Functional Analysis of Components Manufactured by a Sheet-Bulk Metal Forming Process

Abstract

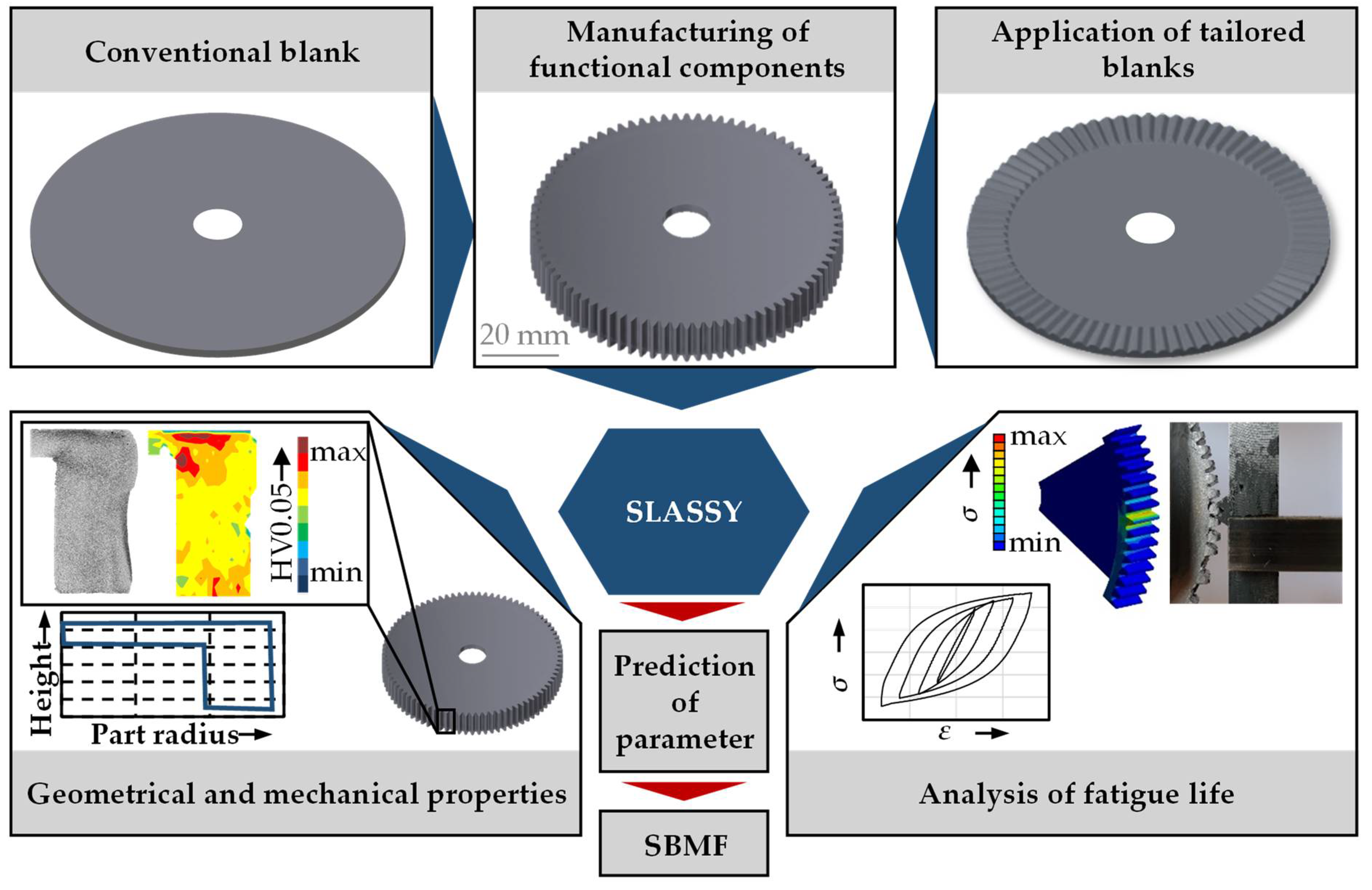

1. Introduction

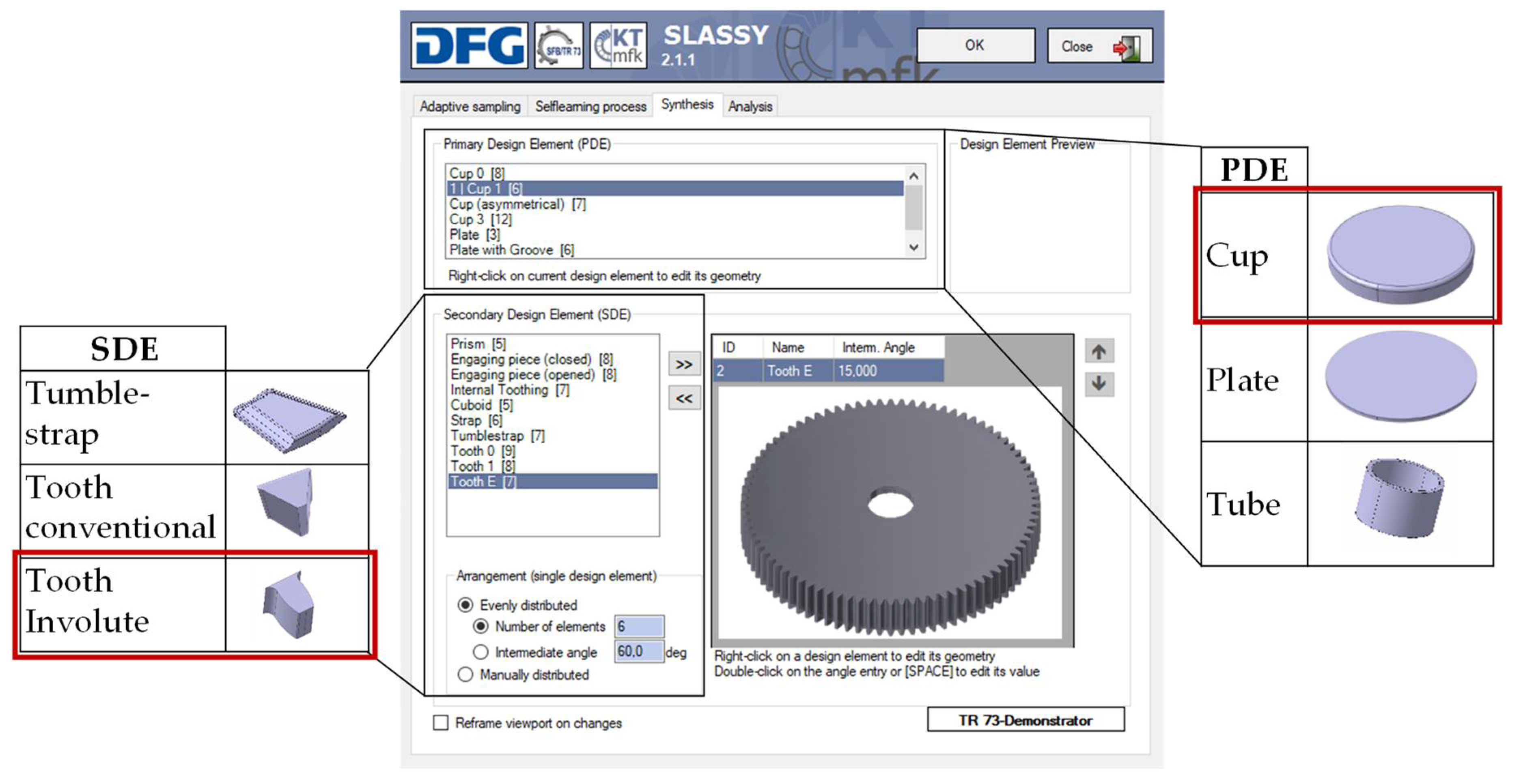

2. Geometry-Based Approach within SLASSY

3. Mechanical Analysis

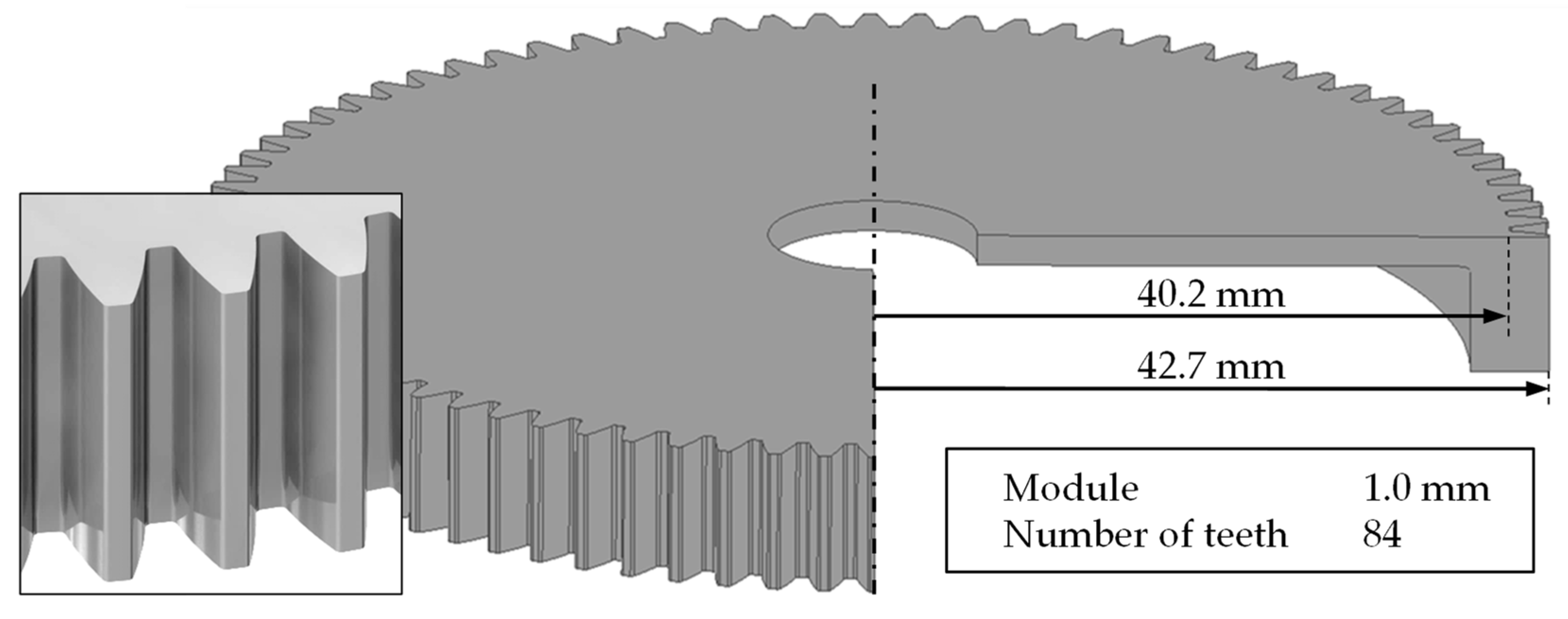

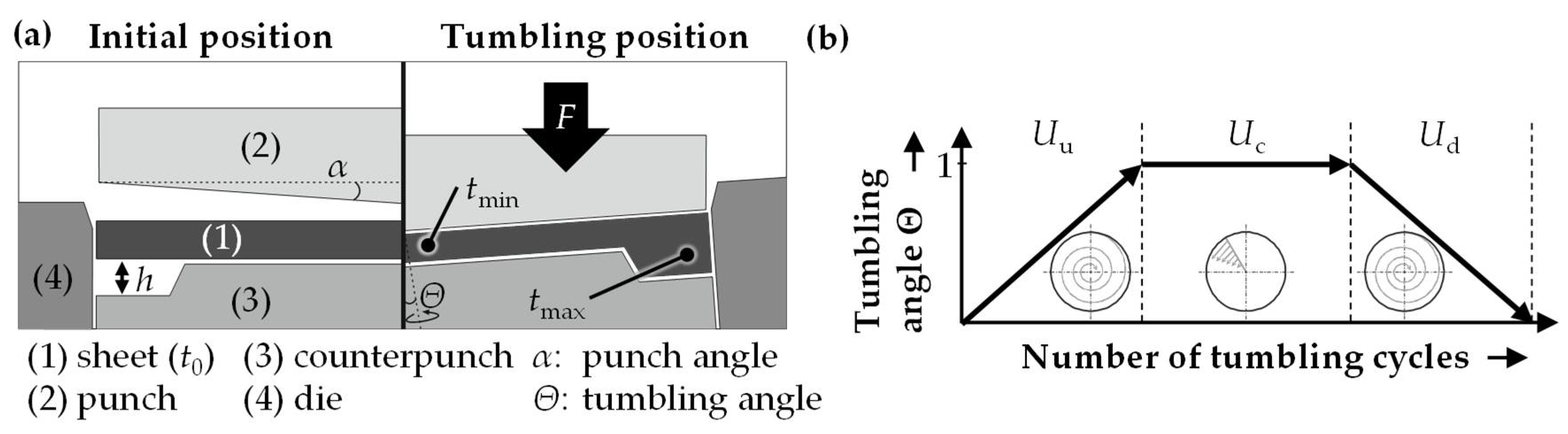

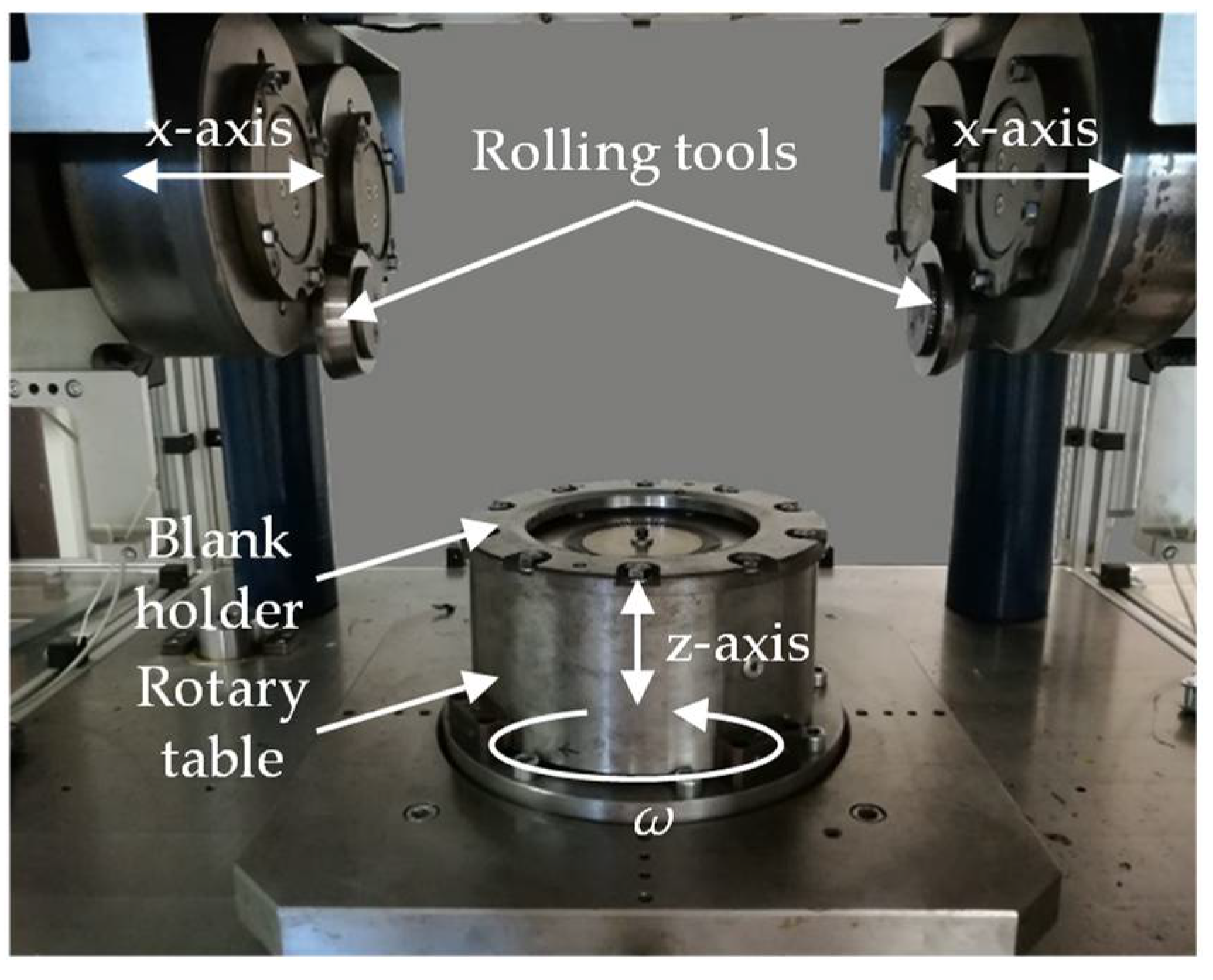

3.1. Forming Process

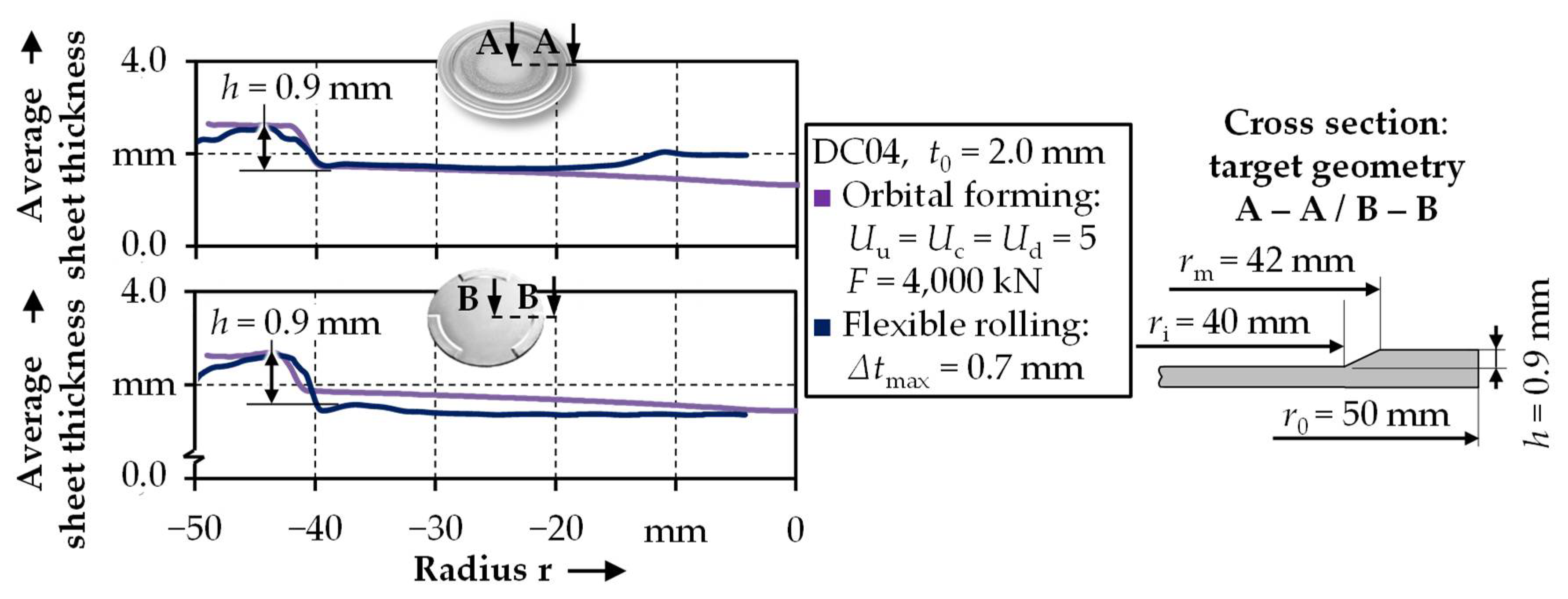

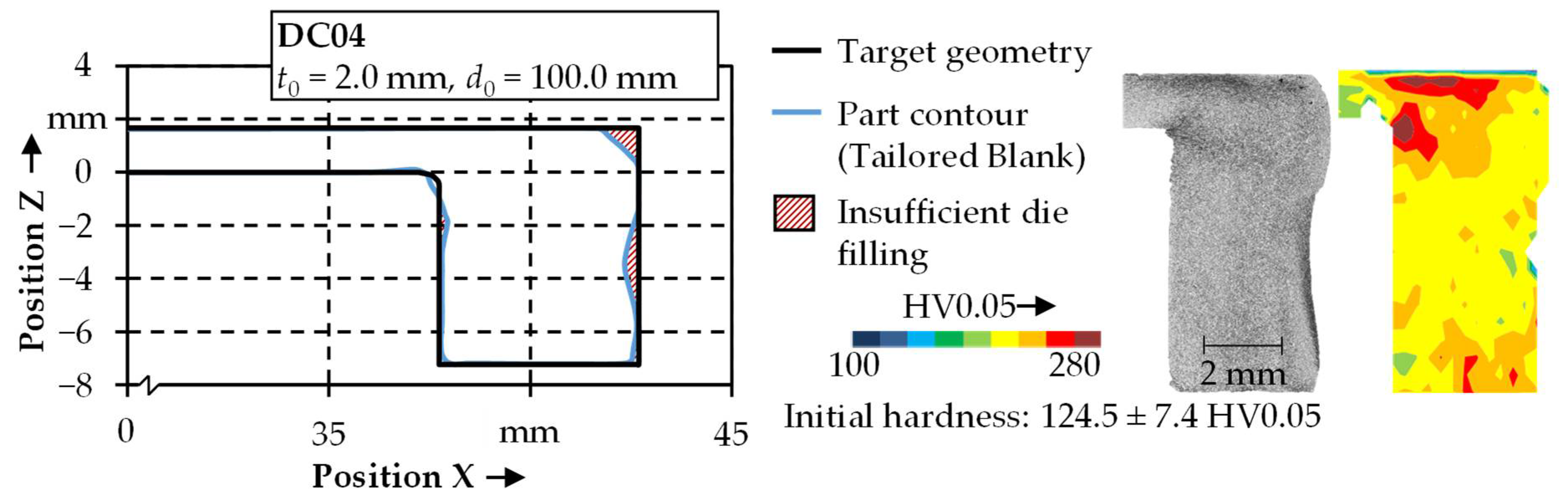

3.2. Forming Results

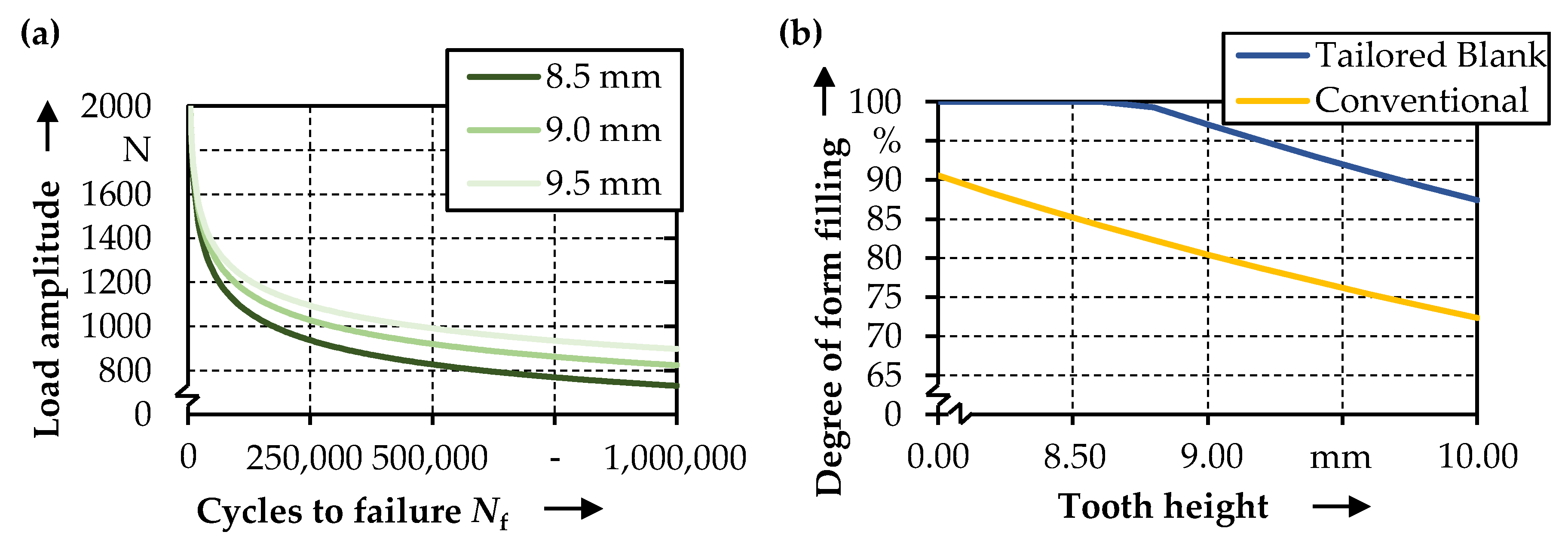

3.3. Process Strategies to Enlarge the Form Filling

4. Fatigue Life Testing and Modeling

4.1. Fatigue Life Modeling

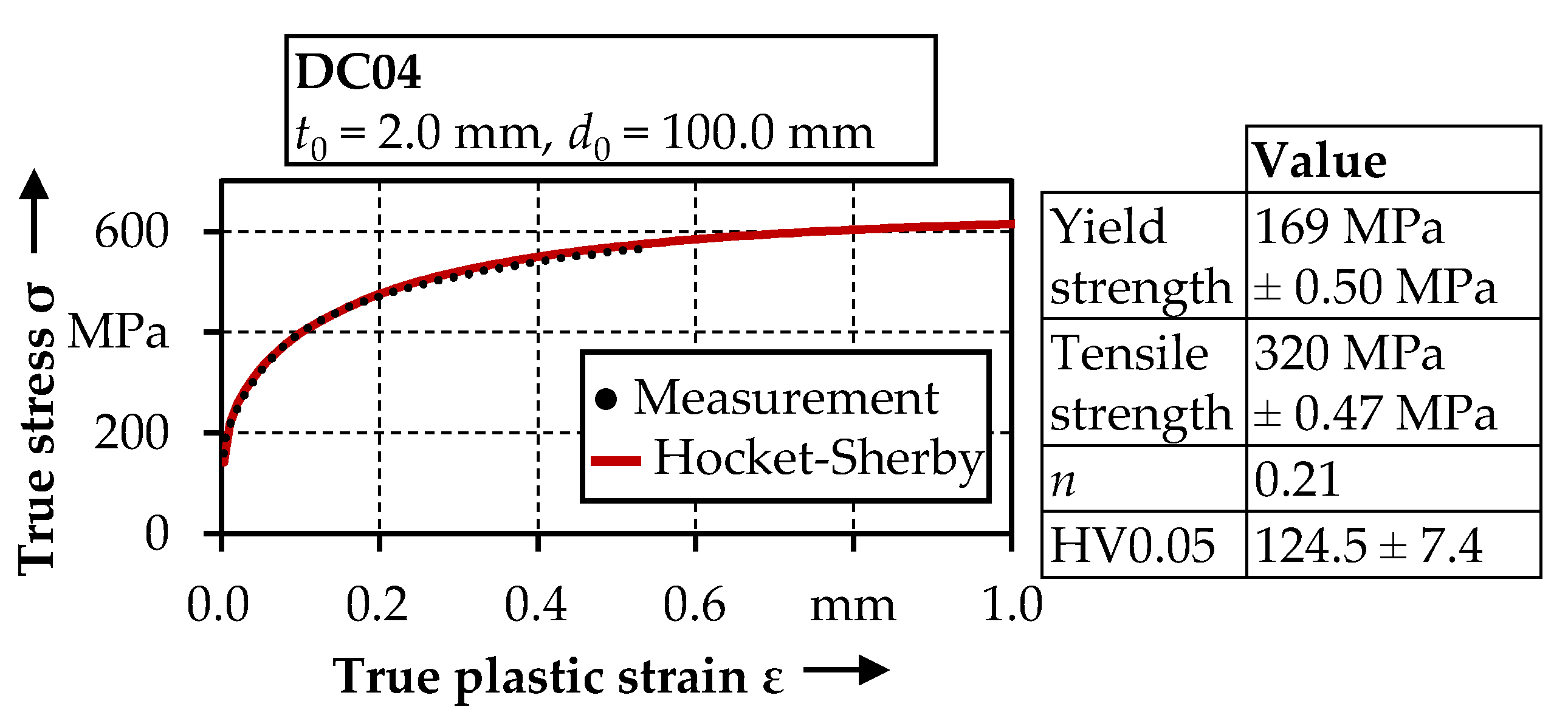

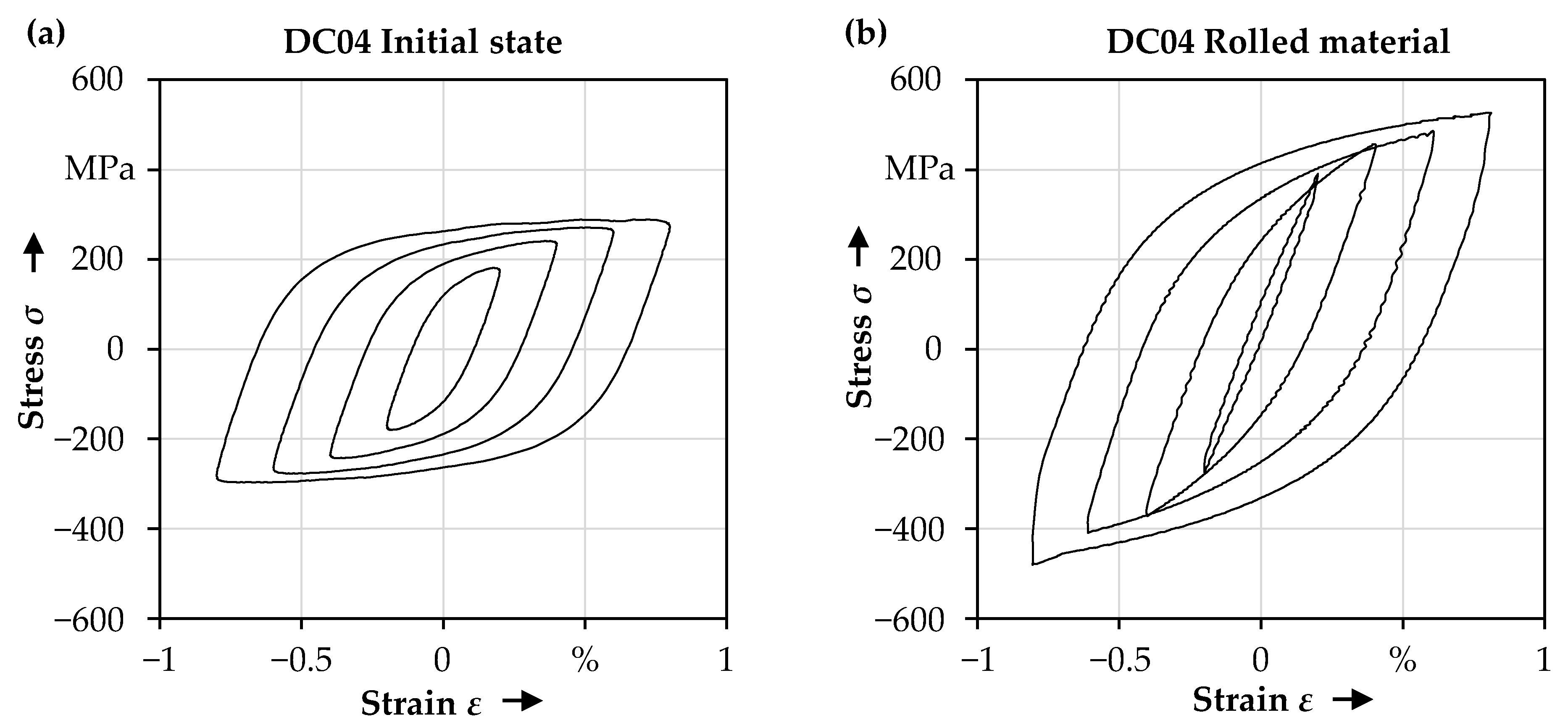

4.2. Data Acquisition on Different Material States

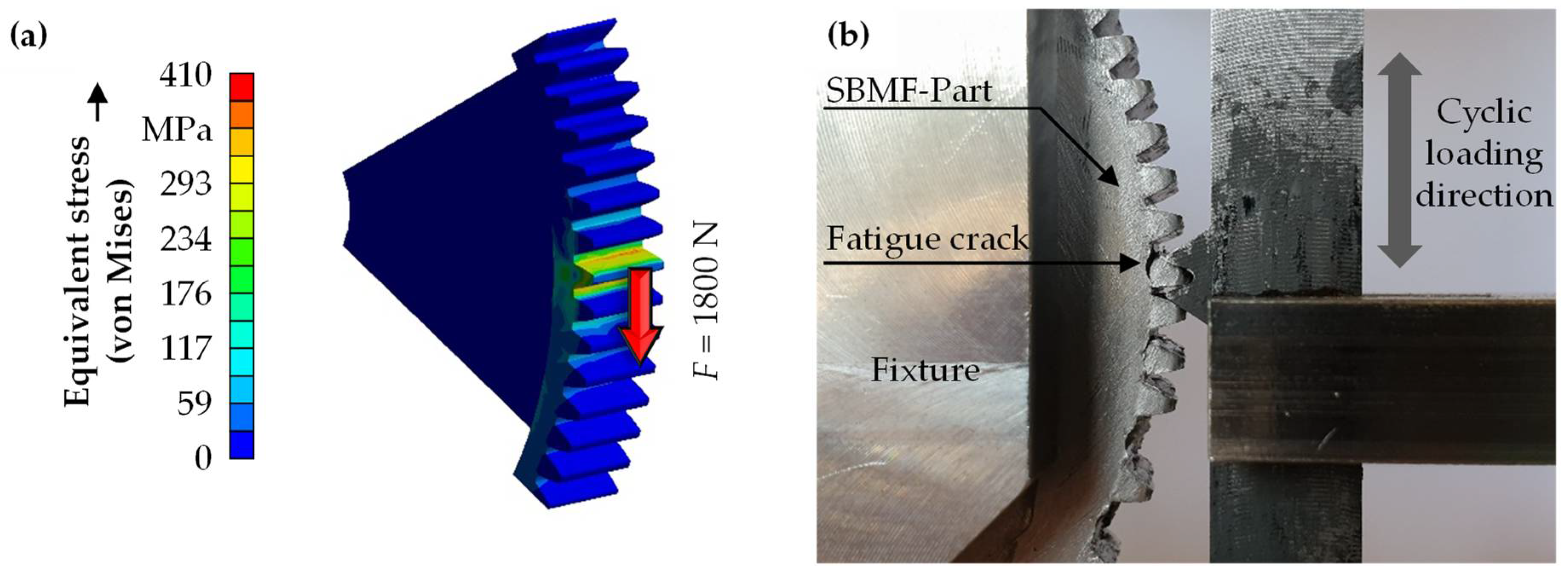

4.3. Fatigue Testing of the SBMF-Components

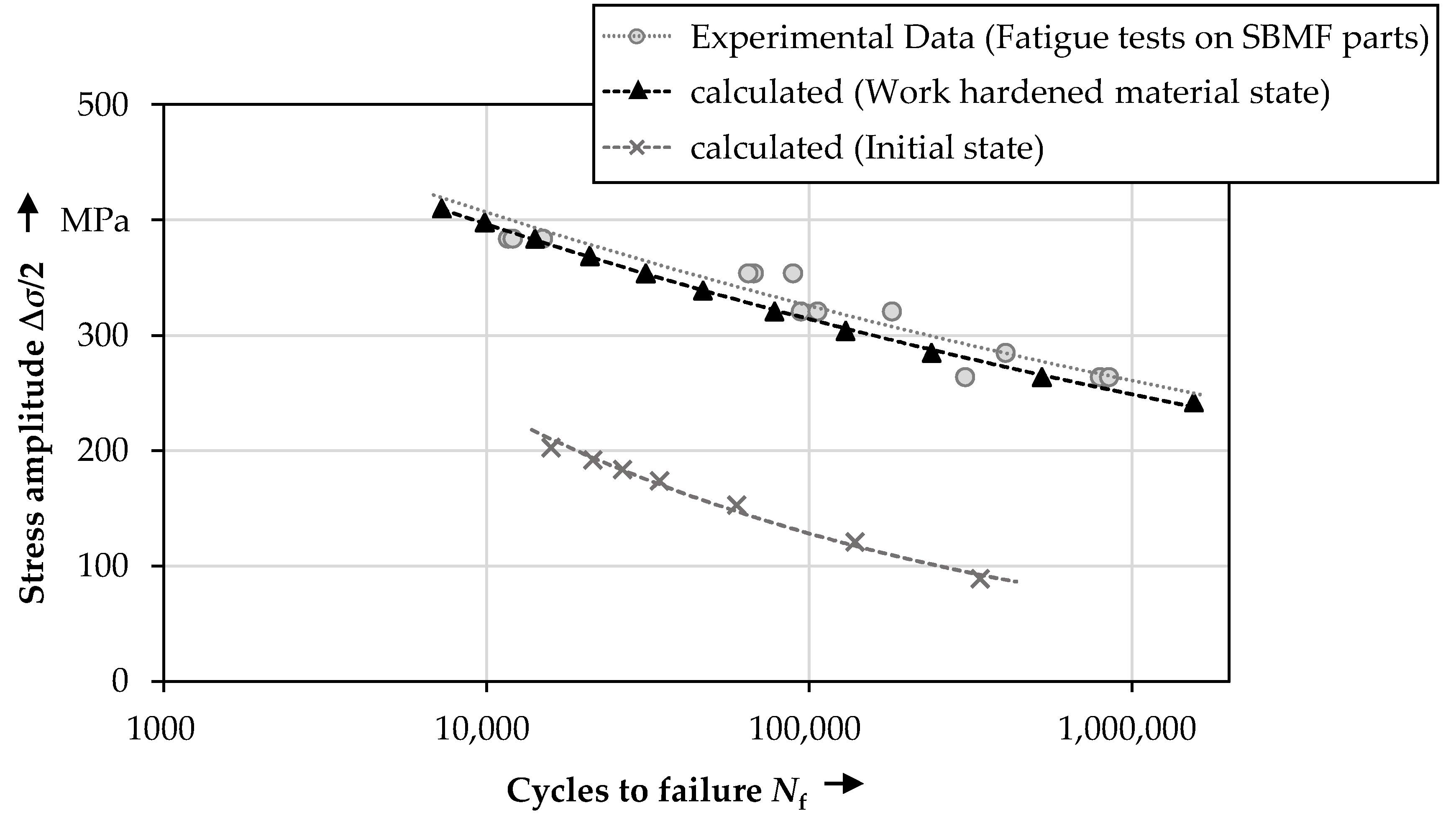

4.4. Fatigue Life Prediction and Experimental Results

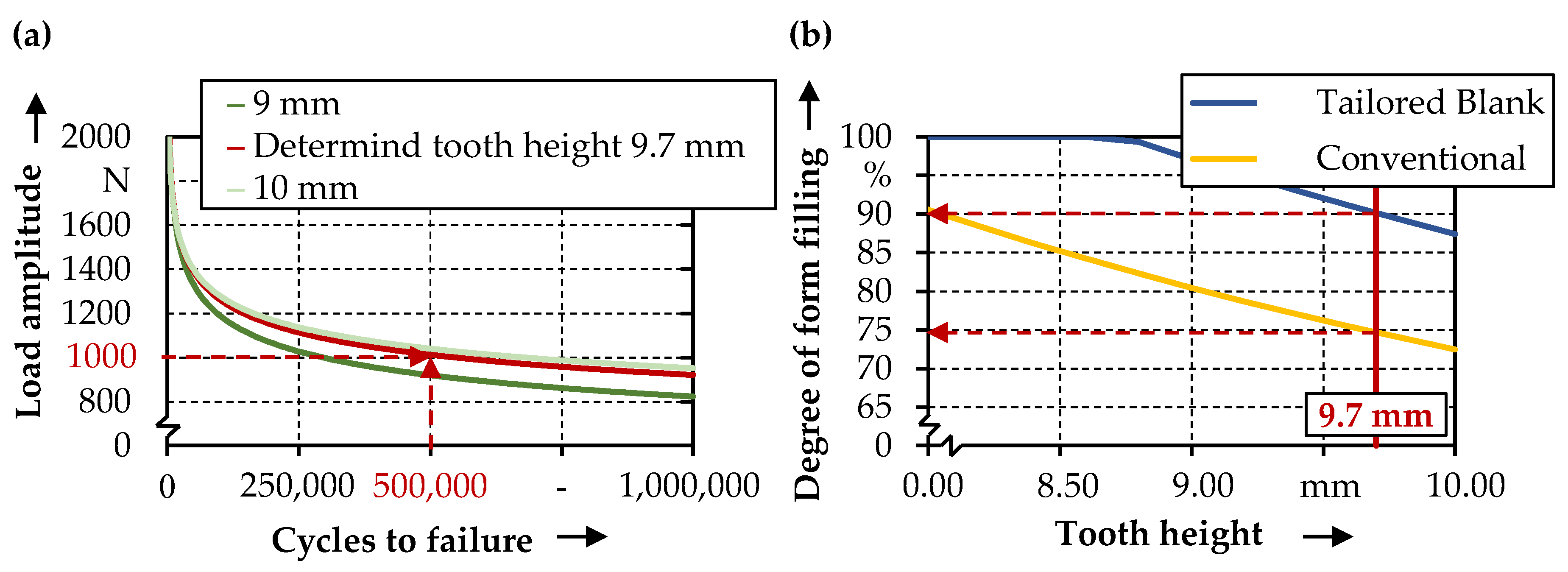

5. Data-Based Approach within SLASSY

5.1. Metamodel Training

5.2. Application inside SLASSY

6. Discussion

7. Conclusions

- A process combination of deep drawing and upsetting within sheet-bulk metal forming can be used to manufacture cup-like components with circumferential involute gearing. However, process failures in the form of folding and buckling were identified during the evaluation of the geometrical and mechanical properties. Since the required material volume in the area of the gearing was not sufficient, possibilities to enlarge the form filling are required.

- By applying orbital formed semi-finished parts in the investigated process combination of deep drawing and upsetting, the maximum form filling can be increased significantly by up to 98%. Furthermore, the process failures can be prevented, and the homogeneity of the hardness distribution outlines the improved forming results.

- The fatigue life of the components can be described well by employing the Z-integral approach. The mechanical properties of the sheet-bulk metal formed material state can be approximated by analyzing a similarly work-hardened state produced by rolling.

- With an assumed initial crack length of 5 µm, the fatigue life is predicted well. By an inverse calculation, the virtual initial crack length was determined to be about 2.5 µm for an optimal fit to the experimental results. With these values, the initial crack length is in the range of the size of microstructural defects such voids that occur due to ductile damage.

- The comparison of the predicted SN-curves for the initial state and the work-hardened material state shows that the fatigue life of the SBMF-components is significantly increased due to work hardening. This shows an advantage of the forming process compared to other manufacturing processes.

- The findings regarding fatigue life could be modeled with the aid of exponential function based metamodels to allow for the prediction of arbitrarily selected part design parameters. The prediction quality is within an acceptable range, as it has shown a coefficient of prognosis of around 95%.

- Moreover, the degree of form filling could be modeled, allowing for the prediction of different selected part design parameters. This data-driven approach allows for further investigations with different part designs or form elements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kishawy, H.; Hegab, H.; Saad, E. Design for Sustainable Manufacturing: Approach, Implementation, and Assessment. Sustainability 2018, 10, 3604. [Google Scholar] [CrossRef]

- Gumpinger, T.; Jonas, H.; Krause, D. New Approach for Lightweight Design: From Differential Design to Integration of Function. In Proceedings of ICED 09, the 17th International Conference on Engineering Design, 6th ed.; Norell Bergendahl, M., Grimheden, M., Leifer, L., Skogstad, P., Lindemann, U., Eds.; Stanford University: Palo Alto, CA, USA, 2009; pp. 201–210. [Google Scholar]

- Mori, K.; Nakano, T. State-of-the-art of plate forging in Japan. Prod. Eng. Res. Dev. 2016, 10, 81–91. [Google Scholar] [CrossRef]

- Gröbel, D.; Schulte, R.; Hildenbrand, P.; Lechner, M.; Engel, U.; Sieczkarek, P.; Wernicke, S.; Gies, S.; Tekkaya, A.E.; Behrens, B.-A.; et al. Manufacturing of functional elements by sheet-bulk metal forming processes. Prod. Eng. Res. Dev. 2016, 10, 63–80. [Google Scholar] [CrossRef]

- Besserer, H.-B.; Nürnberger, F.; Maier, H.J. Fatigue Behavior of Sheet-Bulk Metal Formed Components. In Sheet Bulk Metal Forming; Merklein, M., Tekkaya, A.E., Behrens, B.-A., Eds.; Springer: Cham, Switzerland, 2021; pp. 412–433. [Google Scholar] [CrossRef]

- Sauer, C.; Schleich, B.; Wartzack, S. Simultaneous Development of a Self-learning Engineering Assistance System. In Sheet Bulk Metal Forming; Merklein, M., Tekkaya, A.E., Behrens, B.-A., Eds.; Springer: Cham, Switzerland, 2021; pp. 127–146. [Google Scholar] [CrossRef]

- Simpson, T.W.; Peplinski, J.D.; Koch, P.N.; Allen, J.K. Metamodels for Computer-based Engineering Design: Survey and recommendations. Eng. Comput. 2001, 17, 129–150. [Google Scholar] [CrossRef]

- Vogel, M.; Schulte, R.; Lechner, M.; Merklein, M. Process Combination for the Manufacturing of Toothed, Thin-Walled Functional Elements by Using Process Adapted Semi-finished Products. In Sheet Bulk Metal Forming; Merklein, M., Tekkaya, A.E., Behrens, B.-A., Eds.; Springer: Cham, Switzerland, 2021; pp. 1–29. [Google Scholar] [CrossRef]

- Magrinho, J.P.; Silva, M.B.; Martins, P.A.F. Injection by sheet-bulk forming. Precis. Eng. 2019, 59, 73–80. [Google Scholar] [CrossRef]

- Behrens, B.-A.; Tillmann, W.; Biermann, D.; Hübner, S.; Stangier, D.; Freiburg, D.; Meijer, A.; Koch, S.; Rosenbusch, D.; Müller, P. Influence of Tailored Surfaces and Superimposed-Oscillation on Sheet-Bulk Metal Forming Operations. J. Manuf. Mater. Process. 2020, 4, 41. [Google Scholar] [CrossRef]

- Wernicke, S.; Thier, U.; Hahn, M.; Tekkaya, A.E. Controlling material flow in incremental sheet-bulk metal Forming by thermal grading. Procedia Manuf. 2020, 50, 257–264. [Google Scholar] [CrossRef]

- Hetzel, A.; Lechner, M. Orbital Forming of Tailored Blanks for Industrial Application. In Sheet Bulk Metal Forming; Merklein, M., Tekkaya, A.E., Behrens, B.-A., Eds.; Springer: Cham, Switzerland, 2021; pp. 458–476. [Google Scholar] [CrossRef]

- Kopp, R.; Wiedner, C.; Meyer, A. Flexibly Rolled Sheet Metal and Its Use in Sheet Metal Forming. Adv. Mater. Res. 2005, 6–8, 81–92. [Google Scholar] [CrossRef]

- Lucas, H.; Denkena, B.; Grove, T.; Krebs, E.; Freiburg, D.; Biermann, D.; Kersting, P. Analysis of Residual Stress States of Structured Surfaces Manufactured by High-Feed and Micromilling. J. Heat Treat. Mater. 2015, 70, 183–189. [Google Scholar] [CrossRef]

- Dowling, N.; Begley, J. Fatigue Crack Growth During Gross Plasticity and the J-Integral. In STP590-EB Mechanics of Crack Growth; Rice, J., Paris, P., Eds.; ASTM International: West Conshohocken, PA, USA, 1976; pp. 82–103. [Google Scholar] [CrossRef]

- Wüthrich, C. The extension of the J-integral concept to fatigue cracks. Int. J. Fract. 1982, 20, 35–37. [Google Scholar] [CrossRef]

- Heitmann, H. Betriebsfestigkeit von Stahl: Vorhersage der technischen Anrisslebensdauer unter Berücksichtigung des Verhaltens von Mikrorissen. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 1983. [Google Scholar]

- Heitmann, H.; Vehoff, H.; Neumann, P. Life prediction for random load fatigue based on the growth behaviour of microcracks. In Advances of Fracture Research; Valluri, S.R., Ed.; Pergamon Press: Oxford, UK, 1985; pp. 3599–3606. [Google Scholar]

- Haibach, E. Betriebsfestigkeit. Verfahren und Daten zur Bauteilberechnung; Springer: Berlin, Germany, 2006. [Google Scholar] [CrossRef]

- Tekkaya, A.E.; Bouchard, P.-O.; Bruschi, S.; Tasan, C.C. Damage in metal forming. CIRP Ann. 2020, 69, 600–623. [Google Scholar] [CrossRef]

- Goods, S.H.; Brown, L.M. Overview No. 1: The nucleation of cavities by plastic deformation. Acta Metall. 1979, 27, 1–15. [Google Scholar] [CrossRef]

- Gerstein, G.; Besserer, H.-B.; Nürnberger, F.; Maier, H.J. Comparison of the mechanisms of void formation by plastic deformation in single- and dual phase steels. In Proc. TMS Annual Meeting 2015. Characterization of Minerals, Metals, and Materials; Carpenter, J., Bai, C., Pablo Escobedo-Diaz, J., Hwang, J.-Y., Ikhmayies, S., Li, B., Li, J., Neves, S., Peng, Z., Zhang, M., Eds.; Wiley: Hoboken, NJ, USA, 2015; pp. 75–81. [Google Scholar]

- Besserer, H.-B.; Hildenbrand, P.; Gerstein, G.; Rodman, D.; Nürnberger, F.; Merklein, M.; Maier, H.J. Ductile damage and fatigue behavior of semi-finished tailored blanks for sheet-bulk metal forming processes. J. Mater. Eng. Perform. 2016, 25, 1136–1142. [Google Scholar] [CrossRef]

- Most, T.; Will, J. Metamodel of Optimal Prognosis-an automatic approach for variable reduction and optimal metamodel selection. Proc. Weimarer Optim. Stochastiktage 2008, 5, 20–21. [Google Scholar] [CrossRef]

- Breiman, L.; Friedman, J.H.; Olshen, R.A.; Stone, C.J. Classification and Regression Trees; Wadsworth Inc.: New York, NY, USA, 1984. [Google Scholar]

- Hastie, T.; Tibshirani, R.; Friedman, J. The Elements of Statistical Learning, 2nd ed.; Springer: New York, NY, USA, 2017. [Google Scholar] [CrossRef]

- Weber, C. An extended theoretical approach to modelling products and product development processes. Proc. 2nd Ger. Isr. Symp. Adv. Methods Syst. Dev. Prod. Process. 2005, 2, 159–179. [Google Scholar]

- Küstner, C.; Beyer, F.; Kumor, D.; Loderer, A.; Wartzack, S.; Willner, K.; Blum, H.; Rademacher, A.; Hausotte, T. Simulation-based Development of Pareto-optimized Tailored Blanks for the use within Sheet-Bulk Metal Forming. In Proceedings of the DESIGN 2016 14th International Conference; Marjanović, D., Storga, M., Pavković, N., Bojcetic, N., Skec, S., Eds.; Design Society: Dubrovnik, Croatia, 2016; pp. 291–300. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hetzel, A.; Schulte, R.; Vogel, M.; Lechner, M.; Besserer, H.-B.; Maier, H.J.; Sauer, C.; Schleich, B.; Wartzack, S.; Merklein, M. Functional Analysis of Components Manufactured by a Sheet-Bulk Metal Forming Process. J. Manuf. Mater. Process. 2021, 5, 49. https://doi.org/10.3390/jmmp5020049

Hetzel A, Schulte R, Vogel M, Lechner M, Besserer H-B, Maier HJ, Sauer C, Schleich B, Wartzack S, Merklein M. Functional Analysis of Components Manufactured by a Sheet-Bulk Metal Forming Process. Journal of Manufacturing and Materials Processing. 2021; 5(2):49. https://doi.org/10.3390/jmmp5020049

Chicago/Turabian StyleHetzel, Andreas, Robert Schulte, Manfred Vogel, Michael Lechner, Hans-Bernward Besserer, Hans Jürgen Maier, Christopher Sauer, Benjamin Schleich, Sandro Wartzack, and Marion Merklein. 2021. "Functional Analysis of Components Manufactured by a Sheet-Bulk Metal Forming Process" Journal of Manufacturing and Materials Processing 5, no. 2: 49. https://doi.org/10.3390/jmmp5020049

APA StyleHetzel, A., Schulte, R., Vogel, M., Lechner, M., Besserer, H.-B., Maier, H. J., Sauer, C., Schleich, B., Wartzack, S., & Merklein, M. (2021). Functional Analysis of Components Manufactured by a Sheet-Bulk Metal Forming Process. Journal of Manufacturing and Materials Processing, 5(2), 49. https://doi.org/10.3390/jmmp5020049