Multi-Layer Path Planning for Complete Structural Inspection Using UAV †

Abstract

Highlights

- The proposed algorithm can generate suitable inspection paths for different inspection purposes (distances), including crack detection and photogrammetry.

- The proposed optimization method generates a feasible inspection path that shows improvement in terms of overall turning angle and acceleration when compared with conventional approaches.

- A mixed-viewpoint generation technique is essential in generating suitable inspection path for different purposes while satisfying the varying coverage requirements.

- The inclusion of turning angle in the optimization objective can help improving the overall smoothness of the inspection path, reducing the traversal difficulty.

Abstract

1. Introduction

- 1.

- Mixed-viewpoint generation that can generate a scalable viewpoint set that suits different inspection purposes.

- 2.

- A newly proposed ML-ADTSP that can generate a kinodynamically feasible inspection path to ease trajectory optimization in future processes while increasing energy efficiency.

- 3.

- Numerical simulations are performed to extensively study the effects of including kinodynamic constraints during preliminary path planning.

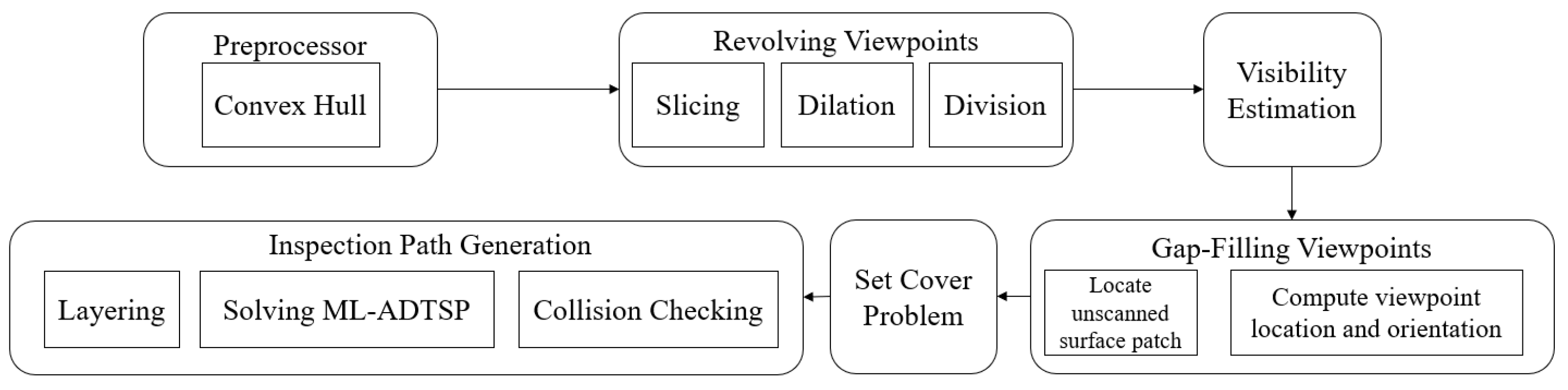

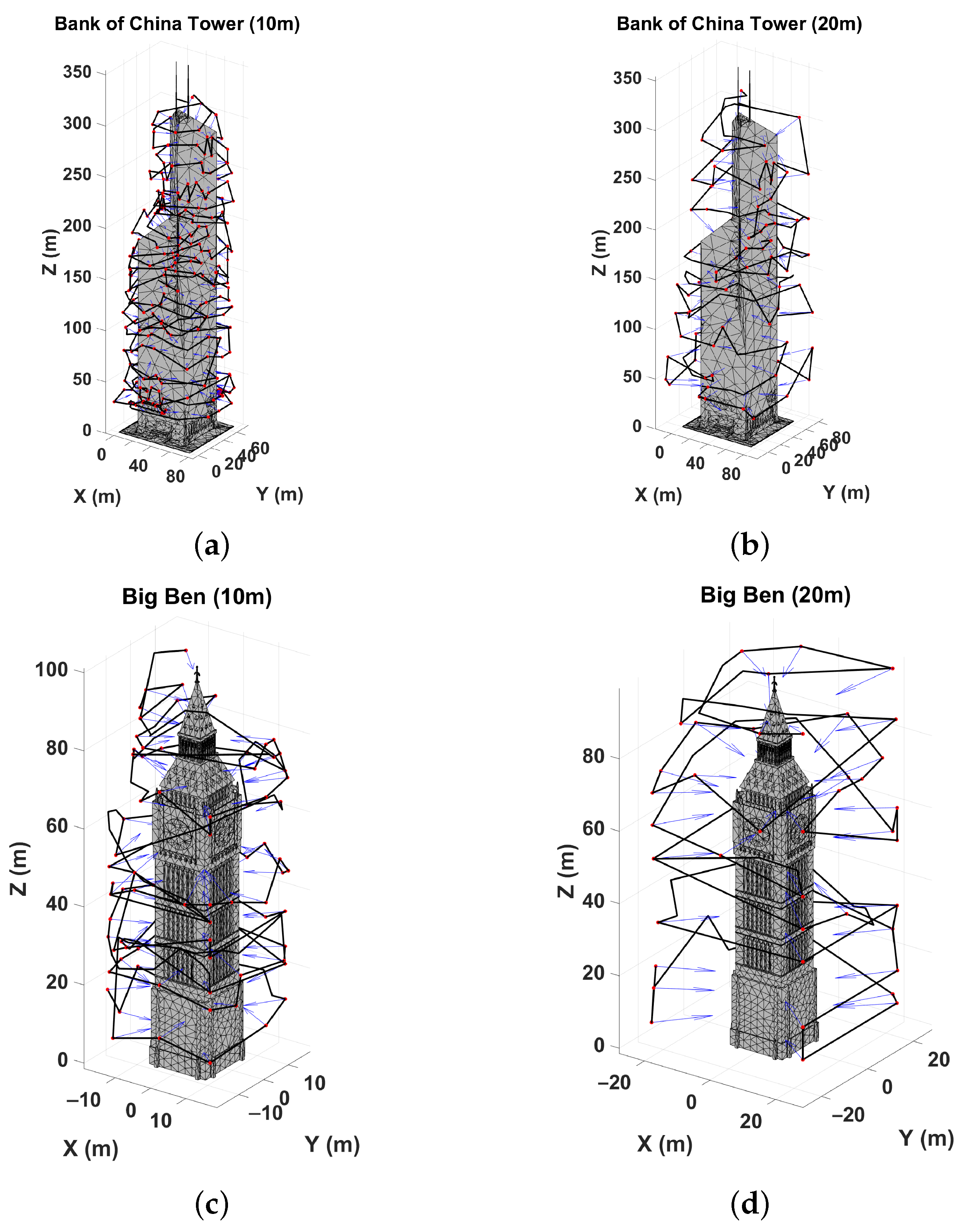

2. Mixed-Viewpoint Generation

2.1. Problem Statement

2.2. Model Preprocessor

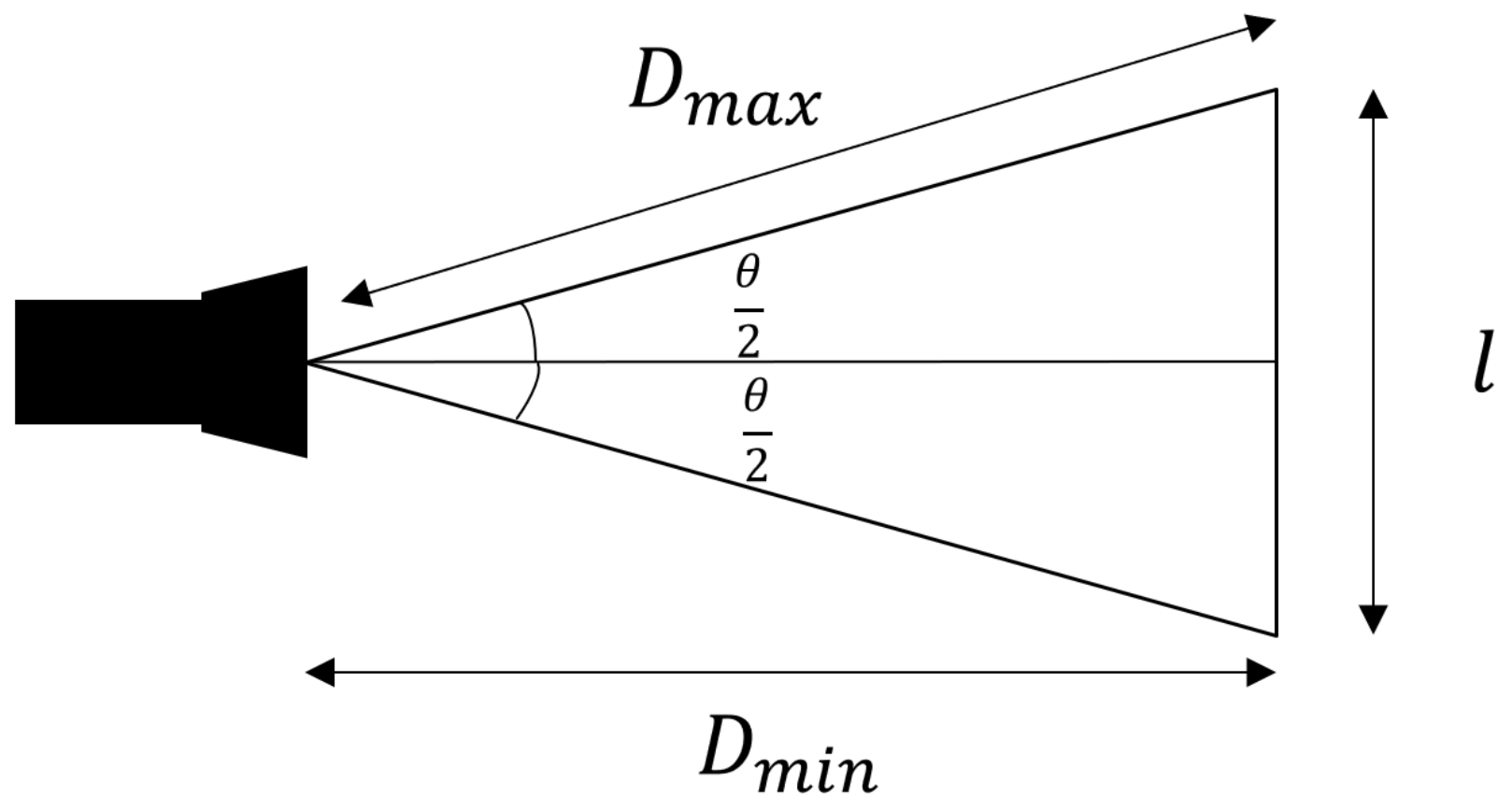

2.3. Revolving Viewpoint Generation

| Algorithm 1 Viewpoint Base Generation |

| Input: Surface patches of the 3D model , Camera matrix , Camera minimum viewing distance , Overlapping rate .

Output: Viewpoint base

|

2.4. Gap-Filling Viewpoint Generation

| Algorithm 2 Gap-Filling Viewpoint Generation |

| Input: Unscanned surface patches , Surface patches of 3D model , Minimum viewing distance , Normal vectors of unscanned surface patches Output: Gap-filling viewpoints , Viewing direction

|

2.5. Time Complexity–Viewpoint Generation

2.6. Set Cover Problem

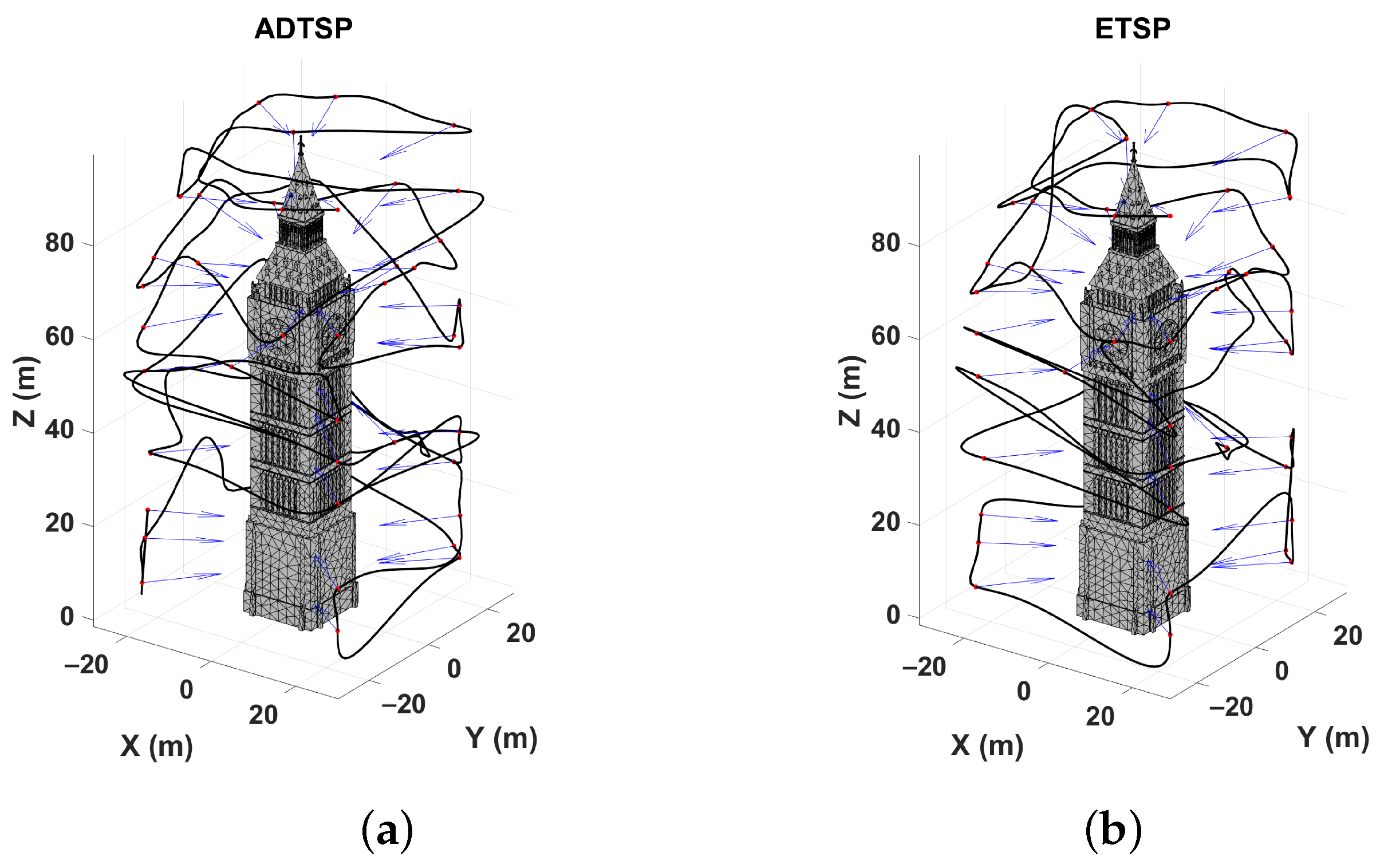

3. Multi-Layered Angle-Distance Traveling Salesman Problem

3.1. Angle-Distance Traveling Salesman Problem (ADTSP)

| Algorithm 3 Genetic Algorithm for ADTSP |

| Input: Number of generations , Population Size , Elitism Rate , Crossover Rate , Mutation Rate .

Output: Close Loop Tour for the ADTSP T

|

- 1.

- Swap Mutation: Two random cities are selected, and their positions within the solution are swapped, while the positions of the remaining cities remain unchanged.

- 2.

- Scramble Mutation: A subtour of random size within the child is conserved, while the other cities are redistributed at random.

- 3.

- Inverse Mutation: The direction of a subtour of random size is inverted.

| Algorithm 4 ADTSP |

| Input: Revolving Viewpoints , Gap-filling Viewpoints , Output: Close Loop ASTSP Tour

|

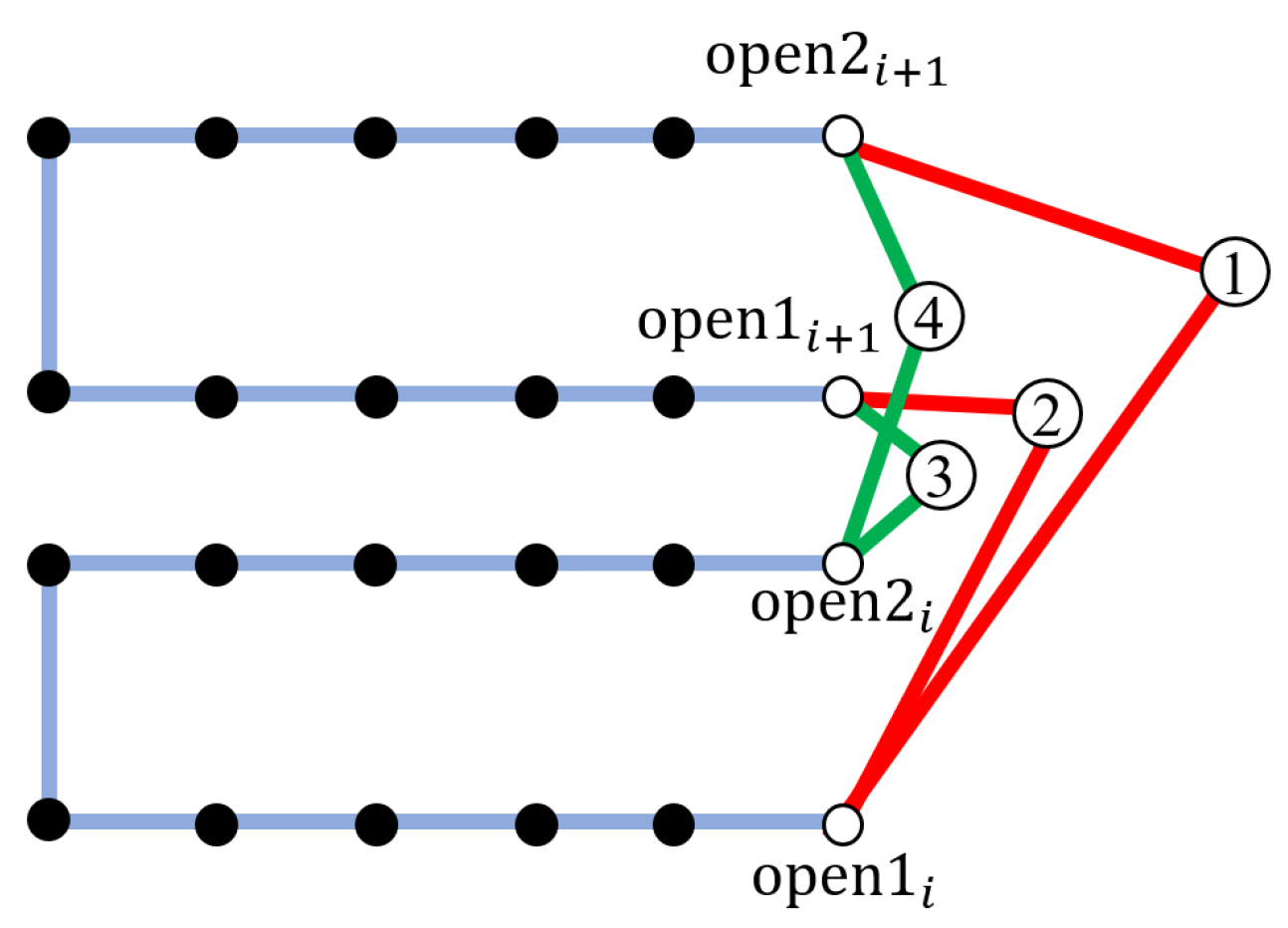

3.2. Open-Loop Angle-Distance Traveling Salesman Problem

3.3. Time Complexity—ADTSP

3.4. Inter-Layer Connection

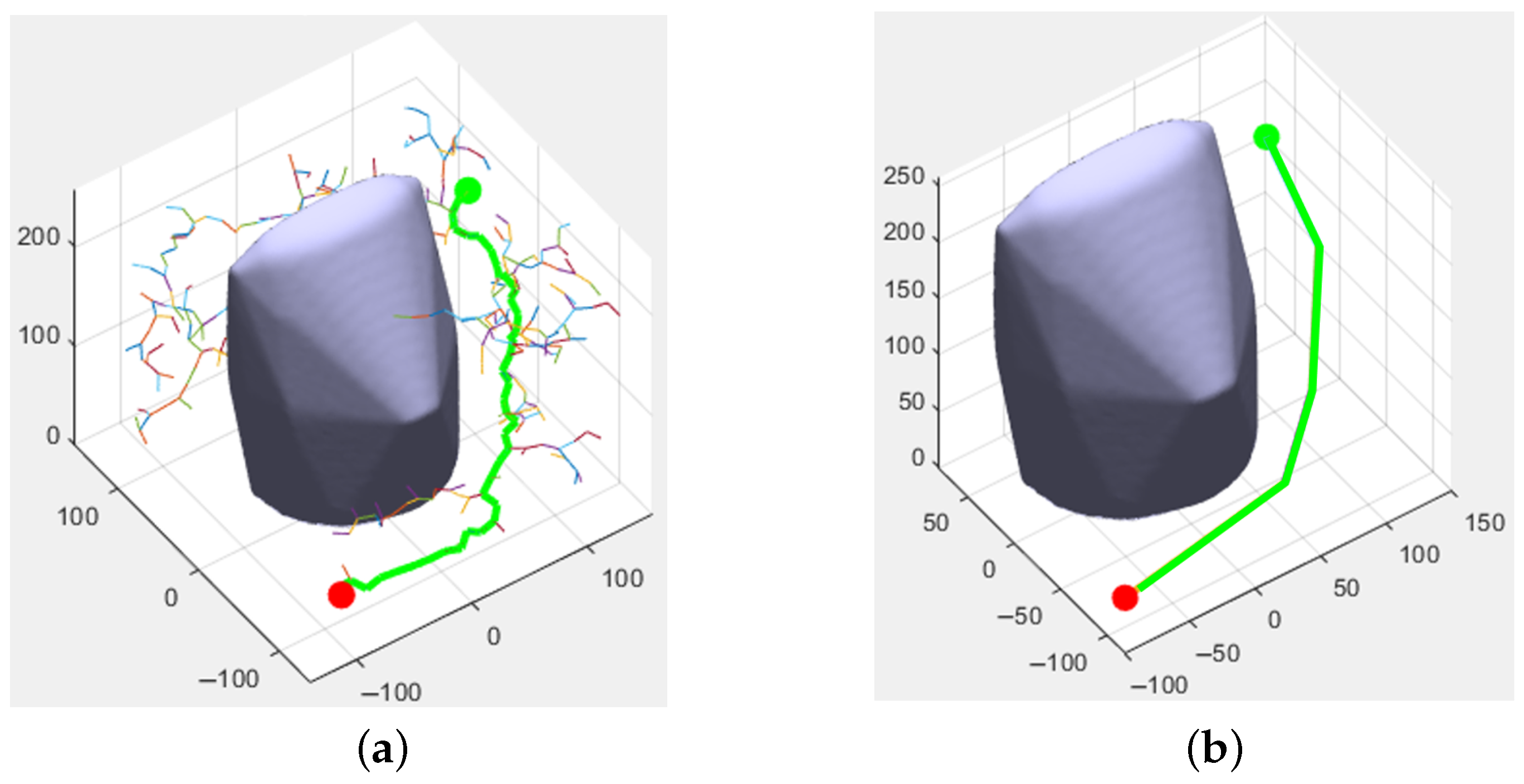

3.5. Collision Check

| Algorithm 5 RRT Smoothening |

| Input: RRT Path Output: Smoothened RRT Path

|

4. Simulation Results and Discussion

5. Conclusions

- 1.

- Accurate viewpoint generation, which seeks to reduce overall computation time while maintaining scalability.

- 2.

- Multi-agent inspection systems, aimed at reducing overall mission time and further improving information gain.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Scott, W.R. Model-based view planning. Mach. Vis. Appl. 2009, 20, 47–69. [Google Scholar] [CrossRef]

- Alexis, K.; Papachristos, C.; Siegwart, R.; Tzes, A. Uniform coverage structural inspection path–planning for micro aerial vehicles. In Proceedings of the 2015 IEEE International Symposium on Intelligent Control (ISIC), Sydney, NSW, Australia, 21–23 September 2015; pp. 59–64. [Google Scholar] [CrossRef]

- Englot, B.; Hover, F.S. Sampling-based sweep planning to exploit local planarity in the inspection of complex 3D structures. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Vilamoura-Algarve, Portugal, 7–12 October 2012; pp. 4456–4463. [Google Scholar] [CrossRef]

- Tarbox, G.; Gottschlich, S. Planning for Complete Sensor Coverage in Inspection. Comput. Vis. Image Underst. 1995, 61, 84–111. [Google Scholar] [CrossRef]

- Jing, W.; Polden, J.; Lin, W.; Shimada, K. Sampling-based view planning for 3D visual coverage task with Unmanned Aerial Vehicle. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Republic of Korea, 9–14 October 2016; 2016; pp. 1808–1815. [Google Scholar] [CrossRef]

- Papachristos, C.; Alexis, K.; Carrillo, L.R.G.; Tzes, A. Distributed infrastructure inspection path planning for aerial robotics subject to time constraints. In Proceedings of the 2016 International Conference on Unmanned Aircraft Systems (ICUAS), Arlington, VA, USA, 7–10 June 2016; pp. 406–412. [Google Scholar] [CrossRef]

- Biundini, I.Z.; Pinto, M.F.; Melo, A.G.; Marcato, A.L.M.; Honório, L.M.; Aguiar, M.J.R. A Framework for Coverage Path Planning Optimization Based on Point Cloud for Structural Inspection. Sensors 2021, 21, 570. [Google Scholar] [CrossRef] [PubMed]

- Gu, W.; Hu, D.; Cheng, L.; Cao, Y.; Rizzo, A.; Valavanis, K.P. Autonomous Wind Turbine Inspection using a Quadrotor. In Proceedings of the 2020 International Conference on Unmanned Aircraft Systems (ICUAS), Athens, Greece, 1–4 September 2020; pp. 709–715. [Google Scholar] [CrossRef]

- Mansouri, S.S.; Kanellakis, C.; Fresk, E.; Kominiak, D.; Nikolakopoulos, G. Cooperative coverage path planning for visual inspection. Control Eng. Pract. 2018, 74, 118–131. [Google Scholar] [CrossRef]

- Almadhoun, R.; Taha, T.; Seneviratne, L.; Dias, J.; Cai, G. GPU accelerated coverage path planning optimized for accuracy in robotic inspection applications. In Proceedings of the 2016 IEEE 59th International Midwest Symposium on Circuits and Systems (MWSCAS), Abu Dhabi, United Arab Emirates, 16–19 October 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Song, S.; Jo, S. Online inspection path planning for autonomous 3D modeling using a micro-aerial vehicle. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; pp. 6217–6224. [Google Scholar] [CrossRef]

- Cheng, P.; Keller, J.; Kumar, V. Time-optimal UAV trajectory planning for 3D urban structure coverage. In Proceedings of the 2008 IEEE/RSJ International Conference on Intelligent Robots and Systems, Nice, France, 22–26 September 2008; pp. 2750–2757. [Google Scholar] [CrossRef]

- Almadhoun, R.; Taha, T.; Dias, J.; Seneviratne, L.; Zweiri, Y. Coverage Path Planning for Complex Structures Inspection Using Unmanned Aerial Vehicle (UAV). In Intelligent Robotics and Applications; Springer: Cham, Switzerland, 2019; pp. 243–266. [Google Scholar] [CrossRef]

- Jing, W.; Deng, D.; Xiao, Z.; Liu, Y.; Shimada, K. Coverage Path Planning using Path Primitive Sampling and Primitive Coverage Graph for Visual Inspection. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; pp. 1472–1479. [Google Scholar] [CrossRef]

- Jung, S.; Song, S.; Youn, P.; Myung, H. Multi-Layer Coverage Path Planner for Autonomous Structural Inspection of High-Rise Structures. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 1–9. [Google Scholar] [CrossRef]

- Jing, W.; Deng, D.; Wu, Y.; Shimada, K. Multi-UAV Coverage Path Planning for the Inspection of Large and Complex Structures. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 24 October 2020–24 January 2021; pp. 1480–1486. [Google Scholar] [CrossRef]

- Freimuth, H.; König, M. Planning and executing construction inspections with unmanned aerial vehicles. Autom. Constr. 2018, 96, 540–553. [Google Scholar] [CrossRef]

- Jing, W.; Polden, J.; Tao, P.Y.; Lin, W.; Shimada, K. View planning for 3D shape reconstruction of buildings with unmanned aerial vehicles. In Proceedings of the 2016 14th International Conference on Control, Automation, Robotics and Vision (ICARCV), Phuket, Thailand, 13–15 November 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Almadhoun, R.; Taha, T.; Gan, D.; Dias, J.; Zweiri, Y.; Seneviratne, L. Coverage Path Planning with Adaptive Viewpoint Sampling to Construct 3D Models of Complex Structures for the Purpose of Inspection. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 7047–7054. [Google Scholar] [CrossRef]

- Bircher, A.; Alexis, K.; Burri, M.; Oettershagen, P.; Omari, S.; Mantel, T.; Siegwart, R. Structural inspection path planning via iterative viewpoint resampling with application to aerial robotics. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 6423–6430. [Google Scholar] [CrossRef]

- Liu, X.; Yi, W.; Chen, P.; Tan, Y. Flight path planning of UAV-driven refinement inspection for construction sites based on 3D reconstruction. Autom. Constr. 2025, 177, 106360. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, X.; Li, J. Intelligent Path Planning with an Improved Sparrow Search Algorithm for Workshop UAV Inspection. Sensors 2024, 24. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Cui, C.; Ji, Y.; Li, X.; Li, S. A UAV path planning algorithm for bridge construction safety inspection in complex terrain. Sci. Rep. 2025, 15, 13564. [Google Scholar] [CrossRef] [PubMed]

- Song, S.; Jo, S. Surface-Based Exploration for Autonomous 3D Modeling. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, QLD, Australia, 21–25 May 2018; pp. 4319–4326. [Google Scholar] [CrossRef]

- Palazzolo, E.; Stachniss, C. Effective Exploration for MAVs Based on the Expected Information Gain. Drones 2018, 2, 9. [Google Scholar] [CrossRef]

- Rakha, T.; Gorodetsky, A. Review of Unmanned Aerial System (UAS) applications in the built environment: Towards automated building inspection procedures using drones. Autom. Constr. 2018, 93, 252–264. [Google Scholar] [CrossRef]

- Ellenberg, A.; Kontsos, A.; Bartoli, I.; Pradhan, A. Masonry Crack Detection Application of an Unmanned Aerial Vehicle. In Proceedings of the 2014 International Conference on Computing in Civil and Building Engineering, Orlando, FL, USA, 23–25 June 2014; Volume 93, pp. 1788–1795. [Google Scholar] [CrossRef]

- Yu, H.; Yang, W.; Zhang, H.; He, W. A UAV-based crack inspection system for concrete bridge monitoring. In Proceedings of the 2017 IEEE International Geoscience and Remote Sensing Symposium (IGARSS), Fort Worth, TX, USA, 23–28 July 2017; pp. 3305–3308. [Google Scholar] [CrossRef]

- Maes, W.H.; Huete, A.R.; Steppe, K. Optimizing the Processing of UAV-Based Thermal Imagery. Remote Sens. 2017, 9, 476. [Google Scholar] [CrossRef]

- Lee, E.J.; Shin, S.Y.; Ko, B.C.; Chang, C. Early sinkhole detection using a drone-based thermal camera and image processing. Infrared Phys. Technol. 2016, 78, 223–232. [Google Scholar] [CrossRef]

- Zulgafli, M.N.; Tahar, K.N. Three dimensional curve hall reconstruction using semi-automatic UAV. ARPN J. Eng. Appl. Sci. 2017, 12, 3228–3232. [Google Scholar]

- Haala, N.; Cramer, M.; Weimer, F.; Trittler, M. Performance Test on Uav-Based Photogrammetric Data Collection. Int. Arch. Photogramm. Remote Sens. Spatial Inf. Sci. 2011, XXXVIII-1/C22, 7–12. [Google Scholar] [CrossRef]

- Tong, H.W.; Li, B.; Huang, H.; Wen, C. UAV Path Planning for Complete Structural Inspection using Mixed Viewpoint Generation. In Proceedings of the 2022 17th International Conference on Control, Automation, Robotics and Vision (ICARCV), Singapore, 11–13 December 2022; pp. 727–732. [Google Scholar] [CrossRef]

- Cignoni, P.; Callieri, M.; Corsini, M.; Dellepiane, M.; Ganovelli, F.; Ranzuglia, G. MeshLab: An Open-Source Mesh Processing Tool. In Eurographics Italian Chapter Conference; The Eurographics Association: Eindhoven, The Netherlands, 2008; Volume 29, pp. 129–136. [Google Scholar] [CrossRef]

- Hartley, R.; Zisserman, A. Multiple View Geometry in Computer Vision; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Abeywickrama, H.V.; Jayawickrama, B.A.; He, Y.; Dutkiewicz, E. Comprehensive Energy Consumption Model for Unmanned Aerial Vehicles, Based on Empirical Studies of Battery Performance. IEEE Access 2018, 6, 58383–58394. [Google Scholar] [CrossRef]

- Abeywickrama, H.V.; Jayawickrama, B.A.; He, Y.; Dutkiewicz, E. Empirical Power Consumption Model for UAVs. In Proceedings of the 2018 IEEE 88th Vehicular Technology Conference (VTC-Fall), Chicago, IL, USA, 27–30 August 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Alyassi, R.; Khonji, M.; Karapetyan, A.; Chau, S.C.K.; Elbassioni, K.; Tseng, C.M. Autonomous Recharging and Flight Mission Planning for Battery-Operated Autonomous Drones. IEEE Trans. Autom. Sci. Eng. 2022, 20, 1034–1046. [Google Scholar] [CrossRef]

- Fischer, A.; Fischer, F.; Jäger, G.; Keilwagen, J.; Molitor, P.; Grosse, I. Exact algorithms and heuristics for the Quadratic Traveling Salesman Problem with an application in bioinformatics. Discret. Appl. Math. 2014, 166, 97–114. [Google Scholar] [CrossRef]

- Holland, J.H. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, and Artificial Intelligence; MIT Press: Cambridge, UK, 1992. [Google Scholar]

- Larrañaga, P.; Kuijpers, C.; Murga, R.; Inza, I.; Dizdarevic, S. Genetic Algorithms for the Travelling Salesman Problem: A Review of Representations and Operators. Artif. Intell. Rev. 1990, 13, 129–170. [Google Scholar] [CrossRef]

- Alok, A.; Don, C.; Sanjeev, K.; Rajeev, M.; Baruch, S. The Angular-Metric Traveling Salesman Problem. SIAM J. Comput. 2000, 29, 697–711. [Google Scholar] [CrossRef]

| OX | ER | BF | |

|---|---|---|---|

| Best tour length | 129 m | 125 m | 125 m |

| Average tour length | 184 m | 150 m | 150 m |

| Required generations | / | 26 | 13 |

| Inspection Method | Crack Detection | Photogrammetry |

|---|---|---|

| Max. Viewing Distance(m) | [10, 15] | [20, 25] |

| Field of View | ||

| Overlapping Rate, | 15 | 20 |

| Viewing Angle, | ||

| Coverage Requirement, | 1 | 3 |

| Parameters | Value |

|---|---|

| Number of Generations, | 500 |

| Population Size, | 300 |

| Elitism Rate, | 0.05 |

| Crossover Rate, | 0.7 |

| Mutation Rate, | 0.3 |

| Number of Viewpoints | Traveling Distance (m) | |||

|---|---|---|---|---|

| Inspection Method | Model 1 | Model 2 | Model 1 | Model 2 |

| Crack Detection | 290 | 87 | 5996 | 2202 |

| Photogrammetry | 87 | 47 | 3676 | 1768 |

| ML-ETSP | ML-ADTSP | % Change | |

|---|---|---|---|

| Mission Time (s) | 1442 | 1768 | |

| Mean Turning Angle (rad) | 1.48 | 1.28 | |

| Mean x-acceleration | 0.06 | 0.055 | |

| Mean y-acceleration | 0.051 | 0.050 | |

| Mean z-acceleration | 0.058 | 0.057 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, H.W.; Li, B.; Huang, H.; Wen, C.-Y. Multi-Layer Path Planning for Complete Structural Inspection Using UAV. Drones 2025, 9, 541. https://doi.org/10.3390/drones9080541

Tong HW, Li B, Huang H, Wen C-Y. Multi-Layer Path Planning for Complete Structural Inspection Using UAV. Drones. 2025; 9(8):541. https://doi.org/10.3390/drones9080541

Chicago/Turabian StyleTong, Ho Wang, Boyang Li, Hailong Huang, and Chih-Yung Wen. 2025. "Multi-Layer Path Planning for Complete Structural Inspection Using UAV" Drones 9, no. 8: 541. https://doi.org/10.3390/drones9080541

APA StyleTong, H. W., Li, B., Huang, H., & Wen, C.-Y. (2025). Multi-Layer Path Planning for Complete Structural Inspection Using UAV. Drones, 9(8), 541. https://doi.org/10.3390/drones9080541