A Study of the Convective Cooling of Large Industrial Billets

Abstract

:1. Introduction

2. Mathematical Theory

2.1. Fundamental Heat Transfer Mechanisms

2.2. Derivation of Dimensionless Parameters

2.3. Natural Convection

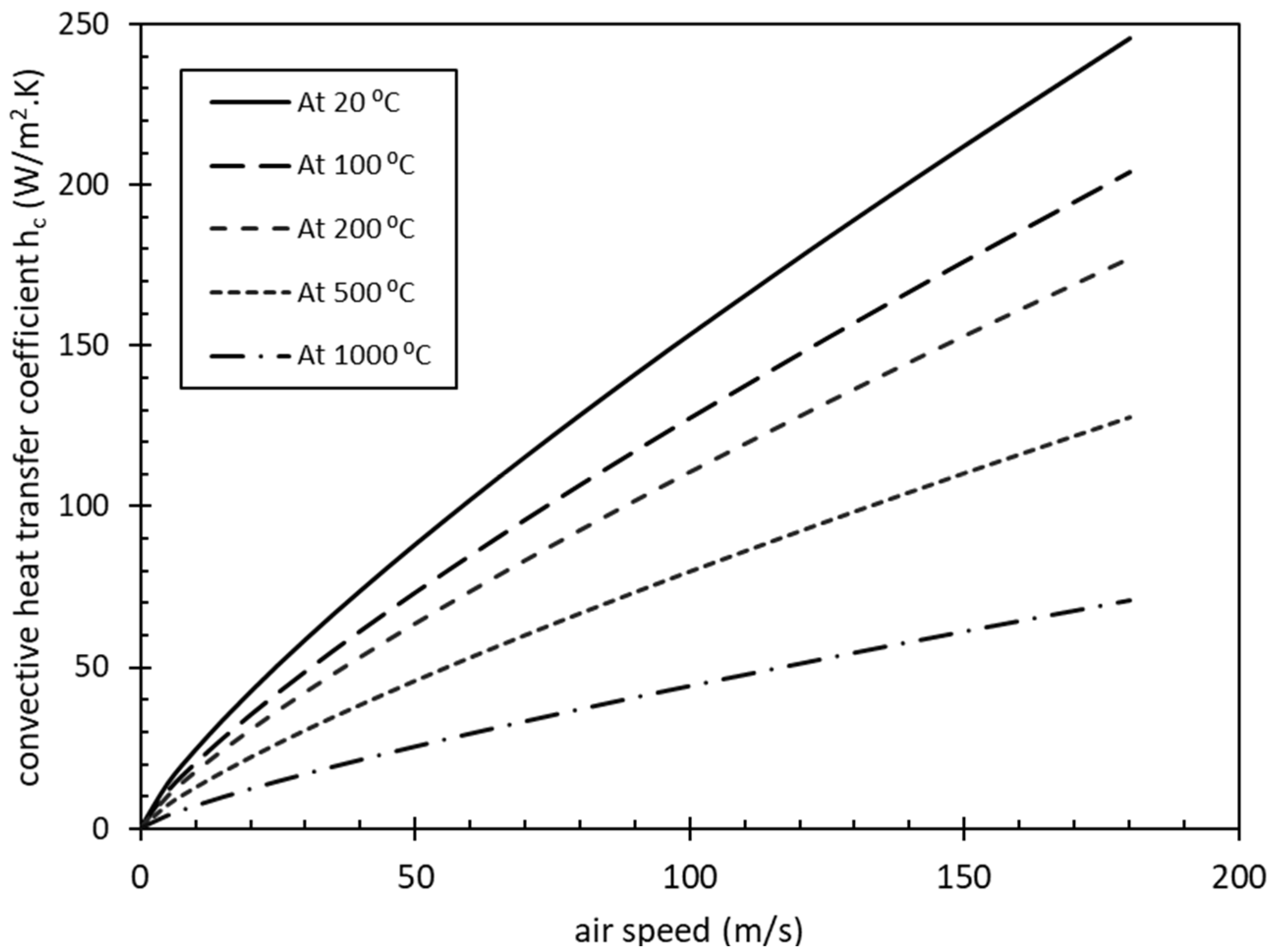

2.4. Forced Convection

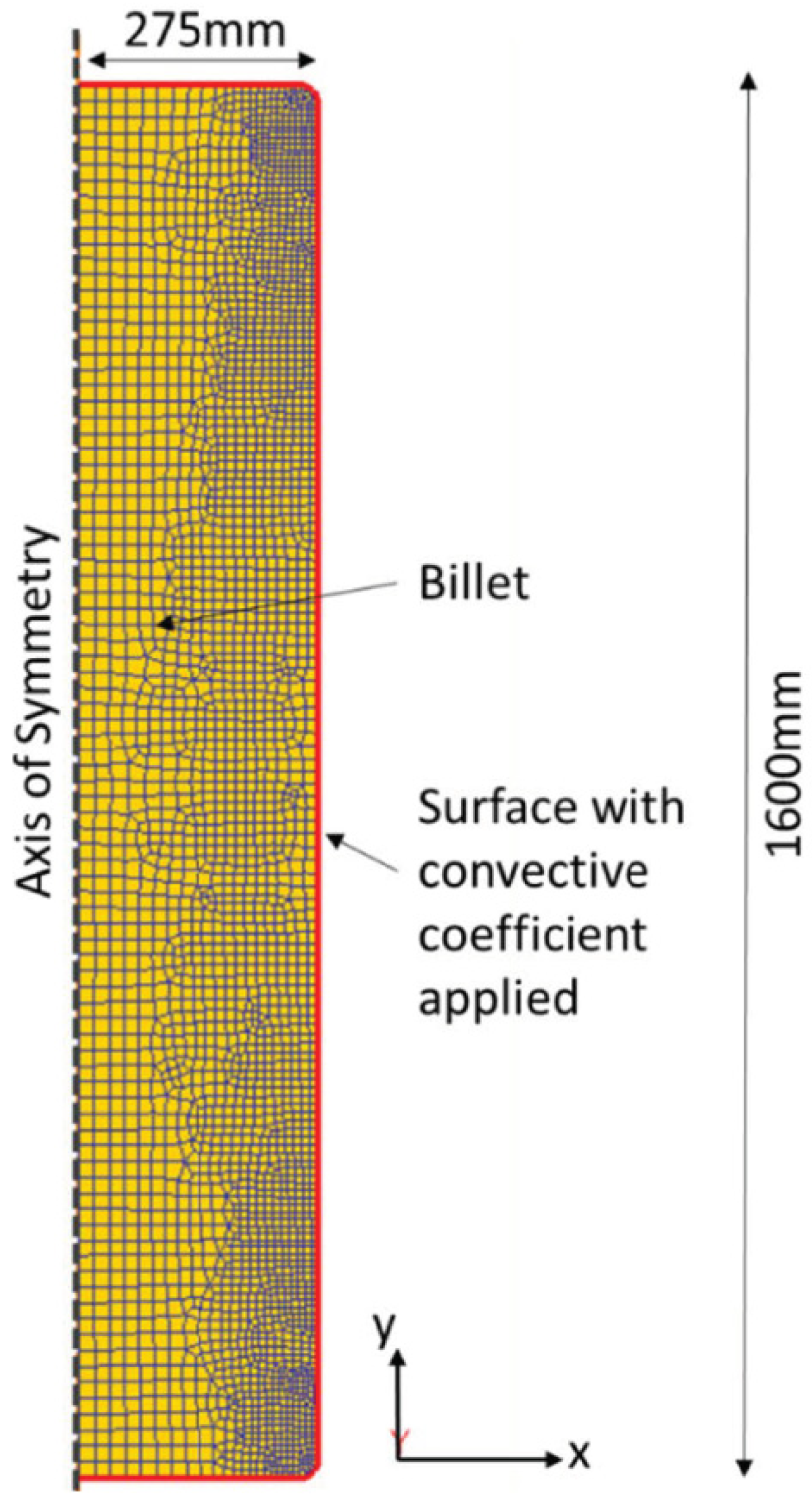

3. FE Modelling Methodology

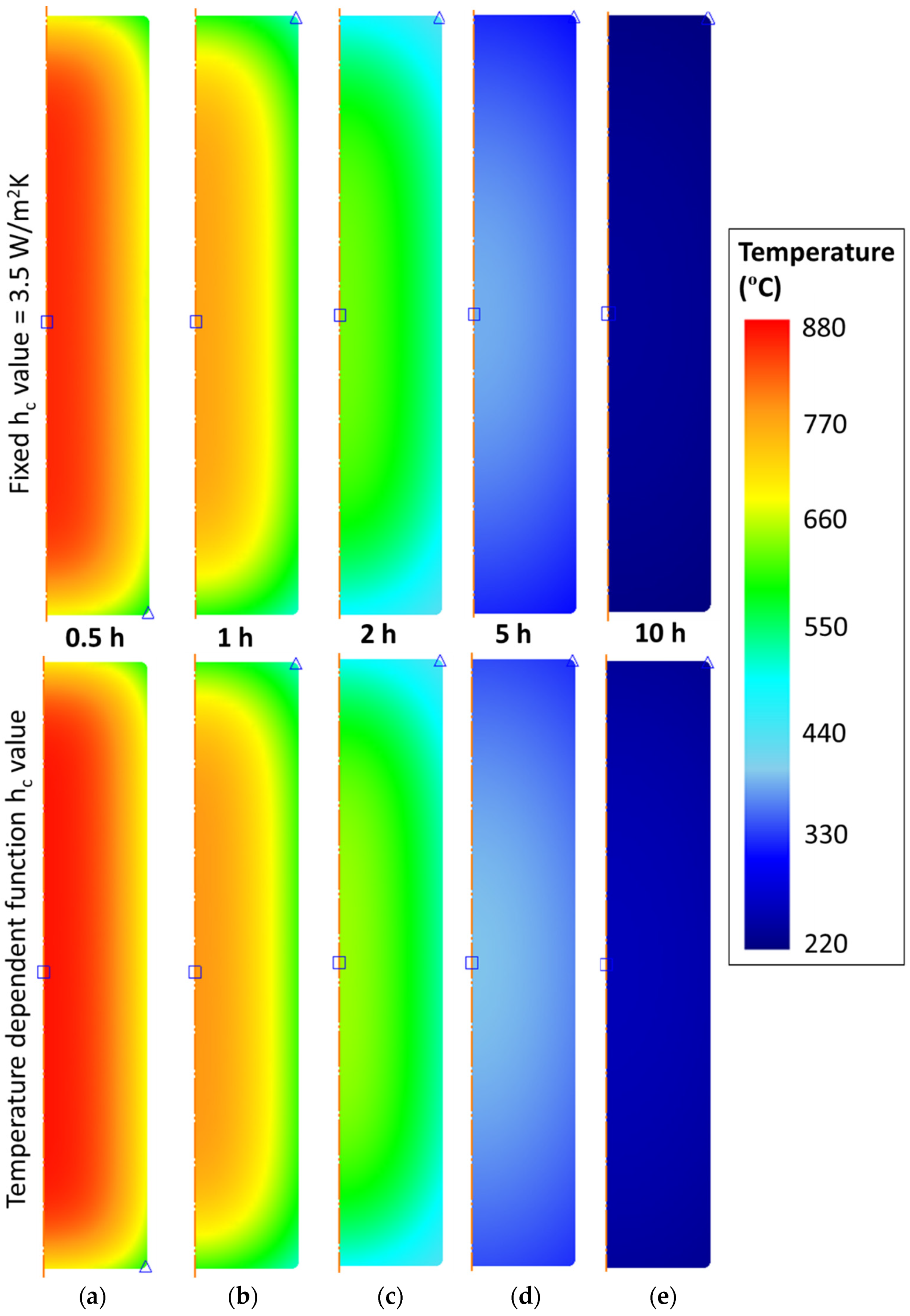

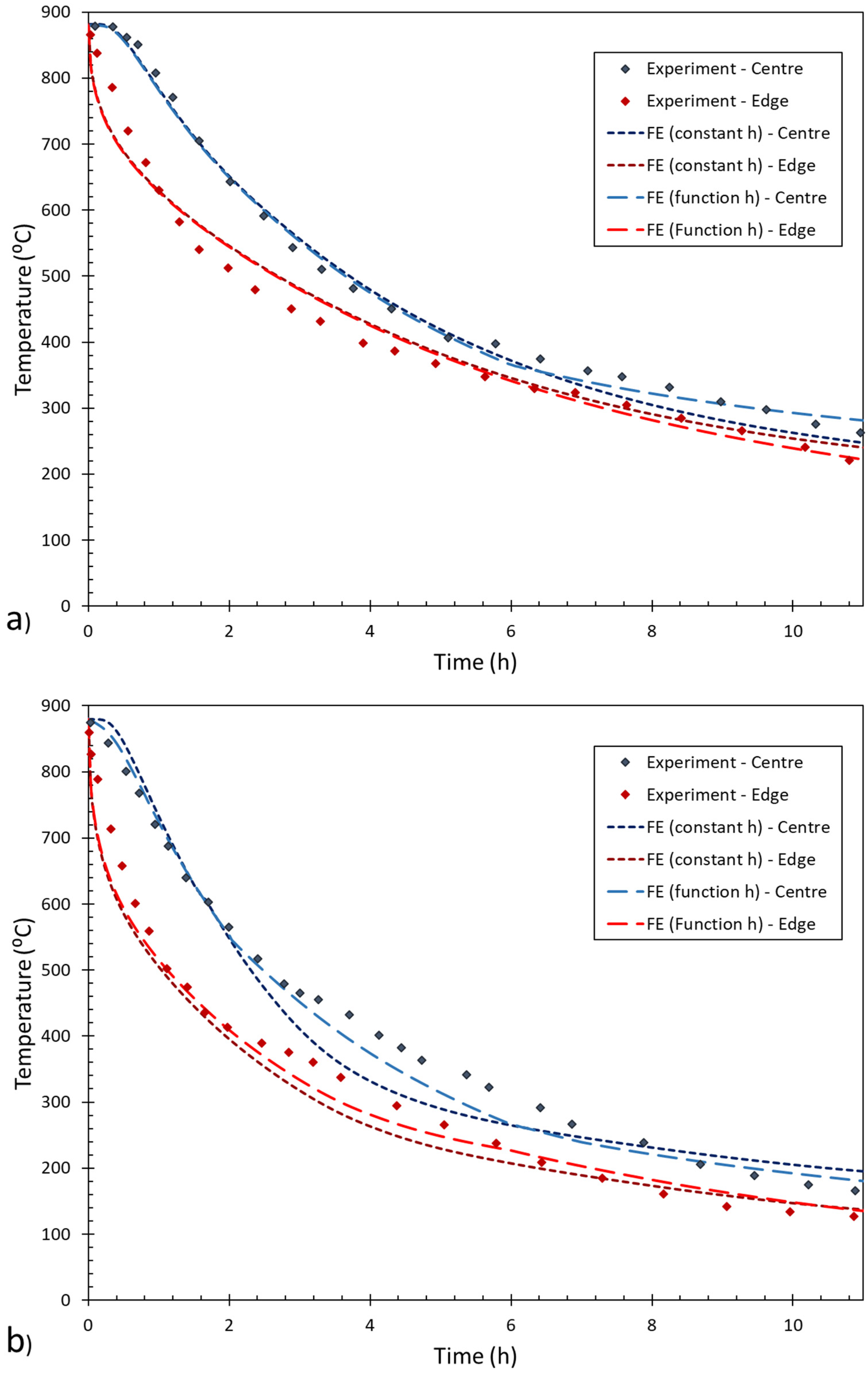

4. Results

5. Discussion

6. Conclusions

- A fundamental calculation of natural convective heat transfer using known empirical relationships which are valid for certain conditions produces a room temperature hc value of approximately 3 W·m−2·K−1 at the bottom-end of the usual quoted range of hc values for air. This ranged up to 9 W·m−2·K−1 at elevated temperatures and plateaued at temperatures above 700 °C due to the effects of increasing kinematic viscosity cancelling with the effects of increasing conductivity.

- The FE analysis for the natural convective cooling shows that the cooling rate at the edge for the temperature dependent hc term matches the experiment marginally better than for fixed cooling, although both models matched one another for the first 7 h. For the centre location during natural convective cooling, the FE prediction matched to experimental measurements was a little more wayward during the first 4 h.

- For the forced convective cooling case, varying the hc term in the FE models produced a more noticeable effect, with the edge node cooling curve matching the result from FE with temperature dependent hc function reasonably well. Similarly, for the centre node, results for the temperature dependent hc term were an improved fit to the experiment compared to fixed hc.

- The validated thermal model was extended to include metallurgical effects. Grain size kinetics were predicted to show that there were negligible effects on the arising grain size for different convective term models. Even a comparison of natural versus forced convective cooling showed only very minor grain size variation. The dominant grain size pattern is for the centre to have coarser grains due to slower cooling, and the edge region grains are smaller due to more rapid cooling. This is present in all grain size FE predictions.

- Thus, the convective heat transfer term is concluded to be only of minor importance to metallurgical features, with a small window of opportunity at the start of the cooling phase, during which the cooling rate dominates the arising grain size and mechanical properties of the material.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Groche, P.; Fittshe, D.; Tekkaya, E.A.; Allwood, J.M.; Hirt, G.; Neugebauer, R. Incremental Bulk Forming. Ann. CIRP 2007, 55, 636. [Google Scholar]

- Liu, Q.; Cho, J.-W.; Pereloma, E. Editorial: Advances in Steel Manufacturing and Processing. Front. Mater. 2021, 8, 201. [Google Scholar] [CrossRef]

- Lucacci, G. Materials for Ultra-Supercritical and Advanced Ultra-Supercritical Power Plants—Ch. 7: Steels and Alloys for Turbine Blades in Ultra-Supercritical Power Plants; Woodhead Publishing: Cambridge, UK, 2017. [Google Scholar]

- World Steel Association—Press Release. 2021. Available online: https://www.worldsteel.org/media-centre/press-releases/2021/Global-crude-steel-output-decreases-by-0.9--in-2020.html (accessed on 12 August 2021).

- Black, J.T.; Kohser, R.A. DeGarmo’s Materials and Processes in Manufacturing, 12th ed.; Wiley & Sons: New York, NY, USA, 2017. [Google Scholar]

- Soleymani, V.; Eghbali, B. Grain Refinement in a Low Carbon Steel through Multidirectional Forging. J. Iron Steel Res. Int. 2012, 19, 74–78. [Google Scholar] [CrossRef]

- Rudnev, V.; Loveless, D.; Cook, R.L. Handbook of Induction Heating; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Chakravarty, K.; Kumar, S. Increase in energy efficiency of a steel billet reheating furnace by heat balance study and process improvement. Energy Rep. 2020, 6, 343–349. [Google Scholar] [CrossRef]

- Thakur, P.K.; Prakash, K.; Muralidharan, K.G.; Bahl, V.; Das, S. A review on: Efficient energy optimization in reheating furnaces, Int. J. Mech. Prod. Eng. 2015, 3, 18–24. [Google Scholar]

- Borisov, I.A.; Goland, L.F. Cooling large forgings in a water-air mixture. Met. Sci. Heat Treat. 1988, 10, 17–22. [Google Scholar] [CrossRef]

- Ma, H.; Silaen, A.; Zhou, C. Numerical Development of Heat Transfer Coefficient Correlation for Spray Cooling in Continuous Casting. Front. Mater. 2020, 7, 397. [Google Scholar] [CrossRef]

- Maisuradze, M.; Yudin, Y.V.; Ryzhkov, M.A. Investigation and Development of Spray Cooling Device for Heat Treatment of Large Steel Forgings. Mater. Perform. Charact. 2014, 3, 449–462. [Google Scholar] [CrossRef]

- Rasouli, D.; Asl, S.K.; Akbarzadeh, A.; Daneshi, G. Effect of cooling rate on the microstructure and mechanical properties of microalloyed forging steel. J. Mater. Process. Technol. 2008, 206, 92–98. [Google Scholar] [CrossRef]

- Pola, A.; Gelfi, M.; La Vecchia, G. Simulation and validation of spray quenching applied to heavy forgings. J. Mater. Process. Technol. 2013, 213, 2247–2253. [Google Scholar] [CrossRef]

- Lacarac, V.; Smith, D.; McMahon, C.; Tierney, M. Evaluation of non-uniform cooling effects for air-cooled forgings. J. Mater. Process. Technol. 2004, 152, 370–383. [Google Scholar] [CrossRef]

- Kosky, P.; Balmer, R.; Keat, W.; Wise, G. Exploring Engineering—An Introduction to Engineering and Design, 5th ed.; Academic Press: Cambridge, MA, USA. [CrossRef]

- Incropera, F.; Dewitt, D.; Bergmann, T.L.; Lavine, A.S. Principles of Heat and Mass Transfer, 7th ed.; Wiley & Sons: Hoboken, NJ, USA, 2013; ISBN 978-0-470-64615-1. [Google Scholar]

- Buckingham, E. On Physically Similar Systems; Illustrations of the Use of Dimensional Equations. Phys. Rev. 1914, 4, 345–376. [Google Scholar] [CrossRef]

- Brown, A.I.; Marco, S.M. Introduction to Heat Transfer, 3rd ed.; McGraw-Hill Book Company: New York, NY, USA, 1958. [Google Scholar]

- Eckert, E.R.G. Heat and Mass Transfer; McGraw-Hill Book Company: New York, NY, USA, 1959. [Google Scholar]

- Engineers Edge. Viscosity of Air, Dynamic and Kinematic; Engineers Edge LLC: Monroe, GA, USA, 2020; Available online: https://www.engineersedge.com/physics/viscosity_of_air_dynamic_and_kinematic_14483.htm (accessed on 12 August 2021).

- Kramarov, M.A.; Kolchin, G.G.; Lebedev, V.N.; Solntsev, Y.P. Resistance to fracture of steel 35KhN3MFA for large machine parts. Met. Sci. Heat Treat. 1976, 18, 18–20. [Google Scholar] [CrossRef]

- Semiatin, S.; Soper, J.; Sukonnik, I. Short-time beta grain growth kinetics for a conventional titanium alloy. Acta Mater. 1996, 44, 1979–1986. [Google Scholar] [CrossRef]

- Yue, C.; Zhang, L.; Liao, S.; Gao, H. Kinetic Analysis of the Austenite Grain Growth in GCr15 Steel. J. Mater. Eng. Perform. 2010, 19, 112–115. [Google Scholar] [CrossRef] [Green Version]

- Illescas, S.; Fernández, J.; Guilemany, J.M. Kinetic analysis of the austenitic grain growth in HSLA steel with a low carbon content. Mater. Lett. 2008, 62, 3478–3480. [Google Scholar] [CrossRef]

- Giumelli, A. Austenite Grain Growth Kinetics and the Grain Size Distribution. Master’s Thesis, University of British Columbia, Vancouver, BC, Canada, 1995. [Google Scholar]

- Fu, B.; Pei, C.; Pan, H.; Guo, Y.; Fu, L.; Shan, A. Hall-Petch relationship of interstitial-free steel with a wide grain size range processed by asymmetric rolling and subsequent annealing. Mater. Res. Express 2020, 7, 116516. [Google Scholar] [CrossRef]

| Type of Convection | Convective Heat Transfer Coefficient, h (W·m−2·K−1) | |

|---|---|---|

| Kosky et al. [16] | Incropera et al. [17] | |

| Air, natural (free convection) | 2.5 to 25 | 2 to 25 |

| Air, forced convection | 10 to 500 | 25 to 250 |

| Liquids, forced convection | 100 to 15,000 | 100 to 20,000 |

| Boiling water (inc. phase change) | 2500 to 25,000 | 2500 to 100,000 |

| Temperature (°C) | Thermal Conductivity, k (W·m−1·K−1) | Kinematic Viscosity (m2·s−1) | Prandtl (-) | Grashof (-) | Rayleigh (-) | Nusselt (-) | Convective Coefficient, h (W·m−2·K−1) |

|---|---|---|---|---|---|---|---|

| 25 | 0.026 | 1.64 × 10−5 | 0.709 | 1.17 × 109 | 8.27 × 108 | 115.84 | 3.01 |

| 30 | 0.026 | 1.68 × 10−5 | 0.707 | 1.67 × 109 | 1.18 × 109 | 129.17 | 3.36 |

| 40 | 0.027 | 1.70 × 10−5 | 0.706 | 2.71 × 109 | 1.92 × 109 | 150.13 | 4.05 |

| 50 | 0.027 | 1.80 × 10−5 | 0.705 | 3.39 × 109 | 2.39 × 109 | 160.78 | 4.34 |

| 100 | 0.031 | 2.30 × 10−5 | 0.701 | 5.04 × 109 | 3.53 × 109 | 181.54 | 5.63 |

| 200 | 0.038 | 3.40 × 10−5 | 0.699 | 5.02 × 109 | 3.51 × 109 | 181.07 | 6.88 |

| 300 | 0.044 | 4.70 × 10−5 | 0.702 | 4.05 × 109 | 2.84 × 109 | 169.61 | 7.46 |

| 400 | 0.05 | 6.20 × 10−5 | 0.706 | 3.14 × 109 | 2.22 × 109 | 157.14 | 7.86 |

| 500 | 0.055 | 7.80 × 10−5 | 0.71 | 2.50 × 109 | 1.77 × 109 | 146.74 | 8.07 |

| 700 | 0.066 | 1.10 × 10−4 | 0.728 | 1.78 × 109 | 1.29 × 109 | 133.46 | 8.80 |

| 1000 | 0.077 | 1.70 × 10−4 | 0.73 | 1.07 × 109 | 7.80 × 108 | 114.25 | 8.78 |

| Element | C | Ni | Cr | Mn | Mo | V | Cu | Si | S | P | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wt % | 0.36 | 2.96 | 1.37 | 0.41 | 0.36 | 0.15 | 0.1 | 0.33 | 0.015 | 0.013 | Bal. |

| Convective Cooling Method | Location in Billet | Grain Size (µm) | Yield Strength (MPa) |

|---|---|---|---|

| Natural convection | Centre | 17.8 | 526 |

| Edge | 8.2 | 585 | |

| Forced convection | Centre | 17.1 | 528 |

| Edge | 7.3 | 596 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turner, R. A Study of the Convective Cooling of Large Industrial Billets. J. Manuf. Mater. Process. 2021, 5, 137. https://doi.org/10.3390/jmmp5040137

Turner R. A Study of the Convective Cooling of Large Industrial Billets. Journal of Manufacturing and Materials Processing. 2021; 5(4):137. https://doi.org/10.3390/jmmp5040137

Chicago/Turabian StyleTurner, Richard. 2021. "A Study of the Convective Cooling of Large Industrial Billets" Journal of Manufacturing and Materials Processing 5, no. 4: 137. https://doi.org/10.3390/jmmp5040137

APA StyleTurner, R. (2021). A Study of the Convective Cooling of Large Industrial Billets. Journal of Manufacturing and Materials Processing, 5(4), 137. https://doi.org/10.3390/jmmp5040137