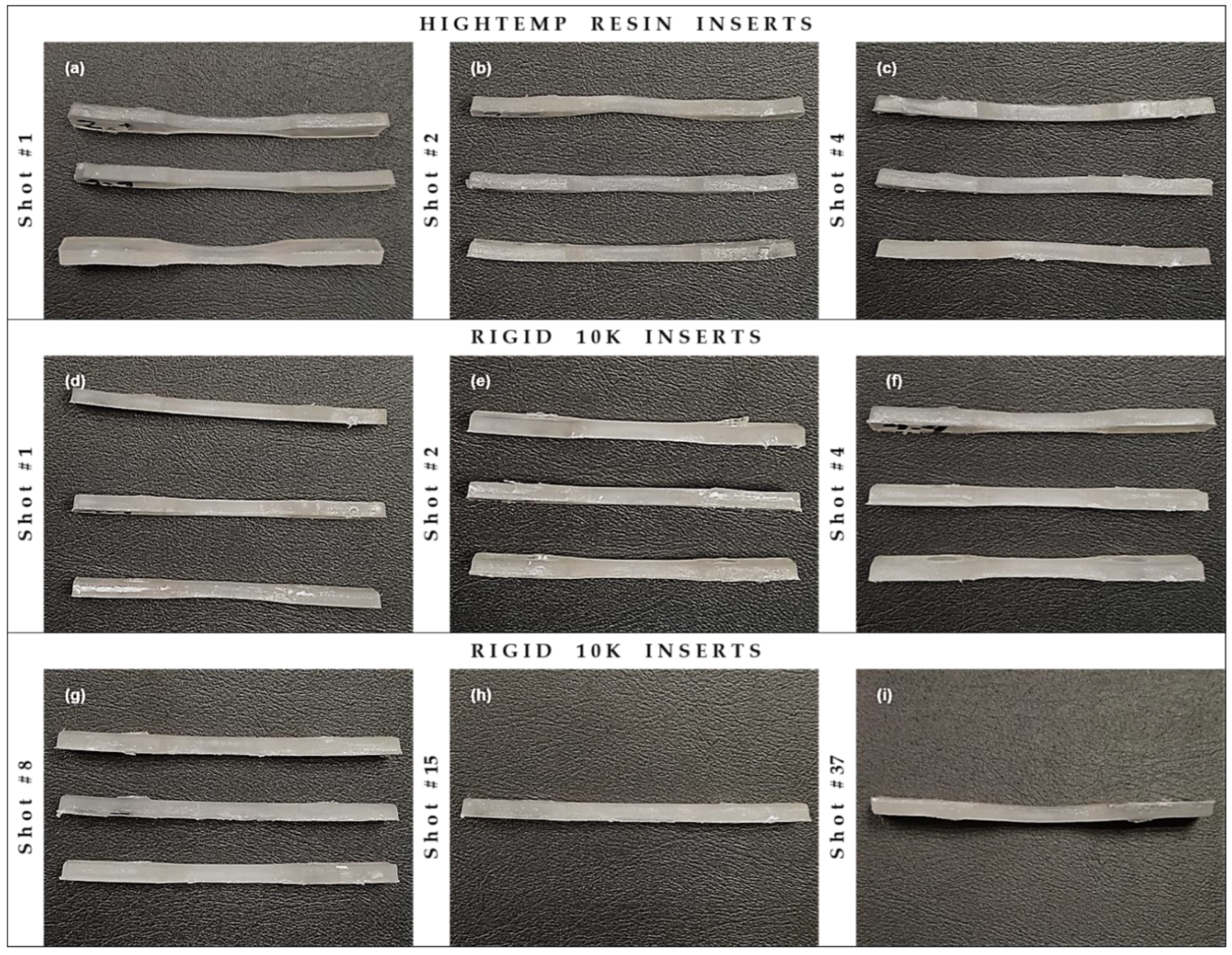

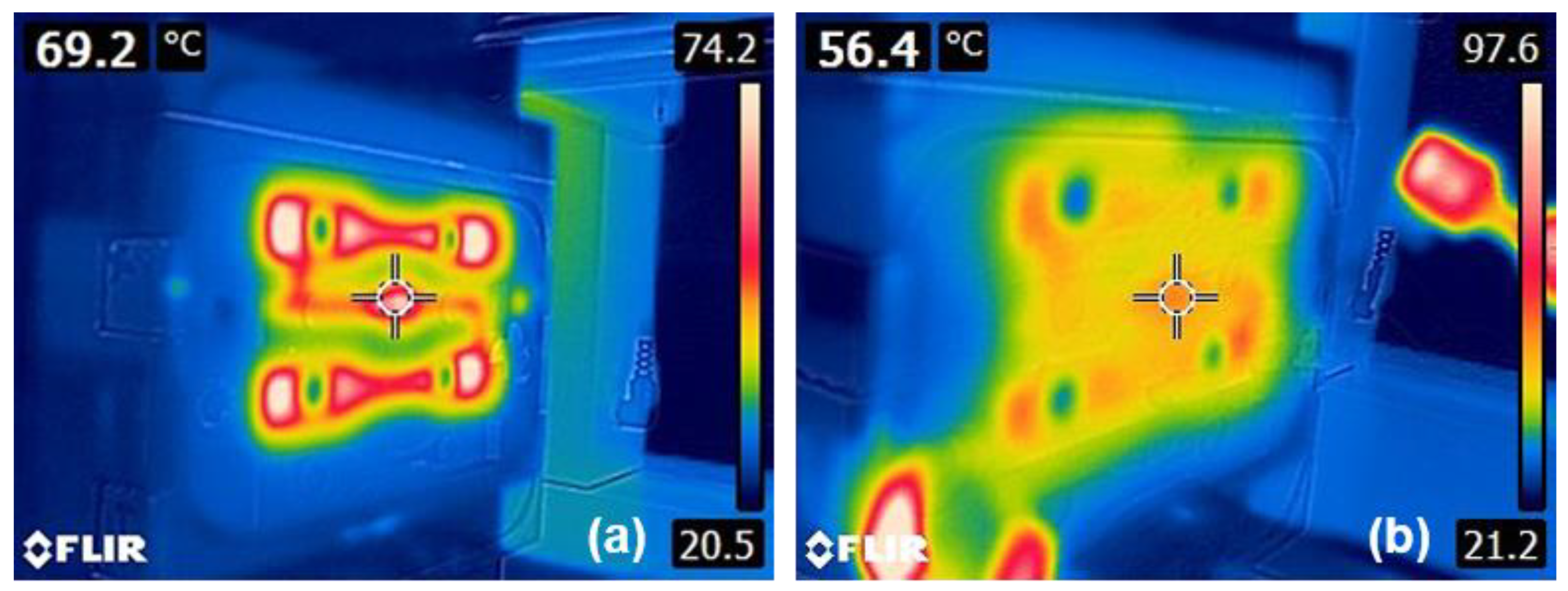

3.1. Observations on Mould Inserts and Injection Moulding

3.2. Thermal and Mechanical Properties of the Photopolymer Resins

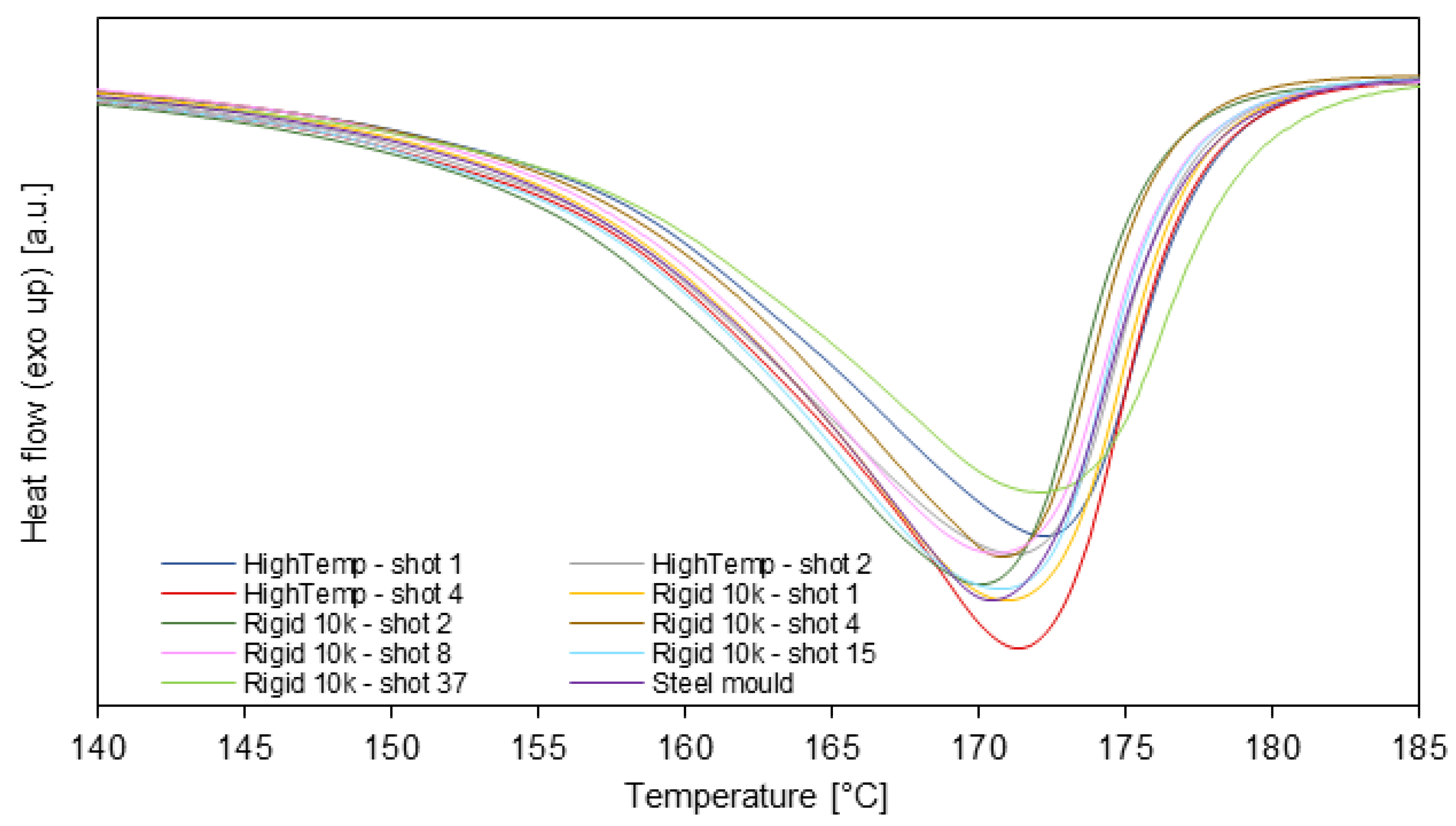

3.3. PP Thermal Characteristics

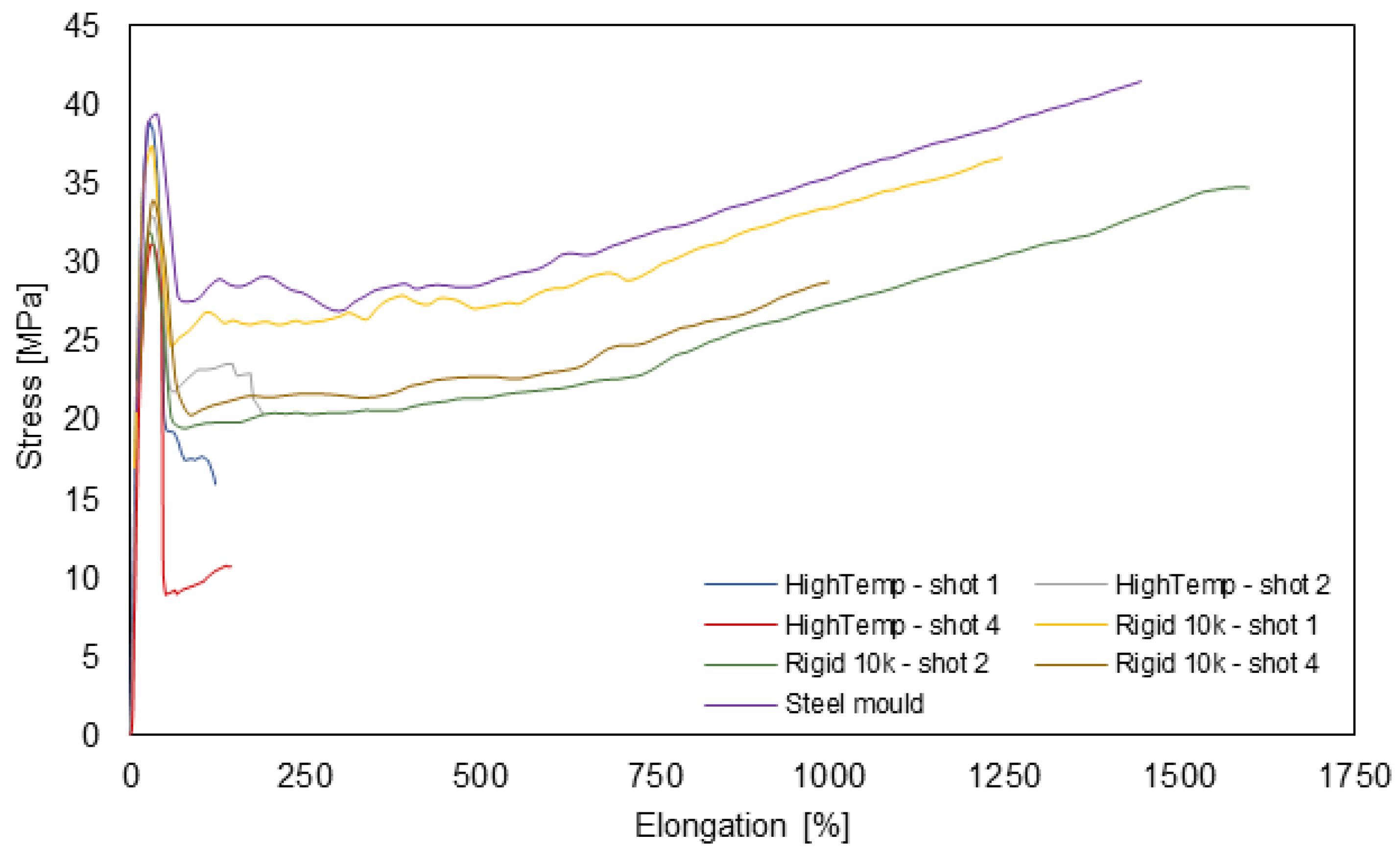

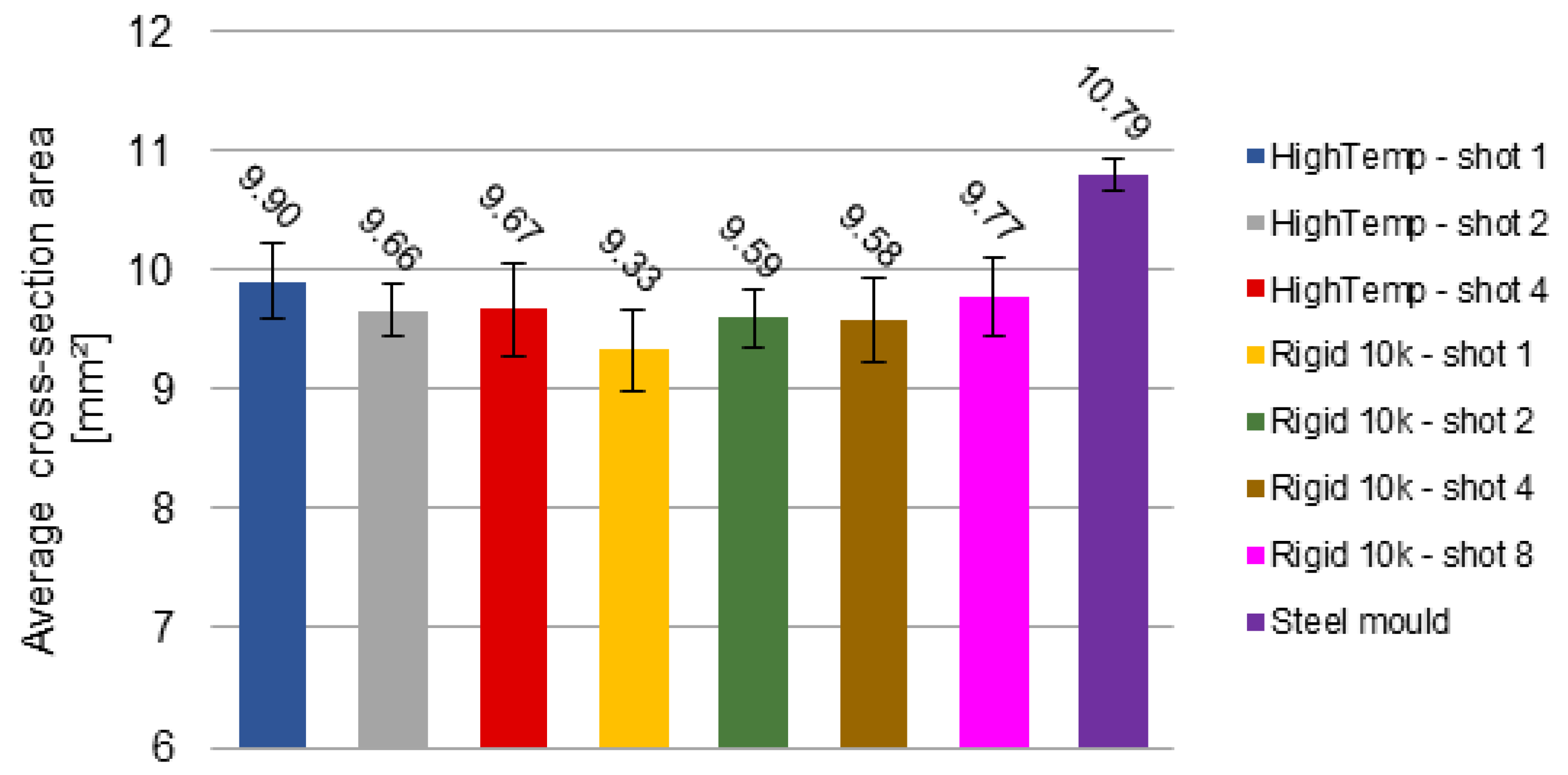

3.4. PP Mechanical Properties and Dimensional Stability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, G.; Verma, A. A Brief Review on injection moulding manufacturing process. Mater. Today Proc. 2017, 4, 1423–1433. [Google Scholar] [CrossRef]

- Maddah, H.A. Polypropylene as a Promising Plastic: A Review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar] [CrossRef]

- Petrova, T.; Kazmer, D. Incorporation of Phenomenological Models in a Hybrid Neural Network for Quality Control of Injection Molding. Polym. Plast. Technol. Eng. 1999, 38, 1–18. [Google Scholar] [CrossRef]

- Levy, G.N.; Schindel, R.; Kruth, J.P. Rapid manufacturing and rapid tooling with layer manufacturing (LM) technologies, state of the art and future perspectives. CIRP Ann. 2003, 52, 589–609. [Google Scholar] [CrossRef]

- Yap, Y.L.; Wang, C.; Sing, S.L.; Dikshit, V.; Yeong, W.Y.; Wei, J. Material jetting additive manufacturing: An experimental study using designed metrological benchmarks. Precis. Eng. 2017, 50, 275–285. [Google Scholar] [CrossRef]

- Pouzada, A.S. Hybrid moulds: A case of integration of alternative materials and rapid prototyping for tooling. Virtual Phys. Prototyp. 2009, 4, 195–202. [Google Scholar] [CrossRef]

- Ribeiro, A.S.; Hopkinson, N.; Ahrens, C.H. Thermal effects on stereolithography tools during injection moulding. Rapid Prototyp. J. 2004, 10, 176–180. [Google Scholar] [CrossRef]

- Westphal, M.G.; Pouzada, A.S.; Salmoria, G.V.; Ahrens, C.H. Performance and Friction Properties of Injection Hybrid Moulds with Stereolithography Moulding Zones. Mater. Sci. Forum. 2006, 514–516, 1673–1677. [Google Scholar] [CrossRef]

- Rahmati, S.; Dickens, P. Rapid tooling analysis of Stereolithography injection mould tooling. Int. J. Mach. Tools Manuf. 2007, 47, 740–747. [Google Scholar] [CrossRef]

- Martinho, P.; Bártolo, P.J.; Queirós, L.M.P.; Pontes, A.J.; Pouzada, A.S. Hybrid moulds: The use of combined techniques for the rapid manufacturing of injection moulds. In Virtual Modeling and Rapid Manufacturing: Advanced Research in Virtual and Rapid Prototyping: Proceedings of the 2nd International Conference on Advanced Research and Rapid Prototyping, Leiria, Portugal, 28 September–1 October 2005; Taylor and Francis: New York, NY, USA, 2005; Available online: http://hdl.handle.net/1822/34152 (accessed on 20 July 2022).

- Gheisari, R.; Bartolo, P.; Goddard, N.; Domingos, M.A.N. An experimental study to investigate the micro-stereolithography tools for micro injection molding. Rapid Prototyp. J. 2017, 23, 711–719. [Google Scholar] [CrossRef]

- Dempsey, D.; McDonald, S.; Masato, D.; Barry, C. Characterization of Stereolithography Printed Soft Tooling for Micro Injection Molding. Micromachines 2020, 11, 819. [Google Scholar] [CrossRef]

- Roy, M.; Dickens, T.J. Additive technology of soluble mold tooling for embedded devices in composite structures: A study on manufactured tolerances. Addit. Manuf. 2017, 15, 78–86. [Google Scholar] [CrossRef]

- Pervaiz, S.; Qureshi, T.A.; Kashwani, G.; Kannan, S. 3D Printing of Fiber-Reinforced Plastic Composites Using Fused Deposition Modeling: A Status Review. Materials 2021, 14, 4520. [Google Scholar] [CrossRef]

- Wu, T.; Jahan, S.A.; Zhang, Y.; Zhang, J.; Elmounayri, H.; Tovar, A. Design Optimization of Plastic Injection Tooling for Additive Manufacturing. Procedia Manuf. 2017, 10, 923–934. [Google Scholar] [CrossRef]

- Natalini, M.; Sasso, M.; Amodio, D. Comparison of Numerical and Experimental Data in Multi-objective Optimization of a Thermoplastic Molded Part. Int. Polym. Process. 2013, 28, 84–106. [Google Scholar] [CrossRef]

- Farotti, E.; Natalini, M. Injection molding. Influence of process parameters on mechanical properties of polypropylene polymer. A first study. Procedia Struct. Integr. 2018, 8, 256–264. [Google Scholar] [CrossRef]

- Zink, B.; Kovács, N.K.; Kovács, J.G. Thermal analysis based method development for novel rapid tooling applications. Int. Commun. Heat Mass Transf. 2019, 108, 104297. [Google Scholar] [CrossRef]

- Mendible, G.A.; Rulander, J.A.; Johnston, S.P. Comparative study of rapid and conventional tooling for plastics injection molding. Rapid Prototyp. J. 2017, 23, 344–352. [Google Scholar] [CrossRef]

- SASOL. Polypropylene Homopolymer (HNR100). 2017. Available online: https://products.sasol.com/pic/products/home/grades/ZA/5hnr100/index.html (accessed on 20 July 2022).

- FormLabs. HighTemp Resin. 2018. Available online: https://formlabs-media.formlabs.com/datasheets/High_Temp_Technical.pdf (accessed on 20 July 2022).

- FormLabs. Rigid 10k Resin. 2020. Available online: https://formlabs-media.formlabs.com/datasheets/2001479-TDS-ENUS-0.pdf (accessed on 20 July 2022).

- Wang, K.; Bahlouli, N.; Addiego, F.; Ahzi, S.; Rémond, Y.; Ruch, D.; Muller, R. Effect of talc content on the degradation of re-extruded polypropylene/talc composites. Polym. Degrad. Stab. 2013, 98, 1275–1286. [Google Scholar] [CrossRef]

- Hopkins, M.; Gunbay, S.; Hayes, C.; Moritz, V.F.; Fuenmayor, E.; Lyons, J.G.; Devine, D.M. Stereolithography (SLA) utilised to print injection mould tooling in order to evaluate thermal and mechanical properties of commercial polypropylene. Procedia Manuf. 2021, 55, 205–212. [Google Scholar] [CrossRef]

- Solanki, B.S.; Sheorey, T.; Singh, H. Experimental and numerical investigation of shrinkage and sink marks on injection molded polymer gears: A case study. Int. J. Interact. Des. Manuf. 2022. [Google Scholar] [CrossRef]

- Lassila, L.; Garoushi, S.; Vallittu, P.K.; Säilynoja, E. Mechanical properties of fiber reinforced restorative composite with two distinguished fiber length distribution. J. Mech. Behav. Biomed. Mater. 2016, 60, 331–338. [Google Scholar] [CrossRef]

- Ebrahimnezhad-Khaljiri, H.; Eslami-Farsani, R. The tensile properties and interlaminar shear strength of microcapsules-glass fibers/epoxy self-healable composites. Eng. Fract. Mech. 2020, 230, 106937. [Google Scholar] [CrossRef]

- Saravanakumar, K.; Arumugam, V.; Souhith, R.; Santulli, C. Influence of Milled Glass Fiber Fillers on Mode I & Mode II Interlaminar Fracture Toughness of Epoxy Resin for Fabrication of Glass/Epoxy Composites. Fibers 2020, 8, 36. [Google Scholar] [CrossRef]

- Rajaguru, J.; Duke, M.; Au, C. Development of rapid tooling by rapid prototyping technology and electroless nickel plating for low-volume production of plastic parts. Int. J. Adv. Manuf. Technol. 2015, 78, 31–40. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, M.; Ding, R.; Shi, Q.; Zhao, M. Preparation of a hybrid photopolymer for stereolithography. In Proceedings of the 5th International Conference on Advanced Design and Manufacturing Engineering—ICADME 2015, Shenzhen, China, 19–20 September 2015; pp. 1628–1632. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.K.; Mahmoodi, M.J.; Safi, M. Effect of adding carbon nanotubes on the thermal conductivity of steel fiber-reinforced concrete. Compos. Part B Eng. 2019, 174, 106972. [Google Scholar] [CrossRef]

- Mulyana, T.; Rahim, E.A.; Yahaya, S.N.M. The influence of cryogenic supercritical carbon dioxide cooling on tool wear during machining high thermal conductivity steel. J. Clean. Prod. 2017, 164, 950–962. [Google Scholar] [CrossRef]

- Kusić, D.; Hančič, A. Influence of molding conditions on the shrinkage and warpage behavior of standardized test specimens. In Proceedings of the Regional Conference Graz 2015—Polymer Processing Society PPS, Graz, Austria, 21–5 September 2015; p. 020017. [Google Scholar] [CrossRef]

- Lam, Y.C.; Zhai, L.Y.; Tai, K.; Fok, S.C. An evolutionary approach for cooling system optimization in plastic injection moulding. Int. J. Prod. Res. 2004, 42, 2047–2061. [Google Scholar] [CrossRef]

- Gradys, A.; Sajkiewicz, P.; Minakov, A.A.; Adamovsky, S.; Schick, C.; Hashimoto, T.; Saijo, K. Crystallization of polypropylene at various cooling rates. Mater. Sci. Eng. A 2005, 413–414, 442–446. [Google Scholar] [CrossRef]

- Rhoades, A.M.; Wonderling, N.; Gohn, A.; Williams, J.; Mileva, D.; Gahleitner, M.; Androsch, R. Effect of cooling rate on crystal polymorphism in beta-nucleated isotactic polypropylene as revealed by a combined WAXS/FSC analysis. Polymer 2016, 90, 67–75. [Google Scholar] [CrossRef]

- Hu, G.; Cao, Z.; Hopkins, M.; Lyons, J.G.; Brennan-Fournet, M.; Devine, D.M. Nanofillers can be used to enhance the thermal conductivity of commercially available SLA resins. Procedia Manuf. 2019, 38, 1236–1243. [Google Scholar] [CrossRef]

- Hu, G.; Cao, Z.; Hopkins, M.; Hayes, C.; Daly, M.; Zhou, H.; Devine, D.M. Optimizing the hardness of SLA printed objects by using the neural network and genetic algorithm. Procedia Manuf. 2019, 38, 117–124. [Google Scholar] [CrossRef]

- Martinho, P.G.; Bártolo, P.J.; Pouzada, A.S. Hybrid moulds: Effect of the moulding blocks on the morphology and dimensional properties. Rapid Prototyp. J. 2009, 15, 71–82. [Google Scholar] [CrossRef]

| Property | FormLabs HighTemp [21] | FormLabs Rigid 10k [22] |

|---|---|---|

| Ultimate tensile strength | 58.3 MPa | 65 MPa |

| Elongation at break | 3.3% | 1.0% |

| Tensile modulus | 2.75 GPa | 10 GPa |

| Flexural strength at break | 94.5 GPa | 126 MPa |

| Flexural modulus | 2.62 GPa | 9 GPa |

| Notched IZOD | 18.2 J·m−1 | 16 J·m−1 |

| Insert Material | Tg [°C] Mean ± SD | E’ at Room Temp. [MPa] Mean ± SD | Stiffness at Room Temp. [kN·m−1] Mean ± SD | Thermal Conductivity [W·m−1·K−1] Mean ± SD | Shore D Hardness Mean ± SD |

|---|---|---|---|---|---|

| HighTemp | 97.8 (±3.5) | 1657 (±84.1) | 104.5 (±2.0) | 0.63 (±0.02) | 80.7 (±1.4) |

| Rigid 10k | 142.3 (±2.3) | 6309 (±422.8) | 362.0 (±12.4) | 0.83 (±0.03) | 90.8 (±0.7) |

| Sample | Tm [°C] | ∆Hf [J·g−1] | %Xc | Tc [°C] | ∆Hc [J·g−1] |

|---|---|---|---|---|---|

| HighTemp—shot 1 | 170.7 | 83.9 | 40.2 | 109.9 | 133.6 |

| HighTemp—shot 2 | 171.3 | 87.1 | 41.7 | 110.3 | 138.9 |

| HighTemp—shot 4 | 171.6 | 87.0 | 41.6 | 109.9 | 139.3 |

| Rigid 10k—shot 1 | 170.9 | 84.0 | 40.2 | 109.7 | 133.5 |

| Rigid 10k—shot 2 | 170.1 | 84.6 | 40.5 | 109.9 | 137.4 |

| Rigid 10k—shot 4 | 170.8 | 82.2 | 39.3 | 110.0 | 134.5 |

| Rigid 10k—shot 8 | 171.1 | 87.3 | 41.8 | 110.1 | 137.7 |

| Rigid 10k—shot 15 | 170.8 | 85.0 | 40.7 | 110.0 | 139.1 |

| Rigid 10k—shot 37 | 172.1 | 85.3 | 40.8 | 109.5 | 129.7 |

| Steel mould | 170.4 | 84.3 | 40.3 | 110.0 | 139.0 |

| Sample | Young’s Modulus [MPa] | Ultimate Tensile Strength [MPa] | Stress at Break [MPa] | Elongation at Break [%] |

|---|---|---|---|---|

| HighTemp—shot 1 | 261.0 | 33.6 | 3.5 | 180.2 |

| HighTemp—shot 2 | 307.1 | 35.4 | 3.2 | 201.0 |

| HighTemp—shot 4 | 289.3 | 32.1 | 2.4 | 137.1 |

| Rigid 10k—shot 1 | 295.4 | 38.4 | 5.1 | 1318.8 |

| Rigid 10k—shot 2 | 293.3 | 34.2 | 1.6 | 1451.5 |

| Rigid 10k—shot 4 | 285.8 | 37.9 | 2.2 | 978.7 |

| Steel mould | 310.8 | 42.9 | 6.2 | 1511.7 |

| HighTemp—Shot 1 | HighTemp—Shot 2 | HighTemp—Shot 4 | Rigid 10k—Shot 1 | Rigid 10k—Shot 2 | Rigid 10k—Shot 4 | Rigid 10k—Shot 8 | Steel Mould | |

| Cross-section area [mm2] | 9.90 | 9.66 | 9.67 | 9.33 | 9.59 | 9.58 | 9.77 | 10.79 |

| Spatial shrinkage [%] | 2.06 | 4.50 | 4.38 | 7.71 | 5.14 | 5.28 | 3.34 | −6.73 |

| Dif. to expected shrinkage [%] | N/A | N/A | N/A | 2.91 | 0.20 | 0.35 | N/A | N/A |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moritz, V.F.; Bezerra, G.S.N.; Hopkins Jnr, M.; Fuenmayor, E.; Günbay, S.; Hayes, C.; Lyons, J.G.; Devine, D.M. Heat Dissipation Plays Critical Role for Longevity of Polymer-Based 3D-Printed Inserts for Plastics Injection Moulding. J. Manuf. Mater. Process. 2022, 6, 117. https://doi.org/10.3390/jmmp6050117

Moritz VF, Bezerra GSN, Hopkins Jnr M, Fuenmayor E, Günbay S, Hayes C, Lyons JG, Devine DM. Heat Dissipation Plays Critical Role for Longevity of Polymer-Based 3D-Printed Inserts for Plastics Injection Moulding. Journal of Manufacturing and Materials Processing. 2022; 6(5):117. https://doi.org/10.3390/jmmp6050117

Chicago/Turabian StyleMoritz, Vicente F., Gilberto S. N. Bezerra, Michael Hopkins Jnr, Evert Fuenmayor, Suzan Günbay, Conor Hayes, John G. Lyons, and Declan M. Devine. 2022. "Heat Dissipation Plays Critical Role for Longevity of Polymer-Based 3D-Printed Inserts for Plastics Injection Moulding" Journal of Manufacturing and Materials Processing 6, no. 5: 117. https://doi.org/10.3390/jmmp6050117

APA StyleMoritz, V. F., Bezerra, G. S. N., Hopkins Jnr, M., Fuenmayor, E., Günbay, S., Hayes, C., Lyons, J. G., & Devine, D. M. (2022). Heat Dissipation Plays Critical Role for Longevity of Polymer-Based 3D-Printed Inserts for Plastics Injection Moulding. Journal of Manufacturing and Materials Processing, 6(5), 117. https://doi.org/10.3390/jmmp6050117