Experimental and Numerical Investigations of the Deep Rolling Process to Analyze the Local Deformation Behavior of Welded Joints

Abstract

1. Introduction

2. Materials and Methods

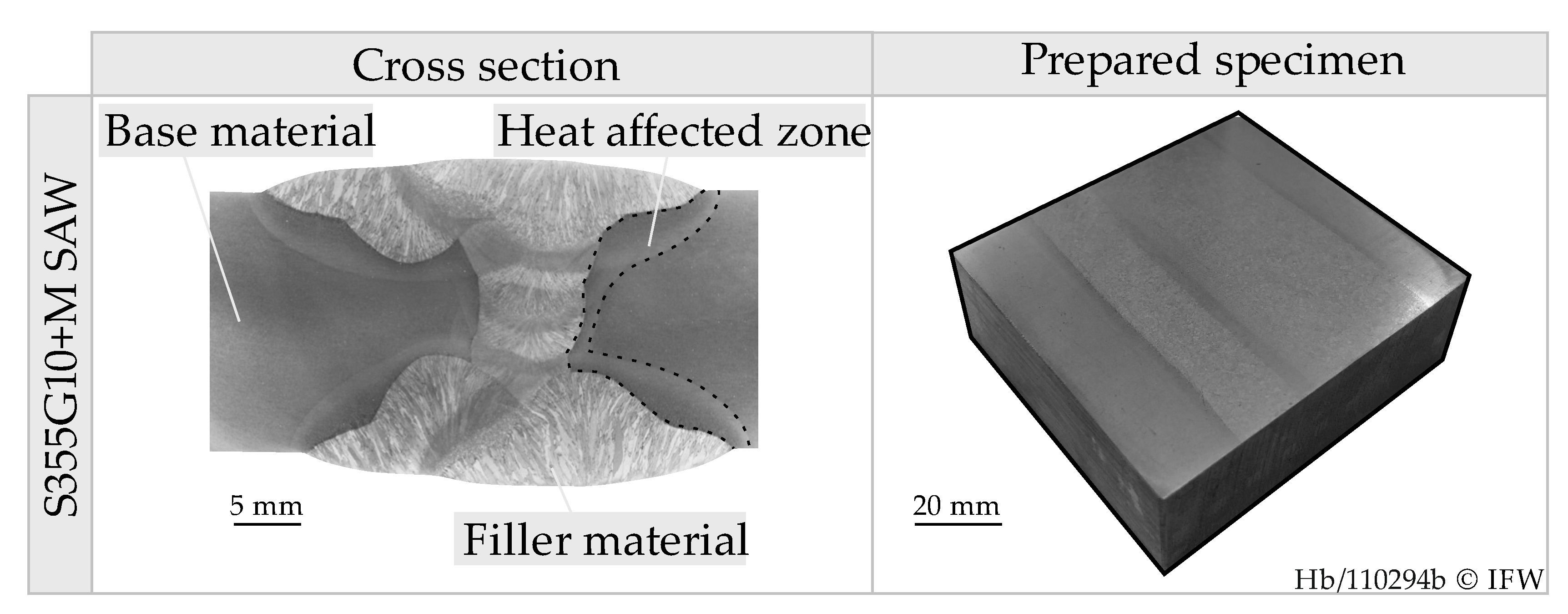

2.1. Preparation of Specimens

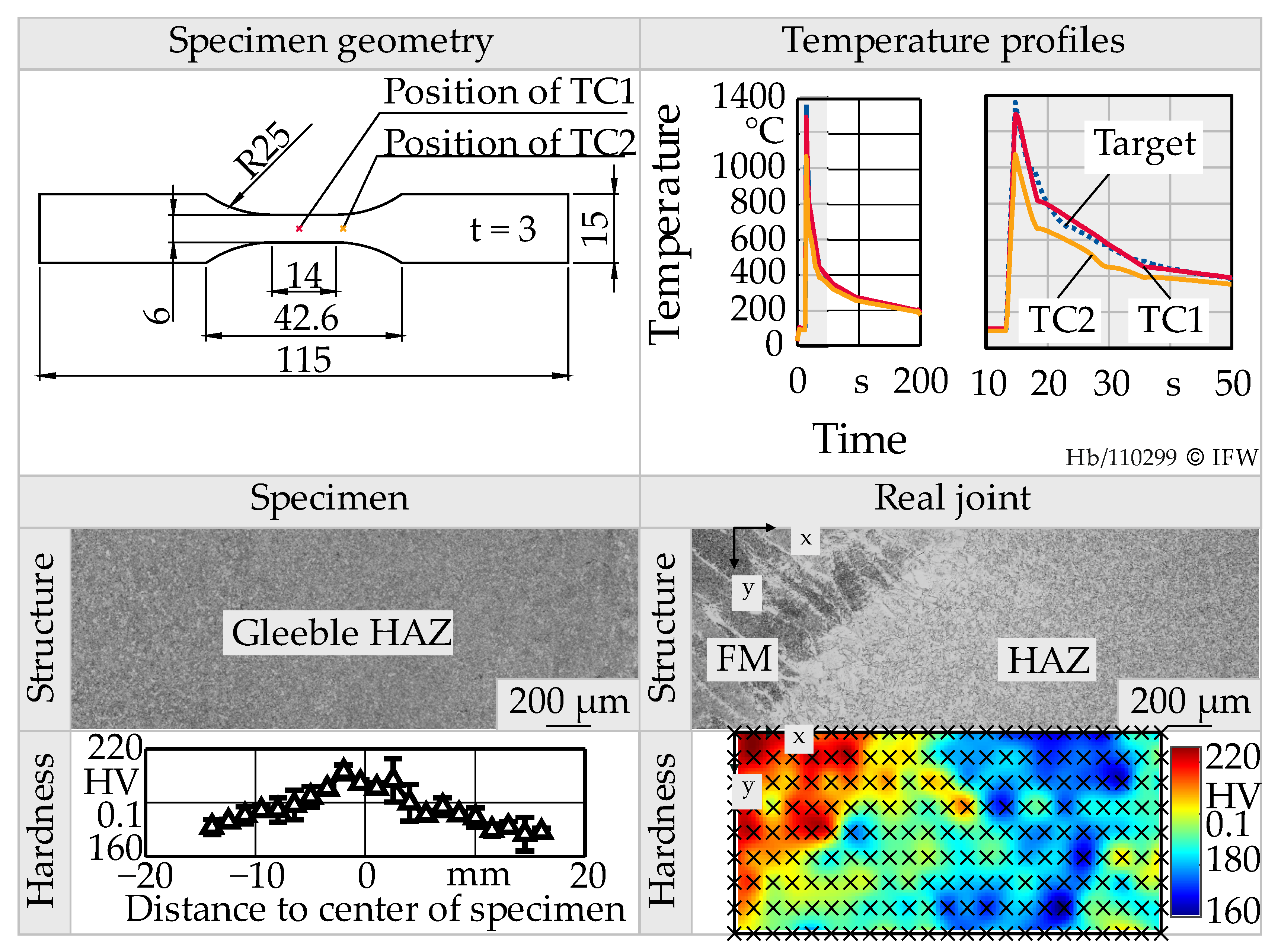

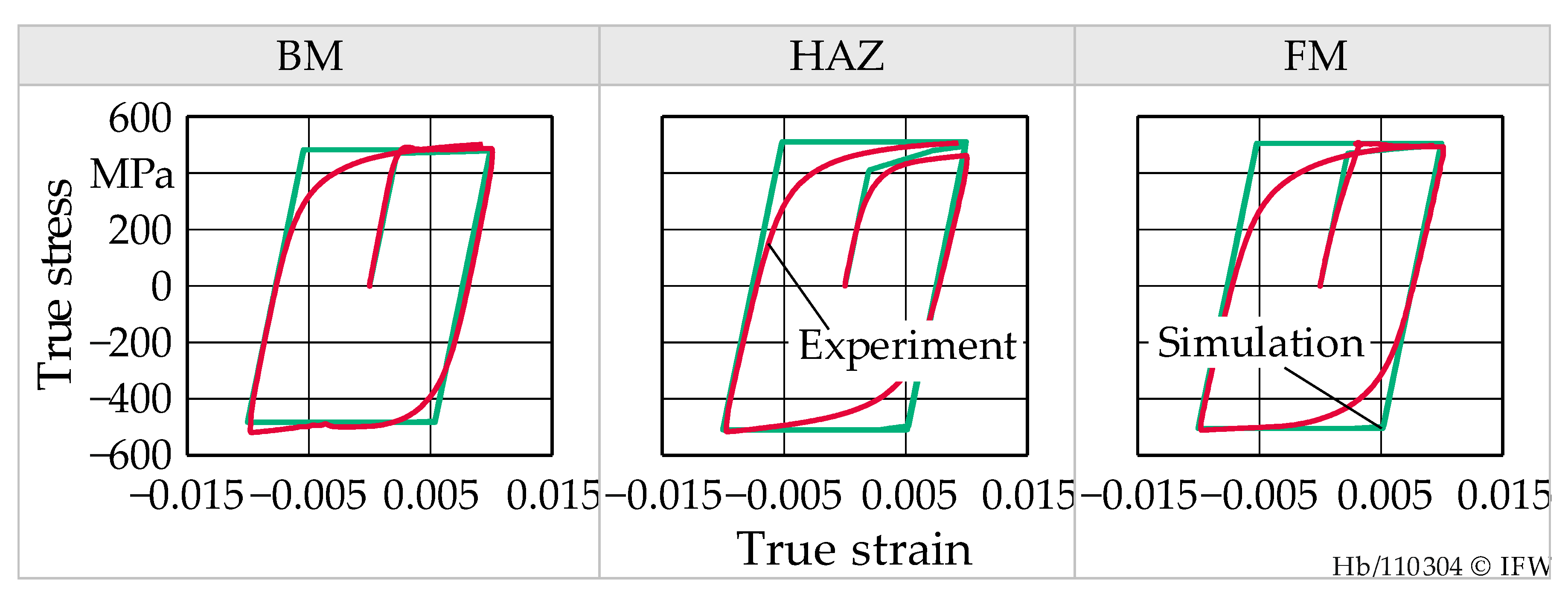

2.2. Investigations of Material Behavior

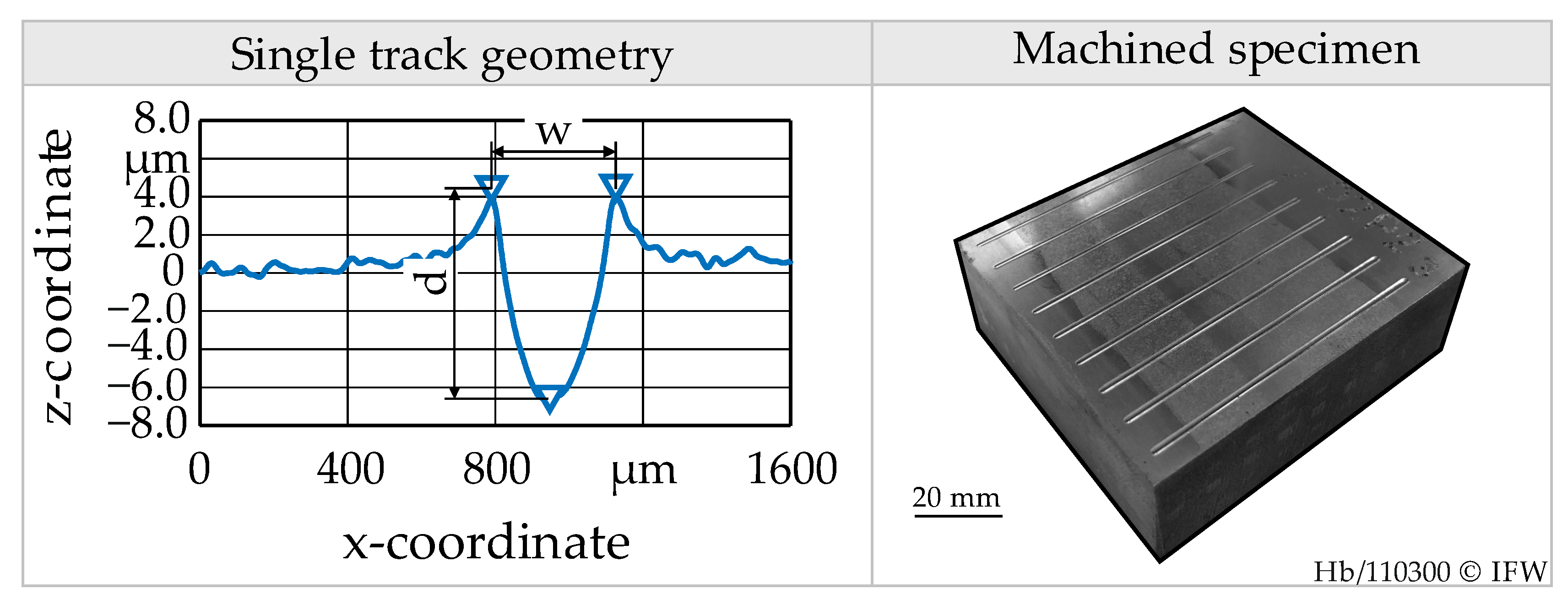

2.3. Deep Rolling of Single Tracks

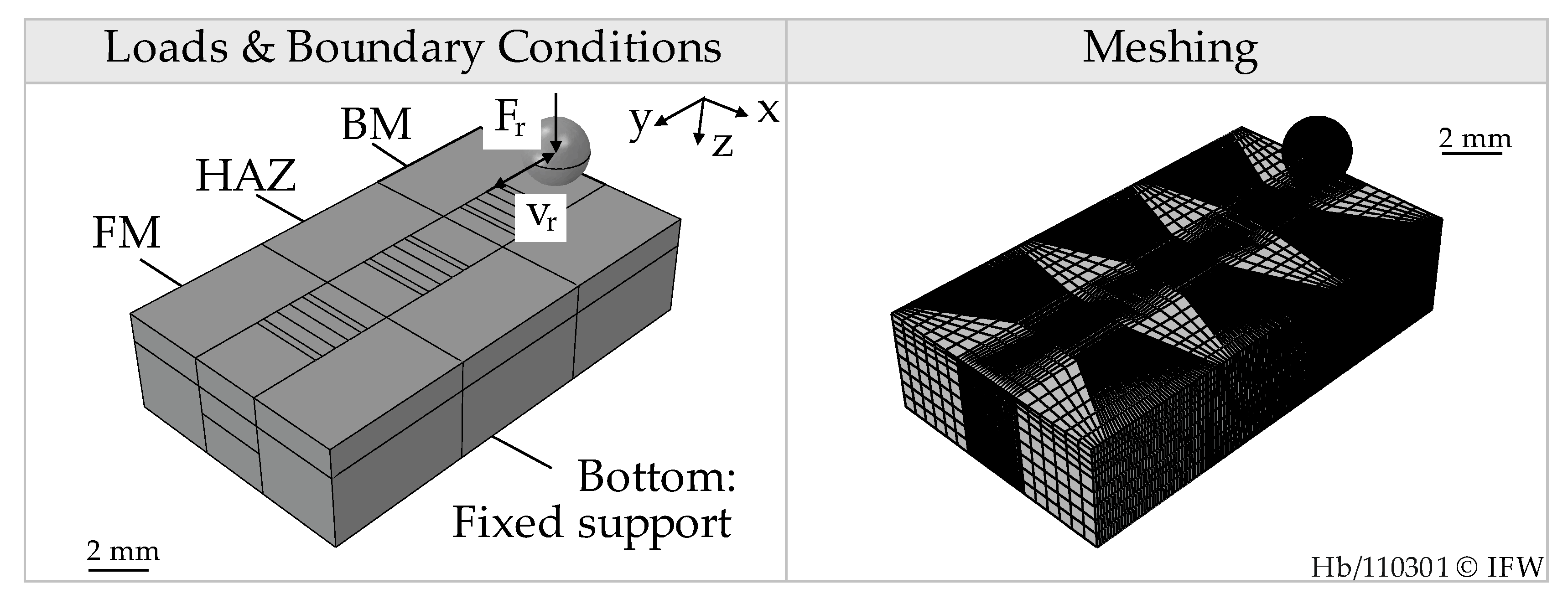

2.4. Numerical Simulation

3. Results

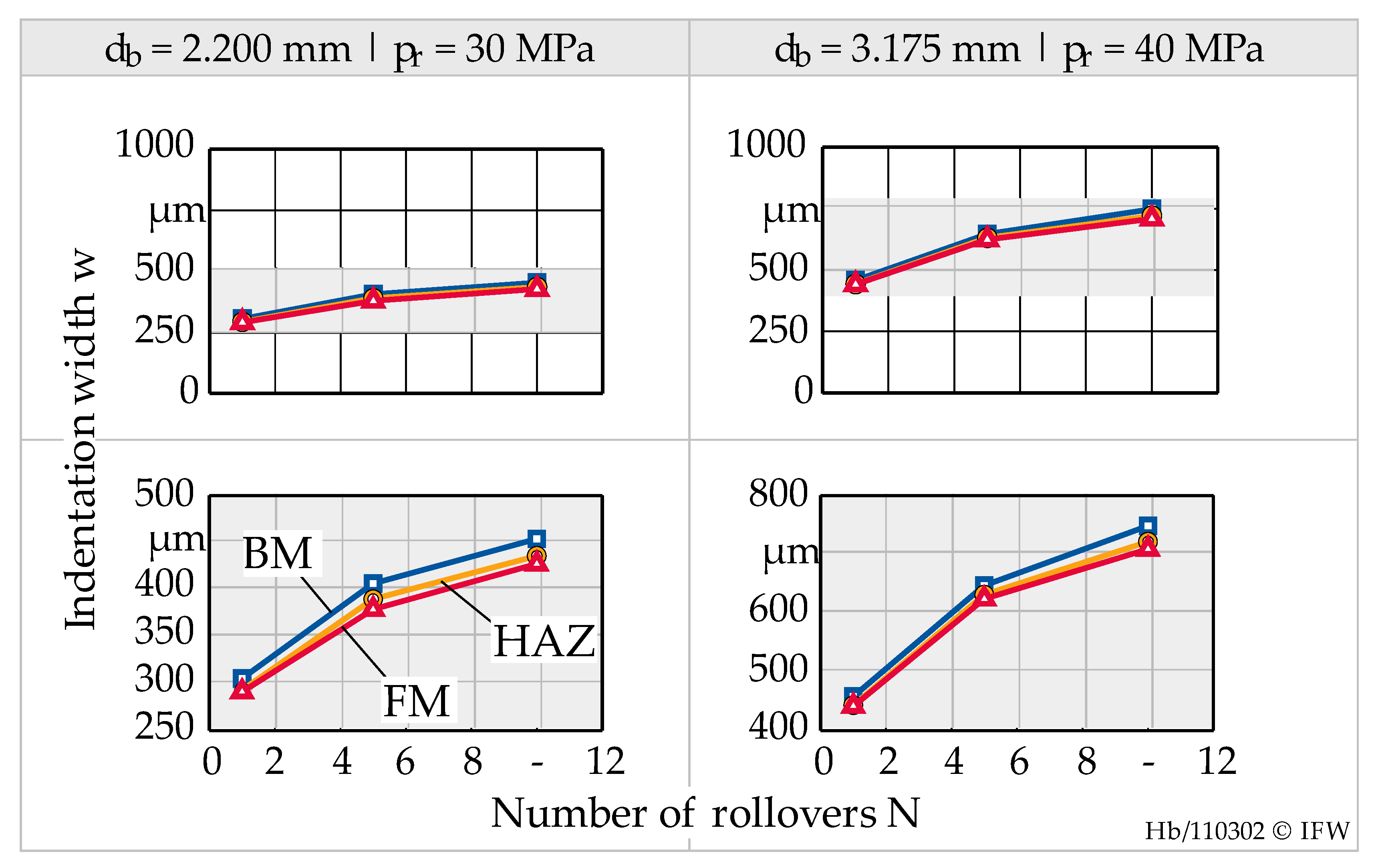

3.1. Experimentally Determined Single Track Geometries

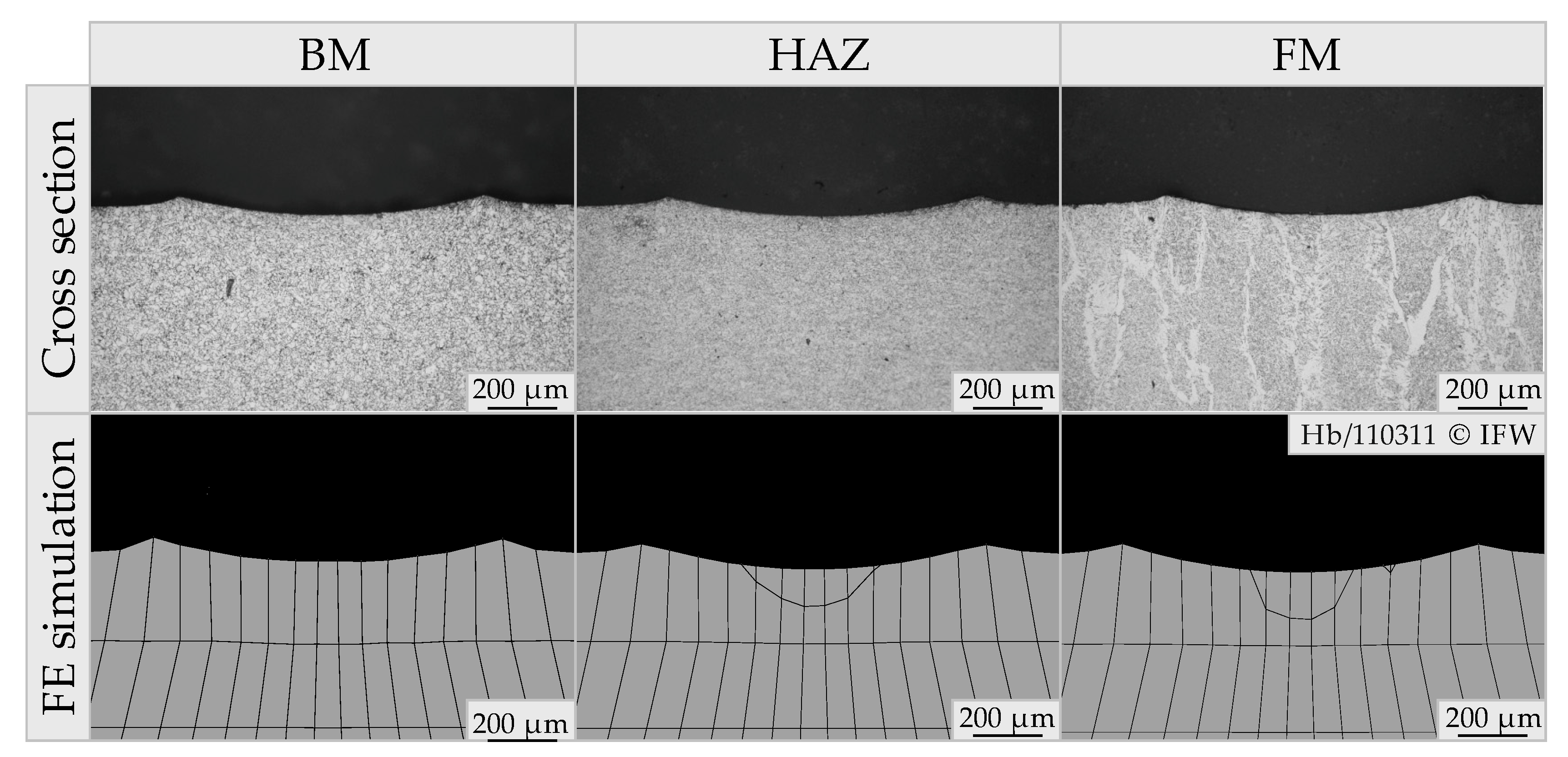

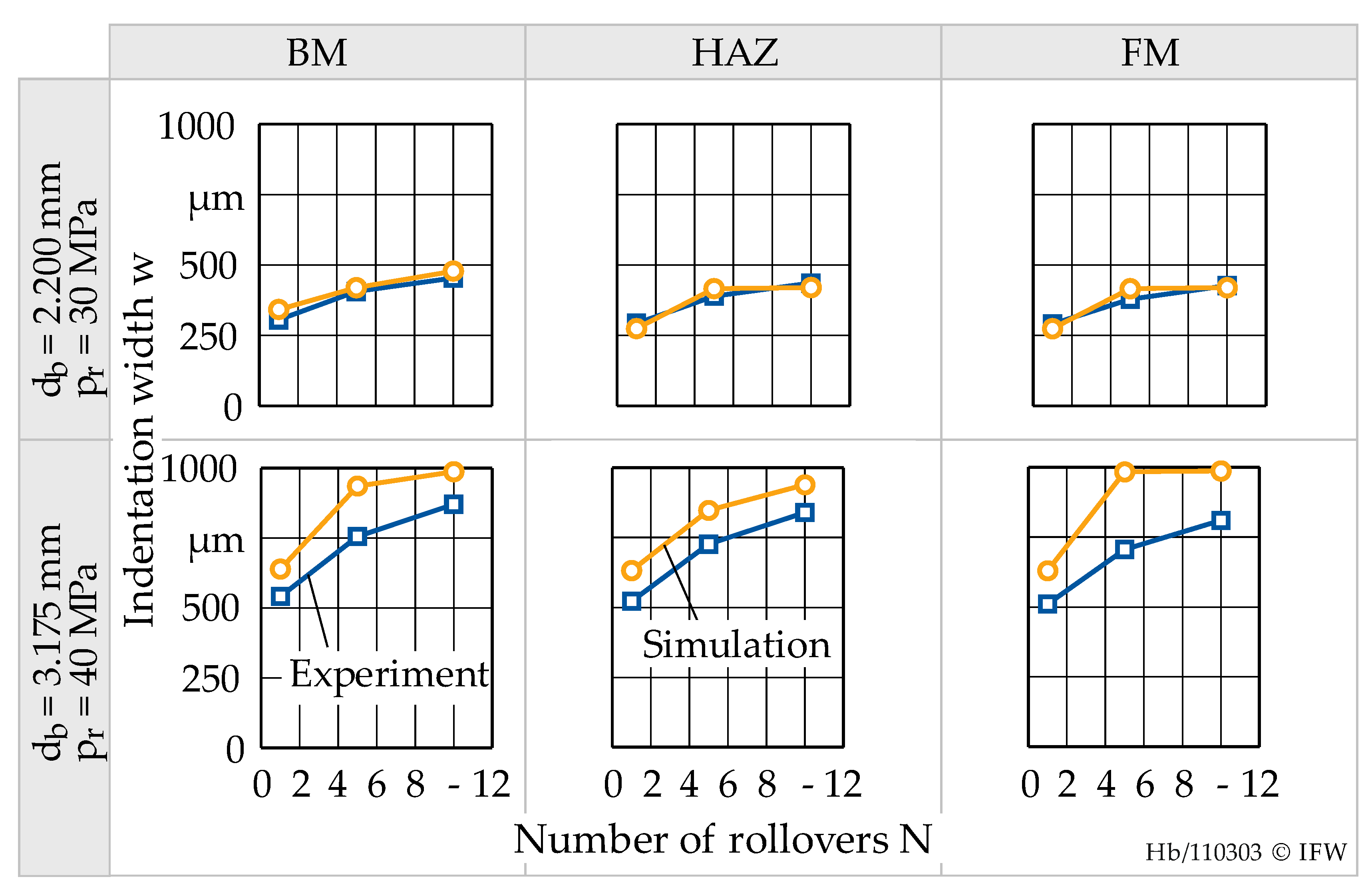

3.2. Numerically Determined Single Track Geometries

4. Discussion

5. Conclusions

- –

- Different material states across the welded joint show different material properties and hardening behavior that can be characterized by the deep rolling process

- –

- An implementation of the different material properties must be used for a numerical simulation of the deep rolling process on welded joints, with a validation directly depending on the quality of the results from material investigations

- –

- Simple multilinear isotropic hardening is not sufficient, but able to describe the yield and hardening behavior during multiple deep rolling

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schubnell, J.; Discher, D.; Farajian, M. Determination of the static, dynamic and cyclic properties of the heat affected zone for different steel grades. Mater. Test. 2019, 61, 635–642. [Google Scholar] [CrossRef]

- Zinn, W.; Scholtes, B. Residual stress formation processess during welding and joining. In Handbook of Residual Stress and Deformation of Steel, First Print; Totten, G.E., Howes, M.A.H., Inoue, T., Eds.; ASM International: Novelty, OH, USA, 2002; pp. 391–396. [Google Scholar]

- Harati, E.; Svensson, L.-E.; Karlsson, L.; Hurtig, K. Effect of HFMI treatment procedure on weld toe geometry and fatigue properties of high strength steel welds. Procedia Struct. Integr. 2016, 2, 3483–3490. [Google Scholar] [CrossRef]

- Hensel, J.; Eslami, H.; Nitschke-Pagel, T.; Dilger, K. Fatigue Strength Enhancement of Butt Welds by Means of Shot Peening and Clean Blasting. Metals 2019, 9, 744. [Google Scholar] [CrossRef]

- Pedersen, M.M.; Mouritsen, O.Ø.; Hansen, M.R.; Andersen, J.G.; Wenderby, J. Comparison of Post-Weld Treatment of High-Strength Steel Welded Joints in Medium Cycle Fatigue. Weld. World 2010, 54, 208–217. [Google Scholar] [CrossRef]

- Lieurade, H.; Huther, I.; Lefebvre, F. Effect of weld quality and postweld improvement techniques on the fatigue resistance of extra high strength steels. Weld. World 2008, 52, 106–115. [Google Scholar] [CrossRef]

- Delgado, P.; Cuesta, I.I.; Alegre, J.M.; Díaz, A. State of the art of Deep Rolling. Precis. Eng. 2016, 46, 1–10. [Google Scholar] [CrossRef]

- Farajian, M.; Barsoum, Z.; Kromm, A. Residual Stress Engineering in Fatigue Resistant Welds. Mater. Sci. Forum 2013, 768–769, 613–619. [Google Scholar] [CrossRef]

- Thanakulwattana, W.; Nakkiew, W. Residual Stress Analysis in Deep Rolling Process on Gas Tungsten Arc Weld of Stainless Steel AISI 316L. Key Eng. Mater. 2021, 880, 23–28. [Google Scholar] [CrossRef]

- Prevéy, P.; Mahoney, M.W. Improved Fatigue Performance of Friction Stir Welds with Low Plasticity Burnishing: Residual Stress Design and Fatigue Performance Assessment. Mater. Sci. Forum 2003, 426–432, 2933–2940. [Google Scholar] [CrossRef]

- Baisukhan, A.; Nakkiew, W. Sequential Effects of Deep Rolling and Post-Weld Heat Treatment on Surface Integrity of AA7075-T651 Aluminum Alloy Friction Stir Welding. Materials 2019, 12, 3510. [Google Scholar] [CrossRef]

- Schubnell, J.; Farajian, M. Fatigue improvement of aluminium welds by means of deep rolling and diamond burnishing. Weld. World 2021, 66, 699–708. [Google Scholar] [CrossRef]

- Denkena, B.; Krödel, A.; Heikebrügge, S.; Meyer, K.; Pillkahn, P. Surface topography after deep rolling with milling kinematics. Prod. Eng. 2021, 15, 587–593. [Google Scholar] [CrossRef]

- Denkena, B.; Abrão, A.; Krödel, A.; Meyer, K. Analytic roughness prediction by deep rolling. Prod. Eng. 2020, 14, 345–354. [Google Scholar] [CrossRef]

- Wielki, N.; Heinz, N.; Meyer, D. Characterizing the Local Material Properties of Different Fe-C-Cr-steels by Using Deep Rolled Single Tracks. Materials 2020, 13, 4987. [Google Scholar] [CrossRef] [PubMed]

- Kinner-Becker, T.; Sölter, J.; Karpuschewski, B. A simulation-based analysis of internal material loads and material modifications in multi-step deep rolling. Procedia CIRP 2020, 87, 515–520. [Google Scholar] [CrossRef]

- Kinner-Becker, T.; Hettig, M.; Sölter, J.; Meyer, D. Analysis of internal material loads and Process Signature Components in deep rolling. J. Manuf. Sci. Technol. 2021, 35, 400–409. [Google Scholar] [CrossRef]

- Kuschel, S.; Kinner-Becker, T.; Zmich, R.; Sölter, J.; Meyer, D. Modelling and Simulation of Mechanical Loads and Residual Stresses in Deep Rolling at Elevated Temperature. J. Manuf. Mater. Processing 2021, 5, 76. [Google Scholar] [CrossRef]

- Lyubenova, N.; Baehre, D. Finite Element Modelling and Investigation of the Process Parameters in Deep Rolling of AISI 4140 Steel. J. Mater. Sci. Eng. B 2015, 5, 277–287. [Google Scholar] [CrossRef][Green Version]

- Majzoobi, G.H.; Teimoorial Motlagh, S.; Amiri, A. Numerical simulation of residual stress induced by roll-peening. Trans. Indian Inst. Met. 2010, 63, 499–504. [Google Scholar] [CrossRef]

- Lim, A.; Castagne, S.; Wong, C.C. Quasi-static Process Modelling of Deep Cold Rolling on Ti-6Al-4V. Mater. Res. Proc. 2016, 2, 7–12. [Google Scholar] [CrossRef]

- Trauth, D.; Klocke, F.; Mattfeld, P.; Klink, A. Time-efficient Prediction of the Surface Layer State after Deep Rolling using Similarity Mechanics Approach. Procedia CIRP 2013, 9, 29–34. [Google Scholar] [CrossRef]

- Bagherifard, S.; Ghelichi, R.; Guagliano, M. A numerical model of severe shot peening (SSP) to predict the generation of a nanostructured surface layer of material. Surf. Coat. Technol. 2010, 204, 4081–4090. [Google Scholar] [CrossRef]

- Foehrenbach, J.; Hardenacke, V.; Farajian, M. High frequency mechanical impact treatment (HFMI) for the fatigue improvement: Numerical and experimental investigations to describe the condition in the surface layer. Weld. World 2016, 60, 749–755. [Google Scholar] [CrossRef]

- Ernould, C.; Schubnell, J.; Farajian, M.; Maciolek, A.; Simunek, D.; Leitner, M.; Stoschka, M. Application of different simulation approaches to numerically optimize high-frequency mechanical impact (HFMI) post-treatment process. Weld. World 2019, 63, 725–738. [Google Scholar] [CrossRef]

| Material | Element 1 | C | Al | Si | Cr | Mn | Co | Ni | Nb | W | B | Ti | Cu | Mo |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S355G10+M | Wt. % | 0.05 | 0.03 | 0.36 | 0.36 | 1.34 | 0.02 | 0.03 | 0.04 | 0.02 | - | - | - | - |

| S2MoTiB | Wt. % | 0.05 | - | 0.43 | 0.07 | 1.55 | - | 0.18 | - | - | 0.01 | 0.14 | 0.05 | 0.19 |

| Material State | Yield Stress | Plastic Strain | ||||||

|---|---|---|---|---|---|---|---|---|

| BM | MPa | 470 | 475 | 483 | % | 0 | 0.5 | 1.0 |

| HAZ | 410 | 480 | 510 | |||||

| FM | 470 | 490 | 505 |

| Ball Diameter db [mm] | Rolling Pressure pr [MPa] | Number of Rollovers N [-] |

|---|---|---|

| 2.2000; 3.175 | 30; 40 | 1; 5; 10 |

| Rolling Pressure pr [MPa] | Ball Diameter db [mm] | |

|---|---|---|

| 2.200 | 3.175 | |

| 30 | 63.5 | 83.3 |

| 40 | 173.2 | 231.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heikebrügge, S.; Breidenstein, B.; Bergmann, B.; Dänekas, C.; Schaumann, P. Experimental and Numerical Investigations of the Deep Rolling Process to Analyze the Local Deformation Behavior of Welded Joints. J. Manuf. Mater. Process. 2022, 6, 50. https://doi.org/10.3390/jmmp6030050

Heikebrügge S, Breidenstein B, Bergmann B, Dänekas C, Schaumann P. Experimental and Numerical Investigations of the Deep Rolling Process to Analyze the Local Deformation Behavior of Welded Joints. Journal of Manufacturing and Materials Processing. 2022; 6(3):50. https://doi.org/10.3390/jmmp6030050

Chicago/Turabian StyleHeikebrügge, Steffen, Bernd Breidenstein, Benjamin Bergmann, Christian Dänekas, and Peter Schaumann. 2022. "Experimental and Numerical Investigations of the Deep Rolling Process to Analyze the Local Deformation Behavior of Welded Joints" Journal of Manufacturing and Materials Processing 6, no. 3: 50. https://doi.org/10.3390/jmmp6030050

APA StyleHeikebrügge, S., Breidenstein, B., Bergmann, B., Dänekas, C., & Schaumann, P. (2022). Experimental and Numerical Investigations of the Deep Rolling Process to Analyze the Local Deformation Behavior of Welded Joints. Journal of Manufacturing and Materials Processing, 6(3), 50. https://doi.org/10.3390/jmmp6030050