Thermomechanical Impact of the Single-Lip Deep Hole Drilling on the Surface Integrity on the Example of Steel Components

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tools

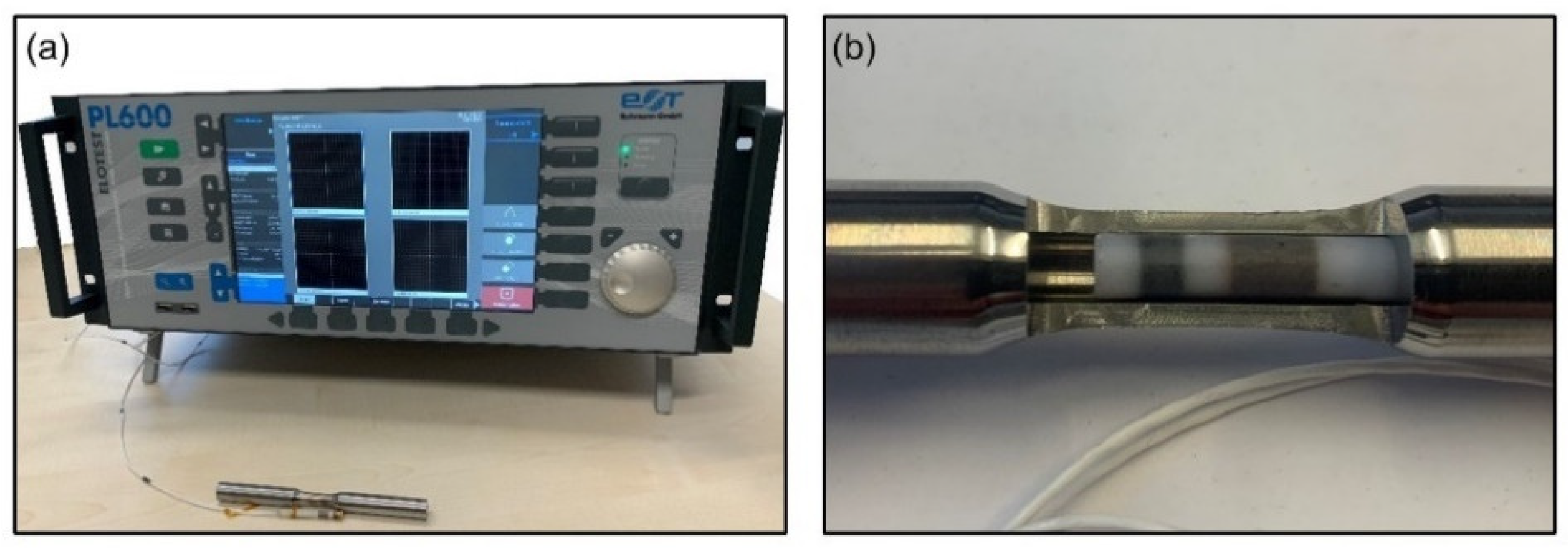

2.2. Mechanical and Thermal Load Measurement

2.3. Post Process Microstructure Analysis and Eddy-Current Measurement

3. Results and Discussion

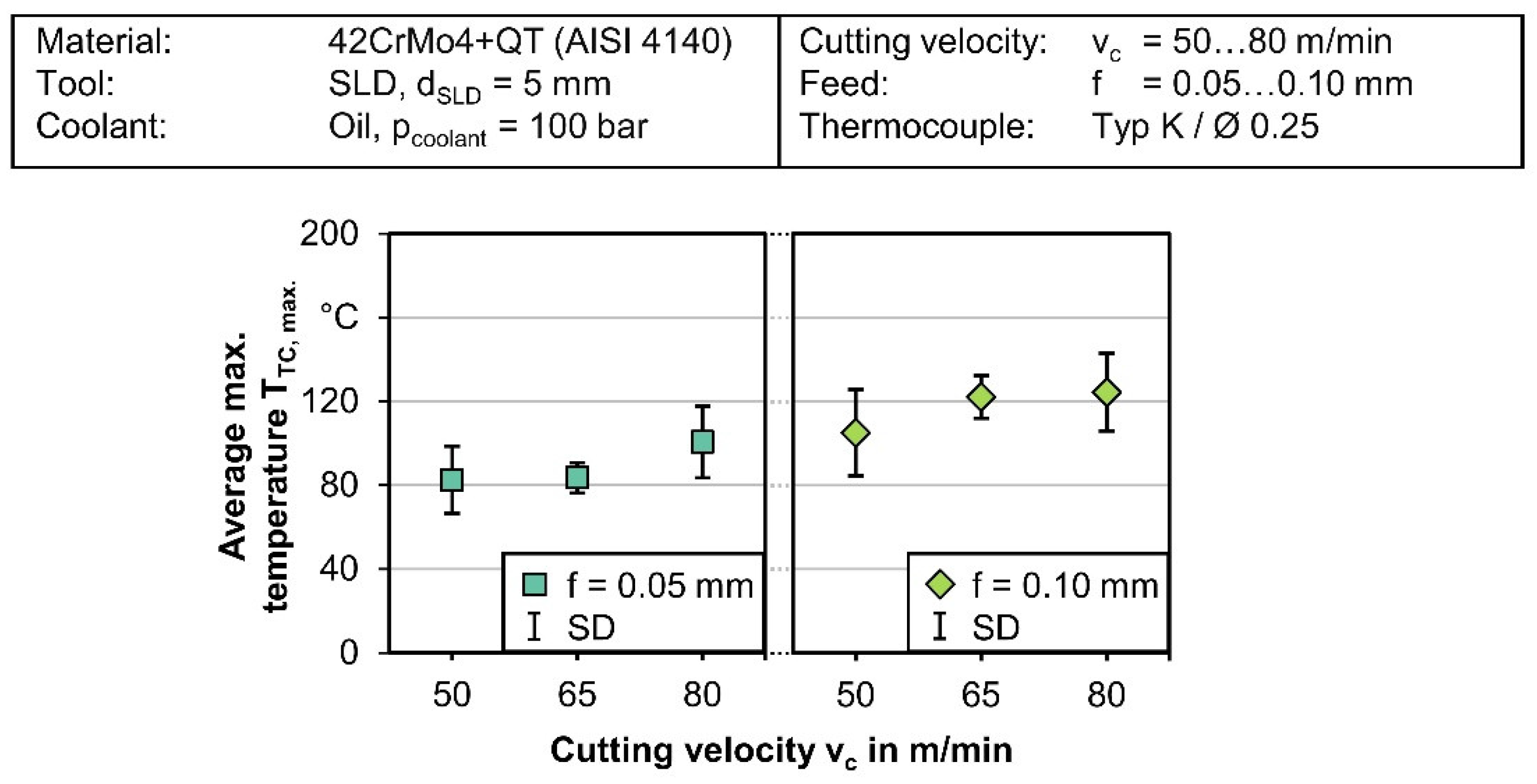

3.1. Thermoelectric In-Process Temperature Measurement

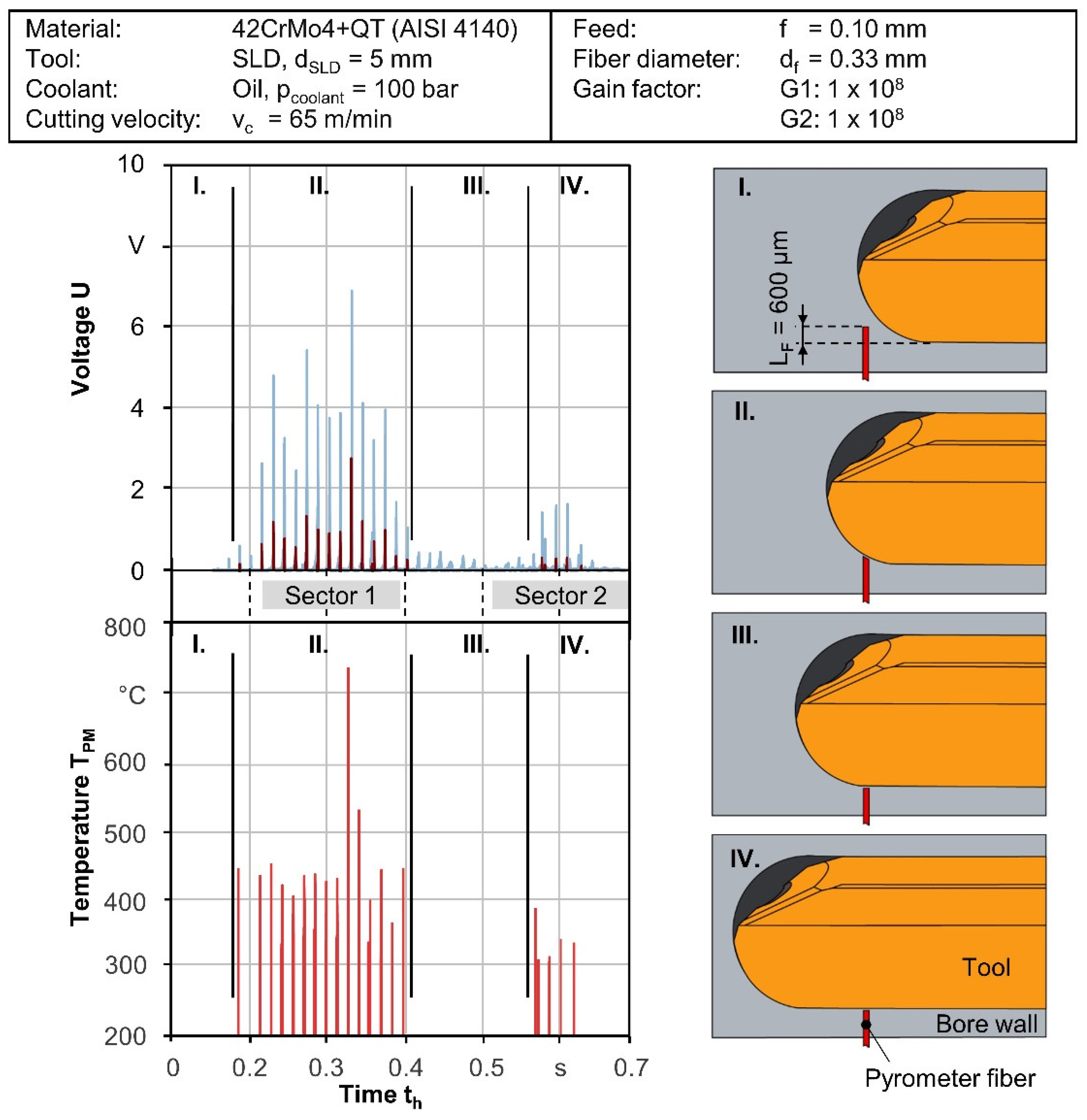

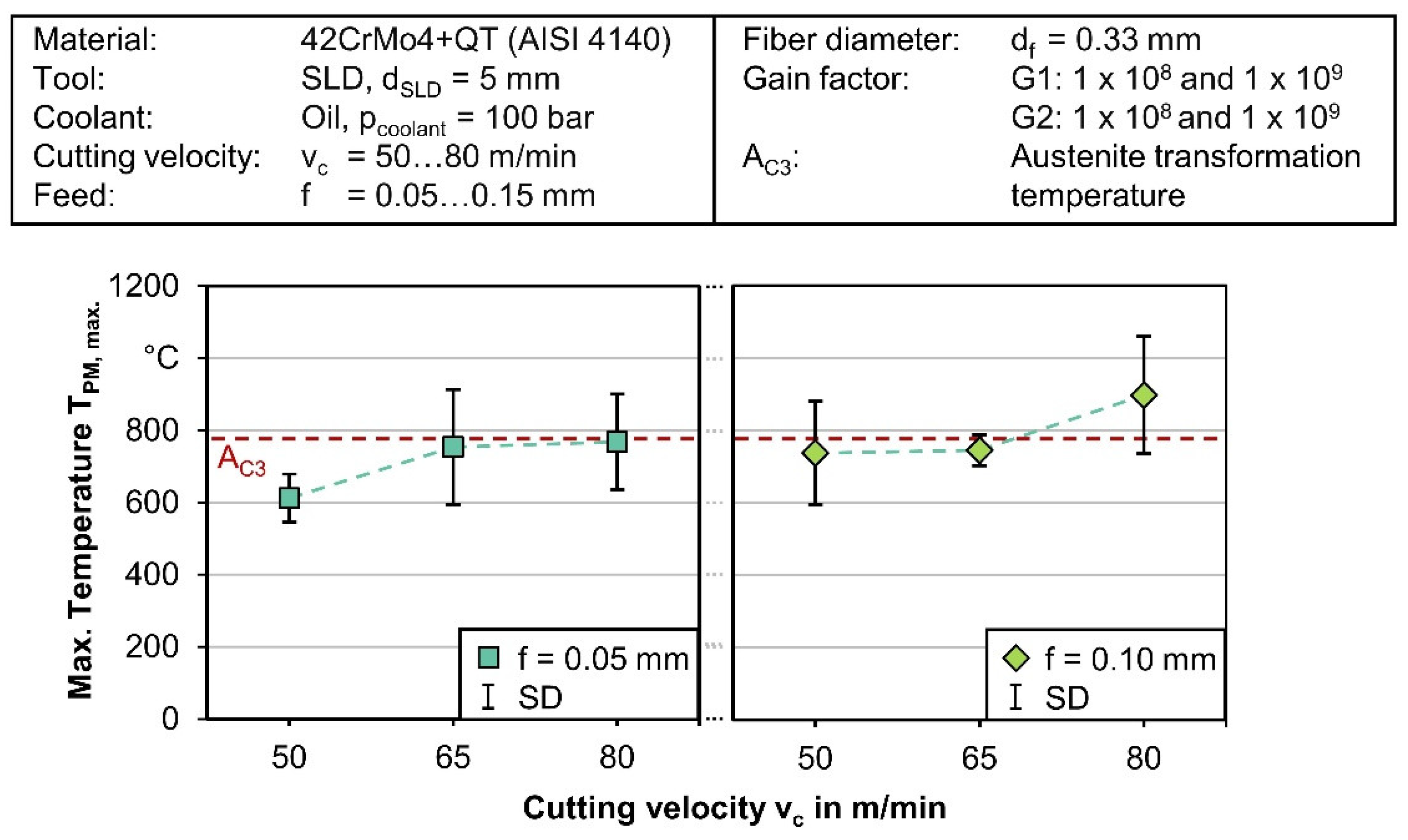

3.2. Pyrometric In-Process Temperature Measurement

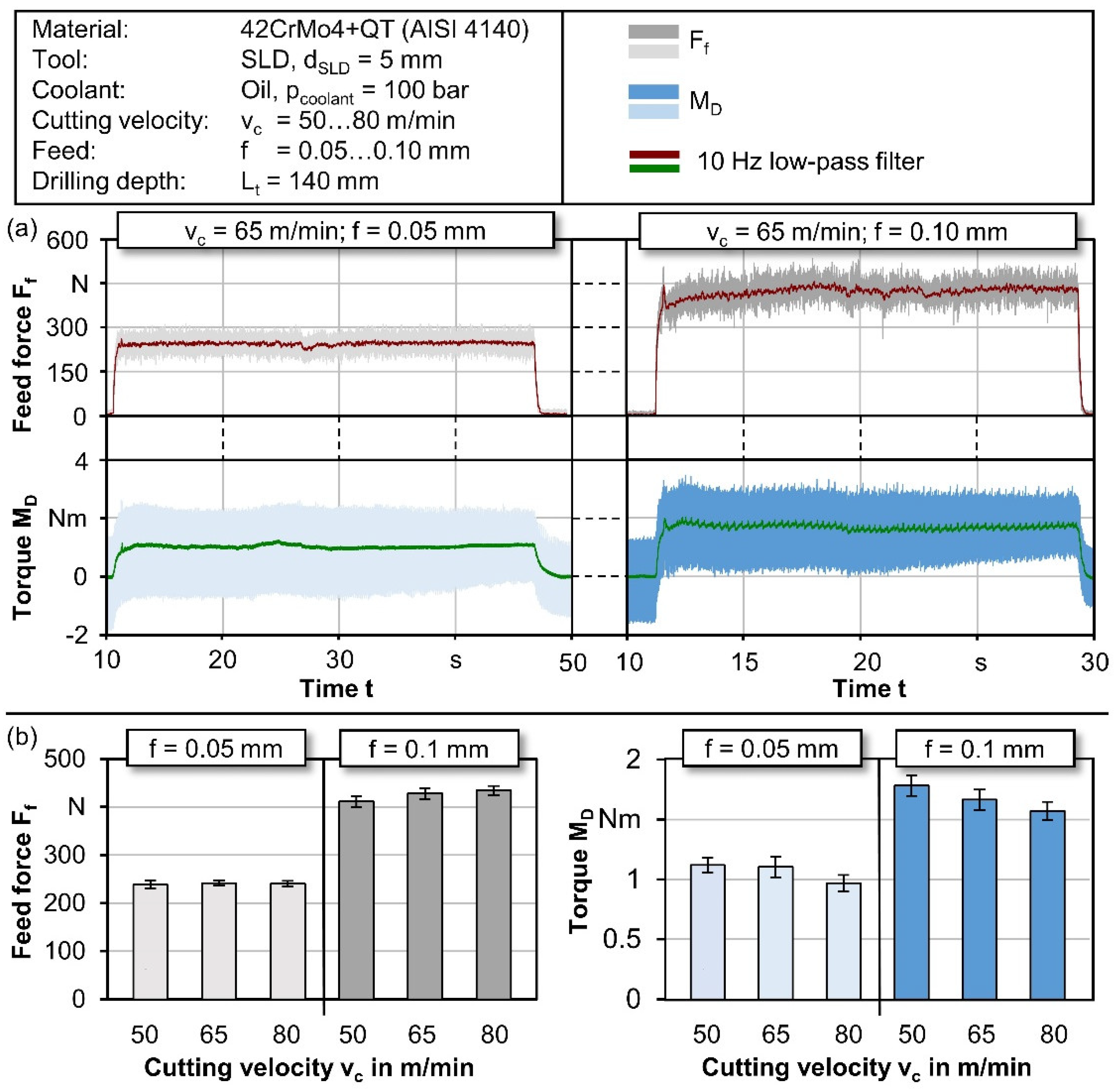

3.3. Analysis of the Mechanical Load on the Bores’ Surface

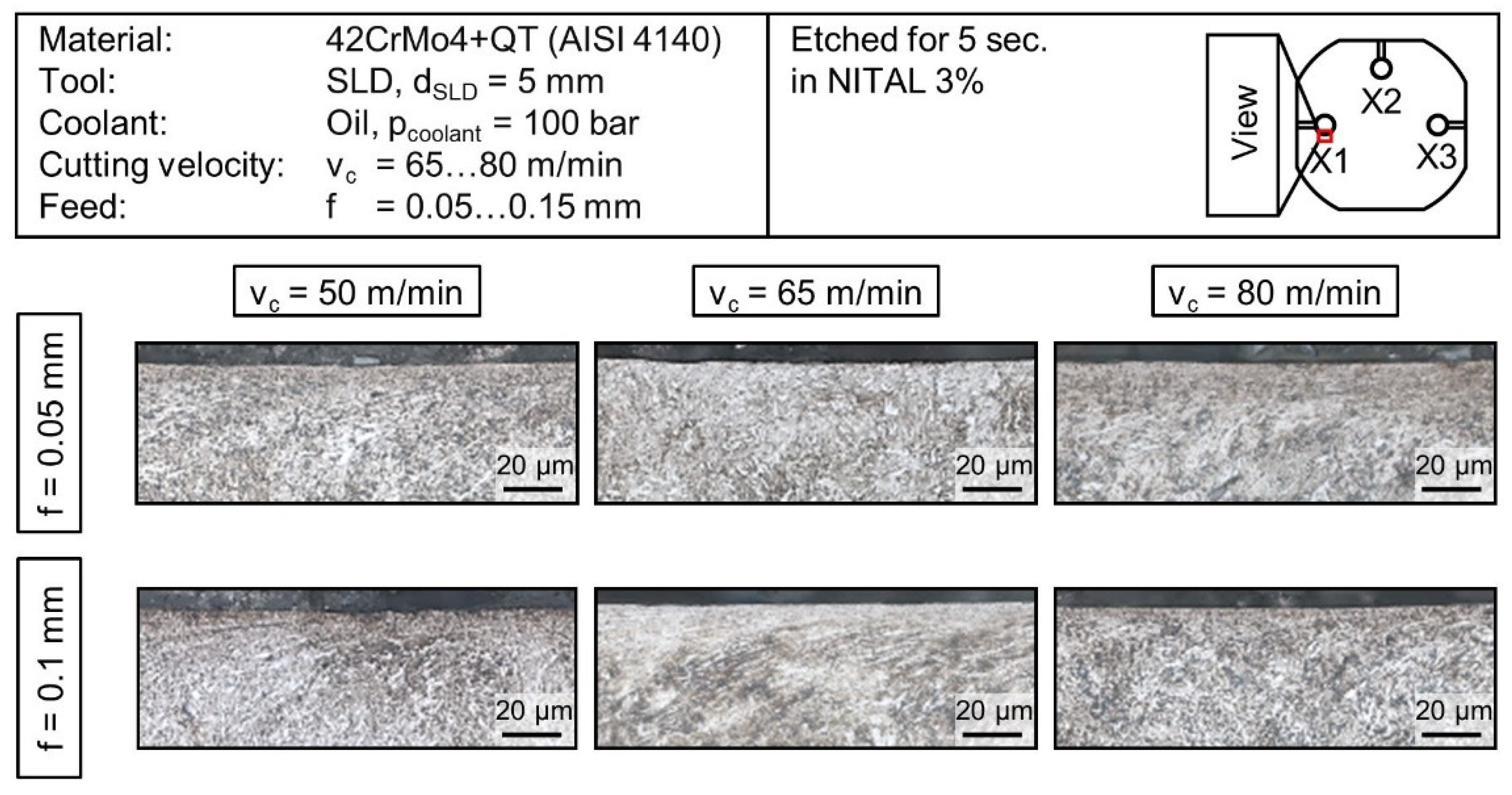

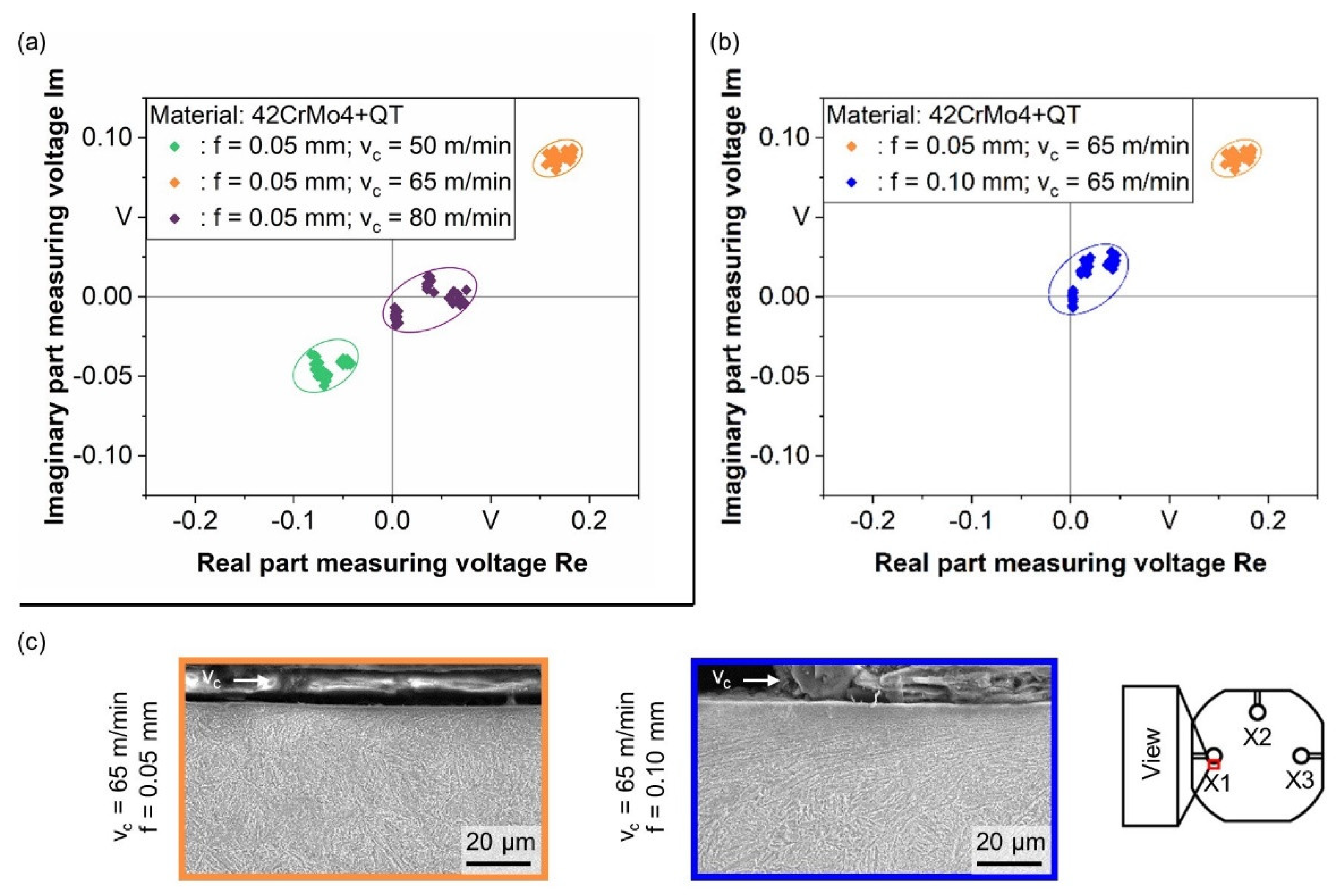

3.4. Surface Integrity Characterization

4. Conclusions and Outlook

- The temperature measurement using thermocouples enables the determination of temperatures in the bores’ subsurface. Both with a higher the feed rate and with an increase in the cutting velocity, the temperatures in the bore wall increased. However, the thermoelectric measurement does not allow a direct assessment of the temperatures prevailing in the tool/workpiece contact zone.

- The temperature measurement by means of ratio pyrometry allows the in-process temperature measurement directly at the tool’s cutting edge and at the guide pads with a frequency of fp = 7 kHz. With variation of the cutting values, an increase of the temperatures in the tool/workpiece contact zone was found, both with an increase of the feed rate from f = 0.05 mm to f = 0.10 mm and with an increase of the cutting velocity in a range from vc = 50–80 m/min. On average, the measured temperature peaks reached up to TPM, max. = 897 °C for the cutting value combination with the highest feed rate and cutting velocity (vc = 80 m/min; f = 0.10 mm).

- The analysis of the mechanical tool load reveals a reduction of the drilling torque with an increase of the cutting velocity. Considering the development of the drilling torque in connection with the temperature measurement results, it appears that a thermally induced softening of the workpiece material occurs at high cutting velocity. This effect has a major impact on the cutting forces, which are reflected in particular in the drilling torque. The objective of inducing a certain plastic deformation into the bore’ subsurface by applying high mechanical loads to the bore wall during single-lip deep hole drilling can be counteracted by effects such as thermal softening.

- The temperature peaks also reach a range above the austenitizing temperature of the workpiece material at higher cutting velocities, potentially increasing the risk of partial WEL formation. In the areas of the bore that could be investigated by microstructural analysis, no WEL formation was found. Nevertheless, differences in the plastic deformation of the microstructure near the edge zone could be detected for the varied cutting value combinations and associated mechanical loads on the bores’ surface layer.

- Using the non-destructive method of eddy-current analysis, the changes in the generated subsurface microstructure conditions could be detected. However, establishing the correlation of the results to thermal and mechanical loads during the drilling process is still challenging. Classification of the surface integrity by eddy-current measurement is to be further explored to estimate damage states and the associated remaining life of components.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Koster, W.P.; Field, M.; Kahles, J.F.; Fritz, L.J.; Gatto, L.R. Surface integrity of machined structural components. In Technical Report AFML-TR-70-11; Metcut Research Associates Inc.: Cincinnati, OH, USA, 1970. [Google Scholar]

- Novovic, D.; Dewes, R.C.; Aspinwall, D.K.; Voice, W.; Bowen, P. The effect of machined topography and integrity on fatigue life. Int. J. Mach. Tools Manuf. 2004, 44, 125–134. [Google Scholar] [CrossRef]

- Nickel, J.; Baak, N.; Biermann, D.; Walther, F. Influence of the deep hole drilling process and sulphur content on the fatigue strength of AISI 4140 steel components. Procedia CIRP 2018, 71, 209–214. [Google Scholar] [CrossRef]

- Nickel, J.; Baak, N.; Walther, F.; Biermann, D. Influence of the feed rate in the single-lip deep hole drilling process on the surface integrity of steel components. In Advanced Surface Enhancement; Itoh, S., Shukla, S., Eds.; Springer: Singapore, 2020; pp. 198–212. [Google Scholar]

- Baak, N.; Schaldach, F.; Nickel, J.; Biermann, D.; Walther, F. Barkhausen noise assessment of the surface conditions due to deep hole drilling and their influence on the fatigue behaviour of AISI 4140. Metals 2018, 8, 720. [Google Scholar] [CrossRef] [Green Version]

- Basara, A.; Nicolas, A.; Schlücker, E. Influence of the pressure holding time on strain generation in fuel injection lines. Int. J. Press. Vessel. Pip. 2011, 88, 132–137. [Google Scholar] [CrossRef]

- Biermann, D.; Bleicher, F.; Heisel, U.; Klocke, F.; Möhring, H.-C.; Shih, A. Deep hole drilling. CIRP Ann. 2018, 67, 673–694. [Google Scholar] [CrossRef]

- Griffiths, B. Manufacturing Surface Technology: Surface Integrity & Functional Performance, 1st ed.; Penton Press: London, UK, 2001. [Google Scholar]

- Pan, R.; Ren, R.; Chen, C.; Zhao, X. The microstructure analysis of white etching layer on treads of rails. Eng. Fail. Anal. 2017, 82, 39–46. [Google Scholar] [CrossRef]

- Radaj, D.; Vormwald, M. Ermüdungsfestigkeit: Grundlagen für Ingenieure, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Beno, T.; Hulling, U. Measurement of cutting edge temperature in drilling. CIRP Ann. 2012, 3, 531–536. [Google Scholar] [CrossRef] [Green Version]

- Bücker, M.; Oezkaya, E.; Strodick, S.; Biermann, D. A thermomechanical analysis leading to a novel flank face design providing longer tool lives for tools used in the drilling of Inconel 718. Int. J. Adv. Manuf. Technol. 2019, 102, 2977–2992. [Google Scholar]

- Michna, J. Numerische und experimentelle Untersuchung zerspanungsbedingter Gefügeumwandlungen und Modellierung des thermo-mechanischen Lastkollektivs beim Bohren von 42CrMo4. Ph.D. Thesis, Karlsruher Institut für Technologie, Karlsruhe, Germany, 2014. [Google Scholar]

- Mondelin, A.; Rech, J.; Feulvarch, E.; Coret, M. Characterisation of surface martensite-austenite transformation during finish turning of an AISI S15500 stainless steel. Int. J. Mach. Mach. Mater. 2014, 15, 101–121. [Google Scholar] [CrossRef] [Green Version]

- Biermann, D.; Iovkov, I.; Blum, H.; Rademacher, A.; Taebi, K.; Suttmeier, F.T.; Klein, N. Thermal aspects in deep hole drilling of aluminium cast alloy using twist drills and MQL. Procedia CIRP 2012, 3, 245–250. [Google Scholar] [CrossRef] [Green Version]

| C | Si | Mn | P | S | Cr | Mo | Fe |

|---|---|---|---|---|---|---|---|

| 0.41 | 0.18 | 0.85 | 0.011 | 0.011 | 1.01 | 0.18 | bal. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nickel, J.; Baak, N.; Volke, P.; Walther, F.; Biermann, D. Thermomechanical Impact of the Single-Lip Deep Hole Drilling on the Surface Integrity on the Example of Steel Components. J. Manuf. Mater. Process. 2021, 5, 120. https://doi.org/10.3390/jmmp5040120

Nickel J, Baak N, Volke P, Walther F, Biermann D. Thermomechanical Impact of the Single-Lip Deep Hole Drilling on the Surface Integrity on the Example of Steel Components. Journal of Manufacturing and Materials Processing. 2021; 5(4):120. https://doi.org/10.3390/jmmp5040120

Chicago/Turabian StyleNickel, Jan, Nikolas Baak, Pascal Volke, Frank Walther, and Dirk Biermann. 2021. "Thermomechanical Impact of the Single-Lip Deep Hole Drilling on the Surface Integrity on the Example of Steel Components" Journal of Manufacturing and Materials Processing 5, no. 4: 120. https://doi.org/10.3390/jmmp5040120

APA StyleNickel, J., Baak, N., Volke, P., Walther, F., & Biermann, D. (2021). Thermomechanical Impact of the Single-Lip Deep Hole Drilling on the Surface Integrity on the Example of Steel Components. Journal of Manufacturing and Materials Processing, 5(4), 120. https://doi.org/10.3390/jmmp5040120