Influence of Tool Length and Profile Errors on the Inaccuracy of Cubic-Machining Test Results

Abstract

1. Introduction

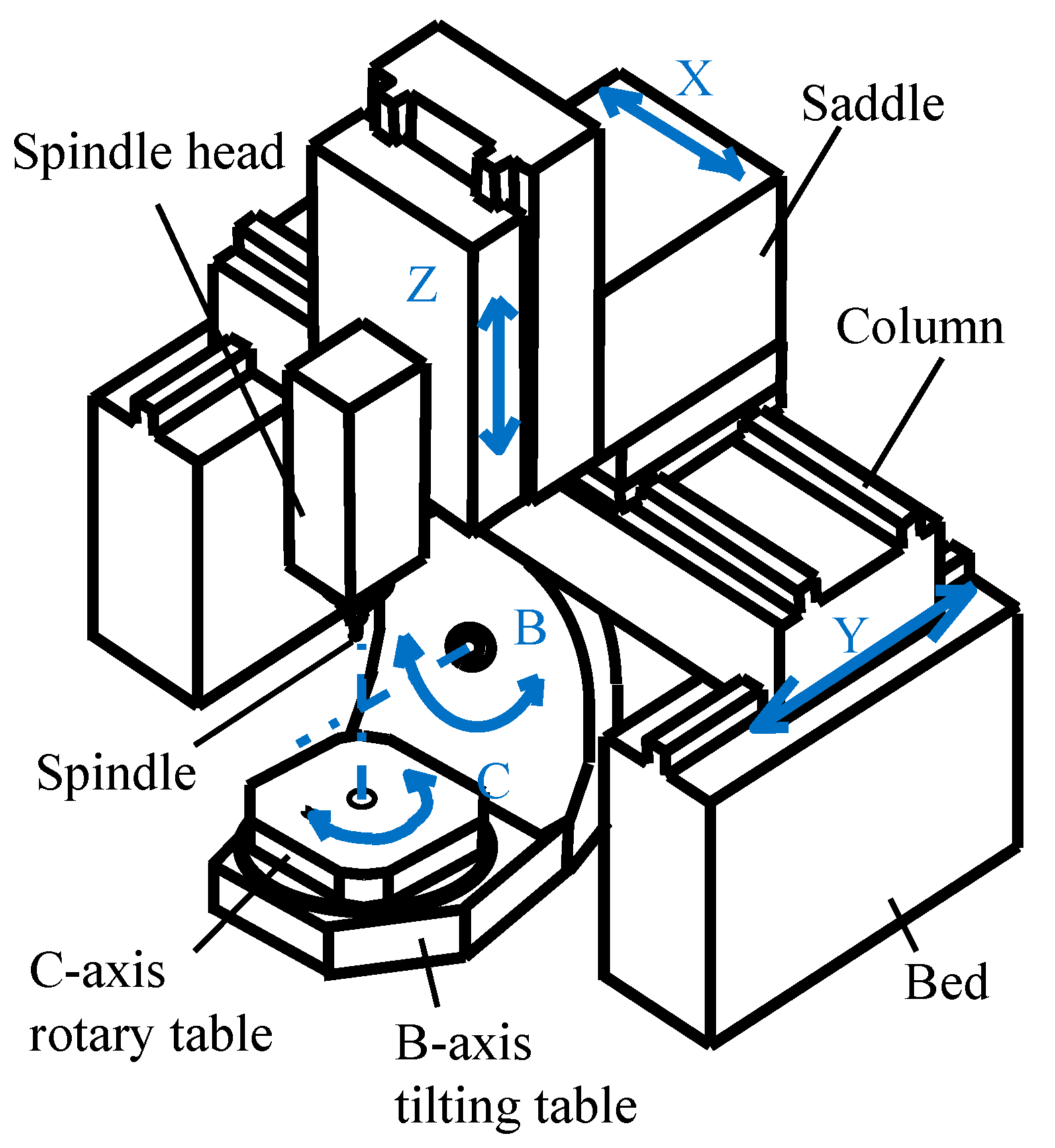

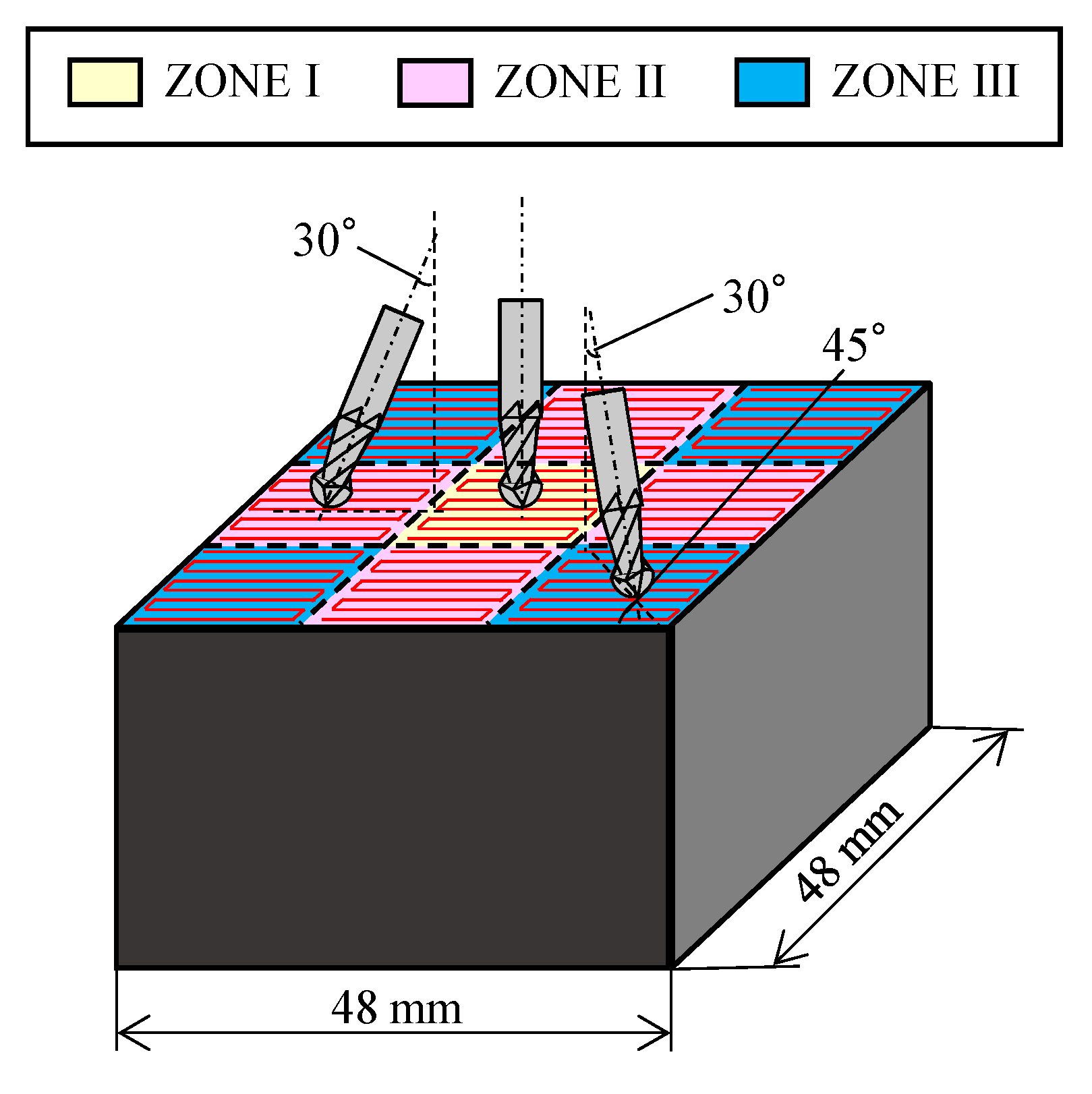

2. Cubic-Machining Test

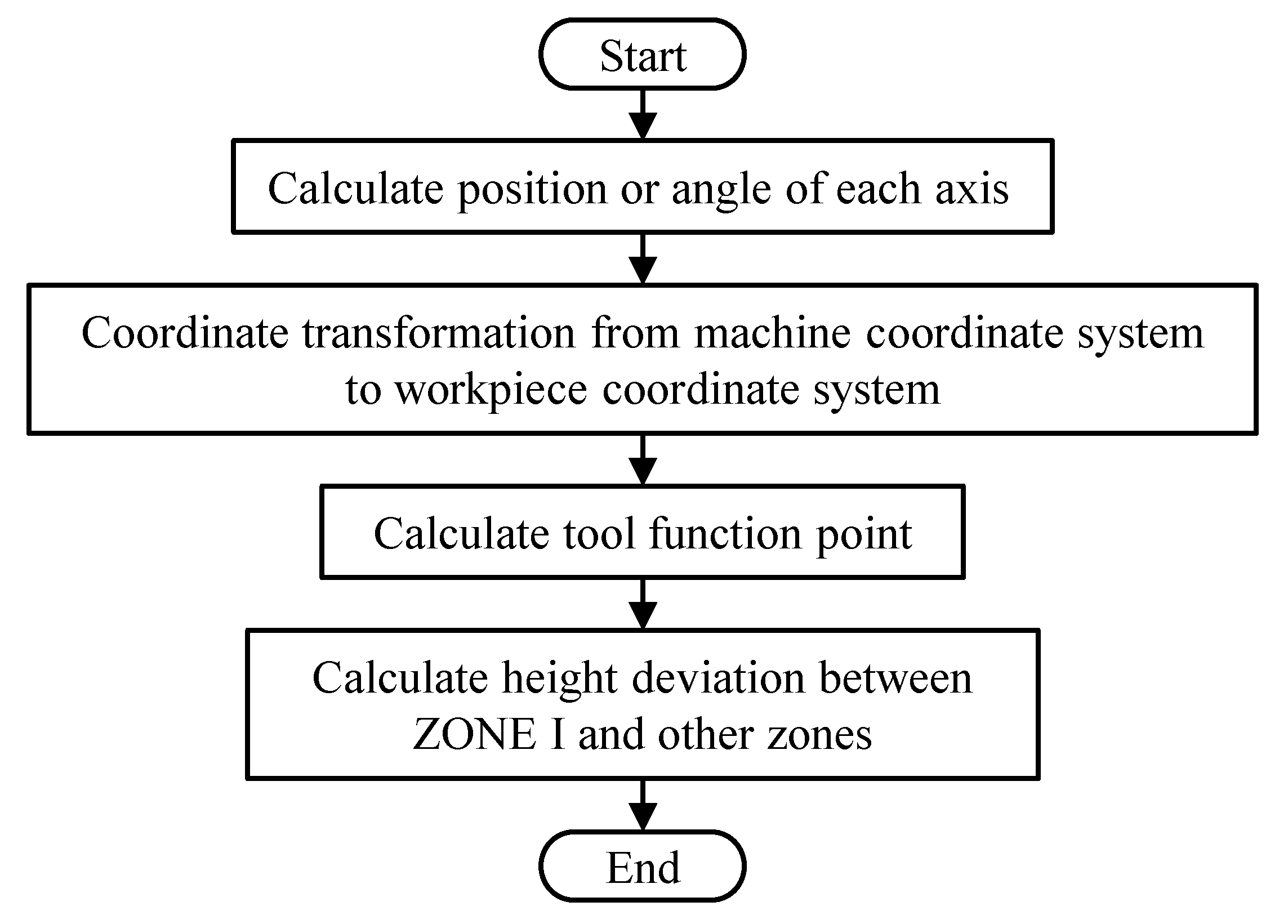

3. Formulation of Tool Length Error Influence

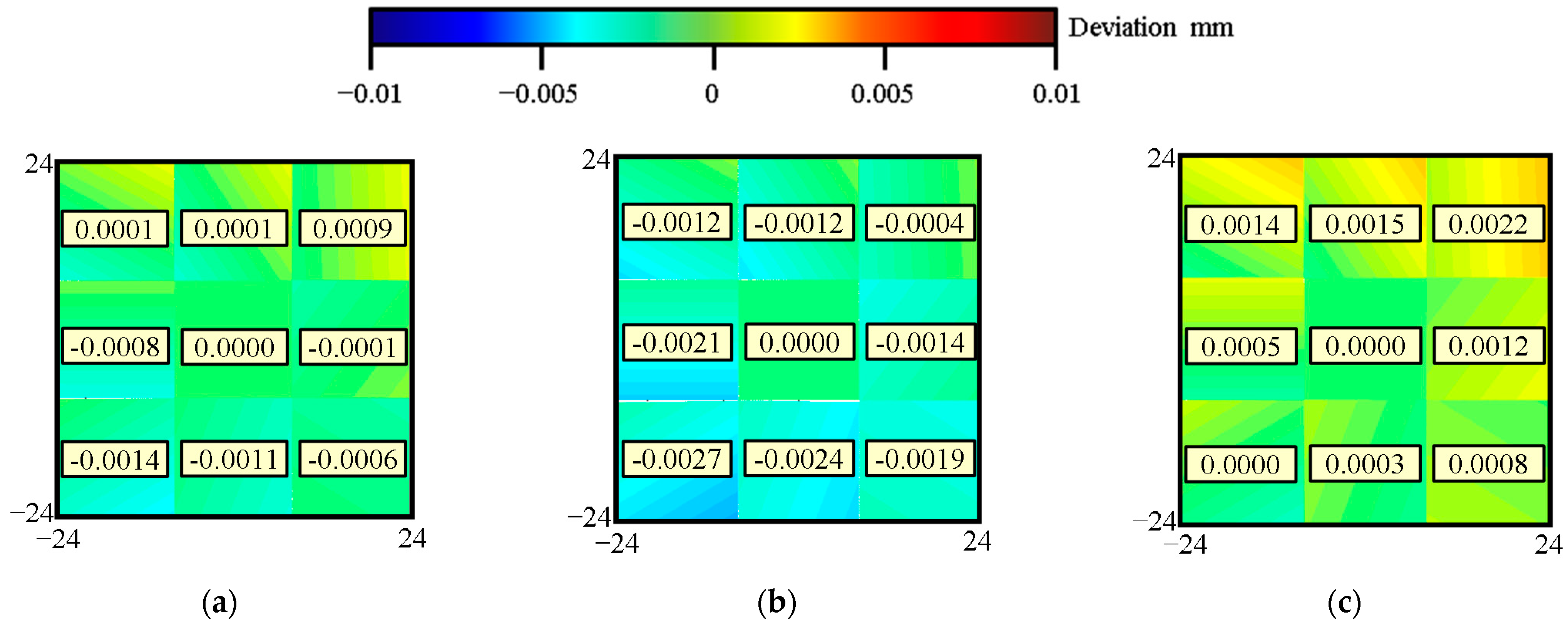

4. Simulation and Experiment with Tool Length Error

4.1. Tool Length Measurement

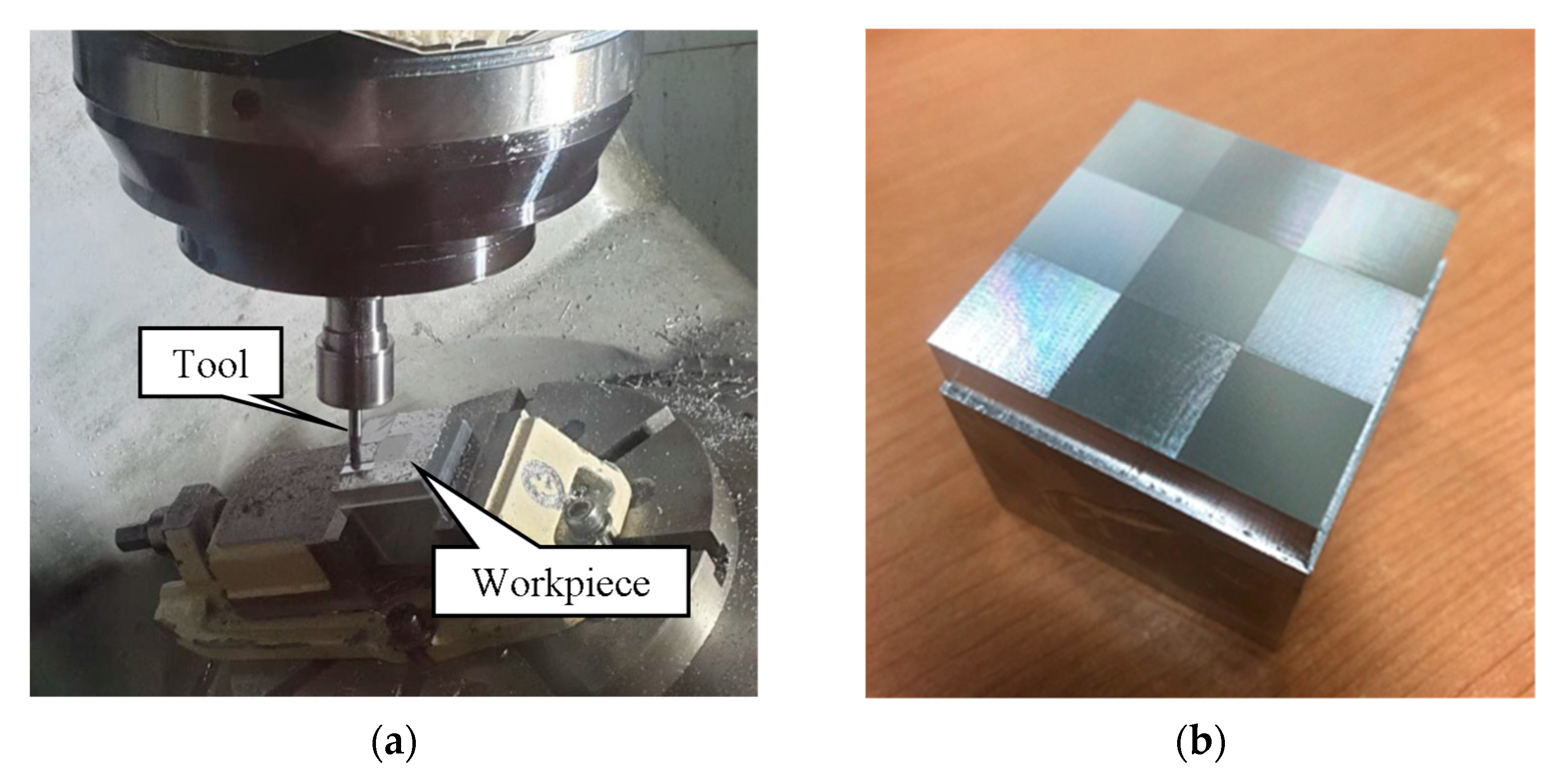

4.2. Experiment with Tool Length Errors

4.3. Simulation with Tool Length Error

5. Tool Profile Accuracy Influence

6. Conclusions

- (1)

- Results of actual machining tests and simulations with intentional tool length errors mentioned in Section 4.2 and Section 4.3 indicate that the tool length error directly affects the machined accuracy, and the tendency of the influence of the error is in agreement with the expected one in general.

- (2)

- Results obtained from comparison between the deviation results in Section 4.2 and the tool profile accuracy in Section 5 suggest that the tool profile should be carefully considered in the evaluation of the cubic-machining test accuracy.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xiang, X.; Altintas, Y. Modeling and compensation of volumetric errors for five-axis machine tools. Int. J. Mach. Tools Manufact. 2016, 101, 65–78. [Google Scholar] [CrossRef]

- Lasemi, A.; Xue, D.; Gu, P. Accurate identification and compensation of geometric errors of 5–axis CNC machine tools using double ball bar. Meas. Sci. Technol. 2016, 27, 055004. [Google Scholar] [CrossRef]

- Fortunato, A.; Valli, G.; Liverani, E.; Ascari, A. Additive manufacturing of WC-Co cutting tools for gear production. Lasers Manuf. Mater. Process. 2019, 6, 247–262. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Wang, D.; Nie, L.; Wellman, D.; Tian, Y. Additive manufacturing of WC-Co hardmetals: A review. Int. J. Adv. Manuf. Technol. 2020, 180, 1653–1673. [Google Scholar] [CrossRef]

- He, Z.; Fu, J.; Zhang, L.; Yao, X. A new error measurement method to identify all six error parameters of a rotational axis of a machine tool. Int. J. Mach. Tools Manuf. 2015, 88, 1–8. [Google Scholar] [CrossRef]

- Fan, J.; Tao, J.H.; Pan, R.; Chen, D. An approach for accuracy enhancement of five-axis machine tools based on quantitative interval sensitivity analysis. Mech. Mach. Theory 2020, 148, 103806. [Google Scholar] [CrossRef]

- ISO 10791-6. Test Condition for Machining Centers—Part 6: Accuracy of Speeds and Interpolations; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Chen, Y.; More, P.; Liu, C. Identification and verification of location errors of rotary axes on five-axis machine tools by using a touch-trigger probe and a sphere. Int. J. Adv. Manuf. Technol. 2019, 100, 2653–2667. [Google Scholar] [CrossRef]

- ISO 10791-7. Test Conditions for Machining Centers—Part 7: Accuracy of Finished Test Pieces; International Organization for Standardization: Geneva, Switzerland, 2020. [Google Scholar]

- Wang, W.; Jiang, Z.; Tao, W.; Zhuang, W. A new test part to identify performance of five-axis machine tool—Part I: Geometrical and kinematic characteristics of S part. Int. J. Adv. Manuf. Tech. 2015, 79, 729–738. [Google Scholar] [CrossRef]

- Wang, W.; Jiang, Z.; Li, Q.; Tao, W. A new test part to identify performance of five-axis machine tool—Part II: Validation of S part. Int. J. Adv. Manuf. Tech. 2015, 79, 739–756. [Google Scholar] [CrossRef]

- Sato, R.; Shirase, K.; Ihara, Y. Influence of NC program quality and geometric errors of rotary axes on S-shaped machining test accuracy. J. Manuf. Mater. Process. 2018, 2, 21. [Google Scholar] [CrossRef]

- Li, Z.; Sato, R.; Shirase, K.; Ihara, Y.; Milutinovic, D. Sensitivity analysis of relationship between error motions and machined shape errors in five-axis machining center—Peripheral milling using square-end mill as test case. Precis. Eng. 2019, 60, 28–41. [Google Scholar] [CrossRef]

- Li, Z.; Sato, R.; Shirase, K.; Ihara, Y. Influence of control mode and position loop gain on S-shape machining accuracy of five-axis machine tools. In Proceedings of the 2018 International Symposium on Flexible Automation (ISFA 2018), Kanazawa, Japan, 15–19 July 2018. ISFA2018-L014. [Google Scholar] [CrossRef]

- Sakamoto, S.; Suzuki, T.; Nakayasu, W. A machining accuracy evaluation of five-axis machining center with a 3 × 3 square-shaped machining test. In Proceedings of the 2019 JSPE annual conference in Spring, Tokyo, Japan, 13–15 March 2019; pp. 185–186. (In Japanese). [Google Scholar] [CrossRef]

- Li, Z.; Sato, R.; Shirase, K.; Sakamoto, S. Study on the influence of geometric errors in rotary axes on cubic-machining test considering the workpiece coordinate system. Precis. Eng. 2021, 71, 36–46. [Google Scholar] [CrossRef]

- Yang, J.; Mei, X.; Zhao, L.; Ma, C.; Shi, H.; Feng, B. Thermal error compensation on a computer numerical control machine tool considering thermal tilt angles and cutting tool length. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 78–97. [Google Scholar] [CrossRef]

- Senda, H.; Sato, R.; Moriwaki, T. Estimation of thermal displacement of machine tool spindles for mass production (1st Report, relation between temperature rise and thermal deformation of main spindle). Trans. JSME Ser. C 2004, 70, 171–175. [Google Scholar] [CrossRef][Green Version]

- Sato, R.; Sato, Y.; Shirase, K.; Campatelli, G.; Scippa, A. Finished surface simulation method to predicting the effects of machine tool motion errors. Int. J. Autom. Technol. 2014, 8, 801–810. [Google Scholar] [CrossRef]

- Tsutsmi, M.; Saito, A. Identification and compensation of systematic deviation particular to 5-axis machining centers. Int. J. Mach. Tools Manuf. 2003, 43, 771–780. [Google Scholar] [CrossRef]

| Tool Type | Ball-End Mill, DLC2MBR0300 from Mitsubishi Materials |

|---|---|

| Tool diameter | ϕ 6 mm |

| Number of flutes | 2 |

| Helix angle | 30° |

| Coating | DLC |

| Experiment I | Experiment II | Experiment III | |

|---|---|---|---|

| Measurement time interval (min) | 5 | 30 | 30 |

| Total time (min) | 70 | 180 | 390 |

| Machining Zones | Positive Tool Length Error Case (μm) | Negative Tool Length Error Case (μm) |

|---|---|---|

| ZONE II-1 | −3.7 | −0.5 |

| ZONE II-2 | −4.0 | 0.8 |

| ZONE II-3 | −2.4 | 2.0 |

| ZONE II-4 | −3.6 | 1.0 |

| ZONE III-1 | −2.2 | 2.9 |

| ZONE III-2 | −2.4 | 1.1 |

| ZONE III-3 | −2.9 | 1.5 |

| ZONE III-4 | −2.0 | 1.5 |

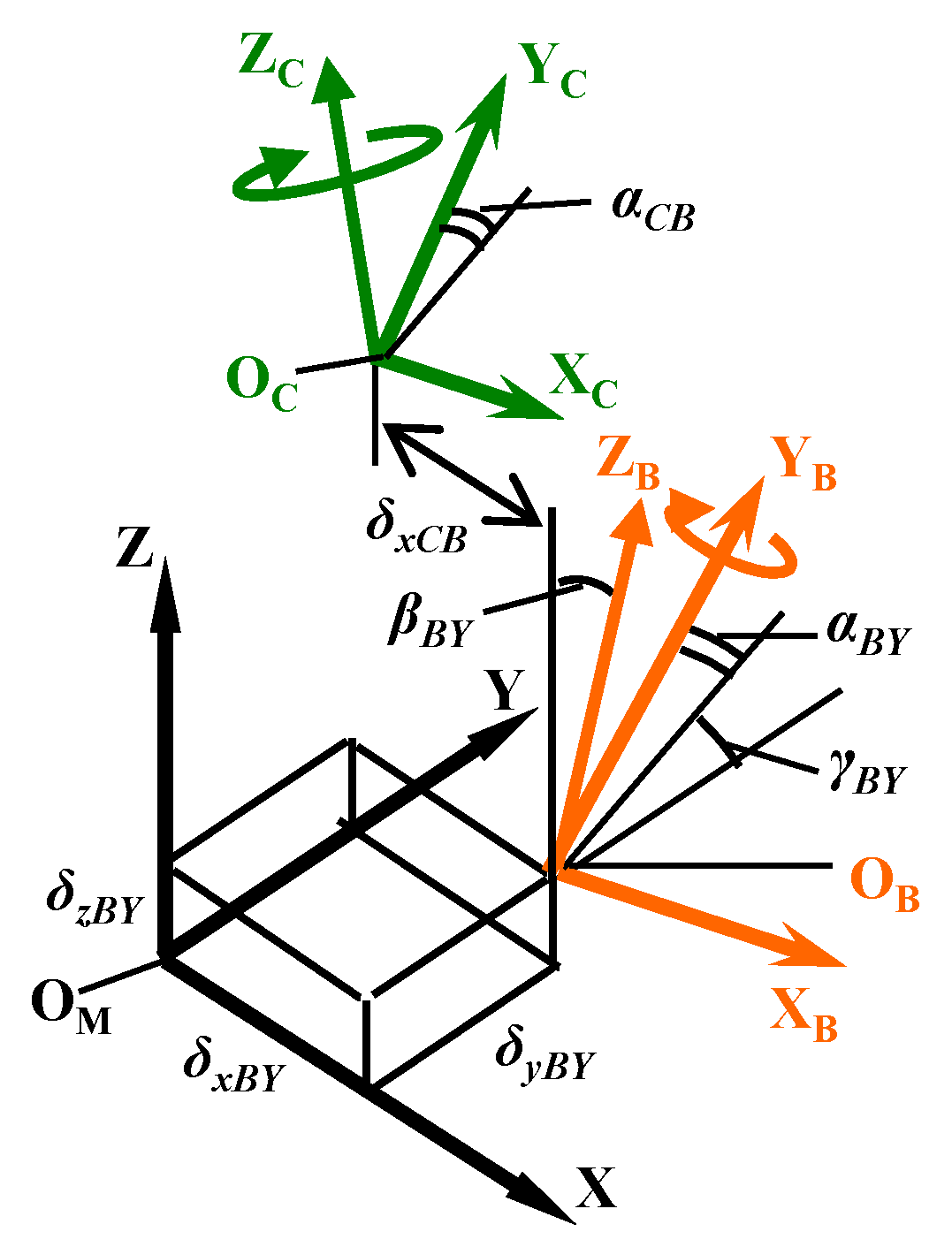

| Symbol | Description |

|---|---|

| δxBY | Positional error of B-axis average line along X-axis direction |

| δyBY | Positional error of B-axis average line along Y-axis direction |

| δzBY | Positional error of B-axis average line along Z-axis direction |

| αBY | Angular error between B-axis and Y-axis around X-axis direction |

| βBY | Angular error between B-axis and Y-axis around Y-axis direction |

| γBY | Angular error between B-axis and Y-axis around Z-axis direction |

| αCB | Angular error between C-axis and B-axis around X-axis direction |

| δxCB | Positional error of C-axis and B-axis along X-axis direction |

| Item | δxBY (µm) | δyBY (µm) | δzBY (µm) | αBY (°) | βBY (°) | γBY (°) | αCB (°) | δxCB (µm) |

|---|---|---|---|---|---|---|---|---|

| Value | 2.0 | −11.0 | −0.647 | 0.0017 | 0.0019 | 0.0210 | −0.0054 | 9.7 |

| Machining Zones | Positive Tool Length Error Case (μm) | Negative Tool Length Error Case (μm) |

|---|---|---|

| ZONE II-1 | −1.3 | 1.3 |

| ZONE II-2 | −1.3 | 1.4 |

| ZONE II-3 | −1.3 | 1.3 |

| ZONE II-4 | −1.3 | 1.4 |

| ZONE III-1 | −1.3 | 1.4 |

| ZONE III-2 | −1.3 | 1.4 |

| ZONE III-3 | −1.3 | 1.3 |

| ZONE III-4 | −1.3 | 1.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Ogata, H.; Sato, R.; Shirase, K.; Sakamoto, S. Influence of Tool Length and Profile Errors on the Inaccuracy of Cubic-Machining Test Results. J. Manuf. Mater. Process. 2021, 5, 51. https://doi.org/10.3390/jmmp5020051

Li Z, Ogata H, Sato R, Shirase K, Sakamoto S. Influence of Tool Length and Profile Errors on the Inaccuracy of Cubic-Machining Test Results. Journal of Manufacturing and Materials Processing. 2021; 5(2):51. https://doi.org/10.3390/jmmp5020051

Chicago/Turabian StyleLi, Zongze, Hiroki Ogata, Ryuta Sato, Keiichi Shirase, and Shigehiko Sakamoto. 2021. "Influence of Tool Length and Profile Errors on the Inaccuracy of Cubic-Machining Test Results" Journal of Manufacturing and Materials Processing 5, no. 2: 51. https://doi.org/10.3390/jmmp5020051

APA StyleLi, Z., Ogata, H., Sato, R., Shirase, K., & Sakamoto, S. (2021). Influence of Tool Length and Profile Errors on the Inaccuracy of Cubic-Machining Test Results. Journal of Manufacturing and Materials Processing, 5(2), 51. https://doi.org/10.3390/jmmp5020051