Abstract

Industry 4.0 requires phenomenon twins to functionalize the relevant systems (e.g., cyber-physical systems). A phenomenon twin means a computable virtual abstraction of a real phenomenon. In order to systematize the construction process of a phenomenon twin, this study proposes a system defined as the phenomenon twin construction system. It consists of three components, namely the input, processing, and output components. Among these components, the processing component is the most critical one that digitally models, simulates, and validates a given phenomenon extracting information from the input component. What kind of modeling, simulation, and validation approaches should be used while constructing the processing component for a given phenomenon is a research question. This study answers this question using the case of surface roughness—a complex phenomenon associated with all material removal processes. Accordingly, this study shows that for modeling the surface roughness of a machined surface, the approach called semantic modeling is more effective than the conventional approach called the Markov chain. It is also found that to validate whether or not a simulated surface roughness resembles the expected roughness, the outcomes of the possibility distribution-based computing and DNA-based computing are more effective than the outcomes of a conventional computing wherein the arithmetic mean height of surface roughness is calculated. Thus, apart from the conventional computing approaches, the leading edge computational intelligence-based approaches can digitize manufacturing processes more effectively.

1. Introduction

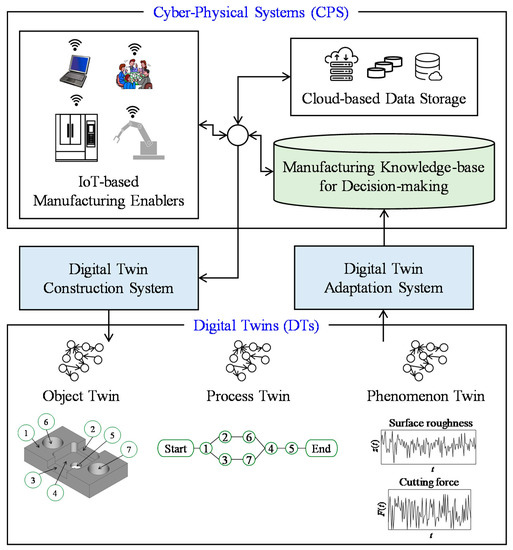

The manufacturing sector has faced four industrial revolutions (i.e., Industry 1.0, Industry 2.0, Industry 3.0, and Industry 4.0). In Industry 1.0, the main theme was to utilize steam engine-based devices. In Industry 2.0, the main theme was to enhance productivity by introducing mass production assembly lines. In Industry 3.0, the main theme was to automate the manufacturing tasks by using numerically controlled devices. Now, the manufacturing sector faces the challenges of Industry 4.0 [1,2,3]. It integrates Information and Communication Technologies (ICT) with manufacturing activities as intensively as possible. The goal is to fulfill some high-level functional requirements such as monitoring, understanding, predicting, decision-making, and adapting [2,4,5,6,7]. To achieve the above-mentioned requirements, Industry 4.0 requires some knowledge-centric embedded systems such as the Internet of Things (IoT), the Industrial Internet of Things (IIoT), and Cyber-Physical Systems (CPS) [8,9,10,11,12]. Consider CPS. These systems are nothing but ever-growing knowledge-based systems that ensure a seamless merger between the physical and cyber worlds [6,10,13,14]. The physical world refers to the manufacturing enablers (e.g., machines, tools, sensors, physical networks among computing devices, actuators, robots, computers, and the like). These are needed to perform the manufacturing activities in the real world. These enablers are linked with each other by the Internet-based infrastructures (e.g., IoT). On the other hand, the cyber world refers to the computational entities (e.g., data analytics, knowledge-based systems, algorithms, decision-making systems, and the like) and cloud-based data storage systems (e.g., historical data, information, big data, and the like). In order to materialize the CPS, the IoT-based enablers, cloud-based data storage systems, and manufacturing knowledge-bases interact with each other whenever needed; this scenario is shown in Figure 1. As seen in Figure 1, the Industry 4.0-based CPS contains Digital Twins (DTs), among others. By definition, a DT means a computable virtual abstraction of a segment of the real world; the aerospace industry originated this idea [15].

Figure 1.

The relative position of digital twins from the perspective of Industry 4.0.

As far as Industry 4.0 is concerned, DTs digitize the objects, processes, and phenomena relevant to manufacturing activities and enablers [16,17]. As such, in Industry 4.0, there are three types of DT, namely object twin, process twin, and phenomenon twin. An object twin is a computable virtual abstraction of the geometrical and topological structures of a product (e.g., a gear) or a facility (a machine tool, an assembly line, and so forth). A process twin is a computable virtual abstraction of a process or production plan (e.g., scheduling for machining a part at different workstations spread in different factories, a bill of materials, and so forth). Finally, a phenomenon twin is a computable virtual abstraction of a manufacturing phenomenon (e.g., the phenomena related to material removal processes, namely cutting force, tool wear, cutting temperature, workpiece deformation, surface roughness, chatter vibration, and so forth). All three types of DT must populate the knowledge-based systems of CPS to achieve the above-mentioned requirements of Industry 4.0. As a result, a system engineering concept called the digital twin construction system evolves, as seen in Figure 1. Its function is to construct the DTs for the intended purposes. At the same time, there must be another system, that is the digital twin adaptation system. Its function is to integrate the DTs into the relevant manufacturing systems. This means that the information of the manufacturing enablers (e.g., description of the manufacturing activities, devices, and systems), the knowledge of manufacturing processes, the information received from a manufacturing processes (e.g., sensor signals), and data from cloud storage (e.g., historical data) [10,16,17,18,19,20] are connected to the digital twin construction and adaptation systems within the framework of CPS, as schematically illustrated in Figure 1.

Though there are many studies regarding Industry 4.0 and its constituents (CPS, DT, and IoT), the construction process of DT has not yet been elucidated as elaborately as is needed for systems engineering. This is particularly true for the phenomenon twin. One of the reasons could be the intrinsic complexity associated with the manufacturing phenomena, which is difficult to digitize using the conventional analytical computational approaches. As an alternative, digitization of manufacturing phenomenon can be carried out using computational intelligence-based approaches. This study takes this alternative path. In particular, this study first proposes a Phenomenon Twin Construction System (PTCS). This study then shows how to construct a phenomenon twin focusing on surface roughness generated due to the material removal process. In this respect, this study applies different approaches within the framework of the proposed PTCS. For the sake of better understanding, the rest of this article is organized as follows: Section 2 presents a literature review on DTs and other relevant issues. Section 3 presents the proposed architecture of the PTCS. Section 4 presents the framework of the phenomenon twin construction process of surface roughness. Section 5 and Section 6 present the efficacy of the applied approaches in constructing. Finally, Section 7 provides the concluding remarks of this study.

2. Literature Review

This section briefly describes some selected articles relevant to this article.

Luo et al. [21] developed a DT for a CNC machine tool. The DT integrates knowledge related to the machine tool, information related to the machining process and sensor signals from the machining environment. It uses a machine learning algorithm for condition monitoring and fault prediction. Tong et al. [22] proposed a DT-driven Intelligent Machine Tool (IMT). The DT comprises a data acquisition system, data processing system, and data analysis system; multi-sensor fusion technology, MTConnect protocols, and HMIs (Human Machine Interfaces) functionalize these systems. These systems use sensor signals from the machining environment and information related to the machine tool and machining process for decision-making. Tao et al. [19] proposed a DT-driven product design, manufacturing, and service approach. The approach integrates information related to the product, design requirements, manufacturing process, historical data (in the form of big data), environmental factors, market survey results, and customer feedback. It helps improve the design, optimize the production and process plan, as well as intelligent service and maintenance. Shafiq et al. [23] coined a concept called Virtual Engineering Object (VEO). The VEO comprises a standard knowledge representation technique called Set of Experience Knowledge Structure (SOEKS) and a computational intelligence-based approach called Decisional DNA (DDNA). It uses shape-related information of an object and experiential knowledge (formal decisions made) for decision-making. In a similar context, Shafiq et al. [24] and Shafiq et al. [25] coined two more concepts, namely Virtual Engineering Process (VEP) and Virtual Engineering Factory (VEF) for decision-making in process planning and factory optimization, respectively. Ahmed et al. [26] and Ahmed et al. [27] added that virtual abstractions of object, process, and factory associated with SOEKS and DDNA help smart knowledge management, which functionalizes the requirements of Industry 4.0. Xu [28] proposed a concept called Machine Tool 4.0 (MT 4.0). MT 4.0 uses data-driven cyber-twins of physical machine tools to achieve self-awareness, self-optimization, and self-maintenance. It requires seamless connectivity between the twins and physical tools for the intended purpose. Kritzinger et al. [29] reviewed various aspects (definition, construction, integration, key enabling technologies, and application) of DTs in manufacturing. They described that DT construction relies on sensor signals, object or shape-related information, web-based technologies, simulation technologies (e.g., discrete event simulation, continuous simulation, deterministic simulation, and the like), and data formatting (e.g., RIDF, XML, AutomationML, and the like). Botkina et al. [30] developed a DT for a cutting tool. The DT incorporates the information related to the tool following the international standard (ISO 13399). It functionalizes information exchange among IoT-based devices. Liu et al. [31] developed a DT-based process planning approach called the Digital Twin-based Process Knowledge Model (DT-PKM). The DT-PKM incorporates information related to process equipment, process, sensor signal, and process knowledge big data. It uses a knowledge filter algorithm and an evaluation approach for decision-making in process planning. Delbrügger et al. [32] introduced a concept called Experimental Digital Twin (EDT)-based multi-level simulation; this optimizes the productivity and efficiency of production systems. The EDT-based multi-level simulation entails three levels, namely process simulation level, factory simulation level, and human interaction level. These levels use AutomationML (AML) for data exchange. Olivotti et al. [33] proposed DTs of manufacturing services. The DTs use sensor signals and installed bases (detailed knowledge of machines, components, and subcomponents associated with a manufacturing facility) for process planning (maintaining high machine availability and reducing downtime). Leng et al. [34] proposed a DT-driven Manufacturing Cyber-Physical System (MCPS). MCPS comprises decentralized DT models and bi-level online intelligence; this facilitates proactive decision-making in controlling and optimizing a manufacturing workshop. Guo et al. [35] proposed a concept called modular-based DT. The concept considers the flexibility of DT a key element for factory design. Zhang et al. [36] addressed a concept called Product Manufacturing Digital Twin (PMDT). The PMDT integrates information related to the product, design requirements, manufacturing process, shop-floor elements (devices, machines, and equipment), and virtual knowledge-bases. The authors also addressed PMDT as a key element for materializing the CPS in a production shop floor. Tao et al. [37] introduced a Digital Twin Shop-floor (DTS). The DTS incorporates information related to the shop-floor, sensor signals, and historical data to monitor the shop-floor and optimizing the process plans. Scaglioni and Ferretti [38] introduced object-oriented modeling to create a DT of a machine tool. The DT comprises an FEM-based description of the structural flexibility of the components of the kinematic structure, the model of the cutting process, the model of the transmission chain, the model of the control system, and the sensor signals. Ullah [16] and Ghosh et al. [17] described that, apart from virtual abstractions of objects and processes, the phenomenon twin must populate the knowledge-based systems of CPS for functionalizing Industry 4.0. In this respect, Ullah [16] introduced a methodology called semantic modeling. The methodology incorporates modeling of the stochastic features associated with the phenomenon, the simulation of the features to recreate the phenomenon, and validation (comparison of the simulated outcomes with the expected one) using a possibility distribution. The author also discussed the integration of the twin with other systems of Industry 4.0 via semantic web representation. Ullah [39] introduced a dynamical system-based approach for modeling non-linear machining phenomena. The approach modifies a segment of a dynamical system called the Q-sequence to model surface roughness. The author also validated the modeled roughness using conventional roughness parameters such as arithmetic mean height roughness (Ra) and peak to valley height roughness (Rz), as well as non-conventional computational approaches such as entropy and the possibility distribution. Ghosh et al. [17] proposed a Hidden Markov Model (HMM)-based approach for constructing the phenomenon twin. The approach models and simulates the surface roughness (manifested in the form of time series) by using a Markov chain and a discrete event Monte Carlo simulation, respectively. The authors also validated the simulated outcomes using the possibility distribution.

In summary, the information of the manufacturing enablers (e.g., description of the manufacturing activities, devices, equipment, and systems), the knowledge of manufacturing processes, the information received from the manufacturing environment (e.g., sensor signals), and data from cloud storage (e.g., historical data) are used to construct different types of DTs. Although different DT construction approaches (e.g., machine learning algorithm, data-driven approach, modular approach, DDNA- and SOEKS-based VEO, VEP, and VEF, semantic modeling, and so forth) are found in the extant literature, the architecture of a DT and its construction process have not yet been elucidated as elaborately as is needed for systems engineering. This is true for the phenomenon twin in particular because most of the machining phenomenon are complex and stochastic.

3. Phenomenon Twin Construction System

As described in the previous section, the architecture of a DT and its construction process have not yet been elucidated as elaborately as is needed for systems engineering. This section fills this gap by proposing a Phenomenon Twin Construction System (PTCS).

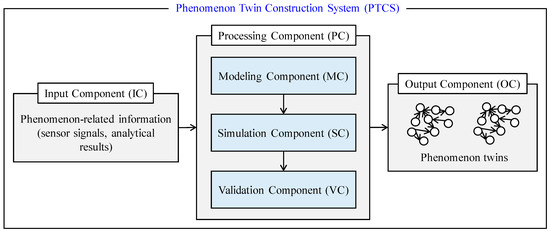

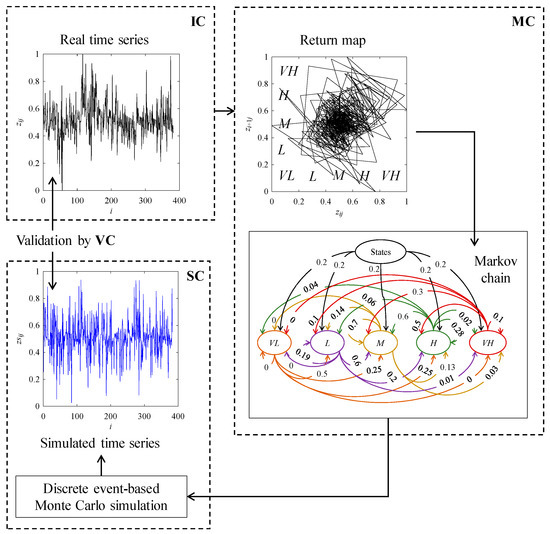

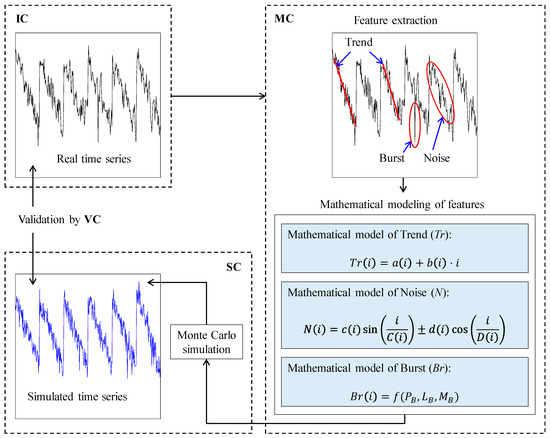

The proposed PTCS is schematically illustrated in Figure 2. It (PTCS) consists of three basic components, namely the Input Component (IC), Processing Component (PC), and Output Component (OC). The IC deals with the input information (e.g., sensor signals, analytical results, and so on) related to a given manufacturing phenomenon (e.g., cutting force, surface roughness, and the like). The PC processes the information obtained from the IC by its subcomponents and preserves the phenomenon in digital form. For the other component, OC injects the outcomes of PC into the knowledge-based systems of the CPS. A general description of the components of PTCS is as follows.

Figure 2.

Proposed architecture of Phenomenon Twin Construction System (PTCS).

First, consider the IC. Manufacturing phenomena (e.g., cutting force, surface roughness, chatter vibration, and the like) are complex and exhibit stochastic features [16,17]. It is a cumbersome task to model such phenomena analytically. In a real-life manufacturing environment, when a phenomenon is studied—either by conducting an experiment or by performing an analysis—the results are recorded using some time series datasets generated from various sensors (e.g., force sensor, pressure sensor, acoustic emission sensor, thermal sensor, and the like). Hence, the most likely manifestation of a manufacturing phenomenon is a time series dataset exhibiting stochastic features. Such a manifestation can provide the underlying process dynamics and performance [16,40]. Therefore, how to obtain and store the time series datasets of a given manufacturing phenomenon become the main concern of the IC.

Next, consider the PC. It must recognize the outcomes of the IC. It consists of three subcomponents, namely the Modeling Component (MC), Simulation Component (SC), and Validation Component (VC). MC encapsulates the dynamics underlying the phenomenon by modeling the relevant time series datasets. In this respect, different modeling approaches reported in the literature (e.g., Q sequence-based approach, Markov chain-based approach, and semantic modeling-based approach) can be used. SC simulates the phenomenon based on the modeling approach used by MC. In this respect, different approaches reported in the literature (e.g., discrete event Monte Carlo simulation and deterministic simulation) can be used. Finally, VC confirms whether or not the simulated phenomenon becomes the replica of the real one. In this respect, the computational approaches based on the concepts of entropy and possibility distribution can be used [16,39,41]. Other approaches, e.g., DNA-based computing [42,43,44] and Decisional DNA (DDNA) [45,46,47], can also be used for the same purpose. Now, validation from the perspective of Industry 4.0 has a special significance. It is vital for pragmatic adaptation, that is the generative integration among the supportive, but independent workspaces [2,4,10,16,42,48,49,50]. This characteristic makes Industry 4.0 different from its immediate predecessor (Industry 3.0) [16].

Finally, consider the OC. It makes the DT compatible with CPS. As such, semantic web-based representation of the DT becomes an issue for OC, since the semantic web supplies contents that are used in CPS for access and reuse [16].

Nevertheless, depending on the nature of the phenomenon, what kind of modeling, simulation, and validation approaches should be used in a phenomenon-specific PTCS is a research question. This question is answered focusing on surface roughness—a complex phenomenon associated with all manufacturing processes—as follows.

4. PTCS for Surface Roughness

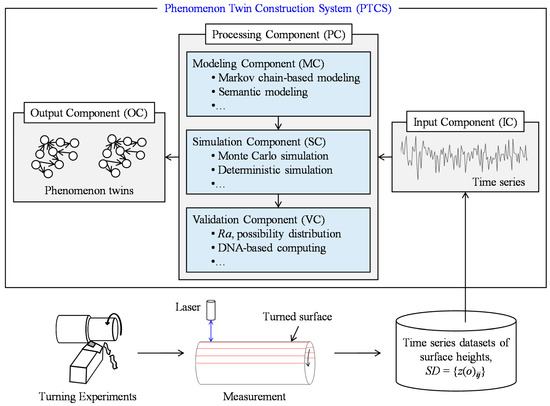

This section presents a general framework to construct a phenomenon twin of surface roughness of a turned surface, as schematically illustrated in Figure 3.

Figure 3.

Outlining the phenomenon twin construction of surface roughness.

As seen in Figure 3, the turning experiment takes place on a workpiece surface under the given cutting conditions (e.g., depth of cut, feed rate, cutting velocity, cutting directions, and the like). When the experiment is completed, the surface heights of the workpiece surface are measured by using noncontact (laser) surface metrology equipment. See the work described in [51] for details. The measurement results’ time series datasets of surface heights are denoted as SD = {z(o)ij ∈ | o = 1,…,O, i = 0,1,…,N, j = 1,…,J}. These time series datasets (collected from the work described in [51]) are shown in Figure A1 in Appendix A. However, as seen in Figure 3, SD becomes the main concern of IC of the PTCS. PC recognizes the outcomes of IC and, thereby, digitizes the surface heights using its three subcomponents: MC, SC, and VC. In this respect, MC uses two modelling approaches, namely Markov chain and semantic modeling, to encapsulate the dynamics underlying SD (time series of surface heights). SC uses a discrete event Monte Carlo simulation approach to recreate the surface heights. VC uses three approaches, namely arithmetic mean height roughness (Ra), possibility distribution, and DNA-based computing, for the sake of validation. The goal is to find the efficacy of these approaches in constructing the phenomenon twin.

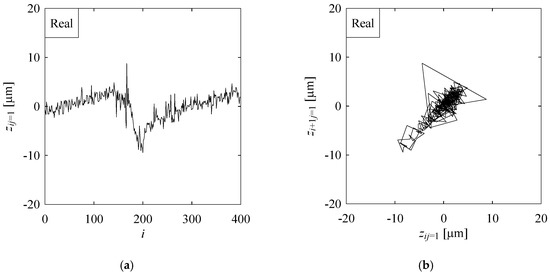

As an example, let IC consider the first time series dataset of surface heights from SD denoted as zij = 1, as seen in Figure 4; this time series is the real or expected one. The return map is also shown to understand the variability associated with the time series.

Figure 4.

Outcomes of IC: (a) real surface heights; (b) return map of (a).

The PC recognizes the outcomes of IC and, thereby, digitizes the surface heights using its three subcomponents: MC, SC, and VC. In this respect, MC, SC, and VC use the above-mentioned approaches. Based on the approach used by MC, the outcomes of SC and VC are affected. Hence, to understand better, the performance of MC, SC, and VC in constructing the phenomenon twin is described in two different sections, namely, “Modeling, Simulation, and Validation Components—Option 1” and “Modeling, Simulation, and Validation Components—Option 2”, as follows.

5. Modeling, Simulation, and Validation Components—Option 1

This section describes the performance of MC, SC, and VC in constructing the phenomenon twin of surface roughness; MC uses the Markov chain-based modeling approach; SC uses a discrete event Monte Carlo simulation approach; and VC uses the arithmetic mean height roughness (Ra), possibility distribution, and DNA-based computing-driven approaches. This section also discusses the results obtained.

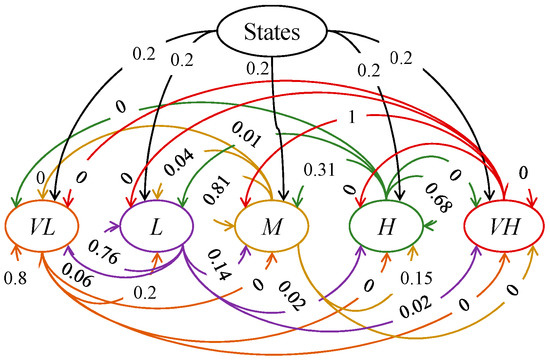

When MC uses the Markov chain-based modeling approach for encapsulating the dynamics underlying a given time series, the scenario as seen in Figure 5 (rearranged from the work described in [17]) evolves. MC recognizes the time series of surface heights from IC and defines its return map by using a set of user-defined discrete states, e.g., {Very Low (VL), Low (L), Moderate (M), High (H), Very High (VH)}. This results in a Markov chain showing the probability of transition from a given state to other possible states, e.g., the transitions to the states denoted as VL, L, M, H, and VH from VL exhibit the following probabilities: P(VL|VL) = 0, P(L|VL) = 0.5, P(M|VL) = 0.25, P(H|VL) = 0.25, and P(VH|VL) = 0. Thus, MC encapsulates the dynamics underlying the time series in terms of a Markov chain. SC simulates the surface heights by using a Monte Carlo simulation of discrete states associated with the Markov chain. Finally, VC validates the simulated time series compared to the real one. Note that the mathematical formulations and simulation algorithm corresponding to MC and SC, respectively, are beyond the scope of this study. One may refer to the work described in [17] for details.

Figure 5.

Outlining phenomenon twin construction of surface roughness using the Markov chain-based modeling approach [17].

Nevertheless, using the above-mentioned contemplation, MC encapsulates the dynamics underlying the real time series of surface heights, that is zij=1 (can also be seen from Figure 4) in terms of a Markov chain, as seen in Figure 6. SC simulates the surface heights by using a Monte Carlo simulation of discrete states associated with the Markov chain. In this respect, Figure 7 shows the simulated time series of surface heights denoted as zsij=1 and its return map. As seen in Figure 4 and Figure 7, zsij = 1 is more stochastic compared to zij=1. In particular, the returns from one point to another are non-identical. This means that zsij=1 is not similar to zij=1. This also means that the Markov chain-based modeling approach is not effective for modeling surface roughness.

Figure 6.

Outcome of Markov chain-based MC.

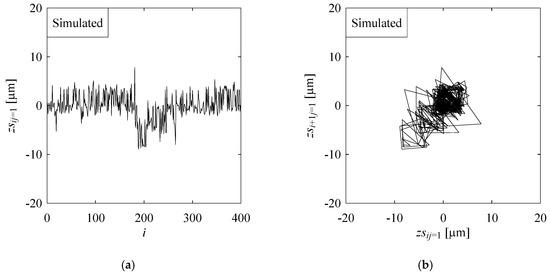

Figure 7.

Outcomes of discrete event Monte Carlo simulation-based SC associated with Markov chain-based MC: (a) simulated surface heights; (b) return map of (a).

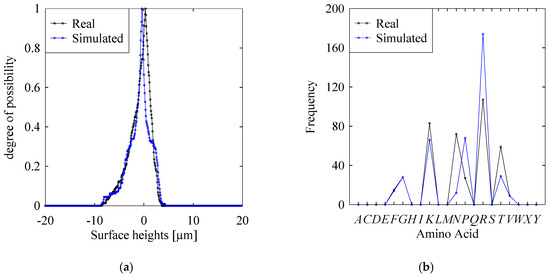

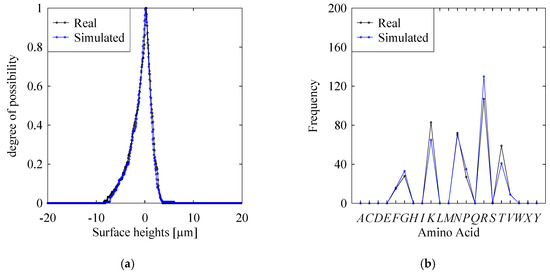

The dissimilarity in the expected and simulated roughness profiles must be detected by the validation approaches in VC. In this respect, the validation by Ra is not effective. The reason is as follows. The values of Ra for zij=1 (expected roughness) and zsij=1 (simulated roughness) are 1.979261025 and 2.014569035, respectively. This means that the values of Ra of two dissimilar roughness profiles (expected and simulated) resemble each other, which should not be the case. On the other hand, the possibility distributions of the expected and simulated surface roughness are not the same, as seen in Figure 8a. This means that the possibility distribution-driven validation approach is comparatively effective. A similar result is obtained for the other validation approach, that is DNA-based computing. The frequencies of the amino acids (generated by applying DNA-based computing) of the expected and simulated roughness profiles exhibit dissimilar patterns, as seen in Figure 8b.

Figure 8.

Outcomes of VC corresponding to Markov chain-based MC and discrete event Monte Carlo simulation-based SC: (a) possibility distribution; (b) DNA-based computing.

6. Modeling, Simulation, and Validation Components—Option 2

This section describes the performance of MC, SC, and VC in constructing the phenomenon twin of surface roughness; MC uses the semantic modeling approach; SC uses a Monte Carlo simulation approach; and VC uses the arithmetic mean height roughness (Ra), possibility distribution, and DNA-based computing-driven approaches. This section also discusses the results obtained.

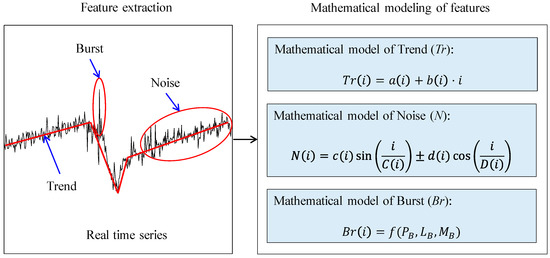

When MC uses the semantic modeling approach for encapsulating the dynamics underlying a given time series, the scenario as seen in Figure 9 (rearranged from the work described in [16]) evolves. MC extracts some stochastic features, namely trend, noise, and burst, exhibited by the time series. Here, trend refers to a straight line with a positive or negative slope associated with the time series. It is worth mentioning that trend may result because of alignment error between the workpiece and cutting tool. Noise refers to a small-magnitude irregularity associated with the time series. Burst refers to a large short-period deviation of time series. MC models these stochastic features by using a set of mathematical formulations. SC simulates the features by using a Monte Carlo simulation approach. This results in the simulated time series of surface heights. VC validates the simulated time series compared to the real one. Note that the mathematical formulations and simulation algorithm corresponding to MC and SC, respectively, are beyond the scope of this study. One may refer to the work described in [16] for details.

Figure 9.

Outlining phenomenon twin construction of surface roughness using the semantic modeling approach [16].

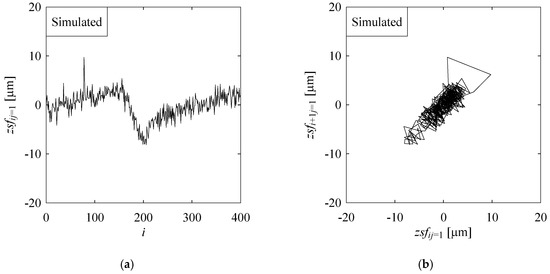

Nevertheless, using the above-mentioned contemplation, MC extracts the stochastic features underlying the real time series of surface heights, that is zij=1 (can also be seen from Figure 4), as seen in Figure 10. The stochastic features contain four trends associated with noise and sudden burst. MC models these features using certain mathematical formulations. SC simulates the surface heights by using a Monte Carlo simulation associated with the models. In this respect, Figure 11 shows the simulated time series of surface heights denoted as zsfij=1 and its return map. As seen in Figure 4 and Figure 11, zsfij=1 resembles zij=1. In particular, the returns from one point to another are identical. This means that zsfij=1 is similar to zij=1. This also means that the semantic modeling approach is effective for modeling surface roughness.

Figure 10.

Outcome of the semantic modeling-based MC.

Figure 11.

Outcomes of the Monte Carlo simulation-based SC associated with the semantic modeling-based MC: (a) simulated surface heights; (b) return map of (a).

The similarity in the expected and simulated roughness profiles must be detected by the validation approaches in VC. In this respect, the validation by Ra is effective. The reason is as follows. The values of Ra for zij=1 (expected roughness) and zsfij=1 (simulated roughness) are 1.979261025 and 2.053738039, respectively. This means that the values of Ra of two similar roughness profiles (expected and simulated) resemble each other. Similar results are obtained for the other validation approaches (possibility distribution and DNA-based computing). The possibility distributions of the expected and simulated surface roughness are the same, as seen in Figure 12a. In the case of DNA-based computing, the frequencies of the amino acids (generated by applying DNA-based computing) of the expected and simulated roughness profiles exhibit similar patterns, as seen in Figure 12b. This means the possibility distribution and DNA-based computing-driven validation approaches are effective. However, the above-mentioned approaches (semantic modeling, possibility distribution, and DNA-based computing) have also been applied to the rest of the real time series datasets of surface heights (see Figure A1b–d in Appendix A), for understanding their (the approaches) efficacy to a vast extent. In this respect, Figure A2, Figure A3 and Figure A4 (in Appendices B–D) show the results corresponding to Figure A1b–d, respectively.

Figure 12.

Outcomes of VC corresponding to the semantic modeling-based MC and Monte Carlo simulation-based SC: (a) possibility distribution; (b) DNA-based computing.

7. Concluding Remarks

In order to achieve the functional requirements of Industry 4.0, embedded systems such as cyber-physical systems are needed. The systems consist of self-growing knowledge-bases that are the outcomes of learning activities within or outside of a production line. The chunks of knowledge associated with the knowledge-bases of cyber-physical systems reside in the digital twins (computable virtual abstractions of real objects, processes, and phenomena). There are three types of digital twins, namely, object twin, process twin, and phenomenon twin. Among these twins, the phenomenon twin is the most difficult to construct and put in practice. The reason is that the manufacturing phenomena are highly nonlinear and difficult to study by using conventional analytical approaches.

There is no systematic approach by which one can construct a phenomenon twin. In order to fill this gap, this study presented a system called the phenomenon twin construction system. This system consists of three components, namely the input component, processing component, and output component. Among these components, the processing component was the critical one that should perform the functions of modeling, simulation, and validation. Therefore, the processing component had three main subcomponents, namely modeling component, simulation component, and validation component. The modeling component modeled the underlying dynamics of a given phenomenon (most likely) from its sensor signals. The simulation component used a discrete event-based Monte Carlo simulation approach to recreate the phenomenon whenever needed. The validation component validated the simulated phenomenon compared to the expected one.

What kind of modeling, simulation, and validation approaches should be used while constructing the subcomponents of the processing component, respectively, for a given phenomenon is a research question. This study answered this question using the case of surface roughness—a complex phenomenon associated with all material removal processes.

This study showed that for modeling the surface roughness of a machined surface, the approach called semantic modeling was more effective than the conventional approach called the Markov chain. It also showed that to validate whether or not a simulated surface roughness resembled the expected roughness, the outcomes of the possibility distribution-based computing and DNA-based computing were more effective than the outcomes of conventional computing wherein the arithmetic mean height of surface roughness was calculated.

As demonstrated in this study, the leading edge computational intelligence-based approaches could achieve a high degree of digitization of manufacturing processes for the sake of Industry 4.0. As a result, computational intelligence-based approaches will be applied more widely in the years to come.

Author Contributions

A.K.G., A.S.U., A.K., T.A., and D.M.D. conceived of the idea. A.K.G. and A.S.U. conducted the literature review. A.K.G., A.S.U., A.K., T.A., and D.M.D. developed the methodology. A.S.U. and A.K. conducted the turning experiments. A.K.G., A.S.U., and A.K. conducted the case study. A.K.G. and A.S.U. wrote the manuscript. A.S.U. supervised the work. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The first author acknowledges the Ministry of Education, Culture, Sports, Science and Technology, Japan for providing him with the MEXT scholarship.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A. Measured Time Series Datasets Used in this Study

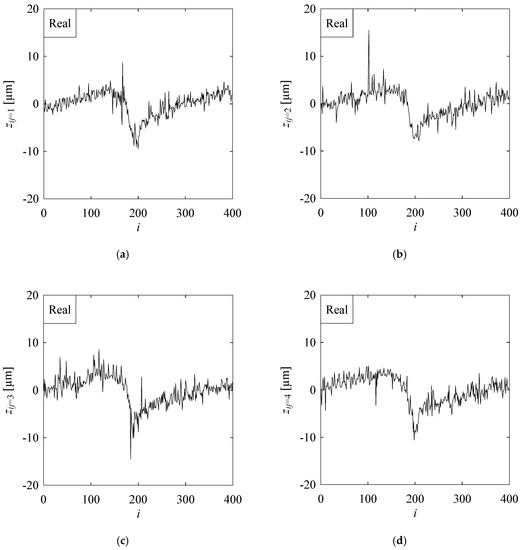

Figure A1.

Measured surface heights [51]: (a) j = 1; (b) j = 2; (c) j = 3; (d) j = 4.

Appendix B. Results Corresponding to Figure A1b

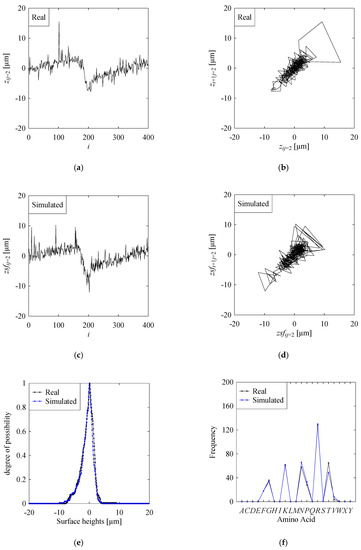

Figure A2.

Outcomes of SC and VC corresponding to the semantic modeling-based MC for zij=2: (a) real surface heights; (b) return map of (a); (c) simulated surface heights; (d) return map of (c); (e) possibility distribution; (f) DNA-based computing.

Appendix C. Results Corresponding to Figure A1c

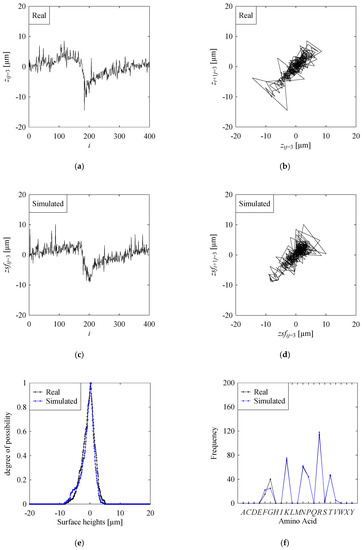

Figure A3.

Outcomes of SC and VC corresponding to the semantic modeling-based MC for zij=3: (a) real surface heights; (b) return map of (a); (c) simulated surface heights; (d) return map of (c); (e) possibility distribution; (f) DNA-based computing.

Appendix D. Results corresponding to Figure A1d

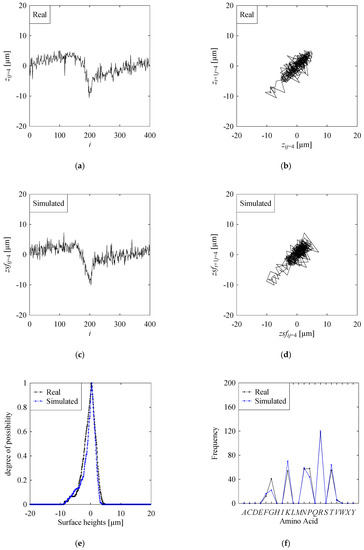

Figure A4.

Outcomes of SC and VC corresponding to the semantic modeling-based MC for zij=4: (a) real surface heights; (b) return map of (a); (c) simulated surface heights; (d) return map of (c); (e) possibility distribution; (f) DNA-based computing.

References

- Kagermann, H.; Helbig, J.; Hellinger, A.; Wahlster, W. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0: Securing the Future of German Manufacturing Industry; Final Report of the Industrie 4.0 Working Group; Forschungsunion; Acatech – National Academy of Science and Engineering: Munich, Germany, 2013. [Google Scholar]

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.-G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Thoben, K.-D.; Wiesner, S.; Wuest, T. “Industrie 4.0” and Smart Manufacturing – A Review of Research Issues and Application Examples. Int. J. Autom. Technol. 2017, 11, 4–16. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Yao, X.; Zhou, J.; Lin, Y.; Li, Y.; Yu, H.; Liu, Y. Smart manufacturing based on cyber-physical systems and beyond. J. Intell. Manuf. 2019, 30, 2805–2817. [Google Scholar] [CrossRef]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar]

- Lu, Y.; Cecil, J. An Internet of Things (IoT)-based collaborative framework for advanced manufacturing. Int. J. Adv. Manuf. Technol. 2016, 84, 1141–1152. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Li, Z.; Pang, L.Y.; Pan, Y.; Qu, T.; Huang, G.Q. RFID-enabled real-time advanced planning and scheduling shell for production decision making. Int. J. Comput. Integr. Manuf. 2013, 26, 649–662. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, Y.; Ji, P.; Xu, W.; Zhou, Z.; Tao, F. Cyber-physical integration for moving digital factories forward towards smart manufacturing: A survey. Int. J. Adv. Manuf. Technol. 2018, 97, 1209–1221. [Google Scholar] [CrossRef]

- Wang, L.; Törngren, M.; Onori, M. Current status and advancement of cyber-physical systems in manufacturing. J. Manuf. Syst. 2015, 37, 517–527. [Google Scholar] [CrossRef]

- Yao, X.; Lin, Y. Emerging manufacturing paradigm shifts for the incoming industrial revolution. Int. J. Adv. Manuf. Technol. 2016, 85, 1665–1676. [Google Scholar] [CrossRef]

- Monostori, L.; Kádár, B.; Bauernhansl, T.; Kondoh, S.; Kumara, S.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-physical systems in manufacturing. Cirp Ann. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.-A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Glaessgen, E.; Stargel, D. The Digital Twin Paradigm for Future NASA and U.S. Air Force Vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 April 2012. [Google Scholar] [CrossRef]

- Sharif Ullah, A.M.M. Modeling and simulation of complex manufacturing phenomena using sensor signals from the perspective of Industry 4.0. Adv. Eng. Inform. 2019, 39, 1–13. [Google Scholar] [CrossRef]

- Ghosh, A.K.; Ullah, A.M.M.S.; Kubo, A. Hidden Markov model-based digital twin construction for futuristic manufacturing systems. Artif. Intell. Eng. Des. Anal. Manuf. 2019, 33, 317–331. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. In Transdisciplinary Perspectives on Complex Systems; Kahlen, F.-J., Flumerfelt, S., Alves, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 85–113. [Google Scholar]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Boschert, S.; Rosen, R. Digital Twin—The Simulation Aspect. In Mechatronic Futures; Hehenberger, P., Bradley, D., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 59–74. [Google Scholar]

- Luo, W.; Hu, T.; Zhang, C.; Wei, Y. Digital twin for CNC machine tool: Modeling and using strategy. J. Ambient Intell. Humaniz. Comput. 2019, 10, 1129–1140. [Google Scholar] [CrossRef]

- Tong, X.; Liu, Q.; Pi, S.; Xiao, Y. Real-time machining data application and service based on IMT digital twin. J. Intell. Manuf. 2019. [Google Scholar] [CrossRef]

- Shafiq, S.I.; Sanin, C.; Toro, C.; Szczerbicki, E. Virtual Engineering Object (VEO): Toward Experience-Based Design and Manufacturing for Industry 4.0. Cybern. Syst. 2015, 46, 35–50. [Google Scholar] [CrossRef]

- Shafiq, S.I.; Sanin, C.; Toro, C.; Szczerbicki, E. Virtual engineering process (VEP): A knowledge representation approach for building bio-inspired distributed manufacturing DNA. Int. J. Prod. Res. 2016, 54, 7129–7142. [Google Scholar] [CrossRef]

- Shafiq, S.I.; Sanin, C.; Szczerbicki, E.; Toro, C. Virtual Engineering Factory: Creating Experience Base for Industry 4.0. Cybern. Syst. 2016, 47, 32–47. [Google Scholar] [CrossRef]

- Ahmed, M.B.; Sanin, C.; Szczerbicki, E. Experience-Based Decisional DNA (DDNA) to Support Product Development. Cybern. Syst. 2018, 49, 399–411. [Google Scholar] [CrossRef]

- Ahmed, M.B.; Imran Shafiq, S.; Sanin, C.; Szczerbicki, E. Towards Experience-Based Smart Product Design for Industry 4.0. Cybern. Syst. 2019, 50, 165–175. [Google Scholar] [CrossRef]

- Xu, X. Machine Tool 4.0 for the new era of manufacturing. Int. J. Adv. Manuf. Technol. 2017, 92, 1893–1900. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. Ifac-Pap. 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Botkina, D.; Hedlind, M.; Olsson, B.; Henser, J.; Lundholm, T. Digital Twin of a Cutting Tool. Procedia Cirp 2018, 72, 215–218. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, H.; Tian, G.; Liu, X.; Jing, X. Digital twin-based process reuse and evaluation approach for smart process planning. Int. J. Adv. Manuf. Technol. 2019, 100, 1619–1634. [Google Scholar] [CrossRef]

- Delbrügger, T.; Meißner, M.; Wirtz, A.; Biermann, D.; Myrzik, J.; Rossmann, J.; Wiederkehr, P. Multi-level simulation concept for multidisciplinary analysis and optimization of production systems. Int. J. Adv. Manuf. Technol. 2019, 103, 3993–4012. [Google Scholar] [CrossRef]

- Olivotti, D.; Dreyer, S.; Lebek, B.; Breitner, M.H. Creating the foundation for digital twins in the manufacturing industry: An integrated installed base management system. Inf. Syst. E-Bus. Manag. 2019, 17, 89–116. [Google Scholar] [CrossRef]

- Leng, J.; Zhang, H.; Yan, D.; Liu, Q.; Chen, X.; Zhang, D. Digital twin-driven manufacturing cyber-physical system for parallel controlling of smart workshop. J. Ambient Intell. Humaniz. Comput. 2019, 10, 1155–1166. [Google Scholar] [CrossRef]

- Guo, J.; Zhao, N.; Sun, L.; Zhang, S. Modular based flexible digital twin for factory design. J. Ambient Intell. Humaniz. Comput. 2019, 10, 1189–1200. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Yan, Q. Digital twin-driven cyber-physical production system towards smart shop-floor. J. Ambient Intell. Humaniz. Comput. 2019, 10, 4439–4453. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M.; Cheng, J.; Qi, Q. Digital twin workshop: A new paradigm for future workshop. Comput. Integr. Manuf. Syst. 2017, 23, 1–9. [Google Scholar] [CrossRef]

- Scaglioni, B.; Ferretti, G. Towards digital twins through object-oriented modelling: A machine tool case study. Ifac-Pap. 2018, 51, 613–618. [Google Scholar] [CrossRef]

- Ullah, A.M.M.S. Surface Roughness Modeling Using Q-Sequence. Math. Comput. Appl. 2017, 22, 33. [Google Scholar] [CrossRef]

- Kan, C.; Yang, H.; Kumara, S. Parallel computing and network analytics for fast Industrial Internet-of-Things (IIoT) machine information processing and condition monitoring. J. Manuf. Syst. 2018, 46, 282–293. [Google Scholar] [CrossRef]

- Ullah, A.S.; Shamsuzzaman, M. Fuzzy Monte Carlo Simulation using point-cloud-based probability–possibility transformation. Simulation 2013, 89, 860–875. [Google Scholar] [CrossRef]

- Ullah, A.M.M.S.; D’Addona, D.; Arai, N. DNA based computing for understanding complex shapes. Biosystems 2014, 117, 40–53. [Google Scholar] [CrossRef]

- Ullah, A.M.M.S. A DNA-based computing method for solving control chart pattern recognition problems. Cirp J. Manuf. Sci. Technol. 2010, 3, 293–303. [Google Scholar] [CrossRef]

- D’Addona, D.M.; Ullah, A.M.M.S.; Matarazzo, D. Tool-wear prediction and pattern-recognition using artificial neural network and DNA-based computing. J. Intell. Manuf. 2017, 28, 1285–1301. [Google Scholar] [CrossRef]

- Shafiq, S.I.; Sanin, C.; Szczerbicki, E.; Toro, C. Decisional DNA Based Conceptual Framework for Smart Manufacturing. In Information Systems Architecture and Technology: Proceedings of 36th International Conference on Information Systems Architecture and Technology–ISAT 2015–Part I. Advances in Intelligent Systems and Computing; Borzemski, L., Grzech, A., Świątek, J., Wilimowska, Z., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; Volume 429, pp. 79–88. [Google Scholar]

- Shafiq, S.I.; Szczerbicki, E.; Sanin, C. Decisional-DNA Based Smart Production Performance Analysis Model. Cybern. Syst. 2019, 50, 154–164. [Google Scholar] [CrossRef]

- Waris, M.M.; Sanin, C.; Szczerbicki, E. Smart innovation process enhancement using SOEKS and decisional DNA. J. Inf. Telecommun. 2017, 1, 290–303. [Google Scholar] [CrossRef]

- Ullah, A.M.M.S.; Arai, N.; Watanabe, M. Concept Map and Internet-aided Manufacturing. Procedia Cirp 2013, 12, 378–383. [Google Scholar] [CrossRef]

- Ullah, A.S. Fundamental Issues of Concept Mapping Relevant to Discipline-Based Education: A Perspective of Manufacturing Engineering. Educ. Sci. 2019, 9, 228. [Google Scholar] [CrossRef]

- Putnik, G.D.; Putnik, Z. A semiotic framework for manufacturing systems integration –Part I: Generative integration model. Int. J. Comput. Integr. Manuf. 2010, 23, 691–709. [Google Scholar] [CrossRef]

- Sharif Ullah, A.M.M.; Fuji, A.; Kubo, A.; Tamaki, J.i.; Kimura, M. On the Surface Metrology of Bimetallic Components. Mach. Sci. Technol. 2015, 19, 339–359. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).