1. Introduction

The production of high-precision components with micro-scale features is becoming increasingly important in almost all industrial sectors. Due to the high requirements and complexity of the field of micro-machining, Uhlmann et al. [

1] proposed dedicated process chains for micro-production engineering. Furthermore, the advances in and limitations of current micro-machine tools in several fields of micro-machining and electro-discharge machining (EDM) were presented. Electro-discharge drilling was shown to be a key technology for manufacturing advanced fuel injection nozzles and cooling holes in turbine blades in the aerospace and automotive industry, respectively [

2]. For the consumer market, micro-holes are required in various micro-components such as watches and camera systems [

3]. Using the non-conventional process of electro-discharge drilling, it is possible to machine electrically conductive materials with effective mechanical properties such as tool steel, carbides, titanium alloys, and super alloys.

A persistent challenge in the field of micro-electrical discharge machining is the formation of debris in the working gap (s) between the electrodes. The metallic nature of the debris acts as an electrical conductor in the electro-discharge drilling process, resulting in electric arcing and short circuits. To avoid these discharge phenomena, pressure flushing is used to remove debris from the lateral working gap (s

l). Even though the process is significantly improved, electric arcing and short circuits still occur in the working gap (s). These electric arcs and short circuits lead to an increased process instability, erosion duration (t

ero), linear tool wear (Δl

e), and conicity of boreholes (α) [

4]. Therefore, enhanced flushing is required to achieve the precise machining of boreholes with high aspect ratios (a).

Uhlmann et al

. [

5] presented an improved method of removing debris by using inverted pressure flushing. Here, pressure (p) is generated above the lateral working gap (s

l), resulting in the removal of debris through the tool electrode′s interior channel. Compared to conventional pressure flushing, the erosion duration (t

ero) can be reduced by 52%. Furthermore, promising approaches to reducing the number of discharges in the lateral working gap (s) have been demonstrated by modifying the tool electrode’s geometry and depositing coatings. Therefore, Uhlmann et al. [

5,

6,

7] used tool electrodes with an external helical structure to increase the removal efficiency of debris. The erosion duration (t

ero) was reduced by 39% for the nickel-based alloy MAR-M247 and 64% for the tool steel Elmax SuperClean without the use of active flushing. However, the usage of these helical electrodes led to an increase in the linear tool wear (Δl

e) by nearly 25% in MAR-M247 [

6]. In addition, applying active flushing through the tool electrodes still led to a decrease in the erosion duration (t

ero) by 20% in Elmax SuperClean.

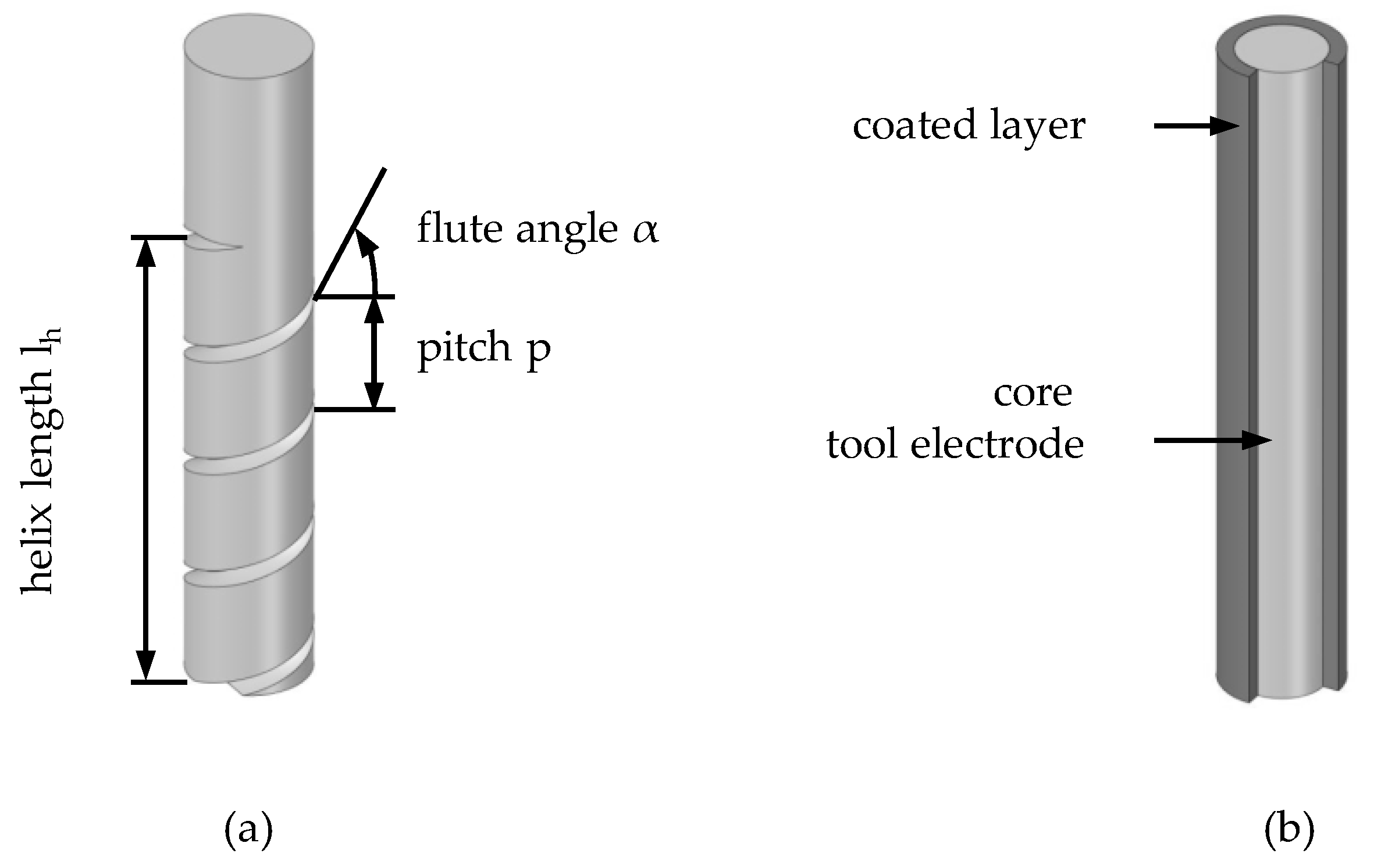

Figure 1 shows approaches for helical and coated tool electrodes.

Ferraris et al. [

8] electrically insulated tool electrodes made of tungsten carbide (WC) by coating them. Due to the high requirements for the mechanical properties of thermal conductivity (λ) and electrical resistance (R), silicon carbonitride–silicon carbide (SiCN-SiC) was used as the ceramic coating material. SiCN-SiC-coated tool electrodes showed a reduction in the erosion duration (t

ero) by 18%. Nevertheless, the application of SiCN-SiC-coated electrodes was limited by the fracture and delamination of the coating. These failures were caused by the thermal impact of the electric discharges. Furthermore, parylene C (2,8-dichloro-tricyclo[8.2.2.24,7]hexadeca-4,6,10,12,13,15-hexaene) was used as a polymer coating material via chemical vapor deposition (CVD). By using parylene C as a coating material for tool electrodes, more reliable results could be achieved due to the reduction in delamination and fracturing. Yuangang et al

. [

9] insulated copper tool electrodes using a zirconium diboride–copper (CuZrB

2) coating with a diameter (d) of 5 mm to increase the wear resistance (R

W) of the tool electrodes.

Despite the potential for significant process improvements, the fracturing and delamination of tool electrode coatings are still challenges in electro-discharge drilling [

8]. Thus, residues from the coatings can lead to biocompatibility restrictions in medical applications.

Another type of passivation is oxidation, which was studied and analyzed by Cabrera and Mott [

10]. The different oxidation behaviors at different temperatures (ϑ) were investigated. Exposing copper to oxygen at low temperatures (ϑ) initiates oxidation, forming a thin oxide layer. This layer is also known as a passivation film, which acts as a diffusion barrier to prevent further oxidation [

11]. At higher temperatures (ϑ), the oxide layer continues to grow by the diffusion of copper into the oxide layer according to the parabolic law [

12]. The resulting oxide layer is composed of two different oxides. The inner layer is red copper (I) oxide, whereas the outer layer is black copper (II) oxide. The outer oxidation layer is thinner than the inner layer due to the higher Gibbs free energy (ΔG

0) and the lower thermal stability above the oxidation temperature (ϑ

oxi = 800 °C) of copper (II) oxide [

13,

14,

15]. Furthermore, both copper oxides show semiconductor properties, which results in their application as materials for thin-film solar cells [

16,

17]. The potential use of copper (I) oxides in solar cells has been known since 1920, before silicon (Si), germanium (Ge), and other semiconducting materials were considered [

18]. In addition, the good environmental compatibility compared to conventional materials such as silicon or gallium arsenide has been emphasized [

16,

17].

In this work, the results of preliminary experiments on a new approach for the passivation of the lateral surface of copper tool electrodes for electro-discharge drilling are presented. Our electrical insulation approach does not require one or multiple coating steps. Instead, the tool electrode is passivated by oxidation according to Uhlmann et al. [

19].

With this novel approach, the existing challenges concerning the use of additional materials could be overcome. It was assumed that the oxide layer of the tool electrode would increase the electrical resistance (R), which would decrease the probability of electric arcing and short circuits in the lateral working gap (sl). Therefore, improved process stability and decreased erosion duration (tero) and linear tool wear (Δle) were expected.

2. Materials and Methods

2.1. Oxidation of Copper

In this work, the surface of copper electrodes with a length (l) of 90.0 mm, a diameter (d) of 2.5 mm and a surface roughness (Ra) of 0.23 µm were oxidized to increase the electrical resistance (R) of the electrode’s surface and thereby improve the processing results of EDM. Prior to the oxidation, the copper tool electrodes were cleaned with isopropanol. The copper tool electrodes were thermally oxidized using an N-11/R furnace (Nabertherm GmbH, Lilienthal, Germany). The electrical resistivity (ρ) of the oxidized tool electrodes was determined by the four-terminal measurement method using Model 175 (Keithley Instruments, Solon, OH, USA) and Model 5001, 3 (Prema Präzisionselektronik GmbH, Mainz, Germany) multimeters for current and voltage measurements at temperatures (ϑmeas) of 20°C. The measurements were taken on the lateral surface with a distance between the inner pins (li) of 47 mm. Furthermore, the surface of the tool electrodes was analyzed by a JCM 5000 NeoScope scanning electron microscope (SEM) (Jeol Ltd., Akishima, Japan), as well as an Axio Imager 2 optical microscope (OM) (Carl Zeiss Microscopy GmbH, Jena, Germany).

As preliminary experiments, extraordinarily high oxidation temperatures (ϑ

oxi) were chosen, see

Table 1. This experiment was intended to show the exemplary use of tool electrodes treated at high oxidation temperatures (ϑ

oxi) for electro-discharge drilling.

2.2. Electro-Discharge Drilling

Electro-discharge drilling was carried out on an Agietron Compact 1 machine tool (GF AgieCharmilles SA, Losone, Switzerland) by machining blind holes with a depth (t) of 14.0 mm. As the workpiece material, Elmax SuperClean tool steel (voestalpine AG, Linz, Austria) was used due to its technical importance in the field of mold- and toolmaking. For the experimental investigations, neither active flushing nor rotation was used to achieve reproducibility. Instead, a passive flushing technique with a stroke length (l

s) of 12 mm and an interval (t

i) of 30 s was applied to remove debris from the cavity. The generator parameters used for electro-discharge drilling are given in

Table 2.

Further investigations were carried out by performing a signal analysis to determine the electric current (i) and voltage (u) in the electro-discharge drilling process. As a measuring device, a Picoscope 3405D (Pico Technology, Cambridgeshire, UK) was used. To investigate whether the different oxide layers influenced the number of lateral discharges, two workpiece electrode halves made of Elmax SuperClean with a thickness (dr) of 5 mm were separated by a non-conductive rubber layer and contacted individually. To prevent the transfer of electric current (i) along the clamping tool, 3D-printed polylactide (PLA) was used as a spacer between the workpiece electrodes and the clamping tool.

Thus, two electric currents (i) could be measured using two TCP303 current probes with an additional TCPA300 current probe amplifier (Tektronix, Inc, Beaverton, OR, USA). The voltage (u) was measured by a TT-HV 150 voltage probe (Testec Elektronik GmbH, Dreieich, Germany

).

Figure 2 illustrates the experimental setup.

During the processing of the bottom workpiece electrode half, this setup allowed for the frontal discharges to be measured in the bottom workpiece electrode half, while the lateral discharges were measured in the top workpiece electrode half. With increasing depth (t), however, lateral discharges were also detected in the bottom workpiece electrode half. Therefore, the initiation of the drilling of the bottom workpiece electrode was also observed.

The signal analysis was carried out using the semi-automatic analysis software implemented by Thißen et al. [

21]. The signals were acquired with a sampling frequency (f

s) of 10.4 MHz for the time of measurement (t

meas) of 24.04 ms. The delay time (t

d) of 172.81 µs, resulting from buffering, transferring, and saving data, led to an overall measurement ratio (r

meas) of 12.2%. Events were registered when the current signal exceeded the current threshold (i

t) of 3.5 A.

The method used by this software to identify the types of discharge event by analyzing the current (i) and the voltage (u) was based on the classification method of Nirala and Saha [

22]. It allowed types of discharge, such as normal discharge, effective discharge, arcing, and short circuits, to be distinguished from each other and the number of each discharge type to be determined. The differentiation of the discharge types was based on thresholds depending on the open-circuit voltage (û

i) and is specified in

Table 3.

Normal and effective pulses are defined as beneficial to the electro-discharge drilling process, whereas arcing and short circuits are maleficial. In this work, short circuits were detected by the short threshold (uts) of 30 V not being exceeded.

It could be anticipated that the isolating oxide layer would lead to the occurrence of fewer discharges on the lateral surface of the tool electrode as well as on the top half of the workpiece electrode.

3. Results and Discussion

3.1. Oxidation of Copper

It was expected that the formation of thicker layers of copper oxide would influence the electrical resistivity (ρ) of the lateral surface of the tool electrode. Valladares et al. [

23] found that the sheet resistance (R

Sh) increased by a factor of 10

2 < F < 10

16 depending on the chosen annealing temperature (ϑ

a) for copper.

Compared to metallic bonds, covalent or ionic bonds mostly produce insulators. The electrons are bound and remain in the full valence band due to the large valence–conduction band gap (EG). This results in a high electrical resistivity (ρ). Semiconductors, such as copper (I) oxide and copper (II) oxide, only show a small valence–conduction band gap (EG). Due to thermal excitation, the electrons of the valence band can rise to the conduction band, creating a hole in the valence band and a partially filled conduction band. Nevertheless, the formation of copper oxides should lead to increased electrical resistivity (ρ) compared to copper.

However, the four-terminal measurement on the lateral surface of the tool electrodes resulted in decreased electrical resistivities (ρ

E1 = 0.01977 Ωmm

2/m and ρ

E2 = 0.02010 Ωmm

2/m) compared to the untreated tool electrode (ρ

Ref = 0.02020 Ωmm

2/m), with a standard deviation of up to 4.5%. These very similar values of electrical resistivity (ρ) could have had their origin in the base material due to an irregular oxide layer. To confirm this hypothesis, SEM and OM images of the oxidized tool electrodes were taken, as shown in

Figure 3. Furthermore, the broken oxide layer was inspected at the fracture surface by SEM to determine the oxide layer thickness (d

oxi).

As indicated, the oxidation of the tool electrode resulted in an irregular oxide layer, shown by the darker areas at the tip of tool electrodes E1 and E2. The delamination of the oxide layer was also seen in the inner channel of tool electrode E1. Furthermore, increased surface roughness due to the nonuniform formation of oxides on the surface and thermal stress (σ

th) caused by a difference in thermal expansion (α) between copper and its oxides was observed for the oxidized electrodes. The thermal stress (σ

th) led to the partial delamination of the oxide layer, with an oxide layer thickness (d

oxi) of up to 60 µm caused by a difference in the thermal expansion coefficient between copper (α

Cu = 17.1 × 10

−6/K) and its oxides (α

CuO = 12.5 × 10

−6/K and α

Cu2O = 2.8 × 10

−6/K) [

24]. Therefore, it is reasonable to assume that the base material may have affected the results of the four-terminal measurement.

In addition to cracks and irregular oxide layers, the thermal exposure also led to recovery and recrystallization processes, which could explain the slight decrease in electrical resistivity (ρ). The recovery process resulted in the removal of defects and dislocations, whereas the recrystallization process led to the formation of a new micro-structure. The chosen oxidation temperature (ϑ

oxi) and slower cooling in air also supported grain coarsening. Cross-sections of the tool electrodes are shown for comparison in

Figure 4.

The reference electrode composed of small grains was elongated by wire drawing along the horizontal axis during its fabrication. This resulted in a grain size (sghoRef) of 57 μm with an aspect ratio (a) of 7.8 along this axis. The oxidation temperature (ϑoxi) of up to 900°C led to recrystallization and additional grain coarsening, resulting in increased grain sizes: sgE1 = 137 µm and sgE2 = 106 µm.

Due to the recrystallization and grain coarsening, the temperature exposure also decreased the strength (f) of the base material, so that tool electrodes with very high aspect ratios (a) suffered from a deviation in straightness. For this reason, the length of the tool electrodes was reduced prior to the oxidation process. However, a small deviation in straightness could not be inhibited. Subsequently, these oxidized tool electrodes were examined in the process of electro-discharge drilling.

3.2. Electro-Discharge Drilling

The processing results concerning erosion duration (t

ero) and linear tool wear (Δl

e) for the machining of blind holes with a depth (t) of 14.0 mm in Elmax SuperClean tool steel are compared between the oxidized tool electrodes and the unoxidized reference tool electrodes in

Figure 5.

The oxidation of the tool electrodes E1 and E2 did not alter the linear tool wear (Δle) significantly. Since the generator and flushing parameters were not modified, it could be deduced that the material removal rate (MRR) and the electrode wear rate (EWR) changed proportionally, resulting in a nearly constant linear tool wear (Δle) of 4.8 mm.

Both treatments of the tool electrodes E1 and E2 led to an improvement in the erosion duration (tero) compared to the unoxidized tool electrodes. For the application of tool electrodes E1 and E2, the erosion duration could be reduced by up to 48%, from tero,Ref = 38.7 min to tero,E1 = 19.8 min and tero,E2 = 20.4 min, respectively. It can be inferred that the oxidation of the tool electrodes and the resulting higher electrical resistivity (ρ) of the oxidized lateral surface led to increased process stability due to the decrease in the number of lateral discharges. Instead, the electrical discharges seemed to preferably occur in the frontal gap (sf).

To confirm this, a signal analysis was carried out. In

Figure 6a,b, the results of the signal analysis are presented after a hole had been drilled through the top workpiece and had reached the bottom workpiece electrode. The whole process was monitored. Due to the differences in the erosion durations (t

ero), the frequency ratio (λ) was calculated based on the beneficial and maleficial event types, related to the pulse frequency (f

p) of the generator.

Compared to the unoxidized reference tool electrode, the beneficial frequency ratios (λ

b) caused by contributing discharges in the bottom half of the workpiece electrode both increased, from λ

b,(b),Ref = 6.17% to λ

b,(b),E1 = 7.44% and λ

b,(b),E2 = 10.23%. In addition, the maleficial frequency ratios (λ

m) caused by arcing and short circuits decreased from λ

m,(b),Ref = 30.43% to λ

m,(b),E1 = 28.78% and λ

m,(b),E2 = 27.24%. Both phenomena led to a decrease in the erosion duration (t

ero) for the oxidized tool electrodes presented in

Figure 5, potentially caused by the lower electrical resistivity (ρ) of the base tool electrode and the oxide layer protecting against lateral discharges. Both resulted in more effective frontal discharges and thus in a lower erosion duration (t

ero).

However, the total frequency ratios (λ

t), calculated as the sum of the beneficial ratio (λ

b) and maleficial ratio (λ

m), increased from λ

t,(a),Ref = 0.65% to λ

t,(a),E1 = 1.29% and λ

t,(a),E2 = 1.98% in the top half of the workpiece electrode for the oxidized tool electrodes. This suggested that more lateral discharges occurred on the oxidized tool electrodes compared to the unoxidized reference tool electrode. However, as the process progresses, it may become more difficult to distinguish frontal and lateral discharges in the bottom half of the workpiece electrode, where the probability of lateral discharges rises due to the increasing lateral surface area (A

SL). To avoid this possibly misleading event localization, the drilling initiation period with an erosion duration (t

ero,start) of 2 min in the bottom workpiece electrode was evaluated separately,

Figure 6c,d.

Here, the same dependencies could be seen for the drilling initiation period as for the whole duration, although the total frequency ratio (λt) slightly decreased for the bottom workpiece electrode half. In comparison, the total frequency ratio (λt) of the top electrode increased from λt,(a),Ref = 1.10% to λt,(c),Ref = 3.10%. This fact suggests that the lateral discharges had a higher probability of occurrence on the top electrode in the drilling initiation period. It also shows that the lateral and frontal discharges could be more easily distinguished.

Since the total frequency ratios (λt) of the top workpiece electrode half increased for the oxidized tool electrodes compared to the reference, from λt,(c),Ref = 3.10% to λt,(c),E1 = 3.52% and λt,(c),E2 = 6.25%, the assumption that the number of lateral discharges would be reduced by the oxide layer could not be verified for the chosen oxidation parameters. The increased conicity caused by lateral discharges (αE1 = 0.034° and αE2 = 0.059°compared to αRef = 0.012°) confirmed this. However, the discontinuous oxide layer caused by delamination resulted in the lateral surface area (ASL) not being insulated completely and therefore still suffering lateral discharges. Furthermore, the slight deviations in straightness of the oxidized tool electrodes caused more electric discharges in the top workpiece electrode half, especially if no rotation was used. To ensure comparability and accuracy, straight tool electrodes are required, which is hardly possible for tool electrodes treated at high oxidation temperatures (ϑoxi).

4. Conclusions

The results of the preliminary experiments presented in this work showed that the thermal oxidation of tool electrodes could result in process improvements, with a 48% reduction in erosion duration (tero) for machining Elmax SuperClean tool steel without any significant change in the linear tool wear (Δle). However, high-temperature oxidation comes with disadvantages due to:

A loss of strength (f);

A deviation in straightness;

A high oxide layer thickness (doxi);

The partial delamination of the oxide layer;

The increased conicity (α) of the borehole.

The loss of strength (f) and the geometrical deviations are especially critical for high-precision processes. Consequently, the results of the signal analysis could not confirm our expectations of reduced lateral discharges for this temperature range.

Future and ongoing investigations will consider lower oxidation temperatures (ϑ

oxi) to avoid the above-mentioned effects and therefore explain and improve the respective processing results for electro-discharge drilling. In addition to different oxidation temperatures (ϑ

oxi) and oxidation times (t

oxi), the oxidation atmosphere, pressure (p), and cooling rate (k) will be addressed by these investigations [

25]. Furthermore, the effects of the thermal exposure, such as recovery, recrystallization, and thermal stresses (σ

th), between the oxide layer and the unoxidized part of the tool electrode have to be considered. As an alternative to thermal oxidation, chemical oxidation may be used to avoid the thermal influence on the tool electrodes.