High-Temperature Equal-Channel Angular Pressing of a T6-Al-Cu-Li-Mg-Ag-Zr-Sc Alloy

Abstract

1. Introduction

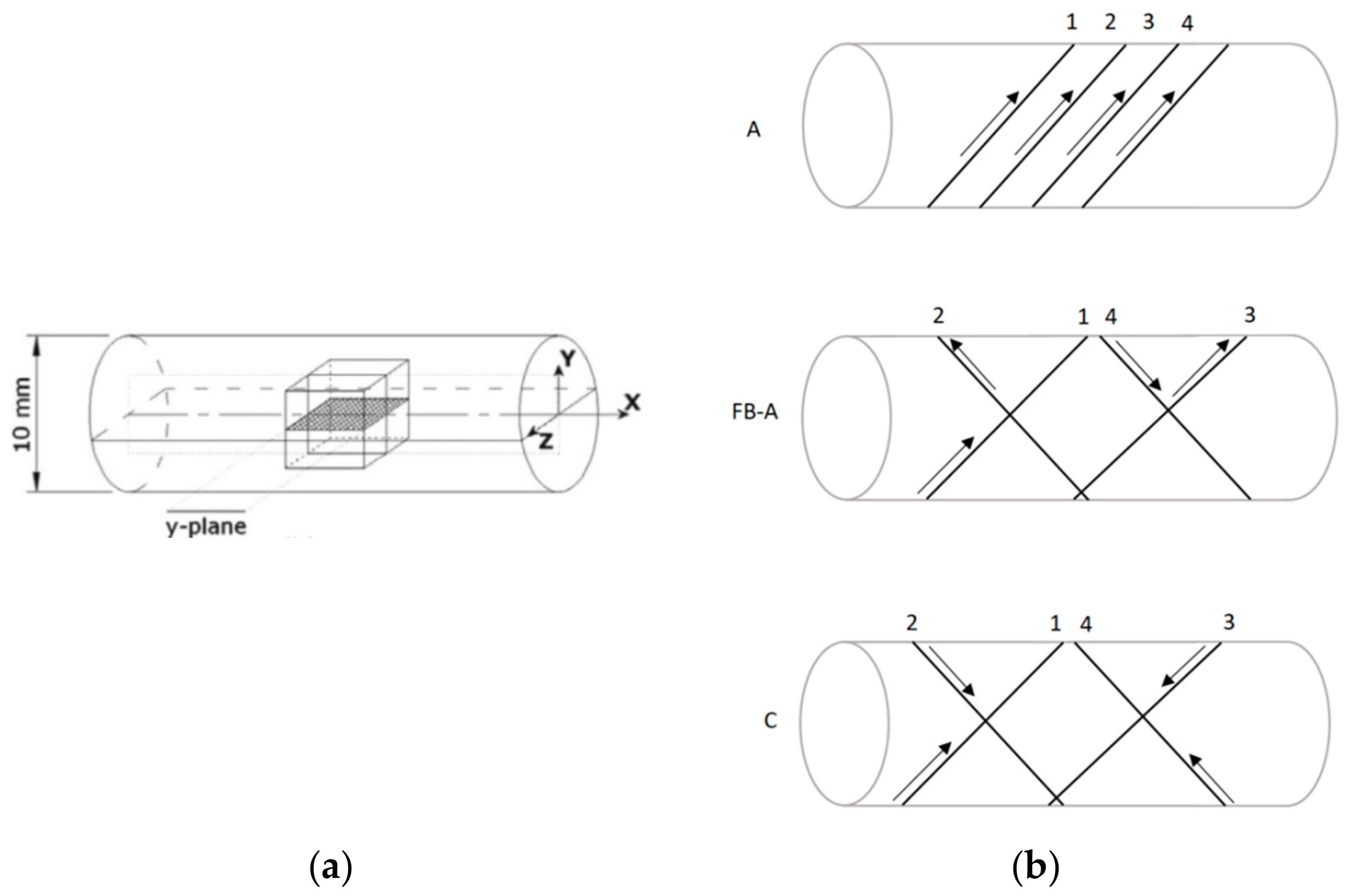

2. Experimental Details and Methods

3. Results

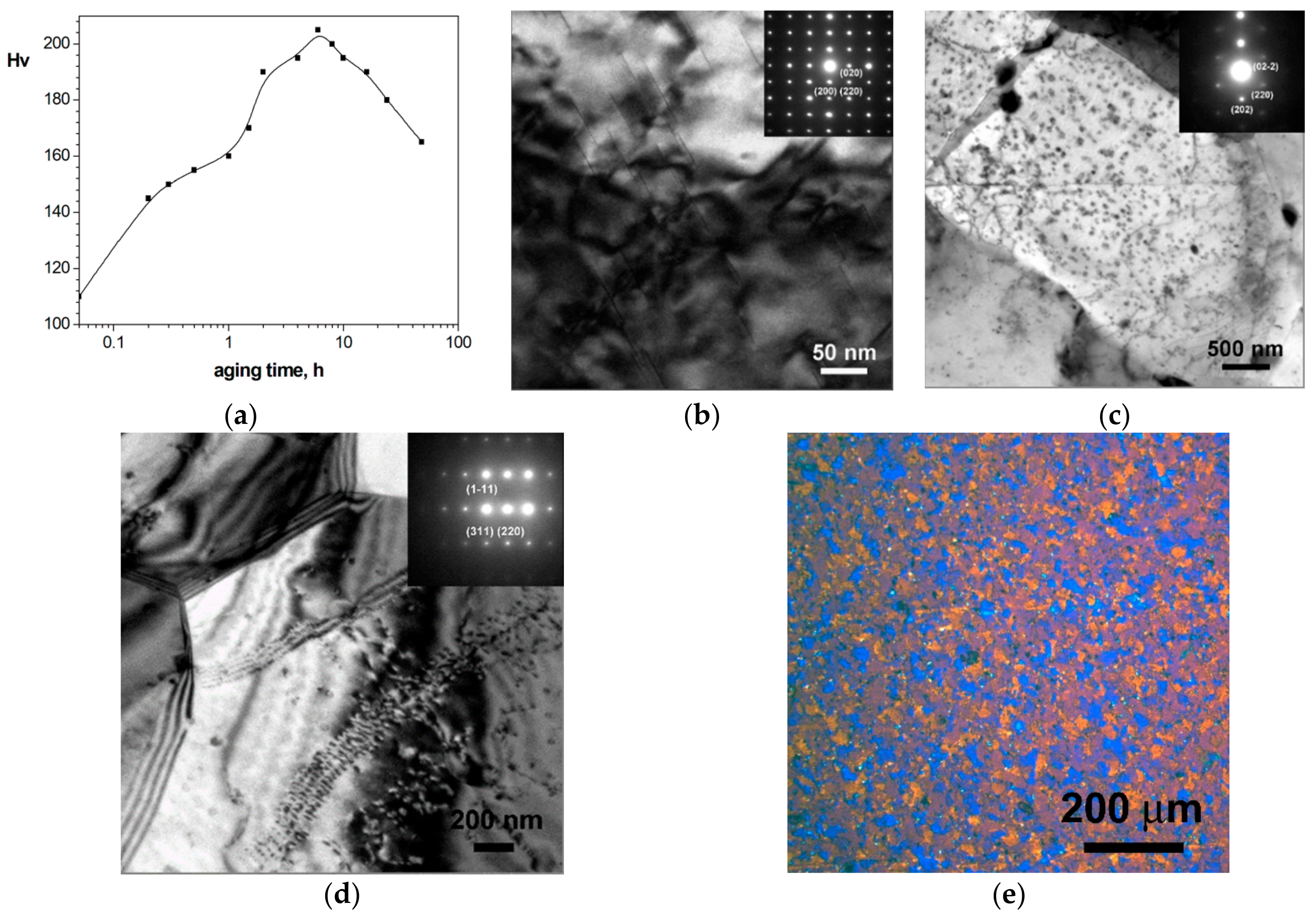

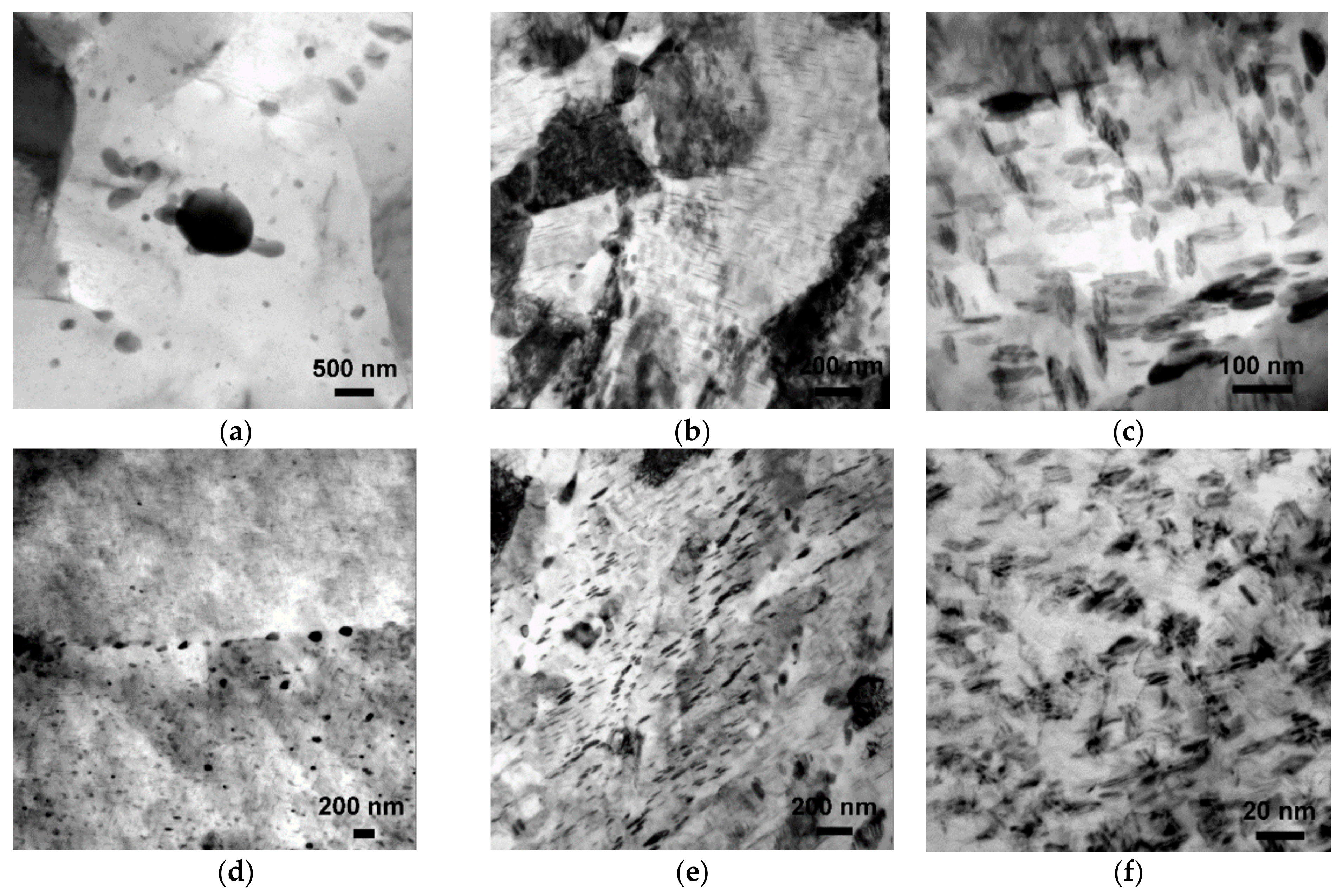

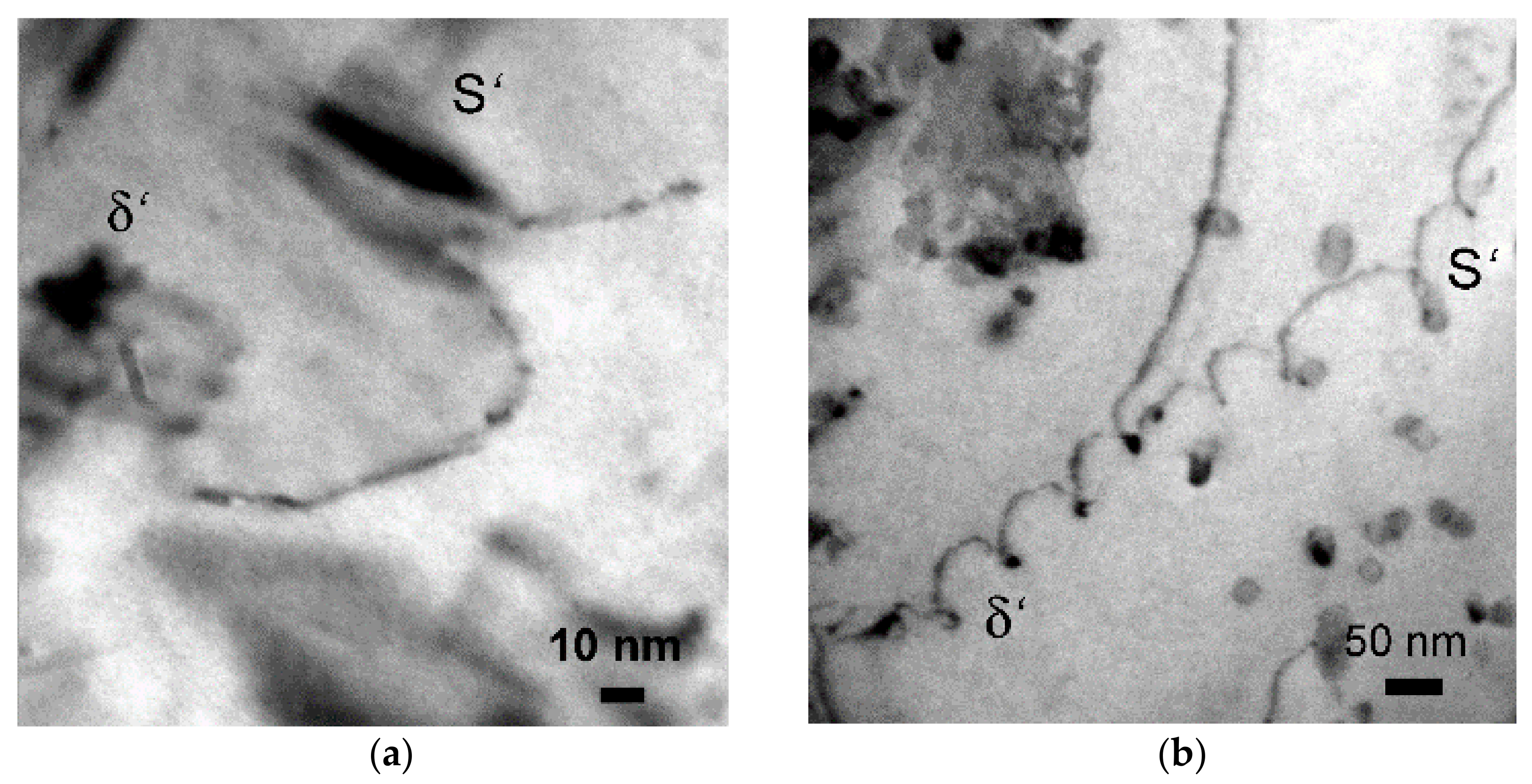

3.1. T6 Temper Microstructure

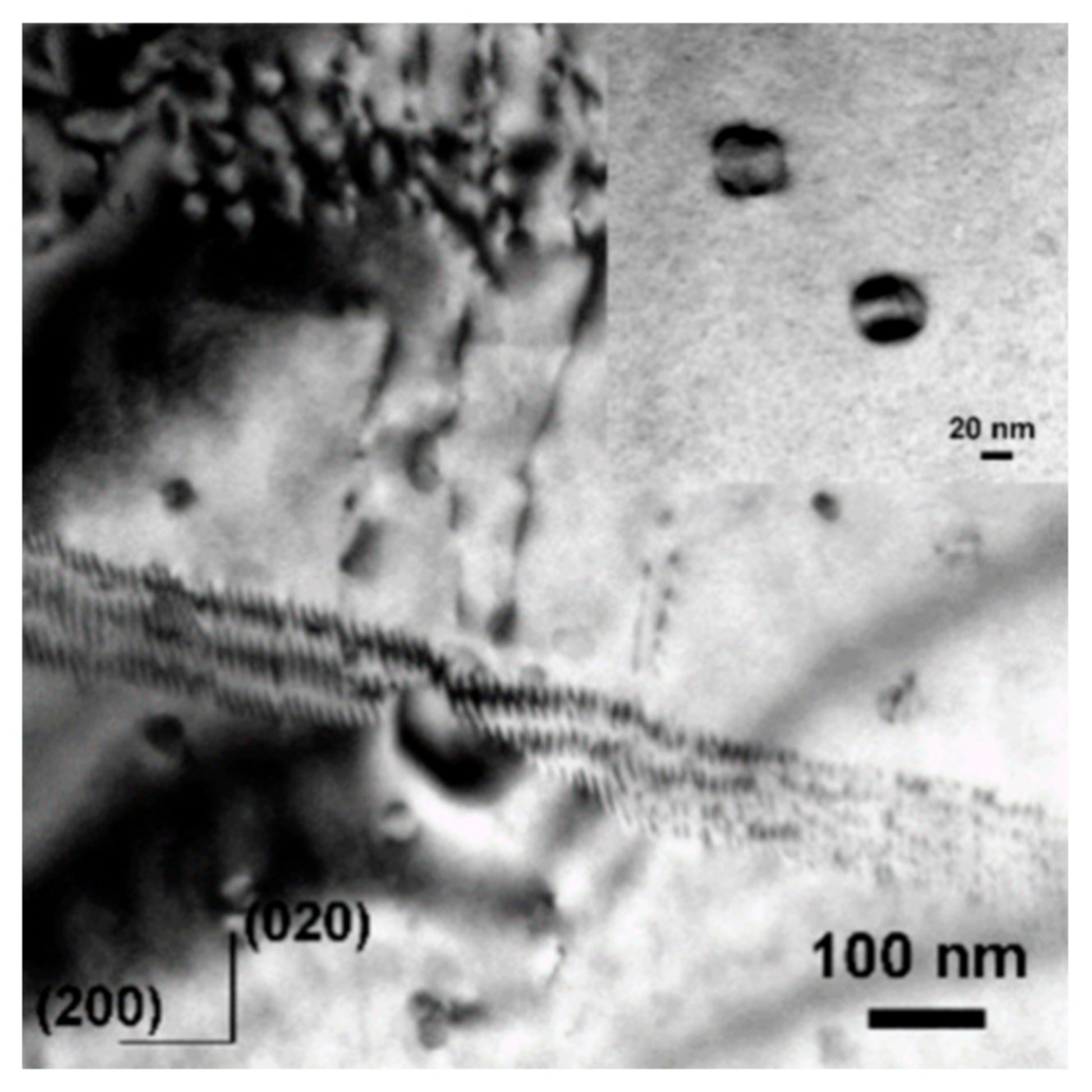

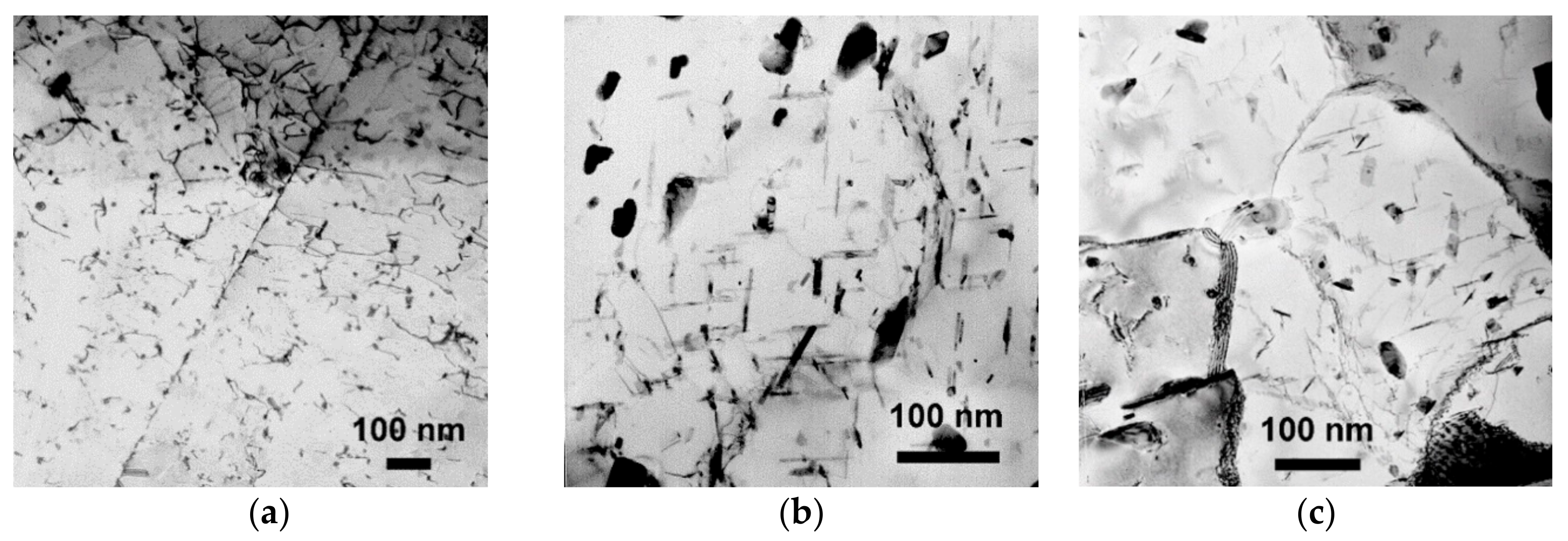

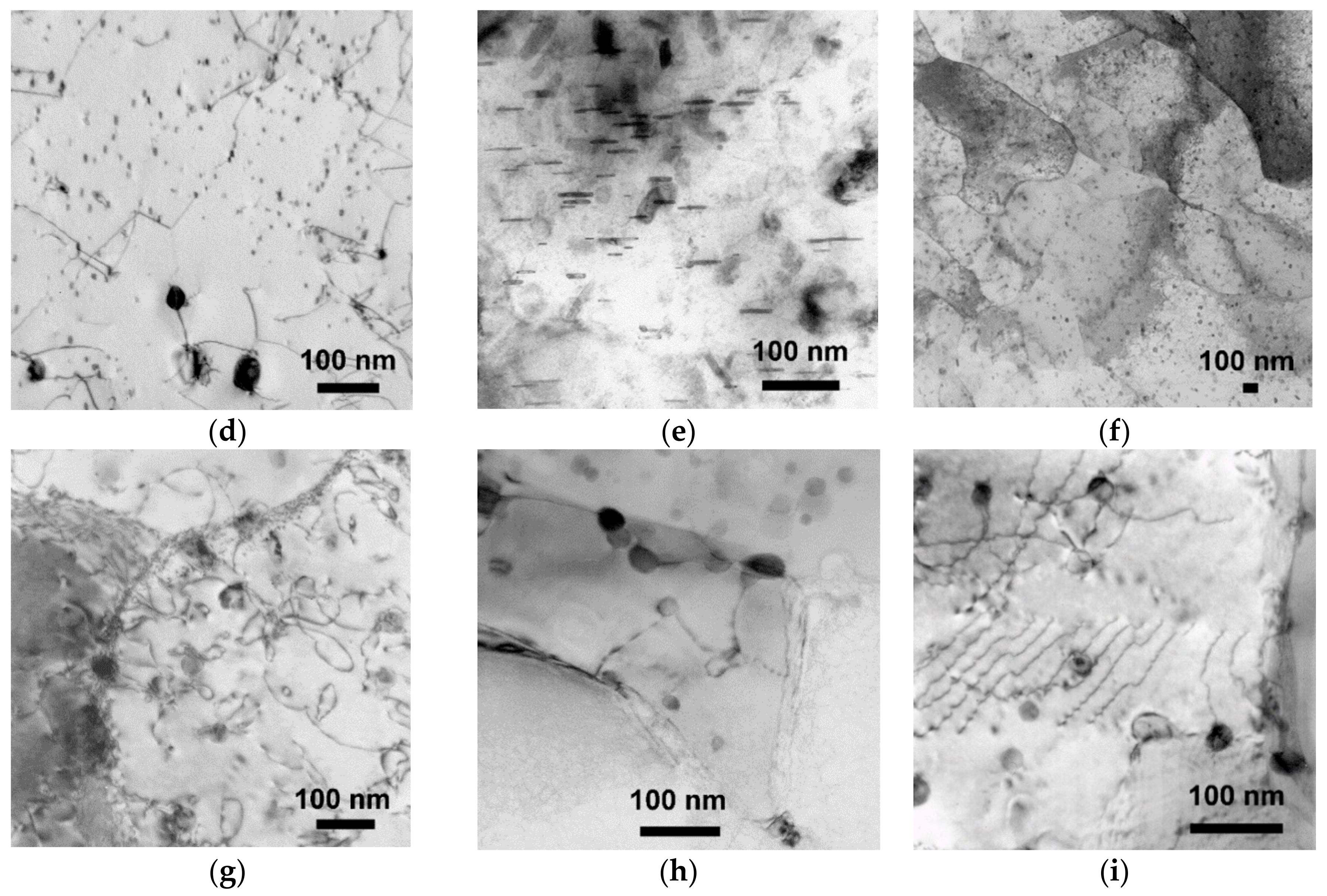

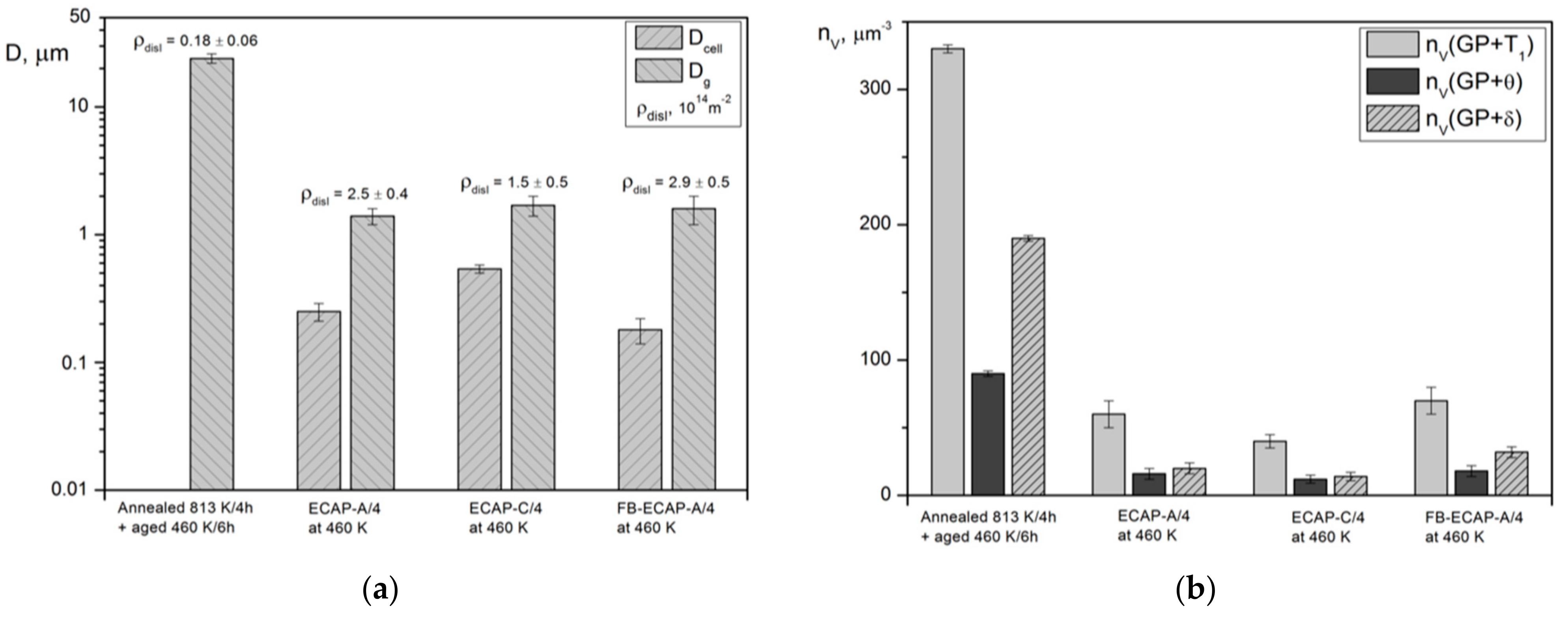

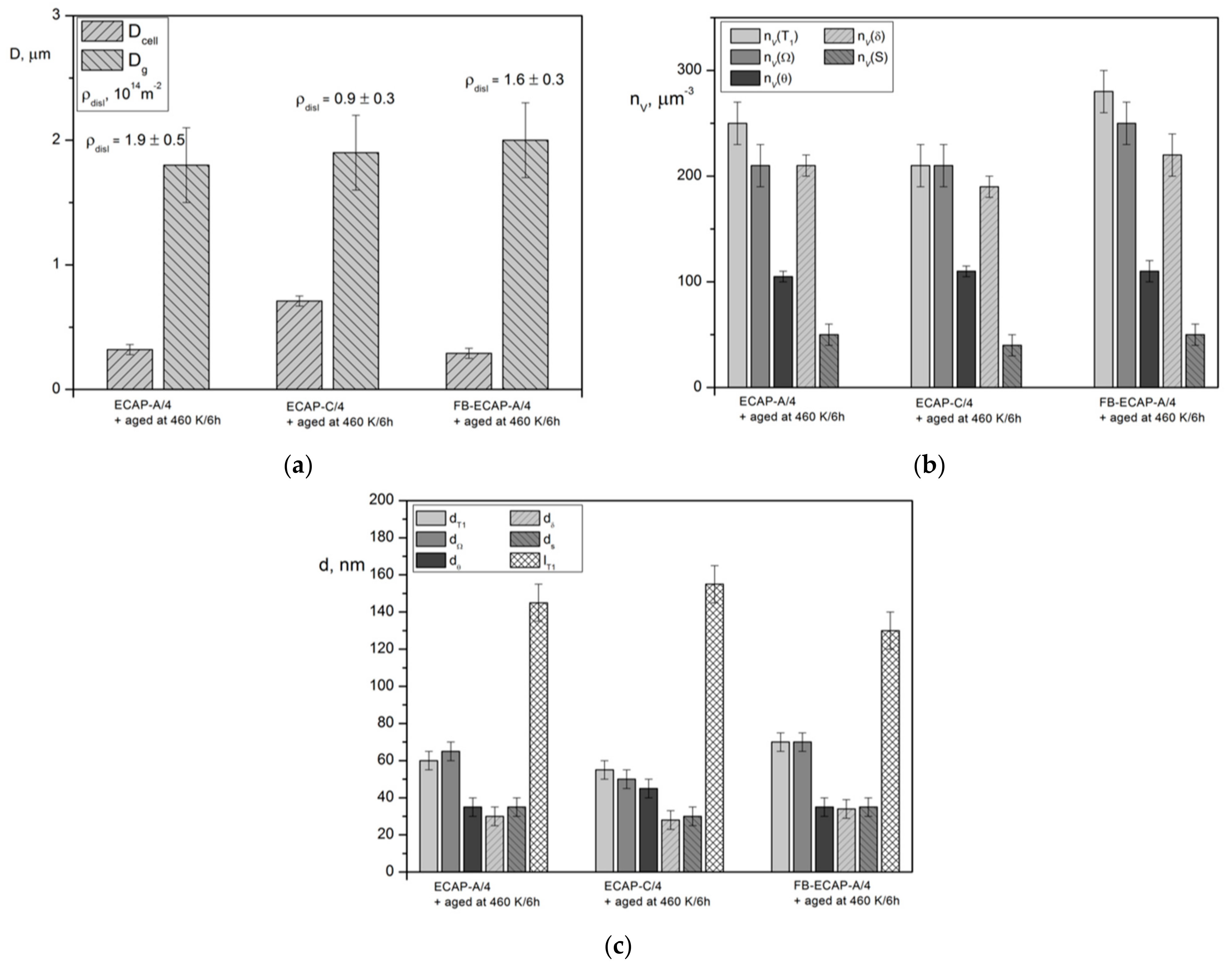

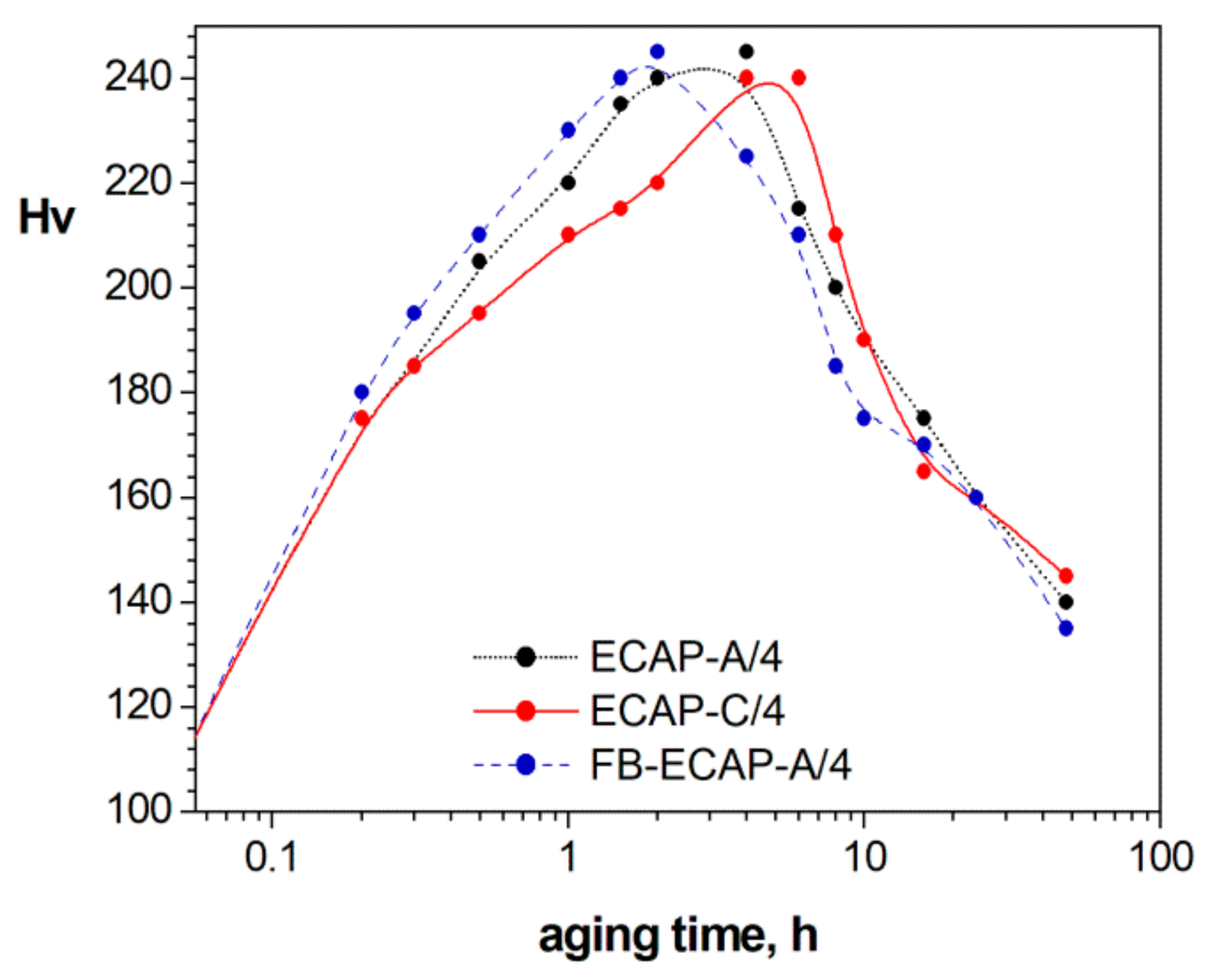

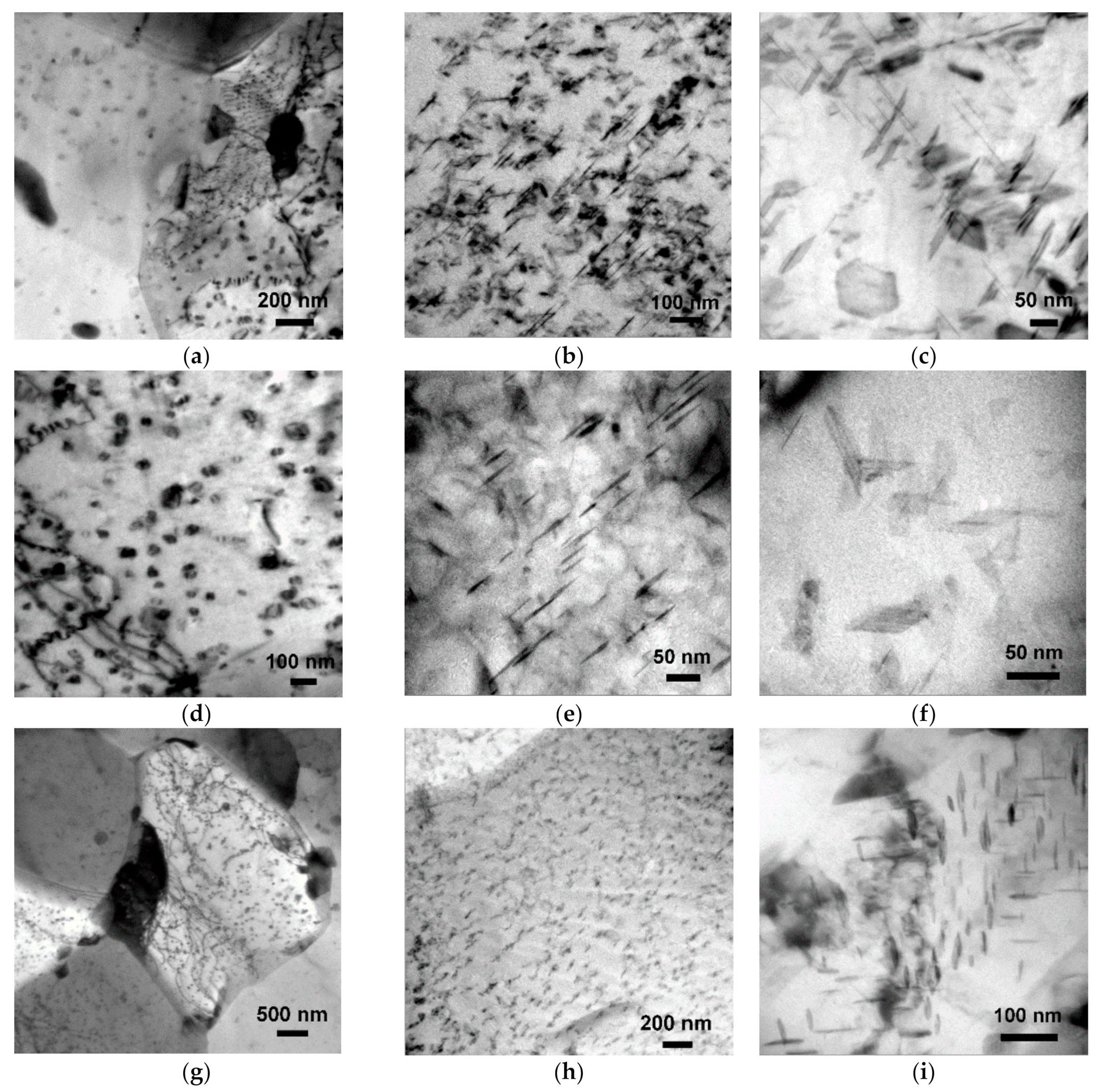

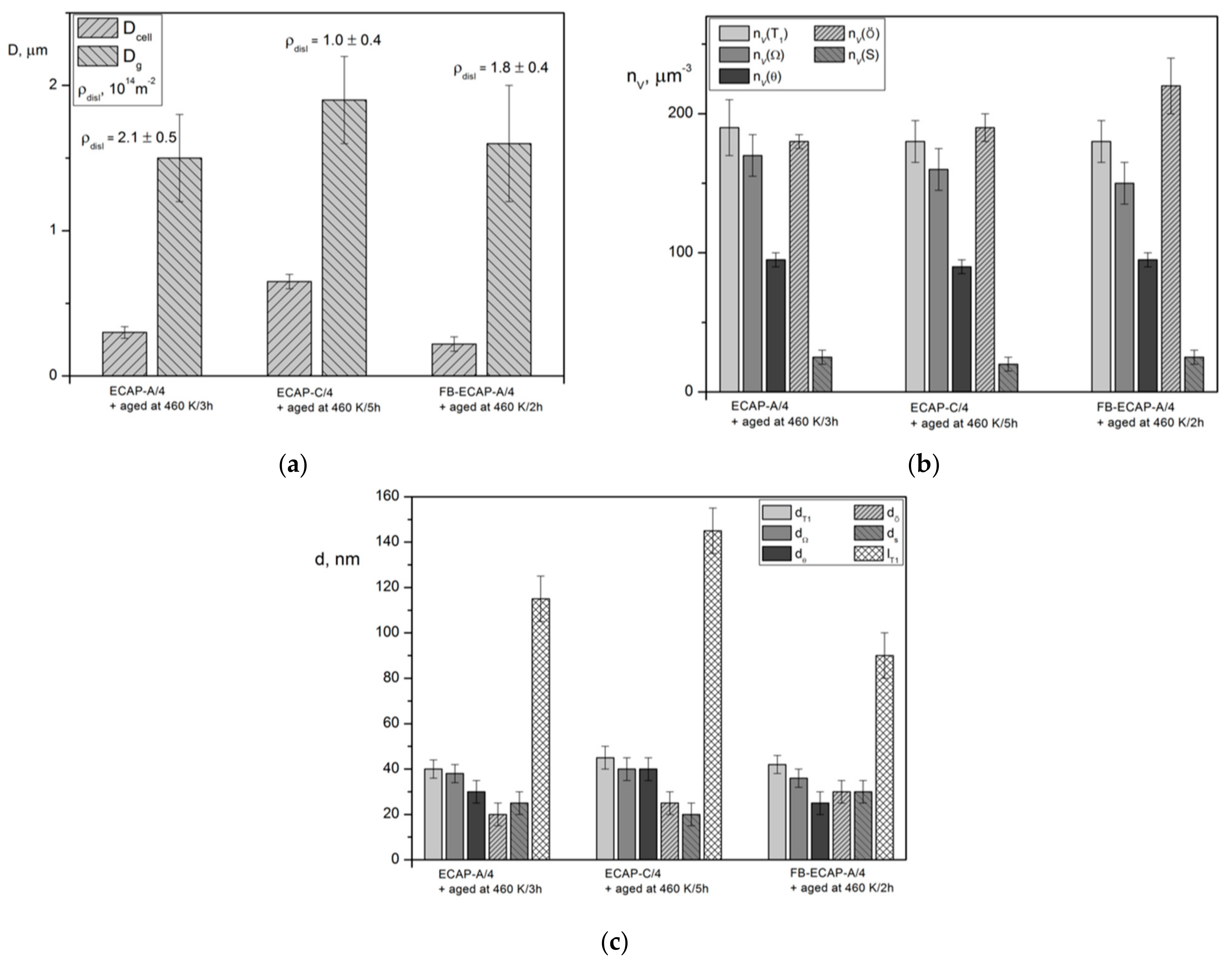

3.2. Microstructure after ECAP

4. Discussion

5. Conclusions

- (i)

- ECAP shearing and the introduced tangled dislocations were identified as responsible for a significant secondary-phase precipitation sequence acceleration. In particular, two phases were found to be greatly influenced by the presence of the tangled dislocations within the grained structure: the platelet T1-Al2CuLi and the lath S-Al2CuMg.

- (ii)

- ECAP + aging was responsible for the lath-shaped S-Al2CuMg phase precipitation, lying parallel to the Al210 planes. This phase evolved and increased in number fraction with aging time at the expense of the T1-Al2CuLi and the platelet-shaped Ω-Alx(CuLi)y precipitate phases both lying at Al111 planes;

- (iii)

- ECAP + aging induced the following precipitation sequence: GP zones + β → θ″ + θ′ + δ′ + β + T1 → β + θ + δ + T1 + (Ω + S − T1).

- (iv)

- The T1 + Ω precipitates coarsening rate with aging time was found to be of a Lifshitz-Slyozov-Wagner (LSW) type, that is, as a power-law: lT1 + Ω = KLSW t1/3, with lT1 + Ω being the platelet and lath longer edge.

- (v)

- T1 and Ω precipitates evolved by following a direct correlation to the tangled dislocation density introduced by pre-aging ECAP. The ECAP routes influenced both the volume fraction of the T1 and Ω precipitate and their growing rate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nakai, M.; Eto, T. New aspect of development of high strength aluminum alloys for aerospace applications. Mater. Sci. Eng. A 2000, 258, 62–68. [Google Scholar] [CrossRef]

- Huda, Z.; Edi, P. Materials selection in design of structures and engines of supersonic aircrafts: A review. Mater. Des. 2013, 46, 552–560. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Paoletti, C.; Regev, M.; Spigarelli, S. Modelling of creep in alloys strengthened by rod-shaped particles: Al-Cu-Mg age-hardenable alloys. Metals 2018, 8, 930. [Google Scholar] [CrossRef]

- Warner, T. Recently-Developed Aluminium Solutions for Aerospace Applications. Mater. Sci. Forum 2006, 519, 1271–1278. [Google Scholar] [CrossRef]

- Rioja, R.J.; Liu, J. The evolution of Al-Li base products for aerospace and space applications. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2012, 43, 3325–3337. [Google Scholar] [CrossRef]

- Prasad, N.E.; Gokhale, A.A.; Wanhill, R.J.H. Aluminium–Lithium Alloys. In Aerospace Materials and Material Technologies; Springer: Singapore, 2014; pp. 53–72. [Google Scholar]

- Lavernia, E.J.; Srivatsan, T.S.; Mohamed, F.A. Strength, deformation, fracture behaviour and ductility of aluminium-lithium alloys. J. Mater. Sci. 1990, 25, 1137–1158. [Google Scholar] [CrossRef]

- Gupta, R.K.; Nayan, N.; Nagasireesha, G.; Sharma, S.C. Development and characterization of Al-Li alloys. Mater. Sci. Eng. A 2006, 420, 228–234. [Google Scholar] [CrossRef]

- Ortiz, D.; Brown, J.; Abdelshehid, M.; DeLeon, P.; Dalton, R.; Mendez, L.; Soltero, J.; Pereira, M.; Hahn, M.; Lee, E.; et al. The effects of prolonged thermal exposure on the mechanical properties and fracture toughness of C458 aluminum-lithium alloy. Eng. Fail. Anal. 2006, 13, 170–180. [Google Scholar] [CrossRef]

- Deschamps, A.; Garcia, M.; Chevy, J.; Davo, B.; De Geuser, F. Influence of Mg and Li content on the microstructure evolution of AlCuLi alloys during long-term ageing. Acta Mater. 2017, 122, 32–46. [Google Scholar] [CrossRef]

- Pérez-Landazábal, J.I.; Nó, M.L.; Madariaga, G.; Recarte, V.; San Juan, J. Quantitative analysis of δ′ precipitation kinetics in Al Li alloys. Acta Mater. 2000, 48, 1283–1296. [Google Scholar] [CrossRef]

- Wei, B.C.; Chen, C.Q.; Huang, Z.; Zhang, Y. Aging behavior of Li containing Al-Zn-Mg-Cu alloys. Mater. Sci. Eng. A 2000, 280, 161–167. [Google Scholar] [CrossRef]

- Gable, B.M.; Zhu, A.W.; Csontos, A.A.; Starke, E.A. The role of plastic deformation on the competitive microstructural evolution and mechanical properties of a novel Al-Li-Cu-X alloy. J. Light Met. 2001, 1, 1–14. [Google Scholar] [CrossRef]

- Yoshimura, R.; Konno, T.J.; Abe, E.; Hiraga, K. Transmission electron microscopy study of the early stage of precipitates in aged Al-Li-Cu alloys. Acta Mater. 2003, 51, 2891–2903. [Google Scholar] [CrossRef]

- Yoshimura, R.; Konno, T.J.; Abe, E.; Hiraga, K. Transmission electron microscopy study of the evolution of precipitates in aged Al-Li-Cu alloys: The θ′ and T1 phases. Acta Mater. 2003, 51, 4251–4266. [Google Scholar] [CrossRef]

- Decreus, B.; Deschamps, A.; De Geuser, F.; Donnadieu, P.; Sigli, C.; Weyland, M. The influence of Cu/Li ratio on precipitation in Al-Cu-Li-x alloys. Acta Mater. 2013, 61, 2207–2218. [Google Scholar] [CrossRef]

- Donnadieu, P.; Shao, Y.; De Geuser, F.; Botton, G.A.; Lazar, S.; Cheynet, M.; De Boissieu, M.; Deschamps, A. Atomic structure of T1 precipitates in Al-Li-Cu alloys revisited with HAADF-STEM imaging and small-angle X-ray scattering. Acta Mater. 2011, 59, 462–472. [Google Scholar] [CrossRef]

- Dwyer, C.; Weyland, M.; Chang, L.Y.; Muddle, B.C. Combined electron beam imaging and ab initio modeling of T1 precipitates in Al-Li-Cu alloys. Appl. Phys. Lett. 2011, 98, 201909. [Google Scholar] [CrossRef]

- Khan, A.K.; Robinson, J.S. Effect of silver on precipitation response of Al-Li-Cu-Mg alloys. Mater. Sci. Technol. 2008, 24, 1369–1377. [Google Scholar] [CrossRef]

- Huang, B.P.; Zheng, Z.Q. Effects of Li content on precipitation in Al-Cu-(Li)-Mg-Ag-Zr alloys. Scr. Mater. 1998, 38, 357–362. [Google Scholar] [CrossRef]

- Huang, Z.W.; Loretto, M.H.; White, J. Influence of lithium additions on precipitation and age hardening of 7075 alloy. Mater. Sci. Technol. 1993, 9, 967–980. [Google Scholar] [CrossRef]

- Sodergren, A.; Lloyd, D.J. The influence of lithium on the ageing of A 7000 series alloy. Acta Metall. 1988, 36, 2107–2114. [Google Scholar] [CrossRef]

- Pickens, J.R.; Heubaum, F.H.; Langan, T.J.; Kramer, L.S.; Starke, J.E.A.; Sanders, J.T.H. Aluminum-lithium alloys. In Proceedings of the 5th International Aluminum-Lithium Conference, Williamsburg, VA, USA, 27–31 March 1989; MCE Publications Ltd.: Birmingham, UK, 1989; pp. 1397–1414. [Google Scholar]

- Liu, X.Y.; Pan, Q.L.; Zhang, X.L.; Liang, S.X.; Zheng, L.Y.; Gao, F.; Xie, H.L. Effects of stress-aging on the microstructure and properties of an aging forming Al–Cu–Mg–Ag alloy. Mater. Des. 2014, 58, 247–251. [Google Scholar] [CrossRef]

- Nie, J.F.; Muddle, B.C. Strengthening of an Al-Cu-Sn alloy by deformation-resistant precipitate plates. Acta Mater. 2008, 56, 3490–3501. [Google Scholar] [CrossRef]

- Kumar, K.S.; Brown, S.A.; Pickens, J.R. Microstructural evolution during aging of an Al-Cu-Li-Ag-Mg-Zr alloy. Acta Mater. 1996, 44, 1899–1915. [Google Scholar] [CrossRef]

- Li, D.Y.; Chen, L.Q. Computer simulation of stress-oriented nucleation and growth of θ′ precipitates inAl–Cu alloys. Acta Mater. 1998, 46, 2573–2585. [Google Scholar] [CrossRef]

- Huang, J.C.; Ardell, A.J. Crystal structure and stability of T 1, precipitates in aged Al–Li–Cu alloys. Mater. Sci. Technol. 1987, 3, 176–188. [Google Scholar] [CrossRef]

- Dorin, T.; Deschamps, A.; De Geuser, F.; Sigli, C. Quantification and modelling of the microstructure/strength relationship by tailoring the morphological parameters of the T1 phase in an Al-Cu-Li alloy. Acta Mater. 2014, 75, 134–146. [Google Scholar] [CrossRef]

- Dorin, T.; De Geuser, F.; Lefebvre, W.; Sigli, C.; Deschamps, A. Strengthening mechanisms of T1 precipitates and their influence on the plasticity of an Al-Cu-Li alloy. Mater. Sci. Eng. A 2014, 605, 119–126. [Google Scholar] [CrossRef]

- Gumbmann, E.; De Geuser, F.; Deschamps, A.; Lefebvre, W.; Robaut, F.; Sigli, C. A combinatorial approach for studying the effect of Mg concentration on precipitation in an Al–Cu–Li alloy. Scr. Mater. 2016, 110, 44–47. [Google Scholar] [CrossRef]

- Gault, B.; de Geuser, F.; Bourgeois, L.; Gabble, B.M.; Ringer, S.P.; Muddle, B.C. Atom probe tomography and transmission electron microscopy characterisation of precipitation in an Al-Cu-Li-Mg-Ag alloy. Ultramicroscopy 2011, 111, 683–689. [Google Scholar] [CrossRef]

- Gilmore, D.L.; Starke, E.A. Trace element effects on precipitation processes and mechanical properties in an Al-Cu-Li alloy. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 1997, 28, 1399–1415. [Google Scholar] [CrossRef]

- Itoh, G.; Cui, Q.; Kanno, M. Effects of a small addition of magnesium and silver on the precipitation of T1 phase in an Al-4%Cu-1.1%Li-0.2%Zr alloy. Mater. Sci. Eng. A 1996, 211, 128–137. [Google Scholar] [CrossRef]

- Zheng, Z.Q.; Liang, S.Q.; Xu, H.; Tan, C.Y.; Yun, D.F. Effect of 0.5% silver on the age hardening behaviour of an Al-Li-Cu-Mg-Zr alloy. J. Mater. Sci. Lett. 1993, 12, 1111–1113. [Google Scholar] [CrossRef]

- Murayama, M.; Hono, K. Role of Ag and Mg on precipitation of T1 phase in an Al-Cu-Li-Mg-Ag alloy. Scr. Mater. 2001, 44, 701–706. [Google Scholar] [CrossRef]

- Huang, B.P.; Zheng, Z.Q. Independent and combined roles of trace Mg and Ag additions in properties precipitation process and precipitation kinetics of Al-Cu-Li-(Mg)-(Ag)-Zr-Ti alloys. Acta Mater. 1998, 46, 4381–4393. [Google Scholar] [CrossRef]

- Duan, S.Y.; Wu, C.L.; Gao, Z.; Cha, L.M.; Fan, T.W.; Chen, J.H. Interfacial structure evolution of the growing composite precipitates in Al-Cu-Li alloys. Acta Mater. 2017, 129, 352–360. [Google Scholar] [CrossRef]

- Radmilovic, V.; Kilaas, R.; Dahmen, U.; Shiflet, G.J. Structure and morphology of S-phase precipitates in aluminum. Acta Mater. 1999, 47, 3987–3997. [Google Scholar] [CrossRef]

- Gu, Y.J.; Wahab, A.; Huang, Z.; Zhang, Y.G.; Chen, C.Q. The structure transformation in an Al-Li-Zn-Mg-Cu-Zr alloy. Mater. Sci. Eng. A 2001, 316, 39–45. [Google Scholar] [CrossRef]

- Fonda, R.W.; Cassada, W.A.; Shiflet, G.J. Accomodation of the misfit strain surrounding {111} precipitates (Ω) in AlCuMg(Ag). Acta Metall. Mater. 1992, 40, 2539–2546. [Google Scholar] [CrossRef]

- Bai, S.; Ying, P.; Liu, Z.; Wang, J.; Li, J. Quantitative transmission electron microscopy and atom probe tomography study of Ag-dependent precipitation of Ω phase in Al-Cu-Mg alloys. Mater. Sci. Eng. A 2017, 687, 8–16. [Google Scholar] [CrossRef]

- Cabibbo, M.; Scalabroni, C.; Evangelista, E.; Meccanica, D.; Politecnica, U. Effects of severe plastic deformation induced by equal channel angular pressing in the AA1200, AA5754, AA6082 and AA6106 modified with ZR and ZR+SC. Eff. Sev. Plast. Deform. Induc. 2013, 24, 31–40. [Google Scholar]

- Cabibbo, M.; Evangelista, E. A TEM study of the combined effect of severe plastic deformation and (Zr), (Sc+Zr)-containing dispersoids on an Al–Mg–Si alloy. J. Mater. Sci. 2006, 41, 5329–5338. [Google Scholar] [CrossRef]

- Amadori, S.; Pasquini, L.; Bonetti, E.; Cabibbo, M.; Scalabroni, C.; Evangelista, E. Anelasticity and Structural Stability of ECAP Processed Al-Mg-Si Alloys Investigated by Mechanical Spectroscopy. In Nanomaterials by Severe Plastic Deformation; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2006; Volume 503, pp. 835–840. [Google Scholar]

- Cavaliere, P.; Cabibbo, M. Effect of Sc and Zr additions on the microstructure and fatigue properties of AA6106 produced by equal-channel-angular-pressing. Mater. Charact. 2008, 59, 197–203. [Google Scholar] [CrossRef]

- Gazizov, M.; Teleshov, V.; Zakharov, V.; Kaibyshev, R. Solidification behaviour and the effects of homogenisation on the structure of an Al-Cu-Mg-Ag-Sc alloy. J. Alloys Compd. 2011, 509, 9497–9507. [Google Scholar] [CrossRef]

- Liu, J.; Yao, P.; Zhao, N.; Shi, C.; Li, H.; Li, X.; Xi, D.; Yang, S. Effect of minor Sc and Zr on recrystallization behavior and mechanical properties of novel Al–Zn–Mg–Cu alloys. J. Alloys Compd. 2016, 657, 717–725. [Google Scholar] [CrossRef]

- Shi, C.; Zhang, L.; Wu, G.; Zhang, X.; Chen, A.; Tao, J. Effects of Sc addition on the microstructure and mechanical properties of cast Al-3Li-1.5Cu-0.15Zr alloy. Mater. Sci. Eng. A 2017, 680, 232–238. [Google Scholar] [CrossRef]

- Bai, S.; Yi, X.; Liu, G.; Liu, Z.; Wang, J.; Zhao, J. Effect of Sc addition on the microstructures and age-hardening behavior of an Al-Cu-Mg-Ag alloy. Mater. Sci. Eng. A 2019, 756, 258–267. [Google Scholar] [CrossRef]

- Røyset, J.; Ryum, N. Scandium in aluminium alloys. Int. Mater. Rev. 2005, 50, 19–44. [Google Scholar] [CrossRef]

- Berbon, P.B.; Tsenev, N.K.; Valiev, R.Z.; Furukawa, M.; Horita, Z.; Nemoto, M.; Langdon, T.G. Fabrication of bulk ultrafine-grained materials through intense plastic straining. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 1998, 29, 2237–2243. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Sabirov, I.; Murashkin, M.Y.; Valiev, R.Z. Nanostructured aluminium alloys produced by severe plastic deformation: New horizons in development. Mater. Sci. Eng. A 2013, 560, 1–24. [Google Scholar] [CrossRef]

- Vinogradov, A.; Estrin, Y. Analytical and numerical approaches to modelling severe plastic deformation. Prog. Mater. Sci. 2018, 95, 172–242. [Google Scholar] [CrossRef]

- Cao, Y.; Ni, S.; Liao, X.; Song, M.; Zhu, Y. Structural evolutions of metallic materials processed by severe plastic deformation. Mater. Sci. Eng. R Rep. 2018, 133, 1–59. [Google Scholar] [CrossRef]

- Iwahashi, Y.; Horita, Z.; Nemoto, M.; Langdon, T.G. An investigation of microstructural evolution during equal-channel angular pressing. Acta Mater. 1997, 45, 4733–4741. [Google Scholar] [CrossRef]

- Cassada, W.A.; Shiflet, G.J.; Starke, E.A. The effect of plastic deformation on Al2CuLi (T1) precipitation. Metall. Trans. A 1991, 22, 299–306. [Google Scholar] [CrossRef]

- Iwahashi, Y.; Horita, Z.; Nemoto, M.; Langdon, T.G. The process of grain refinement in equal-channel angular pressing. Acta Mater. 1998, 46, 3317–3331. [Google Scholar] [CrossRef]

- Furukawa, M.; Horita, Z.; Nemoto, M.; Langdon, T.G. Review: Processing of metals by equal-channel angular pressing. J. Mater. Sci. 2001, 36, 2835–2843. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Balog, M.; Simancik, F.; Bajana, O.; Requena, G. ECAP vs. direct extrusion—Techniques for consolidation of ultra-fine Al particles. Mater. Sci. Eng. A 2009, 504, 1–7. [Google Scholar] [CrossRef]

- Cabibbo, M.; Paoletti, C.; Ghat, M.; Forcellese, A.; Simoncini, M. Post-FSW cold-rolling simulation of ECAP shear deformation and its microstructure role combined to annealing in a FSWed AA5754 plate joint. Materials 2019, 12, 1526. [Google Scholar] [CrossRef]

- Cabibbo, M.; Evangelista, E.; Vedani, M. Influence of severe plastic deformations on secondary phase precipitation in a 6082 Al-Mg-Si alloy. Metall Mater. Trans. A 2005, 36, 1353–1364. [Google Scholar] [CrossRef]

- Cabibbo, M. Partial dissolution of strengthening particles induced by equal channel angular pressing in an Al–Li–Cu alloy. Mater. Charact. 2012, 68, 7–13. [Google Scholar] [CrossRef]

- Viceré, A.; Cabibbo, M.; Paoletti, C.; Roventi, G.; Bellezze, T. Analysis of corrosion behaviour of aluminium alloy AA6012 samples processed by ECAP and cryogenic treatment. Metall. Ital. 2018, 110, 25–33. [Google Scholar]

- Viceré, A.; Roventi, G.; Paoletti, C.; Cabibbo, M.; Bellezze, T. Corrosion behavior of aa6012 aluminum alloy processed by ecap and cryogenic treatment. Metals 2019, 9, 408. [Google Scholar] [CrossRef]

- Yamashita, A.; Yamaguchi, D.; Horita, Z.; Langdon, T.G. Influence of pressing temperature on microstructural development in equal-channel angular pressing. Mater. Sci. Eng. A 2000, 287, 100–106. [Google Scholar] [CrossRef]

- Iwahashi, Y.; Wang, J.; Horita, Z.; Nemoto, M.; Langdon, T.G. Principle of equal-channel angular pressing for the processing of ultra-fine grained materials. Scr. Mater. 1996, 35, 143–146. [Google Scholar] [CrossRef]

- Langdon, T.G. The principles of grain refinement in equal-channel angular pressing. Mater. Sci. Eng. A 2007, 462, 3–11. [Google Scholar] [CrossRef]

- Furukawa, M.; Iwahashi, Y.; Horita, Z.; Nemoto, M.; Langdon, T.G. The shearing characteristics associated with equal-channel angular pressing. Mater. Sci. Eng. A 1998, 257, 328–332. [Google Scholar] [CrossRef]

- Nakashima, K.; Horita, Z.; Nemoto, M.; Langdon, T.G. Influence of channel angle on the development of ultrafine grains in equal-channel angular pressing. Acta Mater. 1998, 46, 1589–1599. [Google Scholar] [CrossRef]

- Furukawa, M.; Horita, Z.; Langdon, T.G. Factors influencing the shearing patterns in equal-channel angular pressing. Mater. Sci. Eng. A 2002, 332, 97–109. [Google Scholar] [CrossRef]

- Cabibbo, M. A TEM Kikuchi pattern study of ECAP AA1200 via routes A, C, BC. Mater. Charact. 2010, 61, 613–625. [Google Scholar] [CrossRef]

- Cabibbo, M. Microstructure strengthening mechanisms in different equal channel angular pressed aluminum alloys. Mater. Sci. Eng. A 2013, 560, 413–432. [Google Scholar] [CrossRef]

- Bruni, C.; Cabibbo, M.; Ciccarelli, D.; Paoletti, C. Characterization of double aluminium alloy specimens after ECAP. Procedia Manuf. 2018, 15, 1517–1524. [Google Scholar] [CrossRef]

- Paoletti, C.; Santecchia, E.; Di Pompeo, V.; Spigarelli, S.; Cabibbo, M. Studio dell’effetto di trattamento criogenico su una lega AA6012 sottoposta a ECAP mediante nanoindentazione. La Metall. Ital. 2020, 112, 31–41. [Google Scholar]

- Miyamoto, H.; Ikeda, T.; Uenoya, T.; Vinogradov, A.; Hashimoto, S. Reversible nature of shear bands in copper single crystals subjected to iterative shear of ECAP in forward and reverse directions. Mater. Sci. Eng. A 2011, 528, 2602–2609. [Google Scholar] [CrossRef]

- Alihosseini, H.; Asle Zaeem, M.; Dehghani, K. A cyclic forward-backward extrusion process as a novel severe plastic deformation for production of ultrafine grains materials. Mater. Lett. 2012, 68, 204–208. [Google Scholar] [CrossRef]

- Alihosseini, H.; Zaeem, M.A.; Dehghani, K.; Shivaee, H.A. Producing ultrafine-grained aluminum rods by cyclic forward-backward extrusion: Study the microstructures and mechanical properties. Mater. Lett. 2012, 74, 147–150. [Google Scholar] [CrossRef]

- Underwood, E.E. Quantitative Stereology; Addison-Wesley Series in Metallurgy and Materials; Addison-Wesley Publishing Company: Boston, MA, USA, 1970. [Google Scholar]

- Dorin, T.; Ramajayam, M.; Babaniaris, S.; Jiang, L.; Langan, T.J. Precipitation sequence in Al–Mg–Si–Sc–Zr alloys during isochronal aging. Materialia 2019, 8, 100437. [Google Scholar] [CrossRef]

- Li, G.; Zhao, N.; Liu, T.; Li, J.; He, C.; Shi, C.; Liu, E.; Sha, J. Effect of Sc/Zr ratio on the microstructure and mechanical properties of new type of Al–Zn–Mg–Sc–Zr alloys. Mater. Sci. Eng. A 2014, 617, 219–227. [Google Scholar] [CrossRef]

- Lefebvre, W.; Danoix, F.; Hallem, H.; Forbord, B.; Bostel, A.; Marthinsen, K. Precipitation kinetic of Al3(Sc,Zr) dispersoids in aluminium. J. Alloys Compd. 2009, 470, 107–110. [Google Scholar] [CrossRef]

- Jiang, J.; Jiang, F.; Zhang, M.; Xu, P.; Tang, Z.; Tong, M. Effects of annealing under fixed temperature and cyclic temperature on strength and microstructure of Al–Mg–Mn-Sc-Zr alloy. Mater. Sci. Eng. A 2019, 764, 138275. [Google Scholar] [CrossRef]

- Herring, R.A.; Gayle, F.W.; Pickens, J.R. High-resolution electron microscopy study of a high-copper variant of weldalite 049 and a high-strength AI-Cu-Ag-Mg-Zr alloy. J. Mater. Sci. 1993, 28, 69–73. [Google Scholar] [CrossRef]

- Cabibbo, M. Shear Induced Low- and High-Angle Boundary Characterization Using Kikuchi Bands in Transmission Electron Microscopy. Mater. Sci. Forum 2008, 584–586, 293–299. [Google Scholar] [CrossRef]

- Cabibbo, M.; Blum, W.; Evangelista, E.; Kassner, M.E.; Meyers, M.A. Transmission electron microscopy study of strain-induced low- and high-angle boundary development in equal-channel angular-pressed commercially pure aluminum. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2008, 39, 181–189. [Google Scholar] [CrossRef]

- Schneider, J.A.; Nunes, A.C.; Chen, P.S.; Steele, G. TEM study of the FSW nugget in AA2195-T81. J. Mater. Sci. 2005, 40, 4341–4345. [Google Scholar] [CrossRef]

- Jiang, B.; Cao, F.; Wang, H.; Yi, D.; Jiang, Y.; Shen, F.; Wang, B.; Liu, H. Effect of aging time on the microstructure evolution and mechanical property in an Al-Cu-Li alloy sheet. Mater. Sci. Eng. A 2019, 740, 157–164. [Google Scholar] [CrossRef]

- Garg, A.; Chang, Y.C.; Howe, J.M. Interfacial structure and transformation mechanism of the μ phase in Al-3.9 Cu-0.5 Mg-0.5 Ag alloy. Acta Metall. Mater. 1993, 41, 235–251. [Google Scholar] [CrossRef]

- Garg, A.; Howe, J.M. Nucleation and growth of Ω phase in Al-4.0 Cu-0.5 Mg-0.5 Ag alloy-An in situ hot-stage TEM study. Acta Metall. Mater. 1991, 39, 1925–1937. [Google Scholar] [CrossRef]

- Muddle, B.C.; Polmear, I.J. The precipitate Ω phase in Al-Cu-Mg-Ag alloys. Acta Metall. 1989, 37, 777–789. [Google Scholar] [CrossRef]

- Cai, B.; Zheng, Z.Q.; He, D.Q.; Li, S.C.; Li, H.P. Friction stir weld of 2060 Al–Cu–Li alloy: Microstructure and mechanical properties. J. Alloys Compd. 2015, 649, 19–27. [Google Scholar] [CrossRef]

- Starink, M.J.; Gregson, P.J. S′ and δ′ phase precipitation in SiCp reinforced Al-1.2wt.%Cu-1wt.%Mg-χLi alloys. Mater. Sci. Eng. A 1996, 211, 54–65. [Google Scholar] [CrossRef]

- Duan, S.Y.; Le, Z.; Chen, Z.K.; Gao, Z.; Chen, J.H.; Ming, W.Q.; Li, S.Y.; Wu, C.L.; Yan, N. Li-atoms-induced structure changes of Guinier–Preston–Bagaryatsky zones in AlCuLiMg alloys. Mater. Charact. 2016, 121, 207–212. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, L.; Wu, G.; Sun, J.; Rong, M.; Hsieh, C.-C.; Yu, Y. Influence of Sc content on the microstructure and mechanical properties of cast Al-2Li-2Cu-0.5Mg-0.2Zr alloy. Mater. Charact. 2018, 142, 223–236. [Google Scholar] [CrossRef]

- Wang, X.-M.; Li, G.-A.; Jiang, J.-T.; Shao, W.-Z.; Zhen, L. Influence of Mg content on ageing precipitation behavior of Al-Cu-Li-x alloys. Mater. Sci. Eng. A 2019, 742, 138–149. [Google Scholar] [CrossRef]

- Li, H.; Tang, Y.; Zeng, Z.; Zheng, Z.; Zheng, F. Effect of ageing time on strength and microstructures of an Al–Cu–Li–Zn–Mg–Mn–Zr alloy. Mater. Sci. Eng. A 2008, 498, 314–320. [Google Scholar] [CrossRef]

- Tao, J.; Zhang, L.; Wu, G.; Chen, A.; Zhang, X.; Shi, C. Effect of heat treatment on the microstructure and mechanical properties of extruded Al–4Cu–1Li–0.4Mg–0.4Ag–0.18Zr Alloy. Mater. Sci. Eng. A 2018, 717, 11–19. [Google Scholar] [CrossRef]

- Liu, F.; Liu, Z.; Liu, M.; Hu, Y.; Chen, Y.; Bai, S. Analysis of empirical relation between microstructure, texture evolution and fatigue properties of an Al-Cu-Li alloy during different pre-deformation processes. Mater. Sci. Eng. A 2018, 726, 309–319. [Google Scholar] [CrossRef]

- Dong, S.L.; Mao, J.F.; Yang, D.Z.; Cui, Y.X.; Jiang, L.T. Age-hardening behavior of a SiCw/Al-Li-Cu-Mg-Zr composite. Mater. Sci. Eng. A 2002, 327, 213–223. [Google Scholar] [CrossRef]

- Li, J.F.; Liu, P.L.; Chen, Y.L.; Zhang, X.H.; Zheng, Z.Q. Microstructure and mechanical properties of Mg, Ag and Zn multi-microalloyed Al-(3.2-3.8)Cu-(1.0-1.4)Li alloys. Trans. Nonferrous Met. Soc. China 2015, 25, 2103–2112. [Google Scholar] [CrossRef]

- Li, H.; Huang, D.; Kang, W.; Liu, J.; Ou, Y.; Li, D. Effect of Different Aging Processes on the Microstructure and Mechanical Properties of a Novel Al–Cu–Li Alloy. J. Mater. Sci. Technol. 2016, 32, 1049–1053. [Google Scholar] [CrossRef]

- Ma, P.; Zhan, L.; Liu, C.; Wang, Q.; Li, H.; Liu, D.; Hu, Z. Pre-strain-dependent natural ageing and its effect on subsequent artificial ageing of an Al-Cu-Li alloy. J. Alloys Compd. 2019, 790, 8–19. [Google Scholar] [CrossRef]

- Lifshitz, I.M.; Slyozov, V.V. The kinetics of precipitation from supersaturated solid solutions. J. Phys. Chem. Solids 1961, 19, 35–50. [Google Scholar] [CrossRef]

- Wagner, C. Theorie der Alterung von Niederschlägen durch Umlösen (Ostwald-Reifung). Z. Elektrochem. Berichte Bunsenges. Phys. Chem. 1961. [Google Scholar]

- Pletcher, B.A.; Wang, K.G.; Glicksman, M.E. Experimental, computational and theoretical studies of δ′ phase coarsening in Al–Li alloys. Acta Mater. 2012, 60, 5803–5817. [Google Scholar] [CrossRef]

- Novotny, G.M.; Ardell, A.J. Precipitation of Al3Sc in binary Al–Sc alloys. Mater. Sci. Eng. A 2001, 318, 144–154. [Google Scholar] [CrossRef]

- Murken, J.; Höhner, R.; Skrotzki, B. Strain path dependence of the precipitate size evolution of an Al–Mg–Li alloy under combined thermal and mechanical loading. Mater. Sci. Eng. A 2003, 363, 159–170. [Google Scholar] [CrossRef]

- Guyot, P.; Cottignies, L. Precipitation kinetics, mechanical strength and electrical conductivity of AlZnMgCu alloys. Acta Mater. 1996, 44, 4161–4167. [Google Scholar] [CrossRef]

- Yang, C.; Shao, D.; Zhang, P.; Gao, Y.H.; Zhang, J.Y.; Kuang, J.; Wu, K.; Liu, G.; Sun, J. The influence of Sc solute partitioning on ductile fracture of Sc-microalloyed Al-Cu alloys. Mater. Sci. Eng. A 2018, 717, 113–123. [Google Scholar] [CrossRef]

- Krug, M.E.; Seidman, D.N.; Dunand, D.C. Creep properties and precipitate evolution in Al-Li alloys microalloyed with Sc and Yb. Mater. Sci. Eng. A 2012, 550, 300–311. [Google Scholar] [CrossRef]

| wt.% | Cu | Li | Mg | Ag | Zr | Sc | Al |

|---|---|---|---|---|---|---|---|

| 5.4 | 1.3 | 0.40 | 0.40 | 0.20 | 0.50 | bal. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cabibbo, M.; Paoletti, C. High-Temperature Equal-Channel Angular Pressing of a T6-Al-Cu-Li-Mg-Ag-Zr-Sc Alloy. J. Manuf. Mater. Process. 2021, 5, 6. https://doi.org/10.3390/jmmp5010006

Cabibbo M, Paoletti C. High-Temperature Equal-Channel Angular Pressing of a T6-Al-Cu-Li-Mg-Ag-Zr-Sc Alloy. Journal of Manufacturing and Materials Processing. 2021; 5(1):6. https://doi.org/10.3390/jmmp5010006

Chicago/Turabian StyleCabibbo, Marcello, and Chiara Paoletti. 2021. "High-Temperature Equal-Channel Angular Pressing of a T6-Al-Cu-Li-Mg-Ag-Zr-Sc Alloy" Journal of Manufacturing and Materials Processing 5, no. 1: 6. https://doi.org/10.3390/jmmp5010006

APA StyleCabibbo, M., & Paoletti, C. (2021). High-Temperature Equal-Channel Angular Pressing of a T6-Al-Cu-Li-Mg-Ag-Zr-Sc Alloy. Journal of Manufacturing and Materials Processing, 5(1), 6. https://doi.org/10.3390/jmmp5010006