Surface Integrity Investigation to Determine Rough Milling Effects for Assessment of Machining Allowance for Subsequent Finish Milling of Alloy 718

Abstract

1. Introduction

1.1. Background and Objective

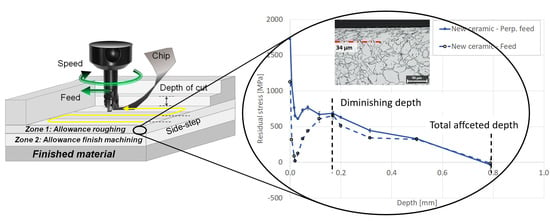

1.2. Surface Integrity in Relation to Machining Allowance

2. Materials and Methods

2.1. Material

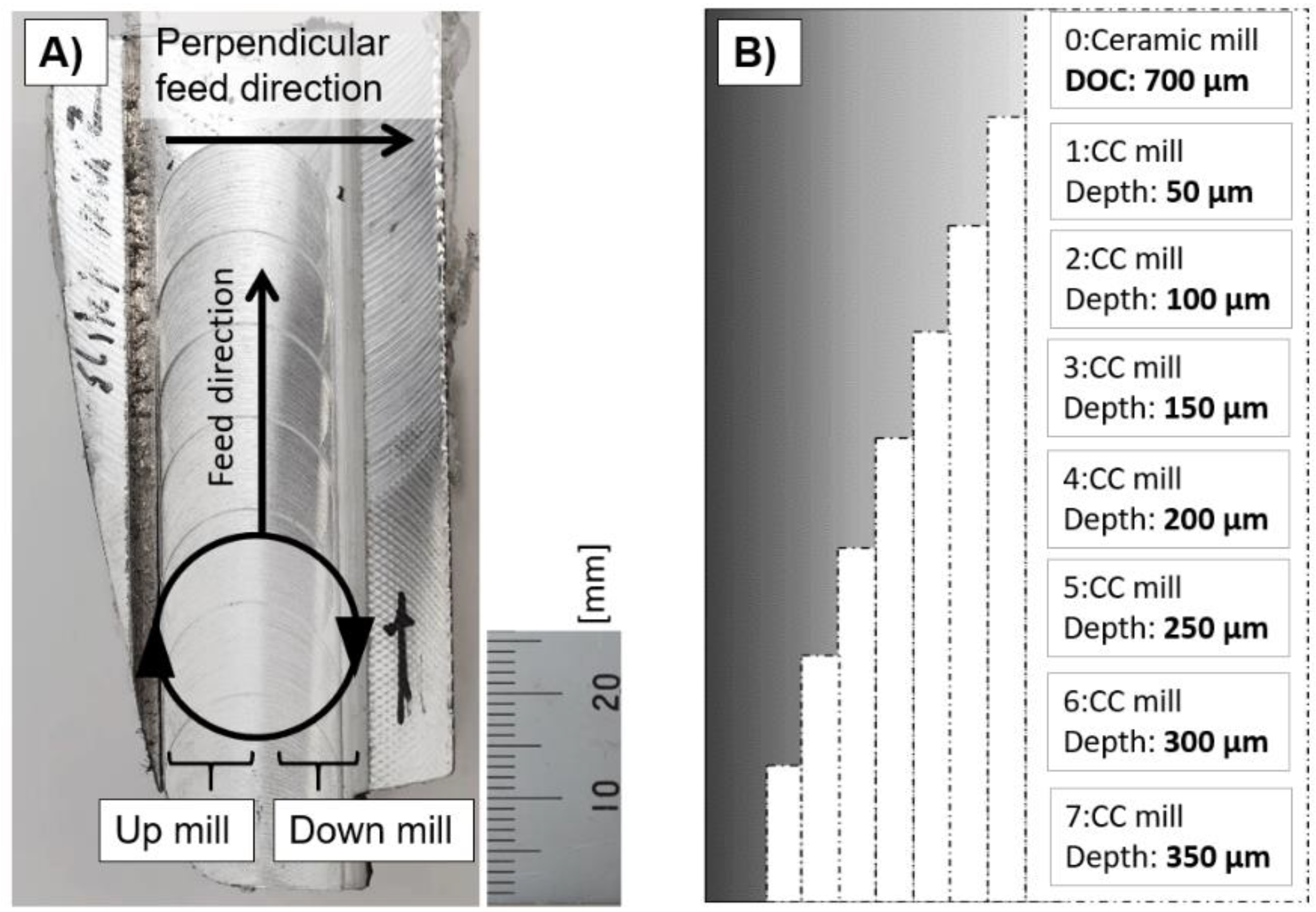

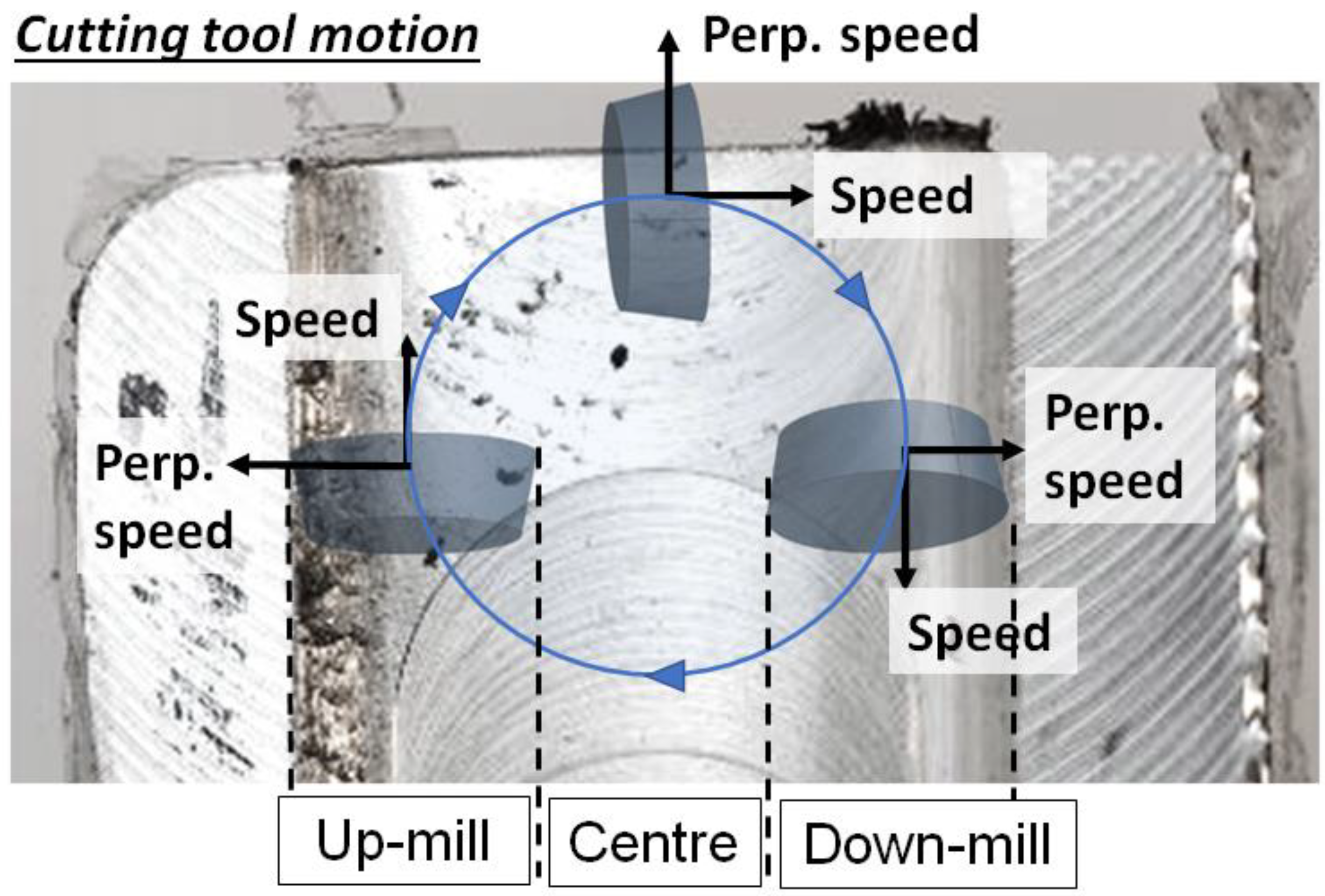

2.2. Methods

2.3. Evaluation Methods

3. Results

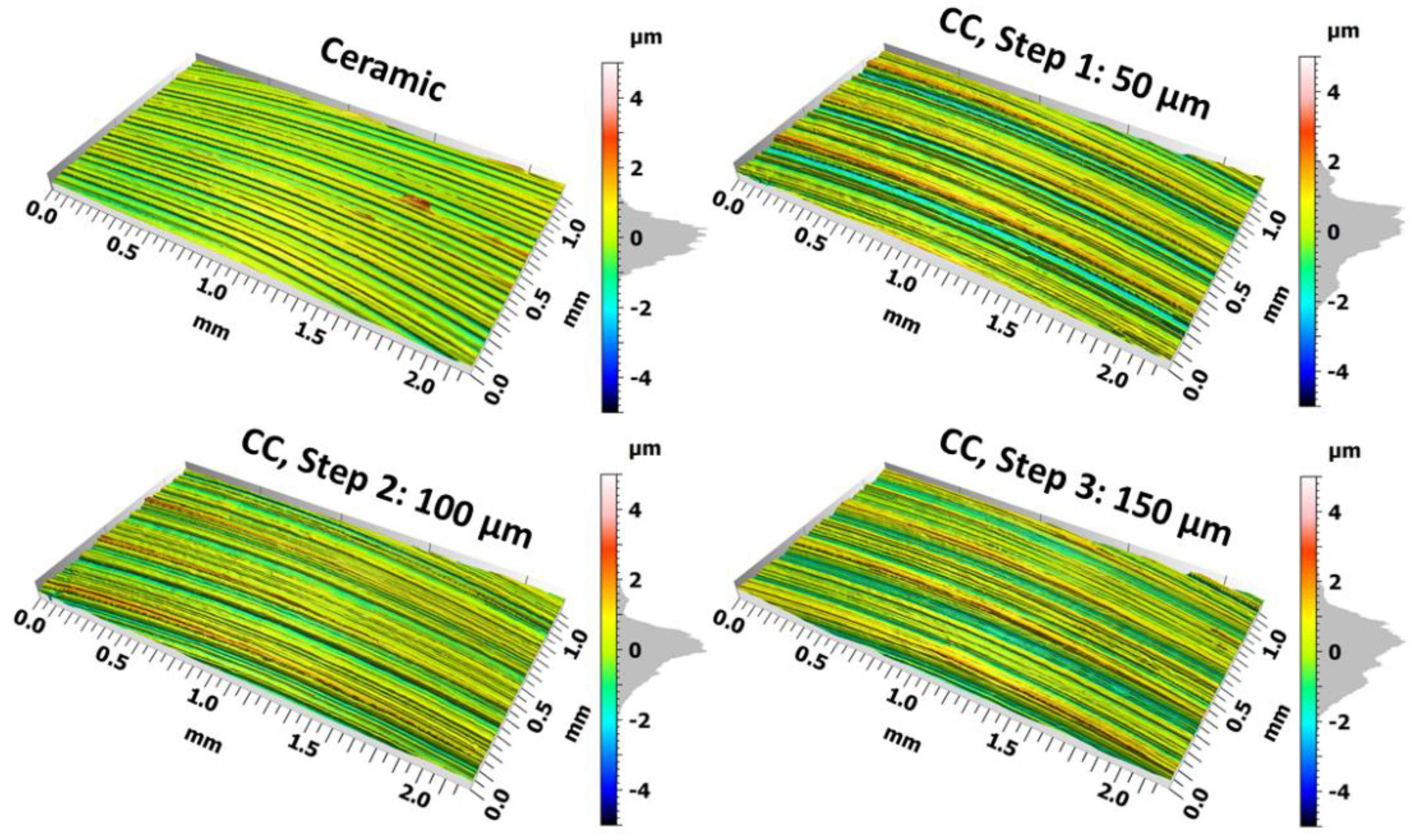

3.1. Surface Topography

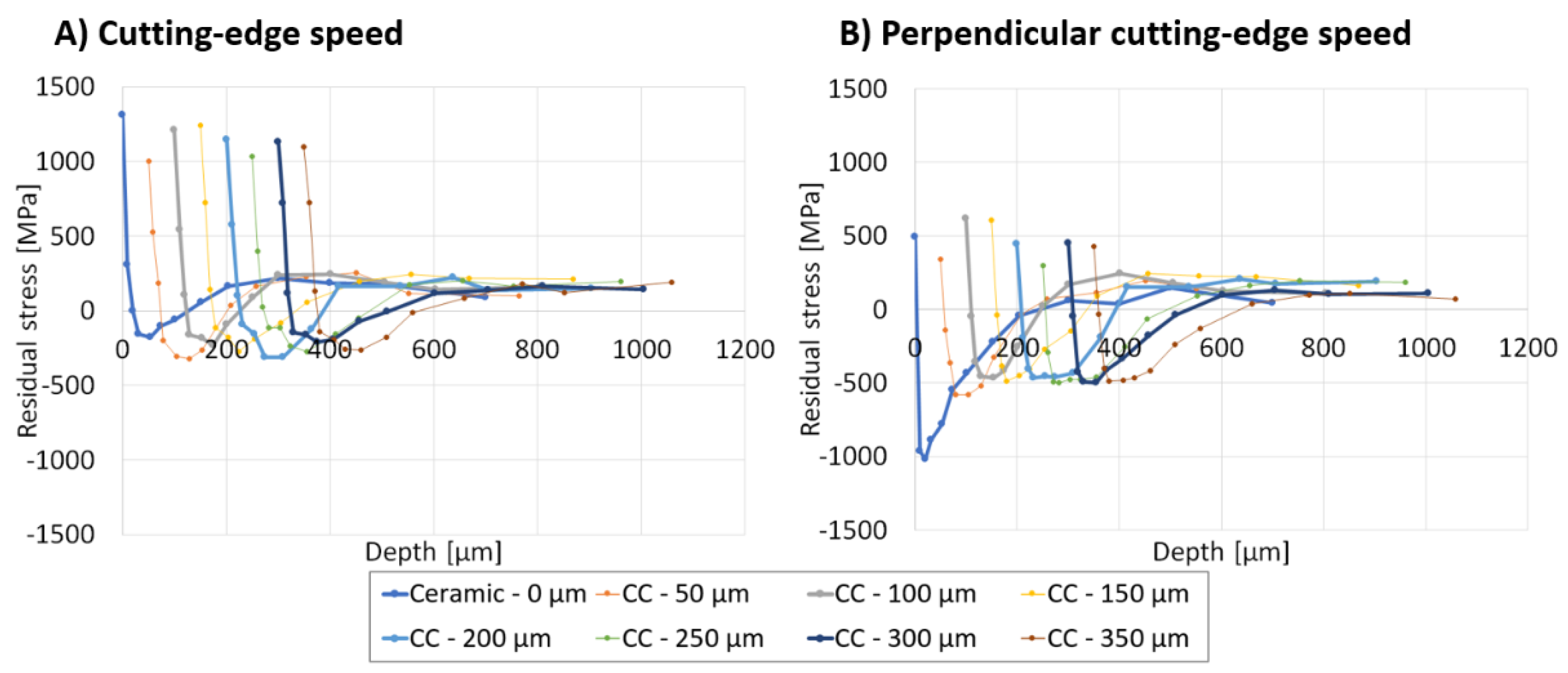

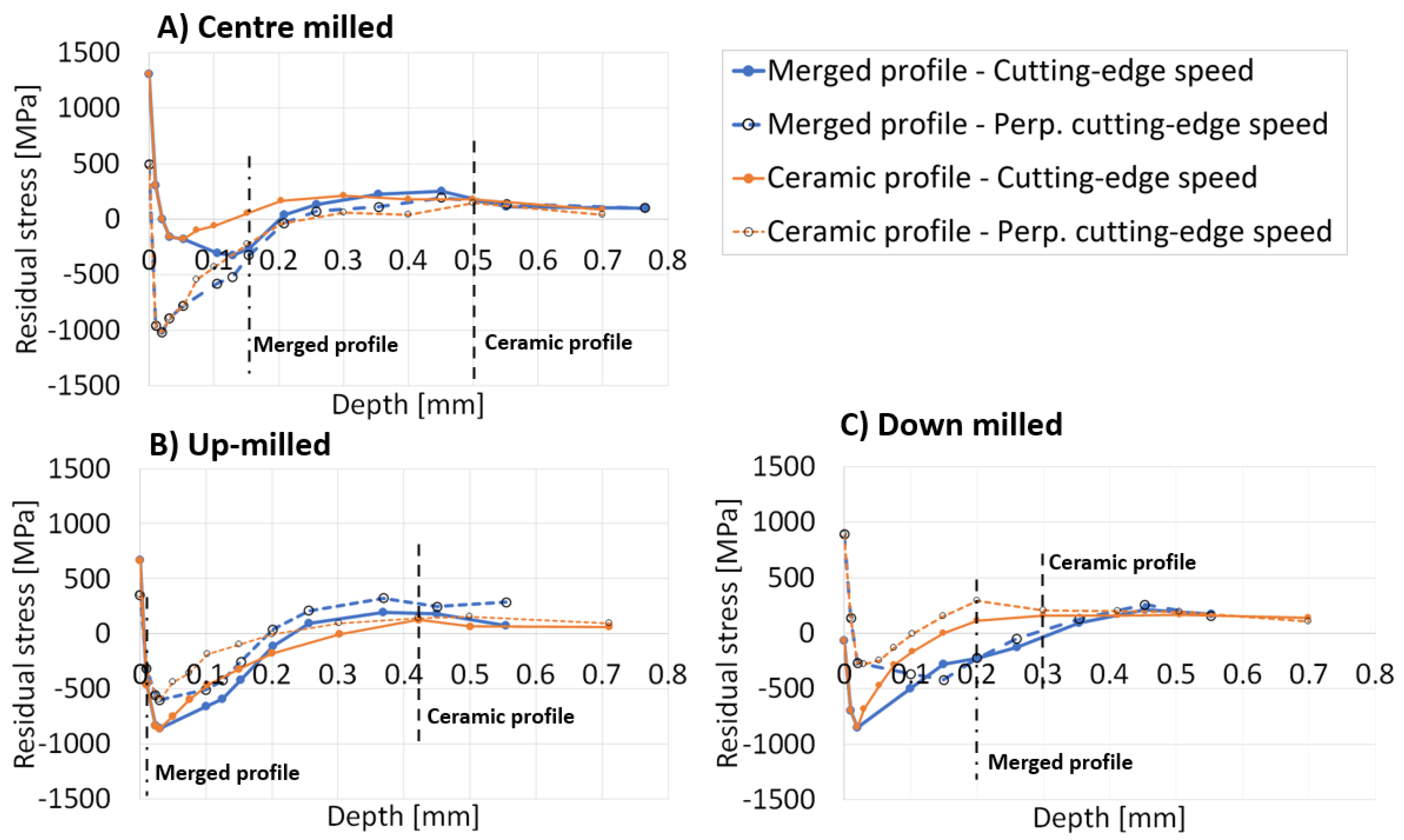

3.2. Residual Stress

4. Discussion and Analysis of Results

5. Conclusions

- Both rough ceramic milling and finish cemented carbide milling induce high tensile stresses that are counterbalanced by a high and deep compressive stress zone below the surface followed by a tensile stress peak.

- The lowest surface residual stress impact for ceramic rough milling was found for up-milling but down milling resulted in lower impact depth. Finish up-milling resulted in the lowest surface stress and residual stress depth impact.

- The depth impact after rough ceramic milling diminished after 2–3 finish milling steps equal to a total depth of cut of 150 µm.

- Measurements of the depth of diminishing of directional influence could be used to assess the impact depth from prior millings steps which correlated well with the total impact depth for ceramic milling but not for cemented carbide milling.

- Based on the diminishing of directional influence impact after ceramic rough milling, the least impact depth was shown for down-milling, 300 µm, and the deepest impact was shown for centre milling, 500 µm. The corresponding influence for cemented carbide milling showed no directional difference at up-milling while centre and down milling resulted in shallow impact depth of 100 µm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shaw, M.C. Metal Cutting Principles; Oxford University Press: New York, NY, USA, 2005. [Google Scholar]

- Rao Ramana, T.V. Metal Casting: Principles and Practice; New Age International Publishers: New Delhi, India, 1996. [Google Scholar]

- Nickel Development Institute. Machining Nickel Alloys; NiDI Publication: Groningen, The Netherlands, 2021; Volume 008. [Google Scholar]

- Ezugwu, E.O.; Bonney, J.; Yamane, Y. An overview of the machinability of aeroengine alloys. J. Mater. Process. Technol. 2003, 134, 233–253. [Google Scholar] [CrossRef]

- Werke, M.; Wretland, A.; Ottosson, P.; Holmberg, J.; Machens, M.; Semere, D. Geometric distortion analysis using a combination of the contour method and machining simulation. Procedia CIRP 2018, 72, 1481–1486. [Google Scholar] [CrossRef]

- Sandvik Coromant. Technical Guide, Metal Cutting Technology; Sandvik Coromant: Stockholm, Sweden, 2010. [Google Scholar]

- Holmberg, J.; Wretland, A.; Berglund, J.; Beno, T. A detailed investigation of residual stresses after milling Inconel 718 using typical production parameters for assessment of affected depth. Mater. Today Commun. 2020, 24, 100958. [Google Scholar] [CrossRef]

- Holmberg, J.; Wretland, A.; Berglund, J.; Beno, T. Selection of milling strategy based on surface integrity investigations of highly deformed Alloy 718 after ceramic and cemented carbide milling. J. Manuf. Process. 2020, 58, 193–207. [Google Scholar] [CrossRef]

- Dumas, M.; Valiorgue, F.; Robaeys, A.V.; Rech, J. Interaction between a roughing and a finishing operation on the final surface integrity in turning. Procedia CIRP 2018, 71, 396–400. [Google Scholar] [CrossRef]

- Outeiro, J.C.; Umbrello, D.; M’Saoubi, R. Experimental and numerical modelling of the residual stresses induced in orthogonal cutting of AISI 316L steel. Int. J. Mach. Tools Manuf. 2006, 46, 1786–1794. [Google Scholar] [CrossRef]

- Liu, C.R.; Guo, Y.B. Finite element analysis of the effect of sequential cuts and tool–chip friction on residual stresses in a machined layer. Int. J. Mech. Sci. 2000, 42, 1069–1086. [Google Scholar] [CrossRef]

- Sasahara, H.; Obikawa, T.; Shirakashi, T. FEM analysis of cutting sequence effect on mechanical characteristics in machined layer. J. Mater. Process. Technol. 1996, 62, 448–453. [Google Scholar] [CrossRef]

- D’Alvise, L.; Chantzis, D.; Schoinochoritis, B.; Salonitis, K. Modelling of Part Distortion Due to Residual Stresses Relaxation: An aeronautical Case Study. Procedia CIRP 2015, 31, 447–452. [Google Scholar] [CrossRef]

- Gao, H.; Zhang, Y.; Wu, Q.; Li, B. Investigation on influences of initial residual stress on thin-walled part machining deformation based on a semi-analytical model. J. Mater. Process. Technol. 2018, 262, 437–448. [Google Scholar] [CrossRef]

- Li, B.; Jiang, X.; Yang, J.; Liang, S.Y. Effects of depth of cut on the redistribution of residual stress and distortion during the milling of thin-walled part. J. Mater. Process. Technol. 2015, 216, 223–233. [Google Scholar] [CrossRef]

- Akhtar, W.; Sun, J.; Chen, W. Effect of Machining Parameters on Surface Integrity in High Speed Milling of Super Alloy GH4169/Inconel 718. Mater. Manuf. 2016, 31, 620–627. [Google Scholar] [CrossRef]

- Cai, X.; Qin, S.; Li, J.; An, Q.; Chen, M. Experimental investigation on surface integrity of end milling nickel-based alloy—Inconel 718. Mach. Sci. Technol. 2014, 18, 31–46. [Google Scholar] [CrossRef]

- Polvorosa, R.; Suárez, A.; López de Lacalle, L.N.; Cerrillo, I.; Wretland, A.; Veiga, F. Tool wear on nickel alloys with different coolant pressures: Comparison of Alloy 718 and Waspaloy. J. Manuf. Process. 2017, 26, 44–56. [Google Scholar] [CrossRef]

- Kaynak, Y. Evaluation of machining performance in cryogenic machining of Inconel 718 and comparison with dry and MQL machining. Int. J. Adv. Manuf. Technol. 2014, 72, 919–933. [Google Scholar] [CrossRef]

- Dhokia, V.; Newman, S.T.; Imani-Asrai, R. An Initial Study of the Effect of Using Liquid Nitrogen Coolant on the Surface Roughness of Inconel 718 Nickel-Based Alloy in CNC Milling. Procedia CIRP 2012, 3, 121–125. [Google Scholar]

- He, Z.-H.; Zhang, X.-M.; Ding, H. Comparison of Residual Stresses in Cryogenic and Dry Machining of Inconel 718. Procedia CIRP 2016, 46, 19–22. [Google Scholar] [CrossRef]

- Pusavec, F.; Hamdi, H.; Kopac, J.; Jawahir, I.S. Surface integrity in cryogenic machining of nickel based alloy—Inconel 718. J. Mater. Process. Technol. 2011, 211, 773–783. [Google Scholar] [CrossRef]

- Suárez, A.; Veiga, F.; Polvorosa, R.; Artaza, T.; Holmberg, J.; López de Lacalle, L.N.; Wretland, A. Surface integrity and fatigue of non-conventional machined Alloy 718. J. Manuf. Process. 2019, 48, 44–50. [Google Scholar] [CrossRef]

- Suárez, A.; Veiga, F.; López de Lacalle, L.N.; Polvorosa, R.; Lutze, S.; Wretland, A. Effects of Ultrasonics-Assisted Face Milling on Surface Integrity and Fatigue Life of Ni-Alloy 718. J. Mater. Eng. Perform. 2016, 25, 5076–5086. [Google Scholar] [CrossRef]

- Aspinwall, D.K.; Dewes, R.C.; Ng, E.-G.; Sage, C.; Soo, S.L. The influence of cutter orientation and workpiece angle on machinability when high-speed milling Inconel 718 under finishing conditions. Int. J. Mach. Tools Manuf. 2007, 47, 1839–1846. [Google Scholar] [CrossRef]

- Alauddin, M.; El Baradie, M.A.; Hashmi, M.S.J. Tool-life testing in the end milling of Inconel 718. J. Mater. Process. Technol. 1995, 55, 321–330. [Google Scholar] [CrossRef]

- Hadi, M.A.; Ghani, J.A.; Che Haron, C.H.; Kasim, M.S. Comparison between up-milling and down-milling operations on tool wear in milling Inconel 718. Procedia Eng. 2013, 68, 647–653. [Google Scholar] [CrossRef]

- Pleta, A.; Nithyanand, G.; Niaki, F.A.; Mears, L. Identification of optimal machining parameters in trochoidal milling of Inconel 718 for minimal force and tool wear and investigation of corresponding effects on machining affected zone depth. J. Manuf. Process. 2019, 43, 54–62. [Google Scholar] [CrossRef]

- Arunachalam, R.M.; Mannan, M.A.; Spowage, A.C. Surface integrity when machining age hardened Inconel 718 with coated carbide cutting tools. Int. J. Mach. Tools Manuf. 2004, 44, 1481–1491. [Google Scholar] [CrossRef]

- Grzesik, W.; Nieslony, P. Prediction of friction and heat flow in machining incorporating thermophysical properties of the coating–chip interface. Wear 2004, 256, 108–117. [Google Scholar] [CrossRef]

- Grzesik, W.; Denkena, B.; Żak, K.; Grove, T.; Bergmann, B. Energy consumption characterization in precision hard machining using CBN cutting tools. Int. J. Adv. Manuf. Technol. 2016, 85, 2839–2845. [Google Scholar] [CrossRef][Green Version]

- Wojciechowski, S.; Twardowski, P.; Pelic, M.; Maruda, R.W.; Barrans, S.; Krolczyk, G.M. Precision surface characterization for finish cylindrical milling with dynamic tool displacements model. Precis. Eng. 2016, 46, 158–165. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Hassui, A.; Wojciechowski, A.; Mia, M.; Magri, A.; Suyama, D.I.; Bustillo, A.; Krolczyk, G.; Gupta, M.K. Effect of the Relative Position of the Face Milling Tool towards the Workpiece on Machined Surface Roughness and Milling Dynamics. Appl. Sci. 2019, 9, 842. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Wang, Z.M.; Machado, A.R. The machinability of nickel-based alloys: A review. J. Mater. Process. Technol. 1999, 86, 1–16. [Google Scholar] [CrossRef]

- International Organisation for Standarization. ISO 25178-2:2012, Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters 2012; International Organisation for Standarization: Genevea, Switzerland, 2012. [Google Scholar]

- Noyan, I.C.; Cohen, J.B. Residual Stress Measurement by Diffraction and Interpretation, 1987 ed.; Springer: New York, NY, USA, 1987. [Google Scholar]

- European Commitee for Standardization. EN 15305:2008, Non-Destructive Testing—Test Method for Residual Stress Analysis by X-ray Diffraction 2008; European Commitee for Standardization: Brussels, Belgium, 2008. [Google Scholar]

- Holmberg, J.; Palosaari, M.; Hosseini, S.; Larjosuo, H.; Andersson, P. Round Robin Study on Residual Stresses Using X-Ray Diffraction for Shot-Peened Tool Steel Specimens. Mater. Res. Proc. 2018, 6, 51–55. [Google Scholar]

- Prevéy, P.S. The measurement of subsurface residual stress and cold work distributions in nickel base alloys. In Proceedings of the ASM’s Conference on Residual Stress in Design, Process, and Materials Selection, Cincinnati, OH, USA, 27–29 April 1987. [Google Scholar]

| Ni | Cr | Fe | Nb | Mo | Ti | Al | Co | C | Mn | P | Si | W | Cu | B | V |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 53.9 | 18.0 | Bal. | 5.2 | 2.9 | 1.0 | 0.5 | 0.2 | 0.02 | 0.7 | 0.01 | 0.7 | 0.02 | 0.04 | 0.004 | 0.03 |

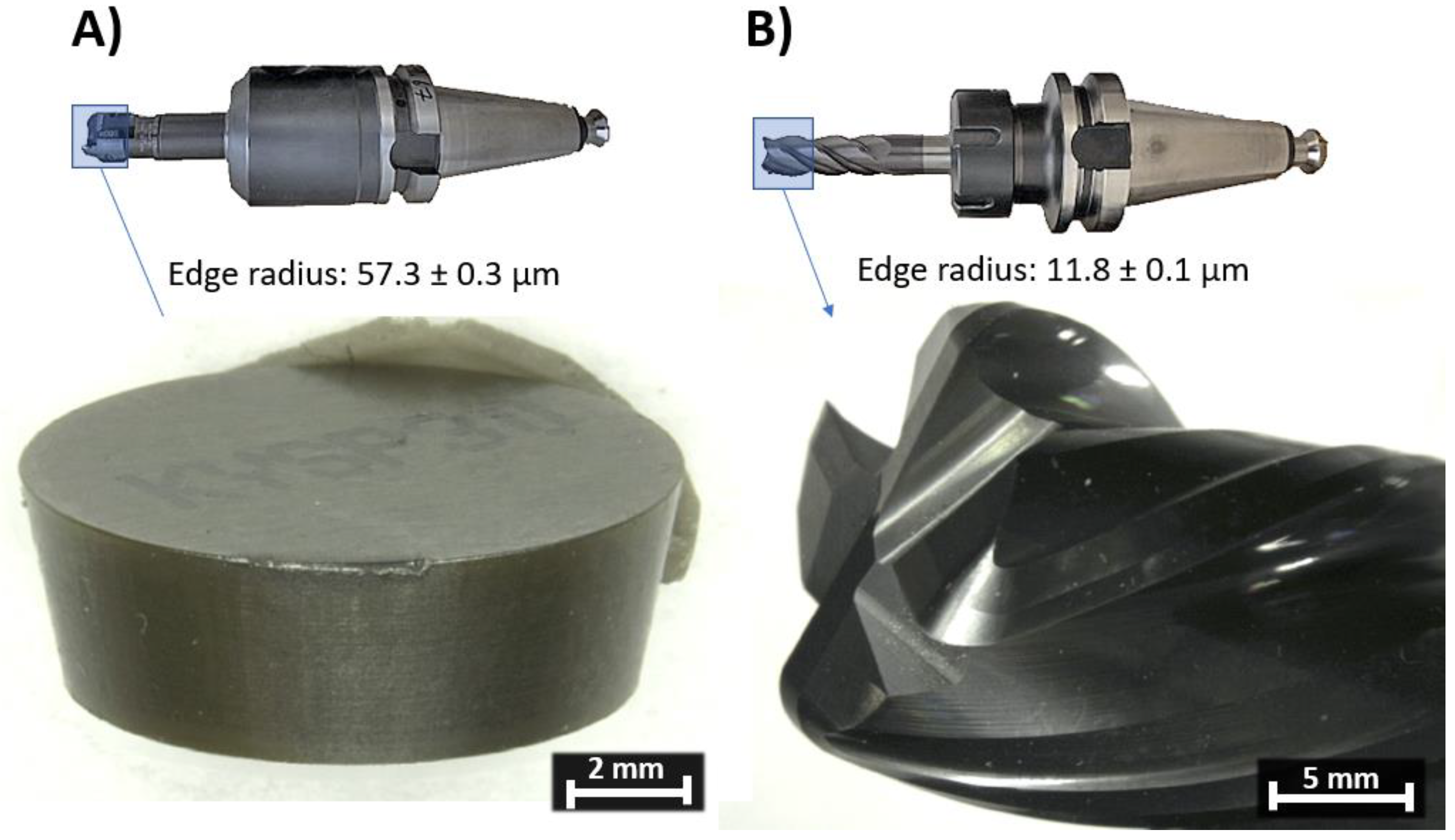

| Insert/Tool | Type | Diameter | No. Teeth | Clearance Angles 1 | Rake Angles 1 | Edge Radius 2 |

|---|---|---|---|---|---|---|

| Material | (mm) | (°) | (°) | (µm) | ||

| Ceramic | Indexable insert | 9 | 1 | 11 | 0 | 56.9 ± 0.2 |

| Cemented carbide | Solid end-mill | 10 | 4 | 6.7, 16.6 | 55.7, 57.4 | 11.8 ± 0.1 |

| Insert/Tool | vc | vc, Engage 1 | vf | s | fz | ap |

|---|---|---|---|---|---|---|

| Material | (m/min) | (m/min) | (mm/min) | (rev/min) | (mm/tooth) | (mm) |

| Ceramic | 800 | 500 | 611 | 10,000 | 0.06 | 0.7 |

| Cemented carbide | 50 | 50 | 127 | 1590 | 0.02 | 0.05 |

| Milling | Step | Sa | Ssk | Sdr |

|---|---|---|---|---|

| Operation | (µm) | (µm) | (-) | (%) |

| Ceramic | 0 | 0.36 | 0.03 | 0.06 |

| Cemented carbide | 50 | 0.62 | −0.33 | 0.80 |

| Cemented carbide | 100 | 0.46 | −0.04 | 0.59 |

| Cemented carbide | 150 | 0.63 | −0.23 | 0.76 |

| Cemented carbide | 200 | 0.64 | −0.21 | 0.84 |

| Cemented carbide | 250 | 0.56 | −0.10 | 0.69 |

| Cemented carbide | 300 | 0.51 | 0.35 | 0.64 |

| Cemented carbide | 350 | 0.56 | 0.34 | 0.71 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Holmberg, J.; Wretland, A.; Berglund, J.; Beno, T.; Milesic Karlsson, A. Surface Integrity Investigation to Determine Rough Milling Effects for Assessment of Machining Allowance for Subsequent Finish Milling of Alloy 718. J. Manuf. Mater. Process. 2021, 5, 48. https://doi.org/10.3390/jmmp5020048

Holmberg J, Wretland A, Berglund J, Beno T, Milesic Karlsson A. Surface Integrity Investigation to Determine Rough Milling Effects for Assessment of Machining Allowance for Subsequent Finish Milling of Alloy 718. Journal of Manufacturing and Materials Processing. 2021; 5(2):48. https://doi.org/10.3390/jmmp5020048

Chicago/Turabian StyleHolmberg, Jonas, Anders Wretland, Johan Berglund, Tomas Beno, and Anton Milesic Karlsson. 2021. "Surface Integrity Investigation to Determine Rough Milling Effects for Assessment of Machining Allowance for Subsequent Finish Milling of Alloy 718" Journal of Manufacturing and Materials Processing 5, no. 2: 48. https://doi.org/10.3390/jmmp5020048

APA StyleHolmberg, J., Wretland, A., Berglund, J., Beno, T., & Milesic Karlsson, A. (2021). Surface Integrity Investigation to Determine Rough Milling Effects for Assessment of Machining Allowance for Subsequent Finish Milling of Alloy 718. Journal of Manufacturing and Materials Processing, 5(2), 48. https://doi.org/10.3390/jmmp5020048