Effects of Heat Treatment on Microstructure and Mechanical Properties of AlSi10Mg Fabricated by Selective Laser Melting Process

Abstract

:1. Introduction

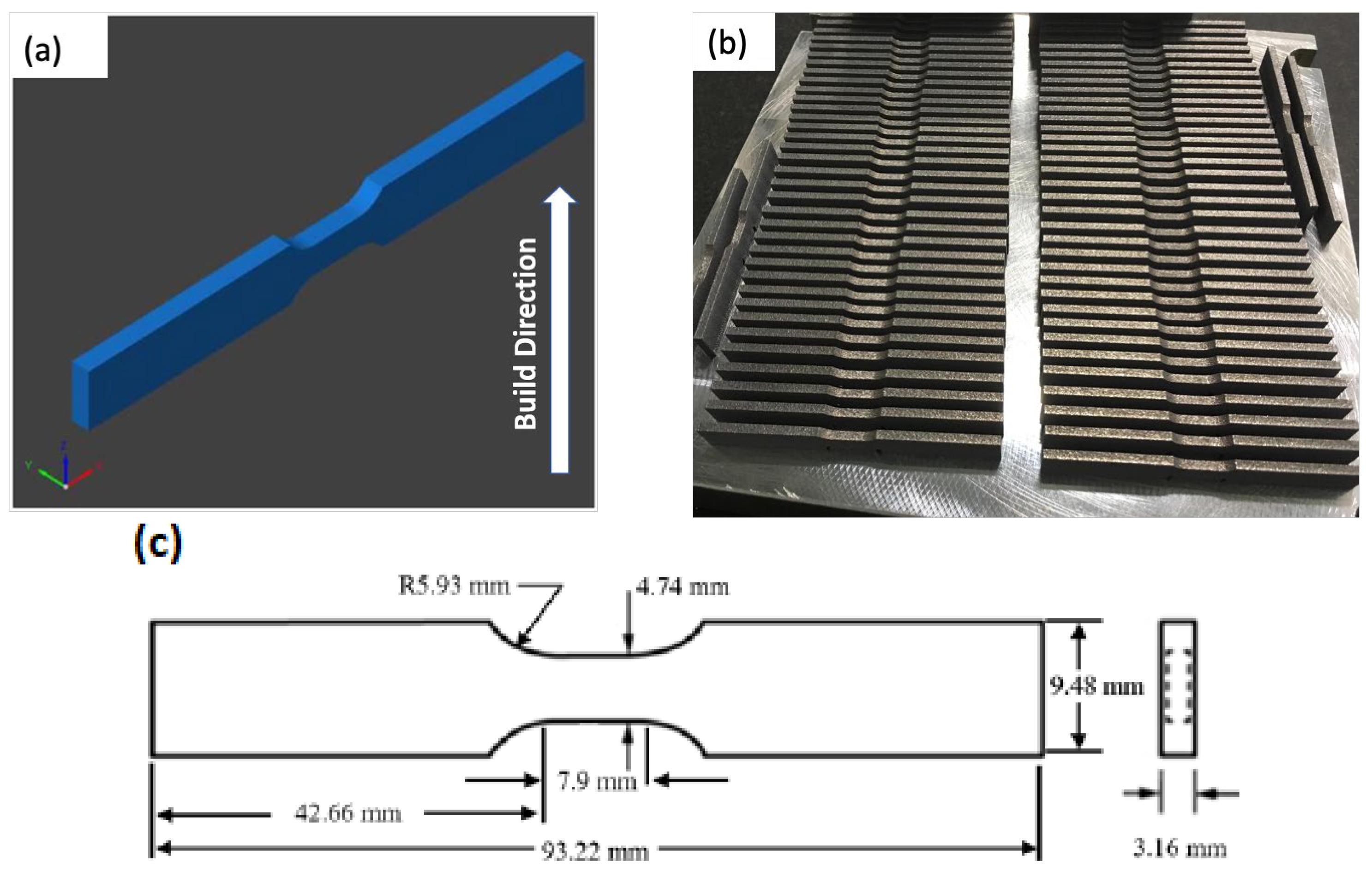

2. Materials and Methods

3. Results and Discussion

4. Conclusions

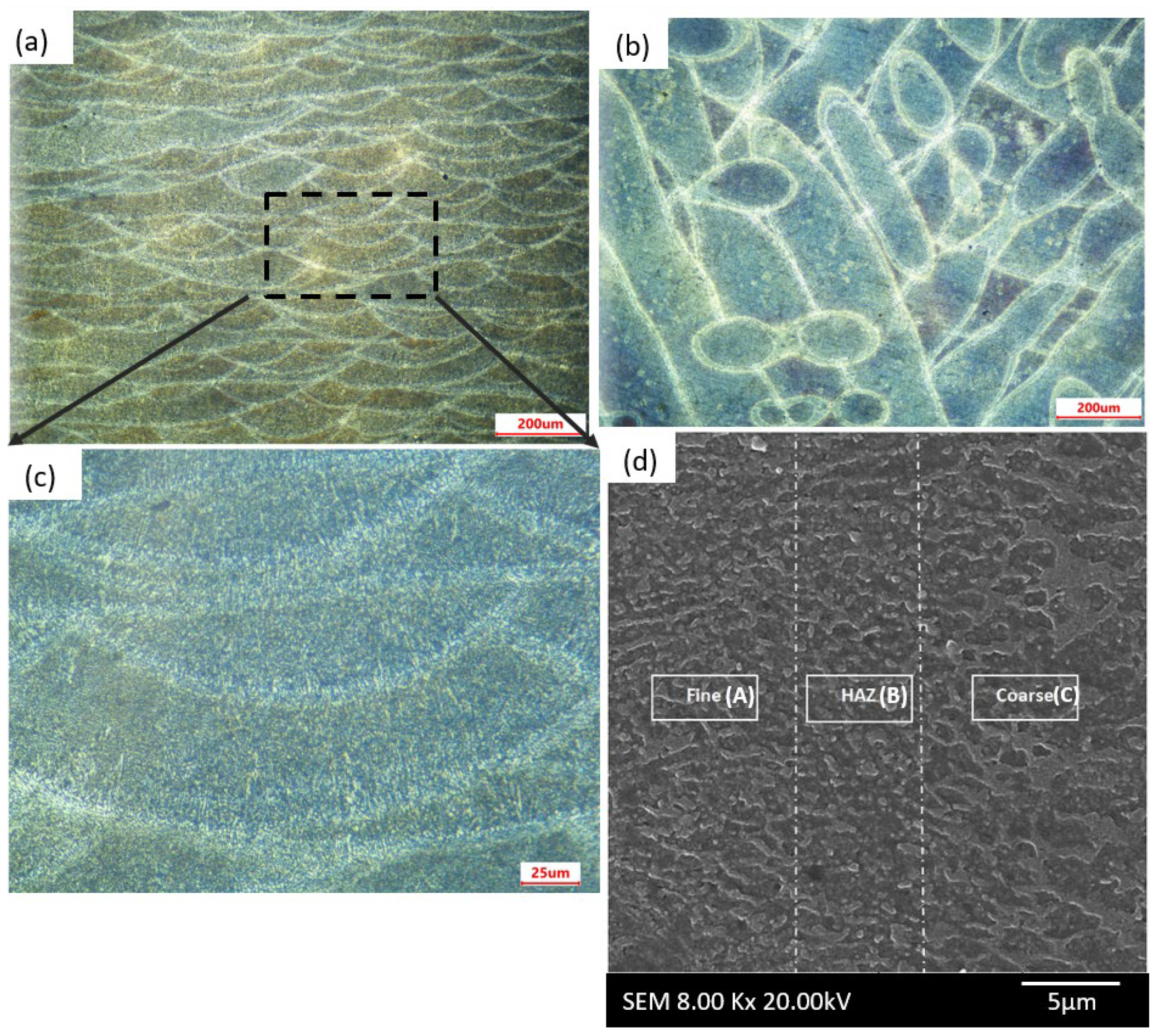

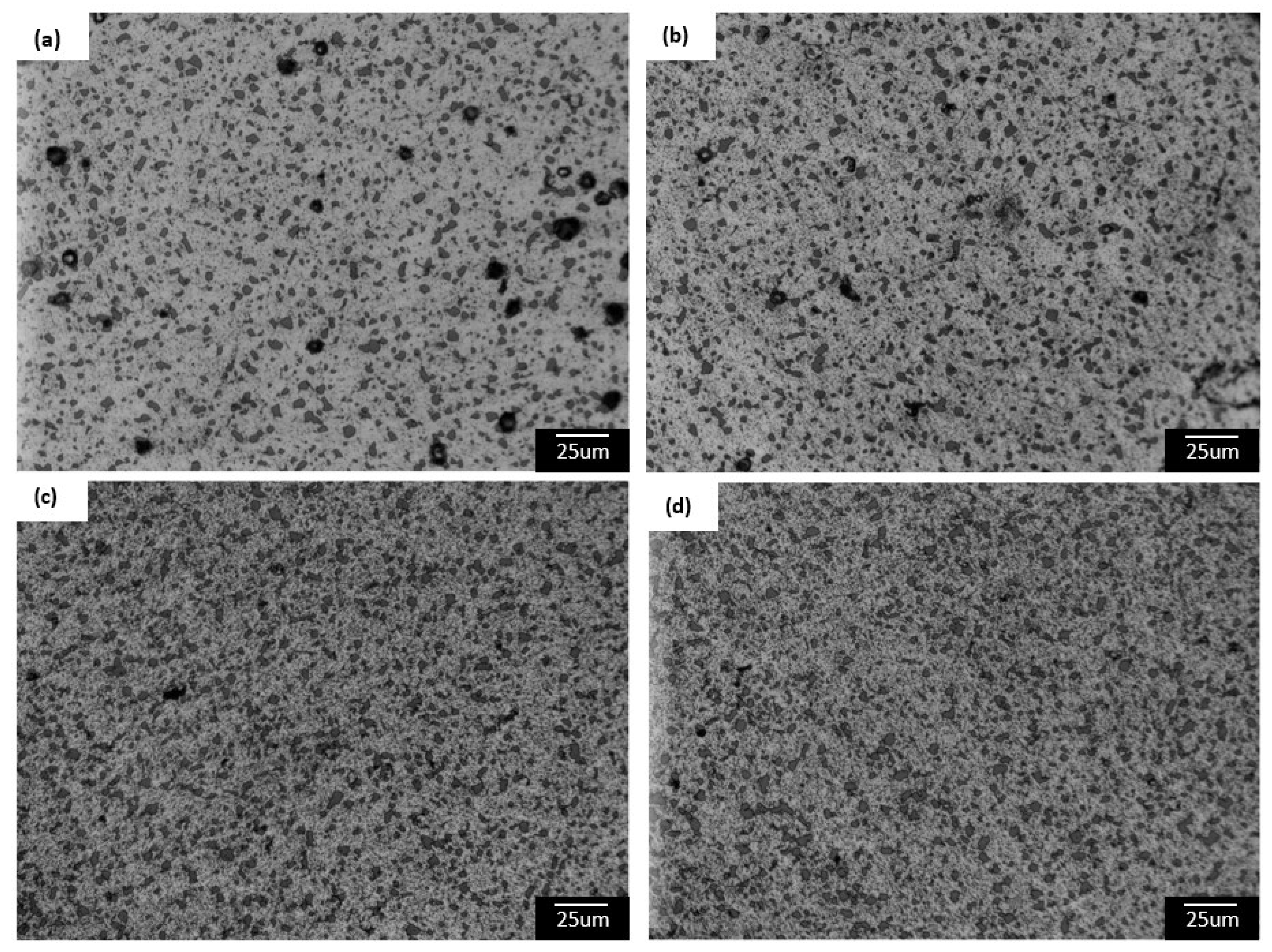

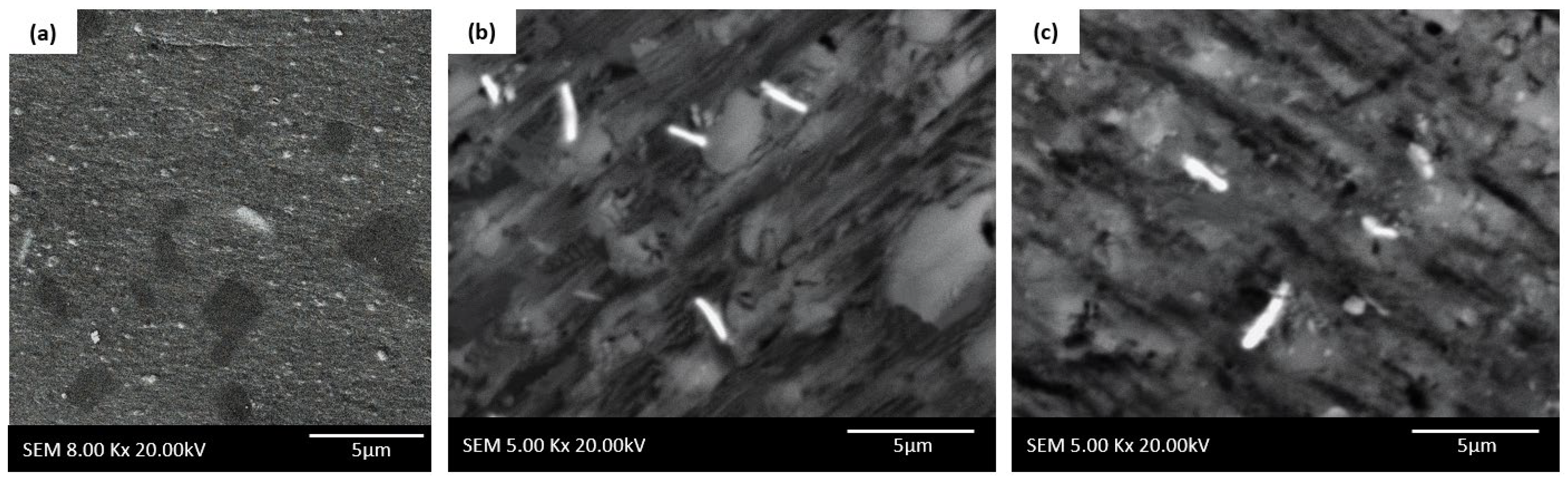

- The microstructure of as-built AlSi10Mg shows a distinct morphology between different sections with a characteristic fish scale pattern for longitudinal sections and a clustered columnar pattern for the transverse sections.

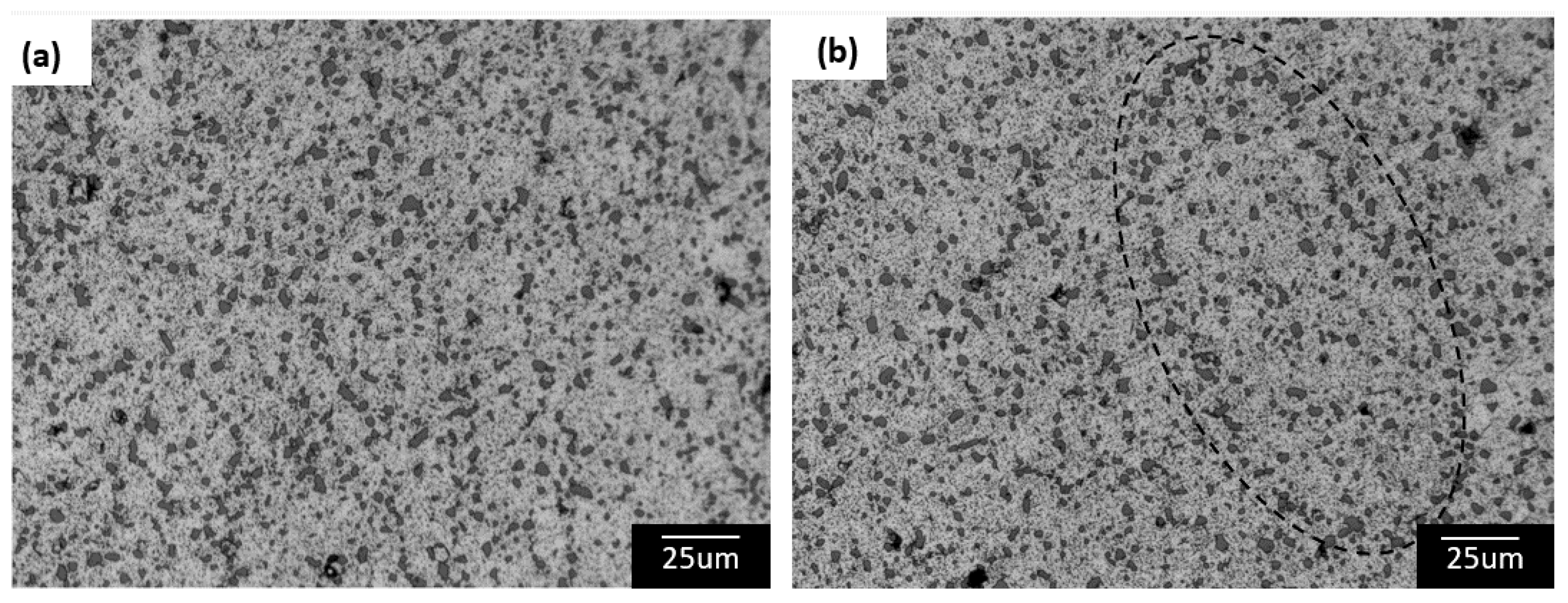

- The inhomogeneity of the melt pool results in a range of varying mechanical properties with a need to homogenize the microstructure to obtain better control over the mechanical properties.

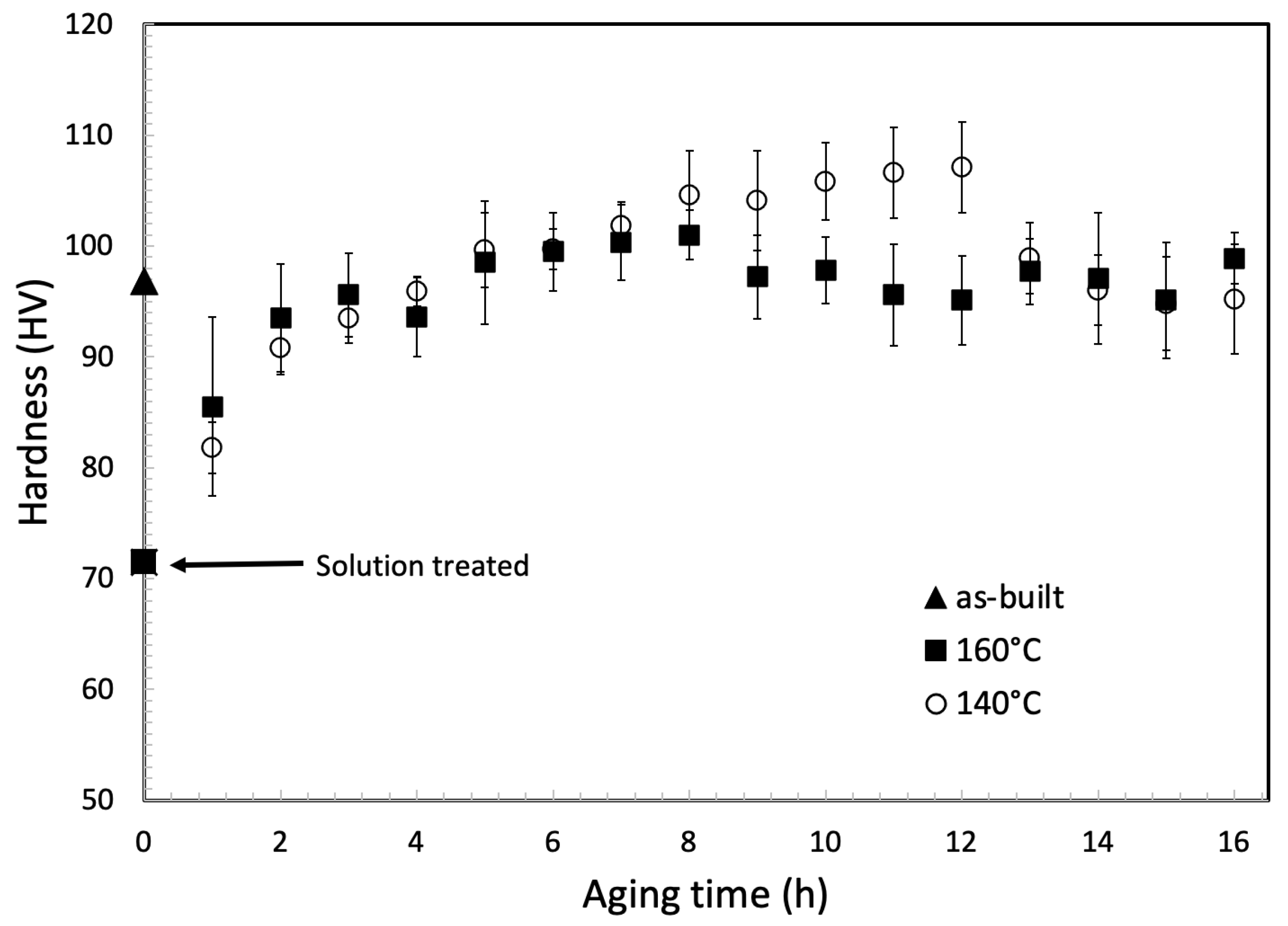

- Though the heat-treated specimens exhibit a homogenized microstructure, it is impossible to completely eliminate all the precipitates. Artificially aged specimens provided maximum hardness at 12 h for 140 °C and 8 h for 160 °C. This represents a 10% increase in hardness values obtained for heat-treated samples compared to as-built specimens due to precipitation hardening. Despite a little increase in the volume percent of Si-rich precipitates and precipitation coarsening, the increase in hardness value may be associated with the increasing Fe-rich precipitates.

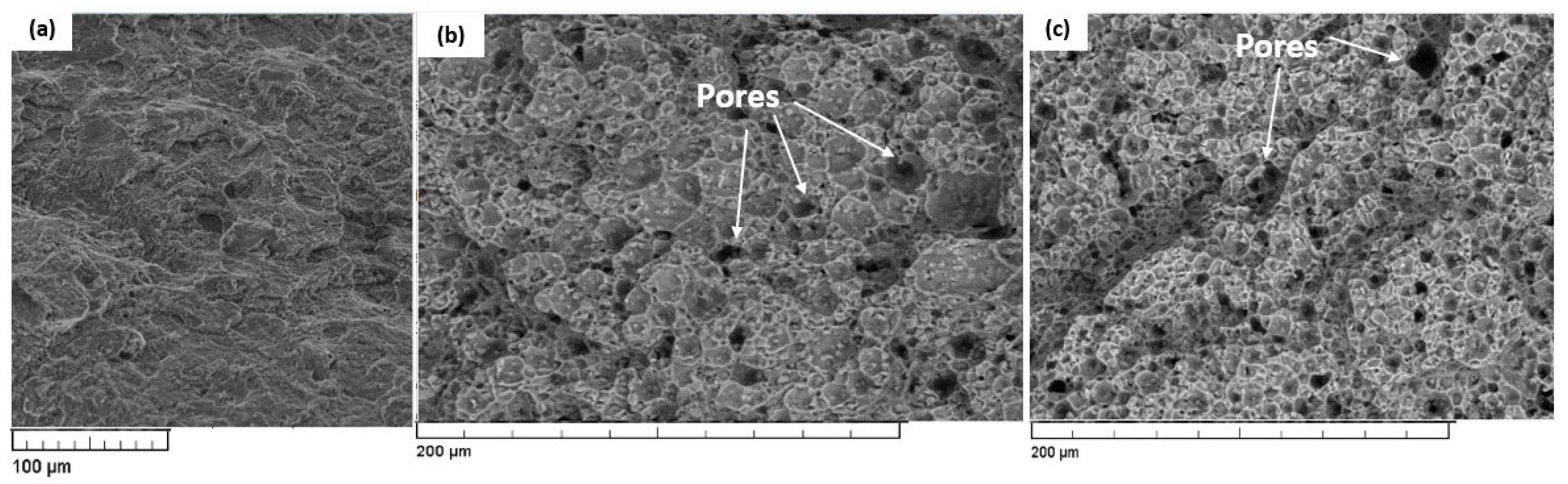

- Tensile strength and elongation at the break of the as-built SLM’ed AlSi10Mg are comparatively higher than that of conventional cast A360 aluminum alloy, although the ultimate tensile strength is slightly lower. This is due to the lower concentration of Mg to form the Mg2Si complex in AlSi10Mg, which is a major contributor to precipitation hardening for A360. The imposition of heat treatment at chosen optimal conditions providing peak hardening induces an increase in yield strength and elongation at break and a decrease in UTS.

- Although higher hardness was obtained after artificial aging at 140 °C compared to 160 °C, tensile strength was found to be higher at 160 °C. Tensile elongation, on the other hand, was significantly higher for the 140 °C specimen. This anomaly was mainly due to the large amount of micro-porosity found in the fracture surface at 160 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Edgar, J.; Tint, S. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing. Johns. Matthey Technol. Rev. 2015, 59, 193–198. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef] [Green Version]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef] [PubMed]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. The microstructure and mechanical properties of selectively laser melted AlSi10Mg: The effect of a conventional T6-like heat treatment. Mater. Sci. Eng. A 2016, 667, 139–146. [Google Scholar] [CrossRef]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Pei, W.; Zhengying, W.; Zhen, C.; Jun, D.; Yuyang, H.; Junfeng, L.; Yatong, Z. The AlSi10Mg samples produced by selective laser melting: Single track, densification, microstructure and mechanical behavior. Appl. Surf. Sci. 2017, 408, 38–50. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Qi, T.; Hu, Z.; Zeng, X. Selective laser melting of high strength Al–Cu–Mg alloys: Processing, microstructure and mechanical properties. Mater. Sci. Eng. A 2016, 656, 47–54. [Google Scholar] [CrossRef]

- Li, J.; Cheng, X.; Li, Z.; Zong, X.; Zhang, S.-Q.; Wang, H.-M. Improving the mechanical properties of Al-5Si-1Cu-Mg aluminum alloy produced by laser additive manufacturing with post-process heat treatments. Mater. Sci. Eng. A 2018, 735, 408–417. [Google Scholar] [CrossRef]

- Rosenthal, I.; Shneck, R.; Stern, A. Heat treatment effect on the mechanical properties and fracture mechanism in AlSi10Mg fabricated by additive manufacturing selective laser melting process. Mater. Sci. Eng. A 2018, 729, 310–322. [Google Scholar] [CrossRef]

- Takata, N.; Kodaira, H.; Sekizawa, K.; Suzuki, A.; Kobashi, M. Change in microstructure of selectively laser melted AlSi10Mg alloy with heat treatments. Mater. Sci. Eng. A 2017, 704, 218–228. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.; Yan, C.; Shi, Y. Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture mechanism. Mater. Sci. Eng. A 2016, 663, 116–125. [Google Scholar] [CrossRef]

- Wang, L.F.; Sun, J.; Yu, X.L.; Shi, Y.; Zhu, X.G.; Cheng, L.Y.; Liang, H.H.; Yan, B.; Guo, L.J. Enhancement in mechanical properties of selectively laser-melted AlSi10Mg aluminum alloys by T6-like heat treatment. Mater. Sci. Eng. A 2018, 734, 299–310. [Google Scholar] [CrossRef]

- Alghamdi, F.; Song, X.; Hadadzadeh, A.; Shalchi-Amirkhiz, B.; Mohammadi, M.; Haghshenas, M. Post heat treatment of additive manufactured AlSi10Mg: On silicon morphology, texture and small-scale properties. Mater. Sci. Eng. A 2020, 783, 139296. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Tuck, C.; Ashcroft, I.; Maskery, I.; Everitt, N.M. On the Precipitation Hardening of Selective Laser Melted AlSi10Mg. Metall. Mater. Trans. A 2015, 46, 3337–3341. [Google Scholar] [CrossRef]

- Mertens, A.; Dedry, O.; Reuter, D.; Rigo, O.; Lecomte-Beckers, J. Thermal Treatments of AlSi10Mg Processed by Laser Beam Melting. In Proceedings of the 26th International Solid Freeform Fabrication Symposium, Austin, TX, USA, 10–12 August 2015. [Google Scholar]

- Iturrioz, A.; Gil, E.; Petite, M.M.; Garciandia, F.; Mancisidor, A.M.; San Sebastian, M. Selective laser melting of AlSi10Mg alloy: Influence of heat treatment condition on mechanical properties and microstructure. Weld. World 2018, 62, 885–892. [Google Scholar] [CrossRef]

- Girelli, L.; Tocci, M.; Montesano, L.; Gelfi, M.; Pola, A. Optimization of heat treatment parameters for additive manufacturing and gravity casting AlSi10Mg alloy. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 2017 International Conference on Building Materials and Materials Engineering (ICBMM 2017), Lyon, France, 21–23 September 2017; IOP Publishing: Bristol, UK, 2017; Volume 264, p. 012016. [Google Scholar] [CrossRef] [Green Version]

- Zhou, L.; Mehta, A.; Schulz, E.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure, precipitates and hardness of selectively laser melted AlSi10Mg alloy before and after heat treatment. Mater. Charact. 2018, 143, 5–17. [Google Scholar] [CrossRef]

- Majeed, A.; Muzamil, M.; Lv, J.; Liu, B.; Ahmad, F. Heat treatment influences densification and porosity of AlSi10Mg alloy thin-walled parts manufactured by selective laser melting technique. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 267. [Google Scholar] [CrossRef]

- Manfredi, D.; Calignano, F.; Krishnan, M.; Canali, R.; Ambrosio, E.; Atzeni, E. From Powders to Dense Metal Parts: Characterization of a Commercial AlSiMg Alloy Processed through Direct Metal Laser Sintering. Materials 2013, 6, 856–869. [Google Scholar] [CrossRef] [Green Version]

- Fousová, M.; Dvorský, D.; Michalcová, A.; Vojtěch, D. Changes in the microstructure and mechanical properties of additively manufactured AlSi10Mg alloy after exposure to elevated temperatures. Mater. Charact. 2018, 137, 119–126. [Google Scholar] [CrossRef]

- Han, Q.; Jiao, Y. Effect of heat treatment and laser surface remelting on AlSi10Mg alloy fabricated by selective laser melting. Int. J. Adv. Manuf. Technol. 2019, 102, 3315–3324. [Google Scholar] [CrossRef] [Green Version]

- Ngnekou, J.N.D.; Nadot, Y.; Henaff, G.; Nicolai, J.; Kan, W.H.; Cairney, J.M.; Ridosz, L. Fatigue properties of AlSi10Mg produced by Additive Layer Manufacturing. Int. J. Fatigue 2019, 119, 160–172. [Google Scholar] [CrossRef]

- Lumley, R.N.; O’Donnell, R.G.; Gunasegaram, D.R.; Givord, M. Heat Treatment of High-Pressure Die Castings. Metall. Mater. Trans. A 2007, 38, 2564–2574. [Google Scholar] [CrossRef]

- Bharath, C.; Shamanth, V.; Hemanth, K. Studies on mechanical behaviour of AlSi10Mg alloy produced by Selective Laser Melting and A360 alloy by die casting. Mater. Today Proc. 2021, 45, 78–81. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Scudino, S.; Eckert, J.; Prakash, O.; Ramamurty, U. Simultaneous enhancements of strength and toughness in an Al-12Si alloy synthesized using selective laser melting. Acta Mater. 2016, 115, 285–294. [Google Scholar] [CrossRef]

- Girelli, L.; Tocci, M.; Gelfi, M.; Pola, A. Study of heat treatment parameters for additively manufactured AlSi10Mg in comparison with corresponding cast alloy. Mater. Sci. Eng. A 2019, 739, 317–328. [Google Scholar] [CrossRef]

| Al | Si | Fe | Cu | Mn | Mg | Ni | Zn | Pb | Sn | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| Bal. | 9.0–11.0 | <0.55 | <0.05 | <0.45 | 0.2–0.45 | <0.05 | <0.10 | <0.05 | <0.05 | <0.15 |

| YS (MPa) (0.2% Offset) | UTS (MPa) | Elongation at Break | |

|---|---|---|---|

| As-built | 200 | 293 | 7.6% |

| ST 540 °C | 130 | 217 | 8.8% |

| ST 540 °C + AA 140 °C (6 h) (12 h) | 195 | 269 | 10.8% |

| ST 540 °C + AA 160 °C (6 h) (8 h) | 220 | 280 | 6.4% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Clement, C.D.; Masson, J.; Kabir, A.S. Effects of Heat Treatment on Microstructure and Mechanical Properties of AlSi10Mg Fabricated by Selective Laser Melting Process. J. Manuf. Mater. Process. 2022, 6, 52. https://doi.org/10.3390/jmmp6030052

Clement CD, Masson J, Kabir AS. Effects of Heat Treatment on Microstructure and Mechanical Properties of AlSi10Mg Fabricated by Selective Laser Melting Process. Journal of Manufacturing and Materials Processing. 2022; 6(3):52. https://doi.org/10.3390/jmmp6030052

Chicago/Turabian StyleClement, Catherine Dolly, Julie Masson, and Abu Syed Kabir. 2022. "Effects of Heat Treatment on Microstructure and Mechanical Properties of AlSi10Mg Fabricated by Selective Laser Melting Process" Journal of Manufacturing and Materials Processing 6, no. 3: 52. https://doi.org/10.3390/jmmp6030052

APA StyleClement, C. D., Masson, J., & Kabir, A. S. (2022). Effects of Heat Treatment on Microstructure and Mechanical Properties of AlSi10Mg Fabricated by Selective Laser Melting Process. Journal of Manufacturing and Materials Processing, 6(3), 52. https://doi.org/10.3390/jmmp6030052