Study of Tailored Hot Stamping Process on Advanced High-Strength Steels

Abstract

1. Introduction

2. Materials and Methods

- i.

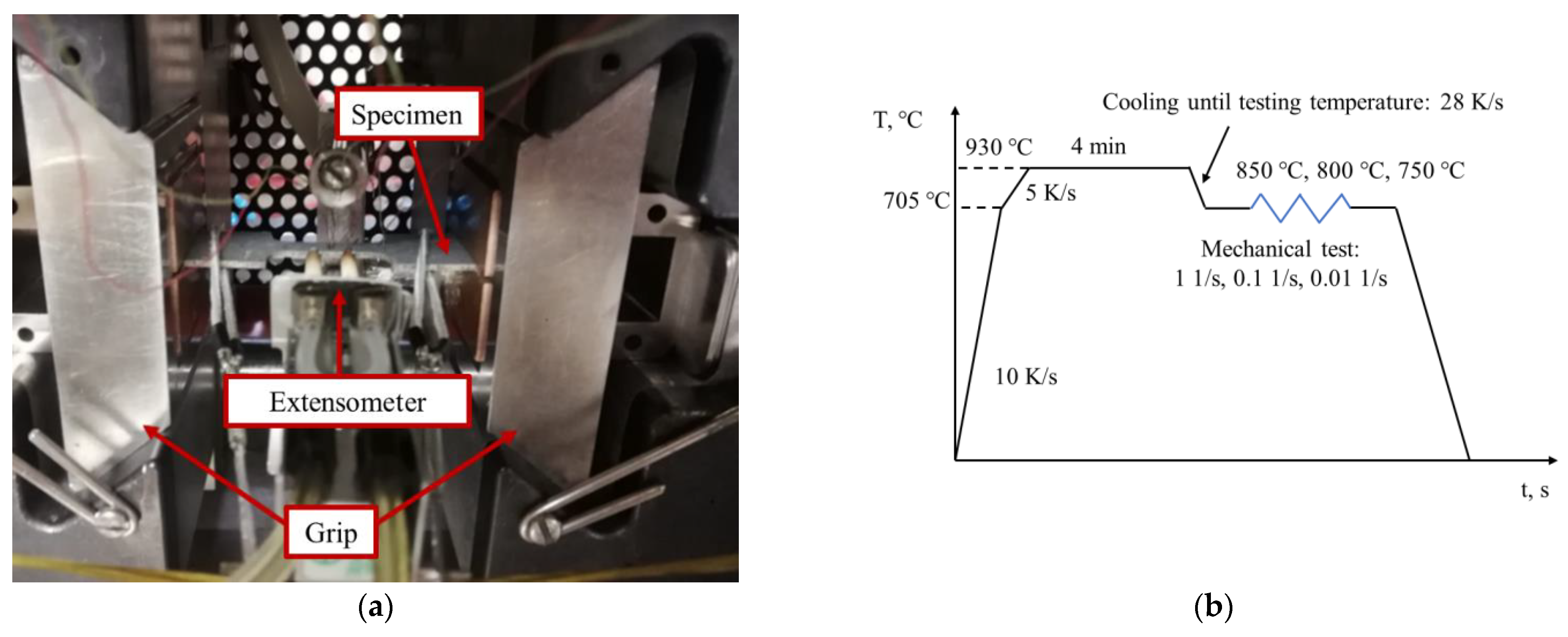

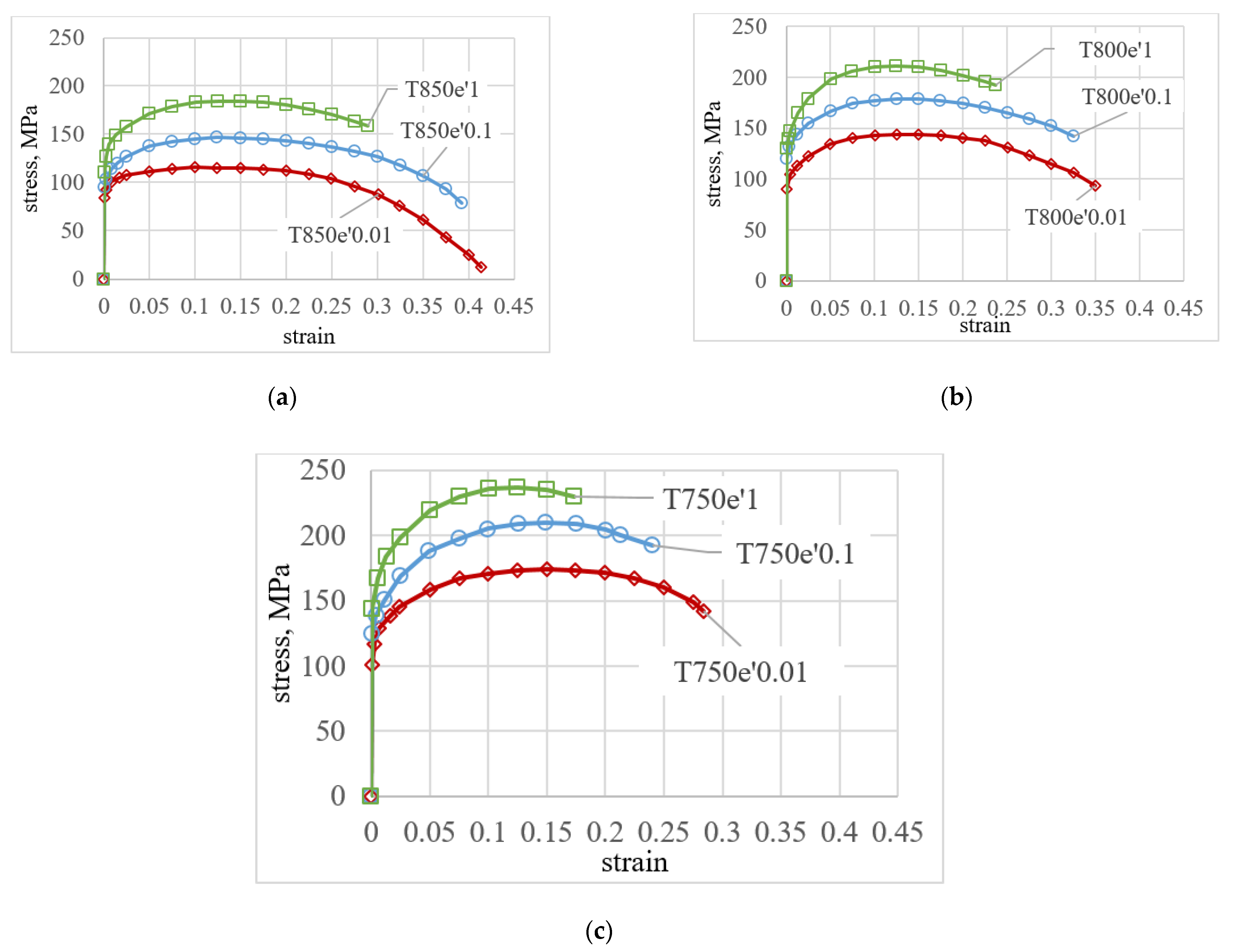

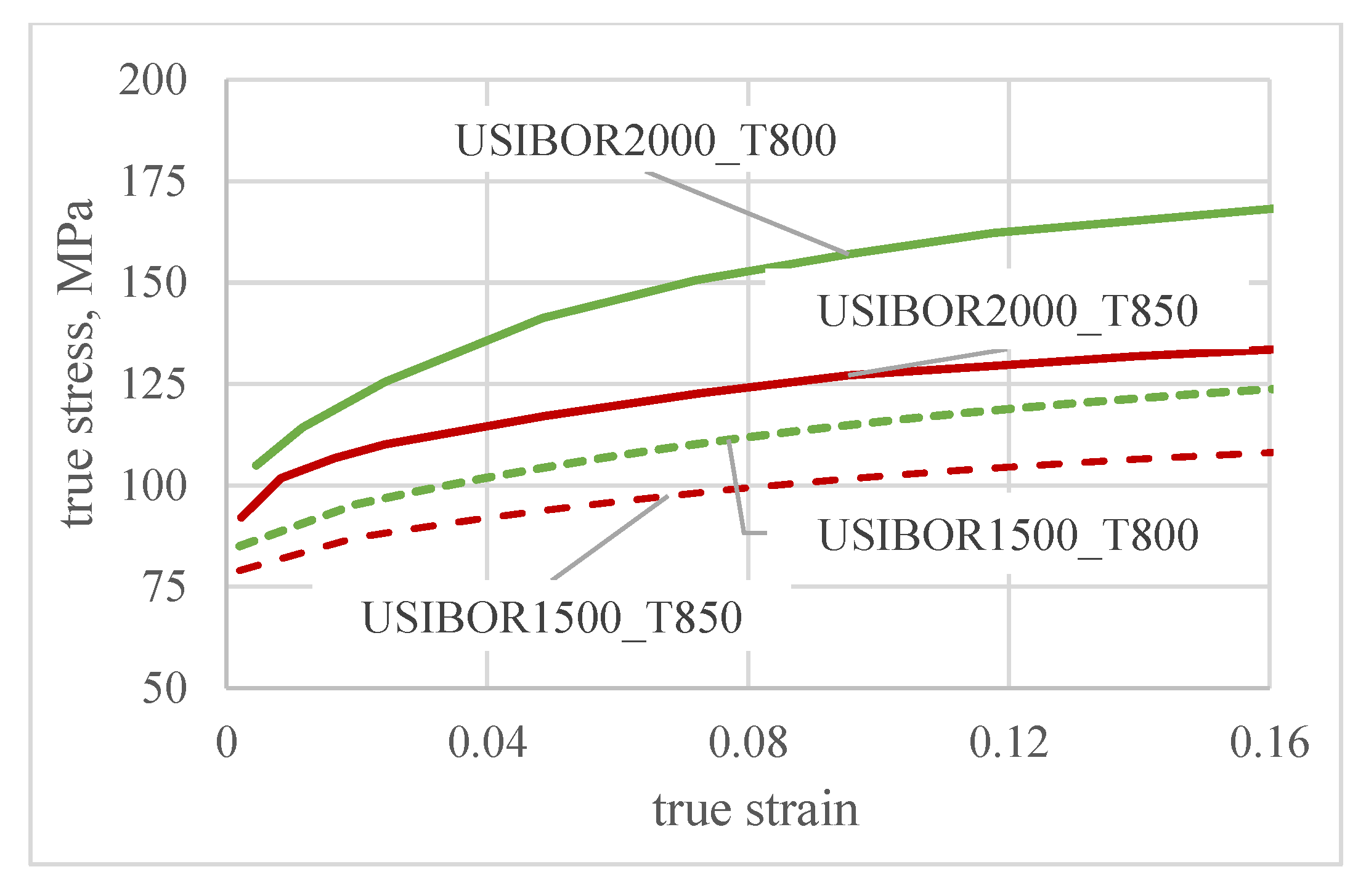

- Design on the Gleeble-3180 physical simulator of an experimental procedure for the high-temperature mechanical characterization of USIBOR®2000 steel and for the physical simulation of thermomechanical cycles on USIBOR®1500 and USIBOR®2000 steel specimens; thermomechanical cycles are those imposed in the B-Pillar during the TTT-press-hardening process simulation. The procedure has been initially implemented for the definition of the hardening curves of USIBOR®2000 steel; the mechanical characterization has been carried out with the material in austenitic phase, varying testing temperatures (750 °C, 800 °C, 850 °C) and strain rates (0.01/s, 0.1/s, 1/s).

- ii.

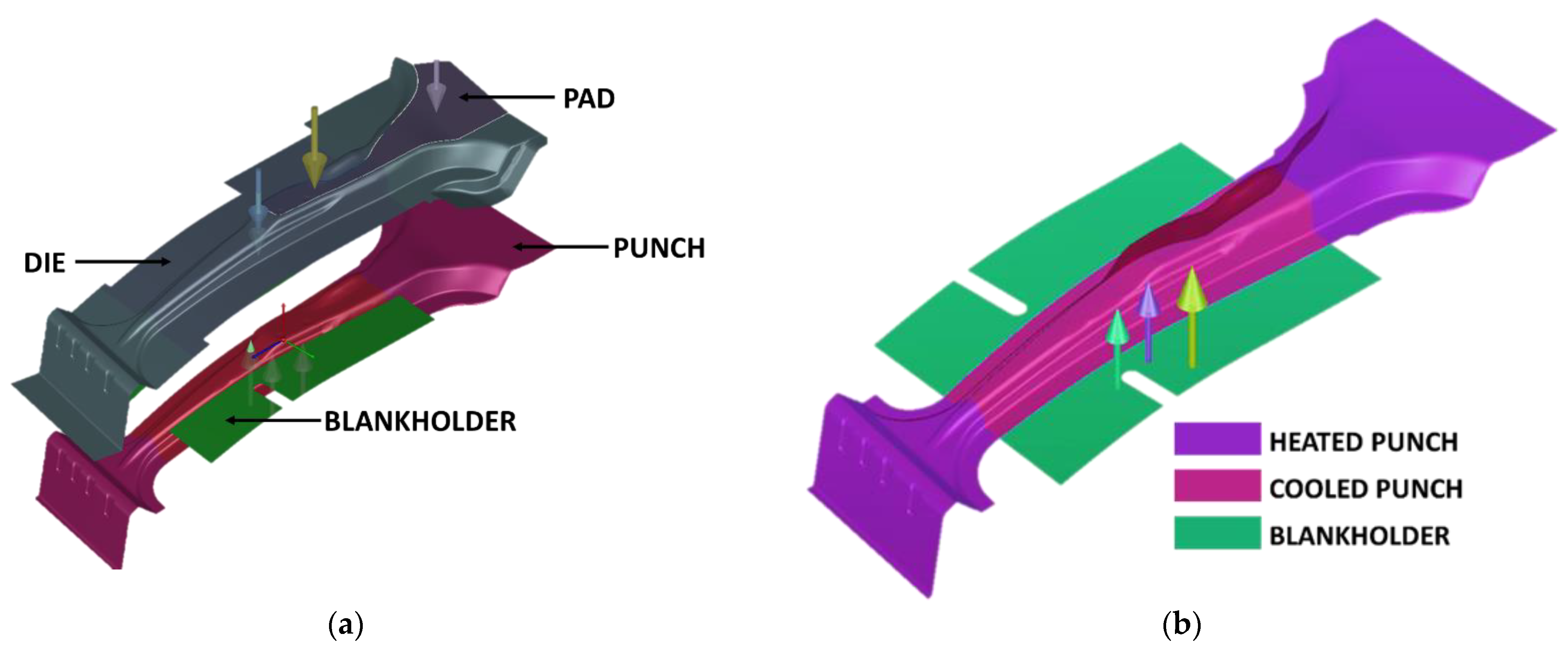

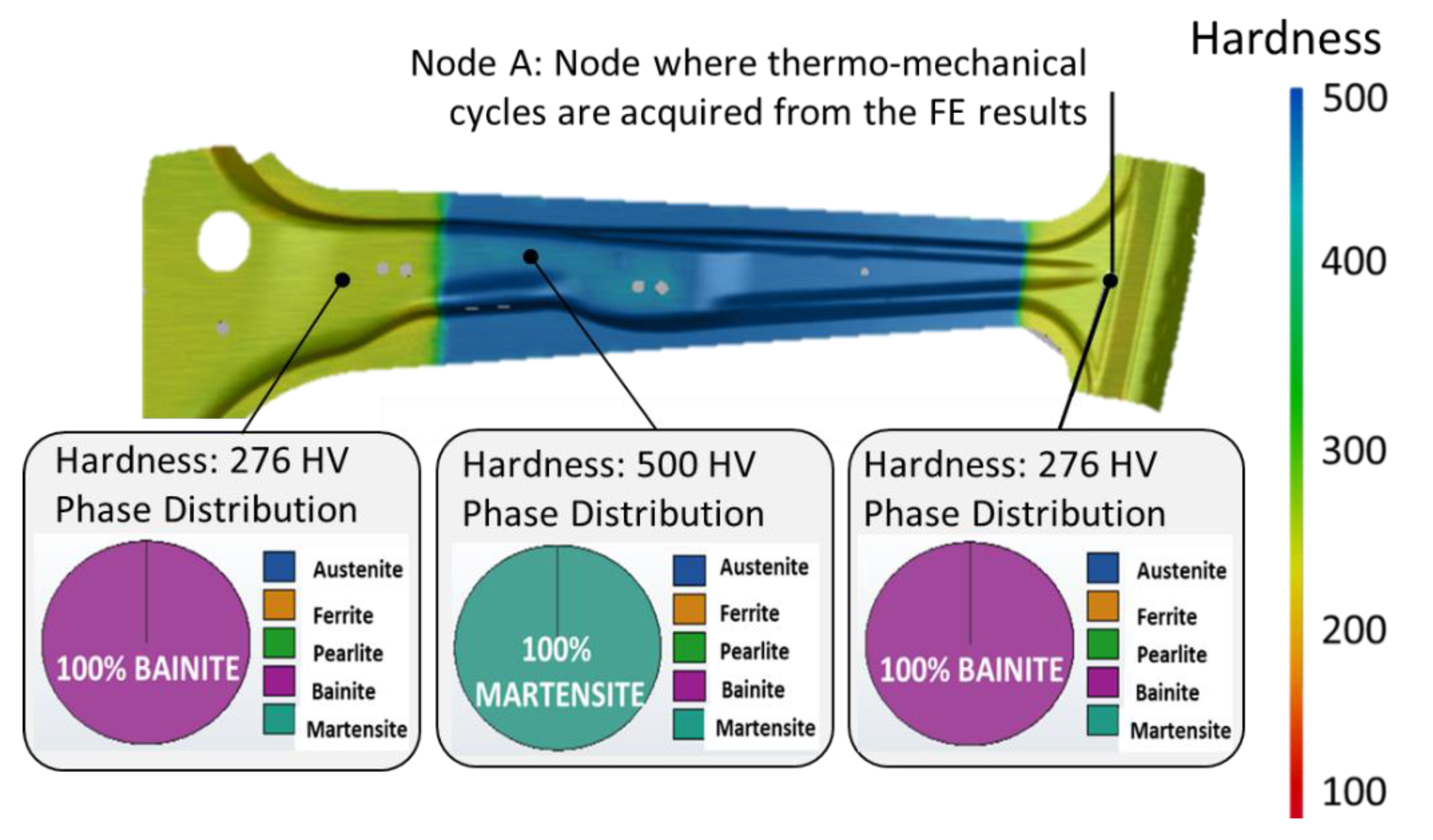

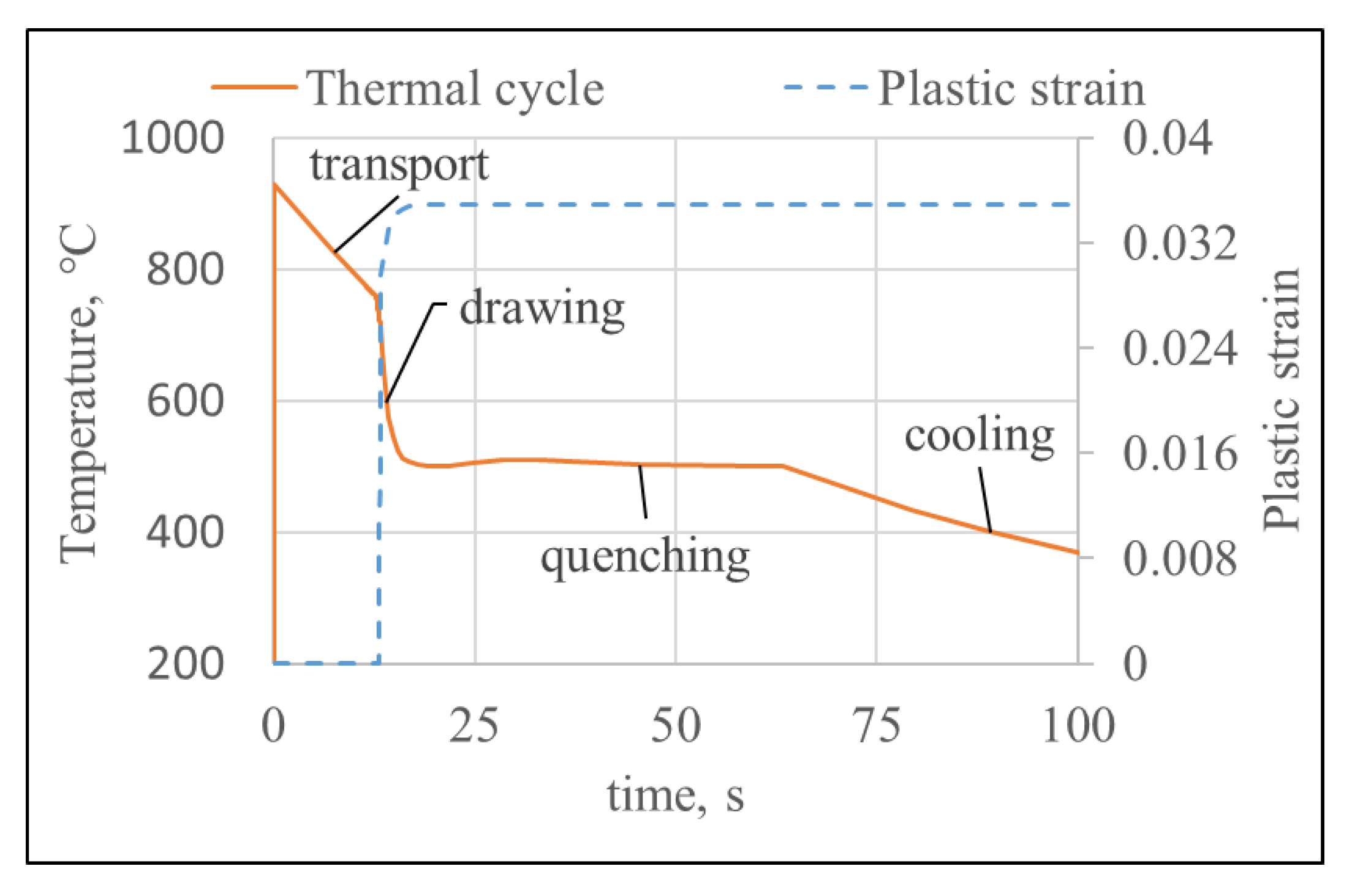

- Definition of thermomechanical cycles through numerical simulation. Using the commercial software AutoForm R8, a FE model has been developed to simulate the TTT-press-hardening process of the B-Pillar. The model has been implemented using data from both USIBOR®1500 and USIBOR® 2000 steels. A simulation plan has been carried out for each steel by varying process parameters of the quenching phase (in particular, the quenching time and the temperature of the heated tools). Finally, a post-processing phase has been designed to obtain, from the simulation results, the thermomechanical cycles in a specific area of the B-Pillar.

- iii.

- Post-forming characterization. Thermomechanical cycles have been physically simulated on USIBOR®2000 and USIBOR®1500 steel specimens. These specimens have been then analyzed through hardness tests. Finally, the process conditions with minimum hardness have been investigated performing tensile tests, while metallographic observations have been carried out to verify the results obtained.

3. Results and Discussion

3.1. Material Model Defonition for USIBOR®2000

3.2. Numerical Simulation of the Press-Hardening Process with TTT Approach

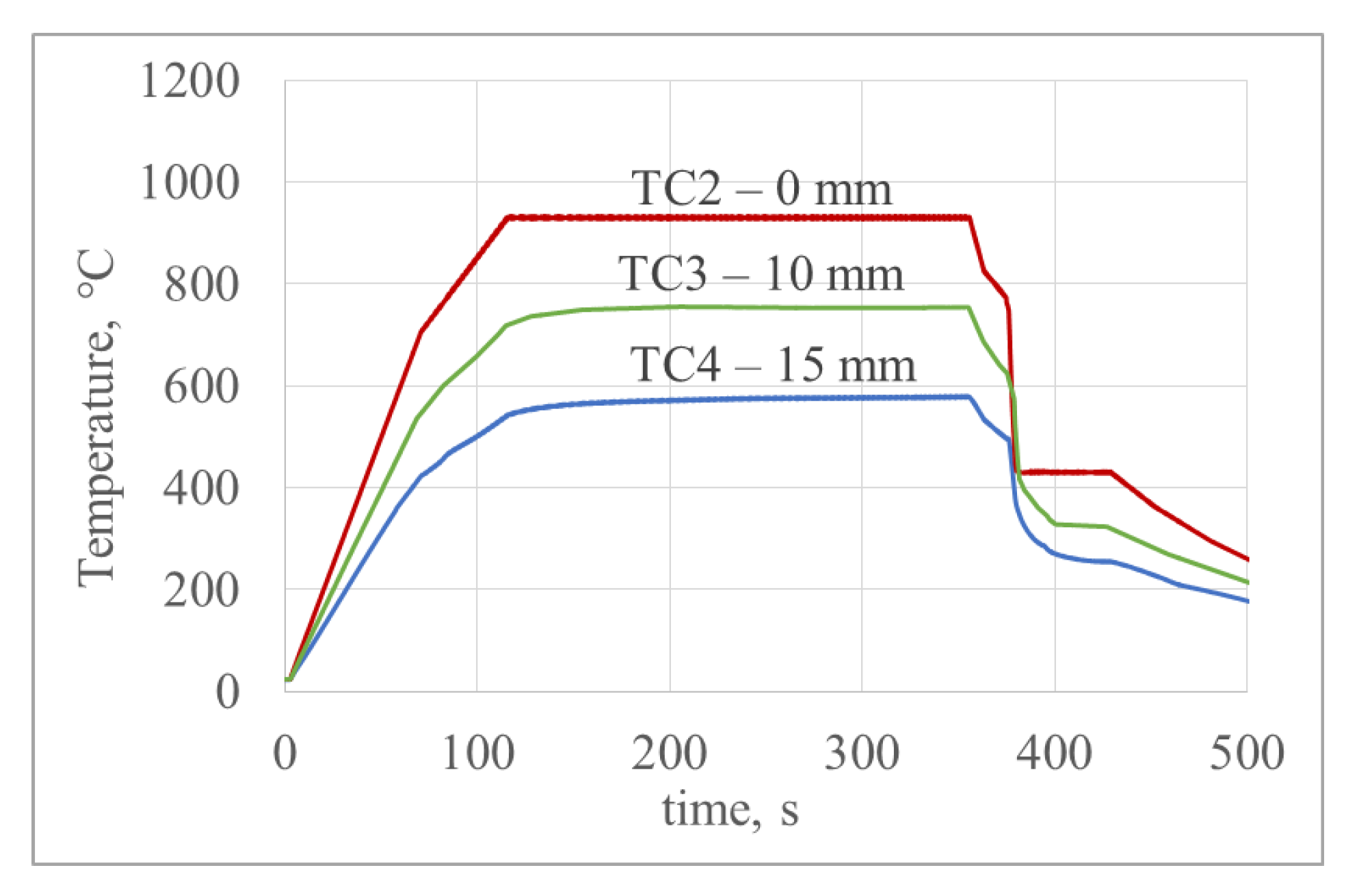

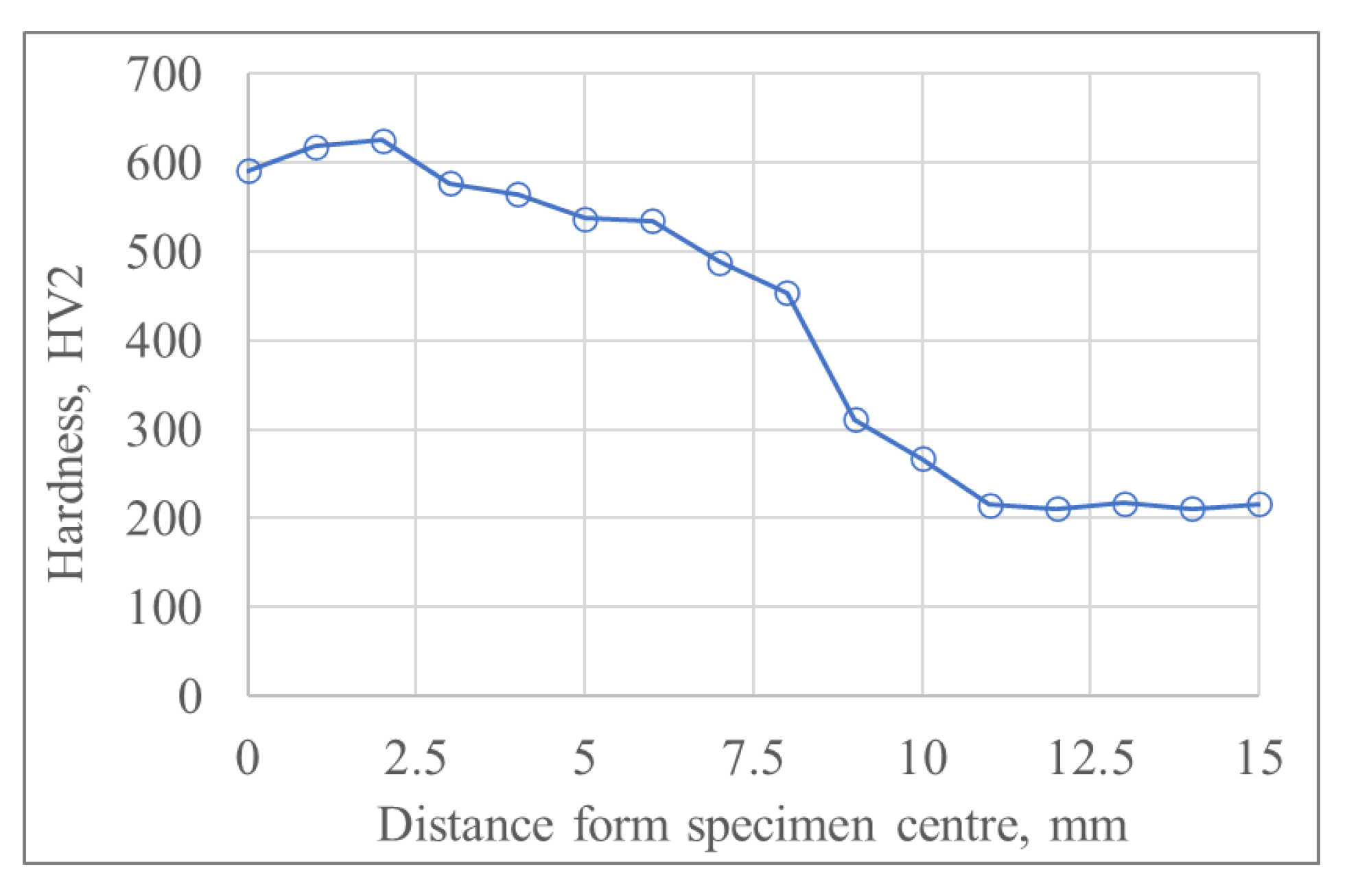

3.3. Physical Simulation of Thermo-Mechanical Press-Hardening Cycles

4. Conclusions

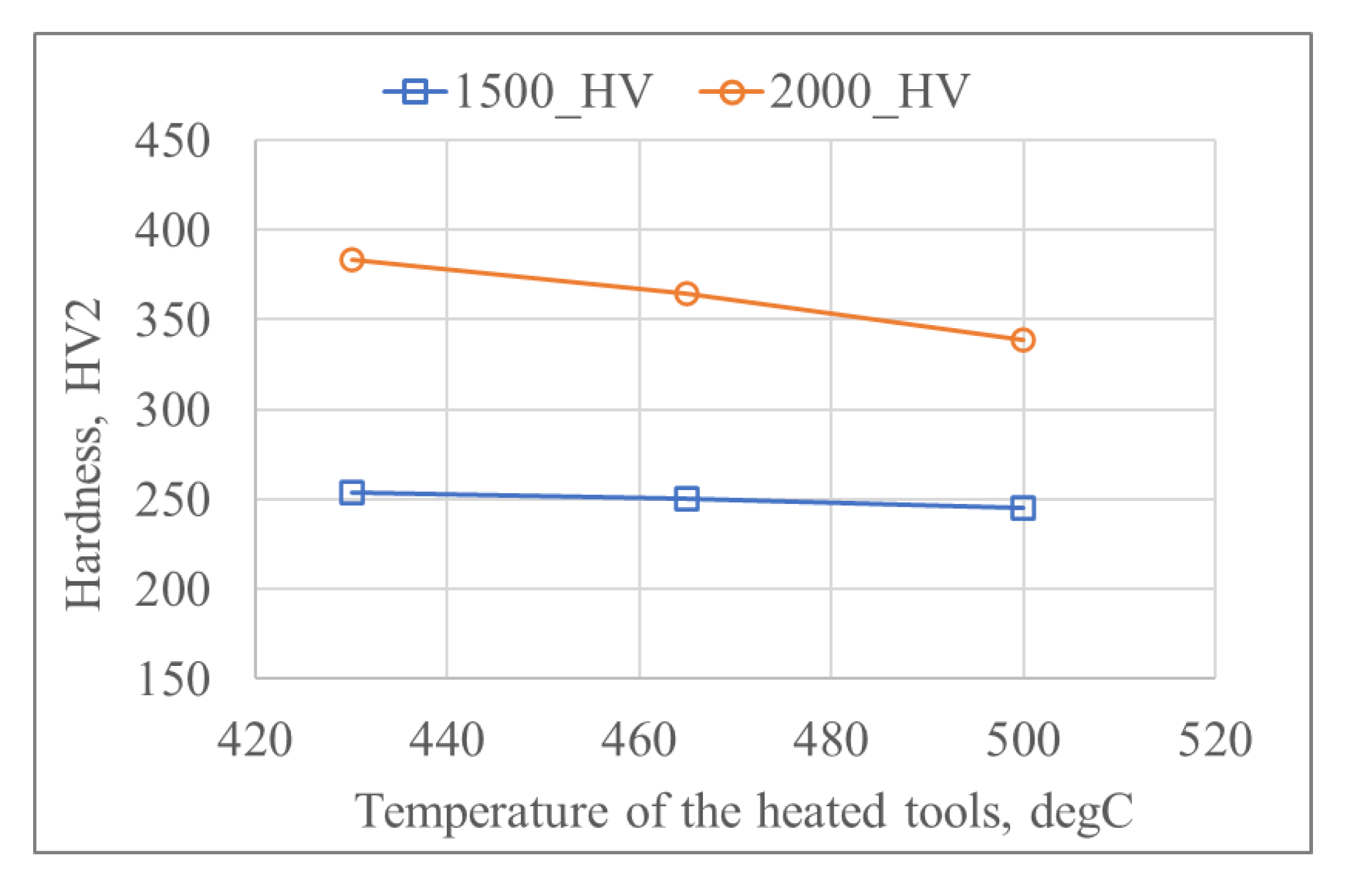

- For each temperature of the heated tools, increasing the quenching time the hardness reduces until it reaches a constant value. Considering steel hardness as representative of its microstructure, it can be stated that a near-complete bainitic transformation is achieved when hardness reaches a constant value. For the USIBOR®1500 steel, the constant hardness value is obtained for quenching times of 20 s when the temperature of heated tools is 430 °C, while when the quenching tool temperature is of 465 °C or 500 °C, the constant hardness value is reached earlier, even for quenching times of 5 s. The reduction in quenching time at higher temperature of the heated tools is justified by the higher part temperature at the end of quenching phase, contributing to the predominant bainitic transformation of residual austenite during the in air-cooling of the quenched part, before reaching the martensite start temperature. On the other hand, for the USIBOR®2000 steel, the constant hardness value is measured for quenching time of 150 s, independently from the temperature of heated tools investigated. The higher quenching time for the near-complete bainitic transformation of USIBOR®2000 steel is justified by its greater carbon content and then its greater hardenability.

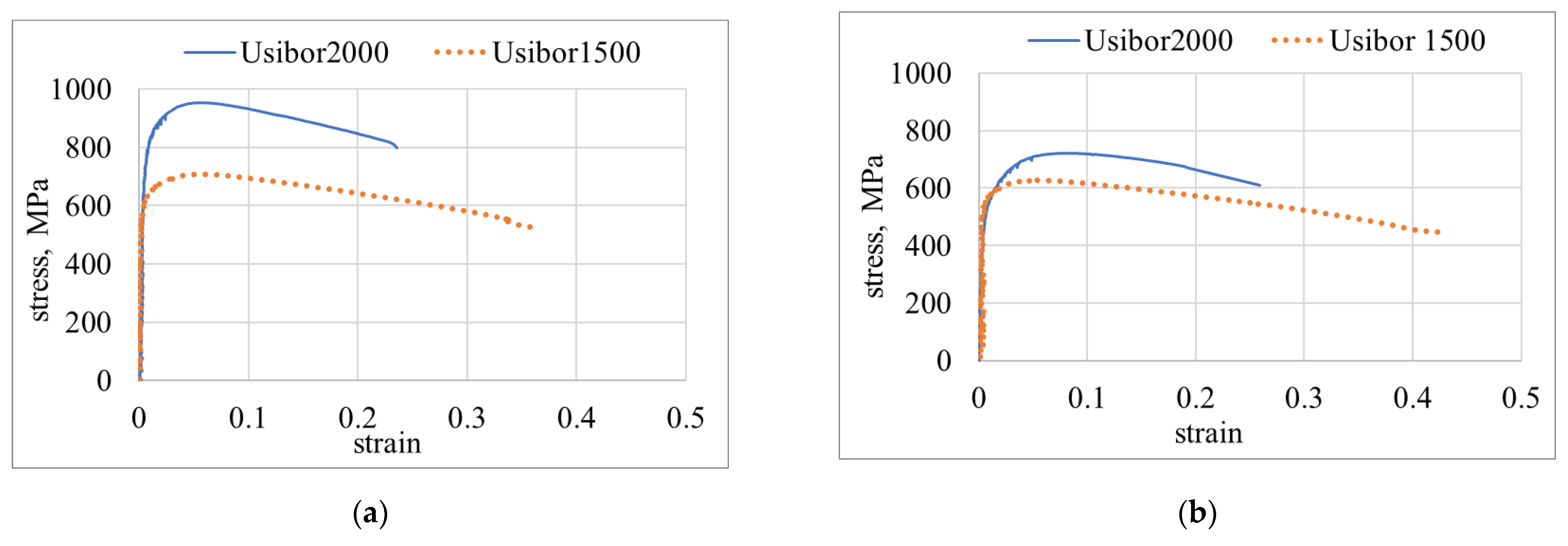

- In correspondence of the greater softening, the hardness of USIBOR®2000 steel is higher than that of USIBOR®1500 steel, but in terms of softening of the ductile zone of the B-Pilar with respect the strength zone, results are comparable (50% for the USIBOR®1500 steel, while in the range 55–60% for the USIBOR®2000 steel). The higher mechanical strength of USIBOR®2000, due to its greater carbon percentage, has been confirmed by tensile tests. The same tests highlighted a sensible elongation increase in the ductile zone with respect to the strength zone. Tensile tests on USIBOR®1500 shows elongations that are greater than 30% and 40% by varying the temperature of the heated tool from 430 °C to 500 °C, while USIBOR®2000 steel shows a more contained increase in elongation, but always greater than 20%.

- By comparing quenching time in correspondence of the minimum constant hardness value, USIBOR®1500 steel shows values in the range of 5–20 s, by varying the temperature of the heated tools from 500 °C to 430 °C. These results are very attractive for the industrial manufacturing of parts in USIBOR®1500 steel using a press-hardening process with a TTT approach. Due to the higher hardenability of USIBOR®2000 steel, quenching time observed are excessive (about 150 s for each temperature of the heating tools analyzed).

- Physical simulation of USIBOR®2000 steel specimens showed that softening of P-Pillar areas with short quenching times, could be obtained by differentiating the blank heating temperature (following a TBH approach). Assuming a heating phase up to 750 °C, a tool temperature of 80 °C and a quenching time equal to 20 s, the experimental results show a ductile zone of about 250 HV and an elongation of about 20%.

- Finally, physical simulation combined with numerical simulation proved to be a valid tool for designing the press-hardening process. The proposed approach allows us to reproduce in a laboratory and in small samples the same thermo-mechanical cycles that are realized on the industrial production line in specific zones of the part. The subsequent tensile and hardness tests on the samples aim to predict the mechanical properties of the post-forming component. In this way, there is a saving in terms of costs and waste.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Huang, G.; Tihay, K.; Sriram, S.; Weber, B.; Dietsch, P.; Cornette, D. Fracture characterization of AHSS using two different experimental methods. IOP Conf. Ser. Mater. Sci. Eng. 2018, 418, 012080. [Google Scholar] [CrossRef]

- Valentini, R.; Tedesco, M.M.; Corsinovi, S.; Bacchi, L.; Villa, M. Investigation of mechanical tests for hydrogen embrittlement in automotive PHS steels. Metals 2019, 9, 934. [Google Scholar] [CrossRef]

- Taylor, T.; Fourlaris, G.; Evans, P.; Bright, G. New generation ultrahigh strength boron steel for automotive hot stamping technologies. Mater. Sci. Technol. 2013, 30, 818–826. [Google Scholar] [CrossRef]

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Liu, S.; Long, M.; Zhang, S.; Zhao, Y.; Zhao, J.; Feng, Y.; Chen, D.; Ma, M. MaM Study on the prediction of tensile strength and phase transition for ultra-high strength hot stamping steel. J. Mater. Res. Technol. 2020, 9, 14244–14253. [Google Scholar] [CrossRef]

- Taylor, T.; McCulloch, J. Effect of Part/Die Boundary Conditions on Microstructural Evolution during Hot Stamping 2000 MPa Class Boron Steel. Steel Res. Int. 2018, 89, 1700495. [Google Scholar] [CrossRef]

- Merklein, M.; Wieland, M.; Lechner, M.; Bruschi, S.; Ghiotti, A. Hot stamping of boron steel sheets with tailored properties: A review. J. Mater. Process. Technol. 2016, 228, 11–24. [Google Scholar] [CrossRef]

- Georgiadis, G.; Tekkaya, A.; Weigert, P.; Weiher, J.; Kurz, H. Investigations on the Manufacturability of Thin Press Hardened Steel Components. Procedia CIRP 2014, 18, 74–79. [Google Scholar] [CrossRef][Green Version]

- Lei, C.; Xing, Z.; Xu, W.; Hong, Z.; Shan, D. Hot stamping of patchwork blanks: Modelling and experimental investigation. Int. J. Adv. Manuf. Technol. 2017, 92, 2609–2617. [Google Scholar] [CrossRef]

- Boeke, J.; Krogmeier, J.; Reinhold, P. Continuous Furnace Used in the Production of Vehicle Components, eg B-Columns, Comprises Two Zones Lying Opposite Each Other and Separated from Each Other by a Thermal Insulating Separating Wall. Germany Patent DE10256621B3, 12 March 2002. [Google Scholar]

- Zhou, J.; Wang, B.-Y.; Huang, M.-D.; Cui, D. Effect of hot stamping parameters on the mechanical properties and microstructure of cold-rolled 22MnB5 steel strips. Int. J. Miner. Met. Mater. 2014, 21, 544–555. [Google Scholar] [CrossRef]

- Palmieri, M.E.; Lorusso, V.D.; Tricarico, L. Laser-induced softening analysis of a hardened aluminum alloy by physical simulation. Int. J. Adv. Manuf. Technol. 2020, 111, 1503–1515. [Google Scholar] [CrossRef]

- AutoForm R8 Software Manual, Release R8; AutoForm Engineering GmbH: Freienbach, Switzerland, 7 December 2018.

- Javaheri, E.; Lubritz, J.; Graf, B.; Rethmeier, M. Mechanical Properties Characterization of Welded Automotive Steels. Metals 2019, 10, 1. [Google Scholar] [CrossRef]

- Zhang, Z.; Hauge, M.; Thaulow, C.; Ødegård, J. A notched cross weld tensile testing method for determining true stress–strain curves for weldments. Eng. Fract. Mech. 2002, 69, 353–366. [Google Scholar] [CrossRef]

- Naderi, M.; Durrenberger, L.; Molinari, A.; Bleck, W. Constitutive relationships for 22MnB5 boron steel deformed isothermally at high temperatures. Mater. Sci. Eng. A 2008, 478, 130–139. [Google Scholar] [CrossRef]

- Xu, Y.; Ji, Q.; Yang, G.; Bao, S.; Zhao, G.; Miao, X.; Mao, X. Effect of Cooling Path on Microstructures and Hardness of Hot-Stamped Steel. Metals 2020, 10, 1692. [Google Scholar] [CrossRef]

- Naderi, M.; Bleck, W. Hot Stamping of Ultra High Strength Steels; Lehrstuhl und Institut für Eisenhüttenkunde: Aachen, Germany, 2008. [Google Scholar]

| Material | C | Mn | Si | B | Fe |

|---|---|---|---|---|---|

| USIBOR®2000 | 0.36 | 0.80 | 0.80 | 0.005 | balanced |

| USIBOR®1500 | 0.25 | 1.4 | 0.4 | 0.005 | balanced |

| Material | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation at Break A50 [2] (%) |

|---|---|---|---|

| USIBOR®2000 | ≥1400 | ≥1800 | 6 |

| USIBOR®1500 | ≥1050 | ≥1400 | 7 |

| Process Parameters | Values |

|---|---|

| Friction coefficient | 0.4 |

| Transport time (s) | 7.5 |

| Forming velocity (mm/s) | 200 |

| Temperature of blank (°C) | 930 |

| Quenching force (kN) | 1.2 × 104 |

| Properties | Values |

|---|---|

| 4.37 | |

| 32 |

| Properties | Values for AUSTENITE | Values for FERRITE | Values for BAINITE | Values for MARTENSITE |

|---|---|---|---|---|

| Expansion coefficient (1/K) | 2.20 × 10−5 | 1.5 × 10−5 | 1.5 × 10−5 | 1.1 × 10−5 |

| Start temperature (°C) | 850 | 780 | 550 | 400 |

| End temperature (°C) | 950 | 550 | 400 | 200 |

| Transformation strain | −0.008 | 0.008 | 0.008 | 0.008 |

| - | 539 | 563 | 563 | |

| Trans plastic coefficient | - | 0.00015 | 0.0001 | 9 × 10−5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palmieri, M.E.; Galetta, F.R.; Tricarico, L. Study of Tailored Hot Stamping Process on Advanced High-Strength Steels. J. Manuf. Mater. Process. 2022, 6, 11. https://doi.org/10.3390/jmmp6010011

Palmieri ME, Galetta FR, Tricarico L. Study of Tailored Hot Stamping Process on Advanced High-Strength Steels. Journal of Manufacturing and Materials Processing. 2022; 6(1):11. https://doi.org/10.3390/jmmp6010011

Chicago/Turabian StylePalmieri, Maria Emanuela, Francesco Rocco Galetta, and Luigi Tricarico. 2022. "Study of Tailored Hot Stamping Process on Advanced High-Strength Steels" Journal of Manufacturing and Materials Processing 6, no. 1: 11. https://doi.org/10.3390/jmmp6010011

APA StylePalmieri, M. E., Galetta, F. R., & Tricarico, L. (2022). Study of Tailored Hot Stamping Process on Advanced High-Strength Steels. Journal of Manufacturing and Materials Processing, 6(1), 11. https://doi.org/10.3390/jmmp6010011