Open Source Vacuum Oven Design for Low-Temperature Drying: Performance Evaluation for Recycled PET and Biomass

Abstract

1. Introduction

2. Materials and Methods

2.1. Design

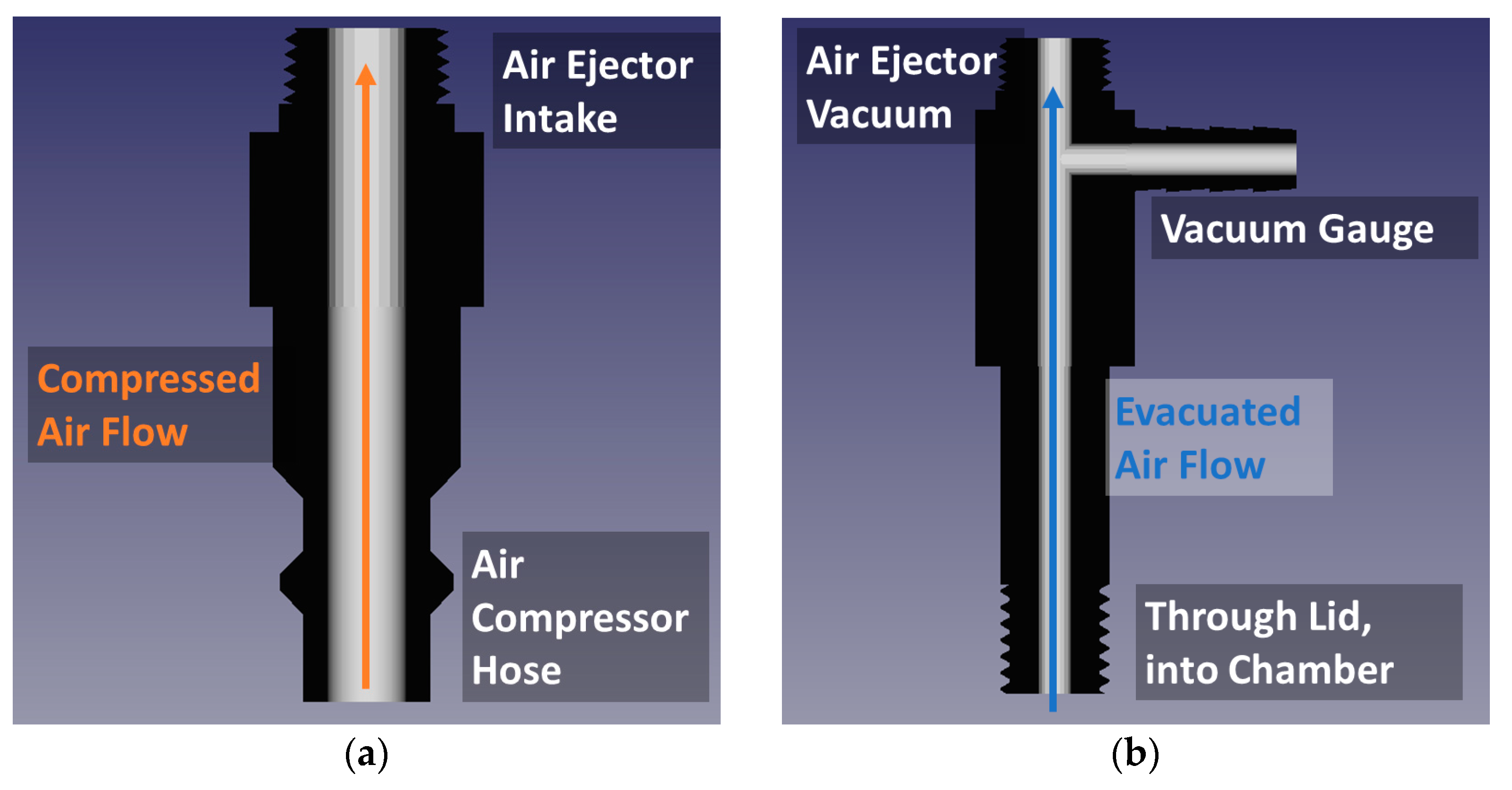

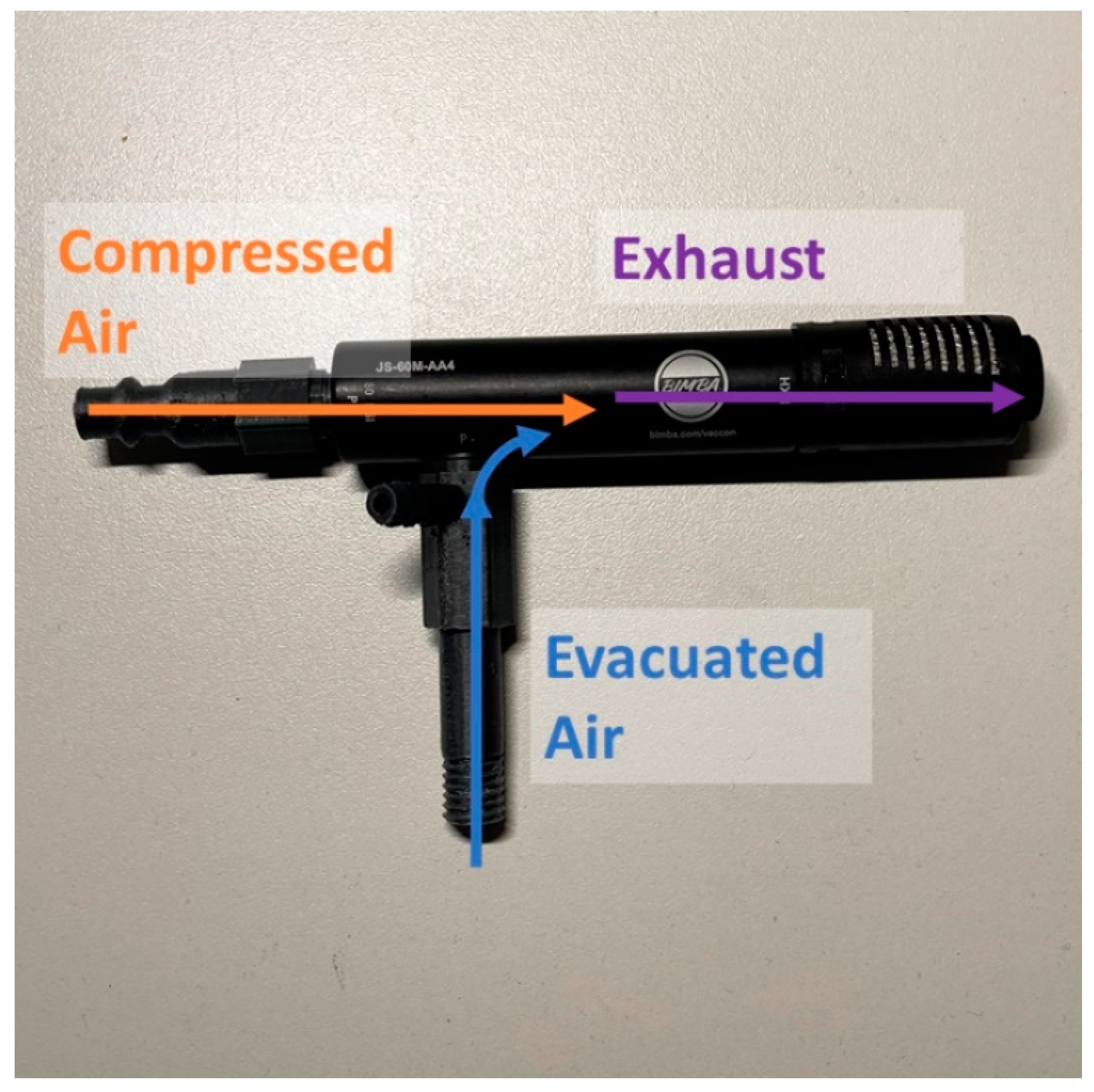

2.1.1. Vacuum System

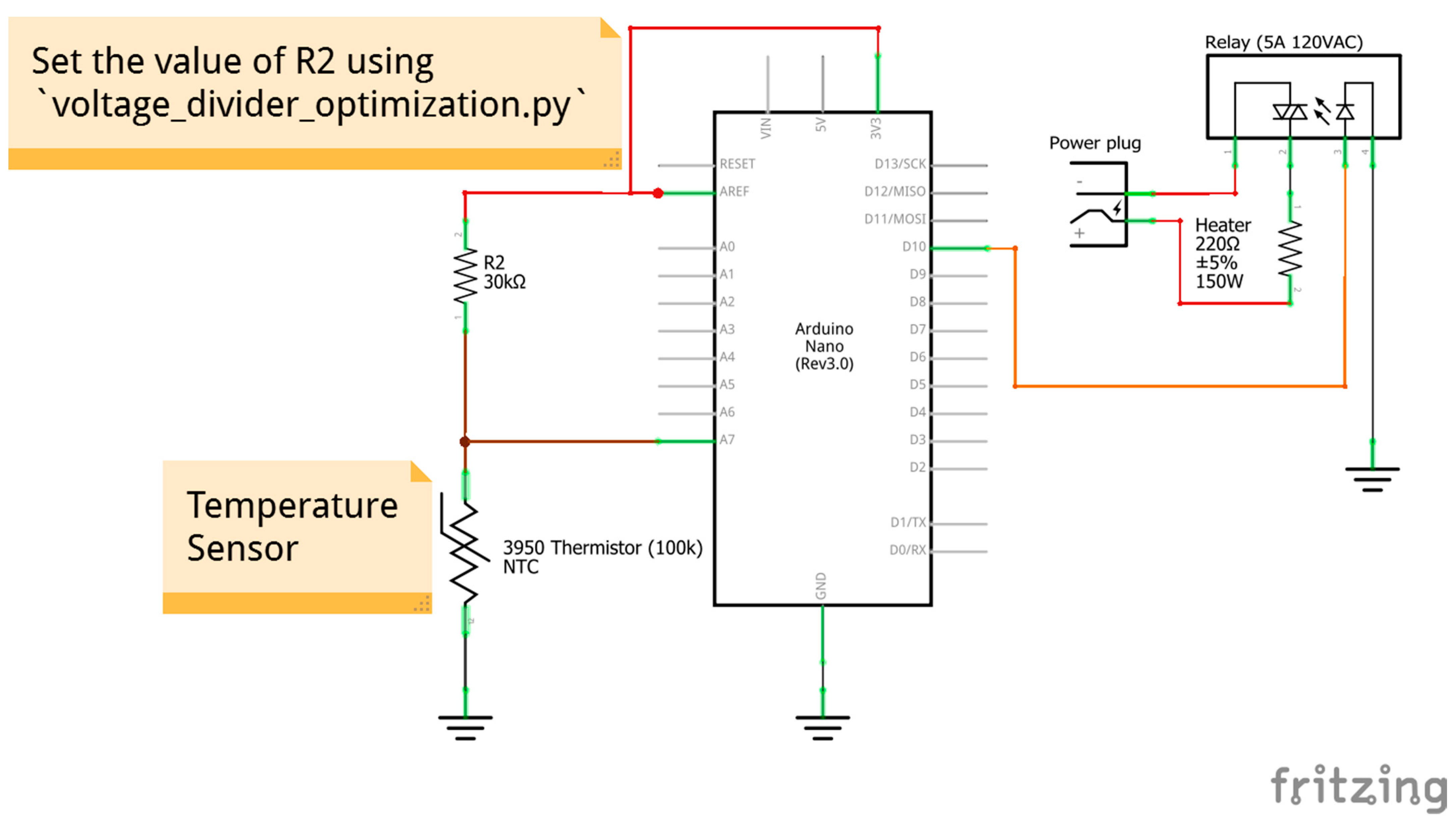

2.1.2. Thermal Controls

2.2. Manufacturing and Assembly

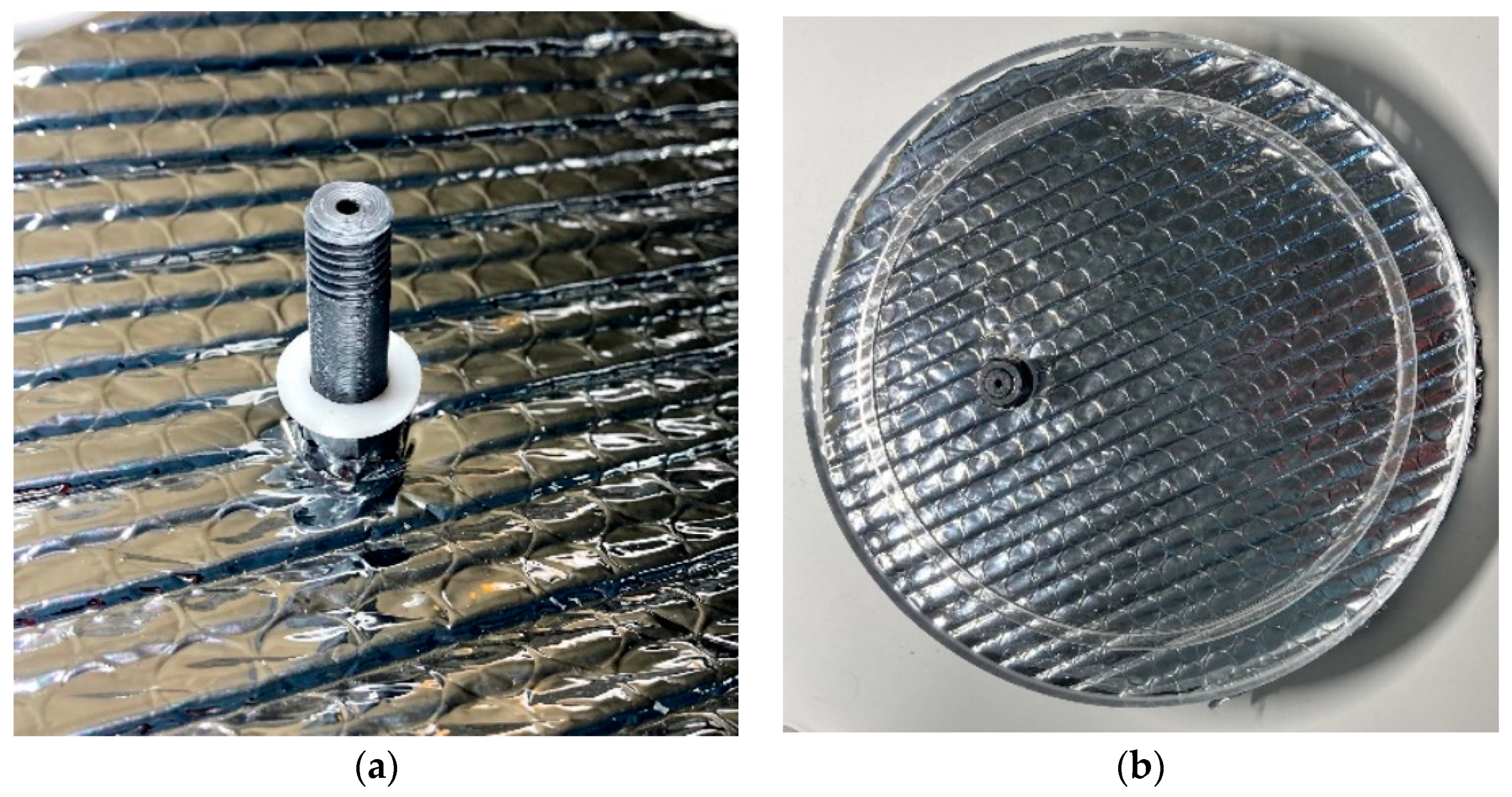

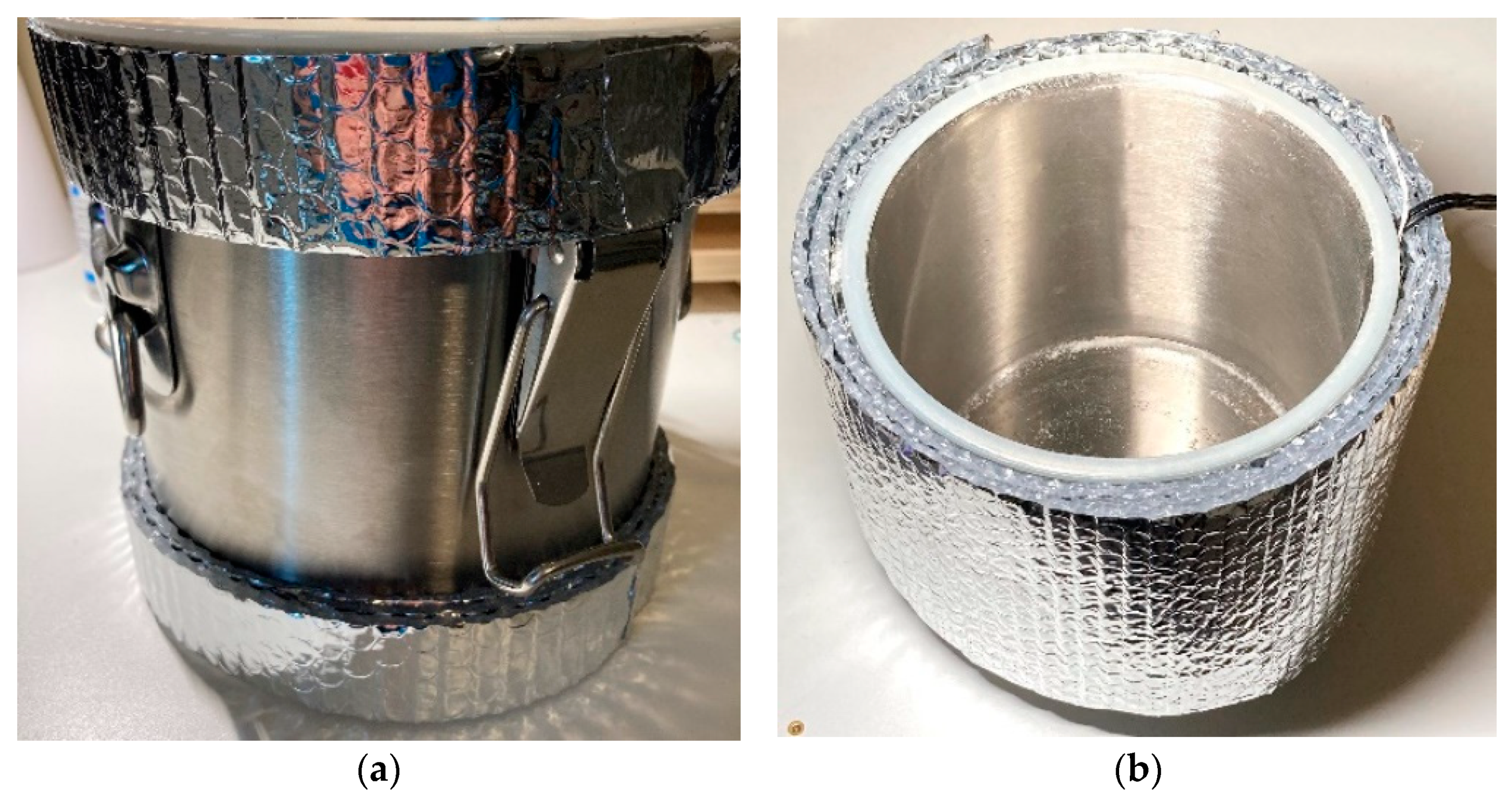

2.2.1. Vacuum Chamber

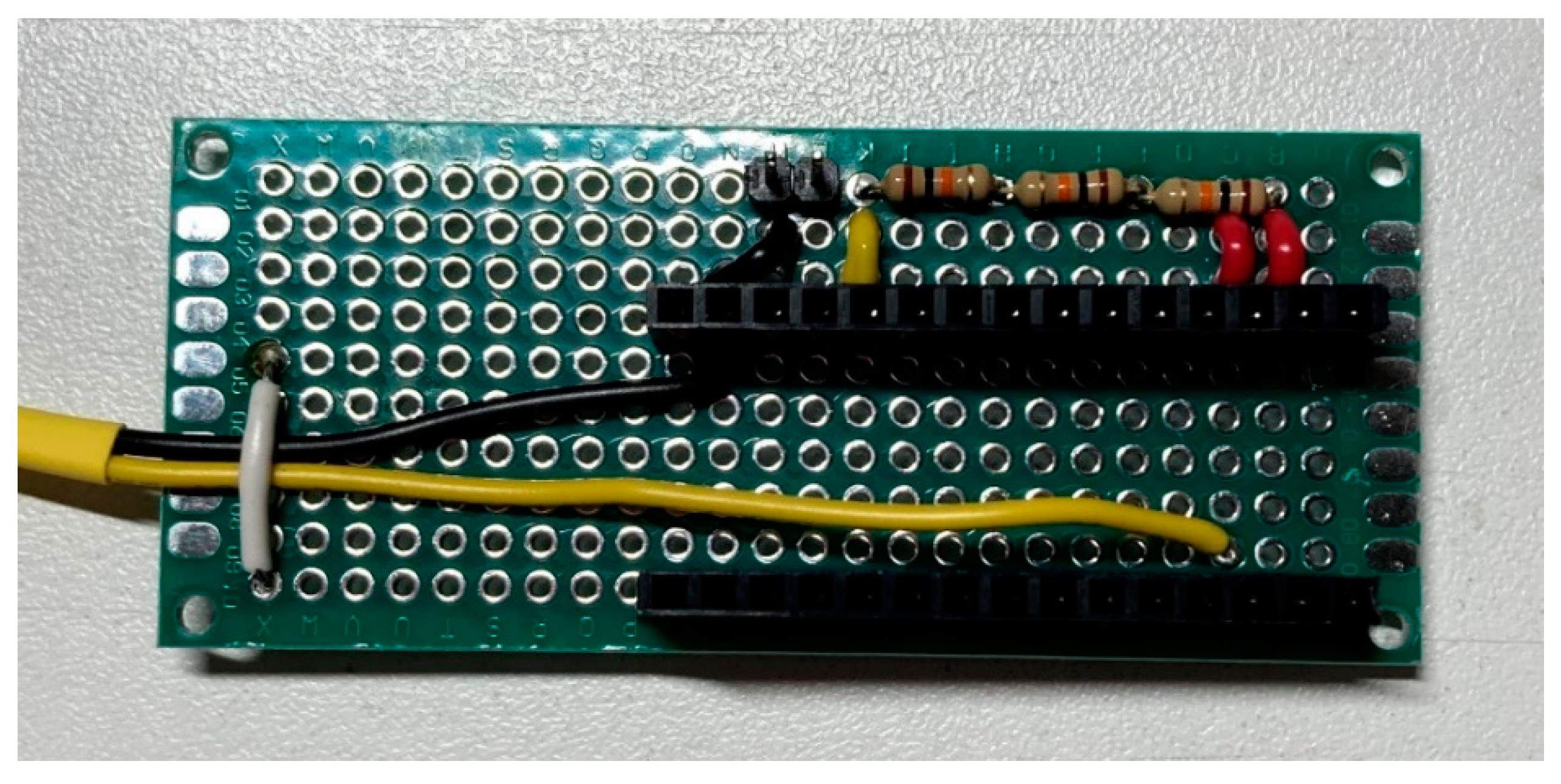

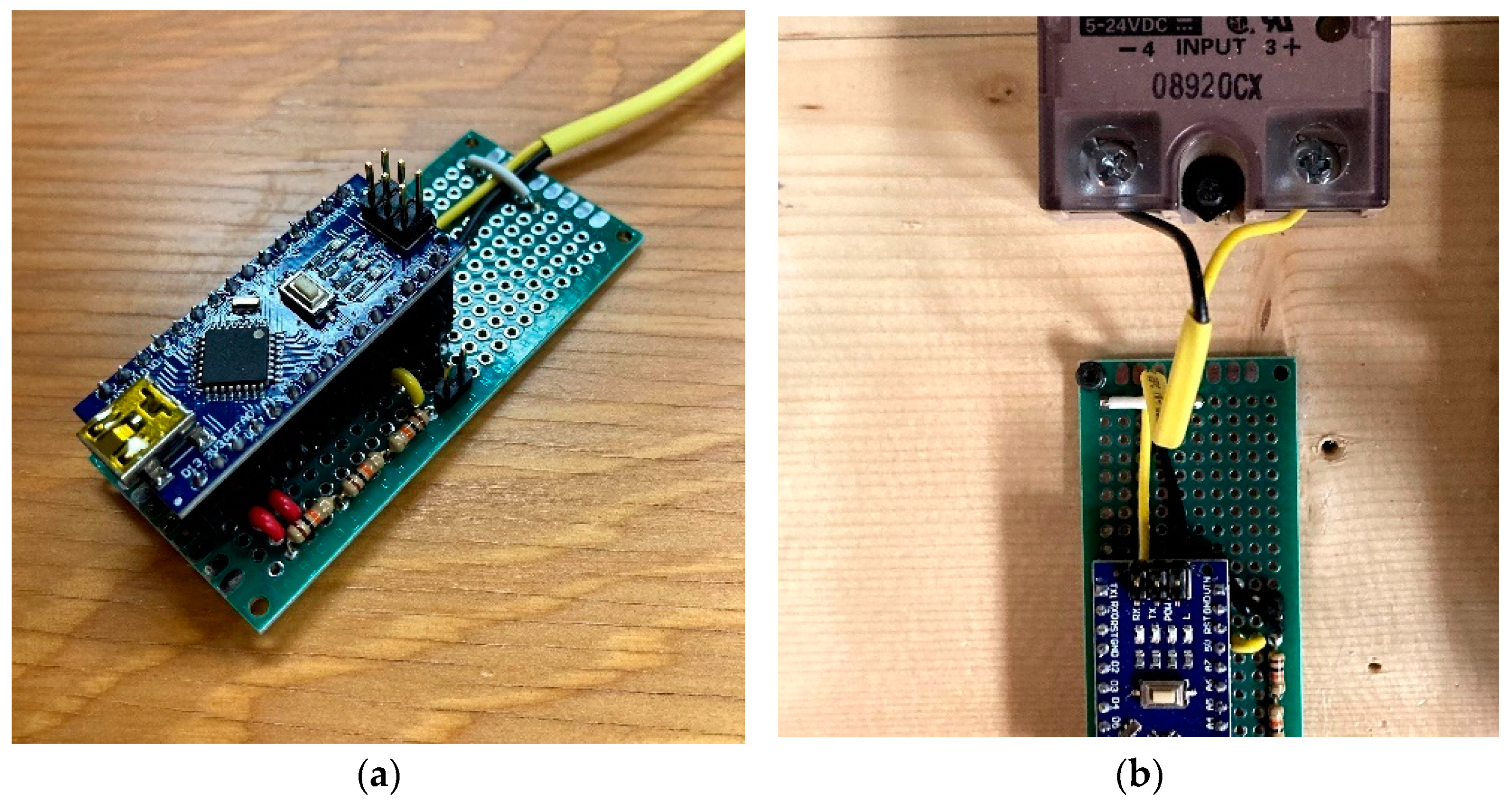

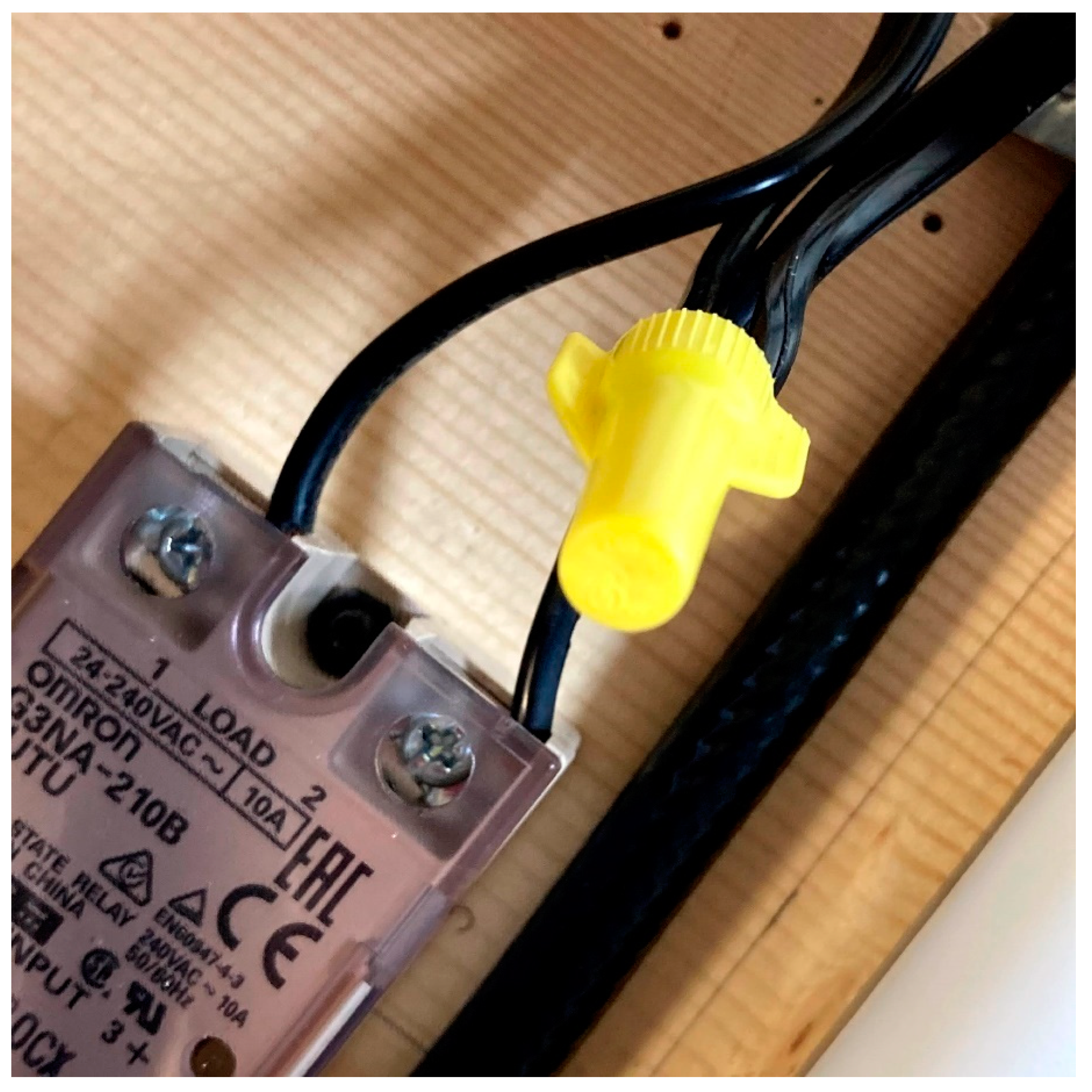

2.2.2. Thermal Control System

2.2.3. Finishing the Assembly

2.3. Code

2.4. Operation

2.5. Materials for Testing

2.5.1. Plastics

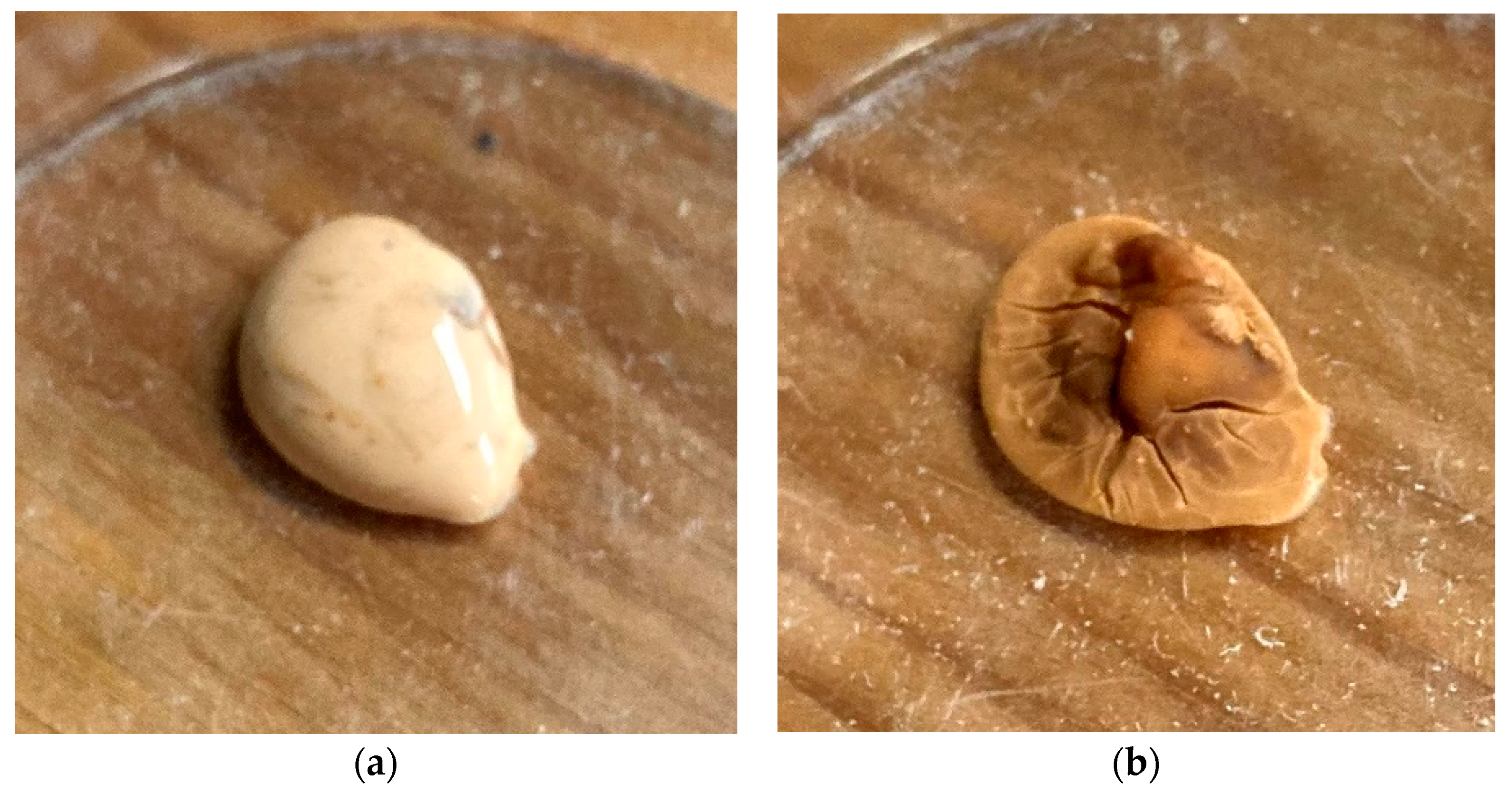

2.5.2. Biomaterials

2.6. Testing

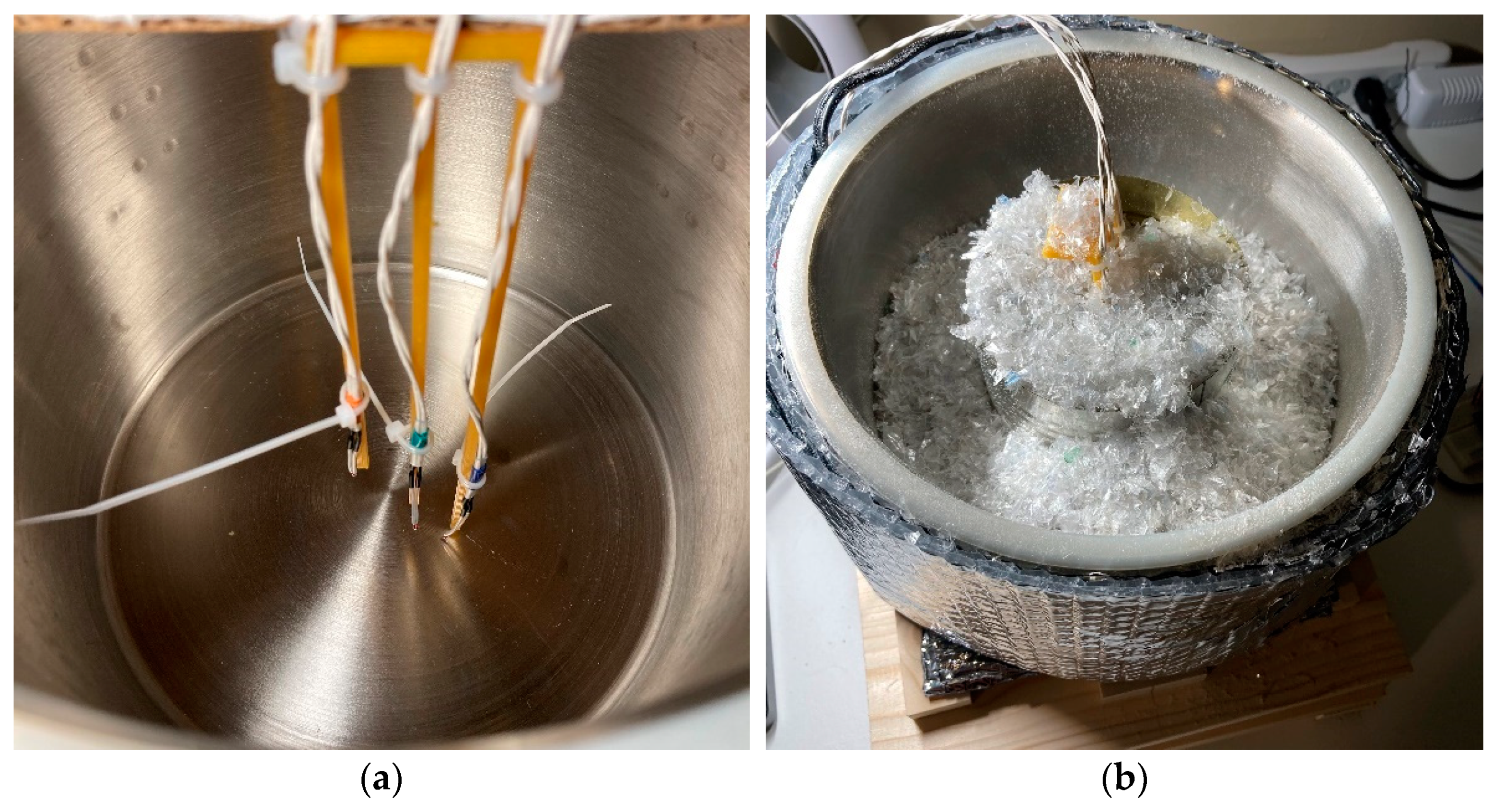

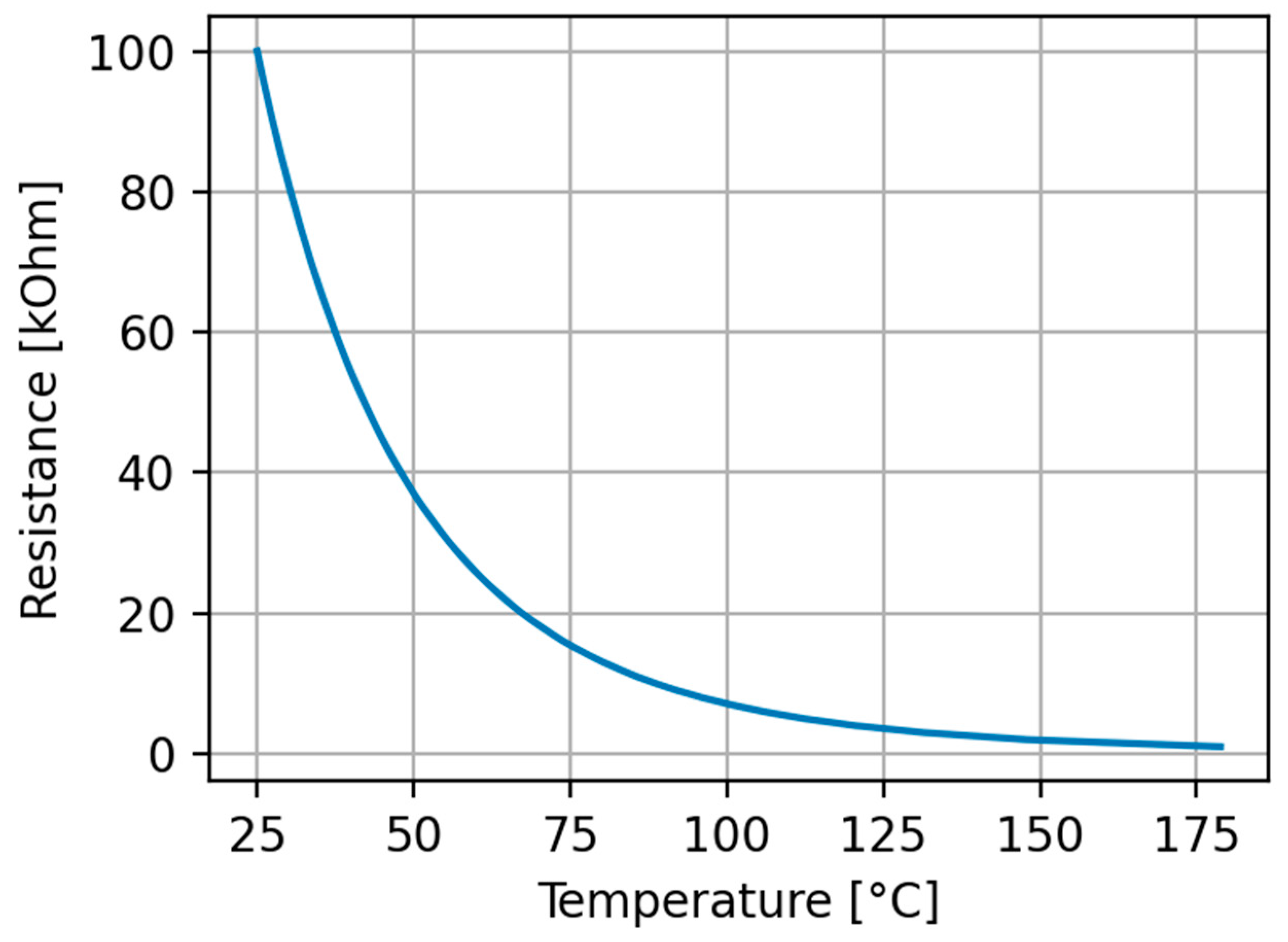

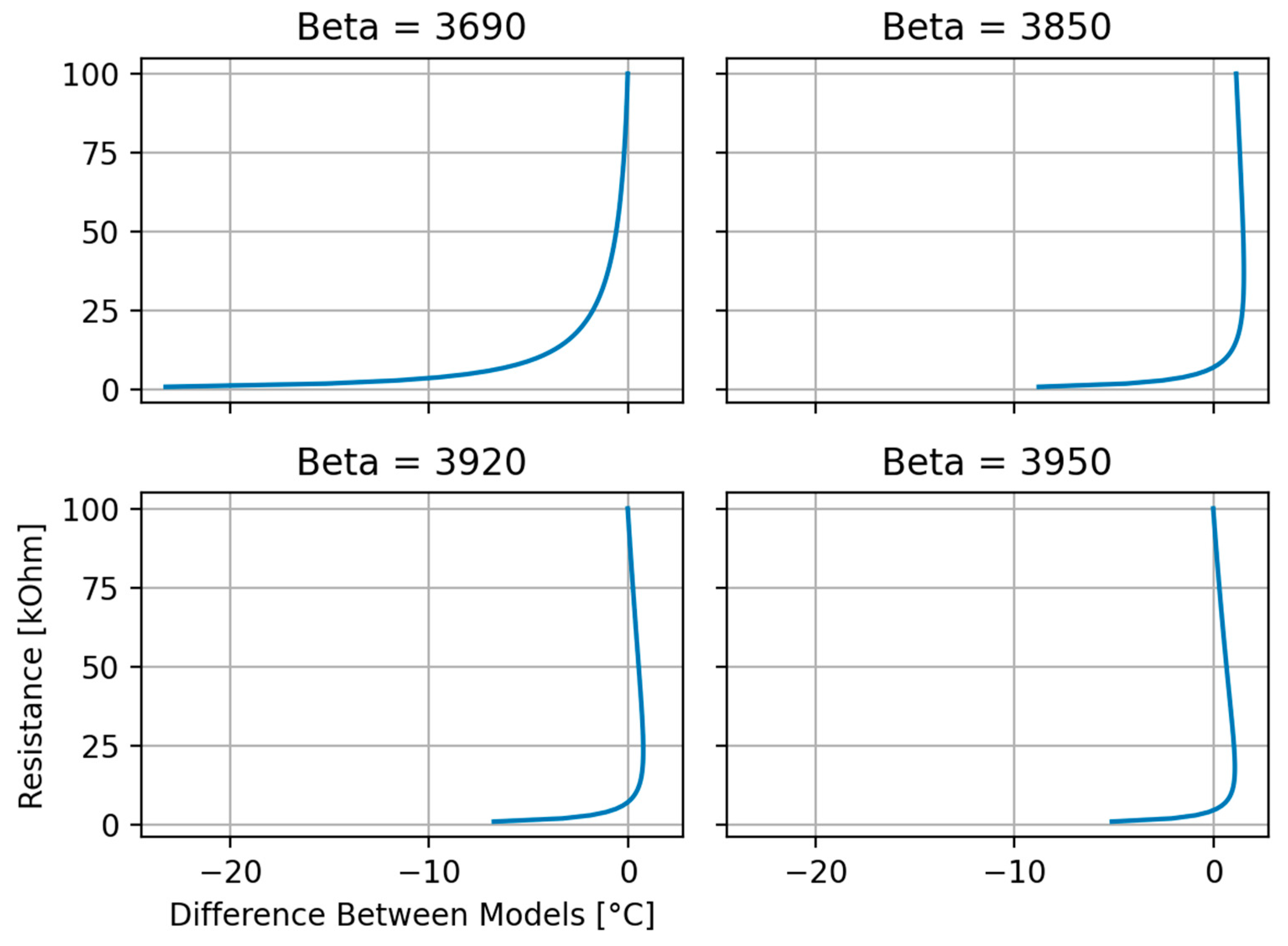

2.6.1. Thermistor Calibration

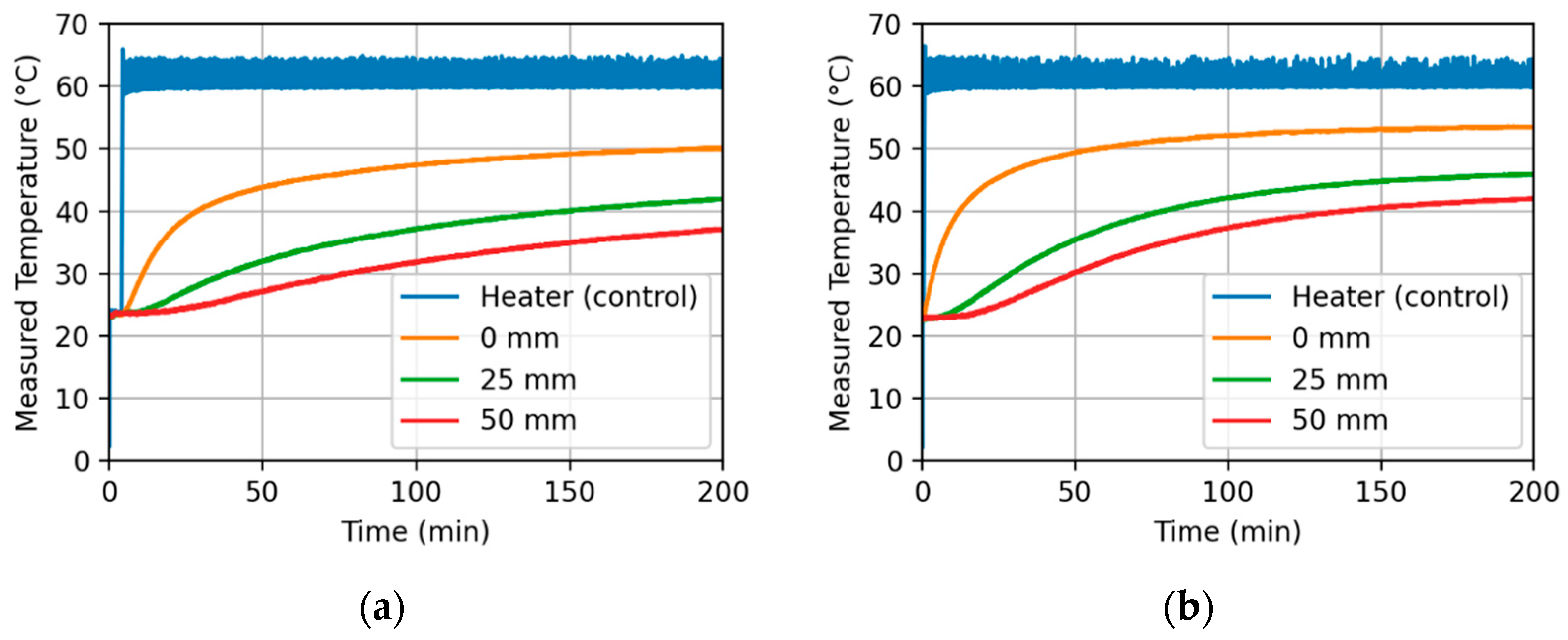

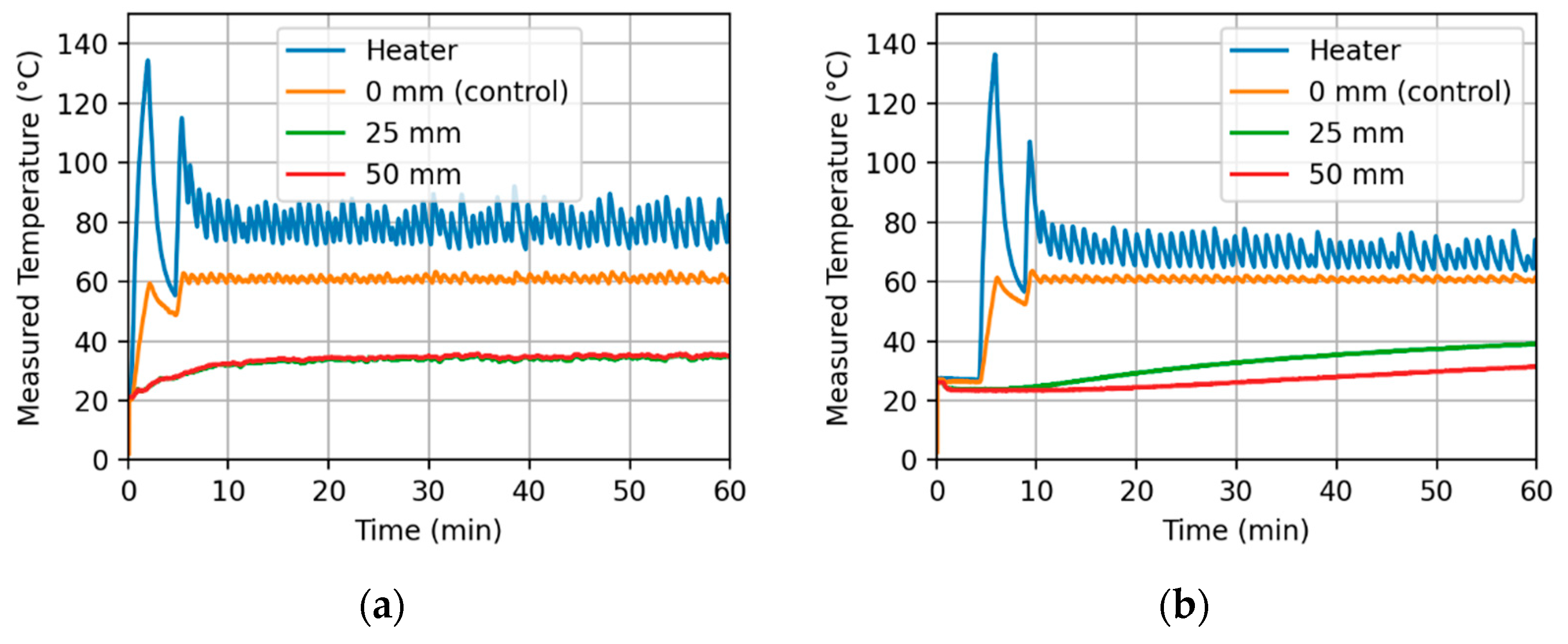

2.6.2. Temperature Gradient Measurements

2.6.3. Drying Rate Comparison

2.6.4. Filament Drying

2.7. Economic Analysis

3. Results

3.1. Thermistor Calibration

3.2. Temperature Gradient Testing

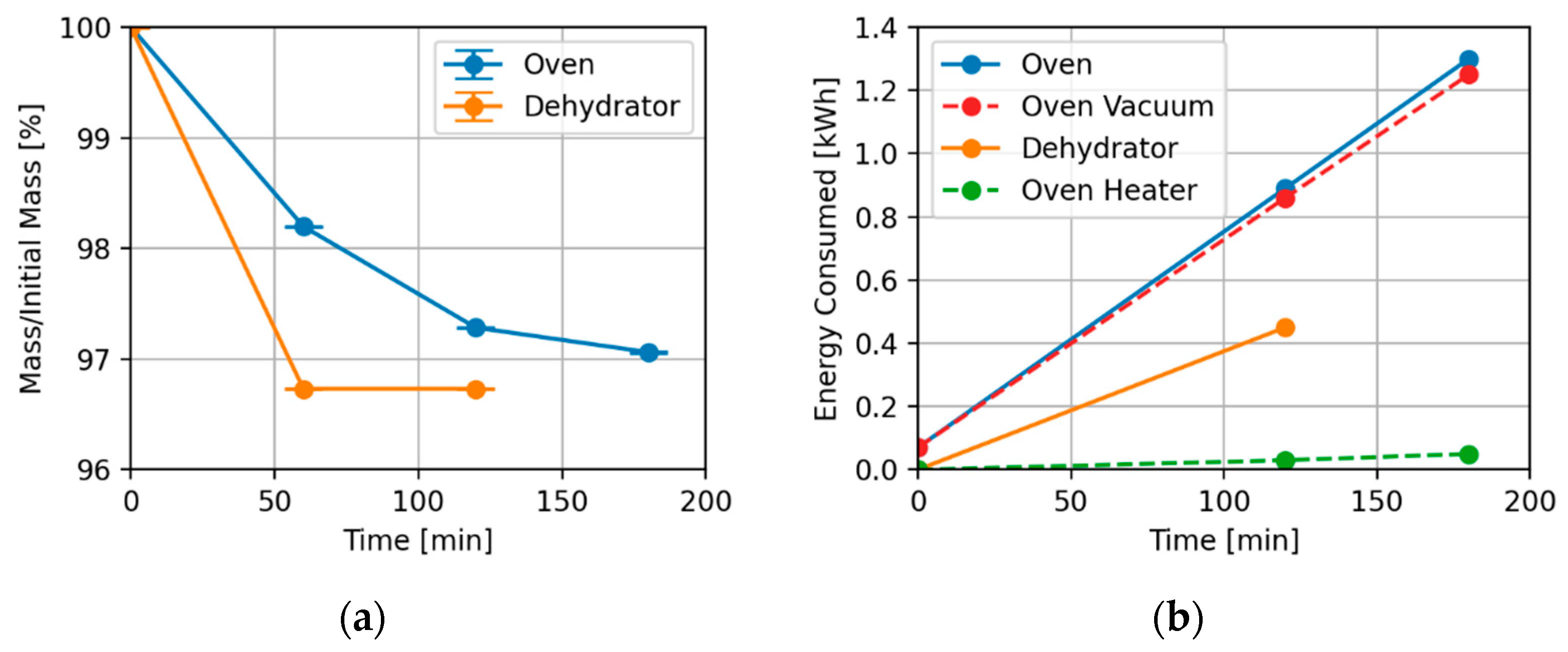

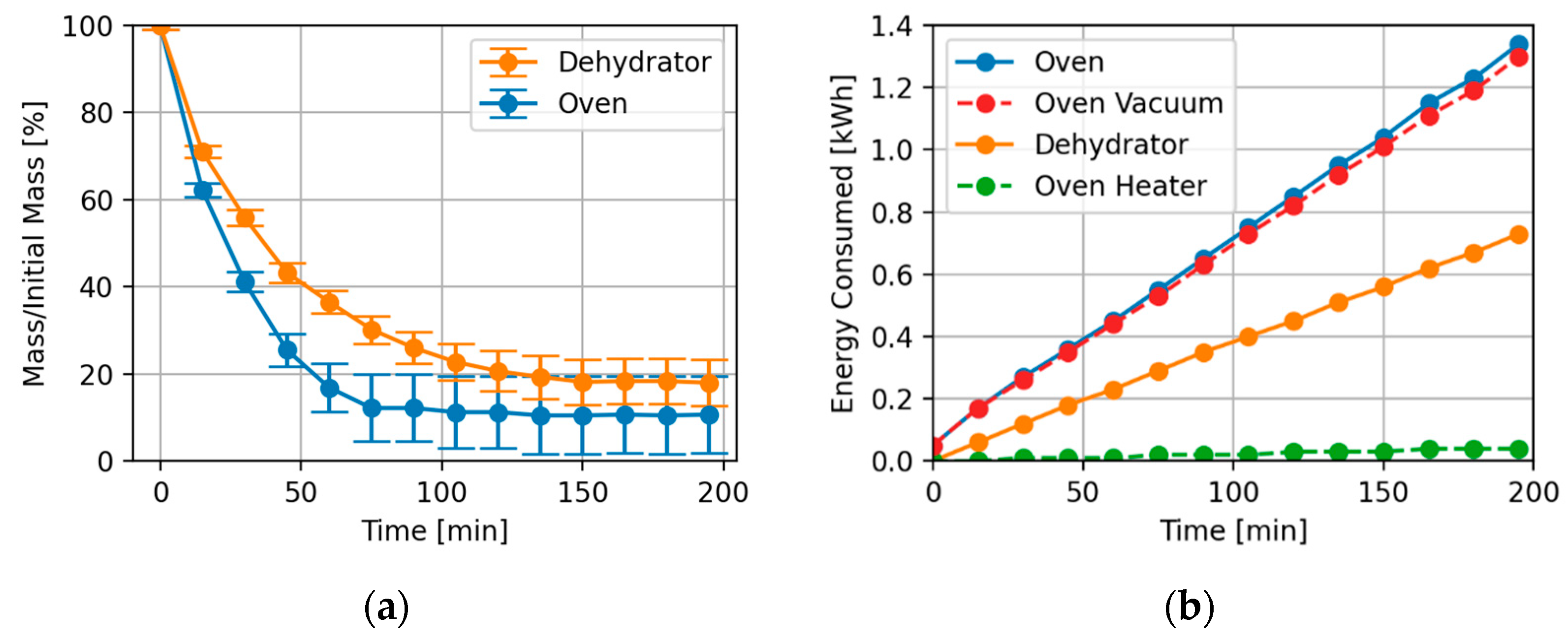

3.3. Drying Tests

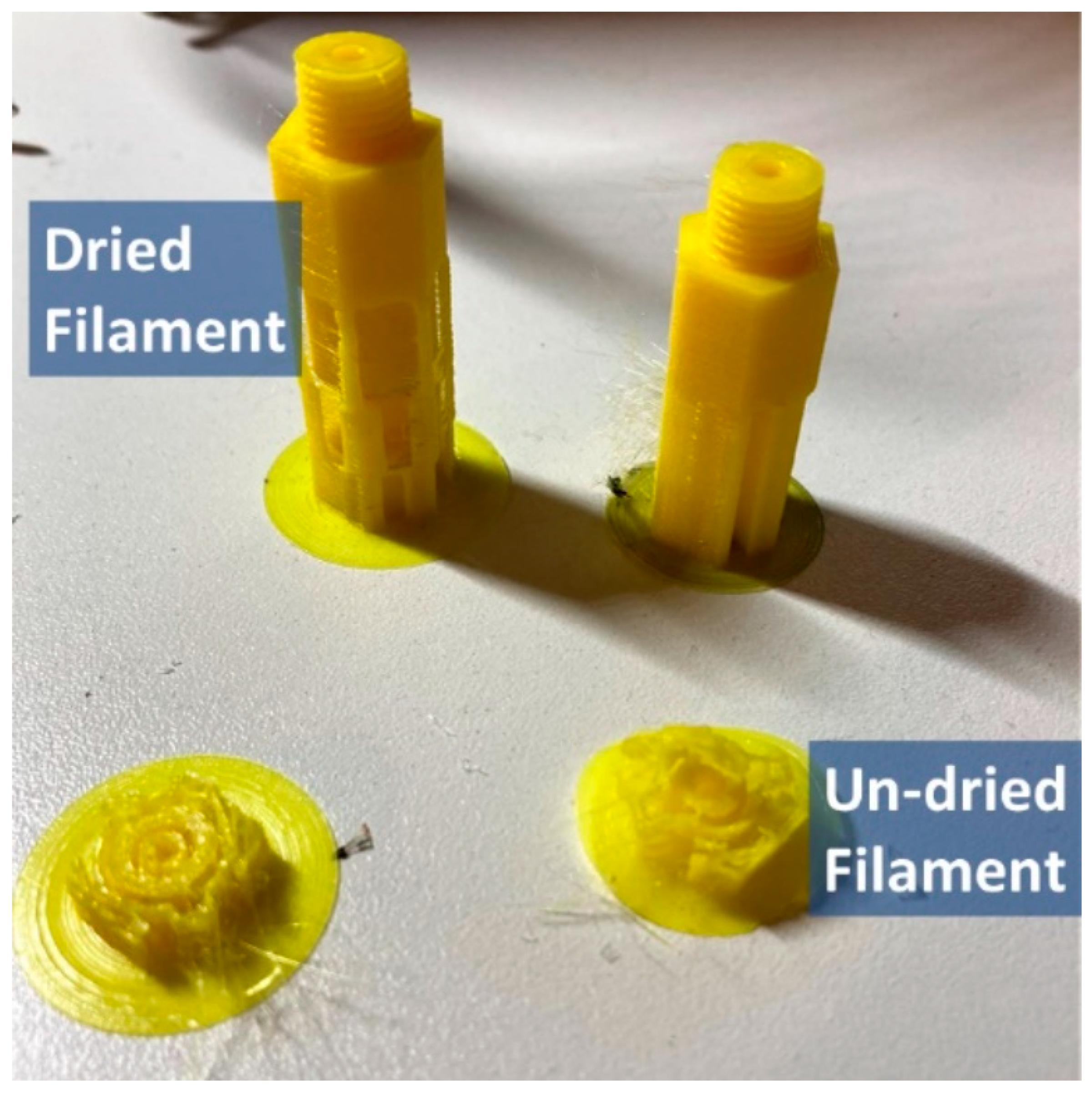

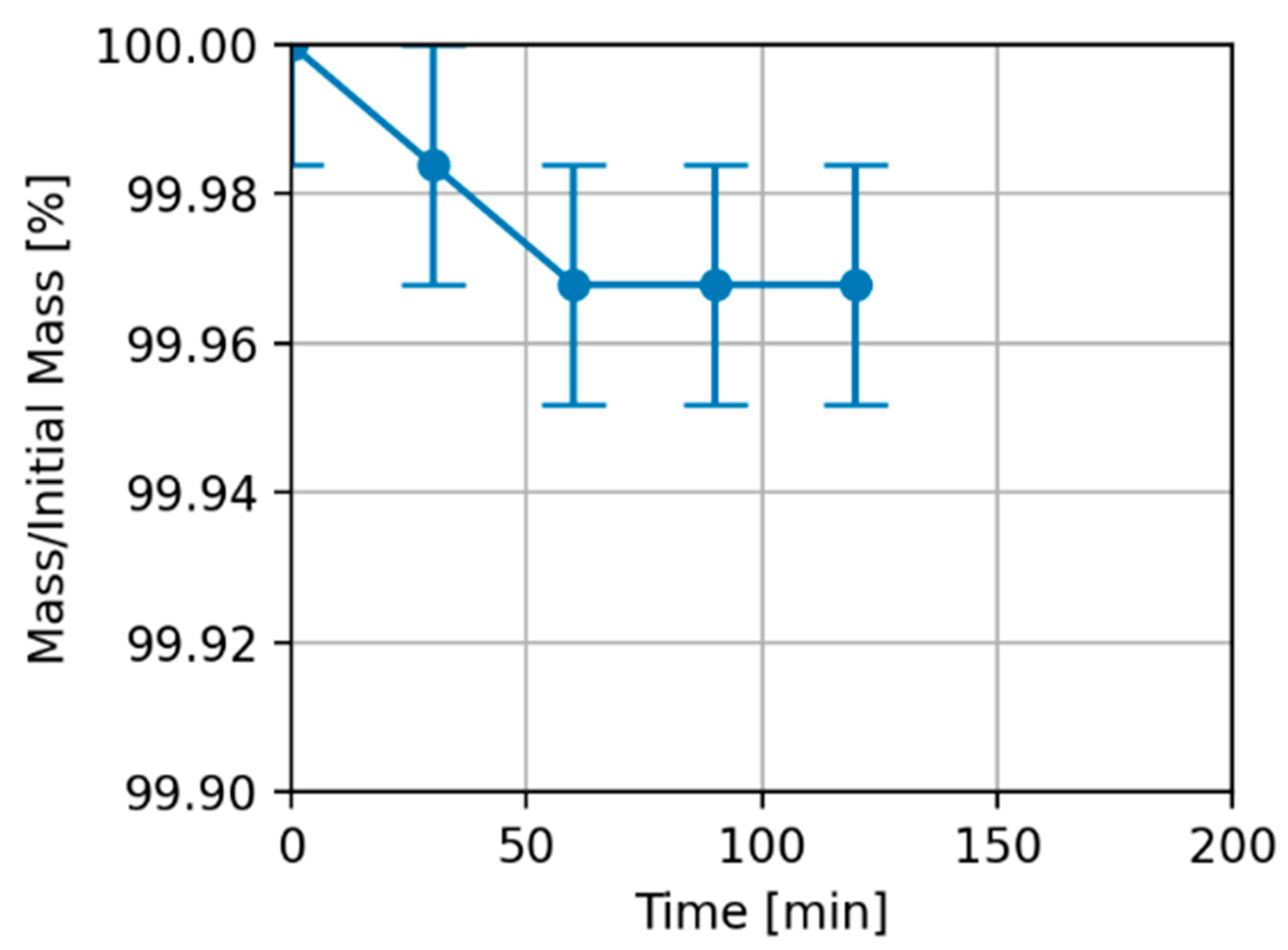

3.4. Filament Drying

3.5. Economic Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Vacuum Selection

Appendix B. Bill of Materials

| Component | Photograph |

|---|---|

| Vacuum Chamber | |

| Air Compressor $99 [31] |  |

| Fixed-Flow Air-Powered Vacuum Pump $79.75 [37] |  |

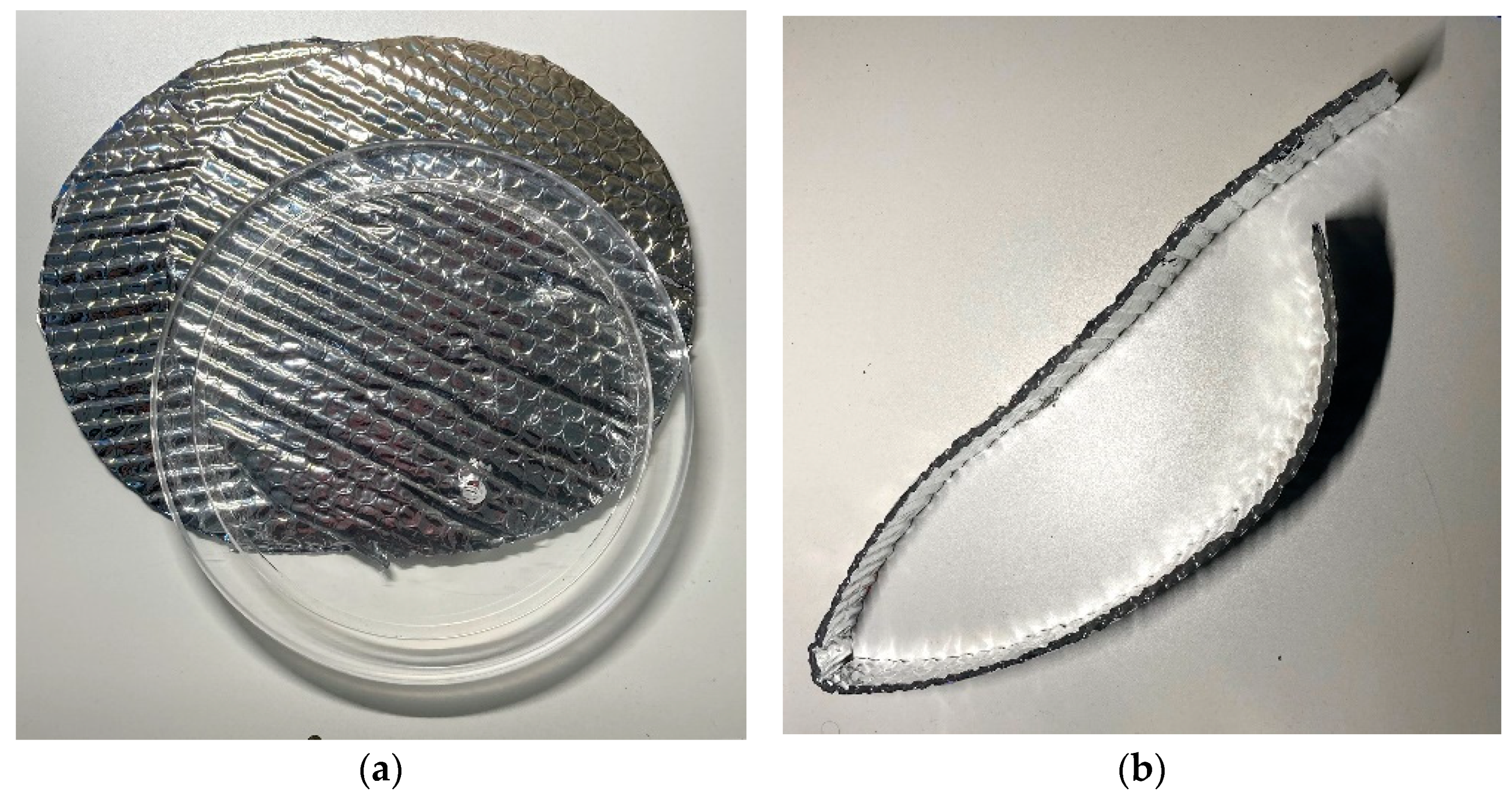

Vacuum Chamber, including:

|  |

| 10 sq ft Reflectix Double Sided Insulation $13.57/33.3 sq ft [46] |  |

| Vacuum Gauge with Rubber Hose $24.99 [30] |  |

| 1 ft High Temperature Flue Tape $8.82/15 ft [47] |  |

| 3-D Printed Vacuum Pump Intake Connector [45] Printed in shown orientation, threads up. |  |

| 3-D Printed Vacuum Pump Vacuum Connector [45] Printed in shown orientation, fine threads up |  |

| Thermal Control System | |

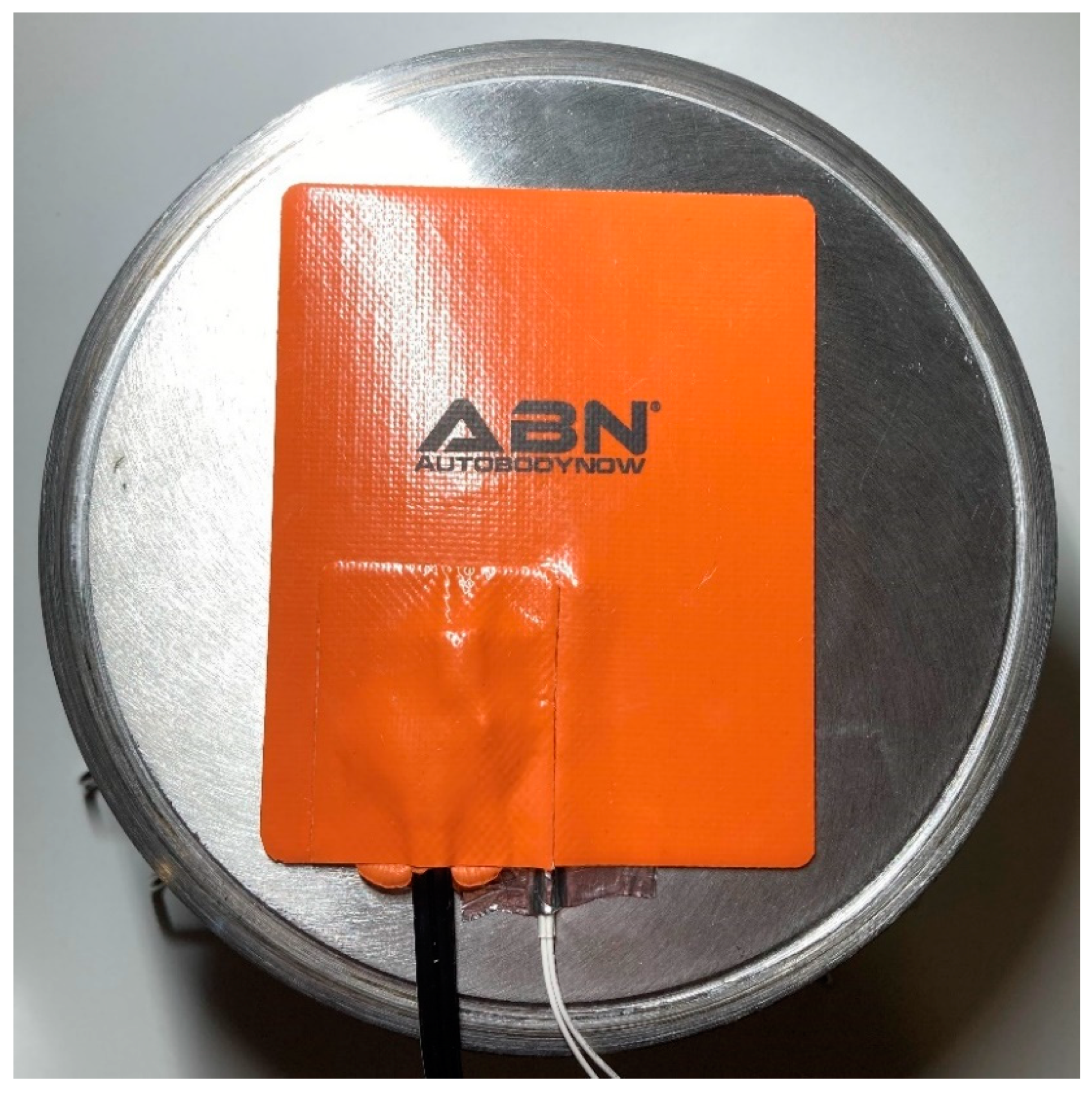

| 120V Silicone Heating Pad, 1.16 W/cm2 (7.5 W/in2) 19.99 [48] |  |

| Solid State Relay (5 V Input, 120 VAC/2 A+ output) $25.44 [49] |  |

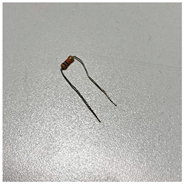

| 1x NTC Thermistor 13.99/5 ea [50] |  |

| 3x 10 kOhm Resistor (or 1x 30 kOhm resistor) $6.42/100 ea [51] |  |

| Arduino Microcontroller (Nano) $20.70 [52] or derivative $15.99/3 ea [53] |  |

| USB-A to USB-mini-B (or USB-micro, or USB-B, depending on the Arduino) $3.84 [54] |  |

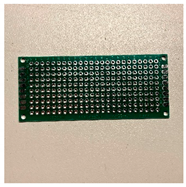

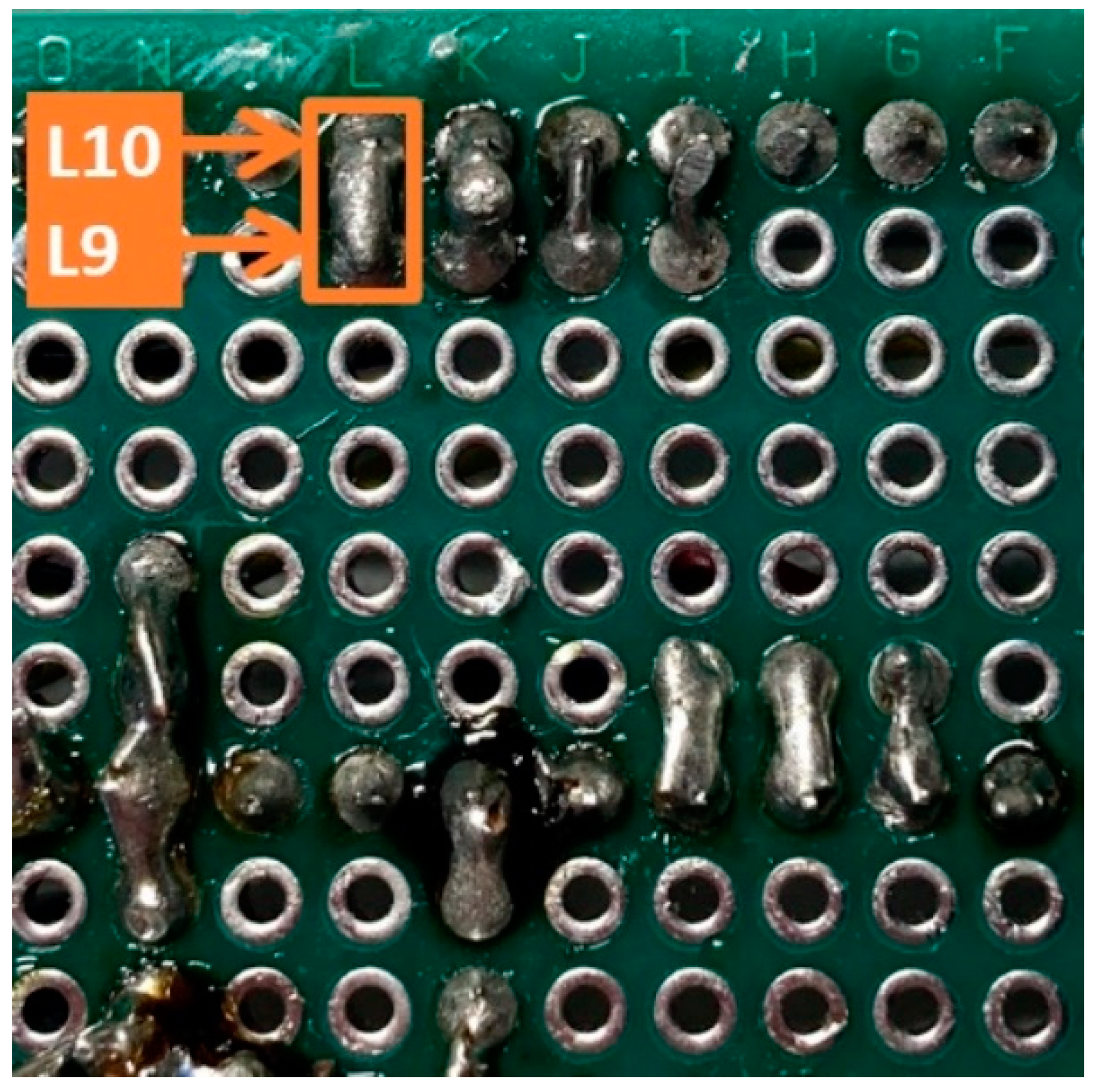

| 1x Solder Breadboard, 3 × 7 cm $11.21/40 ea [55] |  |

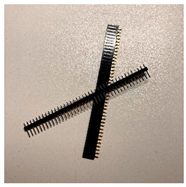

Male and Female Header pins:

|  |

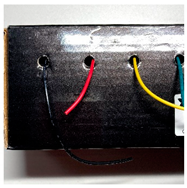

22 AWG Hookup Wires:

|  |

Appendix C. Wiring Instructions

References

- Parikh, D.M. Solids Drying: Basics and Applications. Chem. Eng. 2014, 121, 42–45. [Google Scholar]

- Jansen, J. Plastics Engineering—January 2015—Plastic Failure Through Molecular Degradation. Plast. Eng. Jan. 2015, 71, 34–39. [Google Scholar] [CrossRef]

- Bozzelli, J. Injection Molding: You Must Dry Hygroscopic Resins. Plastics Technology. 2010. Available online: https://www.ptonline.com/articles/you-must-dry-hygroscopic-resins (accessed on 19 May 2021).

- Calovini, L. Everything You Need to Know About Desiccant Drying. Shini USA. 2016. Available online: https://www.shiniusa.com/2016/07/26/everything-you-need-to-know-about-desiccant-drying/ (accessed on 19 May 2021).

- Stoughton, P. How to Dry PET for Container Applications. Plastics Technology. 2014. Available online: https://www.ptonline.com/articles/how-to-dry-pet-for-container-applications (accessed on 19 May 2021).

- Månsson, A. How Moist Filaments Will Screw up Your 3D-Printing. 3DPrinterChat. 2016. Available online: https://3dprinterchat.com/how-moist-filaments-will-screw-up-your-3d-printing/ (accessed on 19 May 2021).

- Dertinger, S.C.; Gallup, N.; Tanikella, N.G.; Grasso, M.; Vahid, S.; Foot, P.J.; Pearce, J.M. Technical pathways for distributed recycling of polymer composites for distributed manufacturing: Windshield wiper blades. Resour. Conserv. Recycl. 2020, 157. [Google Scholar] [CrossRef]

- Sanchez, F.A.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy. J. Clean. Prod. 2020, 264. [Google Scholar] [CrossRef]

- Little, H.A.; Tanikella, N.G.; Reich, M.J.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Towards Distributed Recycling with Additive Manufacturing of PET Flake Feedstocks. Materials 2020, 13, 4273. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Ramaswamy, S.; Bjegovic, P. Pre-Emptive Control of Moisture Content in Paper Manufacturing Using Surrogate Measurements. Trans. Inst. Meas. Control Trans Inst Meas. Control 2003, 25, 36–56. [Google Scholar] [CrossRef]

- Amos, W.A. Report on Biomass Drying Technology; National Renewable Energy Lab.: Golden, CO, USA, 1999. [CrossRef]

- Resin Expert. How to Stabilize Wood—Stabilise Wood the Right Way. Available online: https://resin-expert.com/en/guide/how-to-stabilize-wood (accessed on 27 March 2021).

- Boundless. 6.14E: Desiccation. In Microbiology; LibreTexts: Davis, CA, USA, 2021. [Google Scholar]

- Vega-Mercado, H.; Marcela Góngora-Nieto, M.; Barbosa-Cánovas, G.V. Advances in Dehydration of Foods. J. Food Eng. 2001, 49, 271–289. [Google Scholar] [CrossRef]

- Alibert; Ama-fessional Molder. 3D Print Board Filament Dryer Discussion page 1. Available online: https://3dprintboard.com/showthread.php?27550-Filament-Dryer (accessed on 9 June 2020).

- Sherman, L.M. Resin Dryers: Which Type Is Right for You? Plastics Technology. 2005. Available online: https://www.ptonline.com/articles/resin-dryers-which-type-is-right-for-you (accessed on 19 May 2021).

- Barley, J. Basic Principles of Freeze Drying. Available online: https://www.spscientific.com/freeze-drying-lyophilization-basics/ (accessed on 27 March 2021).

- Yao, C.; Qian, X.-D.; Zhou, G.-F.; Zhang, S.-W.; Li, L.-Q.; Guo, Q.-S. A Comprehensive Analysis and Comparison between Vacuum and Electric Oven Drying Methods on Chinese Saffron (Crocus sativus L.). Food Sci. Biotechnol. 2018, 28, 355–364. [Google Scholar] [CrossRef]

- 3DXTech. Drying Instructions. Available online: https://www.3dxtech.com/drying-instructions/ (accessed on 8 June 2020).

- eSun. EBOX. Available online: http://www.esunchina.net/products/246.html (accessed on 8 June 2020).

- 3D Print Board. Filament Dryer. Available online: https://3devo.com/blog/best-ways-to-store-your-3d-printing-filament/ (accessed on 9 June 2020).

- CNC Kitchen. Investigating Different Methods of Filament Drying (Dehydrator, Vacuum, Oven & Desiccant). Available online: https://www.cnckitchen.com/blog/cyo43tzz88uqge65xgwz0wv8yvv3rs (accessed on 30 March 2020).

- HarvestRight. Home Freeze Dryer. Available online: https://harvestright.com/product/home-freeze-dryer/ (accessed on 30 March 2021).

- AMTechniques. Vacuum Filament Dryer. Available online: https://www.kickstarter.com/projects/gertjan-mulder/vacuum-filament-dryer (accessed on 30 March 2021).

- Novatec. Vacuum Dryers. Available online: https://www.ptonline.com/knowledgecenter/plastics-drying/dryer-types/vacuum-dryers (accessed on 8 June 2020).

- Hubbard, B.R.; Pearce, J.M. Open-Source Digitally Replicable Lab-Grade Scales. Instruments 2020, 4, 18. [Google Scholar] [CrossRef]

- SUNCOO 2 Gallon Stainless Steel Vacuum Chamber for Degassing Urethanes, Resins, Silicones and Epoxies. Available online: https://www.amazon.com/SUNCOO-Stainless-Degassing-Urethanes-Silicones/dp/B078K9Q3F9 (accessed on 29 March 2021).

- Yunus, A.C.; Michael, A.B. Table A-4 Saturated Water. In Thermodynamics: An Engineering Approach 8e; McGraw Hill Education: New York, NY, USA, 2016; pp. 904–905. ISBN 978-93-392-2165-2. [Google Scholar]

- Engineering Toolbox. Water-Boiling Points at Vacuum Pressure. Available online: https://www.engineeringtoolbox.com/water-evacuation-pressure-temperature-d_1686.html (accessed on 29 March 2021).

- INNOVA 3620 Vacuum/Carburetor Fuel Pressure Tester. Available online: https://www.amazon.com/INNOVA-3620-Vacuum-Carburetor-Pressure/dp/B000EW0KPY (accessed on 30 March 2021).

- CRAFTSMAN 6-Gallon Single Stage Portable Electric Pancake Air Compressor. Available online: https://www.lowes.com/pd/CRAFTSMAN-6-Gallon-Single-Stage-Portable-Electric-Pancake-Air-Compressor/1000595167 (accessed on 30 March 2021).

- Blatchley, C.G. Selection of Air Ejectors. Schutte & Koerting. Available online: https://www.s-k.com/technical-references/air_ejector_selection.pdf (accessed on 19 May 2021).

- Dandachi, J.M.A. Steam Air Ejector Performance and Its Dimensional Parameters. Ph.D. Thesis, Loughborough University, Loughborough, UK, 1990. Available online: https://hdl.handle.net/2134/7041 (accessed on 19 May 2021).

- Hill, G.F.; Sachse, G.W. Venturi Air-Jet Vacuum Ejectors for High-Volume Atmospheric Sampling on Aircraft Platforms; NASA: Washington, DC, USA, 1992; p. 45.

- Hall, N. Nozzle Design—Converging/Diverging (CD) Nozzle. Available online: https://www.grc.nasa.gov/WWW/K-12/airplane/nozzled.html (accessed on 18 August 2020).

- Hydraulics Pneumatics. Compressed Air Guide: Pull, Don’t Push. Hydraulics & Pneumatics. 2014. Available online: https://www.hydraulicspneumatics.com/technologies/air-compressors/article/21884511/compressed-air-guide-pull-dont-push (accessed on 19 May 2021).

- Fixed-Flow Air-Powered Vacuum Pump. Available online: https://www.mcmaster.com/9997K15/ (accessed on 29 March 2021).

- BAPI. Thermistor vs RTD Temperature Measurement Accuracy—Application Note. Available online: https://www.bapihvac.com/application_note/thermistor-vs-rtd-temperature-measurement-accuracy-application-note/ (accessed on 9 June 2020).

- Williams, A. Thermistors and 3D Printing. Hackaday. 2017. Available online: https://hackaday.com/2017/12/15/thermistors-and-3d-printing/ (accessed on 19 May 2021).

- Banzi, M.; Shiloh, M. Getting started with Arduino: The Open Source Electronics Prototyping Platform; Maker Media, Inc.: Sebastopol, CA, USA, 2014. [Google Scholar]

- Microstar Laboratories. Calibrate Thermistors. Available online: http://www.mstarlabs.com/sensors/thermistor-calibration.html (accessed on 29 March 2021).

- Amtherm. The Secret to Successful Thermistor Beta Calculations. Available online: https://www.ametherm.com/blog/thermistors/thermistor-beta-calculations (accessed on 7 July 2020).

- Electronics Tutorials. Thermistors and NTC Thermistors. Available online: https://www.electronics-tutorials.ws/io/thermistors.html (accessed on 22 March 2021).

- Tempco. Duraband Maximum Watt Densities. Available online: https://www.tempco.com/Tempco/Resources/01-Band-Resources/DurabandsWattDnsty.pdf (accessed on 30 March 2020).

- Hubbard, B.; Pearce, J.M. Open Source Vacuum Oven for Low-Temperature Drying. Available online: https://osf.io/vf2b8/ (accessed on 19 May 2021).

- Reflectix 16 in. x 25 Ft. Double Reflective Insulation Roll with Staple Tab Edge-ST16025. Available online: https://www.homedepot.com/p/Reflectix-16-in-x-25-ft-Double-Reflective-Insulation-Roll-with-Staple-Tab-Edge-ST16025/100012574 (accessed on 30 March 2021).

- 3M High Temperature Flue Tape, High Heat Sealing Tape up to 600 Degrees, 15-Foot Roll. Available online: https://www.amazon.com/3M-High-Temperature-Flue-15-Foot/dp/B00004Z4DS (accessed on 30 March 2021).

- ABN Silicone Heating Pad 120V—4 × 5 Inch Universal Engine Heater Car Oil Pan Heater Pad, 150W Electric Heater Pad. Available online: https://www.amazon.com/ABN-Automotive-Electric-Silicone-Heating/dp/B077J5DSFJ (accessed on 30 March 2021).

- G3NA-210B-UTU DC5-24 Omron Automation and Safety. Available online: https://www.mouser.com/ProductDetail/653-G3NA210BUTUDC524 (accessed on 30 March 2021).

- Creality 3D Printer NTC Thermistor Temp Sensor 100K for Ender 3/Ender 3 Pro/Ender 5/CR-10/CR-10S. Available online: https://www.amazon.com/Printer-Thermistor-Sensor-Reprap-Comgrow/dp/B0714MR5BC (accessed on 30 March 2021).

- E-Projects 100EP51210K0 10k Ohm Resistors, 1/2 W, 5% (Pack of 100). Available online: https://www.amazon.com/Projects-100EP51210K0-10k-Resistors-Pack/dp/B0185FIOTA (accessed on 30 March 2021).

- Arduino Nano. Available online: https://store.arduino.cc/usa/arduino-nano (accessed on 30 March 2021).

- ELEGOO Nano Board CH340/ATmega328P Without USB Cable, Compatible with Arduino Nano V3.0 (Nano x 3 Without Cable). Available online: https://www.amazon.com/ELEGOO-Arduino-ATmega328P-Without-Compatible/dp/B0713XK923 (accessed on 30 March 2021).

- Monoprice 3-Feet USB A to Mini-B 5pin 28/28AWG Cable (103896) Black. Available online: https://www.amazon.com/Monoprice-3-Feet-mini-B-28AWG-103896/dp/B003L18SHC/ (accessed on 30 March 2021).

- Geekcreit 40pcs FR-4 2.54mm Double Side Prototype PCB Printed Circuit Board. Available online: https://www.banggood.com/Geekcreit-40pcs-FR-4-2_54mm-Double-Side-Prototype-PCB-Printed-Circuit-Board-p-995732.html (accessed on 30 March 2021).

- DEPEPE 30 Pcs 40 Pin 2.54mm Male and Female Pin Headers for Arduino Prototype Shield. Available online: https://www.amazon.com/DEPEPE-2-54mm-Headers-Arduino-Prototype/dp/B074HVBTZ4/ (accessed on 30 March 2021).

- Plusivo 22AWG Hook up Wire Kit—600V Tinned Stranded Silicone Wire of 6 Different Colors x 23 Ft Each. Available online: https://www.plusivo.com/home/67-plusivo-22awg-hook-up-wire-kit-600v-tinned-stranded-silicone-wire-of-6-different-colors-x-23-ft-each.html (accessed on 30 March 2021).

- Reflectix Inc. Installation Instructions for Reflectix, Inc. Double Reflective Insulation. Available online: https://images.homedepot-static.com/catalog/pdfImages/5a/5ab3af4c-631f-416d-af7c-b7aeb41f51a2.pdf (accessed on 30 March 2021).

- FreeCAD. Available online: https://www.freecadweb.org/ (accessed on 30 March 2021).

- OpenSCAD. Available online: http://openscad.org (accessed on 30 March 2021).

- Kirshner, D. Thread-Drawing Modules for OpenSCAD. Available online: https://dkprojects.net/openscad-threads/ (accessed on 30 March 2021).

- GNU General Public License Version 3. Available online: https://www.gnu.org/licenses/gpl-3.0.en.html (accessed on 30 March 2021).

- Corona688. OpenSCAD NPT/Tsmthread 0.4. Available online: https://www.thingiverse.com/thing:3391213 (accessed on 30 March 2021).

- Creative Commons—Attribution-NonCommercial 3.0 Unported—CC BY-NC 3.0. Available online: https://creativecommons.org/licenses/by-nc/3.0/ (accessed on 30 March 2021).

- Anzalone, G.; Wijnen, B.; Pearce, J. Multi-Material Additive and Subtractive Prosumer Digital Fabrication with a Free and Open-Source Convertible Delta RepRap 3-D Printer. Rapid Prototyp. J. 2015, 21, 506–519. [Google Scholar] [CrossRef]

- Ultimaker. Ultimaker Cura 4.7.1. Available online: https://github.com/Ultimaker/Cura (accessed on 30 March 2021).

- Buckeye Hydro. Should I Use Teflon Tape? Available online: https://www.buckeyehydro.com/blog/should-i-use-teflon-tape/ (accessed on 19 May 2021).

- SciPy Optimization and Root Finding (Scipy.Optimize). Available online: https://docs.scipy.org/doc/scipy/reference/optimize.html (accessed on 30 March 2021).

- Hrisko, J. Arduino Thermistor Theory, Calibration, and Experiment. Maker Portal. 2019. Available online: https://makersportal.com/blog/2019/1/15/arduino-thermistor-theory-calibration-and-experiment (accessed on 19 May 2021).

- Salimov, Y. NTC_Thermistor. Available online: https://github.com/YuriiSalimov/NTC_Thermistor (accessed on 30 March 2021).

- Novatec. Hygroscopic VS Non-Hygroscopic Resins. Available online: https://www.ptonline.com/knowledgecenter/plastics-drying/resin-types/hygroscopic-vs-non-hygroscopic-resins (accessed on 8 June 2020).

- Lee, J.H.; Lim, K.; Hahm, W.; Kim, S. Properties of Recycled and Virgin Poly(Ethylene Terephthalate) Blend Fibers. J. Appl. Polym. Sci. 2013, 128. [Google Scholar] [CrossRef]

- Zander, N.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled Polypropylene Blends as Novel 3D Printing Materials. Addit. Manuf. 2018, 25. [Google Scholar] [CrossRef]

- Idrees, M.; Jeelani, S.; Rangari, V. 3D Printed Sustainable Biochar-Recycled PET Composite. Acs Sustain. Chem. Eng. 2018, 6. [Google Scholar] [CrossRef]

- Baechler, C.; DeVuono, M.; Pearce, J.M. Distributed recycling of waste polymer into RepRap feedstock. Rapid Prototyp. J. 2013, 19, 118–125. [Google Scholar] [CrossRef]

- Woern, A.L.; McCaslin, J.R.; Pringle, A.M.; Pearce, J.M. RepRapable Recyclebot: Open source 3-D printable extruder for converting plastic to 3-D printing filament. HardwareX 2018, 4, e00026. [Google Scholar] [CrossRef]

- Karegoudar, T.B.; Pujar, B.G. Degradation of Terephthalic Acid by a Bacillus Species. FEMS Microbiol. Lett. 1985, 30, 217–220. [Google Scholar] [CrossRef]

- Vamsee-Krishna, C.; Mohan, Y.; Phale, P. Biodegradation of Phthalate Isomers by Pseudomonas Aeruginosa PP4, Pseudomonas Sp. PPD and Acinetobacter Lwoffii ISP4. Appl. Microbiol. Biotechnol. 2006, 72, 1263–1269. [Google Scholar] [CrossRef]

- Ritala, A.; Häkkinen, S.T.; Toivari, M.; Wiebe, M.G. Single Cell Protein—State-of-the-Art, Industrial Landscape and Patents 2001–2016. Front. Microbiol. 2017, 8, 2009. [Google Scholar] [CrossRef]

- García Martínez, J.B.; Egbejimba, J.; Throup, J.; Matassa, S.; Pearce, J.; Denkenberger, D. Potential of Microbial Protein from Hydrogen for Preventing Mass Starvation in Catastrophic Scenarios. Sustain. Prod. Consum. 2020, 25, 234–247. [Google Scholar] [CrossRef]

- García Martínez, J.B.; Pearce, J.M.; Cates, J.; Denkenberger, D. Methane Single Cell Protein: Securing Protein Supply During Global Food Catastrophes. Available online: https://osf.io/94mkg (accessed on 19 May 2021).

- Rosewill. Countertop Portable Electric Food Fruit Dehydrator Machine with Adjustable Thermostat, BPA-Free, 5-Tray, RHFD-15001. Available online: /ip/Rosewill-Countertop-Portable-Electric-Food-Fruit-Dehydrator-Machine-with-Adjustable-Thermostat-BPA-Free-5-Tray-RHFD-15001/51409615 (accessed on 31 March 2021).

- P3. Kill A Watt Meter—Electricity Usage Monitor. Available online: http://www.p3international.com/products/p4400.html (accessed on 31 March 2021).

- MH Build Series PLA Filament—1.75mm (1 kg). Available online: https://www.matterhackers.com/store/3d-printer-filament/175mm-pla-filament-red-1-kg (accessed on 31 March 2021).

- Pearce, J.M. Economic Savings for Scientific Free and Open Source Technology: A Review. HardwareX 2020, 8, e00139. [Google Scholar] [CrossRef]

- YamatoADP. Series 220V Vacuum Drying Ovens—Ovens and Furnaces, Vacuum Ovens. Available online: https://www.fishersci.com/shop/products/yamato-adp-series-220v-vacuum-drying-ovens-2/1326320 (accessed on 31 March 2021).

- Oberloier, S.; Pearce, J. General Design Procedure for Free and Open-Source Hardware for Scientific Equipment. Designs 2017, 2, 2. [Google Scholar] [CrossRef]

- Gibb, A. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers; Pearson Education: London, UK, 2014. [Google Scholar]

- Chagas, A.M. Haves and Have Nots Must Find a Better Way: The Case for Open Scientific Hardware. PLoS Biol. 2018, 16, e3000014. [Google Scholar] [CrossRef]

- Powell, A. Democratizing Production through Open Source Knowledge: From Open Software to Open Hardware. Media Cult. Soc. 2012, 34, 691–708. [Google Scholar] [CrossRef]

- Vacuum Science World. The Fundamentals of Vacuum Science. Available online: https://www.vacuumscienceworld.com/vacuum-science (accessed on 29 March 2021).

- ABLAZE 3 Gallon Stainless Steel Vacuum Degassing Chamber and 3 CFM Single Stage Pump Kit. Available online: https://www.amazon.com/ABLAZE-Gallon-Stainless-Degassing-Chamber/dp/B076KNYCZ6/ (accessed on 29 March 2021).

- VAC AERO. International Gas Ballasting of Mechanical Oil Sealed Rotary Vacuum Pumps. Available online: https://vacaero.com/information-resources/vacuum-pump-technology-education-and-training/666-gas-ballasting-of-mechanical-oil-sealed-rotary-vacuum-pumps.html (accessed on 30 July 2020).

- Schach, A. How to Select the Right Vacuum Pump; Labconco: Kansas City, MO, USA, 2016. [Google Scholar]

| Property | Value |

|---|---|

| Layer Height | 0.2 mm |

| Wall Thickness | 2 mm |

| Top/Bottom Thickness | 0.8 mm |

| Infill | Cubic, 20% |

| Nozzle Temperature | 210 °C |

| Print Speed | Infill/Support: 70 mm/s, Wall: 35 mm/s |

| Outer Wall Speed | 35 mm/s |

| Retraction | Yes |

| Print Cooling | No |

| Support | Build-plate only, 50 deg, 15% density |

| Adhesion Type | Brim |

| Temperature Range (°C) | Reference Resistance, R0 (kOhm) | ADC Range Utilized |

|---|---|---|

| 50–60 | 30 | 9% |

| 60–70 | 21 | 9% |

| 70–80 | 15 | 8% |

| 50–80 | 21 | 25% |

| Temperature (°C) | Reference Resistance, R0 (kOhm) |

|---|---|

| 25 | 100 |

| 0 | 310 |

| 100 | 7.1 |

| Coefficient | Value |

|---|---|

| Ka | 6.9 × 10−4 |

| Kb | 2.1 × 10−4 |

| Kc | 1.3 × 10−7 |

| Temperatures Used | Beta |

|---|---|

| 25, 0 | 3690 |

| 0, 100 | 3850 |

| 25, 100 | 3920 |

| Nominal | 3950 |

| Test Description | Device | Drying Time | Energy Consumed (Average Specific Energy) |

|---|---|---|---|

| 10 g rPET, 70 °C | Vacuum Oven | 75 min | 0.51 kWh (1.55 kWh/g) |

| Dehydrator | 60 min | 0.23 kWh (0.70 kWh/g) | |

| 10 g rPET, 80 °C | Vacuum Oven | 45 min | 0.28 kWh (0.80 kWh/g) |

| Dehydrator | 75 min | 0.30 kWh (0.83 kWh/g) | |

| 350 g rPET | Vacuum Oven | 180+ min | 1.30+ kWh (0.12 kWh/g) |

| Dehydrator | 60 min | 0.45 kWh (0.04 kWh/g) | |

| Biomass | Vacuum Oven | 75 min | 0.55 kWh (1.17 kWh/g) |

| Dehydrator | 150 min | 0.56 kWh (1.30 kWh/g) |

| Component | Up-Front Cost as Purchased (USD) | Effective Cost (USD) |

|---|---|---|

| Heater | $116.60 | $58.17 |

| Vacuum | $316.12 | $298.39 |

| Total | $432.72 | $356.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hubbard, B.R.; Putman, L.I.; Techtmann, S.; Pearce, J.M. Open Source Vacuum Oven Design for Low-Temperature Drying: Performance Evaluation for Recycled PET and Biomass. J. Manuf. Mater. Process. 2021, 5, 52. https://doi.org/10.3390/jmmp5020052

Hubbard BR, Putman LI, Techtmann S, Pearce JM. Open Source Vacuum Oven Design for Low-Temperature Drying: Performance Evaluation for Recycled PET and Biomass. Journal of Manufacturing and Materials Processing. 2021; 5(2):52. https://doi.org/10.3390/jmmp5020052

Chicago/Turabian StyleHubbard, Benjamin R., Lindsay I. Putman, Stephen Techtmann, and Joshua M. Pearce. 2021. "Open Source Vacuum Oven Design for Low-Temperature Drying: Performance Evaluation for Recycled PET and Biomass" Journal of Manufacturing and Materials Processing 5, no. 2: 52. https://doi.org/10.3390/jmmp5020052

APA StyleHubbard, B. R., Putman, L. I., Techtmann, S., & Pearce, J. M. (2021). Open Source Vacuum Oven Design for Low-Temperature Drying: Performance Evaluation for Recycled PET and Biomass. Journal of Manufacturing and Materials Processing, 5(2), 52. https://doi.org/10.3390/jmmp5020052