Laser Powder Bed Fusion of Water-Atomized Iron-Based Powders: Process Optimization

Abstract

:1. Introduction

2. Methodology

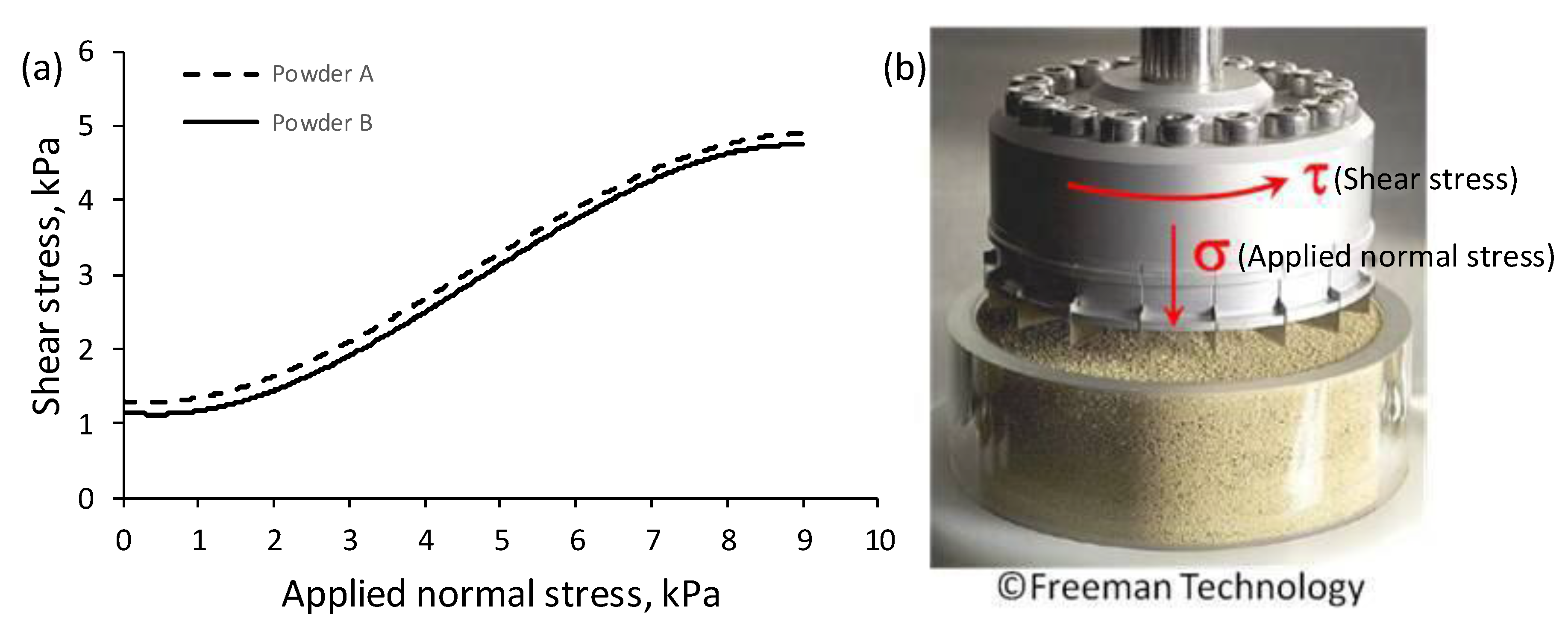

2.1. Powder Feedstock Characterization and Selection of the Best Powder Candidate

2.2. Optimization of L-PBF Processing and Post-Processing Conditions

- Simplified modeling of the L-PBF melt pool with the objective of delimiting the processing window to be studied experimentally;

- Application of the numerically justified L-PBF processing parameters and selection of the most appropriate set of parameters;

- Post-processing and mechanical characterization of L-PBF specimens.

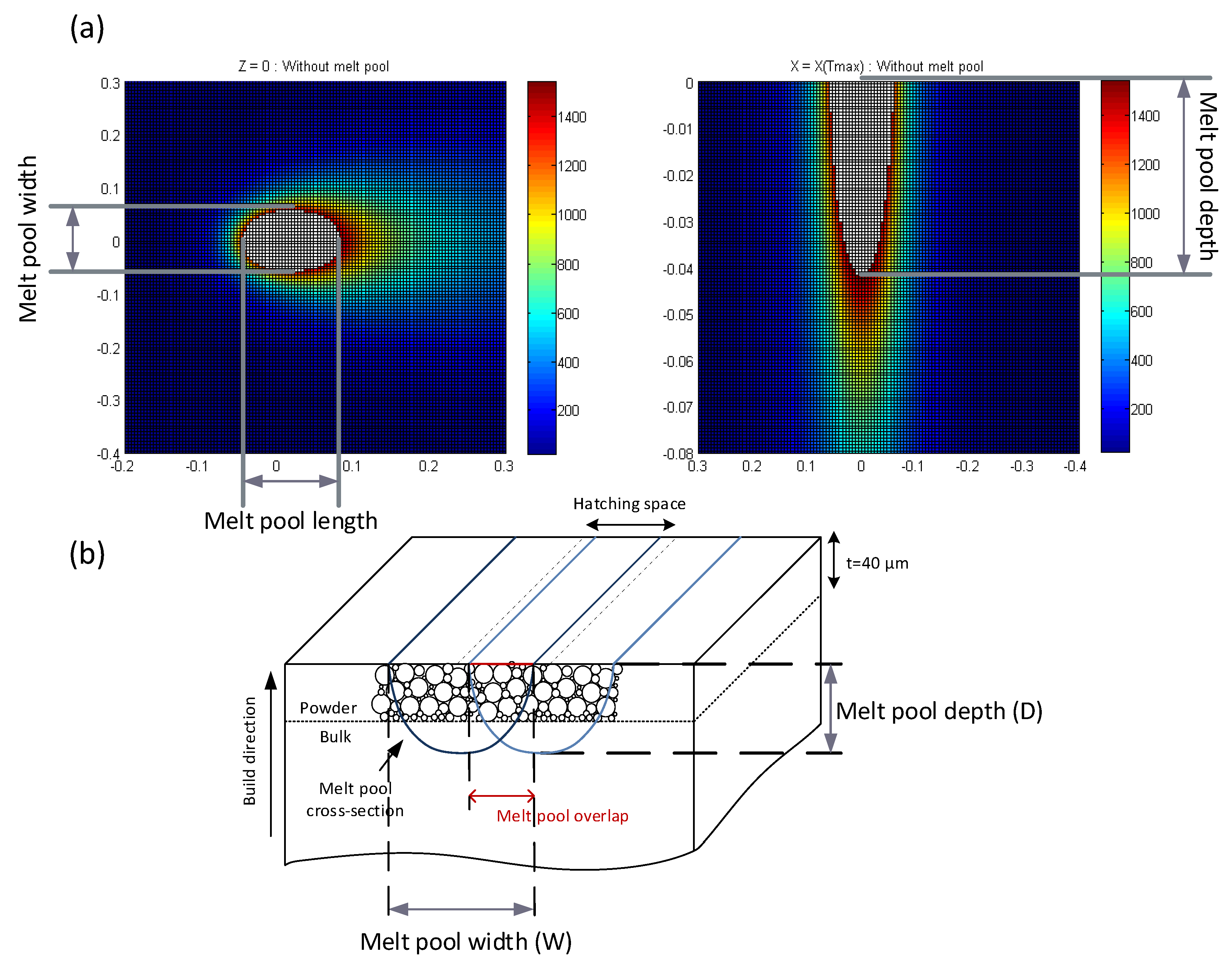

2.2.1. Simplified Modeling of the L-PBF Melt Pool

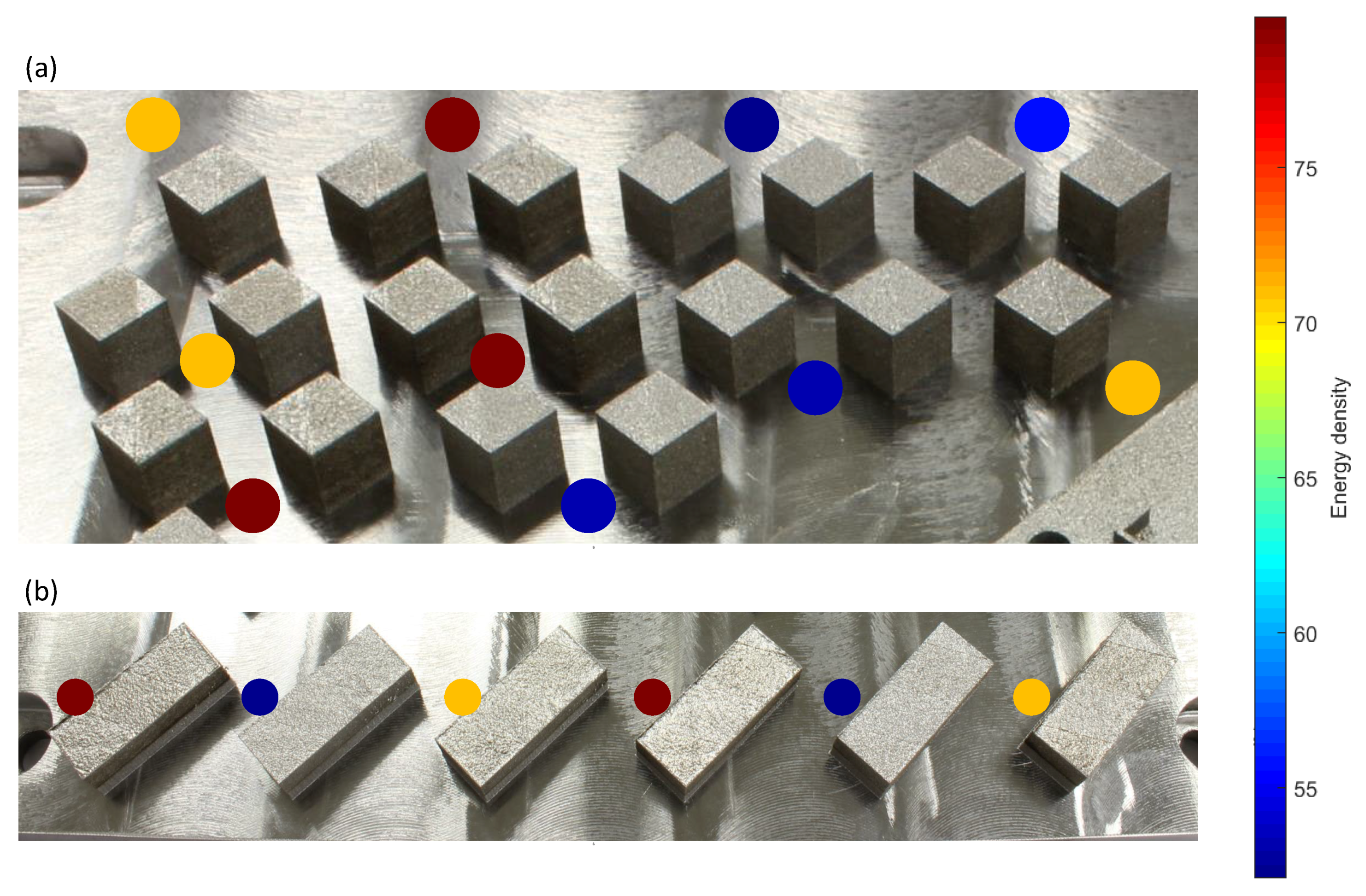

2.2.2. Experimental Study and Selection of the Most Appropriate L-PBF Processing Parameters

2.2.3. Post-Processing of the L-PBF Specimens and Their Tensile Testing, Microstructural Analysis, and Minimum Wall Thickness Measurements

3. Results and Discussion

3.1. Powder Characterization and Selection

3.2. Characterization of the L-PBF Specimens

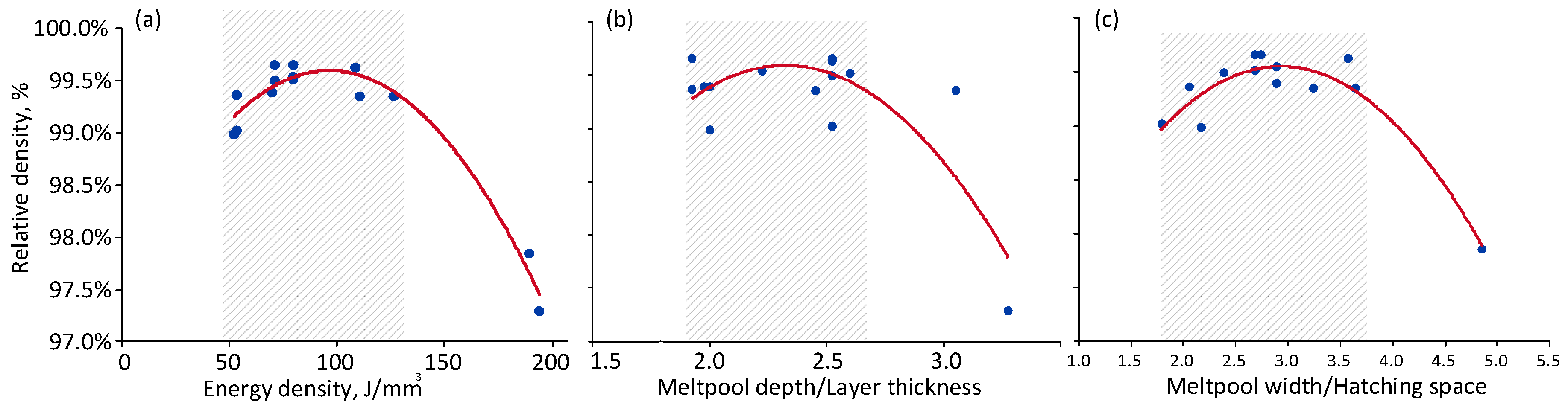

3.2.1. Density Measurements

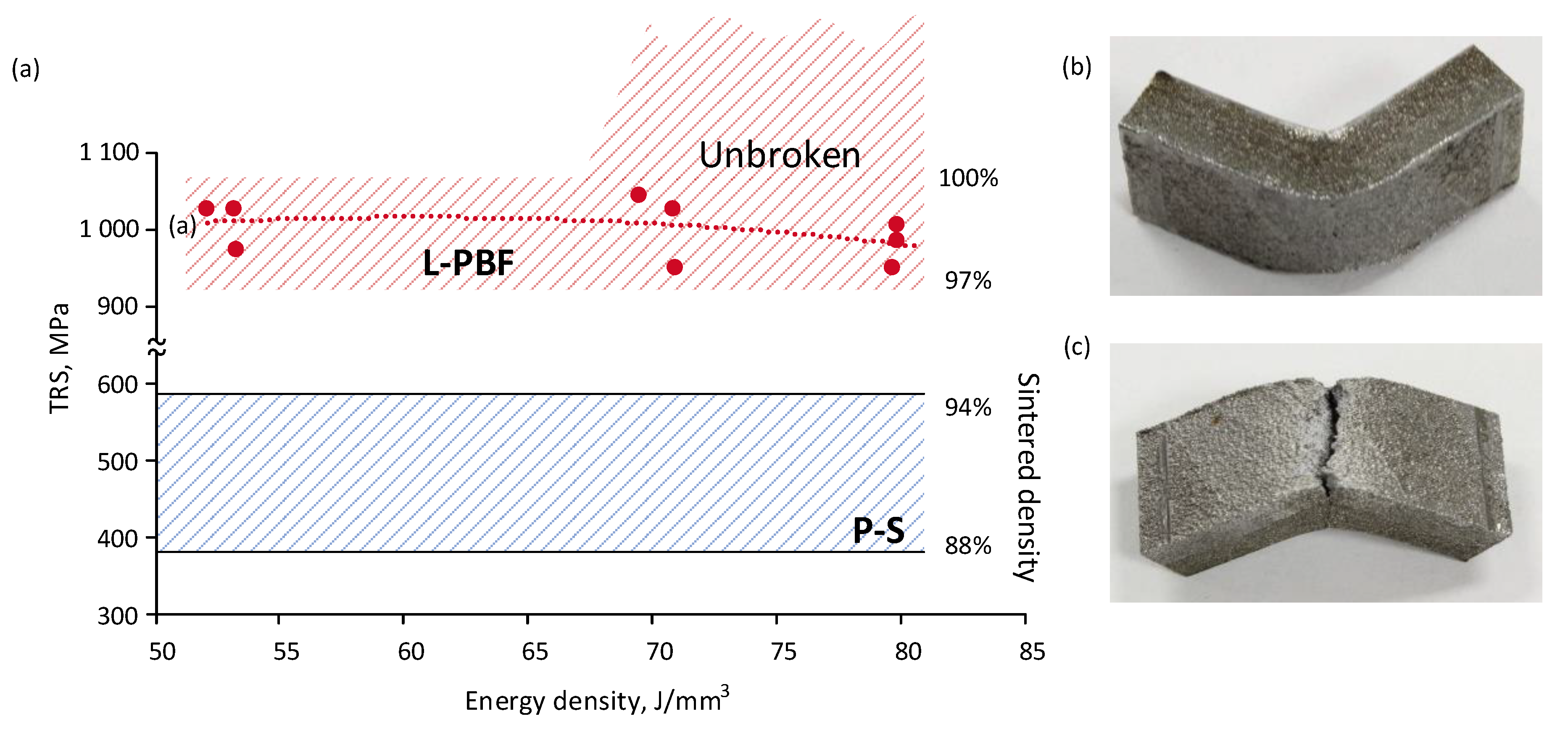

3.2.2. Three-Point Bending Tests (TRS—Transverse Rupture Strength)

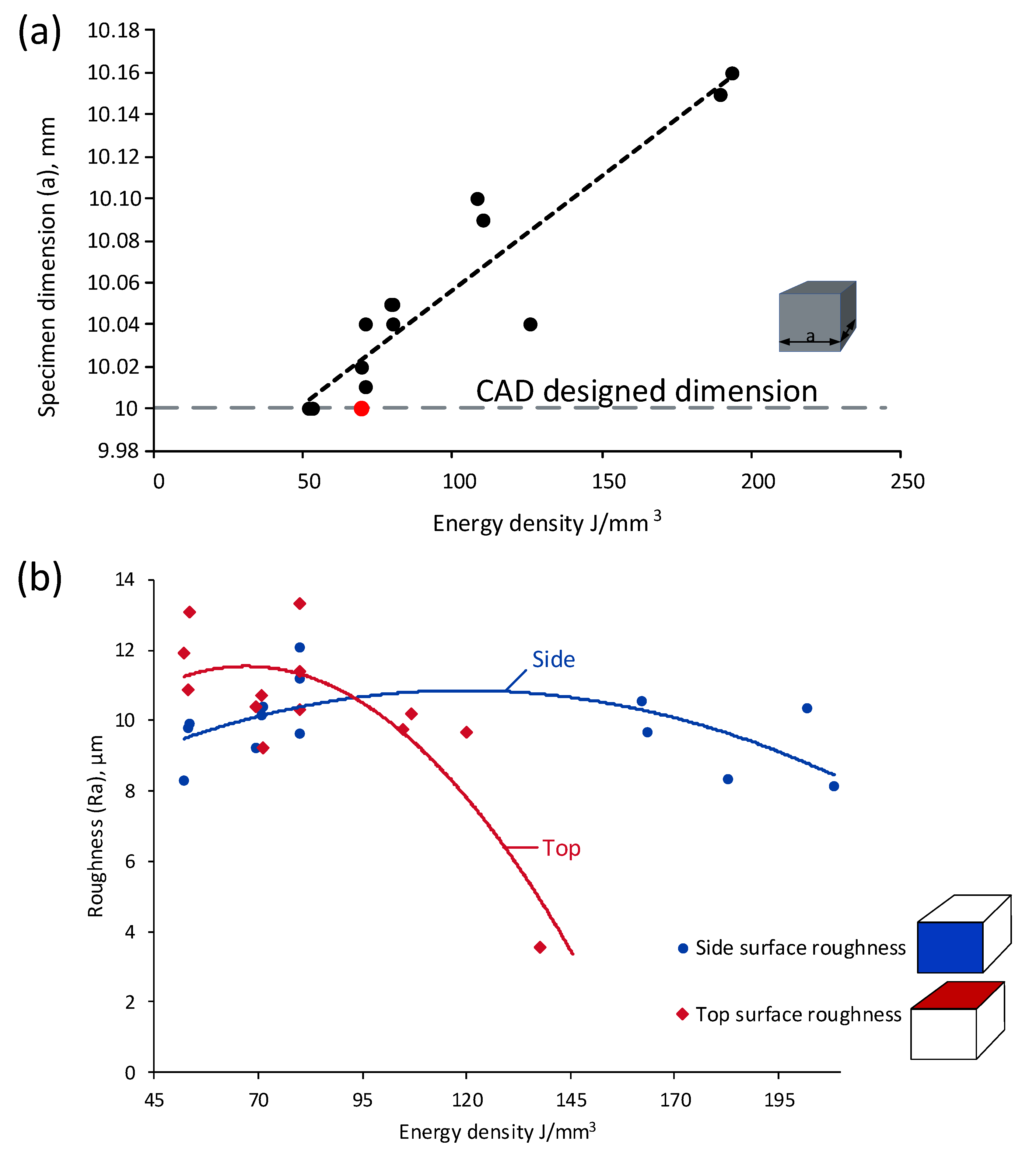

3.2.3. Dimensional Precision and Surface Roughness

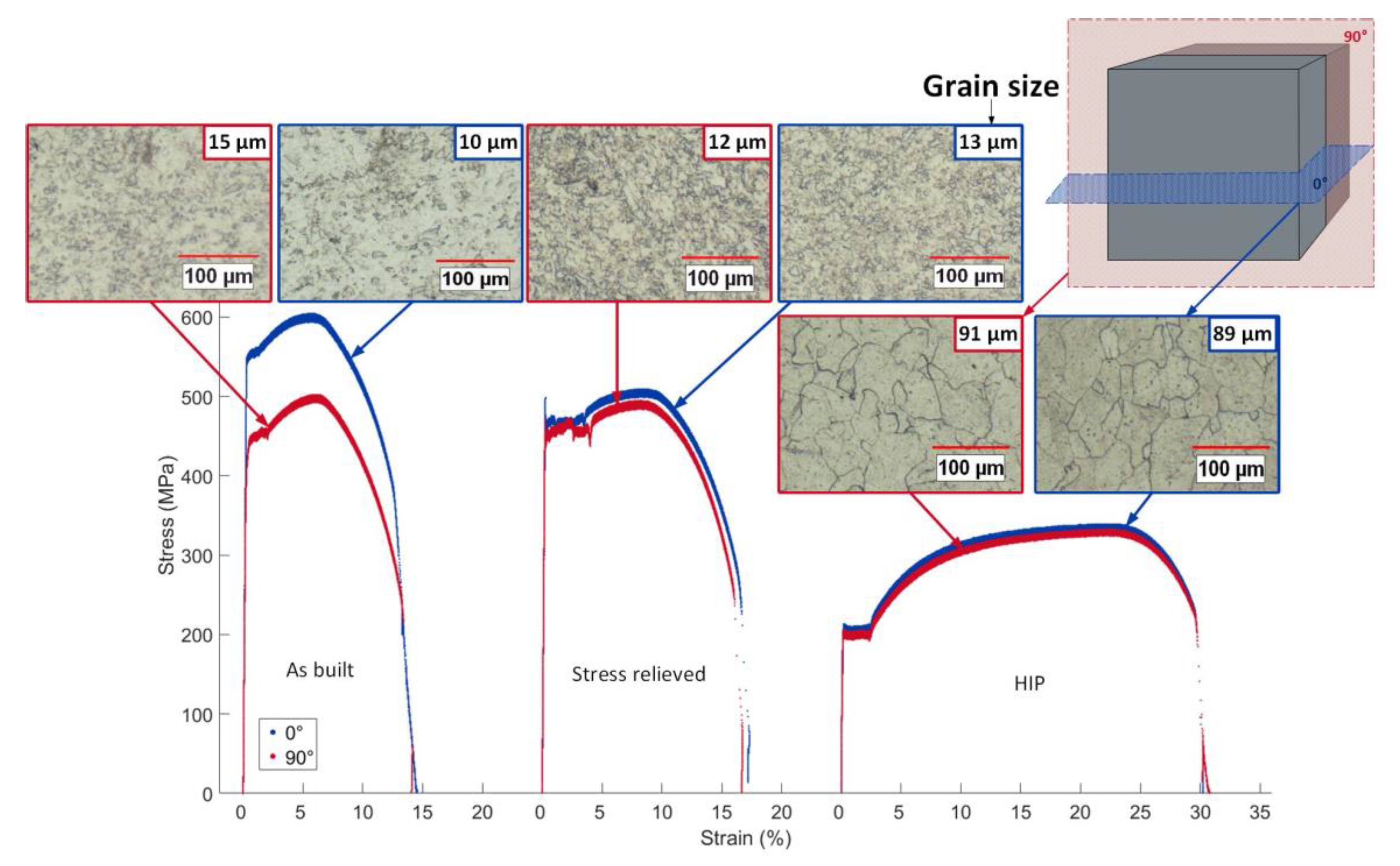

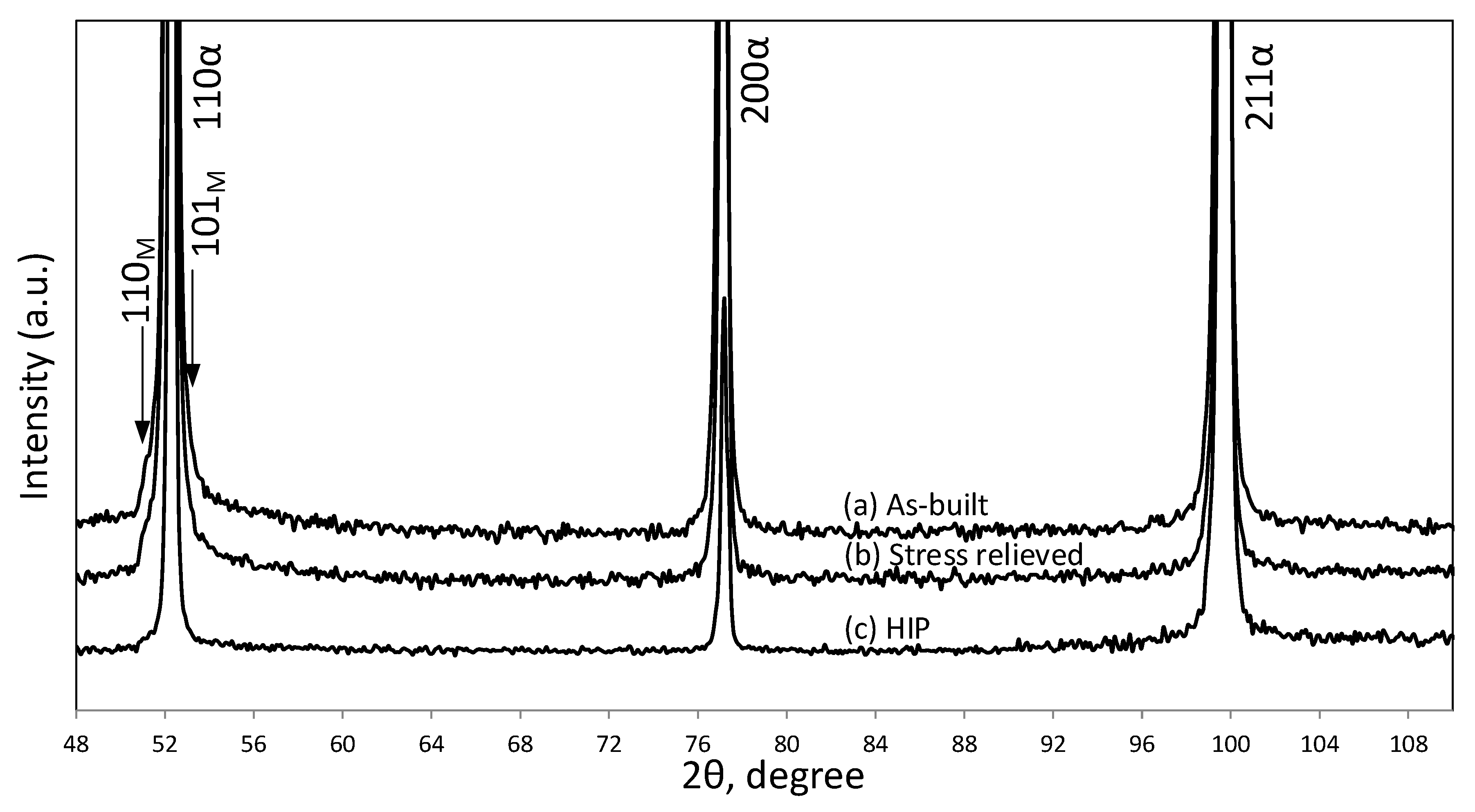

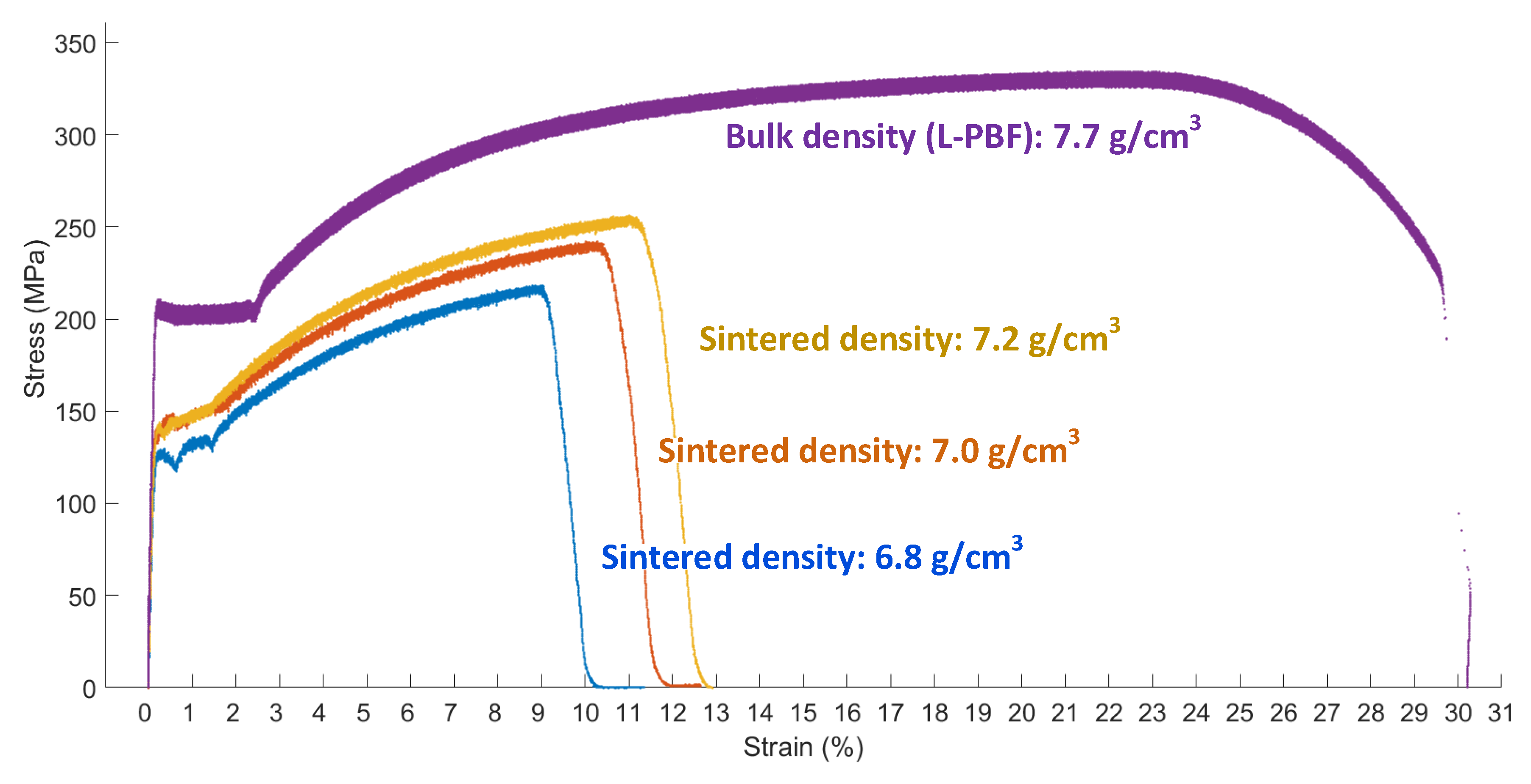

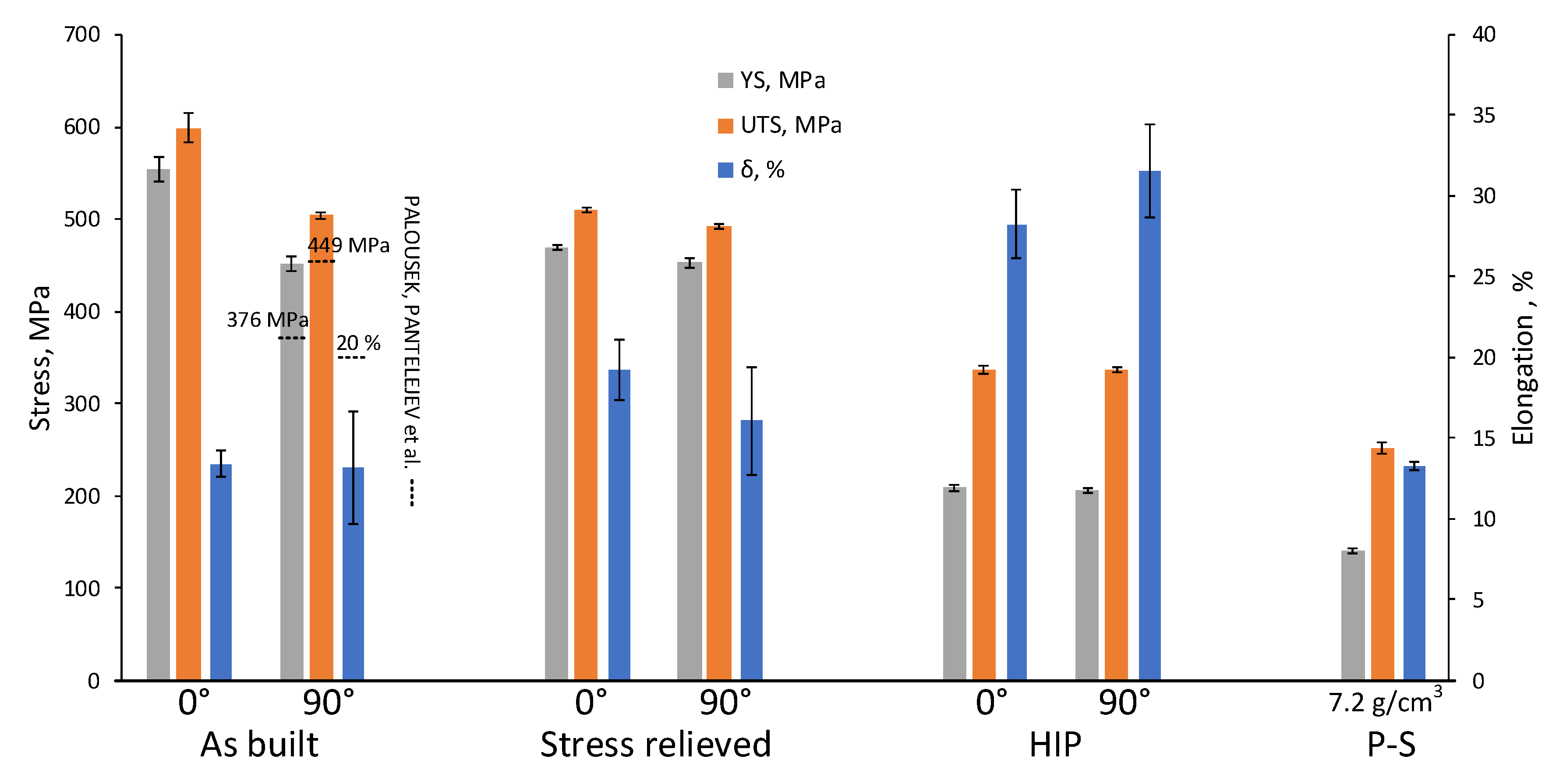

3.2.4. Tensile Properties, Microstructure, and Wall Thickness

3.3. General Discussion on the L-PBF Processing Map

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sutton, A.T.; Kriewall, C.S.; Leu, M.C.; Newkirk, J.W. Powder characterisation techniques and effects of powder characteristics on part properties in powder-bed fusion processes. Virtual Phys. Prototyp. 2017, 12, 3–29. [Google Scholar] [CrossRef]

- Marucci, M.L.; Catanese, J.A. Production of powder metallurgy carbon and low-alloy steels. In ASM Handbook, Volume 7: Powder Metallurgy; ASM International: Almere, The Netherlands, 2015; pp. 311–321. [Google Scholar]

- Palousek, D.; Pantelejev, L.; Zikmund, T.; Koutny, D. Processing of the Nearly Pure Iron Using 400 w Selective Laser Melting–Initial Study. MM Sci. J. 2017. [Google Scholar] [CrossRef]

- Schuöcker, D. Handbook of the Eurolaser Academy; Springer Science & Business Media: Berlin, Germany, 1998; Volume 2. [Google Scholar]

- Kreitcberg, A.; Brailovski, V.; Prokoshkin, S. New biocompatible near-beta Ti-Zr-Nb alloy processed by laser powder bed fusion: Process optimization. J. Mater. Process. Technol. 2018, 252, 821–829. [Google Scholar] [CrossRef]

- Hagen, E.; Rubens, H. Über beziehungen des reflexions-und emissionsvermögens der metalle zu ihrem elektrischen leitvermögen. Ann. Phys. 1903, 316, 873–901. (In German) [Google Scholar] [CrossRef]

- Bala, K.; Pradhan, P.R.; Saxena, N.; Saksena, M. Effective thermal conductivity of copper powders. J. Phys. D Appl. Phys. 1989, 22, 1068. [Google Scholar] [CrossRef]

- Sumirat, I.; Ando, Y.; Shimamura, S. Theoretical consideration of the effect of porosity on thermal conductivity of porous materials. J. Porous Mater. 2006, 13, 439–443. [Google Scholar] [CrossRef]

- Liu, P.; Fu, C.; Li, T. Calculation formula for apparent electrical resistivity of high porosity metal materials. Sci. China Ser. E Technol. Sci. 1999, 42, 294–301. [Google Scholar] [CrossRef]

- Karapatis, N.; Egger, G.; Gygax, P.; Glardon, R. Optimization of powder layer density in selective laser sintering. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 9–11 August 1999; pp. 255–263. [Google Scholar]

- Spierings, A.; Levy, G. Comparison of density of stainless steel 316L parts produced with selective laser melting using different powder grades. In Proceedings of the Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 9–11 August 2010; pp. 342–353. [Google Scholar]

- Igor Yadroitsev, I.Y.; Bertrand, P.; Smurov, I. Factor analysis of selective laser melting process parameters and geometrical characteristics of synthesized single tracks. Rapid Prototyp. J. 2015, 18, 201–208. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing porosity in AlSi10Mg parts processed by selective laser melting. Addit. Manuf. 2014, 1, 77–86. [Google Scholar] [CrossRef]

- Federation, M.P.I. Standard Test Methods for Metal Powders and Powder Metallurgy Products; Metal Powder Industries Federation: Princeton, NJ, USA, 2002. [Google Scholar]

- Dossett, J.L.; White, C.V. Introduction to cast iron heat treatment. In ASM Handbook, Volume 4D: Heat Treating of Irons and Steels; ASM International: Almere, The Netherlands, 2014; pp. 483–492. [Google Scholar]

- Inaekyan, K.; Paserin, V.; Bailon-Poujol, I.; Brailovski, V. Binder-jetting additive manufacturing with water atomized iron powders. In Proceedings of the AMPM 2016 Conference on Additive Manufacturing, Held with MPIF/APMI International Conference on Powder Metallurgy & Particulate Materials, Boston, MA, USA, June 2016. [Google Scholar]

- Moylan, S.; Cooke, A.; Jurrens, K.; Slotwinski, J.; Donmez, M.A. A Review of Test Artifacts for Additive Manufacturing; Report No. NISTIR 7858; National Institute of Standards and Technology (NIST): Gaithersburg, MD, USA, 2012.

- Spierings, A.B.; Voegtlin, M.; Bauer, T.; Wegener, K. Powder flowability characterisation methodology for powder-bed-based metal additive manufacturing. Prog. Addit. Manuf. 2016, 1, 9–20. [Google Scholar] [CrossRef]

- Grey, R.; Beddow, J. On the hausner ratio and its relationship to some properties of metal powders. Powder Technol. 1969, 2, 323–326. [Google Scholar] [CrossRef]

- Geldart, D.; Abdullah, E.C.; Hassanpour, A.; Nwoke, L.C.; Wouters, I. Characterization of powder flowability using measurement of angle of repose. China Particuology 2006, 4, 104–107. [Google Scholar] [CrossRef]

- Cloots, M.; Uggowitzer, P.J.; Wegener, K. Investigations on the microstructure and crack formation of IN738LC samples processed by selective laser melting using gaussian and doughnut profiles. Mater. Des. 2016, 89, 770–784. [Google Scholar] [CrossRef]

- Hoeges, S.; Schade, C.T.; Causton, R. Development of a Maraging Steel Powder for Additive Manufacturing. In Proceedings of the MPIF World Congress on Powder Metallurgy and Particulate Materials, San Diego, CA, USA, 17–28 May 2015. [Google Scholar]

- Cacace, S.; Demir, A.G.; Semeraro, Q. Densification mechanism for different types of stainless steel powders in selective laser melting. Procedia CIRP 2017, 62, 475–480. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: Berlin, Germany, 2010; Volume 238. [Google Scholar]

- Urlea, V.; Brailovski, V. Electropolishing and electropolishing-related allowances for powder bed selectively laser-melted ti-6al-4v alloy components. J. Mater. Process. Technol. 2017, 242, 1–11. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Casalino, G.; Contuzzi, N.; Ludovico, A.D. Taguchi optimization of the surface finish obtained by laser ablation on selective laser molten steel parts. In Proceedings of the 8th CIRP Conference on Intelligent Computation in Manufacturing Engineering, Ischia, Italy, 18–20 July 2012. [Google Scholar]

- Brandt, M. Laser Additive Manufacturing: Materials, Design, Technologies, and Applications; Woodhead Publishing: Sawston, UK, 2016. [Google Scholar]

- Bibby, M.; Parr, J.G. The Martensitic Transformation in Pure Iron; Alberta University Edmonton Department of Mining and Metallurgy: Edmonton, AB, Canada, 1963. [Google Scholar]

- Loh, L.-E.; Chua, C.-K.; Yeong, W.-Y.; Song, J.; Mapar, M.; Sing, S.-L.; Liu, Z.-H.; Zhang, D.-Q. Numerical investigation and an effective modelling on the selective laser melting (SLM) process with aluminium alloy 6061. Int. J. Heat Mass Transf. 2015, 80, 288–300. [Google Scholar] [CrossRef]

- Hosokawa, A.; Ii, S.; Tsuchiya, K. Work hardening and microstructural development during high-pressure torsion in pure iron. Mater. Trans. 2014, 55, 1097–1103. [Google Scholar] [CrossRef]

- Pavel Hanzl, M.Z.; Bakša, T.; Kroupa, T. The influence of processing parameters on the mechanical properties of SLM parts. Procedia Eng. 2014, 100, 1405–1413. [Google Scholar] [CrossRef]

- Kipp, D.O. Metal Material Data Sheets; MatWeb, LLC.: Blacksburg, VA, USA, 2017. [Google Scholar]

- King, W.; Anderson, A.; Ferencz, R.; Hodge, N.; Kamath, C.; Khairallah, S.; Rubenchik, A. Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. Appl. Phys. Rev. 2015, 2, 041304. [Google Scholar] [CrossRef]

- Song, B.; Zhao, X.; Li, S.; Han, C.; Wei, Q.; Wen, S.; Liu, J.; Shi, Y. Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review. Front. Mech. Eng. 2015, 10, 111–125. [Google Scholar] [CrossRef]

| Physical Material Characteristics | L-PBF Processing Parameters | |||

|---|---|---|---|---|

| Bulk | Powder | |||

| Melting temperature, °C | 1538 | 1538 | Laser spot radius r, µm | 50 |

| Density, kg/m3 | 7870 | 3120 | Laser power P, W | 170, 200, 240, 250, 370 |

| Thermal conductivity, W/m·K | 80.4 | 31.8 | Scanning speed v, mm/s | 400, 660, 940, 1000, 1200 |

| Specific heat, J/kg·K | 447.3 | 177.2 | Layer thickness t, µm | 40 |

| Electr. resist., 10−9 Ohm·m | 97.1 | 135.6 | Hatching space h, µm | 40, 60, 80, 120 |

| Powder Characteristics | Powder A | Powder B | |

|---|---|---|---|

| Particle size distribution, µm | D10 | 19 | 15.2 |

| D50 | 33.1 | 29.1 | |

| D90 | 54.6 | 50.7 | |

| Circularity | Mean | 0.65 | 0.67 |

| Mode | 0.50–0.55 | 0.60–0.65 | |

| Median | 0.55–0.60 | 0.62 | |

| Density, g/cm3 | Apparent | 3.03 | 3.49 |

| Tap | 3.83 | 3.99 | |

| Hausner ratio (HR) * | 1.27 | 1.14 | |

| Minimum Wall Sink Gap Thickness Evaluation | |||

|---|---|---|---|

| Nominal Dimensions (CAD), mm | Wall | Sink | Gap |

| 0.1 | X | 0.17 | X |

| 0.2 | 0.25 | 0.21 | 0.17 |

| 0.3 | 0.32 | 0.31 | 0.27 |

| 0.4 | 0.42 | 0.41 | 0.37 |

| 0.5 | 0.52 | 0.49 | 0.47 |

| 0.6 | 0.6 | 0.58 | 0.64 |

| 0.8 | 0.8 | 0.78 | 0.83 |

| 1 | 1 | 1.02 | 1.02 |

| 1.5 | 1.5 | 1.52 | 1.51 |

| 2 | 2 | 1.97 | 2.01 |

| X—print was not successful | |||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Letenneur, M.; Brailovski, V.; Kreitcberg, A.; Paserin, V.; Bailon-Poujol, I. Laser Powder Bed Fusion of Water-Atomized Iron-Based Powders: Process Optimization. J. Manuf. Mater. Process. 2017, 1, 23. https://doi.org/10.3390/jmmp1020023

Letenneur M, Brailovski V, Kreitcberg A, Paserin V, Bailon-Poujol I. Laser Powder Bed Fusion of Water-Atomized Iron-Based Powders: Process Optimization. Journal of Manufacturing and Materials Processing. 2017; 1(2):23. https://doi.org/10.3390/jmmp1020023

Chicago/Turabian StyleLetenneur, Morgan, Vladimir Brailovski, Alena Kreitcberg, Vladimir Paserin, and Ian Bailon-Poujol. 2017. "Laser Powder Bed Fusion of Water-Atomized Iron-Based Powders: Process Optimization" Journal of Manufacturing and Materials Processing 1, no. 2: 23. https://doi.org/10.3390/jmmp1020023

APA StyleLetenneur, M., Brailovski, V., Kreitcberg, A., Paserin, V., & Bailon-Poujol, I. (2017). Laser Powder Bed Fusion of Water-Atomized Iron-Based Powders: Process Optimization. Journal of Manufacturing and Materials Processing, 1(2), 23. https://doi.org/10.3390/jmmp1020023