Nozzle Condition Monitoring System Using Root Mean Square of Acoustic Emissions during Abrasive Waterjet Machining

Abstract

:1. Introduction

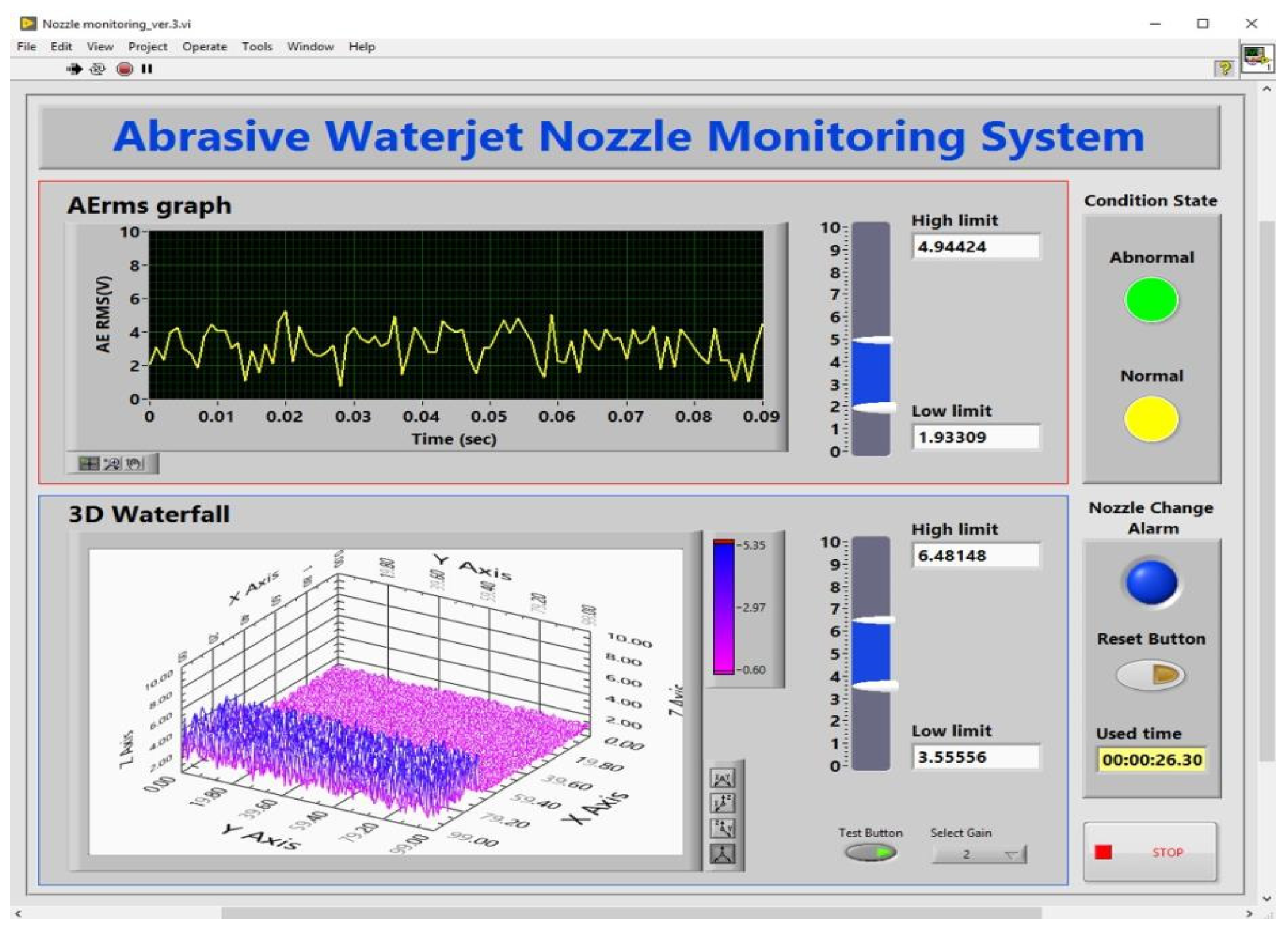

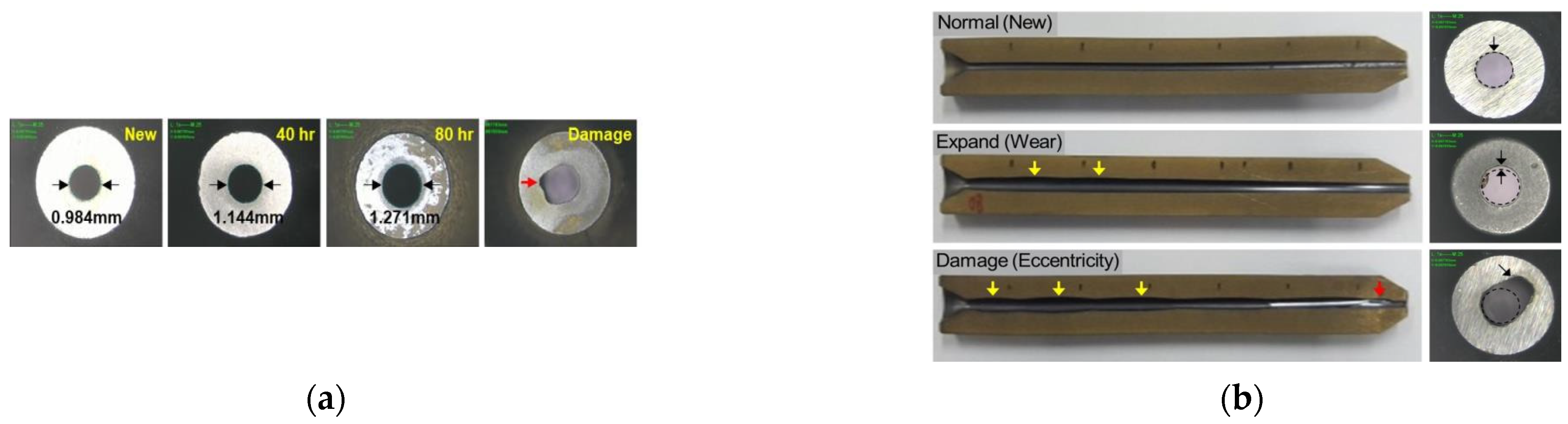

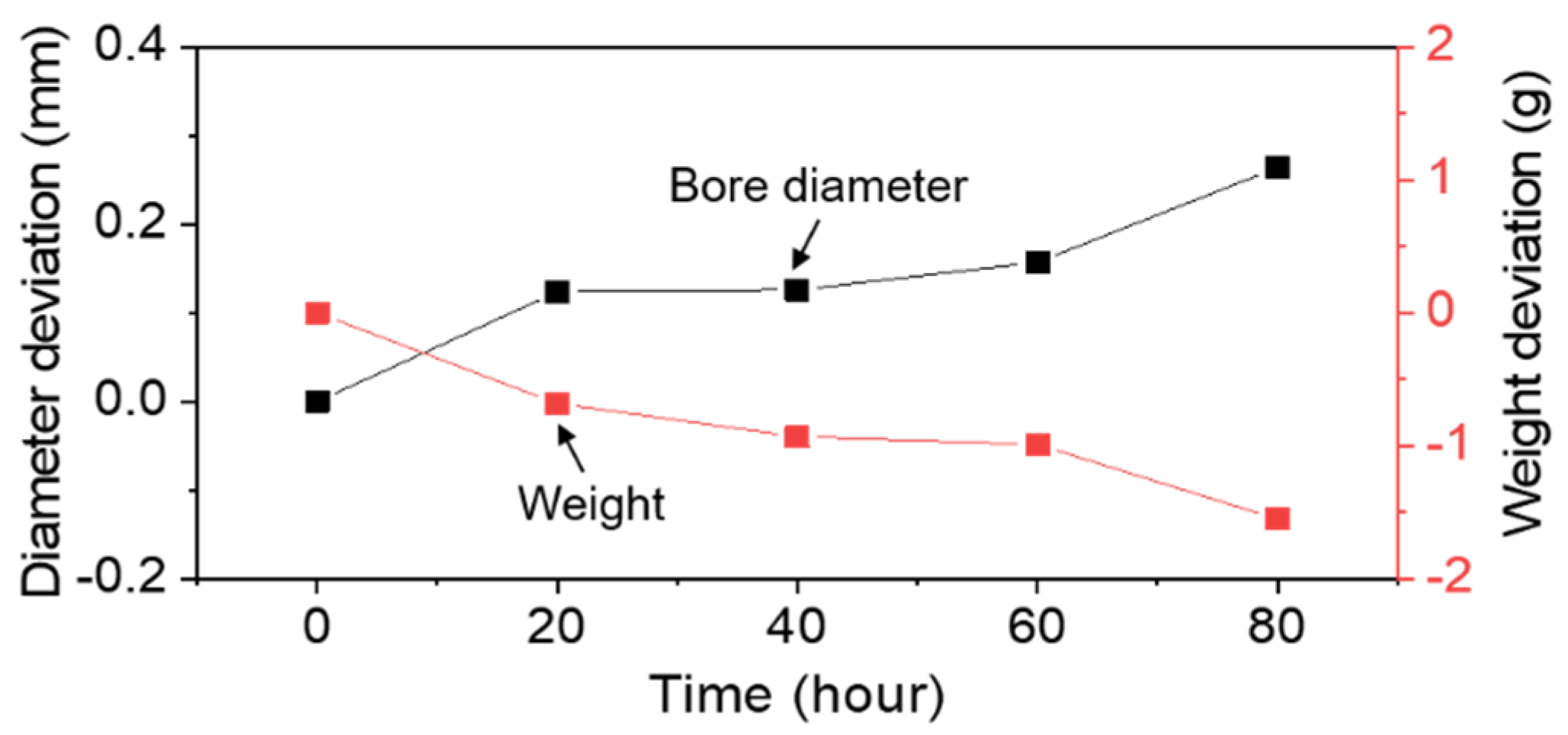

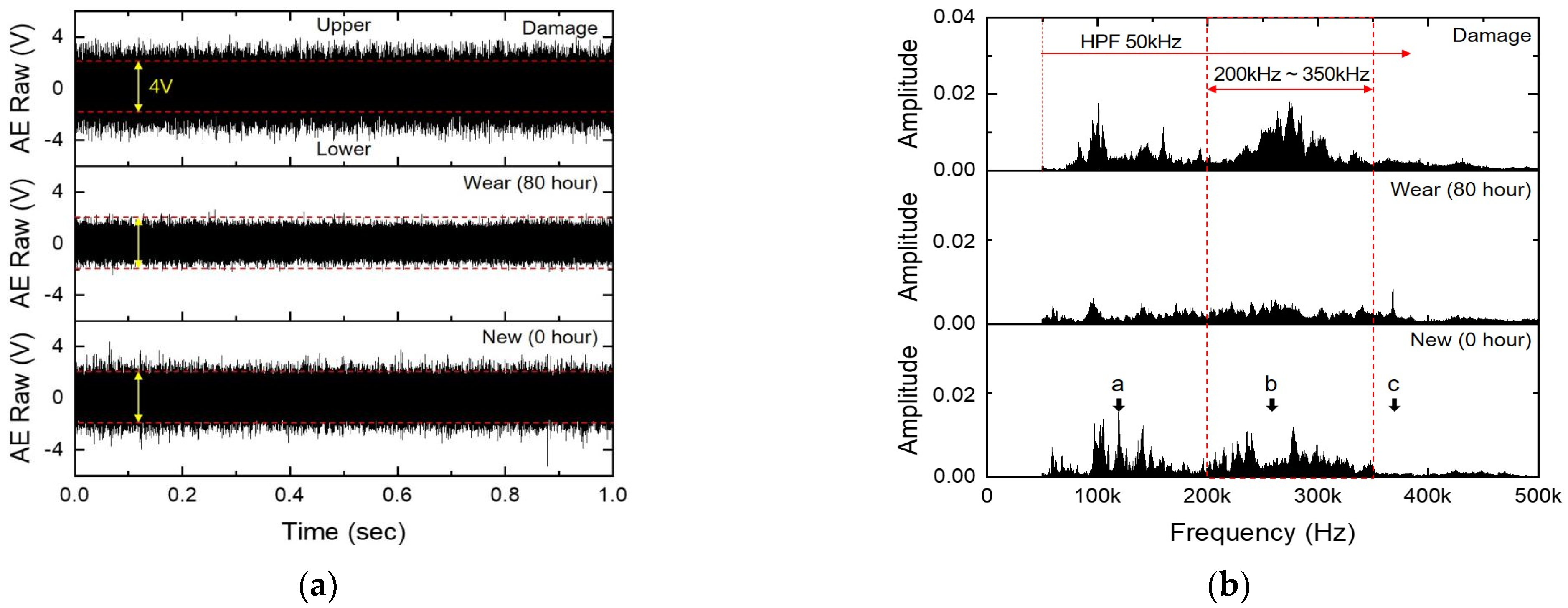

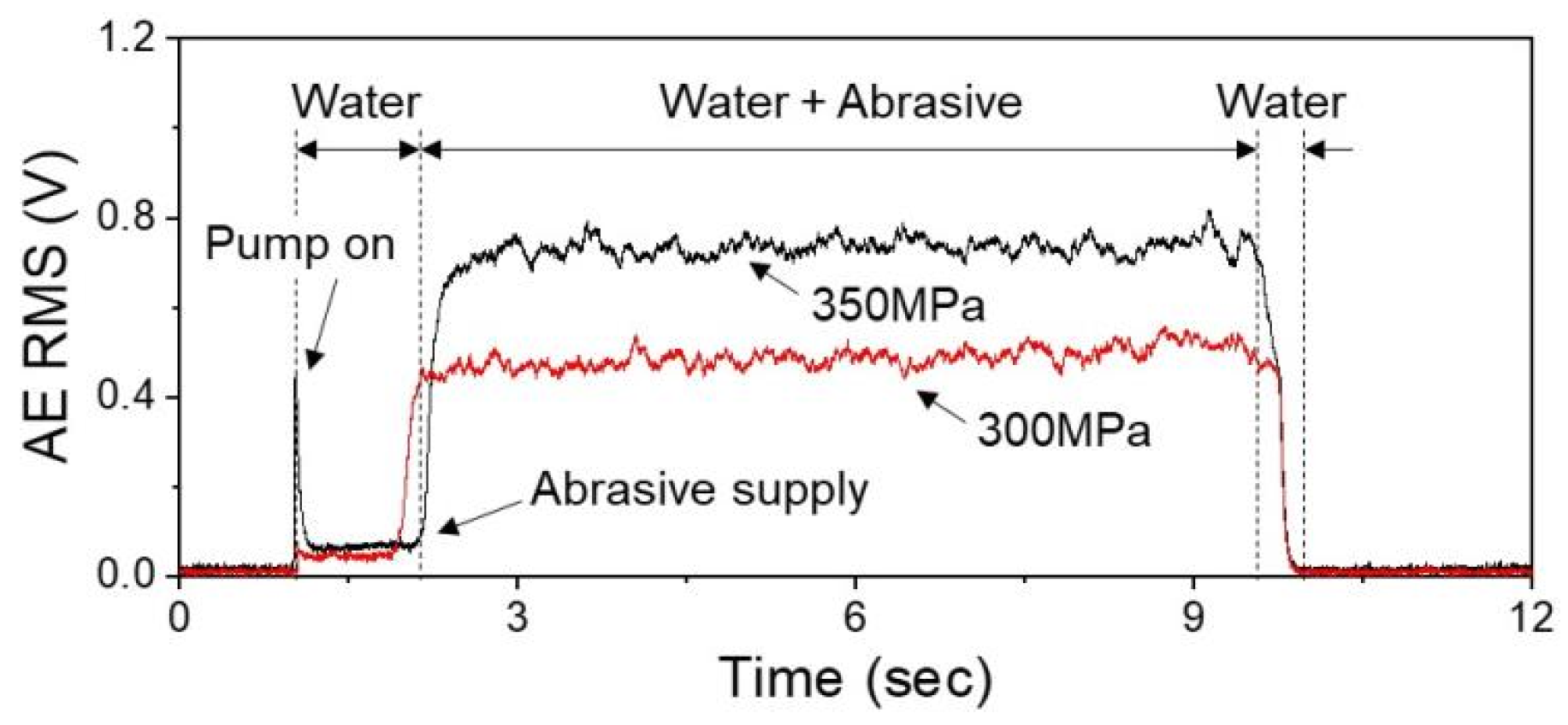

2. Proposed System for Monitoring the Wear Condition of the Focusing Nozzle

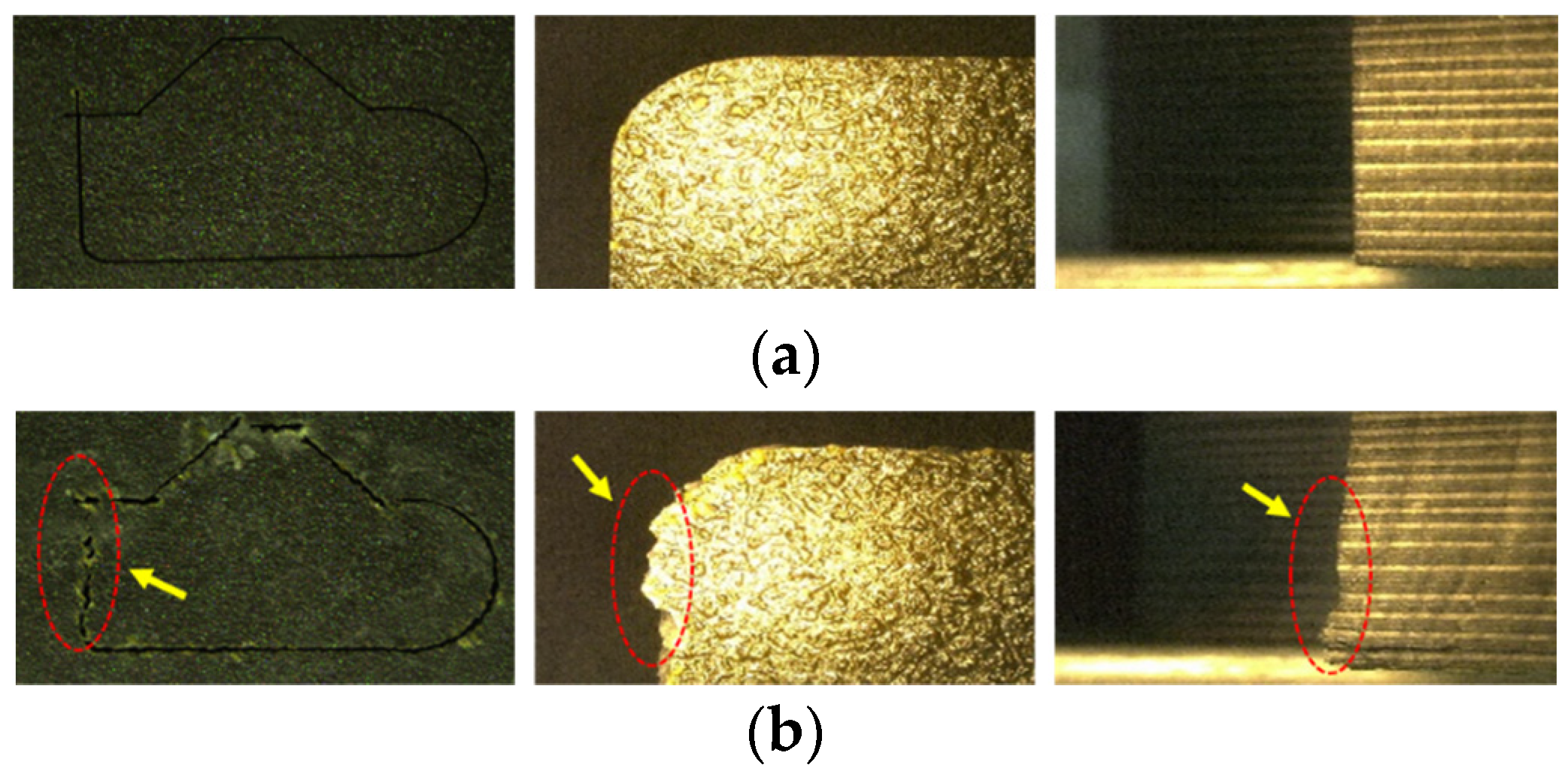

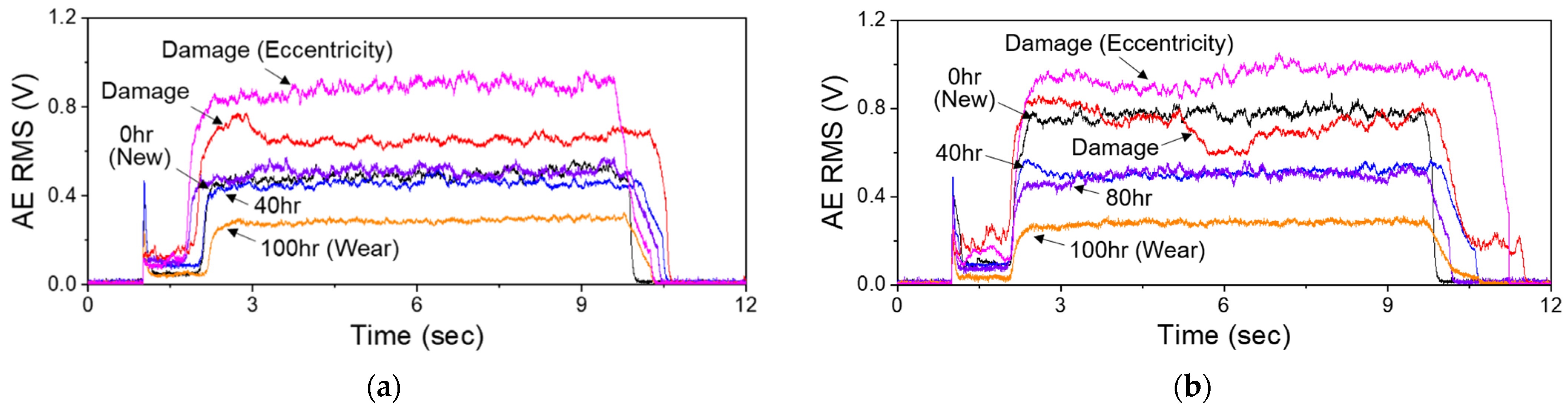

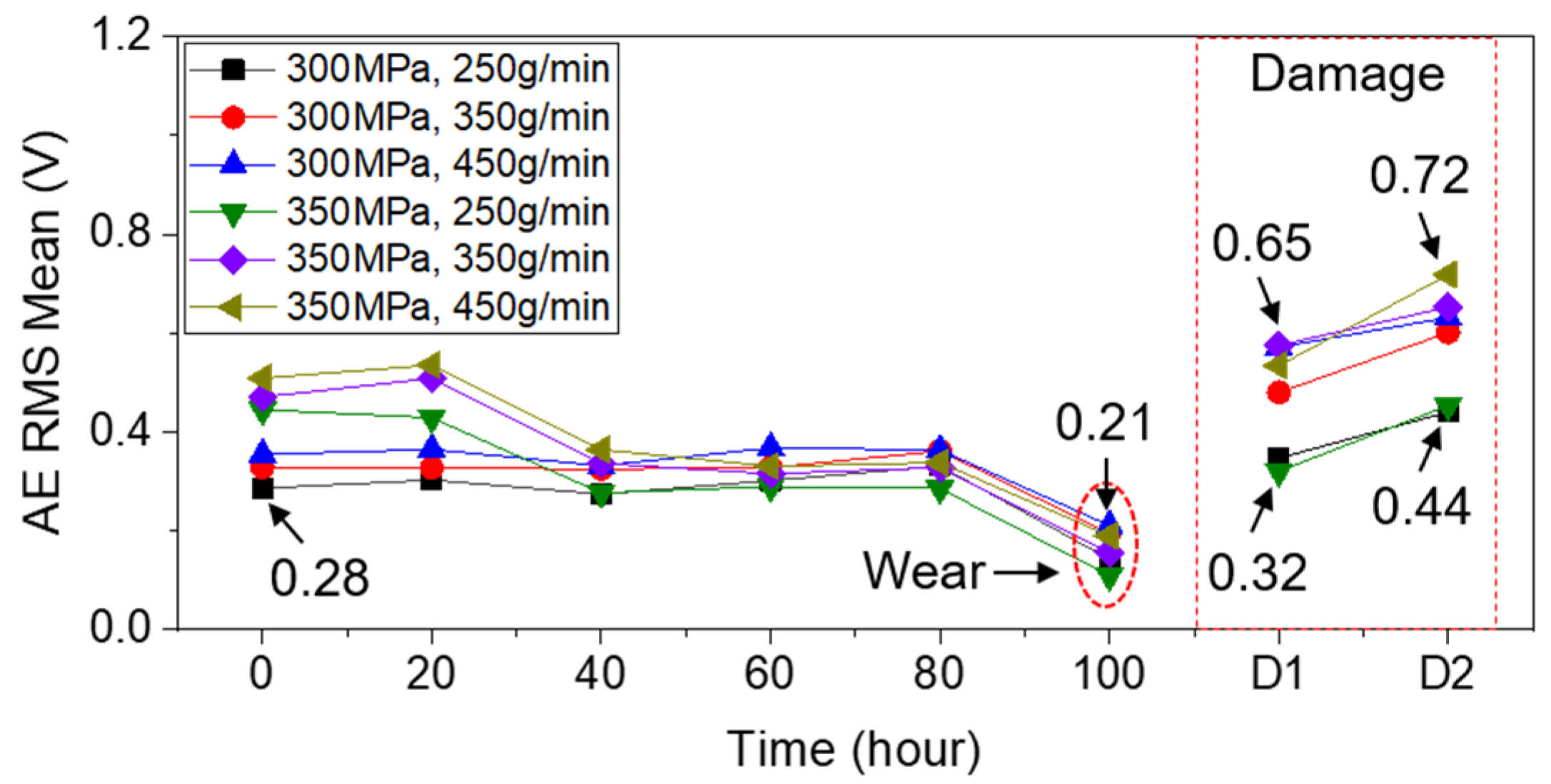

3. Experimental Setup of Our Proposed System

4. Experimental Evaluation of Our Proposed System

5. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hloch, S.; Valíček, J.; Kozak, D.; Tozan, H.; Chattopadhyaya, S.; Adamčík, P. Analysis of acoustic emission emerging during hydroabrasive cutting and options for indirect quality control. Int. J. Adv. Manuf. Technol. 2013, 66, 45–58. [Google Scholar] [CrossRef]

- Sutowski, P.; Sutowska, M.; Kapłonek, W. The use of high-frequency acoustic emission analysis for in-process assessment of the surface quality of aluminium alloy 5251 in abrasive waterjet machining. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 2547–2565. [Google Scholar] [CrossRef]

- Axinte, D.; Kong, M. An integrated monitoring method to supervise waterjet machining. CIRP Ann. 2009, 58, 303–306. [Google Scholar] [CrossRef]

- Liu, H.-T. “7M” Advantage of abrasive waterjet for machining advanced materials. J. Manuf. Mater. Processing 2017, 1, 11. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.-T.; Gershenfeld, N. Performance comparison of subtractive and additive machine tools for meso-micro machining. J. Manuf. Mater. Processing 2020, 4, 19. [Google Scholar] [CrossRef]

- Phokane, T.; Gupta, K.; Gupta, M.K. Investigations on surface roughness and tribology of miniature brass gears manufactured by abrasive water jet machining. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 232, 4193–4202. [Google Scholar] [CrossRef]

- Liu, X.; Liang, Z.; Wen, G.; Yuan, X. Waterjet machining and research developments: A review. Int. J. Adv. Manuf. Technol. 2019, 102, 1257–1335. [Google Scholar] [CrossRef]

- Li, H. Monitoring the abrasive waterjet drilling of Inconel 718 and steel: A comparative study. Int. J. Adv. Manuf. Technol. 2020, 107, 3401–3414. [Google Scholar] [CrossRef]

- Krenicky, T.; Servatka, M.; Gaspar, S.; Mascenik, J. Abrasive Water Jet Cutting of Hardox Steels—Quality Investigation. Processes 2020, 8, 1652. [Google Scholar] [CrossRef]

- Sutowska, M.; Kapłonek, W.; Pimenov, D.Y.; Gupta, M.K.; Mia, M.; Sharma, S. Influence of Variable Radius of Cutting Head Trajectory on Quality of Cutting Kerf in the Abrasive Water Jet Process for Soda–Lime Glass. Materials 2020, 13, 4277. [Google Scholar] [CrossRef]

- Natarajan, Y.; Murugesan, P.K.; Mohan, M.; Khan, S.A.L.A. Abrasive Water Jet Machining process: A State of Art of Review. J. Manuf. Process. 2020, 49, 271–322. [Google Scholar] [CrossRef]

- Deaconescu, A.; Deaconescu, T. Response Surface Methods Used for Optimization of Abrasive Waterjet Machining of the Stainless Steel X2 CrNiMo 17-12-2. Materials 2021, 14, 2475. [Google Scholar] [CrossRef] [PubMed]

- Dixit, N.; Sharma, V.; Kumar, P. Research trends in abrasive flow machining: A systematic review. J. Manuf. Process. 2021, 64, 1434–1461. [Google Scholar] [CrossRef]

- Llanto, J.; Tolouei-Rad, M.; Vafadar, A.; Aamir, M. Impacts of Traverse Speed and Material Thickness on Abrasive Waterjet Contour Cutting of Austenitic Stainless Steel AISI 304L. Appl. Sci. 2021, 11, 4925. [Google Scholar] [CrossRef]

- Llanto, J.M.; Vafadar, A.; Aamir, M.; Tolouei-Rad, M. Analysis and Optimization of Process Parameters in Abrasive Waterjet Contour Cutting of AISI 304L. Metals 2021, 11, 1362. [Google Scholar] [CrossRef]

- Romanowski, M.; Łukianowicz, C.Z.; Sutowska, M.; Zawadka, W.; Pimenov, D.Y.; Nadolny, K. Assessment of the Technological Quality of X5CRNI18-10 Steel Parts after Laser and Abrasive Water Jet Cutting Using Synthetic Index of Technological Quality. Materials 2021, 14, 4801. [Google Scholar] [CrossRef]

- Krenicky, T.; Olejarova, S.; Servatka, M. Assessment of the Influence of Selected Technological Parameters on the Morphology Parameters of the Cutting Surfaces of the Hardox 500 Material Cut by Abrasive Water Jet Technology. Materials 2022, 15, 1381. [Google Scholar] [CrossRef]

- Demiral, M.; Abbassi, F.; Saracyakupoglu, T.; Habibi, M. Damage analysis of a CFRP cross-ply laminate subjected to abrasive water jet cutting. Alex. Eng. J. 2022, 61, 7669–7684. [Google Scholar] [CrossRef]

- Nguyen, T.; Wang, J. A review on the erosion mechanisms in abrasive waterjet micromachining of brittle materials. Int. J. Extreme Manuf. 2019, 1, 012006. [Google Scholar] [CrossRef] [Green Version]

- Vasanth, S.; Muthuramalingam, T.; Vinothkumar, P.; Geethapriyan, T.; Murali, G. Performance Analysis of Process Parameters on Machining Titanium (Ti-6Al-4V) Alloy Using Abrasive Water Jet Machining Process. Procedia CIRP 2016, 46, 139–142. [Google Scholar] [CrossRef] [Green Version]

- Pramanik, A. Developments in the non-traditional machining of particle reinforced metal matrix composites. Int. J. Mach. Tools Manuf. 2014, 86, 44–61. [Google Scholar] [CrossRef] [Green Version]

- Nanduri, M.; Taggart, D.G.; Kim, T.J. The effects of system and geometric parameters on abrasive water jet nozzle wear. Int. J. Mach. Tools Manuf. 2002, 42, 615–623. [Google Scholar] [CrossRef]

- Dolinšek, S.; Kopač, J. Acoustic emission signals for tool wear identification. Wear 1999, 225–229, 295–303. [Google Scholar] [CrossRef]

- Kovacevic, R. A new sensing system to monitor abrasive waterjet nozzle wear. J. Mater. Processing Technol. 1991, 28, 117–125. [Google Scholar] [CrossRef]

- Kovacevic, R.; Wang, L.; Zhang, Y.M. Identification of Abrasive Waterjet Nozzle Wear Based on Parametric Spectrum Estimation of Acoustic Signal. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 1994, 208, 173–181. [Google Scholar] [CrossRef]

- Putza, M.; Dittricha, M.; Dixa, M. Process Monitoring of Abrasive Waterjet Formation. Procedia CIRP 2016, 46, 43–46. [Google Scholar] [CrossRef]

- Prabu, R.; Manivannan, A. Condition Monitoring of Focusing Nozzle in Abrasive Water Jet Machine using Sound Sensor. Indian J. Sci. Technol. 2017, 10, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Kovacevic, R.; Momber, A.W.; Mohen, R.S. Energy Dissipation Control in Hydro-Abrasive Machining Using Quantitative Acoustic Emission. Int. J. Adv. Manuf. Technol. 2002, 20, 397–406. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| waterjet pressure, MPa | 300, 350 |

| abrasive feed rate, kg/min | 250, 350, 450 |

| abrasive material (mesh) | Garnet #80 |

| focusing nozzle length, mm | 101 |

| focusing nozzle diameter, mm | 1.02 |

| orifice diameter, mm | 0.33 |

| nozzle use time, h | 0, 20, 40, 80, 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-U.; Kim, R.-W.; Kim, S.-R.; Kim, H.-H.; Lee, K.-C. Nozzle Condition Monitoring System Using Root Mean Square of Acoustic Emissions during Abrasive Waterjet Machining. J. Manuf. Mater. Process. 2022, 6, 31. https://doi.org/10.3390/jmmp6020031

Kim J-U, Kim R-W, Kim S-R, Kim H-H, Lee K-C. Nozzle Condition Monitoring System Using Root Mean Square of Acoustic Emissions during Abrasive Waterjet Machining. Journal of Manufacturing and Materials Processing. 2022; 6(2):31. https://doi.org/10.3390/jmmp6020031

Chicago/Turabian StyleKim, Jeong-Uk, Roh-Won Kim, Sung-Ryul Kim, Hyun-Hee Kim, and Kyung-Chang Lee. 2022. "Nozzle Condition Monitoring System Using Root Mean Square of Acoustic Emissions during Abrasive Waterjet Machining" Journal of Manufacturing and Materials Processing 6, no. 2: 31. https://doi.org/10.3390/jmmp6020031

APA StyleKim, J.-U., Kim, R.-W., Kim, S.-R., Kim, H.-H., & Lee, K.-C. (2022). Nozzle Condition Monitoring System Using Root Mean Square of Acoustic Emissions during Abrasive Waterjet Machining. Journal of Manufacturing and Materials Processing, 6(2), 31. https://doi.org/10.3390/jmmp6020031