Applications of Open Source GMAW-Based Metal 3-D Printing

Abstract

1. Introduction

2. Materials and Methods

3. Results

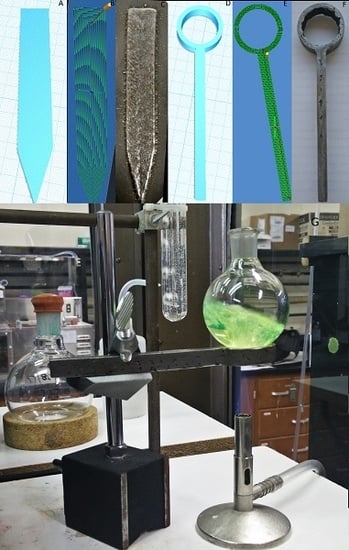

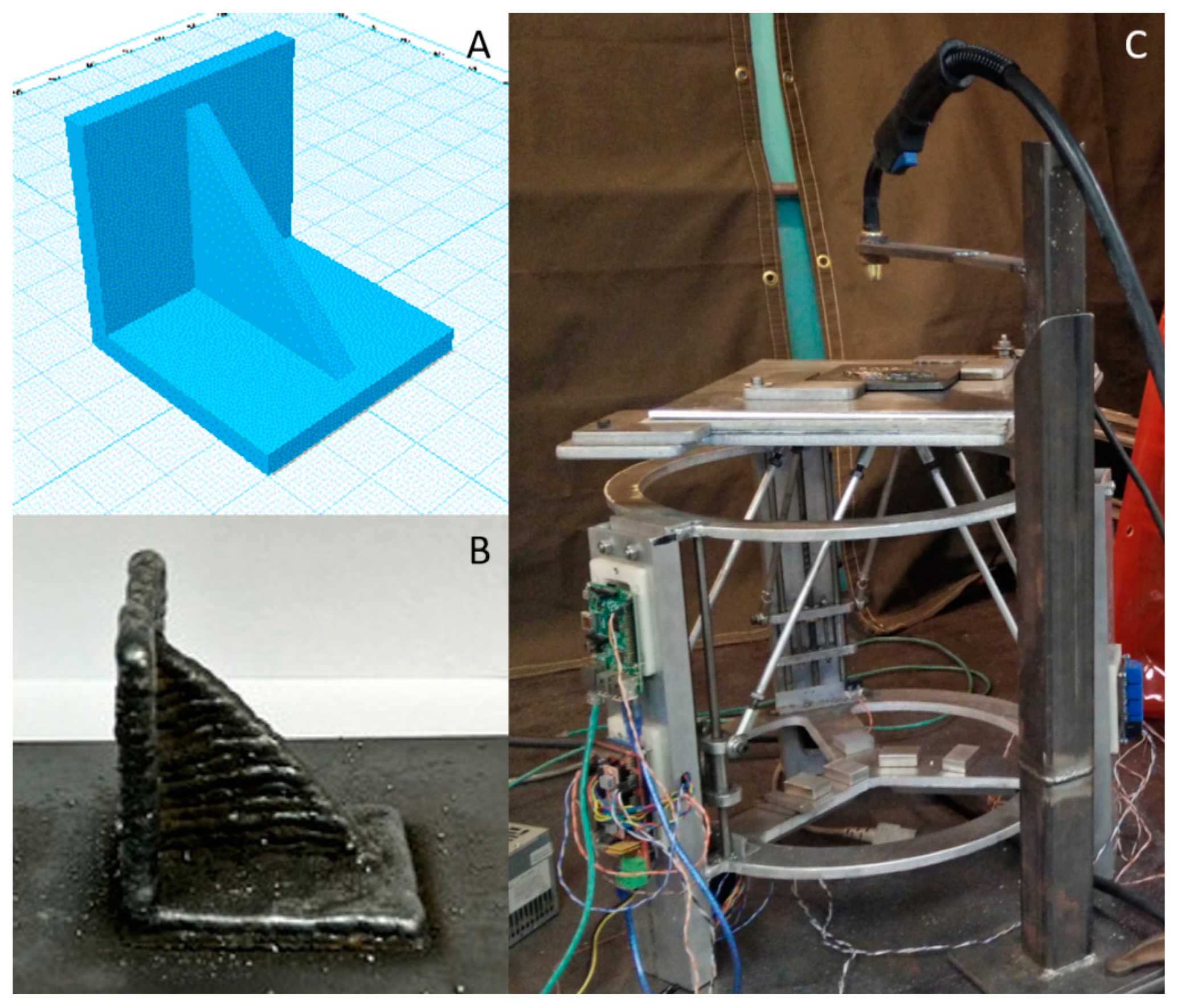

- The system can be used for fixing or printing onto an existing part. A bracket is an example used here where it was printed on the substrate as an existing part (Figure 1). Holes can be printed or drilled on the open end of the bracket, so another part can be attached and secured with nuts and bolts. This can be utilized in fixing broken equipment. A different design of a bracket can optimize its strength, stiffness, size, and weight. For example, General Electric (GE) held a contest for such a bracket design for a jet engine in 2013 [38]. Similar bracket fixes can be useful for a wide range of applications including solar photovoltaic racking [39].

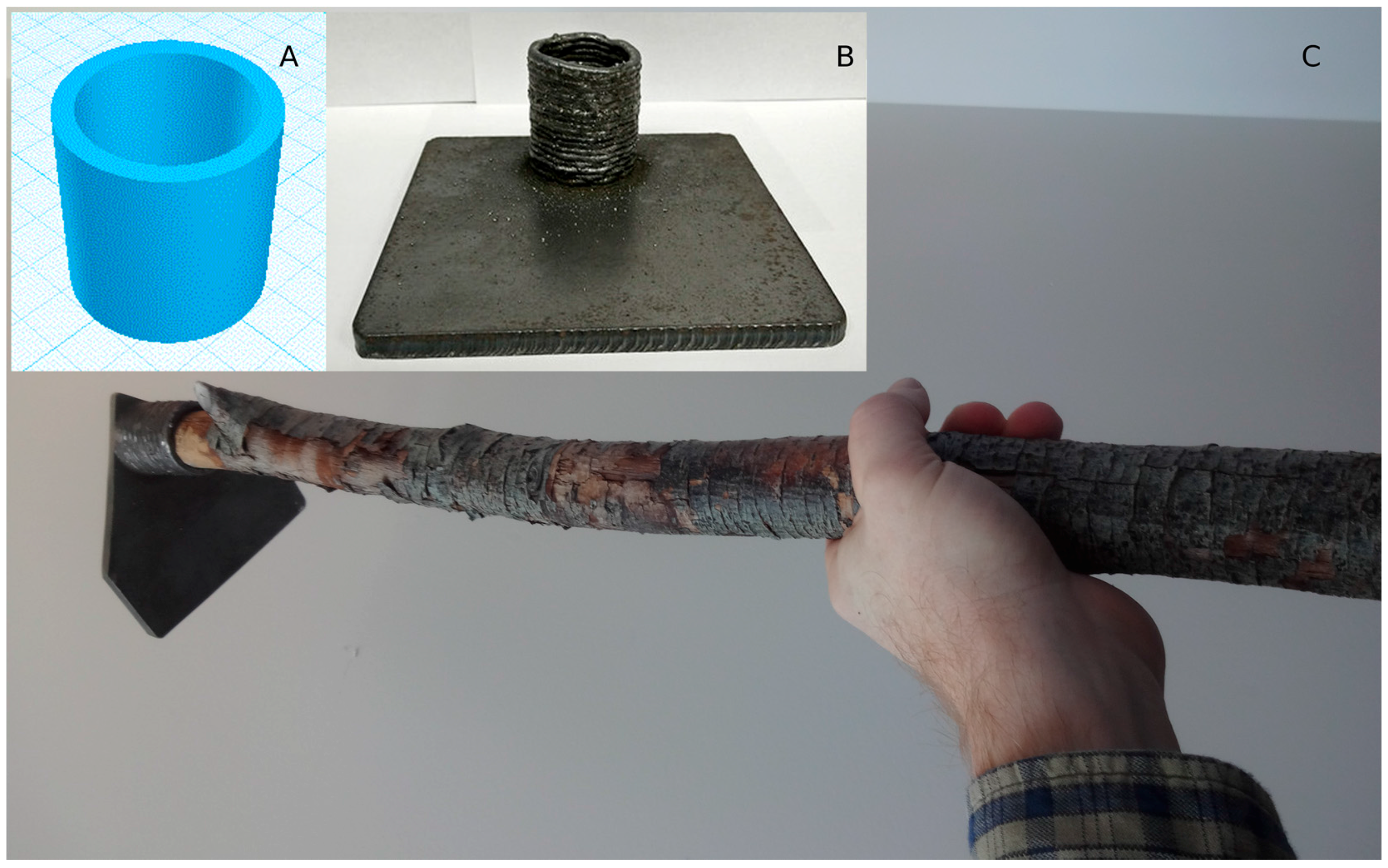

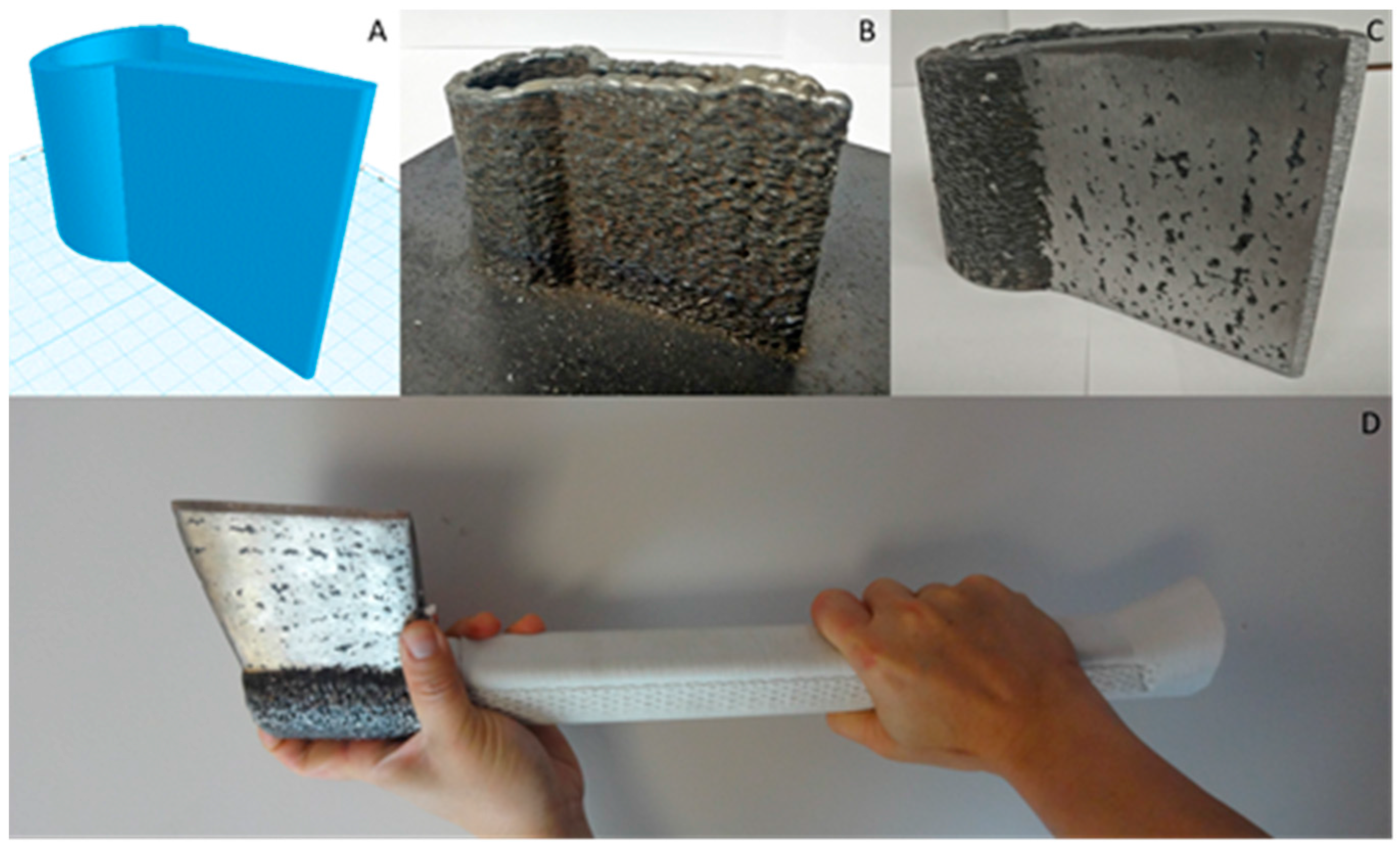

- The system can be used to create a product using metal 3-D printing and a substrate as an integral part of the product. For example, a hoe can be made by 3-D printing a cylinder on the substrate (Figure 2B). Then, the substrate is cut into a shape of a hoe and sharpened on the edge opposite the printed cylinder (Figure 2C). A wood or a polymer 3-D printed stick can be used as a handle for the hoe. Being able to manufacture such a product in an isolated rural community can be considered appropriate technology and can foster sustainable development [40,41,42]. The ability to manufacture metal objects significantly expands the utility of 3-D printing for small farmers in the developing world [43].

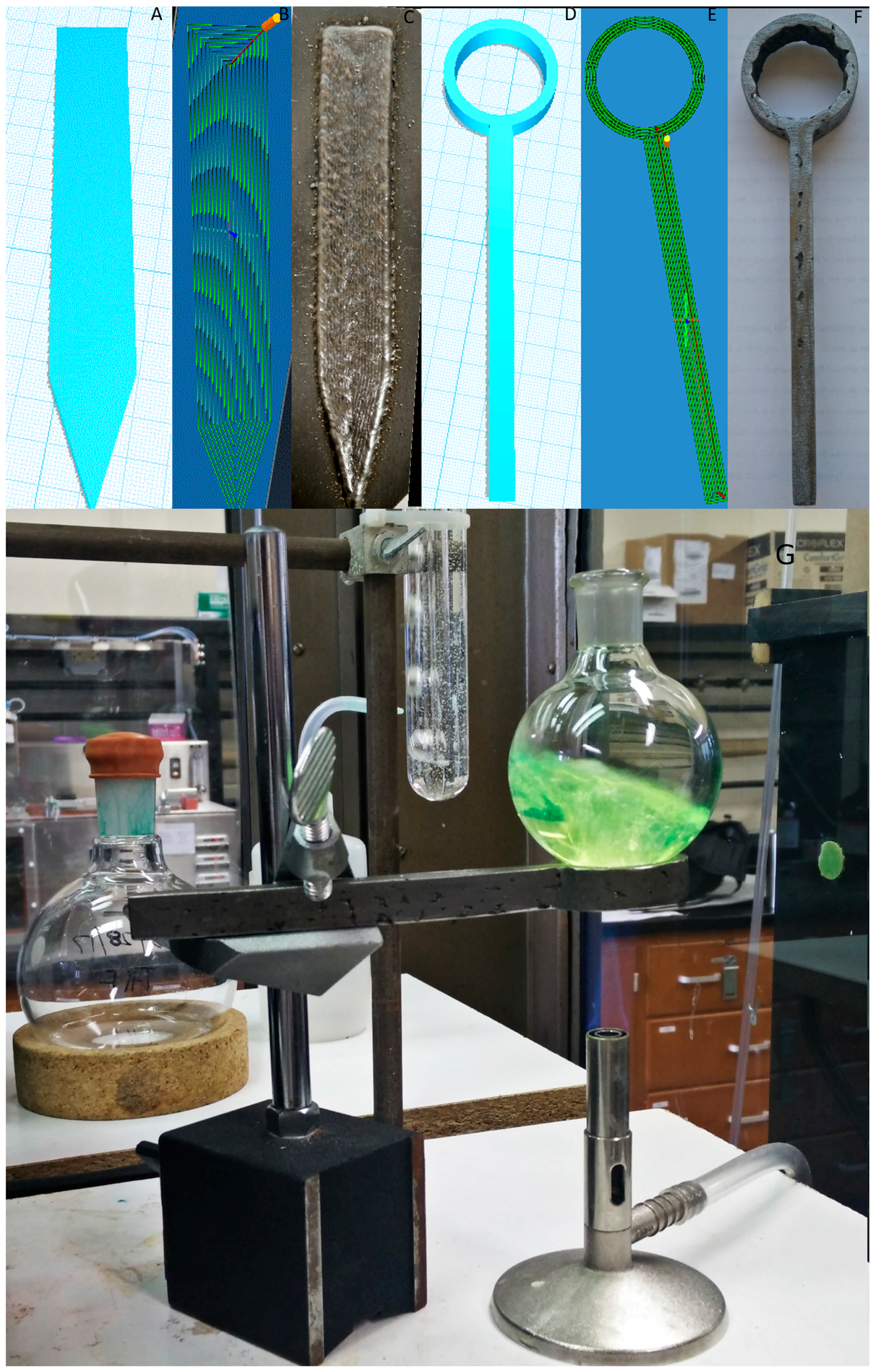

- The system is capable of a higher resolution than previous attempts at GMAW-3-D printing [5]. A high resolution chisel model (Figure 3A) and chemistry laboratory support ring model (Figure 3D) are used to demonstrate this capability. The printed part is ready to use with minimal machining (Figure 3C,F). In Figure 3G, the finished metal 3-D printed ring support was used in a lab. This technique can be applied in similar situations that require a custom part. For example, in the design of open source scientific equipment [44,45,46], a custom size of a ring support or a vial holder for a hot plate can be easily designed and printed. A model with small details can be printed as long as they are not smaller than 1 mm.

- Near-net shape objects can be fabricated with the system. An example of this is a horseshoe (Figure 4), which needs to be customized for specific horses, so it is suitable for metal 3-D printing. The printed part is a near-net shape, so it needs finish machining.

- Finally, fully functional integrated products can be fabricated using a combination of metal and polymer 3-D printing. Here, an axe head was 3-D printed in steel (Figure 5) and a handle was 3-D printed in nylon. A combination process like this can be used to remotely manufacture similar open source instruments such as a hammer or other hand tools that would be useful in the developed and developing world [47,48].

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wohlers, T.T.; Caffrey, T. Wohlers Report 2015: 3D Printing and Additive Manufacturing State of the Industry Annual Worldwide Progress Report; Wohlers Associates: Fort Collins, CO, USA, 2015; ISBN 978-0-9913332-1-9. [Google Scholar]

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper: Maximizing Customizability by Breeding the Means of Production. In Handbook of Research in Mass Customization and Personalization; World Scientific Publishing Company: Singapore, 2009; pp. 568–580. ISBN 978-981-4280-25-9. [Google Scholar]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap—The replicating rapid prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Bowyer, A. 3D Printing and Humanity’s First Imperfect Replicator. 3D Print. Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

- Anzalone, G.C.; Zhang, C.; Wijnen, B.; Sanders, P.G.; Pearce, J.M. A Low-Cost Open-Source Metal 3-D Printer. IEEE Access 2013, 1, 803–810. [Google Scholar] [CrossRef]

- Pinar, A.; Wijnen, B.; Anzalone, G.C.; Havens, T.C.; Sanders, P.G.; Pearce, J.M. Low-Cost Open-Source Voltage and Current Monitor for Gas Metal Arc Weld 3D Printing. J. Sens. 2015, 2015. [Google Scholar] [CrossRef]

- Nilsiam, Y.; Haselhuhn, A.; Wijnen, B.; Sanders, P.; Pearce, J.M. Integrated Voltage—Current Monitoring and Control of Gas Metal Arc Weld Magnetic Ball-Jointed Open Source 3-D Printer. Machines 2015, 3, 339–351. [Google Scholar] [CrossRef]

- Haselhuhn, A.S.; Gooding, E.J.; Glover, A.G.; Anzalone, G.C.; Wijnen, B.; Sanders, P.G.; Pearce, J.M. Substrate Release Mechanisms for Gas Metal Arc Weld 3D Aluminum Metal Printing. 3D Print. Addit. Manuf. 2014, 1, 204–209. [Google Scholar] [CrossRef]

- Haselhuhn, A.S.; Wijnen, B.; Anzalone, G.C.; Sanders, P.G.; Pearce, J.M. In situ formation of substrate release mechanisms for gas metal arc weld metal 3-D printing. J. Mater. Process. Technol. 2015, 226, 50–59. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Y.; Li, P.; Male, A.T. Weld deposition-based rapid prototyping: A preliminary study. J. Mater. Process. Technol. 2003, 135, 347–357. [Google Scholar] [CrossRef]

- Song, Y.-A.; Park, S.; Choi, D.; Jee, H. 3D welding and milling: Part I–a direct approach for freeform fabrication of metallic prototypes. Int. J. Mach. Tools Manuf. 2005, 45, 1057–1062. [Google Scholar] [CrossRef]

- Song, Y.-A.; Park, S.; Chae, S.-W. 3D welding and milling: Part II—Optimization of the 3D welding process using an experimental design approach. Int. J. Mach. Tools Manuf. 2005, 45, 1063–1069. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Spencer, J.D.; Dickens, P.M.; Wykes, C.M. Rapid prototyping of metal parts by three-dimensional welding. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 1998, 212, 175–182. [Google Scholar] [CrossRef]

- Kwak, Y.-M.; Doumanidis, C.C. Geometry Regulation of Material Deposition in Near-Net Shape Manufacturing by Thermally Scanned Welding. J. Manuf. Process. 2002, 4, 28–41. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, G.; Yin, Z.; Wu, L. A 3D dynamic analysis of thermal behavior during single-pass multi-layer weld-based rapid prototyping. J. Mater. Process. Technol. 2011, 211, 488–495. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, G.; Yin, Z.; Wu, L. Effects of Interpass Idle Time on Thermal Stresses in Multipass Multilayer Weld-Based Rapid Prototyping. J. Manuf. Sci. Eng. 2013, 135. [Google Scholar] [CrossRef]

- Dwivedi, R.; Kovacevic, R. Automated torch path planning using polygon subdivision for solid freeform fabrication based on welding. J. Manuf. Syst. 2004, 4, 278–291. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A tool-path generation strategy for wire and arc additive manufacturing. Int. J. Adv. Manuf. Technol. 2014, 73, 173–183. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robot. Comput. Integr. Manuf. 2015, 31, 101–110. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A practical path planning methodology for wire and arc additive manufacturing of thin-walled structures. Robot. Comput. Integr. Manuf. 2015, 34, 8–19. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Qiu, Z.; Li, Y. Vision-sensing and bead width control of a single-bead multi-layer part: Material and energy savings in GMAW-based rapid manufacturing. J. Clean. Prod. 2013, 41, 82–88. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Gao, H.; Wu, L. Modeling of bead section profile and overlapping beads with experimental validation for robotic GMAW-based rapid manufacturing. Robot. Comput. Integr. Manuf. 2013, 29, 417–423. [Google Scholar] [CrossRef]

- Ding, J.; Colegrove, P.; Mehnen, J.; Ganguly, S.; Sequeira Almeida, P.M.; Wang, F.; Williams, S. Thermo-mechanical analysis of Wire and Arc Additive Layer Manufacturing process on large multi-layer parts. Comput. Mater. Sci. 2011, 50, 3315–3322. [Google Scholar] [CrossRef]

- Hildreth, O.J.; Nassar, A.R.; Chasse, K.R.; Simpson, T.W. Dissolvable Metal Supports for 3D Direct Metal Printing. 3D Print. Addit. Manuf. 2016, 3, 90–97. [Google Scholar] [CrossRef]

- Das, S.; Bourell, D.L.; Babu, S.S. Metallic materials for 3D printing. MRS Bull. 2016, 41, 729–741. [Google Scholar] [CrossRef]

- Rostock—RepRapWiki. Available online: http://reprap.org/wiki/Rostock (accessed on 2 March 2017).

- Anzalone, G.C.; Wijnen, B.; Pearce, J.M. Multi-material additive and subtractive prosumer digital fabrication with a free and open-source convertible delta RepRap 3-D printer. Rapid Prototyp. J. 2015, 21, 506–519. [Google Scholar] [CrossRef]

- Zhang, C.; Wijnen, B.; Pearce, J.M. Open-Source 3-D Platform for Low-Cost Scientific Instrument Ecosystem. J. Lab. Autom. 2016, 21, 517–525. [Google Scholar] [CrossRef] [PubMed]

- Wijnen, B.; Anzalone, G.C.; Haselhuhn, A.S.; Sanders, P.G.; Pearce, J.M. Free and Open-source Control Software for 3-D Motion and Processing. J. Open Res. Softw. 2016, 4. [Google Scholar] [CrossRef]

- CNC Router Parts Metal 3D Printer—Appropedia: The Sustainability Wiki. Available online: http://www.appropedia.org/CNC_Router_Parts_metal_3D_printer (accessed on 13 March 2017).

- Benchtop PRO 2424 2′ × 2′ CNC Machine Kit|CNCRouterParts. Available online: http://www.cncrouterparts.com/benchtop-pro-2424-2-x-2-cnc-machine-kit-p-314.html (accessed on 14 March 2017).

- Mach3. Available online: http://www.machsupport.com/software/mach3/ (accessed on 13 March 2017).

- Nilsiam, Y.; Sanders, P.; Pearce, J.M. Slicer and process improvements for open-source GMAW-based metal 3-D printing. Addit. Manuf. 2017, 18, 110–120. [Google Scholar] [CrossRef]

- OpenSCAD. Available online: http://openscad.org (accessed on 6 March 2017).

- Chandra, H.; Skalsky, N.; Oberloier, S.; Laureto, J.; Pearce, J. Large Form Factor Open Source FFF-Based 3-D Printer for Fabrication of Multi-Cubic Meter Models. 2018; submitted. [Google Scholar]

- Nilsiam, Y.; Pearce, J.M. MOST Metal Application Models. Available online: https://osf.io/bbbtd/ (accessed on 14 March 2017).

- GE Jet Engine Bracket Challenge—GrabCAD. Available online: https://grabcad.com/challenges/ge-jet-engine-bracket-challenge (accessed on 14 March 2017).

- Wittbrodt, B.; Pearce, J.M. 3-D printing solar photovoltaic racking in developing world. Energy Sustain. Dev. 2017, 36, 1–5. [Google Scholar] [CrossRef]

- Hazeltine, B.; Bull, C. Appropriate Technology; Tools, Choices, and Implications, 1st ed.; Academic Press, Inc.: Orlando, FL, USA, 1998; ISBN 978-0-12-335190-6. [Google Scholar]

- Bhalla, A.S. Towards Global Action for Appropriate Technology; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 978-1-4831-3997-5. [Google Scholar]

- Smith, A. Transforming technological regimes for sustainable development: A role for alternative technology niches? Sci. Public Policy 2003, 30, 127–135. [Google Scholar] [CrossRef]

- Pearce, J.M. Applications of Open Source 3-D Printing on Small Farms. Org. Farming 2015, 1, 19–35. [Google Scholar] [CrossRef]

- Pearce, J.M. Building Research Equipment with Free, Open-Source Hardware. Science 2012, 337, 1303–1304. [Google Scholar] [CrossRef] [PubMed]

- Pearce, J.M. Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 978-0-12-410486-0. [Google Scholar]

- Baden, T.; Chagas, A.M.; Gage, G.; Marzullo, T.; Prieto-Godino, L.L.; Euler, T. Open Labware: 3-D Printing Your Own Lab Equipment. PLoS Biol. 2015, 13, e1002086. [Google Scholar] [CrossRef] [PubMed]

- Pearce, J.M.; Blair, C.M.; Laciak, K.J.; Andrews, R.; Nosrat, A.; Zelenika-Zovko, I. 3-D Printing of Open Source Appropriate Technologies for Self-Directed Sustainable Development. J. Sustain. Dev. 2010, 3, 17. [Google Scholar] [CrossRef]

- Birtchnell, T.; Hoyle, W. 3D Printing for Development in the Global South: The 3D4D Challenge; Springer: Berlin, Germany, 2014; ISBN 978-1-137-36566-8. [Google Scholar]

- Marketing, O. Component Repair—3D Printed Metals Core Applications; Optomec: Albuquerque, NM, USA, 2017. [Google Scholar]

- BeAM Repairs More than 800 Aerospace Parts with Industrial Metal 3D Printers. Available online: http://www.3ders.org/articles/20160204-beam-repairs-more-than-800-aerospace-parts-with-industrial-metal-3d-printers.html (accessed on 14 Mar 2017).

- Langnau, L. Using 3D Printing to Repair Metal Parts. Available online: https://www.makepartsfast.com/using-3d-printing-repair-metal-parts/ (accessed on 14 March 2017).

- Matisons, M. Sustainable 3D Printing Methods Add to or Subtract from Existing Objects; The Voice of 3D Printing/Additive Manufacturin; 3DR Holdings: San Diego, CA, USA, 2015. [Google Scholar]

- Broeckmann, C. Hot isostatic pressing of near net shape components—Process fundamentals and future challenges. Powder Metall. 2012, 55, 176–179. [Google Scholar] [CrossRef]

- Norfolk, M. Maintenance and Repair—3D Printing Metal Parts. Available online: https://fabrisonic.com/maintenance-repair-3d-printing-metal-parts/ (accessed on 28 February 2018).

- Leno, J. Jay Leno’s 3D Printer Replaces Rusty Old Parts. Available online: https://www.popularmechanics.com/cars/jay-leno/technology/4320759 (accessed on 14 March 2017).

- Petrova, M. Your Car’s Parts Could One Day be Made by a 3D Printer. Available online: https://www.pcworld.com/article/3159056/hardware/your-cars-parts-could-one-day-be-made-by-a-printer.html (accessed on 14 March 2017).

- Lu, X.; Zhou, Y.F.; Xing, X.L.; Shao, L.Y.; Yang, Q.X.; Gao, S.Y. Open-source wire and arc additive manufacturing system: Formability, microstructures, and mechanical properties. Int. J. Adv. Manuf. Technol. 2017, 93, 2145–2154. [Google Scholar] [CrossRef]

- Haden, C.V.; Zeng, G.; Carter, F.M.; Ruhl, C.; Krick, B.A.; Harlow, D.G. Wire and arc additive manufactured steel: Tensile and wear properties. Addit. Manuf. 2017, 16, 115–123. [Google Scholar] [CrossRef]

- Haselhuhn, A.S.; Buhr, M.W.; Wijnen, B.; Sanders, P.G.; Pearce, J.M. Structure-property relationships of common aluminum weld alloys utilized as feedstock for GMAW-based 3-D metal printing. Mater. Sci. Eng. A 2016, 673, 511–523. [Google Scholar] [CrossRef]

- Haselhuhn, A.S.; Sanders, P.G.; Pearce, J.M. Hypoeutectic Aluminum–Silicon Alloy Development for GMAW-Based 3-D Printing Using Wedge Castings. Int. J. Metalcast. 2017, 11, 843–856. [Google Scholar] [CrossRef]

- Tucker, C.S.; Saint John, D.B.; Behoora, I.; Marcireau, A. Open Source 3D Scanning and Printing for Design Capture and Realization. In Proceedings of the ASME 2014 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, New York, NY, USA, 17–20 August 2014. [Google Scholar]

- Nuchitprasitchai, S.; Roggemann, M.; Pearce, J.M. Factors effecting real-time optical monitoring of fused filament 3D printing. Prog. Addit. Manuf. 2017, 2, 133–149. [Google Scholar] [CrossRef]

- Manogharan, G.; Yelamanchi, B.; Aman, R.; Mahbooba, Z. Experimental Study of Disruption of Columnar Grains during Rapid Solidification in Additive Manufacturing. JOM 2016, 68, 842–849. [Google Scholar] [CrossRef]

| Settings | Value (Unit) |

|---|---|

| Voltage on the welder | 5 (unitless) |

| Wire feed rate on the welder | 30 (unitless) |

| Distance between nozzle and substrate | 8 (mm) |

| Wire sticking out from contact tip | 5 (mm) |

| Printing speed | 7 (mm/s) |

| Layer height | 2 (mm) |

| Line or bead width (±0.03) | ~1 (mm) |

| Shield gas | 25 (CFH) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nilsiam, Y.; Sanders, P.G.; Pearce, J.M. Applications of Open Source GMAW-Based Metal 3-D Printing. J. Manuf. Mater. Process. 2018, 2, 18. https://doi.org/10.3390/jmmp2010018

Nilsiam Y, Sanders PG, Pearce JM. Applications of Open Source GMAW-Based Metal 3-D Printing. Journal of Manufacturing and Materials Processing. 2018; 2(1):18. https://doi.org/10.3390/jmmp2010018

Chicago/Turabian StyleNilsiam, Yuenyong, Paul G. Sanders, and Joshua M. Pearce. 2018. "Applications of Open Source GMAW-Based Metal 3-D Printing" Journal of Manufacturing and Materials Processing 2, no. 1: 18. https://doi.org/10.3390/jmmp2010018

APA StyleNilsiam, Y., Sanders, P. G., & Pearce, J. M. (2018). Applications of Open Source GMAW-Based Metal 3-D Printing. Journal of Manufacturing and Materials Processing, 2(1), 18. https://doi.org/10.3390/jmmp2010018