1. Introduction

Unmanned Aerial Vehicles (UAVs), particularly multirotor drones, are increasingly being used in the commercial, industrial, and military sectors due to their ability to operate autonomously or remotely in challenging environments. Applications range from surveillance and disaster response to infrastructure inspection, logistics support, and tactical missions [

1]. As the operational use of UAVs expands, so does the need for reliable, cost-effective, and proactive maintenance systems to ensure safety, reduce downtime, and extend vehicle lifespan [

2,

3].

Structural failures in UAVs often result from cyclic mechanical stress, wear, or environmental conditions. If these faults are not detected before flight, they can lead to catastrophic failures in operation. Traditional visual inspection methods, although widely used, are time-consuming, subjective, and often ineffective in detecting early-stage damage [

4]. Moreover, even when faults are visible, maintenance often depends on access to contextual knowledge, such as repair history, component specifications, and supplier data, which is typically unavailable or unstructured in traditional workflows. This has motivated the adoption of sensor-based structural health monitoring (SHM) systems that offer objective and automated diagnostics [

5]. However, to fully support effective maintenance and decision-making, fault detection must be connected to structured lifecycle data, component metadata, and maintenance history-capabilities that traditional SHM systems often lack. Such integration not only enables more informed repairs but also creates a digital thread of diagnostic and maintenance records across the UAV’s operational lifecycle.

Among these, vibration-based SHM has proven to be an effective non-destructive method for detecting anomalies such as loose motors, damaged propellers, or unbalanced components during the pre-flight stage, when the UAV is powered but stationary. Accelerometers embedded in flight controllers can record time-series vibration data that provide valuable insights into component integrity. Previous studies have applied frequency-domain analyses, statistical features, and spectrum-based classifiers for UAV fault diagnosis [

6,

7,

8,

9], while more recent research has explored deep learning and transfer learning approaches for time-series fault detection in aerial systems [

10,

11,

12].

While vibration-based SHM has gained traction for UAV diagnostics, most existing studies, including recent deep learning-based approaches [

13,

14], focus primarily on improving fault detection accuracy or enhancing signal processing techniques. Few have addressed how SHM data can be systematically integrated into Product Lifecycle Management (PLM) systems to support traceable maintenance decisions, automated repair workflows, and real-time lifecycle feedback. Some studies in aerospace and industrial domains have proposed early frameworks for linking condition monitoring systems with PLM platforms [

15,

16,

17], but these are often conceptual or limited to high-level architectures. Practical implementations of closed-loop SHM–PLM integration for UAVs remain largely unexplored.

Despite these advances, a critical gap remains: few studies provide a fully integrated, real-time SHM-PLM framework capable of directly linking operational diagnostics to automated maintenance workflows and traceable lifecycle management for UAVs. This study addresses this gap by developing and validating a physically implemented closed-loop PLM application for UAV structural health monitoring.

PLM provides a structured framework to manage product data and processes throughout the entire lifecycle, from the initial concept and design to operation, maintenance, and disposal [

18]. When extended with real-time sensing and feedback, it evolves into a Closed-Loop Lifecycle Management (CL2M) system. Closed-loop PLM refers to a system enhanced with real-time operational feedback and predictive analytics, enabling dynamic updates, predictive maintenance, and stakeholder collaboration [

19,

20].

This study demonstrates an operational implementation of a closed-loop PLM system for UAV structural health monitoring, validated through physical experiments involving real UAV hardware, sensor integration, and induced fault scenarios. It integrates vibration-based SHM, deep learning-based fault classification, and automated maintenance workflows. Vibration data collected during pre-flight checks is used to train and evaluate several deep learning models, including Gated Recurrent Units (GRUs), Long Short-Term Memory networks (LSTMs), and Convolutional Neural Networks (CNNs). The best-performing model is deployed to classify inspection data in real-time operation. A custom application interfaces with the UAV via the DroneKit-Python API (v2.9.2) and communicates with the Aras Innovator (v12.0) PLM platform using RESTful web services to trigger safety actions and generate maintenance orders. This closed-loop architecture enables accurate fault detection, traceable maintenance decisions, and structured lifecycle documentation. The work illustrates how closed-loop PLM can move beyond static design-time data to actively support real-time diagnostics and UAV health management across the operational lifecycle.

The remainder of this paper is structured as follows:

Section 2 describes the development of the deep learning-based data analytics models for fault classification.

Section 3 introduces the UAV information repository, the integration of data analytics within the PLM environment, and the real-time deployment of the system and its communication infrastructure.

Section 4 presents the experimental validation results and discusses system performance. Finally,

Section 5 concludes this study and discusses avenues for future research.

2. Predictive Fault Classification Using Vibration Data

This section describes the development of deep learning models for vibration-based fault classification as part of a structural health monitoring (SHM) system for Unmanned Aerial Vehicles (UAVs). Mechanical faults caused by cyclic loading, loosened components, or external impacts often lead to abnormal vibration patterns. If not detected in a timely manner, these anomalies can cause severe structural damage or mission-critical failures.

To reduce this risk, a predictive maintenance methodology is proposed. It utilizes time-domain vibration data collected during the UAV’s pre-flight stage. This data is used to train multiple deep learning models capable of identifying and classifying structural faults. The selected model is then integrated into a custom UAV information management system developed within the Aras Innovator Product Lifecycle Management (PLM) platform. The architecture and system integration are detailed in

Section 3.

2.1. Data Collection and System Overview

The UAV platform used in this study is equipped with a Pixhawk 2.4.8 flight controller (Holybro, Shenzhen, China), which manages low-level motor control and overall flight control. Communication between the Pixhawk and an external processing unit is established via MAVLink (Micro Air Vehicle Link), a lightweight telemetry protocol commonly used for data exchange between unmanned systems and ground stations.

The Pixhawk incorporates an onboard MPU6000 inertial measurement unit (IMU) (InvenSense, Sunnyvale, CA, USA), which provides six degrees of freedom by combining a three-axis accelerometer and a three-axis MEMS gyroscope. The gyroscopes in the MPU6000 operate based on the Coriolis effect: as the UAV rotates along any of its axes, the motion induces a shift in a vibrating internal MEMS structure, which is sensed by a capacitive pickoff mechanism. This allows accurate measurement of angular velocity. Although the MPU6000 supports sampling rates up to 8 kHz, the vibration data in this study is collected at approximately 250 Hz, which offers sufficient temporal resolution to capture the structural dynamics of interest.

In this implementation, real-time vibration data is acquired using the DroneKit-Python API, which provides high-level access to telemetry and control functions via the MAVLink protocol. This interface allows direct data transmission to the processing environment, eliminating the need for post-flight log extraction.

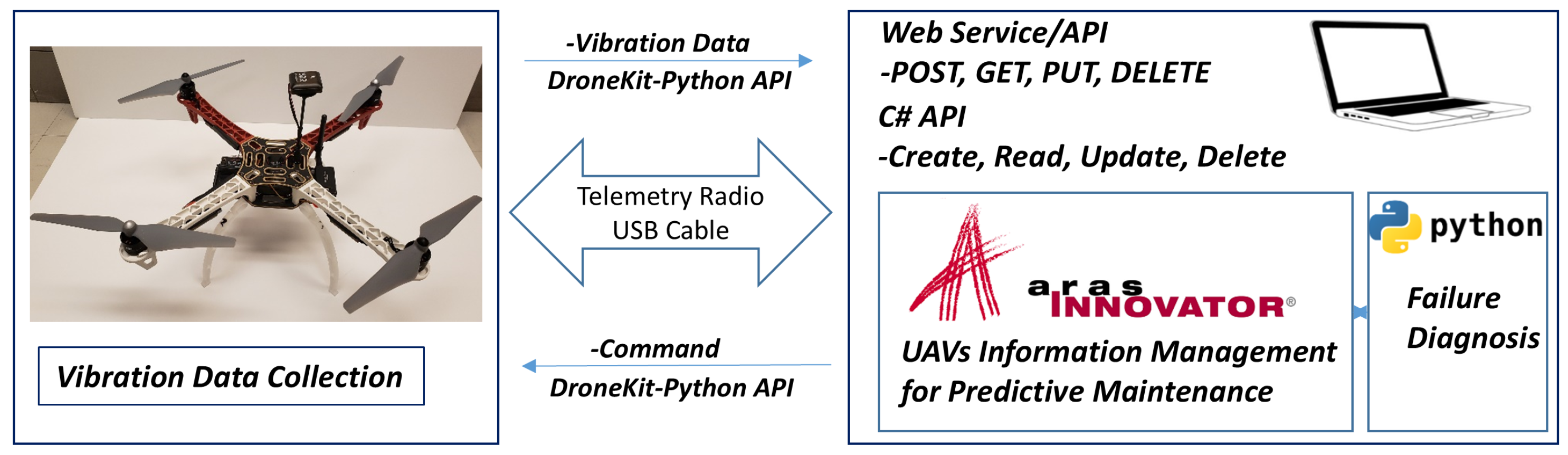

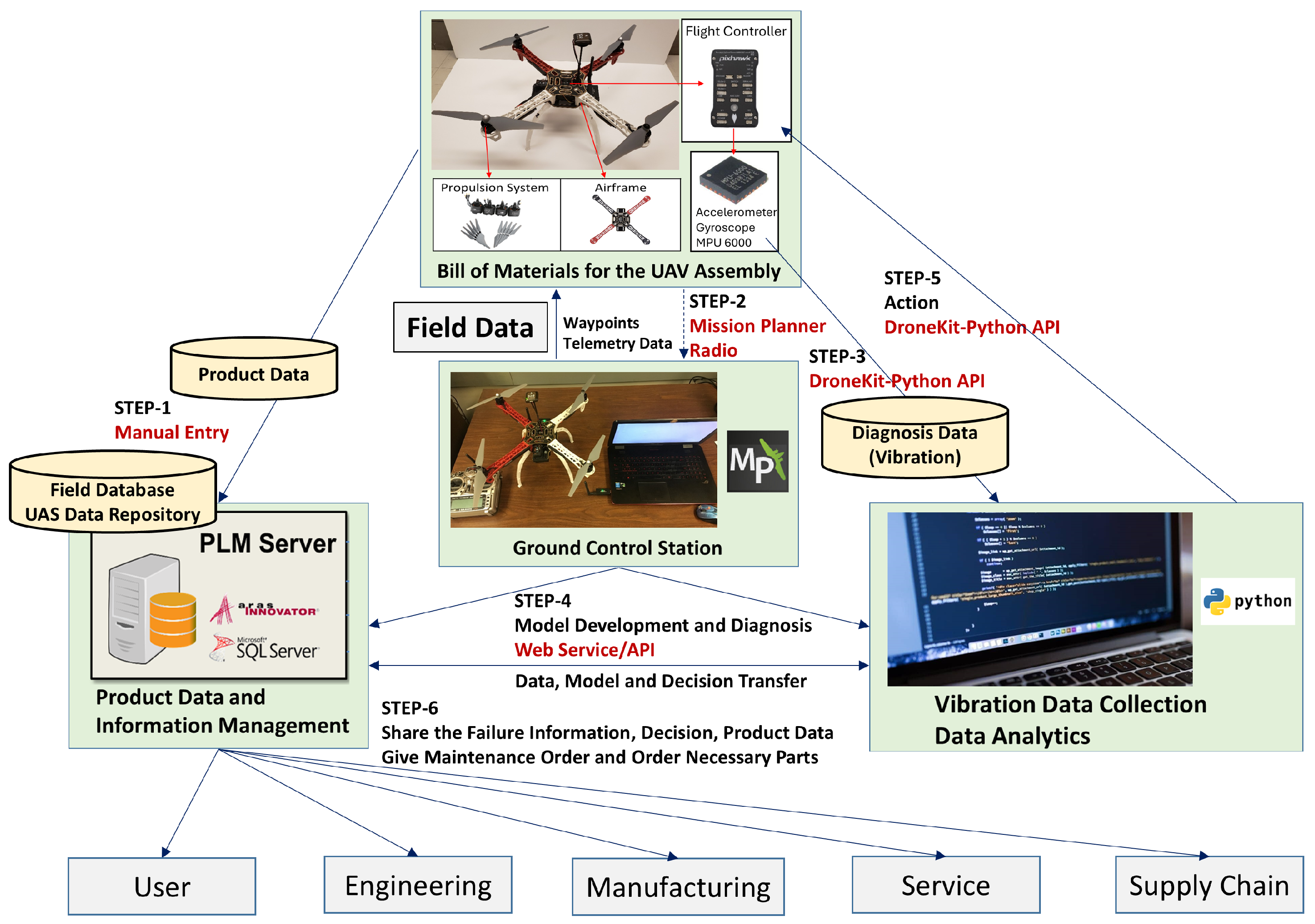

As illustrated in

Figure 1, vibration data is transmitted from the UAV to the computer using either a USB cable or telemetry radio. In this study, a USB connection is used during the pre-flight stage to ensure reliable, high-bandwidth data transfer. The system architecture illustrating real-time vibration data acquisition from the UAV using DroneKit-Python API, followed by fault classification and integration with the Aras Innovator PLM platform for maintenance data management, is depicted in

Figure 1.

Details of the processing environment are discussed in subsequent sections.

The data acquisition protocol begins once the UAV is armed and stabilized. The system performs a five-second initialization check, during which it monitors telemetry parameters such as battery voltage, system attitude, and velocity to ensure flight readiness. After these checks, 30 s of vibration data is recorded while the UAV remains powered and stationary, simulating pre-flight conditions.

To simulate realistic fault scenarios, time-domain acceleration signals are collected under eight distinct structural conditions, each labeled for supervised learning:

(I) Healthy-no structural defect, (II) missing propeller on motor 1 -simulating full thrust loss on one arm, (III) damage on propeller 1, (IV) damage on propeller 2, (V) damage on propeller 3, (VI) damage on propeller 4, (VII) loose screws on leg 1 -emulates structural instability in the frame, and (VIII) loose screws on motor 1 -simulates vibration due to motor mount issues.

These scenarios are intentionally induced under controlled conditions to reflect common mechanical failures encountered in UAV operations. Each condition produces a distinct vibration signature, which serves as a diagnostic pattern for classification.

The labeled dataset is then passed to a Python-based deep learning environment, (Python 3.7.3 and PyTorch 1.13.1) for further processing and classifier development, as described in the following section.

2.2. Vibration Dataset and Properties

The raw vibration data collected from the UAV’s onboard MPU6000 IMU includes high-resolution time-series acceleration measurements across three orthogonal axes (X, Y, Z). The unit of measurement for all acceleration data is meters per second squared (m/s2). Each 30 s vibration sample consists of 7500 time steps recorded at 250 Hz across three axes (X, Y, Z), resulting in a total of 22,500 data points per sample.

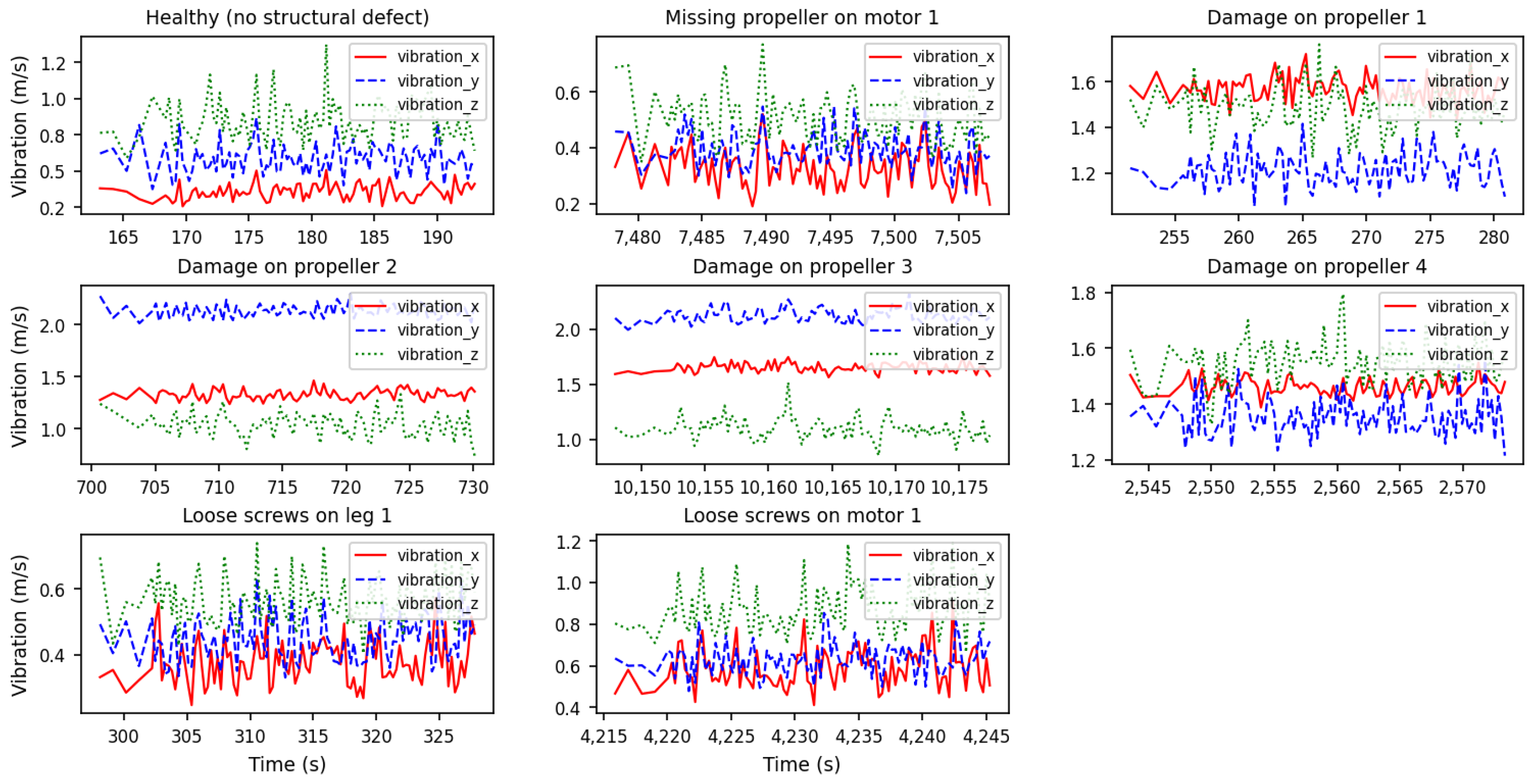

An example segment of the raw vibration data is presented in

Figure 2. It shows four columns: time, and acceleration values along the X, Y, and Z axes, respectively. These raw data form the foundation of the deep learning-based classification approach presented in this study.

Although the timestamps recorded in the dataset appear to exhibit high decimal precision due to Python’s default floating-point formatting, the actual system sampling resolution is constrained by the hardware (MPU6000 sensor) and the software communication stack (MAVLink and DroneKit-Python). The practical timing resolution is on the order of milliseconds to microseconds. This floating-point behavior does not impact the authenticity of the recorded acceleration values nor the validity of the vibration patterns used for model training. The focus of the analysis remains on the temporal evolution of acceleration signals rather than on absolute timestamp precision.

Unlike traditional structural health monitoring (SHM) methods that convert vibration signals into the frequency domain for spectral analysis, this study retains the data in its original time-domain format. This approach preserves the temporal and sequential characteristics of the signal and allows deep learning models to directly learn discriminative features from raw time-series input, without requiring manual feature engineering or transformation. In order to maintain their original properties and to conform to the real-time data format examined during pre-flight inspection, raw signals are utilized without filtering or normalization. Preprocessing is not necessary because deep learning models can automatically extract discriminative features from unprocessed data; in fact, it may even eliminate valuable information.

To see the character of how different mechanical faults affect UAV vibration behavior, labeled data across eight predefined structural conditions, including both healthy and damaged configurations, is visualized. The vibration profiles associated with each fault exhibit distinct patterns across the three axes. As shown in

Figure 3, each structural condition results in a unique vibration signature across the three axes:

The healthy condition produces moderate, consistent vibration levels across all directions.

A missing propeller (motor 1) causes a significant reduction in overall vibration, especially along the Z-axis due to thrust loss.

A clipped or damaged propeller 1 results in increased vibration across all axes, most prominently in the X direction.

A clipped or damaged propeller 4 shows a similar trend, with elevated vibration in both Y and Z directions.

Clipped or damaged propeller 2 and 3 faults primarily affect the Y-axis, though propeller 3 also elevates the X-axis signal.

Loose screws on leg 1 result in low-magnitude but irregular vibrations, indicating frame-level instability.

Loose screws on motor 1 cause sharp, high-magnitude fluctuations, especially in the X and Y directions due to localized looseness.

These observed patterns summarized in

Table 1 confirm that different mechanical faults produce distinct time-domain vibration profiles, which can be effectively captured by the onboard IMU and used for automated fault classification via deep learning.

2.3. Model Training and Deployment

This section presents the development and deployment of deep learning models for UAV fault classification using raw time-domain vibration data. While a variety of time-series classification methods exist, this study focuses on three widely recognized deep neural network architectures: Long Short-Term Memory (LSTM), Gated Recurrent Unit (GRU), and Convolutional Neural Network (CNN). These models are well established for their ability to capture complex temporal patterns and have demonstrated robust performance across diverse sequential data applications. These methods are preferred over classical machine learning algorithms such as Support Vector Machines (SVMs) or Random Forests, as they are better suited for directly processing raw sequential vibration data without requiring manual feature extraction or handcrafted features.

Three deep learning architectures are implemented and compared:

Long Short-Term Memory (LSTM) networks, introduced by Hochreiter and Schmidhuber [

21], enhance traditional recurrent neural networks (RNNs) by incorporating memory cells capable of retaining long-term dependencies in sequential data.

Gated Recurrent Unit (GRU) networks, introduced by Cho et al. [

22], simplify the LSTM structure by combining the forget and input gates, thereby reducing computational complexity while maintaining comparable performance.

Convolutional Neural Networks (CNNs), although originally designed for image recognition tasks [

23], have been successfully adapted for time-series classification [

24,

25] due to their ability to extract local temporal features through one-dimensional convolutions.

In this study, the labeled vibration dataset consisted of a total of 520 samples, each representing one of eight predefined structural fault conditions. The datasets are divided into training and test subsets using a stratified sampling strategy to preserve class balance. In total, 367 samples (approximately 70%) are used for training, and 135 samples (approximately 30%) are reserved for testing, including 30 samples from the healthy class and 15 samples from each of the seven fault classes. Each sample contained raw time-domain acceleration signals collected from the UAV’s IMU along the X, Y, and Z axes during the pre-flight stage. Although the dataset size is relatively small, it sufficiently captures representative fault vibration patterns under controlled conditions, and stratified sampling is applied to ensure balanced training and testing subsets.

The deep learning models are trained directly on raw vibration data collected from the UAV’s onboard IMU, without applying any normalization, augmentation, or feature engineering. This end-to-end learning approach enables the models to extract relevant temporal patterns from unfiltered sensor readings autonomously. Because the data format is identical during both training and deployment, captured consistently through the DroneKit Python interface, the system ensures reliable, real-world performance without the need for manual transformations. This approach maintains simplicity, enhances generalization, and closely ties the diagnostic process to the UAV’s physical sensor behavior, supporting robust structural health monitoring.

The classification task involves eight classes with near-balanced distribution, reducing bias toward any particular fault type. All models are developed in Python using the PyTorch framework. The categorical cross-entropy loss function is employed for multi-class classification. Training uses the Adam optimizer with a learning rate of 0.001 and a batch size of five samples. A small batch size of five samples is used to accommodate the dataset size and encourage better model generalization. The models are trained for up to 500 epochs.

To avoid overfitting on the moderately sized dataset, early stopping is employed with a patience of 40 epochs, monitoring validation loss and halting training when no further improvement is observed. Consequently, training terminates at 398 epochs for GRU, 155 epochs for CNN, and 361 epochs for LSTM, achieving efficient convergence and preserving model generalization.

Model evaluation is based on four metrics: accuracy, macro precision, macro recall, and macro F1-score.

Table 2 summarizes the classification performance achieved by each model. For reference, a Support Vector Machine (SVM) classifier is implemented as a baseline using the same vibration dataset. The superior performance of the deep learning models is confirmed by the SVM’s 96.3% overall accuracy (macro F1 = 0.9618). The SVM works with fixed input features and does not explicitly model sequential relationships, in contrast to CNN, GRU, and LSTM architectures that automatically learn temporal features from raw vibration data [

26].

As shown, the GRU and CNN models achieve the highest test accuracy (99.26%), with very similar precision, recall, and F1-scores. Although CNN achieves comparable results, the GRU model is selected for deployment within the UAV predictive maintenance framework. The selection is based on practical considerations: GRU networks have fewer parameters, offer faster inference speeds, and demand lower computational resources compared to CNNs. These characteristics make GRUs highly suitable for real-time UAV inspection workflows, particularly in resource-constrained environments integrated with closed-loop Product Lifecycle Management (PLM) systems.

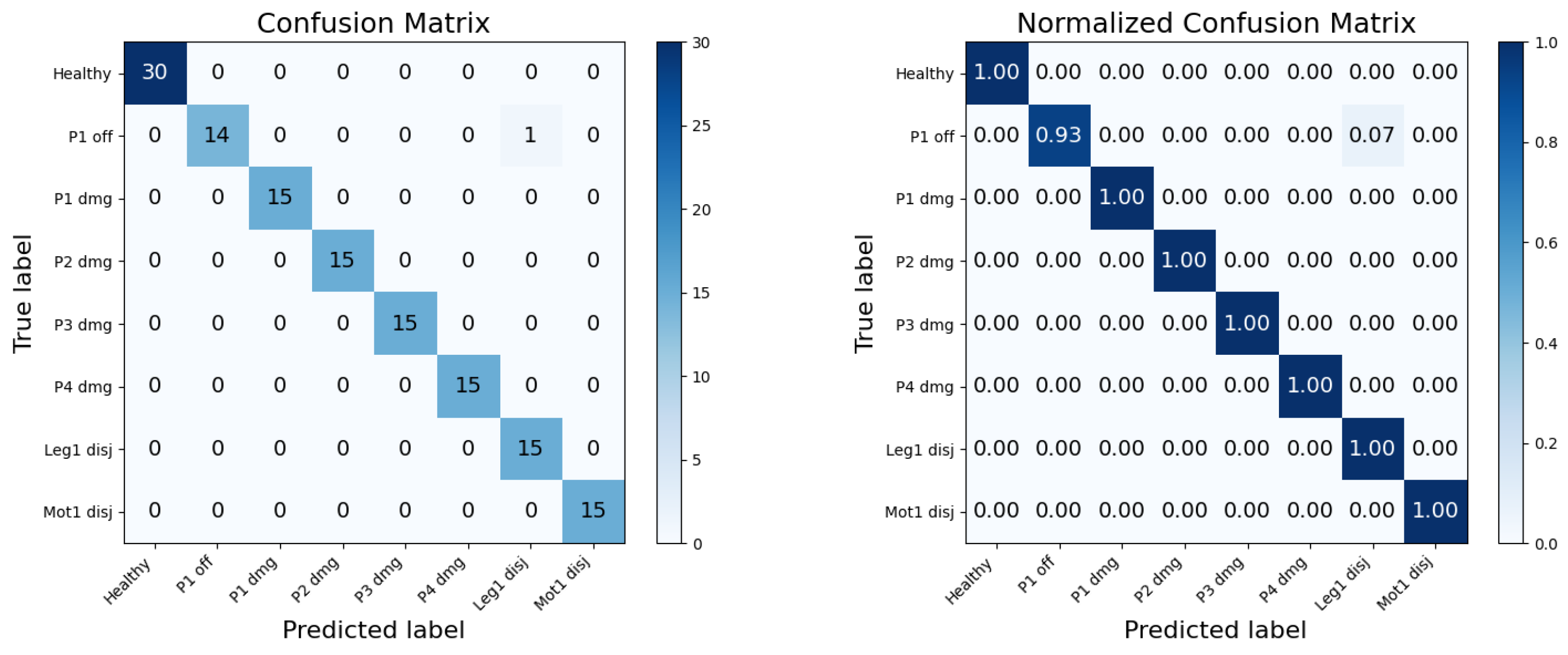

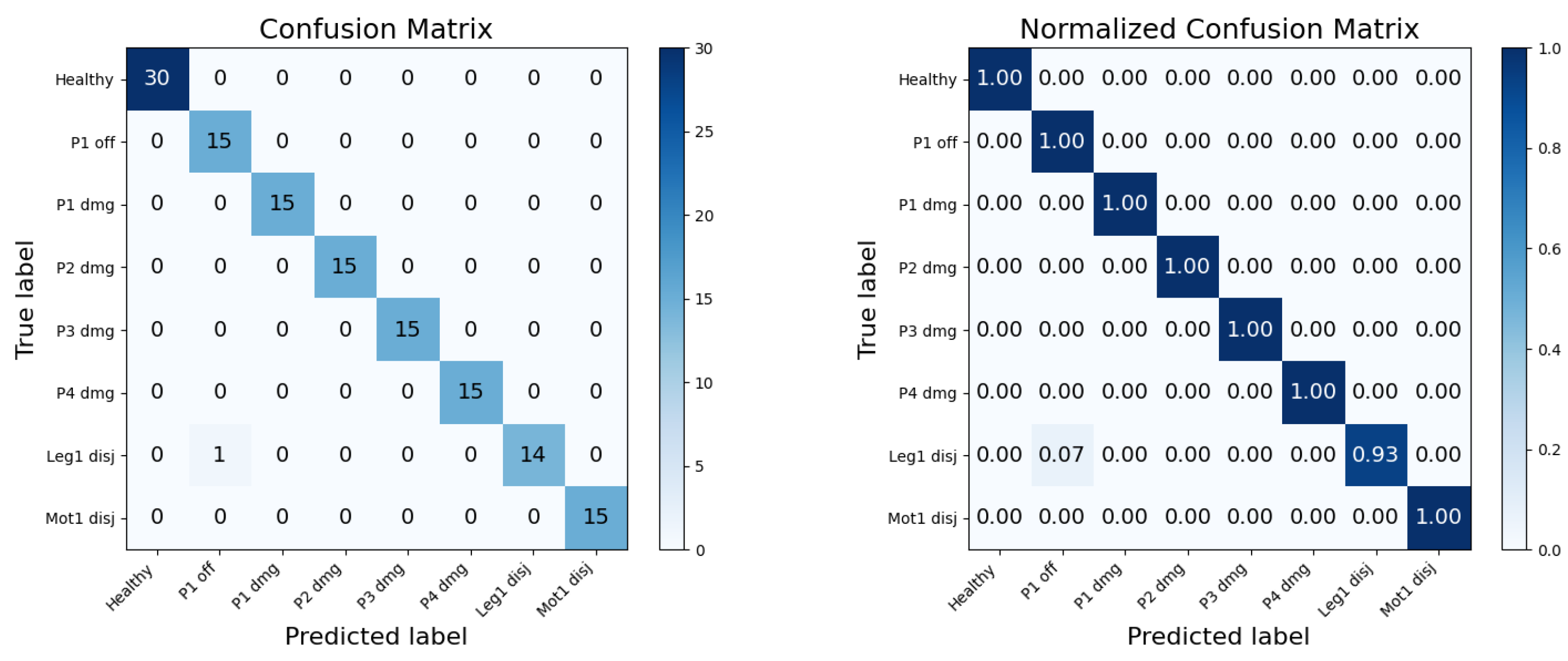

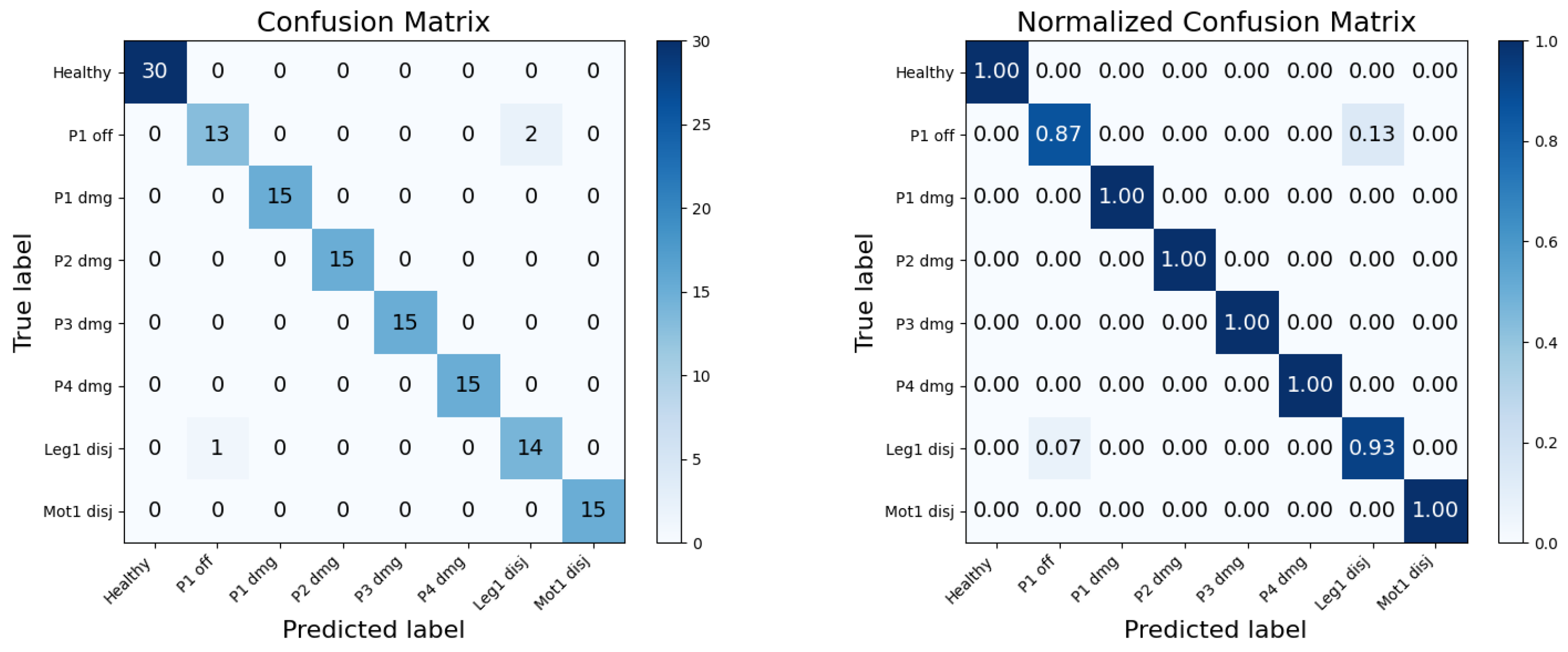

Figure 4,

Figure 5 and

Figure 6 present the confusion matrices and normalized confusion matrices for the CNN, GRU, and LSTM models, respectively, illustrating classification performance across all eight structural conditions. Overall classwise precision and recall are higher than 0.95, and the majority of fault categories are correctly identified. Some cases result in minor misclassifications: the GRU shows slight confusion between the “leg disjoint” and “propeller off” scenarios, the CNN occasionally confuses the “propeller off” and “propeller damaged” conditions due to overlapping vibration patterns, and the LSTM shows marginal cross-predictions between “propeller off” and “motor disjoint” faults. According to these findings, all models perform well and fairly, but the location of the fault and the signal properties affect how sensitive they are to minute vibration variations.

This training and evaluation process ensures that the deployed predictive model is both lightweight and robust, minimizing operational overhead while maintaining high fault detection reliability. To ensure consistency of the results, each experiment is conducted five times using stratified sampling and various random initializations. Weight initialization and data shuffling are examples of stochastic variations in model training that are taken into account by this repetition. The trained models are robust and repeatable, as evidenced by the accuracy standard deviation across runs being less than 0.5%.

3. System Architecture of the UAS Predictive Maintenance Platform

The proposed system implements a closed-loop Product Lifecycle Management (PLM) application tailored for vibration-based structural health monitoring (SHM) of Unmanned Aerial Vehicles (UAVs). While conventional PLM systems are primarily designed for managing engineering documents and part configurations [

27], the Closed-Loop Lifecycle Management (CL2M) approach emphasizes real-time data integration, embedded diagnostics, and continuous lifecycle feedback. This architecture enhances collaboration among stakeholders, including UAV operators, engineers, maintainers, and suppliers by enabling traceable, actionable, and timely maintenance decisions across the product lifecycle. It is important to note that the system described in this section represents a proof-of-concept implementation designed to demonstrate the technical feasibility of integrating SHM and PLM in UAV platforms.

The physical UAV platform used in this study is a quadcopter constructed on the DJI FlameWheel F450 frame (DJI, Shenzhen, China), categorized as a micro/mini UAV under Class I-Small Tactical Units. The vehicle features a wheelbase of 0.45 m, a wingspan of 0.48 m, and a total takeoff weight of approximately 1250 g. Its key components include the following:

Airframe: DJI F450 modular frame with replaceable base plates and arms.

Propulsion System: DJI E310 (DJI, Shenzhen, China) system comprising four 2312 brushless motors with matched 9450 CW/CCW propellers.

Control System: Pixhawk PX4 (v2.4.8) flight controller with integrated MPU6000 inertial measurement unit (IMU).

Sensors: Six-degrees-of-freedom IMU providing three-axis acceleration and gyroscopic data.

Communication: FrSky L9R long-range receiver (FrSky Electronic Co., Ltd., Wuxi, China) for remote control; USB and telemetry radio options for vibration data transfer.

This configuration supports stationary operation during the pre-flight phase, during which 30 s vibration datasets are captured to detect anomalies in structural components such as propellers and mounts.

Figure 7 presents an overview of the proposed UAV structural health monitoring architecture. The system consists of four main layers:

- 1.

The physical product, the UAV, and its embedded sensors and flight control hardware;

- 2.

A data analytics environment that processes time-domain vibration data using a trained deep learning model;

- 3.

A custom-built UAV PLM repository, implemented using the Aras Innovator platform; and

- 4.

A communication layer linking the UAV, diagnostics system, and PLM database.

The physical UAV system incorporates critical components for both flight control and monitoring of structural conditions. These include the Pixhawk 2.4.8 flight controller, an onboard MPU6000 accelerometer, four brushless motors with propellers, the airframe, and associated structural assemblies. During operation, particularly in the pre-flight stage, vibration data is acquired via the UAV’s internal IMU sensor. This data is then transmitted in real time to a computational platform using the DroneKit-Python API, enabling prompt fault detection and response.

Each UAV component is digitally mirrored within the PLM platform following a digital-twin paradigm. This digital representation captures the bill of materials (BOM), component specifications, lifecycle status, supplier records, historical faults, and maintenance events. The system improves traceability, diagnostic precision, and maintenance decision-making throughout the operating lifecycle of the UAV by mapping the physical structure of the UAV to a digital environment.

The platform architecture is designed to support scalability across multiple UAVs, with each vehicle represented by a distinct digital-twin instance within the PLM repository. Although multi-UAV deployment is not experimentally tested in this study, the system captures the MAVLink system ID embedded in each incoming message during real-time data collection, allowing for automatic association of diagnostic data with the correct digital twin. This approach ensures traceable, parallel health monitoring and lifecycle tracking without manual intervention.

The Data Analytics Layer incorporates the trained GRU-based fault classification model developed in

Section 2.3, enabling real-time evaluation of vibration data collected from the UAV during pre-flight inspections.

The subsequent subsections describe the remaining elements of the system in detail, including the following:

The development and structure of the UAV PLM platform;

The data and file exchange mechanisms between the drone, computational environment, and PLM system;

The integration of predictive models within the UAV platform to enable intelligent, automated health assessments and fault responses.

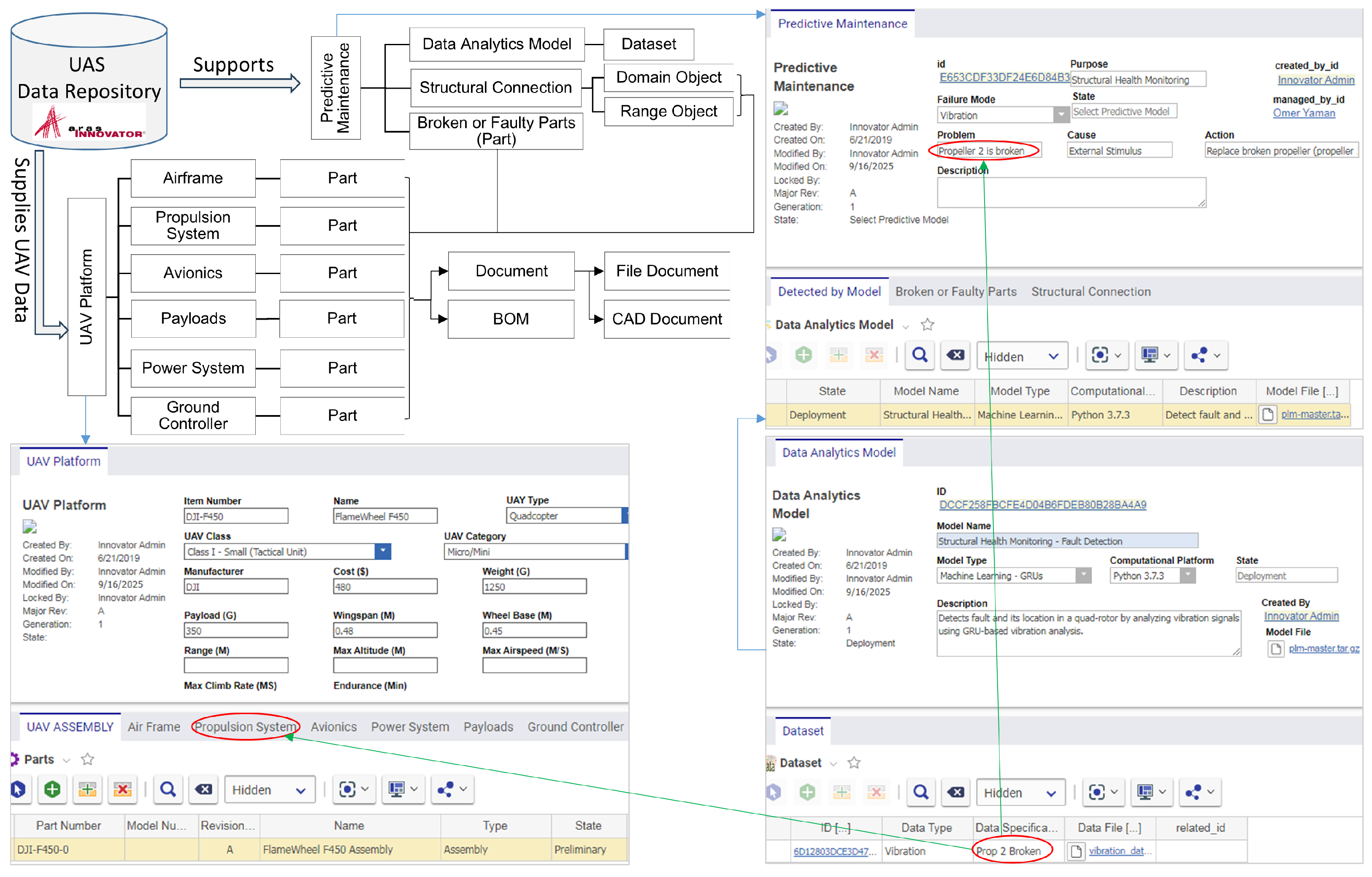

3.1. UAV Information Management System for Predictive Maintenance

The core of the proposed system is a customized Product Lifecycle Management (PLM) platform built on Aras Innovator, serving as a centralized repository and decision-support environment for UAV health monitoring and predictive maintenance. This platform integrates a relational database, file storage, analytics models, and web interfaces to manage documents, UAV configurations, diagnostic outputs, and maintenance workflows.

Unlike traditional document-centric PLM systems, this architecture implements real-time feedback mechanisms based on vibration diagnostics, enabling closed-loop structural health monitoring (SHM) and predictive analytics. The system design aligns with established methodologies and standards, including NATO STANAG 4586 [

28] for UAV metadata standardization, a PLM-UAS framework based on Sassanelli et al. [

29], and the CRISP-DM [

30] methodology to structure analytics-driven maintenance cycles. The platform is structured around three integrated layers:

UAV Data Repository-A structured database storing UAV platforms, subsystems, parts, associated technical documents (CAD files and BOMs), and maintenance records.

Data Analytics Layer-Supports development, deployment, and lifecycle tracking of deep learning models for fault detection. Model performance is continuously evaluated using datasets collected from UAV operations.

Predictive Maintenance Layer-Hosts the deployed deep learning model for real-time fault classification, links diagnostic outputs to UAV components and maintenance actions, closing the loop between real-world faults and engineering data within the PLM platform.

In Aras Innovator, all entities are represented as items interconnected through relationships, which define structural, historical, and functional associations. This flexible structure enables detailed modeling of UAV platforms, subsystems, diagnostics history, and predictive maintenance actions. All models, datasets, and documents are stored with full version control and lifecycle traceability.

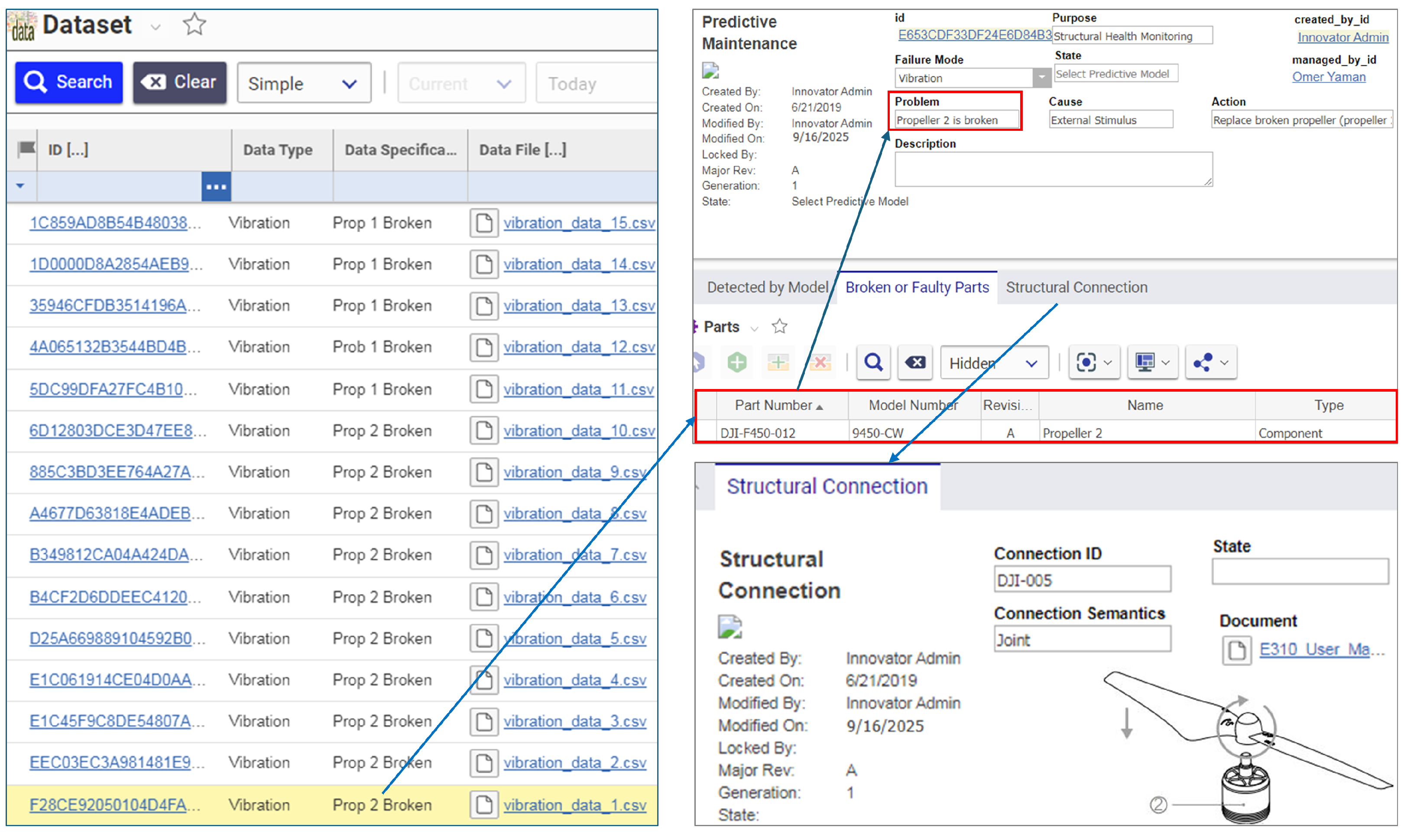

As shown in

Figure 8, the system enables end-to-end predictive maintenance workflows. A Predictive Maintenance Item is linked to a trained data analytics model, which processes historical and real-time vibration datasets to detect potential faults. Identified anomalies are mapped via structural connections to specific UAV parts, each embedded in the UAV’s bill of materials (BOM) and linked to engineering artifacts such as CAD models and maintenance procedures. This full digital thread allows users to trace fault impact from anomaly detection to physical components, supporting proactive decision-making.

Both static data, such as platform structures and payload specifications, and dynamic operational data, such as vibration time-series and fault predictions, are managed through a CRISP-DM aligned process layer. This structure guarantees data integrity, traceability, and readiness for analytics, while enabling continuous model refinement and adaptive maintenance strategies based on the evolving operational history of UAVs.

Data entry into the PLM system can occur manually or automatically via APIs. Vibration data is transmitted during pre-flight checks, processed by the deep learning diagnostics environment, and the resulting health assessments are seamlessly integrated back into the PLM repository. Maintenance teams, engineers, and operators access synchronized diagnostic insights to initiate early repairs, schedule inspections, or update part statuses.

This architecture ensures traceable, real-time predictive maintenance for UAV platforms, improving safety, reducing downtime, and closing the loop between operational data collection and lifecycle decision support.

The following section describes the communication infrastructure that connects the UAV platform, diagnostics engine, and PLM system in real time.

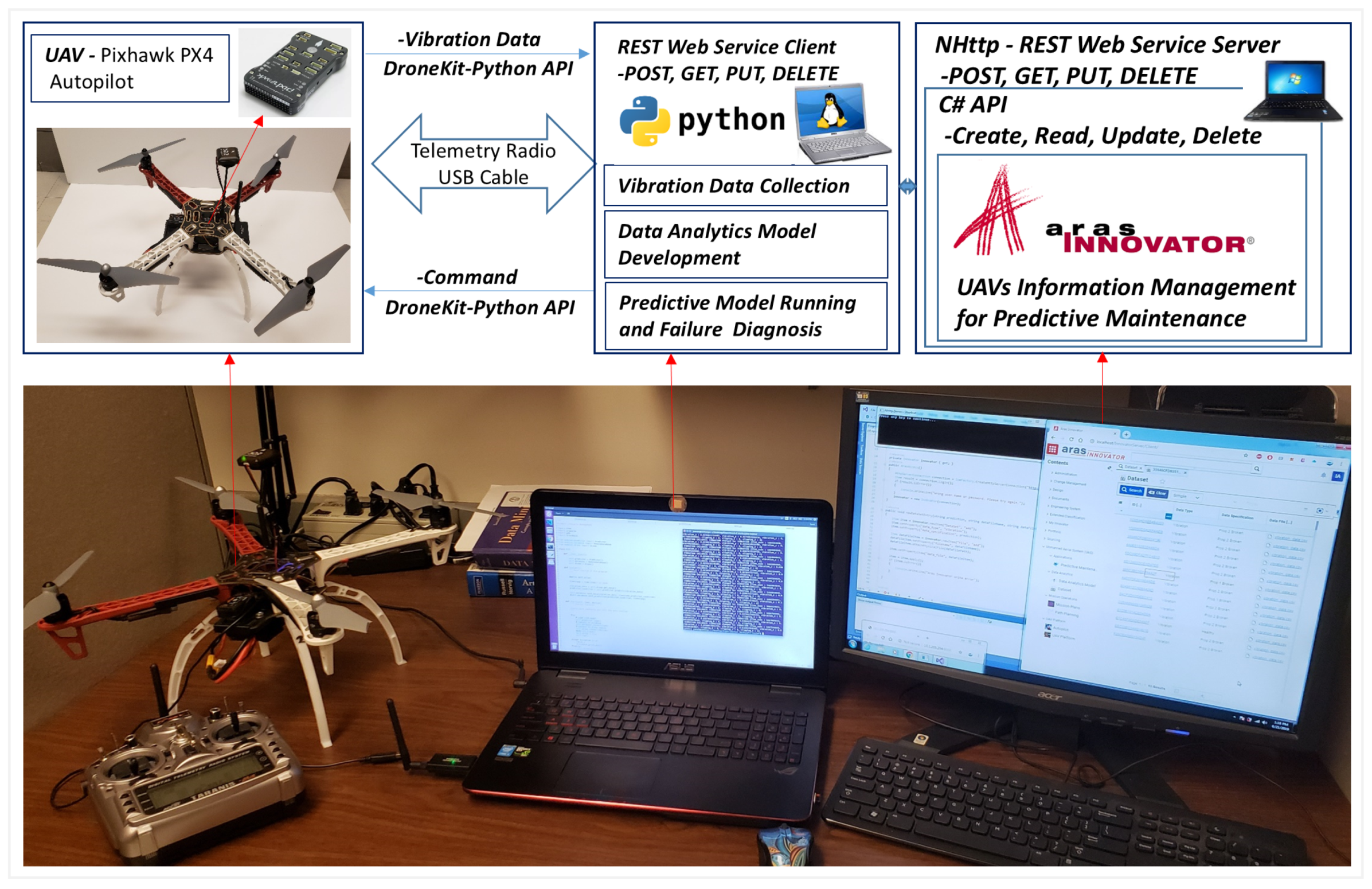

3.2. Data and File Exchange

To enable seamless integration among the UAV, the diagnostic environment, and the UAV management platform, a robust two-tier communication architecture was developed. This architecture supports real-time data acquisition, analytics-driven fault detection, and maintenance data synchronization, thereby reinforcing the predictive maintenance framework and enhancing operational responsiveness. As illustrated in

Figure 9, the experimental setup consists of a UAV equipped with an MPU6000 IMU sensor, a Python-based computational environment running trained deep learning models, and a workstation hosting the Aras Innovator PLM system.

The UAV interfaces directly with the computational environment via telemetry or USB connection, utilizing the DroneKit-Python API. This API facilitates the collection of real-time vibration signals and supports the transmission of operational commands. Vibration data is continuously streamed to the Python environment, where it is evaluated using the deployed GRU-based fault classification model. Upon reception, each data stream is tagged with the UAV’s MAVLink system ID, ensuring that diagnostic results can be accurately associated with the correct UAV record in the PLM repository. In cases where a critical structural anomaly is detected, an immediate DISARM command is issued to the UAV, preventing further mechanical stress. Since data collection occurs during the pre-flight phase when the UAV is stationary, this action mitigates risk without introducing mid-flight hazards. The DISARM action is triggered only in pre-flight mode, during stationary inspection, when the UAV is powered and vibration analysis is performed. To avoid risky flight operations, the system sends out the DISARM command prior to takeoff if a structural fault is found. This prevents any interference with in-flight control logic by guaranteeing that all diagnostic responses are carried out solely on the ground.

Simultaneously, diagnostic outcomes including classification results and detected fault metadata are transmitted to the Aras Innovator PLM system via a RESTful communication channel. The Python environment functions as a REST client, interfacing with an asynchronous NHttp-based REST server designed for the .NET platform. This server acts as a gateway, receiving analytics outputs and forwarding structured updates to the PLM repository. Each transmitted update includes the UAV’s MAVLink system ID, enabling the server to accurately associate diagnostic results with the corresponding UAV record within the PLM system.

The RESTful interface supports standard HTTP methods (POST, GET, PUT, DELETE) to perform full lifecycle operations on PLM items. On the server side, Aras.IOM C# API is employed to construct AML (Aras Markup Language) queries and manage the UAV platform’s digital artifacts, including fault records, parts, and maintenance documentation. Consequently, the architecture enables the automated exchange of the following:

Vibration data files acquired from UAV telemetry;

Fault prediction results generated by the GRU diagnostic model;

Trained analytics models (for retraining, evaluation, or updates within PLM).

Although real-time latency metrics such as model inference time, data transmission delay, etc., are not quantitatively measured in the current prototype, preliminary testing indicated that USB-based data transfer and the compact architecture of the GRU model allow for rapid diagnostics, typically completing within a few hundred milliseconds per sample. Future versions will include rigorous latency benchmarking under different hardware configurations to support deployment in time-sensitive operational contexts.

This tightly integrated communication framework ensures that real-time UAV health assessments are immediately reflected in the PLM environment, supporting proactive maintenance decisions and continuous lifecycle visibility.

3.3. UAV Platform Integration and Predictive Analytics Application

The integration of predictive analytics with the UAV management platform is realized through a closed-loop workflow that connects real-time data acquisition, GRU model inference, and lifecycle management operations within the Aras Innovator PLM environment. As illustrated in

Figure 8, the system enables direct interaction between the UAV, the Python diagnostics environment, and the PLM database through RESTful APIs and C# connectors, supporting fully automated, traceable fault management.

During the pre-flight phase, once the UAV is armed and stabilized, vibration data is transmitted to the ground station using the DroneKit-Python interface. The GRU model, selected based on superior classification performance (

Section 2.3), is deployed in the Python environment to classify incoming signals. If a structural anomaly or fault is detected, two concurrent actions are triggered:

Operational Response-A DISARM command is immediately sent to the UAV via the DroneKit-Python API, preventing further mechanical damage. Since inspections occur during the pre-flight phase with the UAV stationary, this command ensures operational safety without introducing in-flight hazards.

Lifecycle Management Response-A structured maintenance order is automatically generated within the Aras Innovator PLM system. The maintenance record includes the following:

- -

Component Identification-Specifies the faulty component such as Propeller 2, using structured metadata.

- -

Fault Description-Captures the diagnosed anomaly, its severity, and probable cause.

- -

Maintenance Instructions-Provide visual and textual guidance for part replacement and repair.

- -

Supporting Documents-Link CAD drawings, technical manuals, and supplier information to the affected part.

- -

Ordering Information-Lists approved vendors, lead times, and associated costs to facilitate procurement.

The maintenance order and associated fault metadata are immediately accessible through the PLM web interface, ensuring that operators, engineers, and service teams can view, track, and act upon the detected issue in real time. This information also feeds into a growing digital fault history, supporting statistical trend analysis, reliability assessments, and iterative model retraining.

The proposed system embeds predictive diagnostics directly within the PLM platform. It automates the transition from fault detection to maintenance action. As a result, it reduces downtime, improves UAV reliability, and supports data-driven decisions throughout the vehicle’s lifecycle.

4. Results and Discussion

This section presents the experimental validation of a fully implemented closed-loop PLM system for UAV structural health monitoring. The system integrates trained deep learning models, real-time diagnostics, and PLM-based maintenance workflows on a physical UAV platform.

Vibration datasets are collected from a quadcopter to train and evaluate three different time-series classification models: Gated Recurrent Units (GRUs), Long Short-Term Memory (LSTM), and Convolutional Neural Networks (CNNs). The GRU model, selected based on accuracy and efficiency, is deployed for real-time fault classification during UAV operation. This model, along with associated training and test datasets, is stored and versioned within the Aras Innovator PLM system, making it readily accessible during development and deployment stages.

Over fifty experimental test runs are conducted using the physical UAV platform to evaluate system behavior across both healthy and faulty conditions. For each run, a specific structural fault, such as a damaged propeller or loosened mounting, is manually induced, or no fault is introduced in the case of healthy scenarios. The deployed GRU model successfully classified the structural state in each instance. When no fault is detected, the UAV continues operation. When a fault is identified, the system immediately issues a DISARM command via the DroneKit-Python interface. Simultaneously, a structured maintenance order is generated and recorded in the Aras Innovator PLM system, confirming successful end-to-end validation of the sensing, classification, response, and documentation pipeline. The validation focused on single-fault detection accuracy; the classification of combined or compound faults is reserved for future work. While a wide variety of conditions are tested, some fault types, particularly propeller 1 and propeller 2 damage, are repeated multiple times to confirm repeatability and are highlighted in

Figure 10.

The generated maintenance order includes structured metadata linking the predicted fault to its corresponding physical component through a structural connection object, along with a detailed description of the fault and failure mode, visual documentation (e.g., CAD drawings), replacement instructions, supplier and cost information, and part ordering details. These outcomes are not simulated but executed through the live PLM interface, demonstrating the system’s ability to autonomously generate actionable, traceable maintenance responses based on real-time UAV health diagnostics.

This information becomes immediately accessible to all relevant stakeholders, including operators, engineers, designers, suppliers, and maintenance teams through the PLM web interface. The live sharing of diagnostic results and maintenance instructions enables rapid decision-making, minimizes UAV downtime, and contributes to a continuously evolving digital thread of operational knowledge for each UAV instance.

Additionally, the PLM repository retains a detailed history of vibration records, diagnostic results, and corrective actions, supporting trend analyses, model refinement, and future product development. Over time, the continuous accumulation of field data, diagnostic outputs, and maintenance events strengthens the closed-loop feedback between UAV operations, predictive maintenance, and lifecycle management processes.

These results demonstrate the technical feasibility and operational value of integrating predictive analytics directly within a closed-loop UAV lifecycle management system. While the experimental validation demonstrates strong preliminary results, further large-scale testing across diverse UAV platforms and fault types is planned to generalize and refine the system’s predictive capabilities.

The results validate the system as a reliable foundation for UAV health monitoring and predictive maintenance and demonstrate the feasibility of applying closed-loop PLM to manage UAVs under real operational conditions.

5. Conclusions

This study presents an operational closed-loop Product Lifecycle Management (PLM) system for vibration-based structural health monitoring (SHM) of Unmanned Aerial Vehicles (UAVs). The proposed system integrates deep learning–based fault detection with a customized PLM platform to enable real-time predictive maintenance and lifecycle traceability.

Experimental validation using a physical UAV platform demonstrated that the trained GRU model achieved high fault classification accuracy (99.26%, macro F1 = 0.9917) based on raw vibration data collected during pre-flight inspections. Upon detecting faults, the system automatically triggered safety protocols, disarming UAVs, and generated structured maintenance orders within the PLM environment. This seamless integration closes the loop between field diagnostics and maintenance workflows while maintaining a traceable digital thread across the UAV lifecycle.

The results confirm both the technical feasibility and operational benefits of embedding predictive analytics into PLM workflows. The proposed system enhances UAV reliability, reduces unplanned downtime, and empowers stakeholders with actionable, data-driven insights for maintenance and lifecycle management.

Diagnosing multiple co-occurring faults during pre-flight inspections will be a key focus of future work. The classification of combined or compound faults is not addressed in the current implementation due to several practical constraints. First, collecting a representative dataset for multiple co-occurring faults is challenging, as the number of possible fault combinations increases combinatorially and requires careful isolation during testing. Second, overlapping vibration signatures from different faults can result in non-linearly superimposed signals, making it difficult for models to distinguish individual fault contributions without more advanced feature disentanglement techniques. Lastly, sensor resolution and noise may further obscure the subtle differences between compound and single-fault scenarios. These factors collectively make multi-fault classification a non-trivial extension and a clear direction for future research.

The current validation is limited to a single UAV platform and a relatively small dataset, which may constrain generalization to other configurations or environmental conditions. Additional efforts will include extending data collection to in-flight UAV operations, incorporating additional operational parameters such as battery health, and exploring lightweight on-board inference architectures for real-time diagnostics while expanding the fault library to cover more complex structural damages such as cracks, delaminations, and adhesive failures. The framework will be expanded in future work to facilitate coordinated monitoring across multiple UAVs, allowing for data exchange and fleet-level health management via encrypted cloud-based PLM repositories. Data integrity and confidentiality across several operators will be guaranteed by putting in place access-controlled interfaces and secure data transfer protocols.