1. Introduction

As unmanned aerial vehicle (UAV) technology leaps forward, becoming more accessible, affordable, and adept [

1], society is on the cusp of a new era where the skies become increasingly populated with drones, with applications of deliveries, infrastructure inspection, and farming, among many others. However, this increasing use of drones has also brought about challenges, particularly in terms of noise pollution and aerodynamic efficiency. This requires the exploration of novel technologies and design optimisations to mitigate these issues. A systematic review by Schäffer et al. [

2] reveals that drone noise is significantly more annoying than road traffic or aircraft noise, attributed to its unique acoustic characteristics such as pure tones and high-frequency broadband noise. In addition, Ivošević et al. [

3] conducted subjective assessments of UAV noise perception. This showed that even low-frequency noise present in the spectrum of drones can be distinguished by listeners and often lead to negative experiences. The routing and operation of UAVs within cities will likely be constrained by noise considerations in the future [

4].

The integration of winglets on UAV propellers stands out as a promising approach to addressing this dual challenge. Hariyadi et al. [

5] reveal that wingtip fences—a type of winglet—on a fixed wing can significantly reduce vorticity behind the wing, thus diminishing the potential for noise while enhancing lift. Furthermore, Arshad et al. [

6] conducted a CFD analysis on blended, wingtip fence, and raked winglet types on fixed wing slow-speed small UAVs. This investigation found that blended winglets introduced an 11% increase in aerodynamic quality compared to baseline wings without winglets, demonstrating their effectiveness in improving both aerodynamics and noise profiles. Optimisation studies have further refined the effectiveness of these technologies. Gölcük and Kurtuluş [

7] explored the impact of elliptical winglet designs on fixed wing low-altitude solar-powered UAVs, resulting in an 8.32% enhancement in the lift-to-drag ratio compared to the baseline wing. Further, Afshari and Karimian [

8] redesigned the tip geometry of a rectangular helicopter rotor blade, advancing aerodynamic efficiency and noise reduction techniques. The introduction of anhedral and eagle winglet configurations on rotor blades demonstrate up to 21% improvement in the Figure of Merit (FoM) ratio—a measure of aerodynamic performance considering the coefficient of thrust versus the coefficient of torque—while concurrently achieving a notable decrease in noise levels by up to 4.5%.

Trailing edge serrations have also been explored to reduce tonal and broadband noise associated with rotor blades without a reduction in aerodynamic performance.

A detailed review of the mechanisms of noise reduction can be found in Lee et al. [

9]. The mechanisms associated with the noise reduction were investigated parametrically by Pereira et al. [

10]. This work showed that trailing-edge serrations reduce broadband noise by disrupting the spanwise coherence of turbulent pressure fluctuations. Serrations therefore introduce spanwise variations in the scattering surface, causing phase differences in the scattered acoustic waves. This leads to destructive interference in the far field, effectively lowering noise levels. Additionally, the transition from the airfoil surface to the serrated edge lowers wall-pressure fluctuations towards the serration tips, reducing low-frequency noise generation. However, flow acceleration through the serration gaps can increase pressure fluctuations near the tips, limiting noise reduction at high frequencies. Under aerodynamic loading, serrations can induce counter-rotating vortices along their edges, which amplifies wall-pressure fluctuations and can increase noise levels.

Cao et al. [

11] showcased that serrations can achieve a noise reduction of about 2 dB at low-to-moderate frequency ranges for small angles of attack, alongside suppressing fluctuation of aerodynamic forces. Further, Chen et al. [

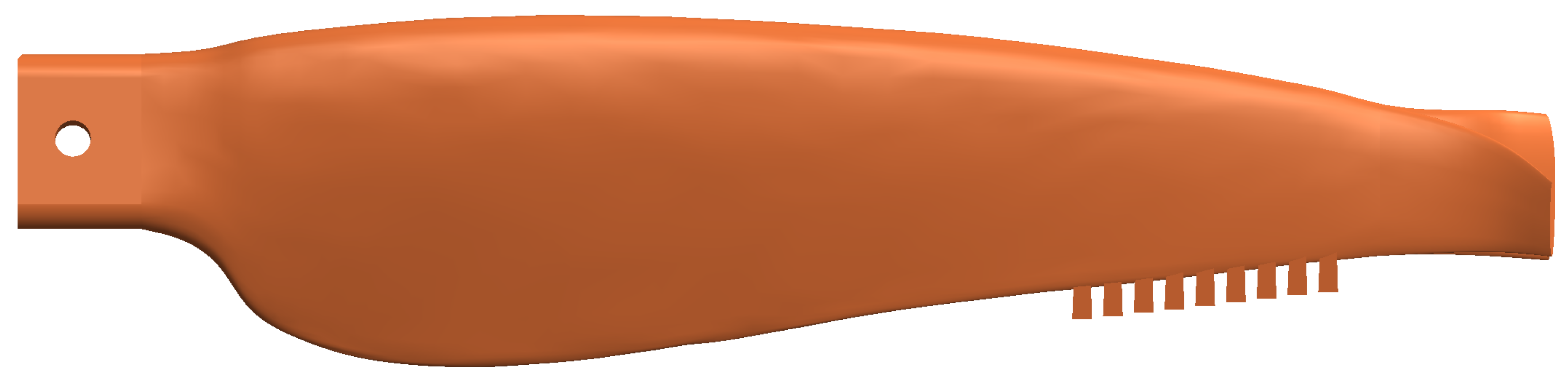

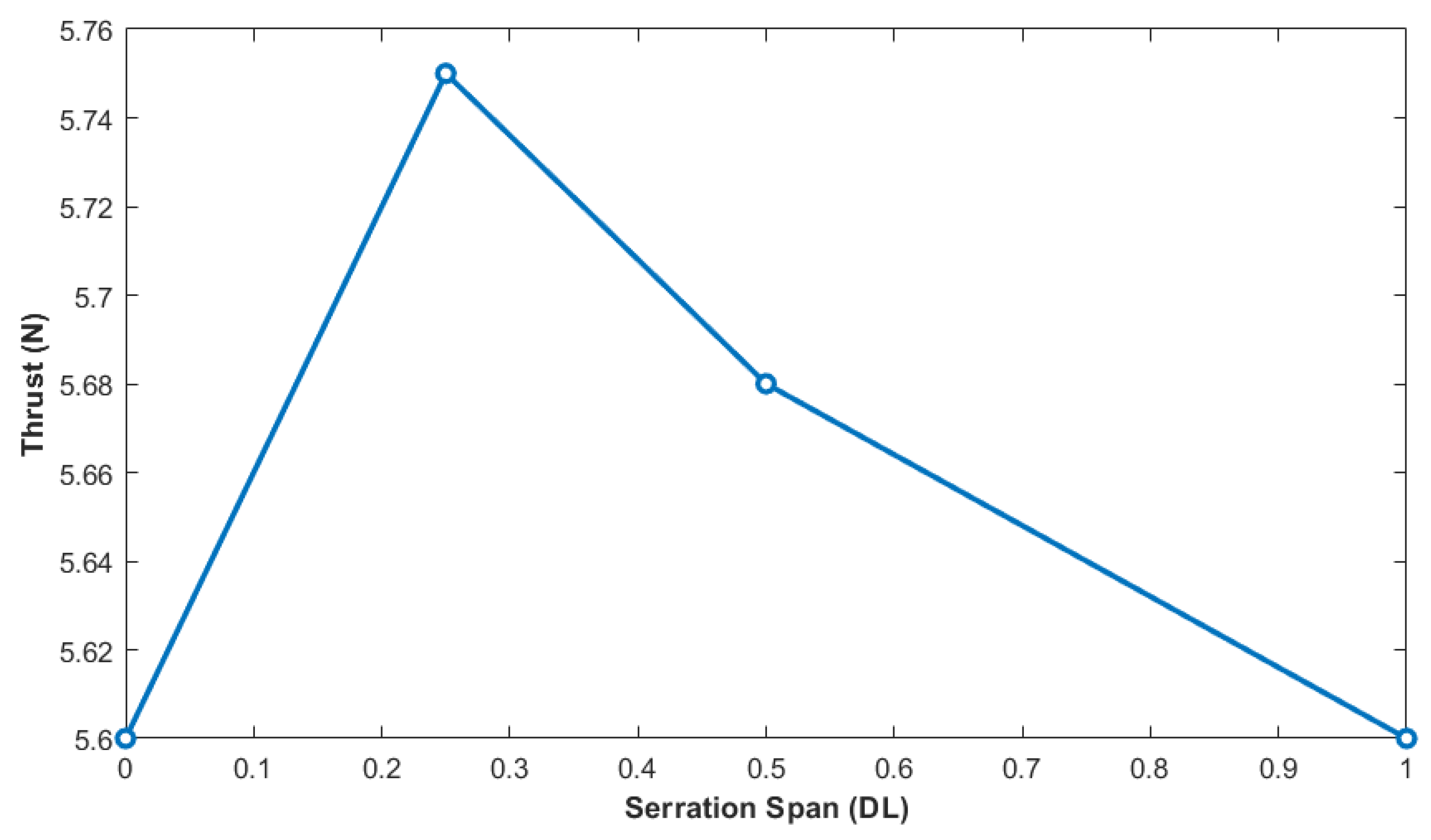

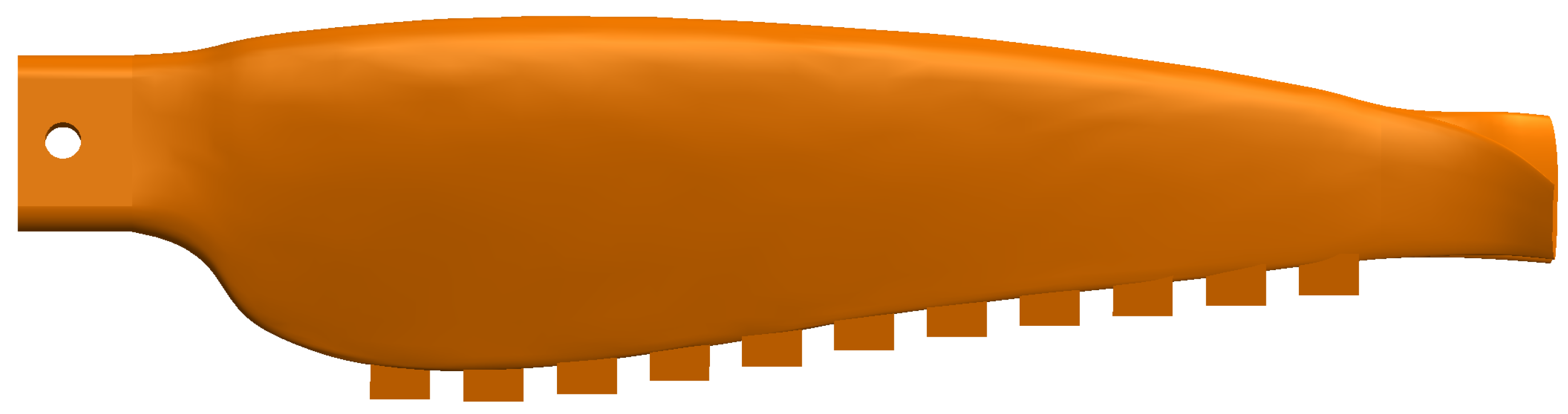

12] computationally investigated the effect of half span serrations. The half-tip wide-serrated blade was effective in reducing broadband noise by up to 3.3 dBA without detrimentally affecting aerodynamic performance. The effect of serration span was investigated by Yuliang et al. [

13]. This experimental study showcased that the three-quarter serrated span propeller had up to a 3.0 dB noise reduction with an overall 6.7% higher thrust force than the baseline propeller. Yang et al. [

14] explored noise reduction in multi-copter rotors by modifying the baseline rotor into a wavy design, which reduced overall sound pressure level by up to 2 dB without compromising thrust and power loading, demonstrating a practical approach to alleviate rotor noise through structural design changes. Yu et al. [

15] implemented an integrated aerodynamic and aeroacoustic design method for propeller optimisation, successfully reducing the maximum total sound pressure level by 5 dB without affecting aerodynamic performance. This study showcases the potential of comprehensive optimisation in propeller design. Sun et al. [

16] studied the effects of blade twist on multirotor propellers, finding a 9.3% increase in the figure of merit and a 4.3 dB noise reduction. This research highlights the significance of the blade twist in improving both aerodynamic and acoustic performance.

Recent advancements in additive manufacturing (AM) have opened new frontiers in the design and production of UAV rotor blades, showcasing significant improvements in aerodynamics, weight reduction, and manufacturing efficiency. Kovacevic et al. [

17] optimised composite rotor blades for small UAVs using a genetic algorithm. The optimised blades demonstrated a deviation within 15% for thrust and torque measurements when compared to baseline models. This result validates the efficacy of AM in tailoring UAV components for specific aerodynamic requirements. Further, Balasubramanian et al. [

18] emphasised AM’s operational advantages of reiterating designs, rapid prototyping, and testing through the results of weight reductions and flight time extensions, by 18% and 33%, respectively. These benefits were achieved without the extensive time and material costs associated with traditional manufacturing methods.

The necessity of blade noise reduction without a compromise of thrust is apparent. The literature provides a robust baseline of the two main noise reduction and thrust improvement methodologies, and its potential for achievement through additive manufacturing techniques. However, this work’s aims to contribute to the literature lacks in three main areas:

Performance Characteristics of AM Blades:

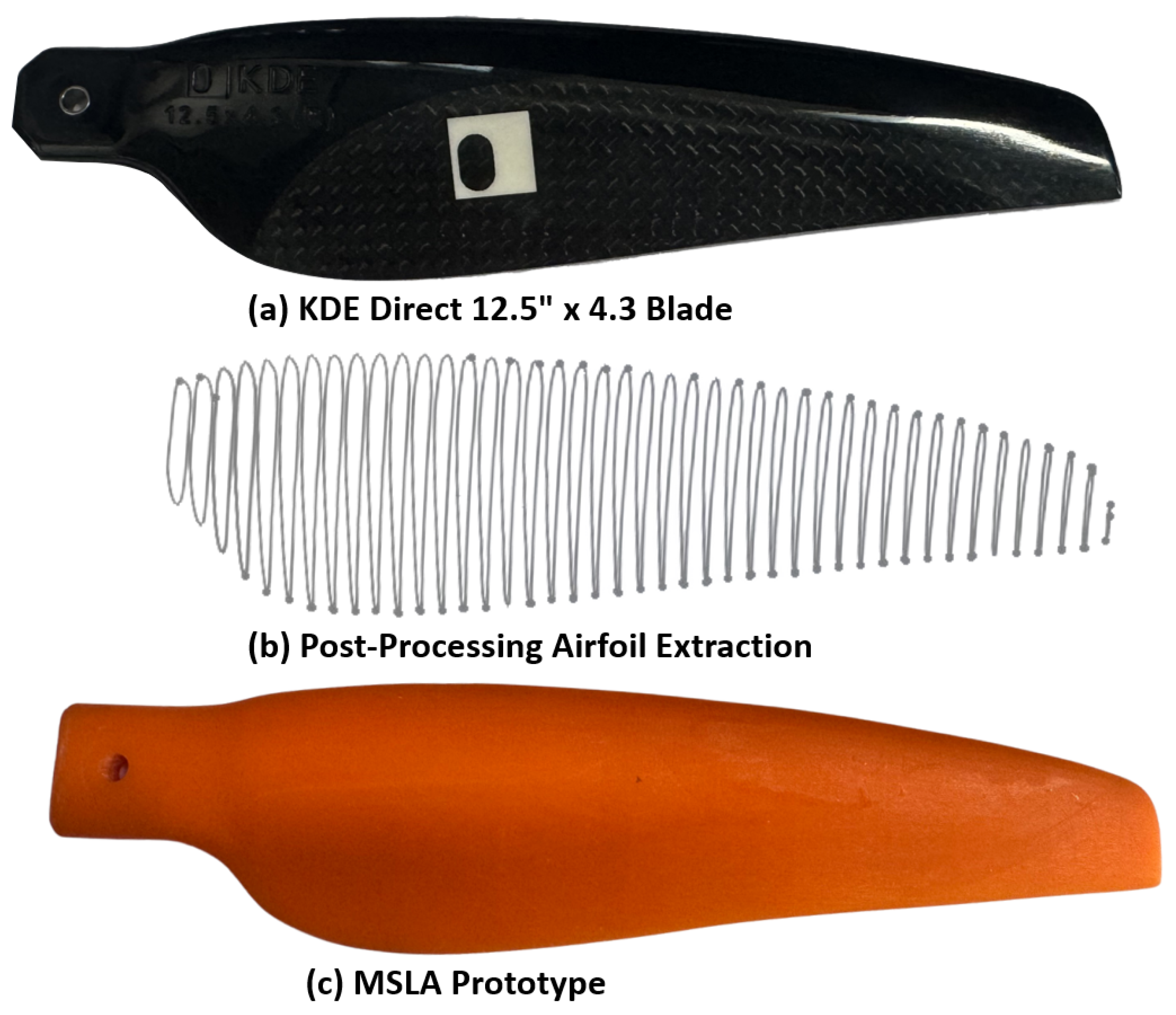

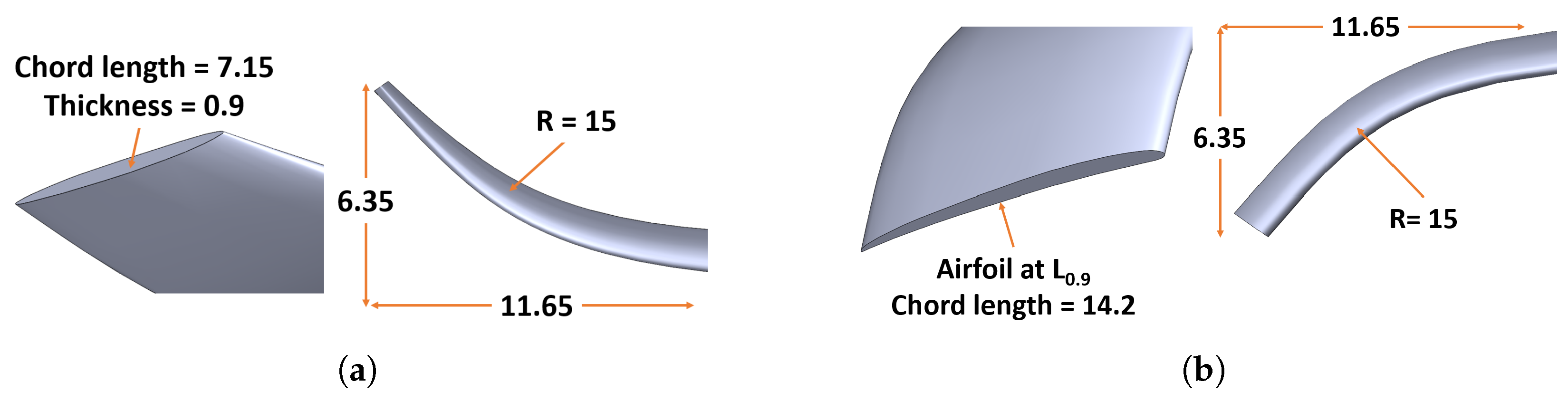

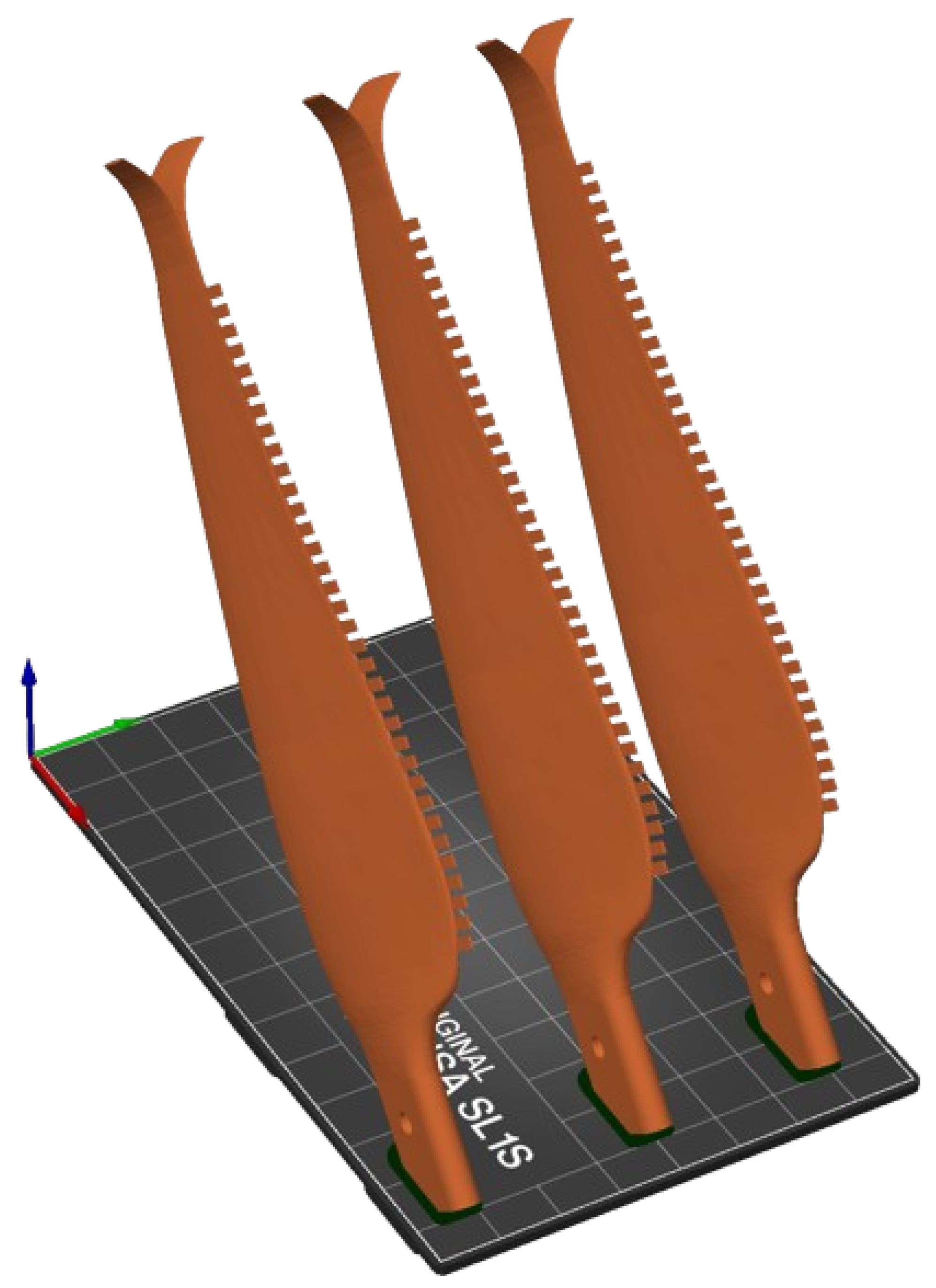

Rotor blades are commercially made of carbon fibre—a material that is both costly and requires specialised handling. This presents opportunities for innovation in prototype manufacturing. This study investigates the feasibility of utilising cost-effective additive manufacturing techniques for the prompt prototyping of modified blades. It aims to evaluate their performance by examining thrust capabilities as well as broadband and tonal noise characteristics and comparing these results with those of the commercial counterpart.

Superposition of Winglets and Serrations:

While the literature provides separate, in-depth analyses for winglets and serrations, which are both promising avenues for noise reduction and aerodynamic improvement, to date there is no research combining these two inventions.

Parametric Analysis of Serrations:

The literature is extensive on the integration of protruding serrations on baseline blades. Some of the literature has even explored the effects of serration span. However, serrations are dependent on numerous factors, such as serration width and the ratio of serration spacing, which are yet to be explored sufficiently.

The combination of these contributions leads to a framework for early stage blade design which avoids the needs for high cost CFD, optimisation, and manufacturing steps. The output of the framework demonstrated here could lead directly to the production of modified blades or as a start point for more detailed design and optimisation steps. It should be noted that, unlike other aerospace applications, UAVs are often designed and operated by small-scale enterprises. These industries require a robust approach to blade design and modification that avoids high-cost development steps. The intention is to allow all UAV manufacturers and operators to address the noise challenge with available resources.

4. Conclusions

The integration of winglets and serrated edges into UAV propellers significantly enhances aerodynamic efficiency and reduces noise emissions. These findings highlight the potential for improvements in UAV operational performance and positive environmental impacts achieved through rapid low-cost prototyping. Blades manufactured using MSLA technology represent a significant advancement for the rapid production of novel concepts. This innovative approach allows for the creation of highly precise and customised blades, setting new standards for optimisation in manufacturing processes through its repeatability and reliability. By utilising MSLA technology, baselines for optimisation can be established, enhancing efficiency in the design process. This is particularly beneficial in the early stages of development, where time and cost are of paramount importance. Each set of blades used in this study were produced with a material cost of EUR 2.20 and in less than 4 h print time, enabling a very rapid and lost cost methodology for the development of advanced blade concepts. The flight worthiness of these modifications is an open question and likely a UAV operator would realise the final design iteration with a traditional manufacturing choice to increase reliability in flight. During the laboratory testing there were no failures of the MLSA blades despite extensive testing on multiple printed copies of each design which suggests the blades may be worthy of in-flight tests in controlled settings.

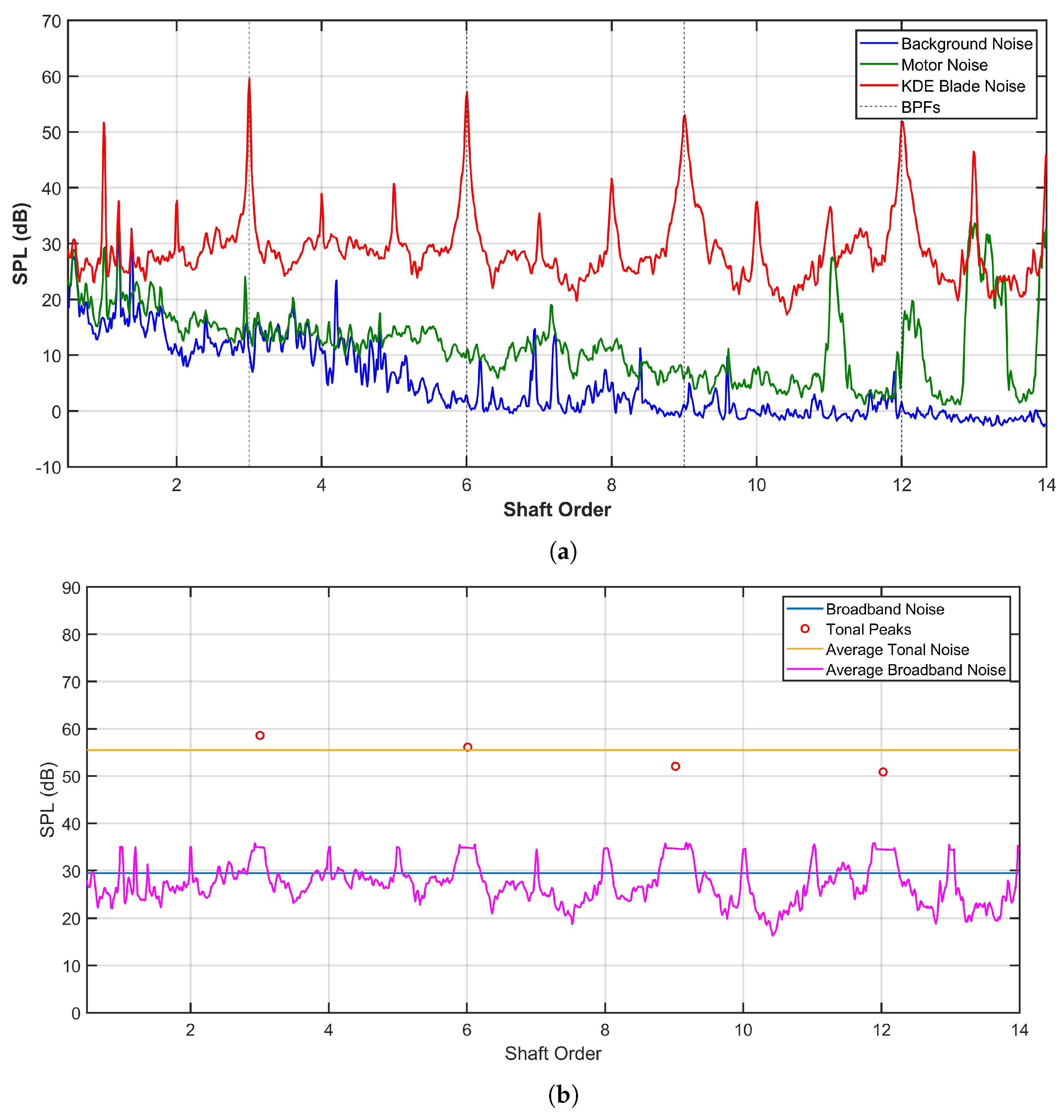

The designs used in this study provided up to a 10% increase in thrust. Expectations for flaplet serrations in isolation based on the work of Yuliang et al. [

13] would also be for a 10% increase in thrust and therefore the winglets used in this study may not be providing significant improvements in the aerodynamic performance of the blades. A direct comparison with noise reductions reported in the literature is challenging since there are few works which report low-noise technologies applied in combination. The propeller designs tested here are smaller and operate at a lower Reynolds number range than several examples reported in the literature. The noise emission analysis reported in this work is limited to the range of 14 shaft orders, or approximately 1200 Hz. Considering the total noise emission in this range, both tonal and broadband, there was a range of over 5 dB between the best and worst performing designs tested. The best performing design achieved a total reduction of 14 dB in this frequency range. This is significantly higher than the 3 dB improvements reported by Yuliang et al. [

13]. Therefore, the noise reduction of the winglet and serrations is likely to be additive. An optimisation of multiple low-noise technologies applied in combination using traditional techniques may be prohibitively expensive for the UAV industry. This work demonstrates that a parametric experimental investigation may provide significantly improved performance in the frequency range of interest for a UAV operator.

This study further underscores a complex balance between thrust enhancement and noise reduction, including both broadband and tonal noise over a range of 14 shaft orders. Notably, doubling the serration width provides the most significant thrust enhancement and noise reduction. Tripling the serration width yields a similar increase in thrust and reduces low-frequency broadband noise. Conversely, half span serrations succeed in reducing both types of noise, though this comes at the expense of a reduced thrust gain. These results highlight the advantages of superimposing winglets and flaplet edges, emphasising the utility of detailed parametric studies for the low-cost optimisation of UAV propeller designs. While this study establishes a foundational understanding, future research is warranted to explore the comparative performance of carbon-fibre manufactured propellers against the MSLA prototypes used in this study. High performance engineering printing materials, combined with higher fidelity scanning techniques could further improve the match between the commercial blade and the 3D-printed copy. The research outlines a framework which could be utilised by any UAV manufacturer or operator to implement a low-cost design study with the intention of achieving low-noise UAV operations.