Fabrication of Punch and Die Using Plasma-Assisted 3D Printing Technology for Piercing Sheet Metals

Abstract

:1. Introduction

2. Experimental Procedure

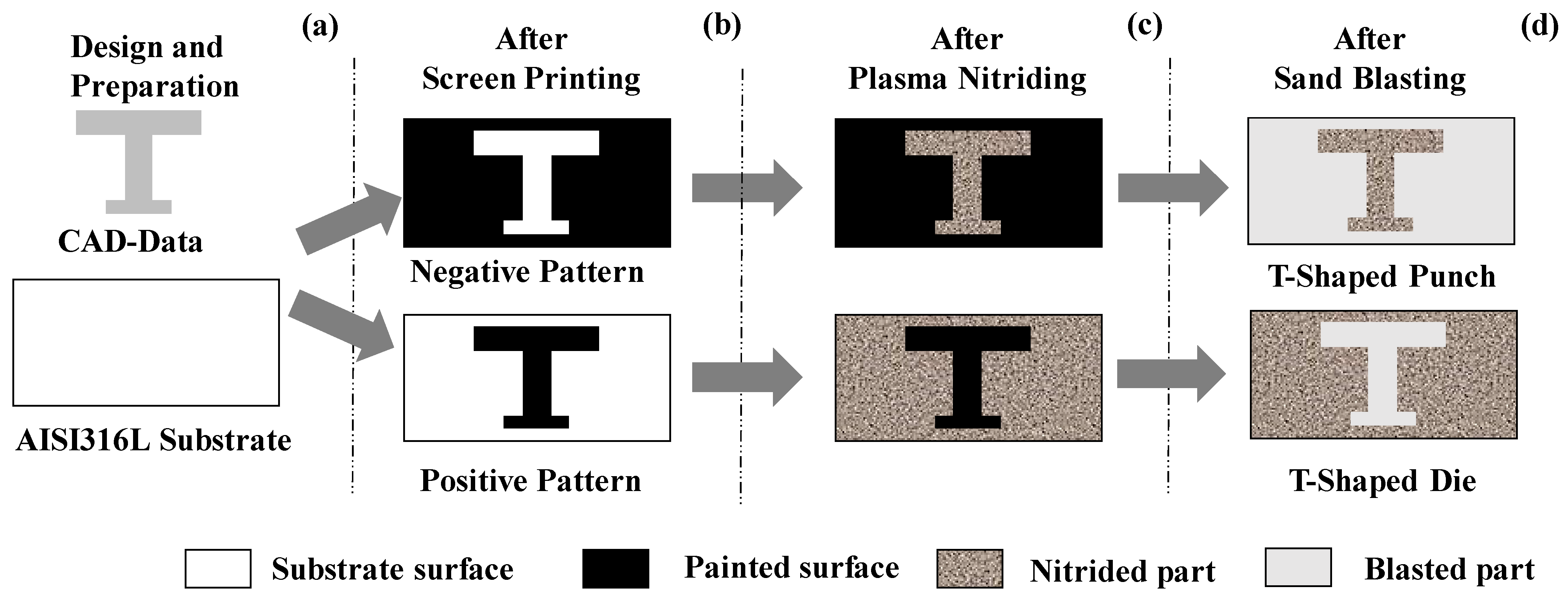

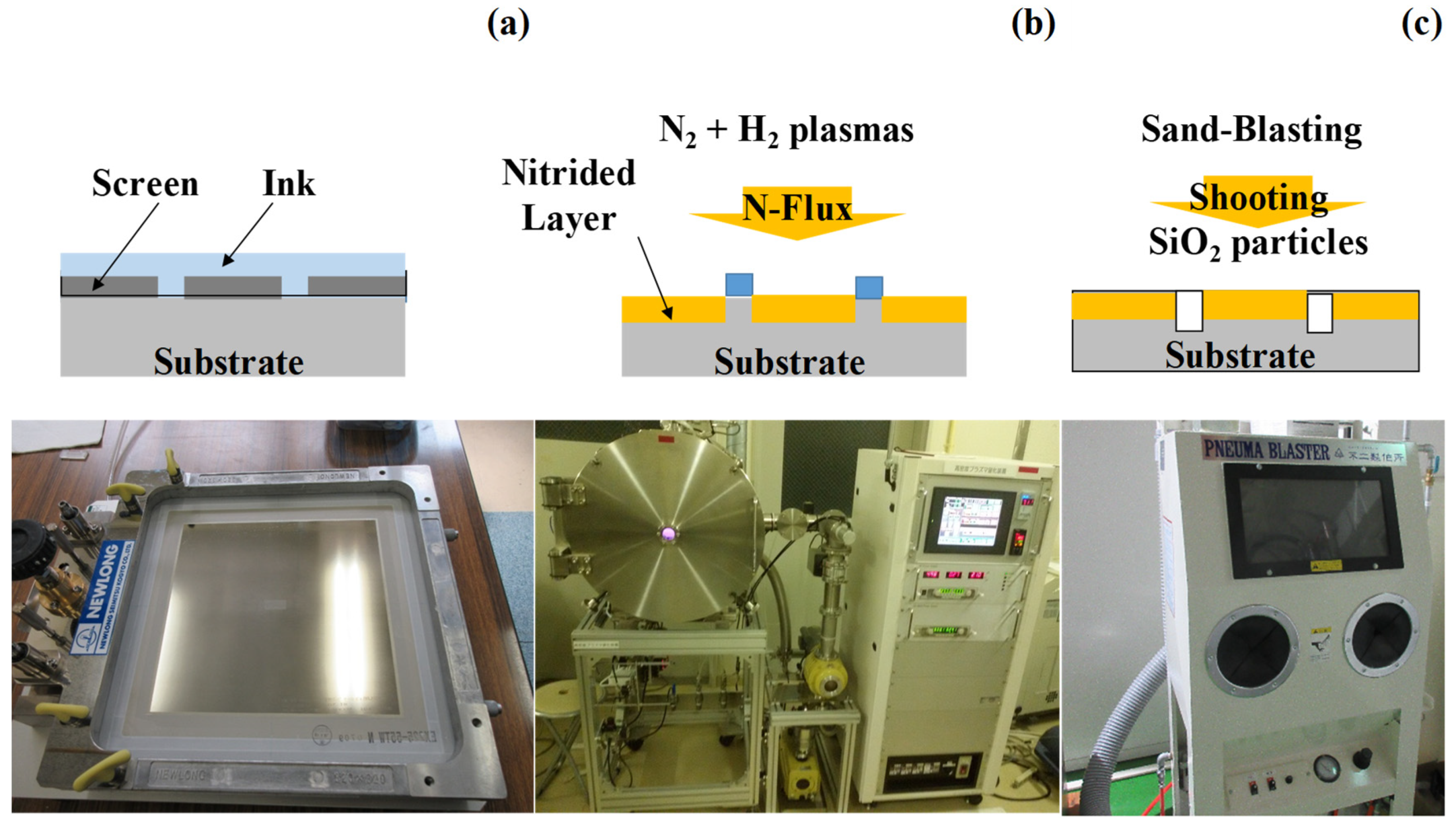

2.1. Plasma-Assisted 3D-Printing Procedure

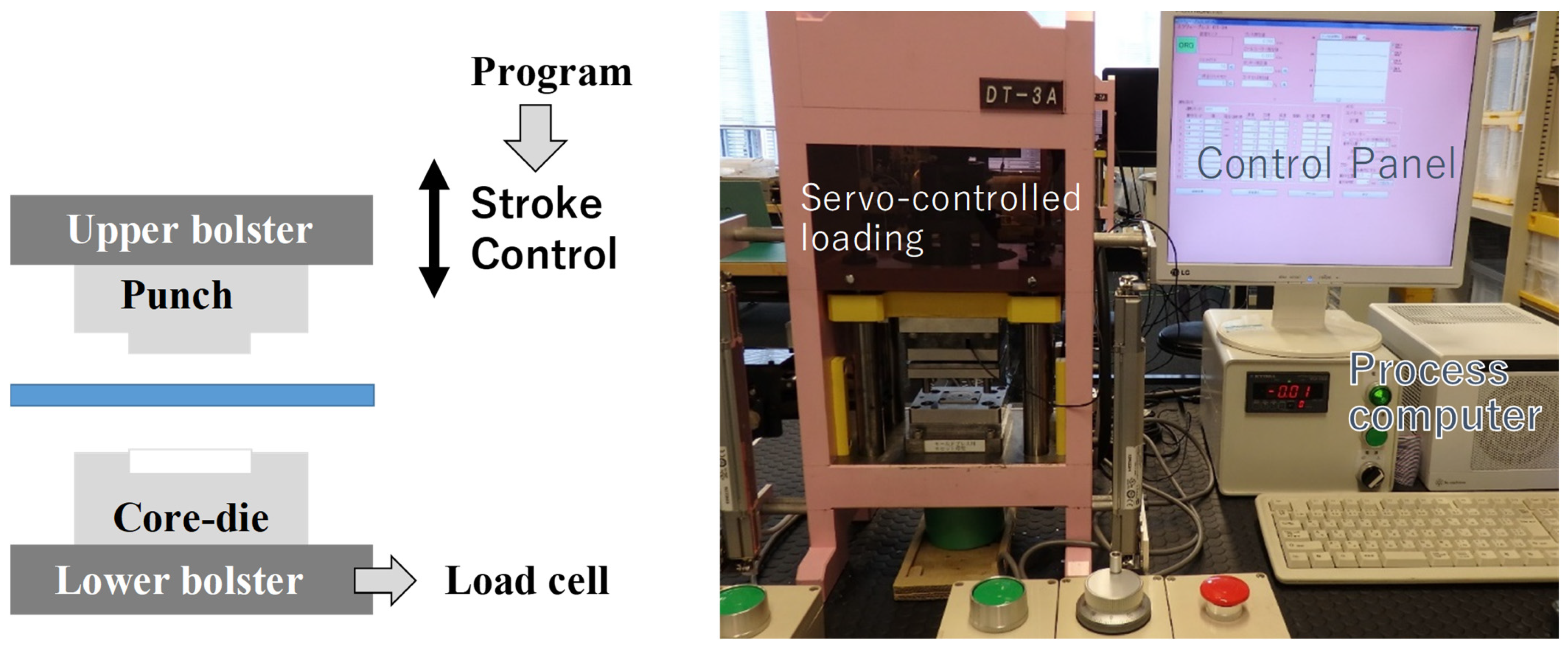

2.2. Piercing Experimental Procedure

3. Experimental Results

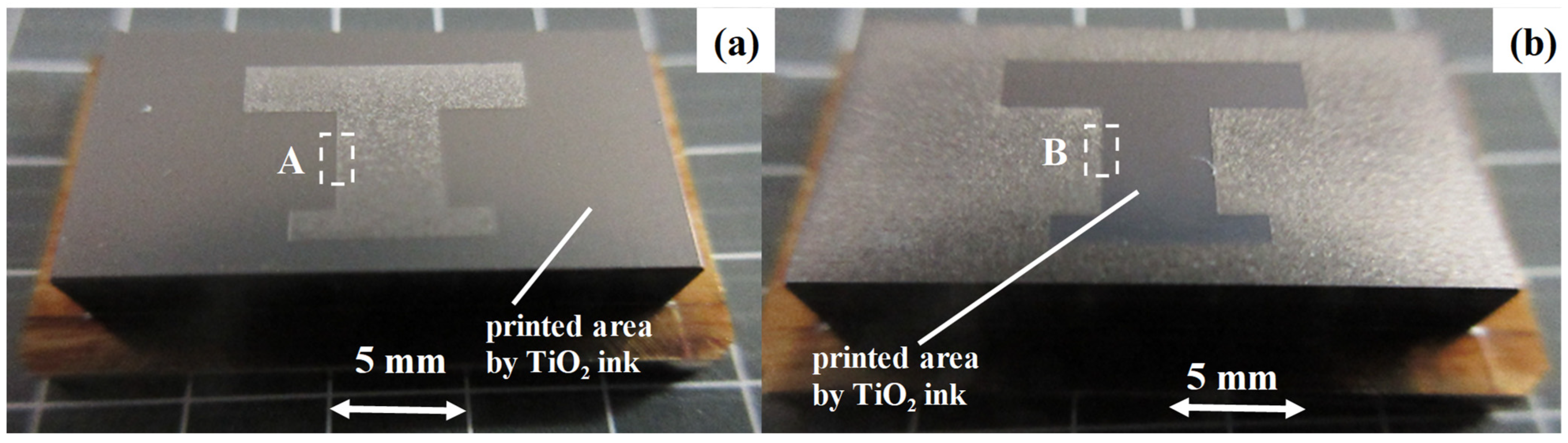

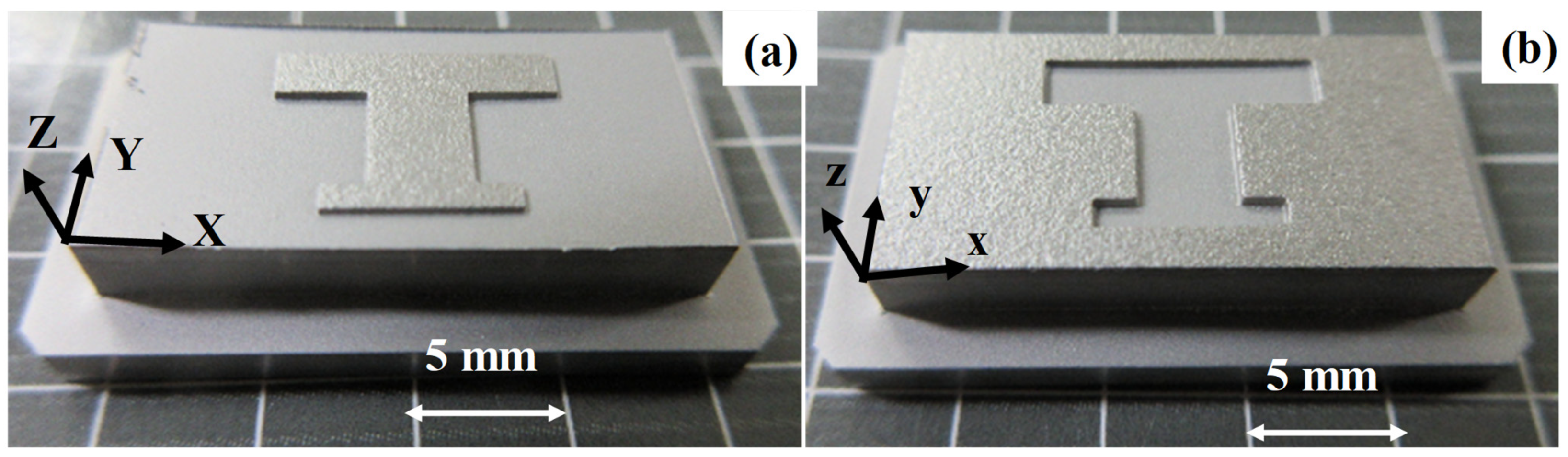

3.1. Screen Printing of Positive and Negative Micropatterns onto the Die Substrate Surfaces

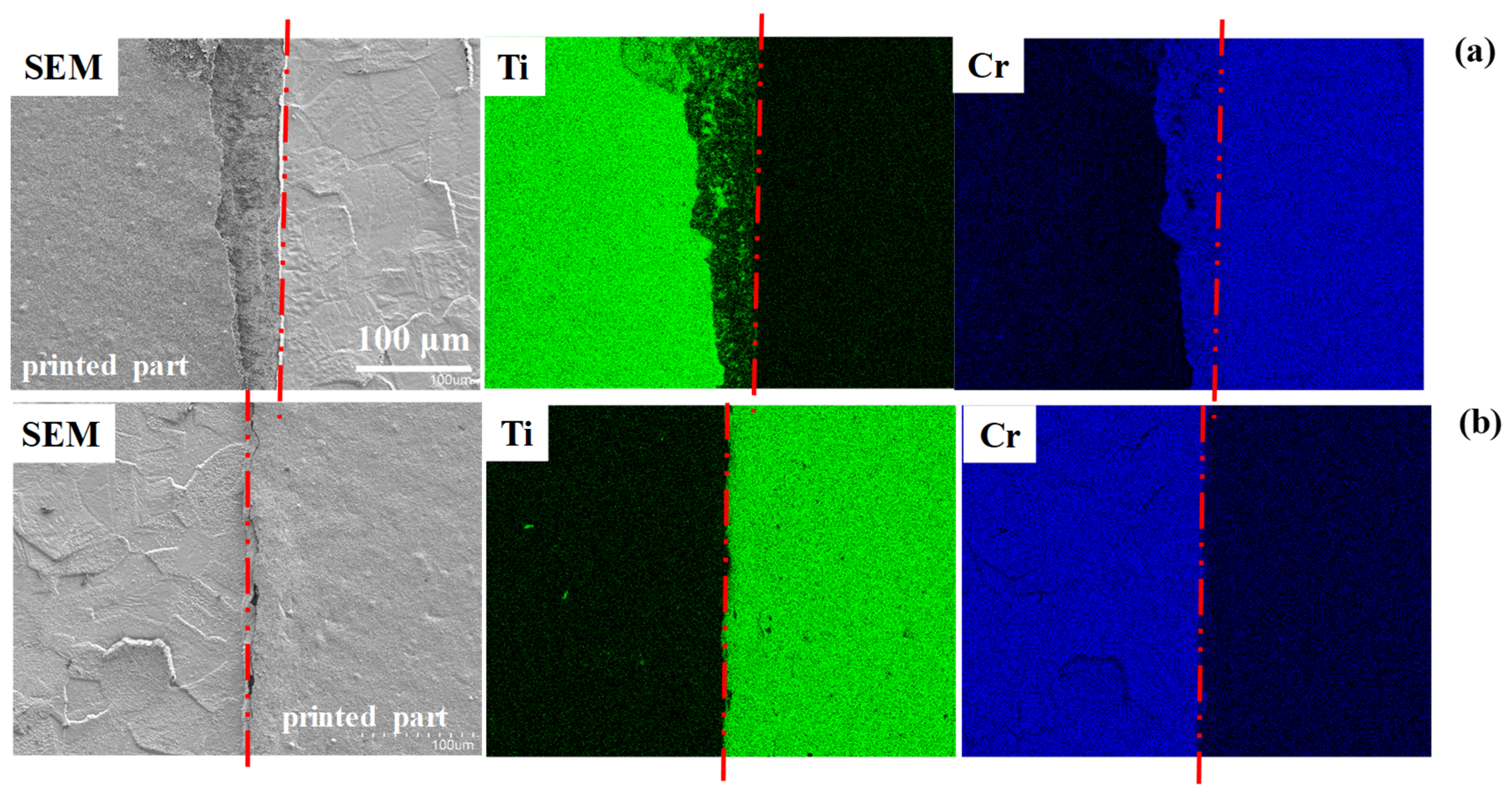

3.2. Selective Nitrogen Supersaturation to Unprinted Surfaces

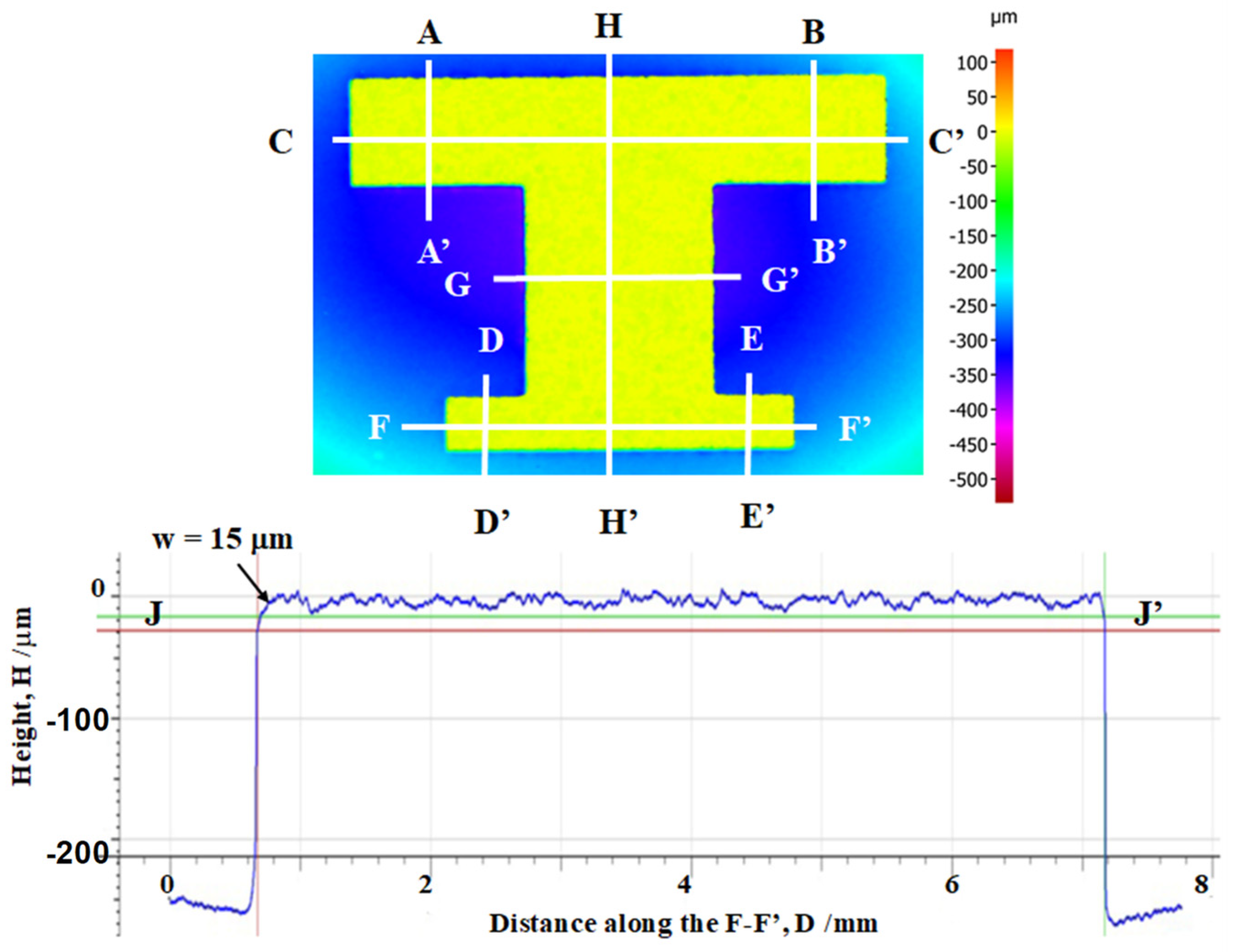

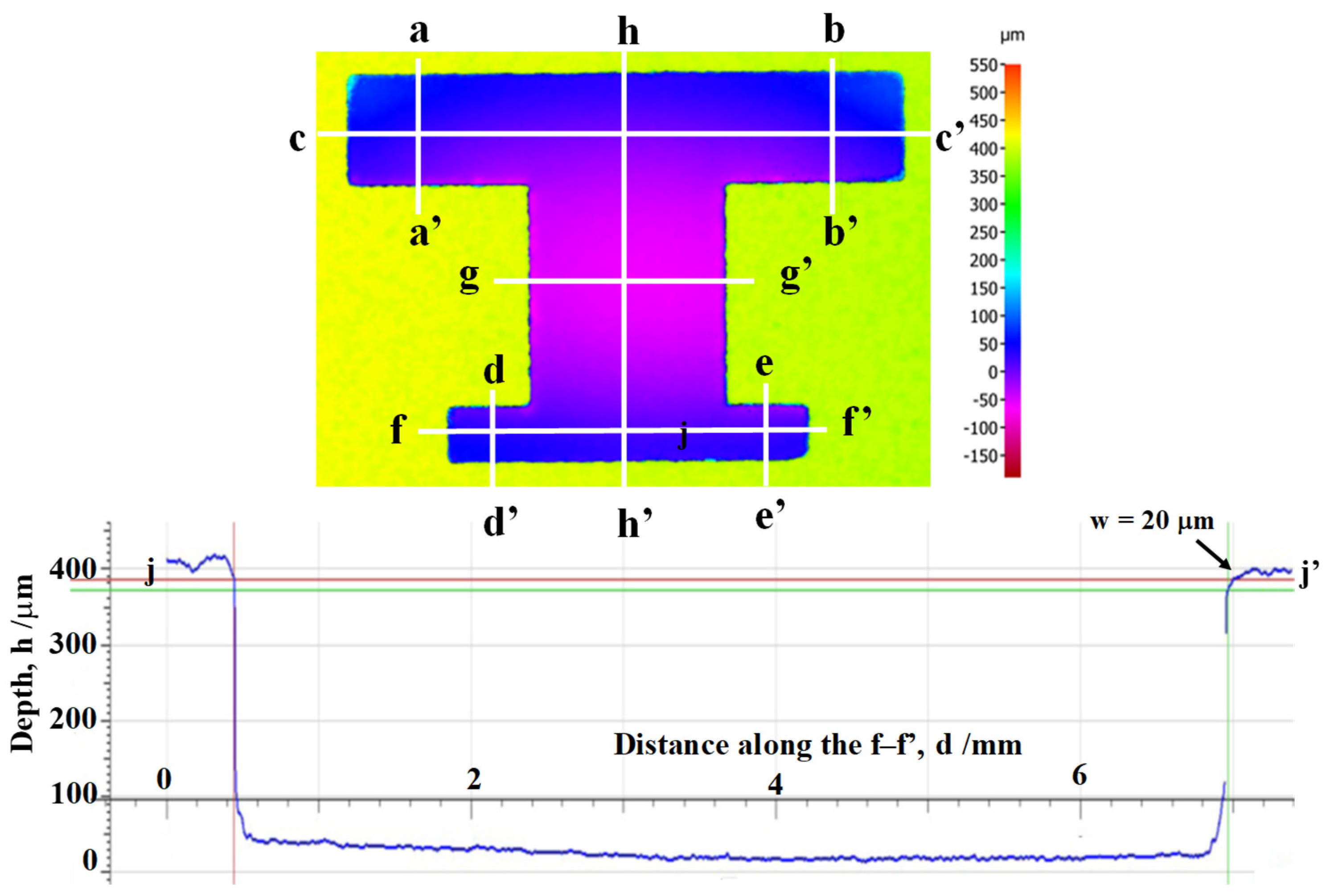

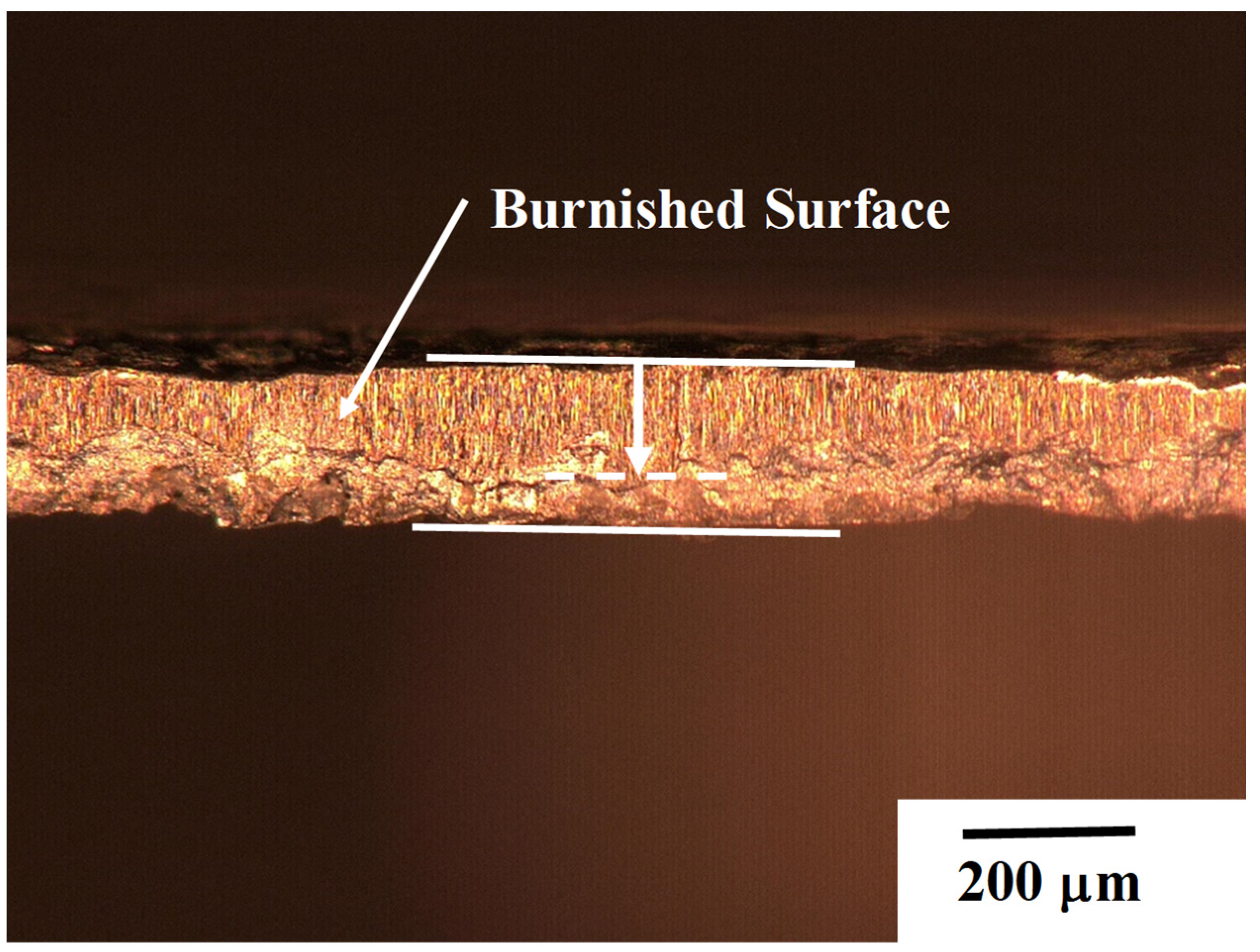

3.3. Selective Removal of Un-Nitrided Parts by Mechanical Blasting

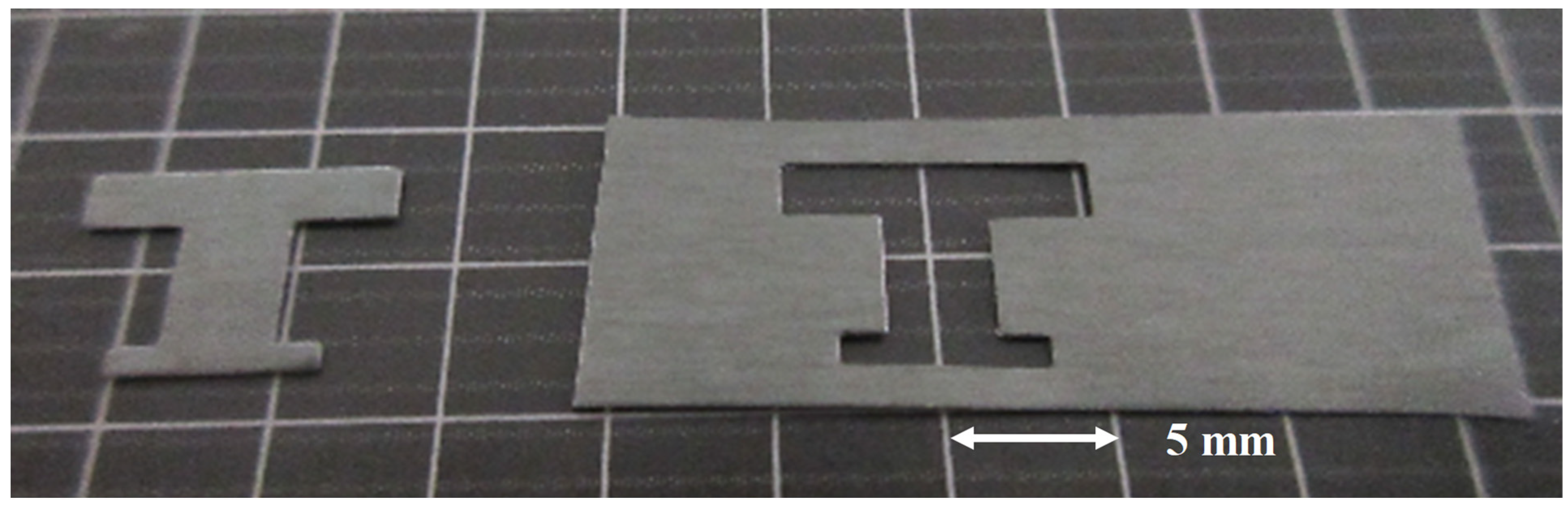

3.4. Fine Piercing of Electrical Steel Sheets

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Schmidt, K. Manufacturing Processes for Engineering Materials, 5th ed.; Prentice Hall: Hoboken, NJ, USA, 2008. [Google Scholar]

- Avanish, D. Laser beam machining—A review. Int. J. Mach. Tools Manuf. 2008, 48, 609–628. [Google Scholar]

- Gaertner, E.; Polise, V.; Tagliaferri, F.; Palumno, B. Laser micro machining of alumina by a picosecond laser. J. Laser Micro/Nanoeng. 2018, 13, 76–84. [Google Scholar]

- Aizawa, T.; Inohara, T. Pico- and Femto-Second Laser Micromachining for Surface Texturing. In Micromachining; Stanimirovíc, Z., Stanimirovíc, I., Eds.; IntechOpen: London, UK, 2019; pp. 1–23. [Google Scholar]

- Zhang, J.; Jung, Y.G. (Eds.) Additive Manufacturing—Materials, Processes, Qualifications and Applications; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Surface Finishing for Additive Manufacturing. Available online: https://isofinishing.com/additive-manufacturing/ (accessed on 4 April 2020).

- Gaffet, E.; Caër, G.L. Micro-milling. In NanoMaterials and NanoChemistry; Bréchignac, C., Houdy, P., Lahmani, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Tyagi, P.; Goulet, T.; Riso, C.; Stephenson, R.; Chuenprateep, N.; Schlitzer, J.; Benton, C.; Garcia-Moreno, F. Reducing the roughness of internal surface of an additive manufacturing produced 316 steel component by chempolishing and electropolishing. Addit. Manuf. 2019, 25, 32–38. [Google Scholar] [CrossRef] [Green Version]

- Chen, N.; Ma, G.; Zhu, W.; Godfrey, A.; Shen, Z.; Wu, G.; Huang, X. Enhancement of an additive-manufactured austenitic stainless steel by post-manufacture heat-treatment. Mater. Sci. Eng. A 2019, 759, 65–69. [Google Scholar] [CrossRef]

- Katoh, T.; Aizawa, T.; Yamaguchi, T. Plasma assisted nitriding for micro-texturing onto martensitic stainless steels. Manuf. Rev. 2015, 2, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Shiratori, T.; Aizawa, T.; Saito, Y.; Wasa, K. Plasma printing of an AISI316 micro-meshing punch array for micro-embossing onto copper plates. J. Met. 2019, 9, 396. [Google Scholar] [CrossRef] [Green Version]

- Aizawa, T.; Saito, Y.; Hasegawa, H.; Wasa, K. Fabrication of optimally micro-textured copper substrates by plasma printing for plastic mold packaging. Int. J. Autom. Technol. 2020, 14, 200–207. [Google Scholar] [CrossRef]

- Aizawa, T.; Shiratori, T.; Komatsu, T. Micro-/nano-structuring in stainless steels by metal forming and materials processing. In Electron Crystallography; IntechOpen: London, UK, 2020; Chapter 5; pp. 101–122. [Google Scholar]

- Aizawa, T. Low temperature plasma nitriding of austenitic stainless steels. In Stainless Steels and Alloys; IntechOpen: London, UK, 2018; Chapter 3; pp. 31–50. [Google Scholar]

- Borgioli, F.; Galvanetto, E.; Bacci, T. Low temperature nitriding of AISI300 and 200 series austenitic stainless steels. Vacuum 2016, 127, 51–60. [Google Scholar] [CrossRef]

- Farghali, A.; Aizawa, T.; Yoshino, T. Microstructure/mechanical characterization of plasma nitrided fine-grain austenitic stainless steels in low temperature. J. Nitrogen 2021, 2, 244–258. [Google Scholar] [CrossRef]

- Borgioli, F.; Galvanetto, E.; Bacci, T. Corrosion behavior of low temperature nitrided nickel-free, AISi200 and AISI300 series austenitic stainless steels in NaCl solution. Corros. Sci. 2018, 136, 352–365. [Google Scholar] [CrossRef]

- Aizawa, T.; Yoshihara, S.-I. Microtexturing into AISI420 dies for fine piercing of micropatterns into metallic sheets. J. JSTP 2019, 60, 53–57. [Google Scholar] [CrossRef]

- Marcos, G.; Guilet, S.; Clymand, F.; Thiriet, T.; Czerwuec, T. Stainless steel patterning by combination of micro-patterning and driven strain produced by plasma assisted nitriding. Surf. Coat. Technol. 2011, 205, 5275–5279. [Google Scholar] [CrossRef]

- Kurosaki, Y.; Mogi, H.; Fujii, H.; Kubota, T.; Shiozaki, M. Importance of punching and workability in non-oriented electrical steel sheets. J. Magn. Magn. Mater. 2008, 320, 2474–2480. [Google Scholar] [CrossRef]

- Aizawa, T.; Rsasi, I.; Yunata, E.E. High density RF-DC plasma nitriding under optimized conditions by plasma-diagnosis. J. Appl. Sci. 2022, 12, 3706. [Google Scholar] [CrossRef]

- Farghali, A.; Aizawa, T. Nitrogen supersaturation process in the AISI420 martensitic stainless steels by low temperature plasma nitriding. ISIJ Int. 2018, 58, 401–407. [Google Scholar] [CrossRef] [Green Version]

- Aizawa, T.; Shiratori, T.; Komatsu, T. Integrated manufacturing of fine-grained stainless steels for industries and medicals. In Engineering Steels and High Entropy-Alloys; IntechOpen: London, UK, 2020; Chapter 1; pp. 3–26. [Google Scholar]

- Katsuta, E.; Aizawa, T.; Morita, H.; Dohda, K.; Anzai, M. Fine piercing of electromagnetic steel sheets by micro-punches under nearly zero clearance. Procedia Manuf. 2018, 15, 1459–1466. [Google Scholar] [CrossRef]

- Susman, G.; Warren, A.; Ding, M. Product and Service Innovation in Small and Medium-Sized Enterprises; NIST-REP 05-480-5834; 2006. Available online: https://www.smeal.psu.edu/fcfe/research/white/nist06.pdf (accessed on 4 April 2020).

- Pratap, A.; Patra, K.; Dyakonov, A.A. Manufacturing miniature products by micro-grinding: A review. Procedia Eng. 2016, 150, 969–974. [Google Scholar] [CrossRef] [Green Version]

- Aizawa, T.; Wasa, K. Plasma printing of micro-nozzles with complex shaped outlets into stainless steel sheets. J. Micro-Nano-Manuf. 2019, 7, 034502. [Google Scholar] [CrossRef]

- Bell, T. Surface engineering of austenitic stainless steels. Surface Eng. 2002, 18, 415–422. [Google Scholar] [CrossRef]

- Wang, L.; Ji, S.; Sun, J. Effect of nitriding time on the nitrided layer of AISI304 austenitic stainless steel. Surf. Coat. Technol. 2006, 200, 5067–5070. [Google Scholar] [CrossRef]

- Kuwahara, H. Surface Modification of Iron Alloys by Plasma Nitriding and Carburizing. Ph.D. Thesis, Kyoto University, Kyoto, Japan, 1992. [Google Scholar]

- Hiraoka, Y.; Inoue, K. Prediction of nitrogen distribution in steels after plasma nitriding. Denki-Seiko 2010, 86, 15–24. [Google Scholar]

- Lu, S.; Zhao, X.; Wang, S.; Li, J.; Wei, W.; Hu, J. Enhancement by plasma nitriding at low gas pressure for 304 austenitic stainless steel. Vacuum 2018, 145, 334–339. [Google Scholar] [CrossRef]

- Dong, H. S-phase surface engineering of Fe-Cr, Co-Cr and Ni-Cr alloys. Int. Mater. Rev. 2011, 55, 65–98. [Google Scholar] [CrossRef]

- Murata, I.; Sakamoto, M. Properties of High Nitrogen Steels. Agune 2005, 166–168. [Google Scholar]

- Karino, K. Machining and Milling of Die Materials; Nikkan-Kogyo-Shinbun: Tokyo, Japan, 2011. [Google Scholar]

- Aizawa, T.; Morita, H. Dry progressive stamping of copper-alloy snaps by the plasma nitrided punches. Mater. Sci. Forum 2018, 920, 28–33. [Google Scholar] [CrossRef]

- McCarthy, C.T.; Hussey, M.; Gilchrist, M.D. On the sharpness of straight edge blades in cutting soft solids; Part I—Indentation experiments. Eng. Fract. Mech. 2007, 74, 2205–2224. [Google Scholar] [CrossRef]

- Shiratori, T.; Yoshino, T.; Suzuki, Y.; Aizawa, T. Deformation and transformation characteristics in micropunching of stainless steel AISI304. In Proceedings of the 3rd WCMNM, Raleigh, NC, USA, 10 September 2019; pp. 130–133. [Google Scholar]

- Miniature Motors. Available online: https://rdc.portescap.com/products (accessed on 4 April 2020).

- Production Line of Lead Frames. Available online: https://www.mitsui-high-tec.com/ja/products/lf/feature.php (accessed on 4 April 2020).

- Miniature Copper-Alloy Connectors. Available online: http://www.farnell.com/datasheets/1072747.pdf (accessed on 4 April 2020).

| . | A-A’ a-a’ | B-B’ b-b’ | C-C’ c-c’ | D-D’ d-d’ | E-E’ e-e’ | F-F’ f-f’ | G-G’ g-g’ | H-H’ h-h’ |

|---|---|---|---|---|---|---|---|---|

| Screen (mm) | 2.0 | 2.0 | 10.0 | 1.0 | 1.0 | 6.5 | 3.5 | 7.0 |

| T-shaped punch (mm) | 2.001 | 1.991 | 10.001 | 0.978 | 0.971 | 6.512 | 3.476 | 6.990 |

| T-shaped die (mm) | 2.023 | 2.039 | 10.045 | 1.047 | 1.039 | 6.531 | 3.561 | 7.073 |

| Clearance (mm) | 0.011 | 0.024 | 0.022 | 0.034 | 0.035 | 0.0095 | 0.043 | 0.0415 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aizawa, T.; Suzuki, Y.; Yoshino, T.; Shiratori, T. Fabrication of Punch and Die Using Plasma-Assisted 3D Printing Technology for Piercing Sheet Metals. J. Manuf. Mater. Process. 2022, 6, 49. https://doi.org/10.3390/jmmp6030049

Aizawa T, Suzuki Y, Yoshino T, Shiratori T. Fabrication of Punch and Die Using Plasma-Assisted 3D Printing Technology for Piercing Sheet Metals. Journal of Manufacturing and Materials Processing. 2022; 6(3):49. https://doi.org/10.3390/jmmp6030049

Chicago/Turabian StyleAizawa, Tatsuhiko, Yohei Suzuki, Tomoaki Yoshino, and Tomomi Shiratori. 2022. "Fabrication of Punch and Die Using Plasma-Assisted 3D Printing Technology for Piercing Sheet Metals" Journal of Manufacturing and Materials Processing 6, no. 3: 49. https://doi.org/10.3390/jmmp6030049

APA StyleAizawa, T., Suzuki, Y., Yoshino, T., & Shiratori, T. (2022). Fabrication of Punch and Die Using Plasma-Assisted 3D Printing Technology for Piercing Sheet Metals. Journal of Manufacturing and Materials Processing, 6(3), 49. https://doi.org/10.3390/jmmp6030049