Hydrostatic Bandsaw Blade Guides for Natural Stone-Cutting Applications

Abstract

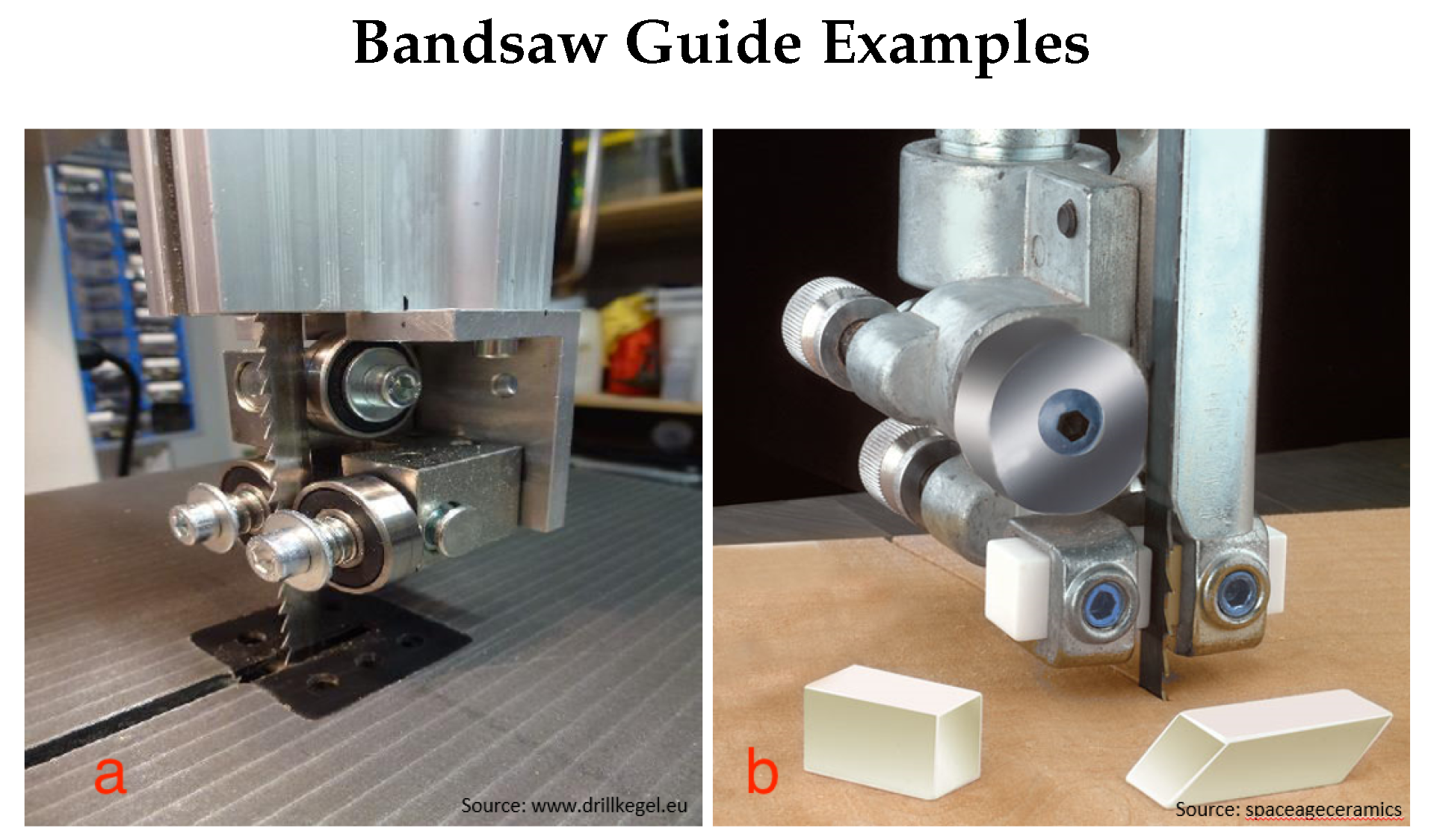

1. Introduction

2. Materials and Methods

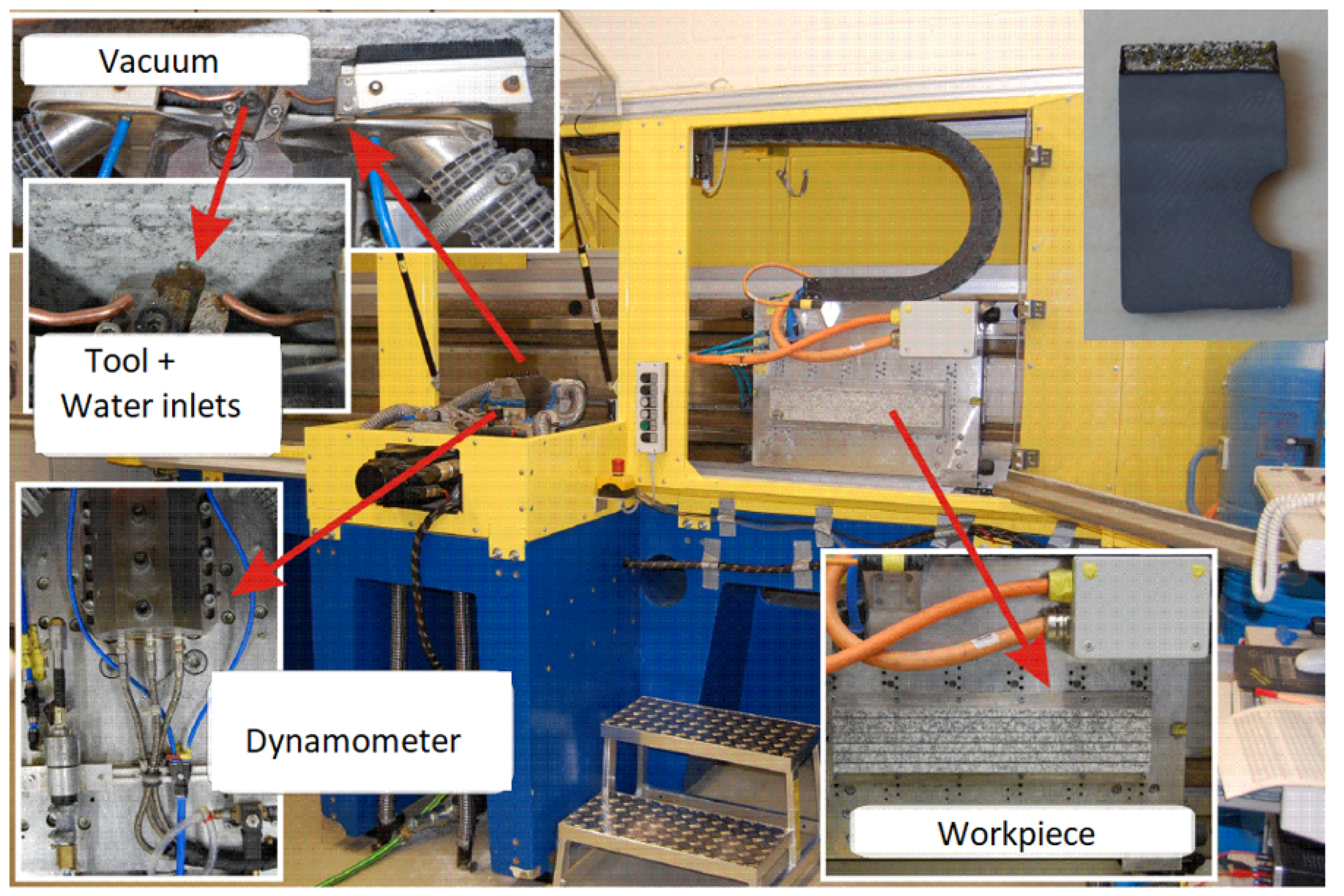

2.1. Bandsaw Machine

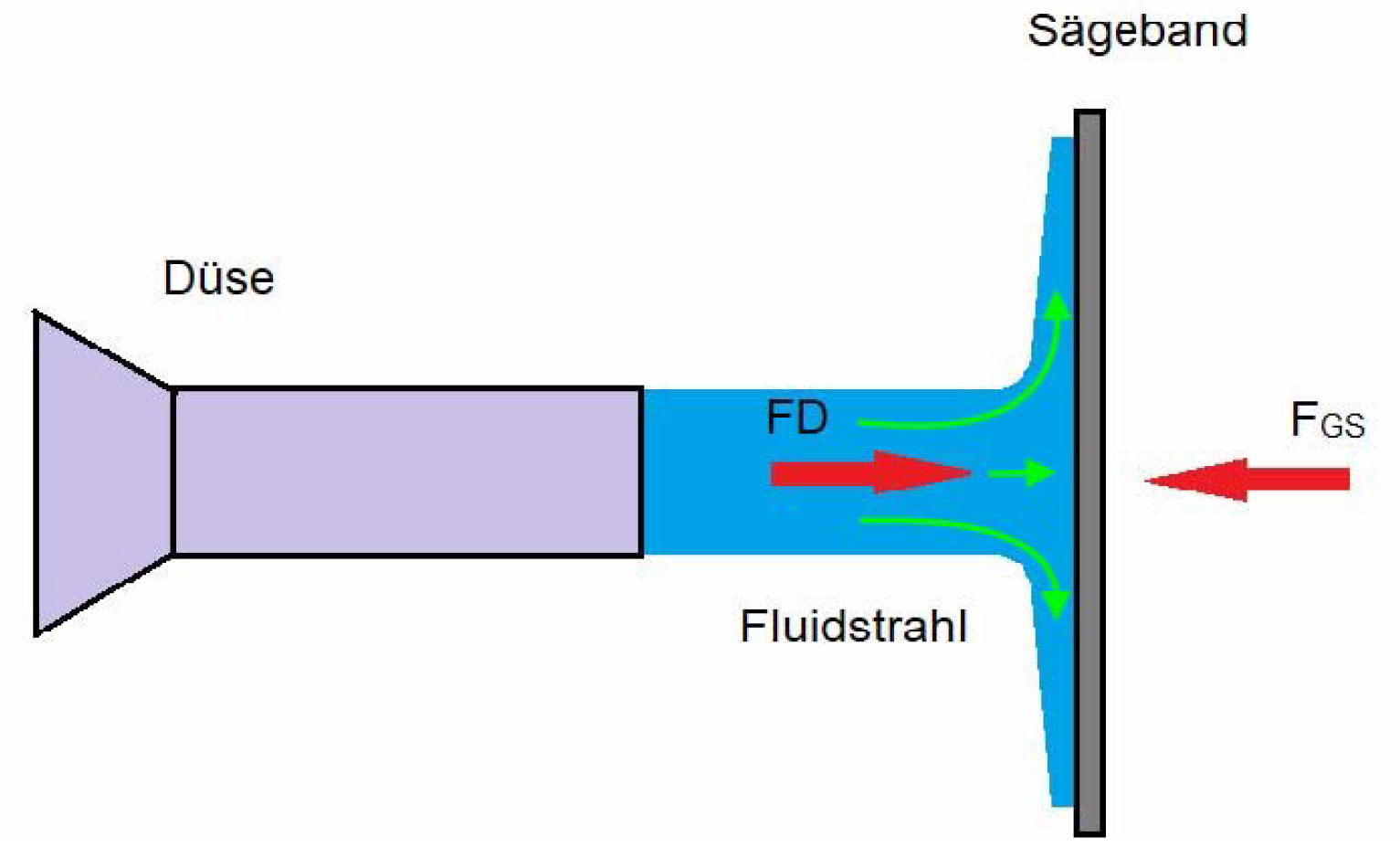

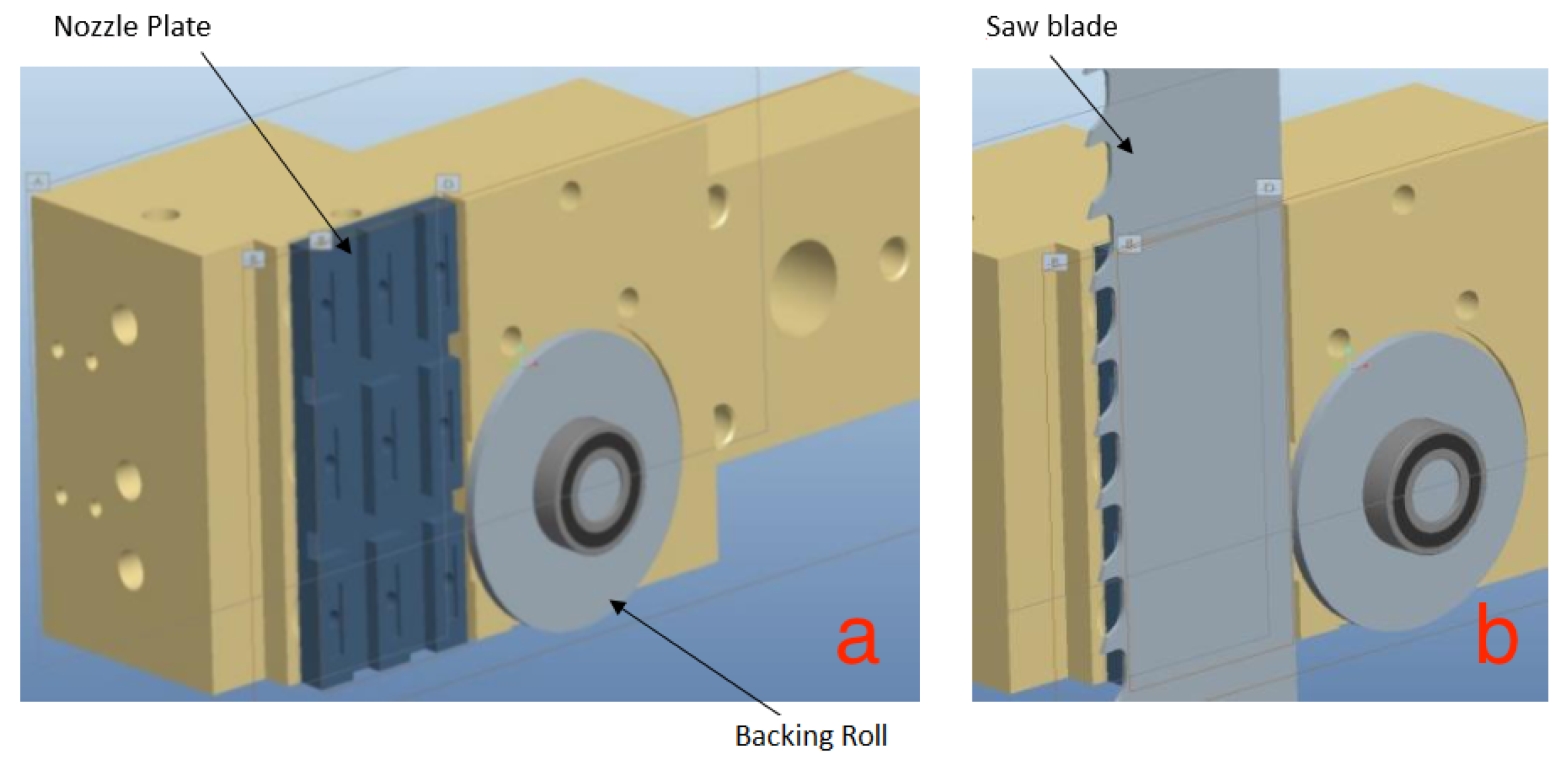

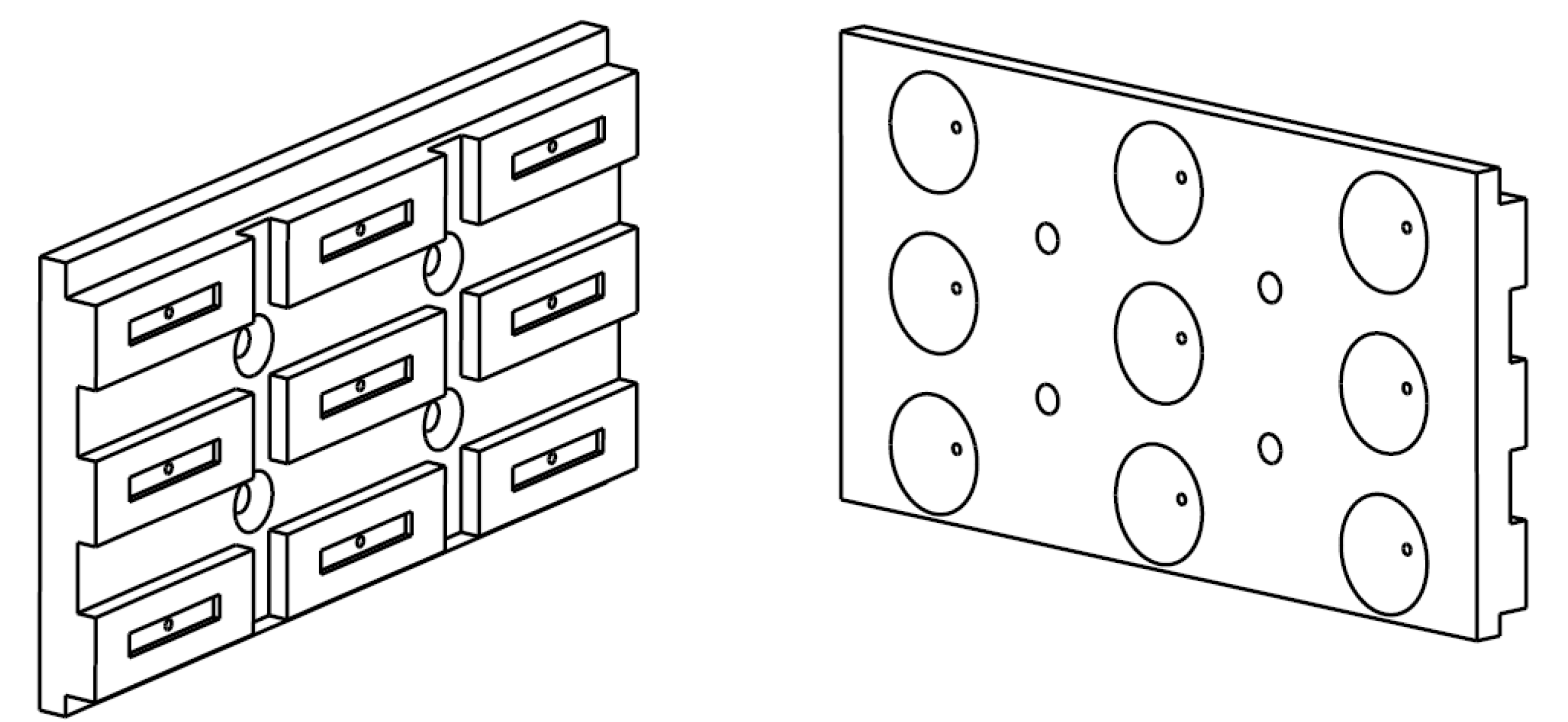

2.2. Hydrostatic Blade Guide System

2.3. Stone-Cutting Tests

3. Results

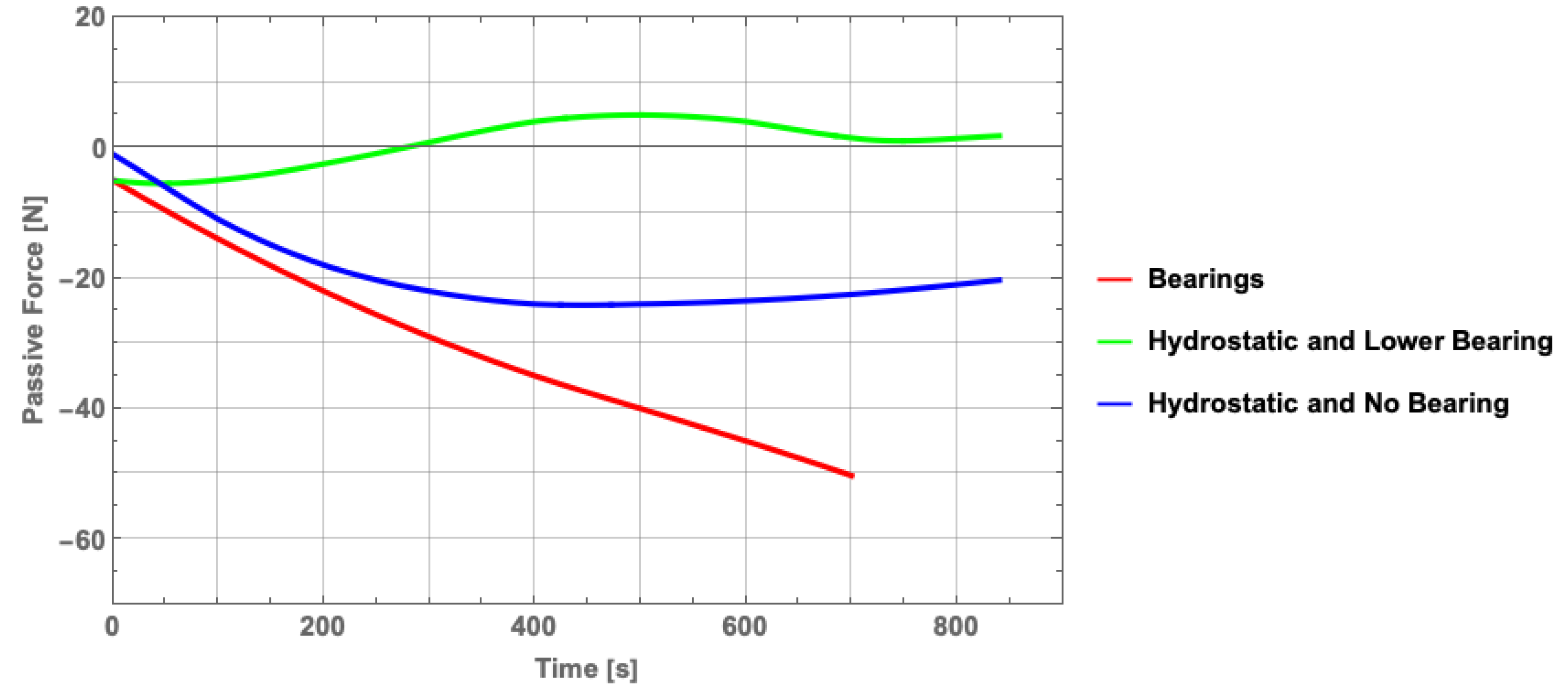

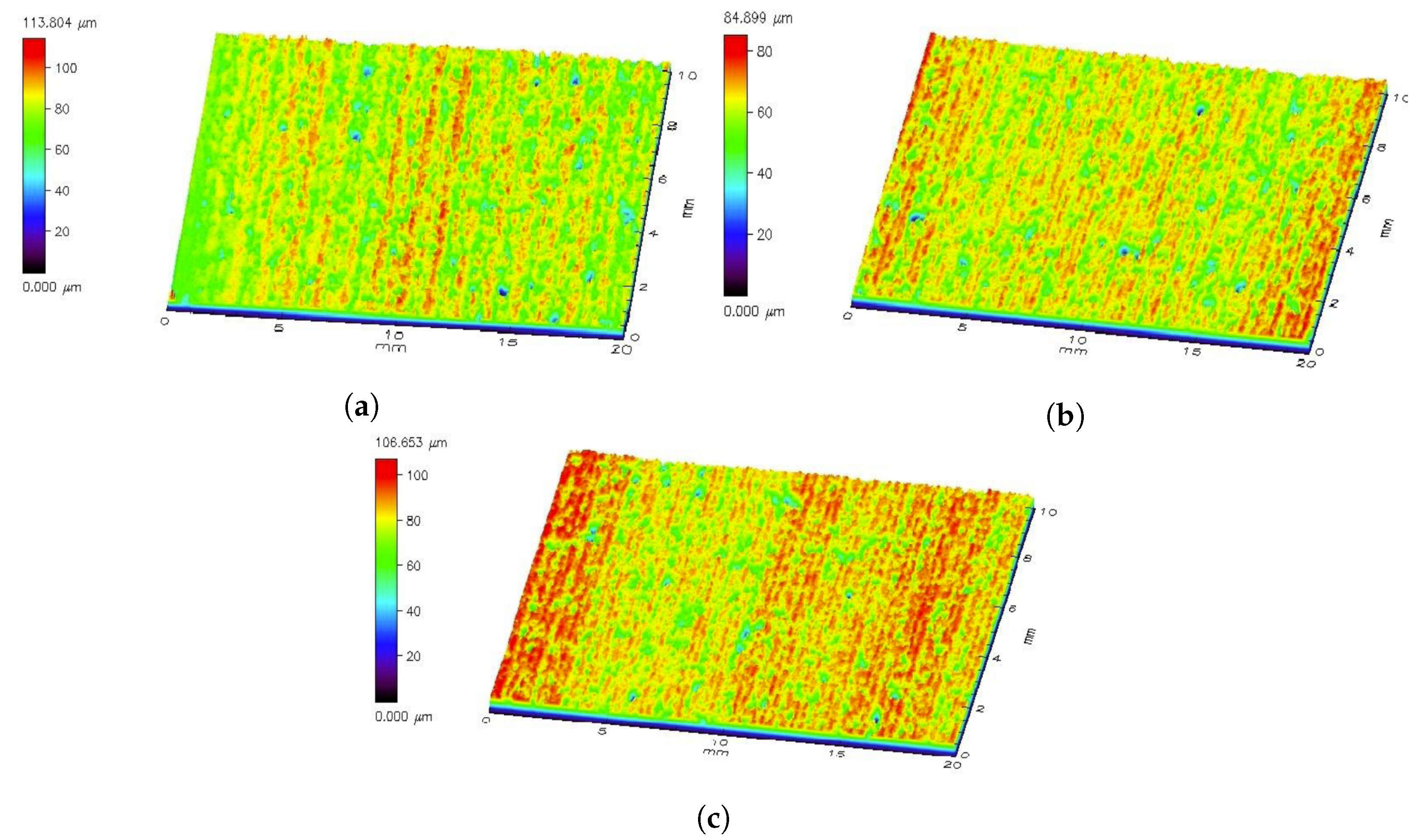

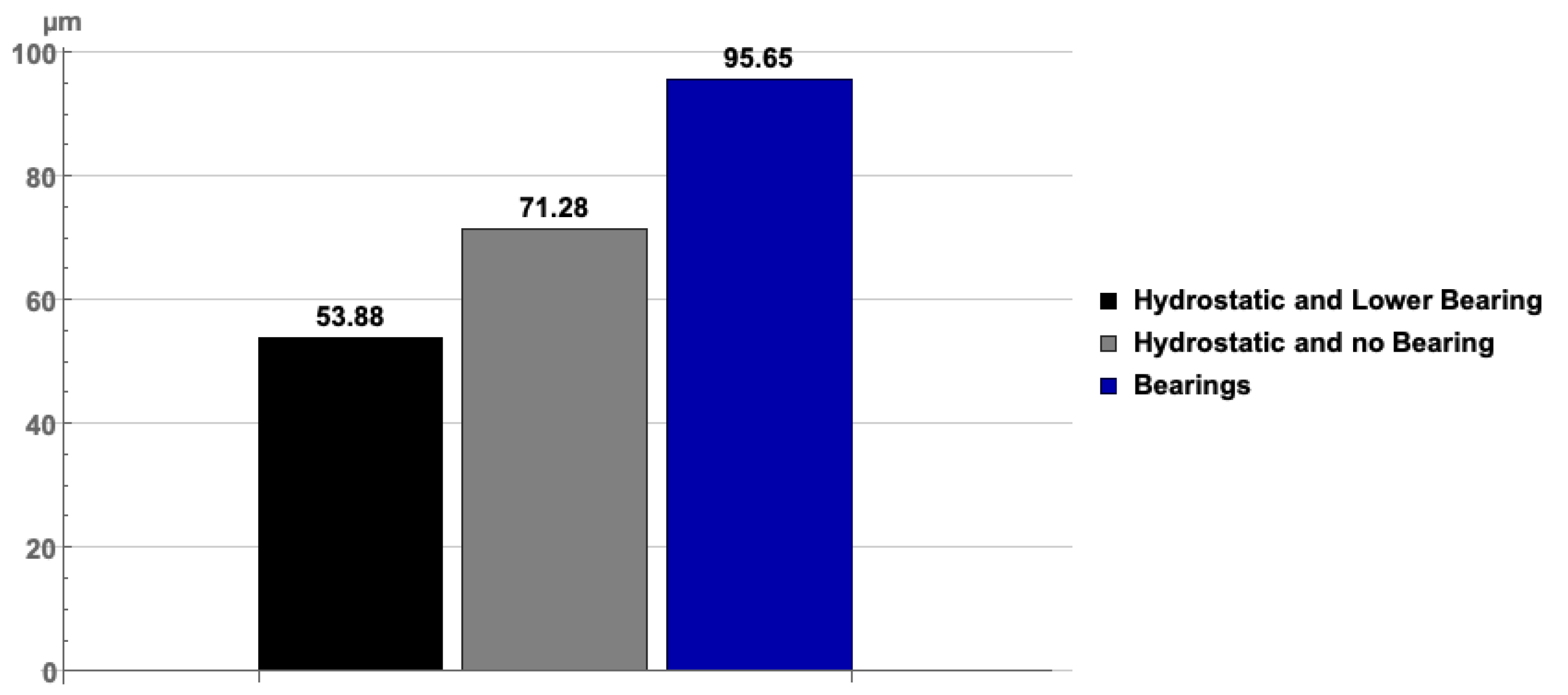

3.1. Hydrostatic Guides for Straight Cuts

3.2. Band Deflection with Hydrostatic Guides

4. Discussion

5. Conclusions

- With the upper blade guide replaced with hydrostatic guides, the average passive force reduces to almost zero and remains relatively constant throughout the cutting cycle. In contrast, the bearing guides cause the passive force to increase continuously until the end of the cutting cycle indicating a blade drift (see Figure 8).

- A reduction in surface roughness of the marble plates from of 96 m with the bearing guides to of 54 m when the upper bearing guide was replaced with a hydrostatic guide (see Figure 10) was observed. The result indicates a reduction in lateral vibration of the saw band due to hydrostatic guides.

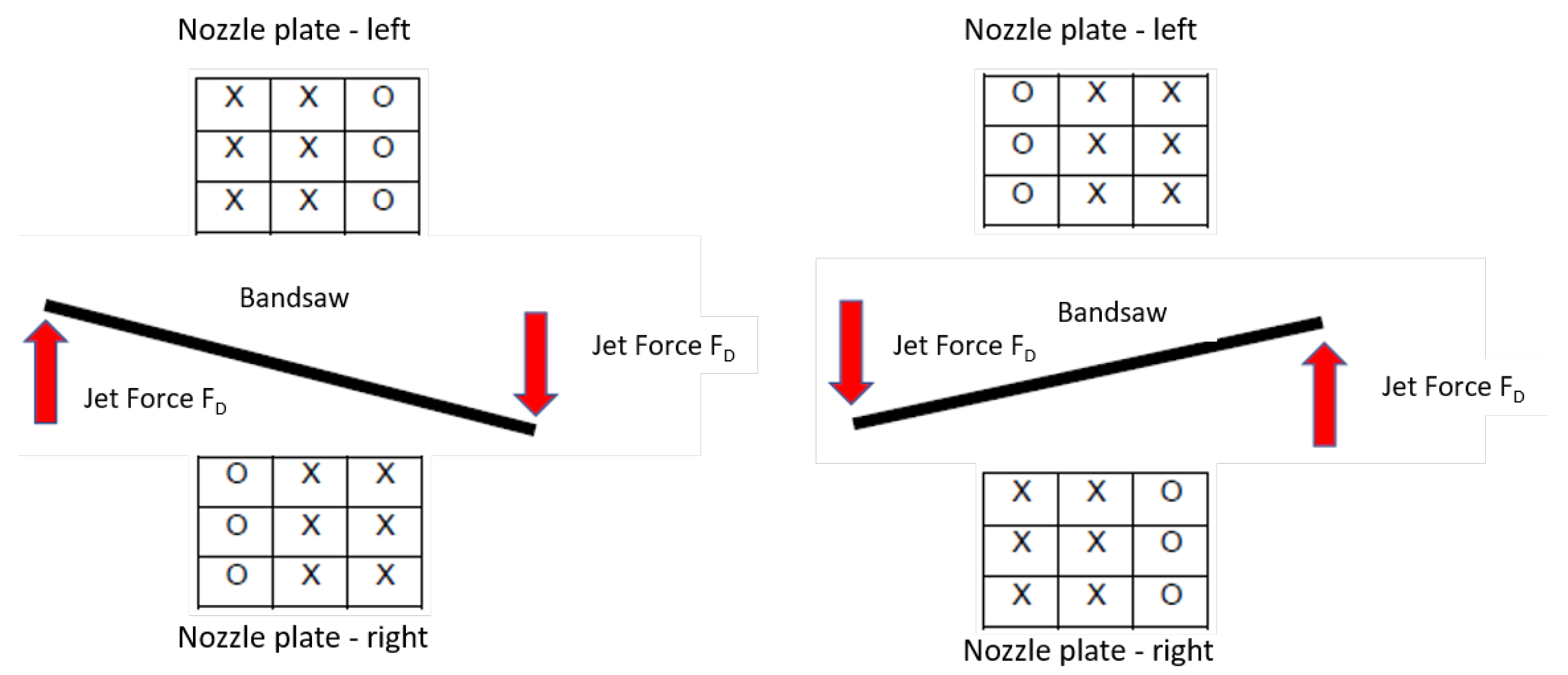

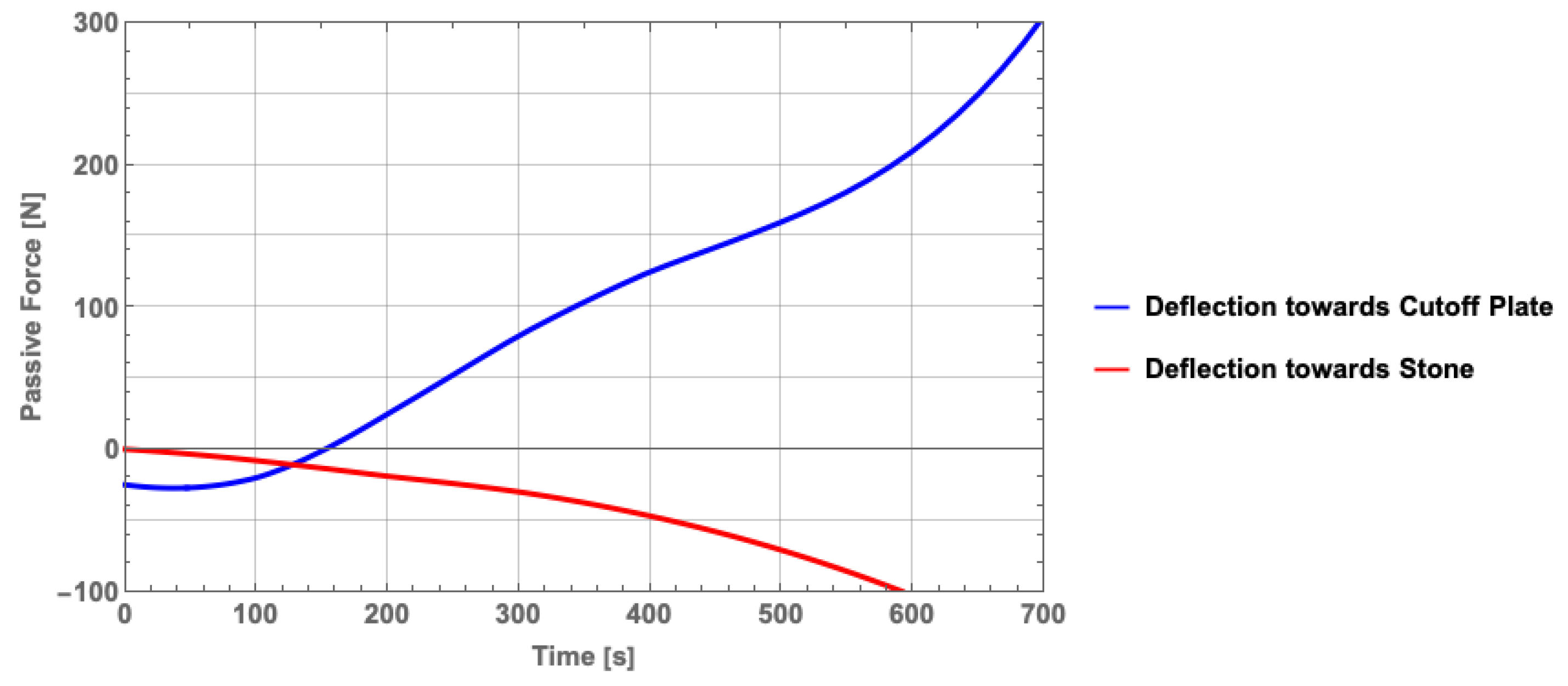

- Hydrostatic guides are also able to compensate for the blade drift by turning nozzles on and off in certain configurations (see Figure 11) and tilt the blade in the opposite direction to the drift resulting in a straight cut.

Author Contributions

Funding

Conflicts of Interest

References

- Böhm, S.; Scherm, W.; Reichenbächer, H. Steinbearbeitung mit geometrisch bestimmter Schneide aus PKD. Diam. Hochleist. Dihw Mag. 2011, 3, 32–35. [Google Scholar]

- Böhm, S.; Scherm, W.; Schwarte, S.; Heise, C. Bearbeitung von Stahlbeton mit geometrisch bistimmter Schneide aus PKD. Diam. Hochleist. (Dihw) 2012, 2, 28–35. [Google Scholar]

- Reichenbächer, H. Trennen Mineralischer Werkstoffe Mit Geometrisch Bestimmten Schneiden; Kassel University Press GmbH: Kassel, Germany, 2010. [Google Scholar]

- Heise, C.; Böhm, S.; Schwarte, S.; Roscher, H.J.; Kranz, B. Hybrid cutting of granite by use of ultrasonic assistance. Prod. Eng. 2014, 8, 567–575. [Google Scholar] [CrossRef]

- Wong, D.; Schajer, G. Factors controlling bandsaw tracking. Holz Als-Roh-Und Werkst. 2002, 60, 141–145. [Google Scholar] [CrossRef]

- Ulsoy, A.; Mote, C.; Szymni, R. Principal developments in band saw vibration and stability research. Holz Als-Roh-Und Werkst. 1978, 36, 273–280. [Google Scholar] [CrossRef]

- Prokofiev, G.F. Squeezing Aerostatic Guide for Band Saw. Russian Patent. 2011. Available online: https://patents.google.com/patent/RU117848U1/en (accessed on 8 February 2020).

- Samsonov, G.V. Handbook of the Physicochemical Properties of the Elements; Springer Science & Business Media: Berlin, Germany, 2012; p. 432. [Google Scholar]

- Wikus. Cause of Failures. Available online: http://www.wikus.de/en/guidebook/practice-tips/cause-of-failures (accessed on 18 February 2020).

- Gendraud, P.; Roux, J.C.; Bergheau, J.M. Vibrations and stresses in band saws: A review of literature for application to the case of aluminium-cutting high-speed band saws. J. Mater. Process. Technol. 2003, 135, 109–116. [Google Scholar] [CrossRef]

- Prokof’ev, G. Design Development of a Band Saw with Curvilinear Aerostatic Guides. Lesn.-Zhurnal-For. J. 2018, 99–108. [Google Scholar] [CrossRef]

- Prokof’ev, G. Opredelenie parametrov mekhanizma privoda pily lentochnopil’nogo stanka s krivolineynymi aerostaticheskimi napravlyayushchimi [Parameters Determination of the Saw Drive Mechanism of a Band Saw with Curvilinear Aerostatic Guides]. Lesn. Zhurnal 1991, 4, 55–58. [Google Scholar]

- Cleave, R. Active Bandsaw Control. Ph.D. Thesis, University of Canterbury, Christchurch, Newzealand, 2001. [Google Scholar]

- Huang, D. Experimental active vibration control of moving wood saw bands. Noise Control. Eng. J. 2008, 56, 176–182. [Google Scholar] [CrossRef]

- Sigloch, H. Technische Fluidmechanik; Springer: Berlin, Germany, 2012; Volume 1. [Google Scholar]

- Ahsan, A.; Kryukov, I.; Böhm, S. Laser Surface Structuring of Cemented Carbide for improving the Strength of Induction Brazed Joints. J. Manuf. Mater. Process. 2019, 3, 44. [Google Scholar] [CrossRef]

| Parameters | |

|---|---|

| 0.778 m/h | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahsan, A.; Kenney, K.; Kröger, J.; Böhm, S. Hydrostatic Bandsaw Blade Guides for Natural Stone-Cutting Applications. J. Manuf. Mater. Process. 2020, 4, 20. https://doi.org/10.3390/jmmp4010020

Ahsan A, Kenney K, Kröger J, Böhm S. Hydrostatic Bandsaw Blade Guides for Natural Stone-Cutting Applications. Journal of Manufacturing and Materials Processing. 2020; 4(1):20. https://doi.org/10.3390/jmmp4010020

Chicago/Turabian StyleAhsan, Ammar, Kyle Kenney, Jonas Kröger, and Stefan Böhm. 2020. "Hydrostatic Bandsaw Blade Guides for Natural Stone-Cutting Applications" Journal of Manufacturing and Materials Processing 4, no. 1: 20. https://doi.org/10.3390/jmmp4010020

APA StyleAhsan, A., Kenney, K., Kröger, J., & Böhm, S. (2020). Hydrostatic Bandsaw Blade Guides for Natural Stone-Cutting Applications. Journal of Manufacturing and Materials Processing, 4(1), 20. https://doi.org/10.3390/jmmp4010020