Batch Processing in Preassembled Die Sets—A New Process Design for Isothermal Forging of Titanium Aluminides

Abstract

:1. Introduction

2. Literature Review

3. Materials and Methods

3.1. FEA Development

3.2. Material and Workpiece

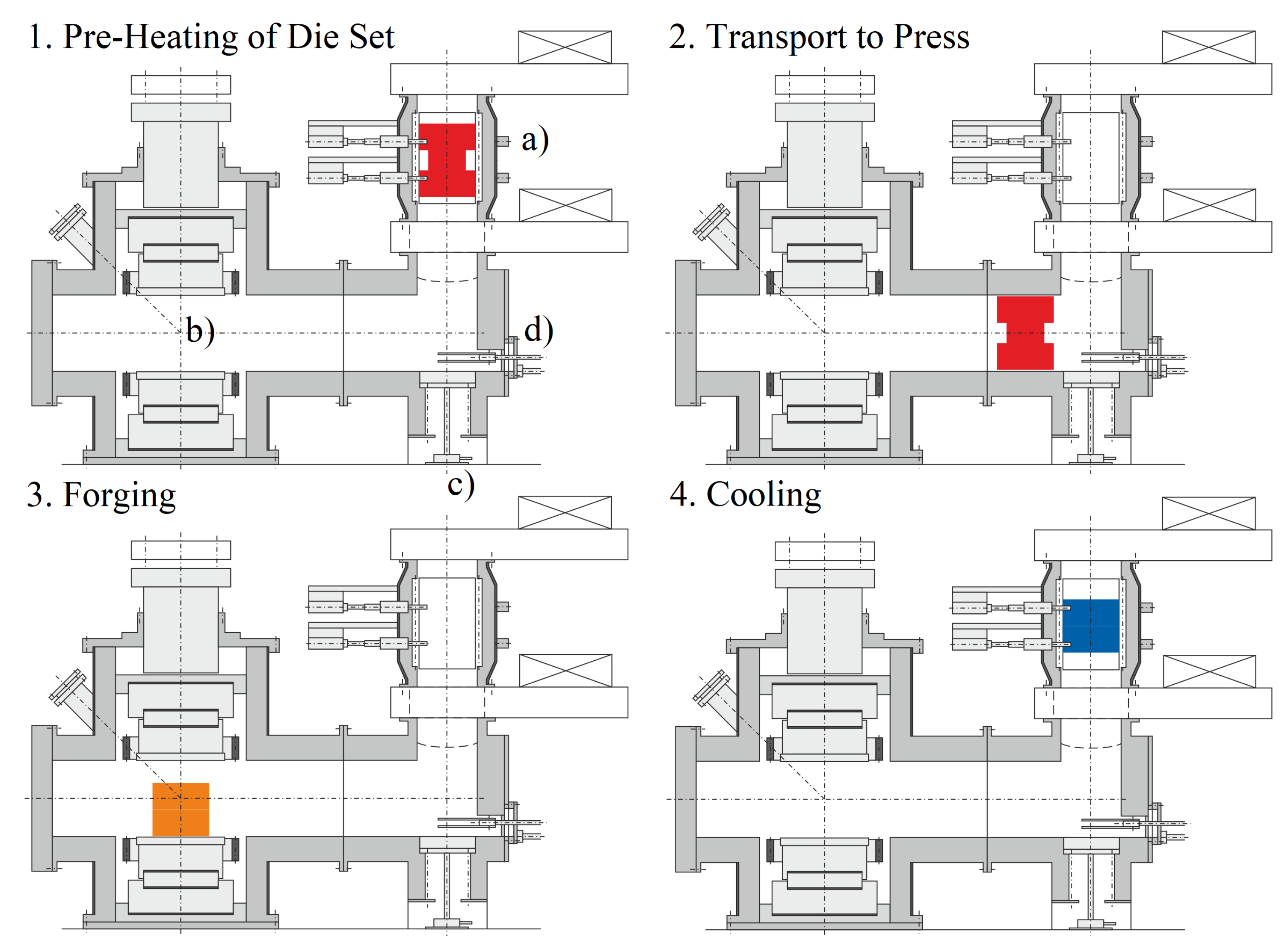

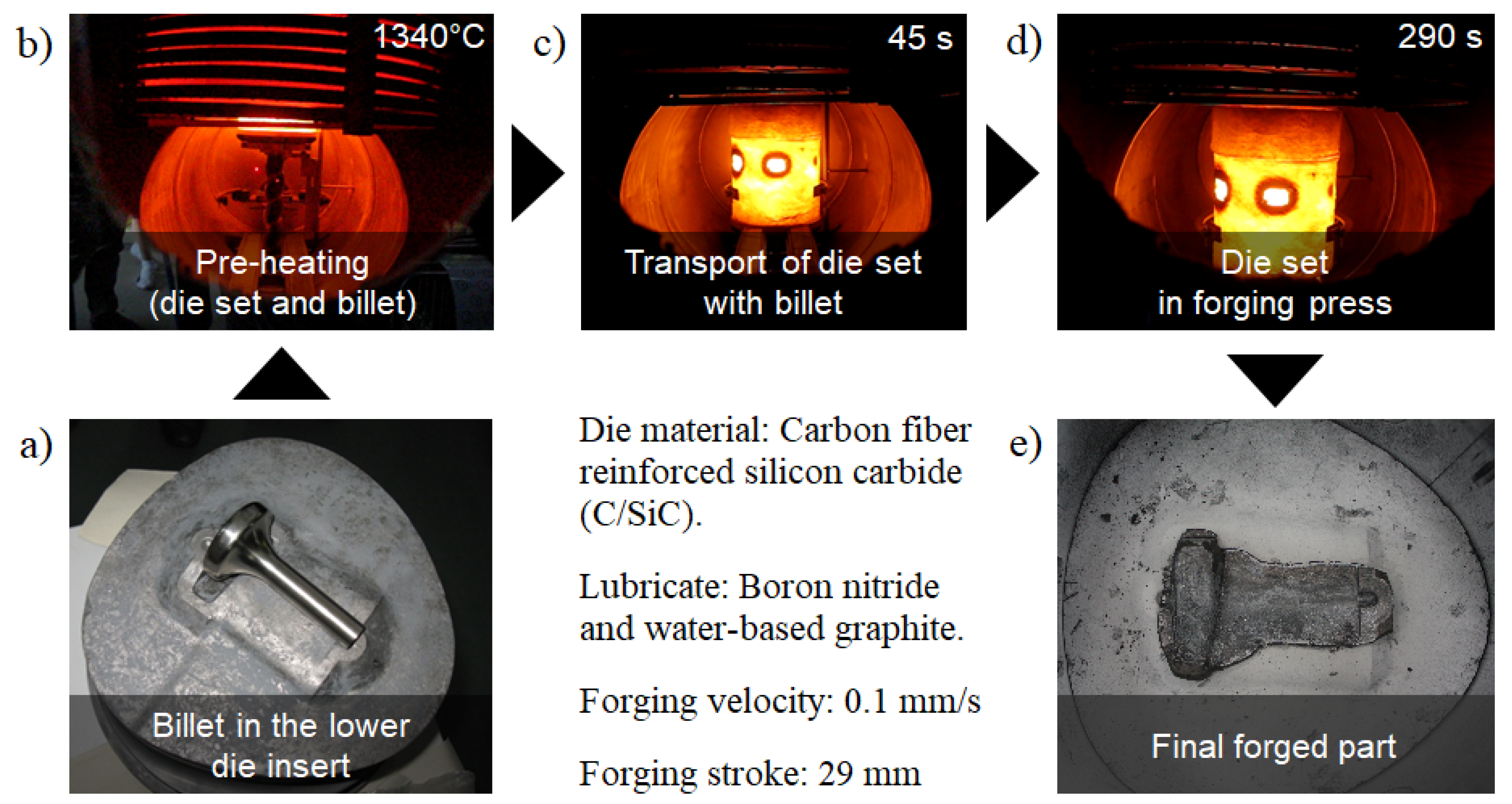

3.3. Batch Process Design

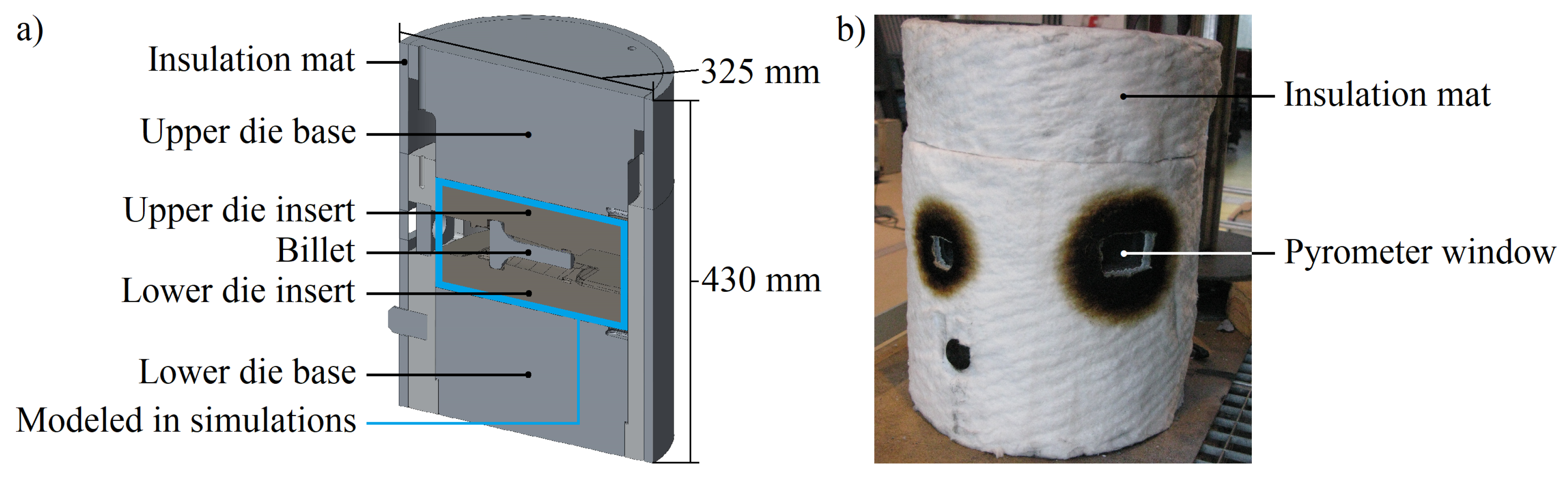

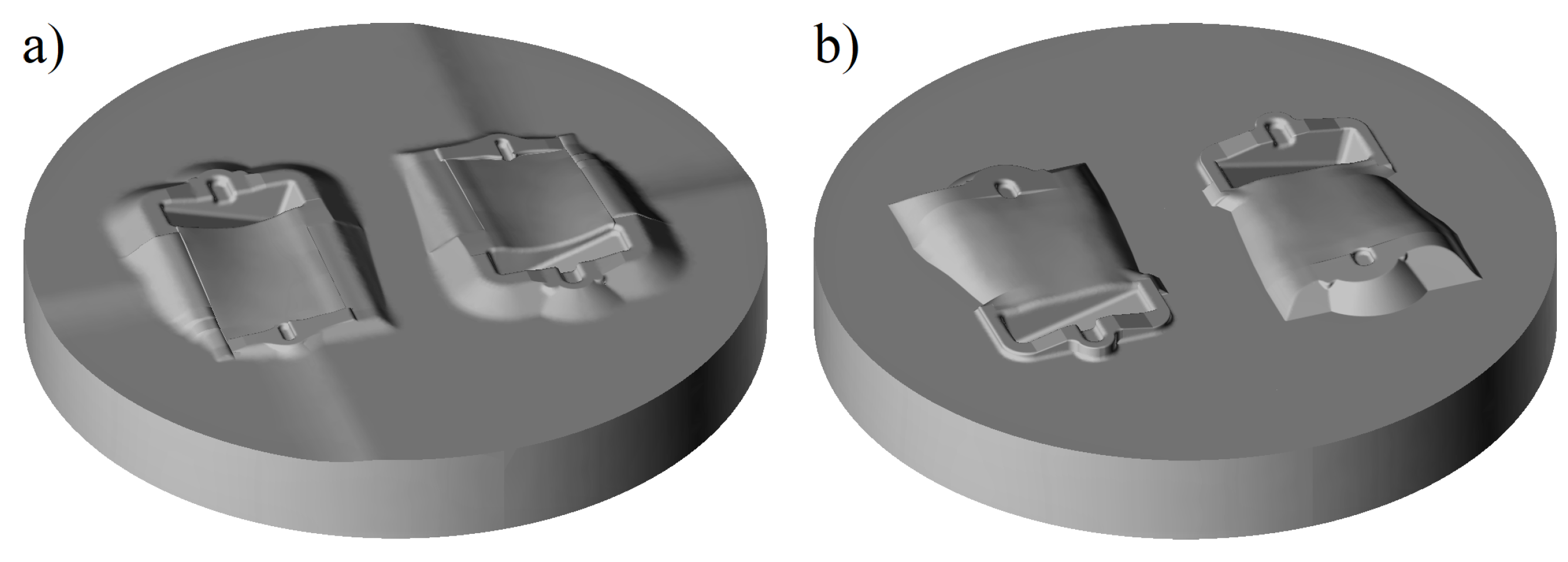

3.4. Die Set Design

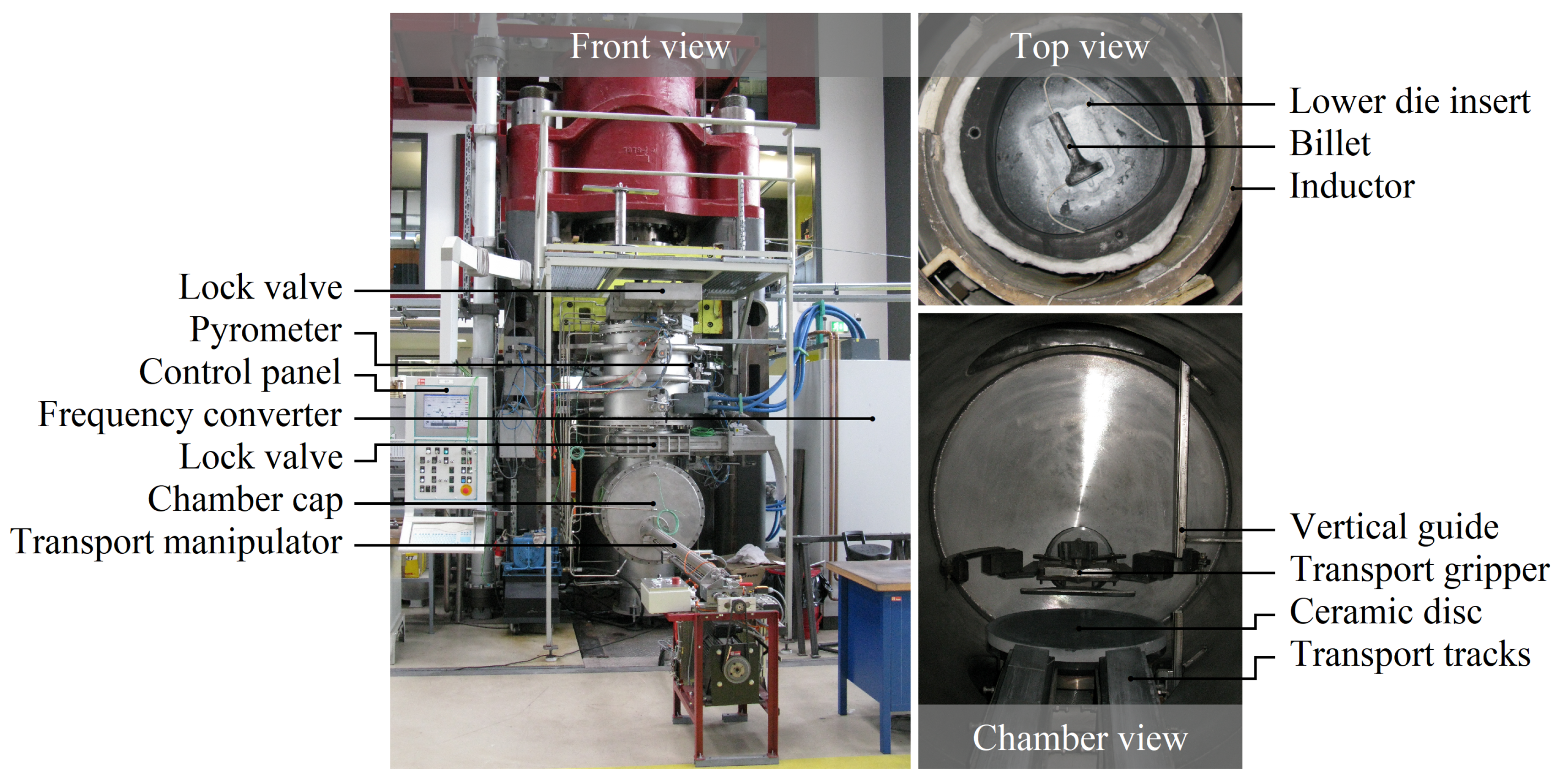

3.5. Forging Trials

3.6. Heating Trials

4. Results and Discussion

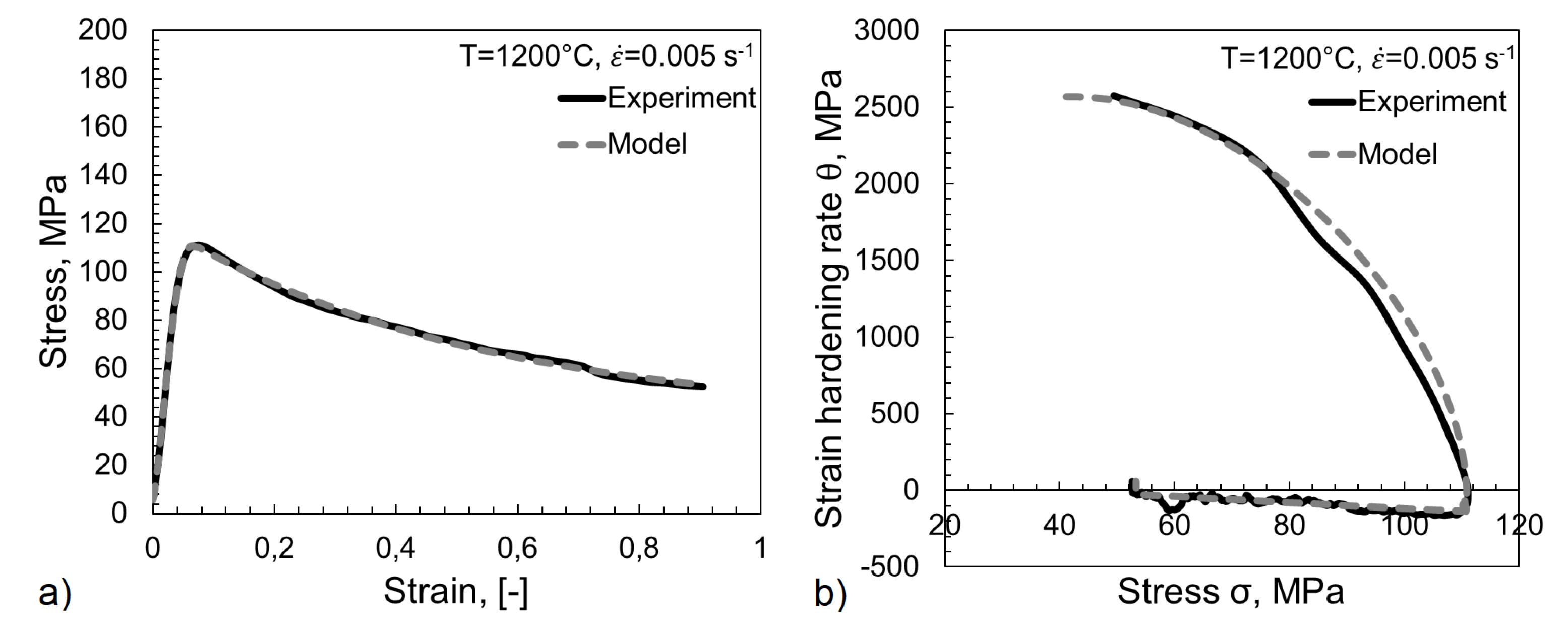

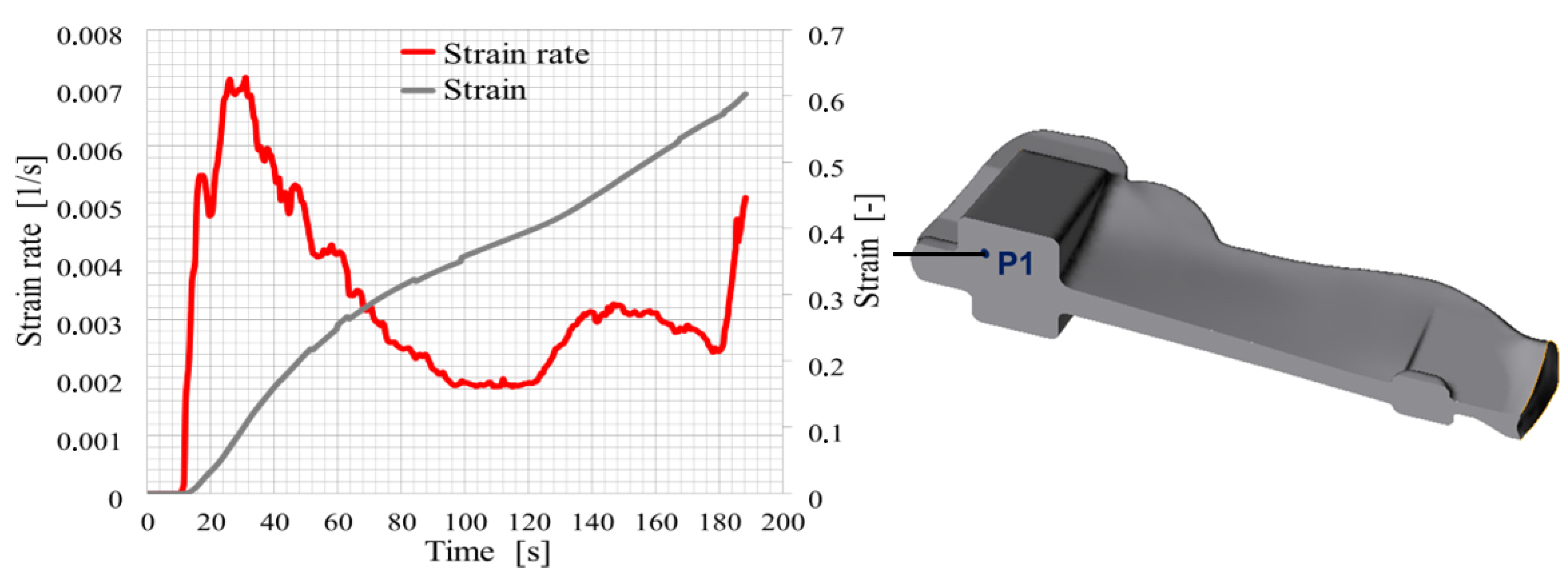

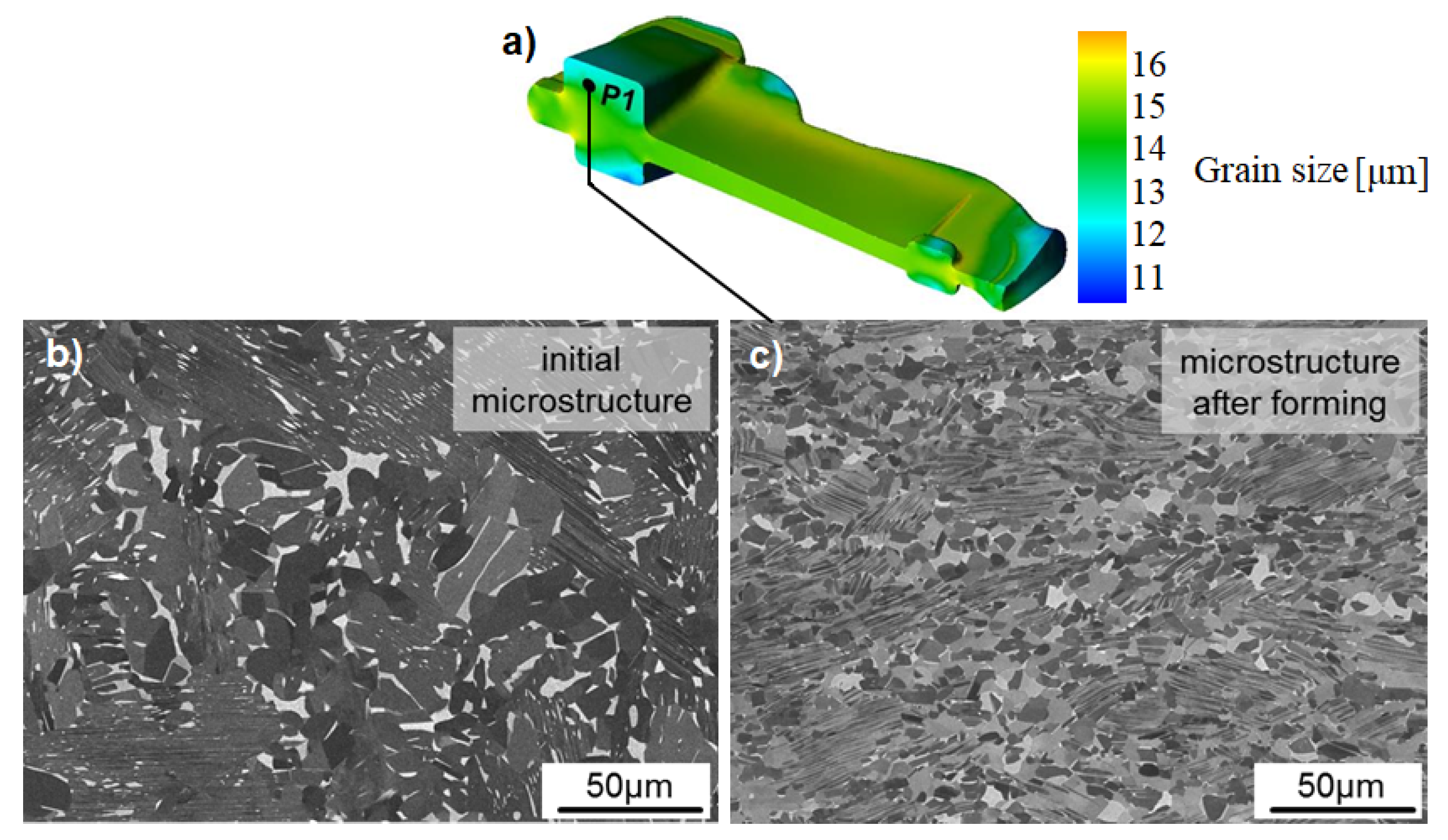

4.1. Model Validation

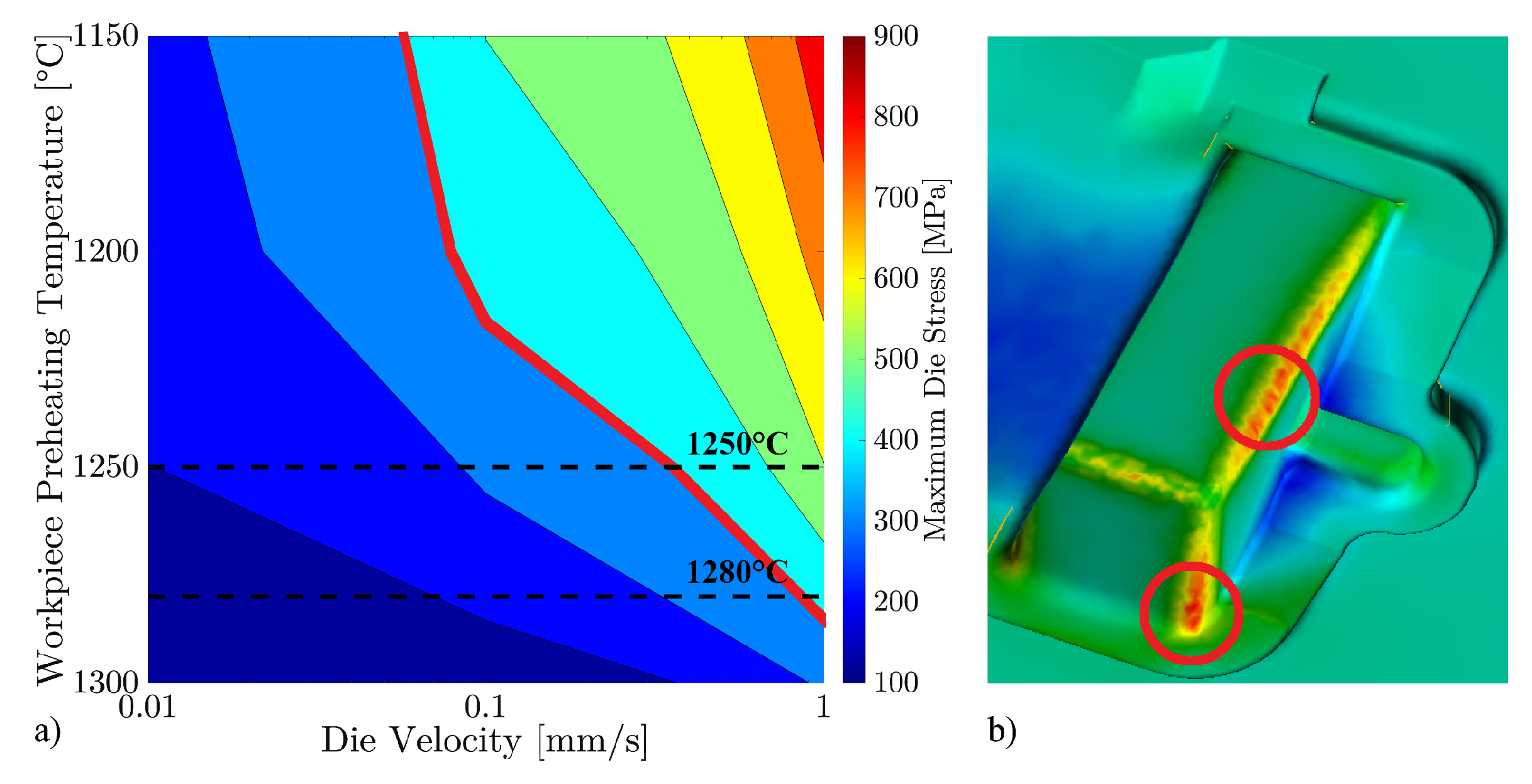

4.2. Simulated Die Stresses

4.3. Forging

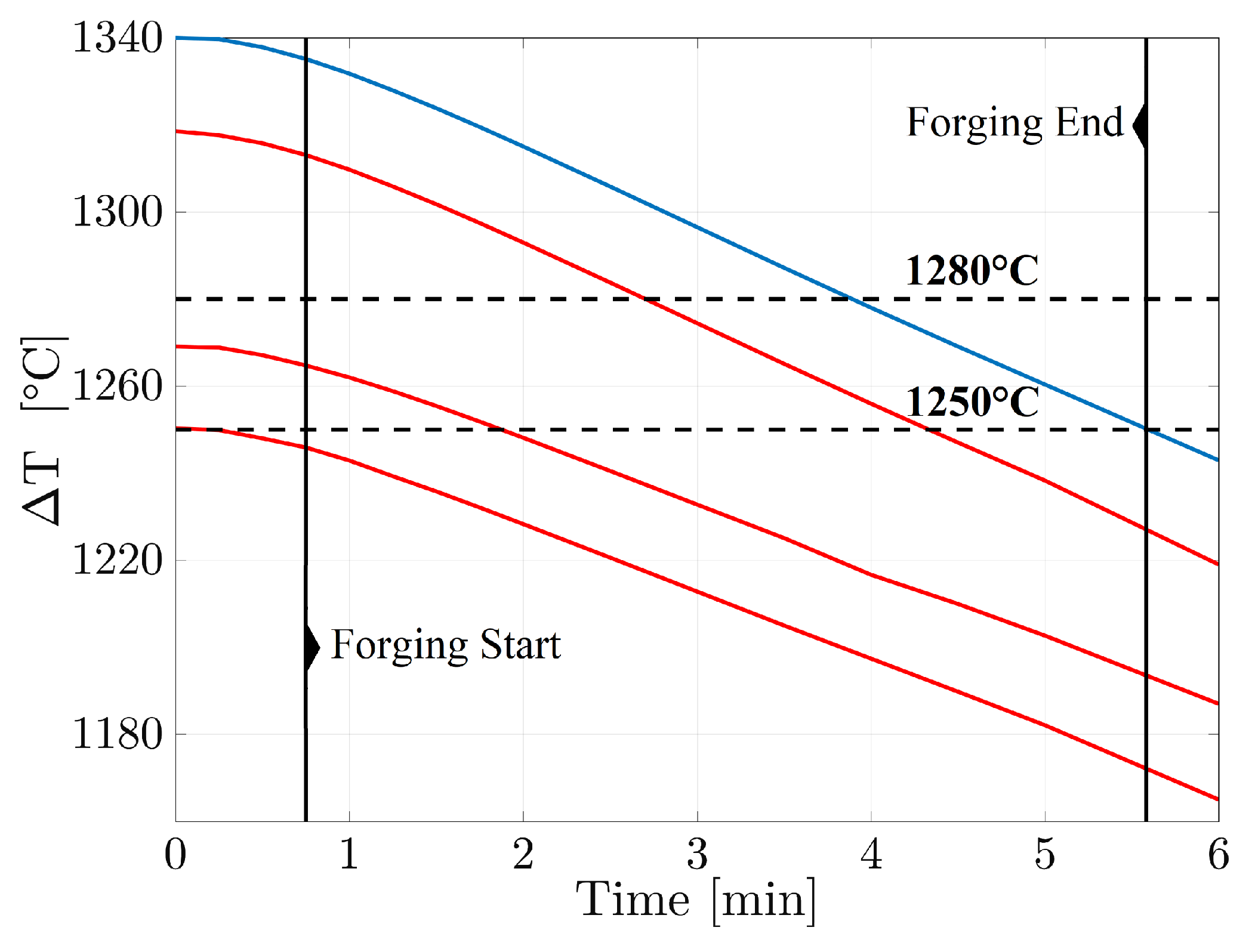

4.4. Heat Loss

4.5. Scaling Up of the Process

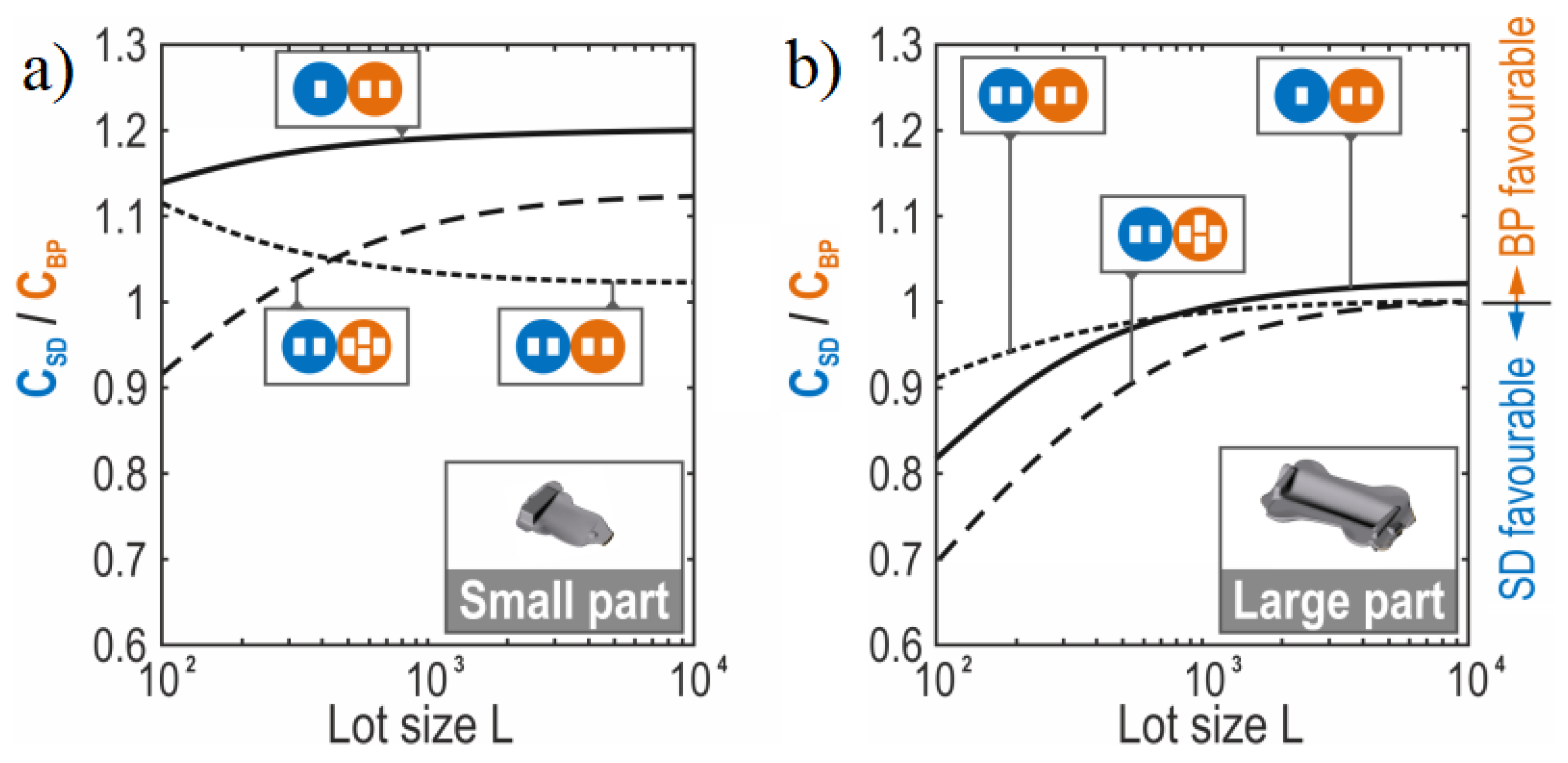

5. Cost Analysis

6. Conclusions

- A material model was successfully implemented into the FE program Q-Form, validated and applied to identify the TNB-V4 process window, forging speed and die stresses. The grain sizes predicted by the model showed good agreement with the experimental ones.

- Due to transport time and insufficient insulation, overheating the die set above the process window was necessary. Future research should aim at investigating the potentially negative effects of overheating TiAl alloys, and determining the amount of time overheating can be applied.

- Batch processing seems to offer cost advantages for smaller parts and large lot sizes, while stationary dies are favorable for larger parts and smaller production lots.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| TNB | TiAl with Nb and B as the main alloying elements |

| TNM | TiAl with Nb and Mo as the main alloying elements |

| DRX | Dynamic Recrystallization |

| DRV | Dynamic Recovery |

| VAR | Vacuum Arc Remelting |

| FE | Finite Element |

| KuF | Chair of Mechanical Design and Manufacturing |

References

- Clemens, H.; Kestler, H. Processing and applications of intermetallic γ-TiAl based alloys. Adv. Eng. Mater. 2000, 2, 551–570. [Google Scholar] [CrossRef]

- Clemens, H.; Smarsly, W. Light-weight Intermetallic Titanium Aluminides—Status of Research and Development. Adv. Mater. Res. 2011, 78, 551–556. [Google Scholar] [CrossRef]

- Aguilar, J.; Schievenbusch, A.; Kättlitz, O. Investment casting technology for production of TiAl low pressure turbine blades—Process engineering and parameter analysis. Intermetallics 2011, 19, 757–761. [Google Scholar] [CrossRef]

- Hautmann, D. Titanium Aluminide—A Class All by Itself; Aero Report; MTU Aero Engines AG: Munich, Germany, 2013. [Google Scholar]

- Olofson, C.T.; Boulger, F.W.; Gurklis, J.A. Machining and Grinding of Titanium and Its Alloys; NASA Technical Memorandum; NASA George C. Marshall Space Flight Center: Huntsville, AL, USA, 1965.

- Beranoagirre, A.; López de Lcalle, L.N. Grinding of Gmma TiAl Intermetallic Alloys. Procedia Eng. 2013, 63, 489–498. [Google Scholar] [CrossRef]

- Wu, F.; Xu, W.; Jin, X.; Zhong, X.; Wan, X.; Shan, D.; Guo, B. Study on Hot Deformation Behavior and Microstructure Evolution of Ti-55 High-Temperature Titanium Alloy. Metals 2017, 7, 319. [Google Scholar] [CrossRef]

- Millett, J.C.F.; Brooks, J.W.; Jones, I.P. Assessment and modelling of isothermal forging of intermetallic compounds Part 1—TiAl. Mat. Sci. Technol. 1999, 15, 697–704. [Google Scholar] [CrossRef]

- Blackwell, P.L.; Brooks, J.W.; Bate, P.S. Development of microstructure in isothermally forged Nimonic alloy AP1. Mat. Sci. Technol. 1998, 14, 1181–1188. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V.; Ghosh, A.K. Plastic flow, microstructure evolution, and defect formation during primary hot working of titanium and titanium aluminide alloys with lamellar colony microstructures. Philos. Trans. R. Soc. Lond. A 1999, 357, 1487–1512. [Google Scholar] [CrossRef]

- Tetsui, T.; Shindo, K.; Kaji, S.; Kobayashi, S.; Takeyama, M. Fabrication of TiAl components by means of hot forging and machining. Intermetallics 2005, 13, 971–978. [Google Scholar] [CrossRef]

- Brooks, J.W.; Dean, T.A.; Hu, Z.M.; Wey, E. Three-dimensional finite element modelling of a titanium aluminide aerofoil forging. J. Mater. Process. Technol. 1998, 80–81, 149–155. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Frey, N.; El-Soudani, S.M.; Bryant, J.D. Flow Softening and Microstructure Evolution during Hot Working of Wrought Near-Gamma Titanium Aluminides. Metall. Trans. A 1992, 23, 1719–1735. [Google Scholar] [CrossRef]

- Schmoelzer, T.; Liss, K.D.; Kirchlechner, C.; Mayer, S.; Stark, A.; Peel, M.; Clemens, H. An in-situ high-energy X-ray diffraction study on the hot-deformation behavior of a beta-phase containing TiAl alloy. Intermetallics 2013, 39, 25–33. [Google Scholar] [CrossRef]

- Cheng, L.; Xue, X.; Tang, B.; Kou, H.; Li, J. Flow characteristics and constitutive modeling for elevated temperature deformation of a high Nb containing TiAl alloy. Intermetallics 2014, 49, 23–28. [Google Scholar] [CrossRef]

- Laasraoui, A.; Jonas, J.J. Prediction of steel flow stresses at high temperatures and strain rates. Metall. Mat. Trans. A 1991, 22, 1545–1558. [Google Scholar] [CrossRef]

- Werner, R.; Lindemann, J.; Clemens, H.; Mayer, S. Constitutive Analysis of the Flow Curve Behavior of an Intermetallic β-solidifying γ-TiAl-based Alloy and Microstructural Characterization of the Deformed State. BHM 2014, 159, 286–288. [Google Scholar] [CrossRef]

- Godor, F.; Werner, R.; Lindemann, J.; Clemens, H.; Mayer, S. Characterization of the high temperature deformation behavior of two intermetallic TiAl–Mo alloys. Mater. Sci. Eng. A 2015, 648, 208–216. [Google Scholar] [CrossRef]

- Schwaighofer, E.; Clemens, H.; Lindemann, J.; Stark, A.; Mayer, S. Hot-working behavior of an advanced intermetallic multi-phase γ-TiAl based alloy. Mater. Sci. Eng. A 2014, 614, 297–310. [Google Scholar] [CrossRef]

- Cingara, A.; McQueen, H.J. New formula for calculating flow curves from high temperature constitutive data for 300 austenitic steels. J. Mater. Process. Technol. 1992, 36, 31–42. [Google Scholar] [CrossRef]

- Bambach, M.; Sizova, I.; Bolz, S.; Weiß, S. Devising Strain Hardening Models Using Kocks–Mecking Plots—A Comparison of Model Development for Titanium Aluminides and Case Hardening Steel. Metals 2016, 6, 204. [Google Scholar] [CrossRef]

- Hufenbach, W.; Behnisch, T.; Richter, H.; Langkamp, A.; Janschek, P.; Bauer-Partenheimer, K.; Turley, F. Development of Hybrid CMC Forming Dies for High Temperature Precision Forging of Titanium Aluminide. In Proceedings of the 7th International Conference on High Temperature Ceramic Matrix Composites (HT-CMC 7), 20–22 September 2010; pp. 531–536. [Google Scholar]

- Krenkel, W. Carbon Fibre Reinforced Silicon Carbide Composites (C/SiC, C/C-SiC). In Handbook of Ceramic Composites; Springer: New York, NY, USA, 2005; pp. 117–148. [Google Scholar]

- Jaffee, R.I.; Promisel, N.E. The Science, Technology and Application of Titanium; Pergamon Press Ltd.: Oxford, UK, 2013; pp. 79–84. [Google Scholar]

| Zener Hollomon parameter | (1) | |

| Strain hardening | (2) | |

| Critical strain | (3) | |

| Peak strain | (4) | |

| Steady state strain | (5) | |

| Peak stress | (6) | |

| Steady state stress | (7) | |

| DRX grain size | (8) | |

| DRX kinetics | (9) | |

| Flow stress | (10) |

| Al | Nb | Mo | B |

|---|---|---|---|

| 44.5 | 6.25 | 0.8 | 0.1 |

| Point P1 | Calculated Grain Size [m] | Measured Grain Size [m] |

|---|---|---|

| -phase | 12.71 | 10.37 |

| /-phase | 12.86 | 10.24 |

| Cost Type | Symbol | Unit | Value |

|---|---|---|---|

| Cost of die material | USD/kg | 140 | |

| Cost of TiAl | USD/kg | 200 | |

| Density Mo | kg/ | 10,200 | |

| Density TiAl | kg/ | 4200 | |

| Labour cost per hour | USD/h | 175 | |

| Equipment hourly rate | USD/h | 590 | |

| Forging ram speed | V | mm/s | 0.1 |

| Handling time single part | s | 10 | |

| Handling time die set | s | 35 |

| Parameter | Symbol | Unit | Small Part | Large Part |

|---|---|---|---|---|

| Billet volume | 60,000 | 100,000 | ||

| Die volume | 4,200,000 | 11,000,000 | ||

| Chip volume | 1,000,000 | 900,000 | ||

| Set-up time | s | 28,800 | 60 | |

| Forging time | s | 310 | 380 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bambach, M.; Sizova, I.; Sviridov, A.; Stendal, J.A.; Günther, M. Batch Processing in Preassembled Die Sets—A New Process Design for Isothermal Forging of Titanium Aluminides. J. Manuf. Mater. Process. 2018, 2, 1. https://doi.org/10.3390/jmmp2010001

Bambach M, Sizova I, Sviridov A, Stendal JA, Günther M. Batch Processing in Preassembled Die Sets—A New Process Design for Isothermal Forging of Titanium Aluminides. Journal of Manufacturing and Materials Processing. 2018; 2(1):1. https://doi.org/10.3390/jmmp2010001

Chicago/Turabian StyleBambach, Markus, Irina Sizova, Alexander Sviridov, Johan Andreas Stendal, and Martin Günther. 2018. "Batch Processing in Preassembled Die Sets—A New Process Design for Isothermal Forging of Titanium Aluminides" Journal of Manufacturing and Materials Processing 2, no. 1: 1. https://doi.org/10.3390/jmmp2010001

APA StyleBambach, M., Sizova, I., Sviridov, A., Stendal, J. A., & Günther, M. (2018). Batch Processing in Preassembled Die Sets—A New Process Design for Isothermal Forging of Titanium Aluminides. Journal of Manufacturing and Materials Processing, 2(1), 1. https://doi.org/10.3390/jmmp2010001