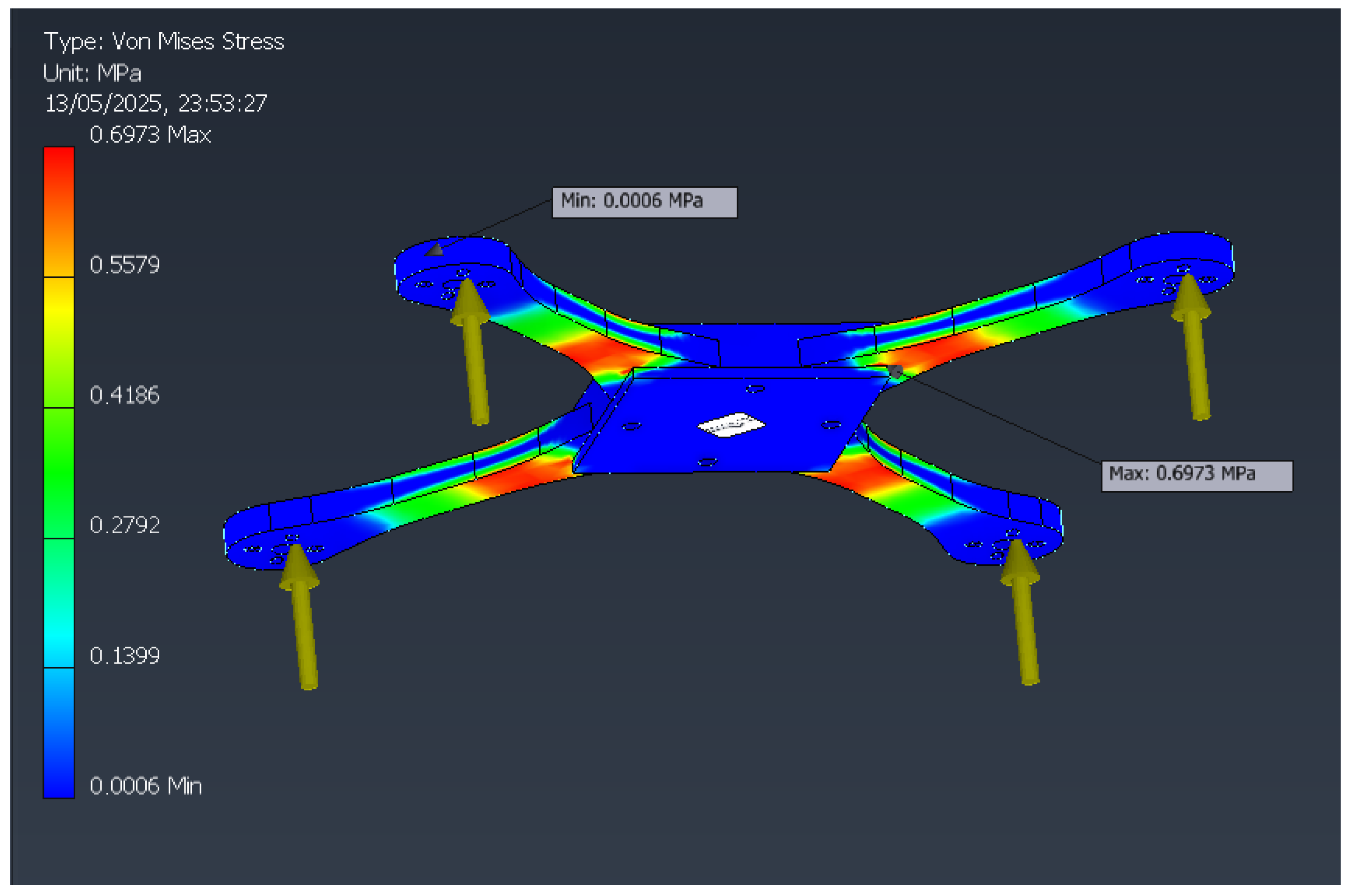

The structural evaluation of the drone chassis was conducted under representative flight conditions using the Finite Element Method (FEM). Different load cases were simulated in order to determine the structural integrity, stress distribution, and deformation of the printed frame. The first case corresponds to hovering flight, which establishes a reference baseline for subsequent analyses under more demanding manoeuvres.

3.4.1. Hovering Flight Analysis

In this scenario, the drone is simulated under steady hovering conditions, where the lift force generated by the rotors exactly balances the vehicle’s weight. This represents the baseline structural load case and serves as a reference for more complex operational scenarios. The load distribution is assumed to be uniform across the four arms, enabling a straightforward evaluation of stresses, displacements, and the safety factor using the Finite Element Method (FEM).

Applying Newton’s second law, the equivalent force acting on each arm is:

The total force generated by the four rotors is therefore:

The resulting vertical acceleration is:

This case corresponds to a hovering flight condition with a vertical acceleration of 1.0 G representing static lift equilibrium. The parameters applied in the simulation are summarized in

Table 6.

The PETG used for the 3D-printed chassis has an approximate yield strength of:

The maximum Von Mises stress obtained in this case is:

The resulting safety factor is:

This indicates that, under normal hovering conditions, the structure operates far below its material limit, with a very wide safety margin (

Table 7).

Figure 4 shows the distribution of Von Mises stresses, with maximum concentrations at the arm–chassis junction.

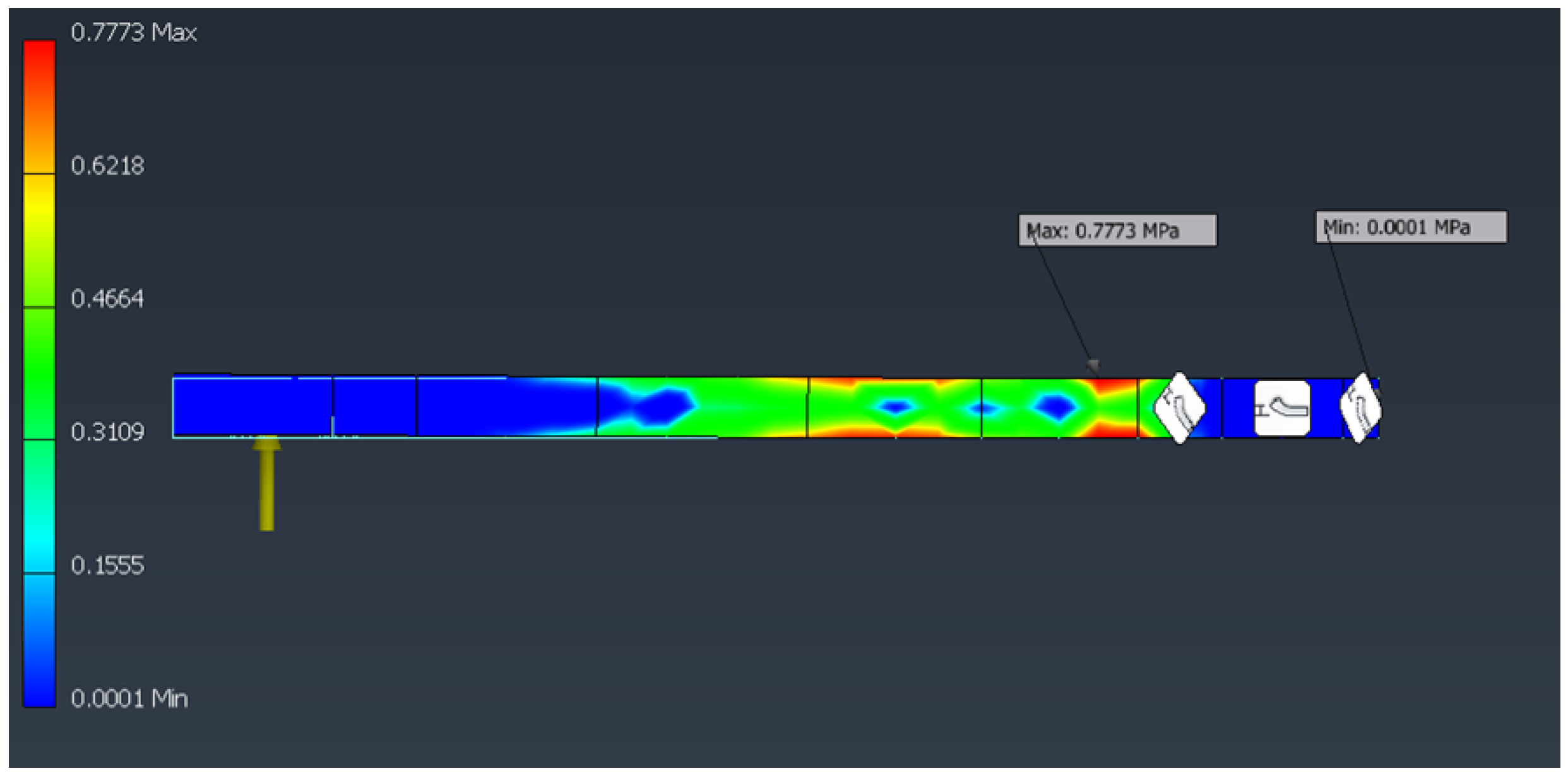

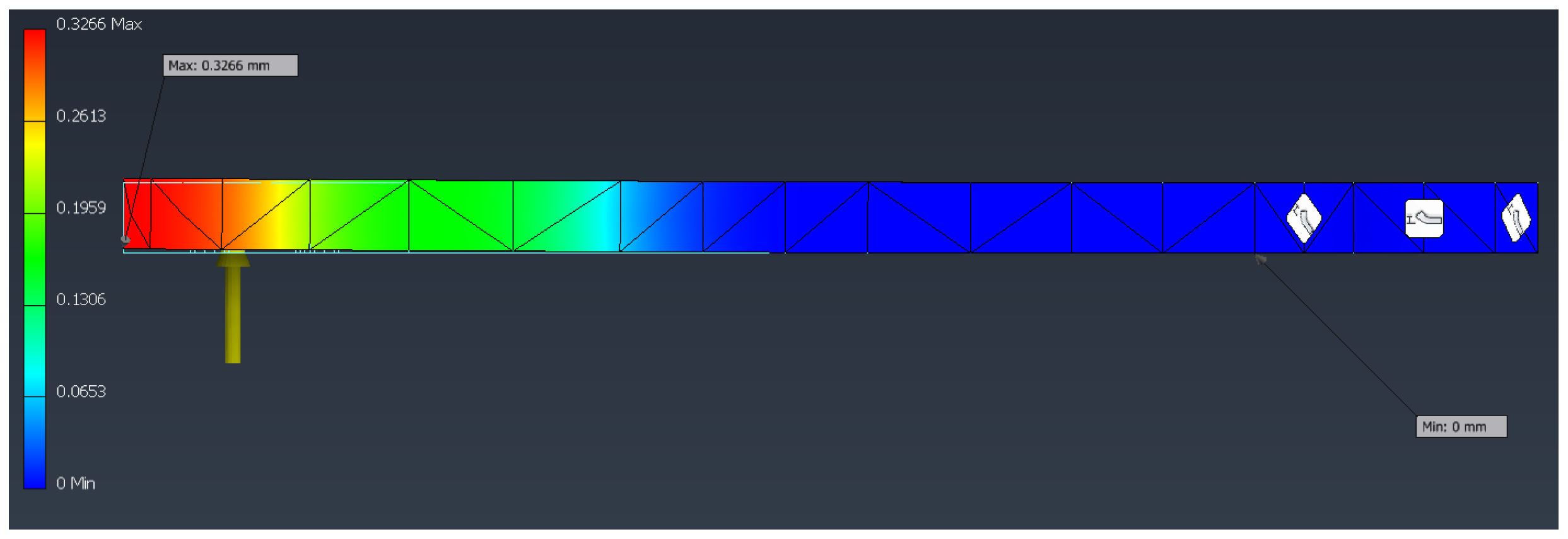

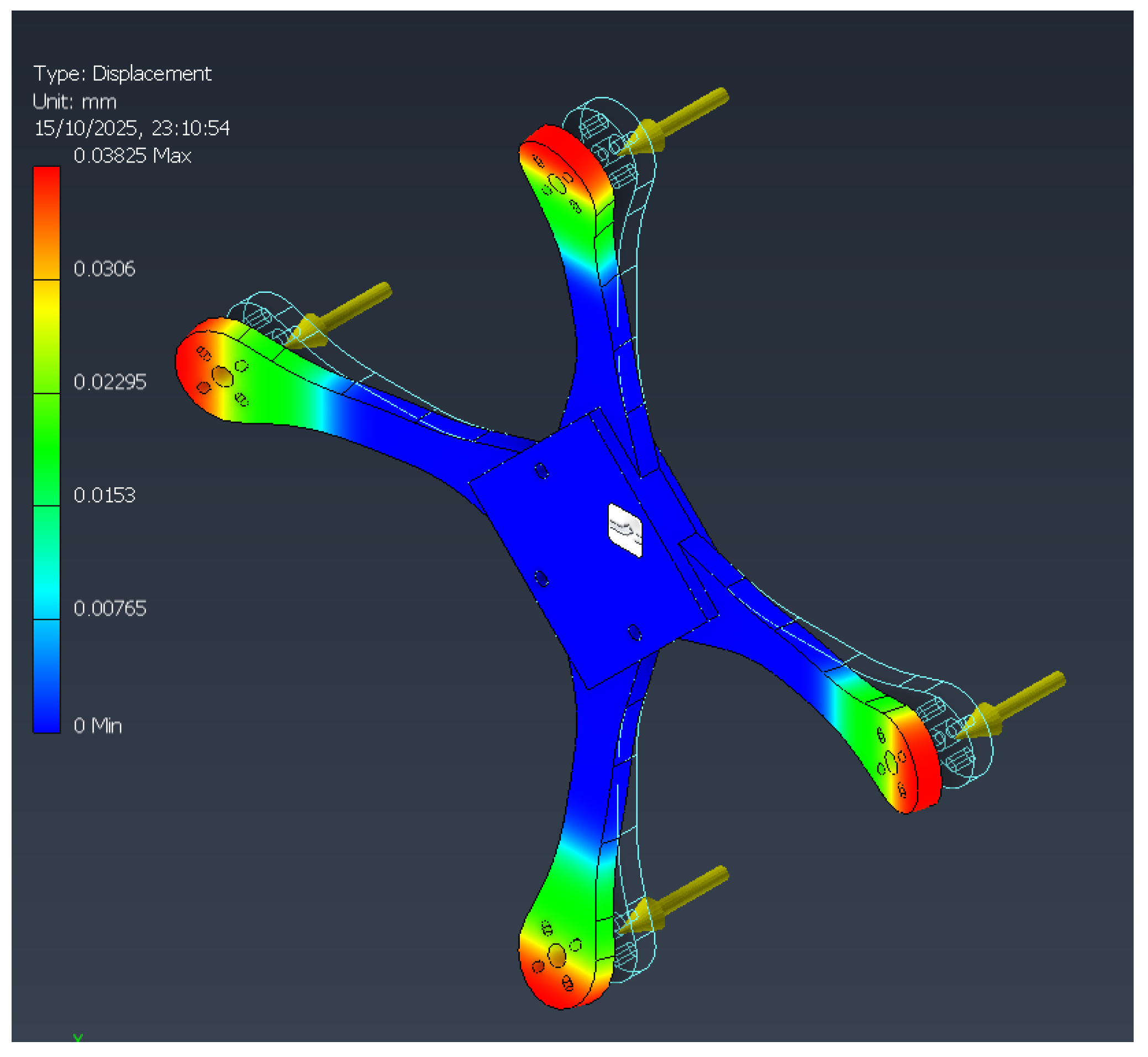

Figure 5 indicates that the maximum displacement (

mm) occurs at the free ends of the arms.

To validate the numerical simulations, a simplified theoretical model was implemented, representing the drone arm as a cantilever beam with an equivalent rectangular cross-section. This approximation provides a first-order estimation of stresses and displacements and allows comparison with the results obtained from FEM simulations of both the individual arm and the fully assembled structure.

Model data:

Cantilever beam with rectangular cross-section

Length: mm

Width: mm

Height: mm

Point load: N applied at the free end in direction

Young’s modulus (PETG): Pa

CalculationsComparison of results: To compare the simplified model against numerical simulations, a load of

N was applied, corresponding to the thrust generated by a single motor under hovering conditions.

Table 8 summarizes the results.

The simplified beam model provides a conservative estimate of stresses and displacements. As expected, the inclusion of the actual geometry and the structural connection of the arm to the chassis increases stiffness, thereby reducing both stresses and deflections under identical load conditions. The difference between the individual arm and the assembled model is mainly attributed to the boundary conditions: in the assembled configuration, the frame corner acts as a stiffer constraint, reducing the effective bending moment.

The results obtained from the mechanical and static analyses confirm the validity of the PETG model under the expected operating conditions. The relatively low applied loads, the limited Von Mises stresses, and the small displacements observed indicate that the structure operates well within safe limits, thus validating the chosen manufacturing process and material assumptions. Consequently, these findings support the feasibility of future production using carbon fiber composites, which, due to their significantly higher stiffness and strength, would further enhance the structural performance and reliability of the final design.

The FEM results for the individual arm under hovering load are shown in

Figure 6 and

Figure 7.

3.4.2. FEM Structural Study at Maximum Motor Thrust (10.4 G)

This analysis evaluates the structural behavior of the 3D-printed frame under the most demanding loading scenario: the maximum thrust is delivered by the motors at full throttle. Unlike the hovering condition, this case does not represent a realistic steady flight state but rather an idealized vertical acceleration situation, introduced to assess the structural safety margins of the chassis under extreme conditions.

When the motors operate at 100% throttle, each motor produces a thrust of approximately 650 g (647 g according to the manufacturer’s data sheet). The model assumes that the total thrust acts directly on the arms, while the central base of the frame is fully constrained. This conservative simplification allows a direct evaluation of the maximum stresses and displacements that the structure could undergo. A summary of the simulation conditions can be found in

Table 9.

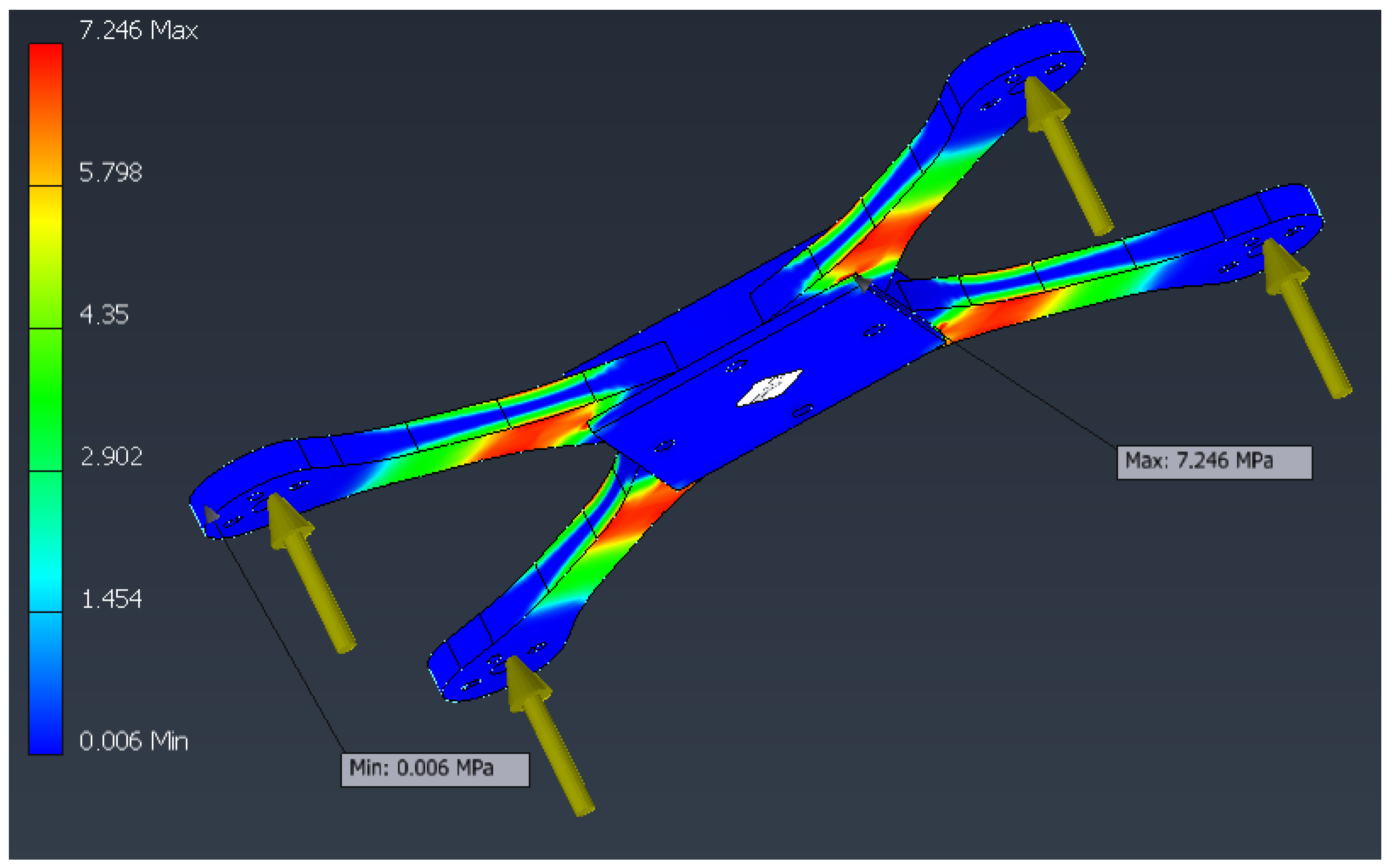

From the FEM simulation, the maximum Von Mises stress was observed at 7.25 MPa, concentrated near the arm–frame junction (

Figure 8). The maximum displacement, 2.43 mm, occurs at the free end of the arms (

Figure 9). Considering the PETG yield strength of 40 MPa, the safety factor is:

A summary of the simulation results can be found in

Table 10.

The simplified cantilever beam model was tested under the same extreme condition of 6.38 N applied at the free end. The objective is to validate the order of magnitude of stresses and displacements compared with the CAD-based FEM simulation.

Model data:

Cantilever beam with rectangular cross-section.

Length: mm.

Width: mm.

Height: mm.

Point load: N in direction.

Young’s modulus (PETG): Pa.

Calculations:

The comparison under high-load conditions is summarized in

Table 11.

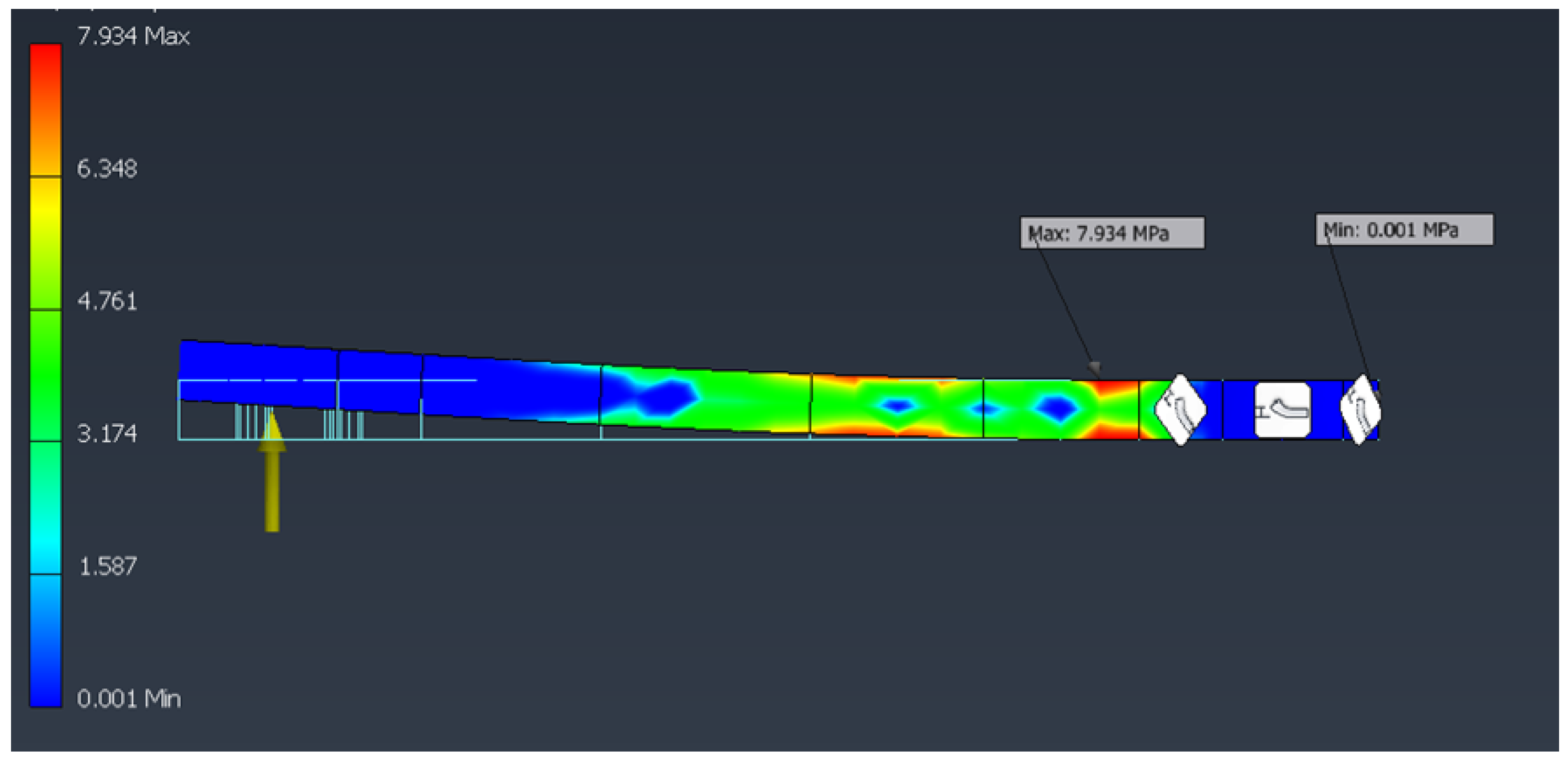

As in the hovering case, the simplified model predicts slightly higher stresses than the CAD simulations. This difference is explained by the stiffening features of the real arm geometry, which help reduce stresses under the same load.The Von Mises stress and displacement distributions are shown in

Figure 10 and

Figure 11, respectively.

The FEM simulations for PETG and carbon fiber under the same loading conditions reveal substantial differences in mechanical performance, primarily due to the superior stiffness and strength of the carbon fiber material, while the stress levels remain similar between both cases, the displacement and safety factor show remarkable improvements when using carbon fiber.

Table 12 summarizes the comparison between the analyzed materials.

Considering the carbon fiber yield strength of 300 MPa, the safety factor is calculated as follows:

The maximum Von Mises stress remains constant at 7.25 MPa for both materials, as the geometry and load conditions are identical. However, the maximum displacement decreases from 2.43 mm with PETG to only 0.038 mm with carbon fiber, representing a drastic improvement in stiffness and deformation control.

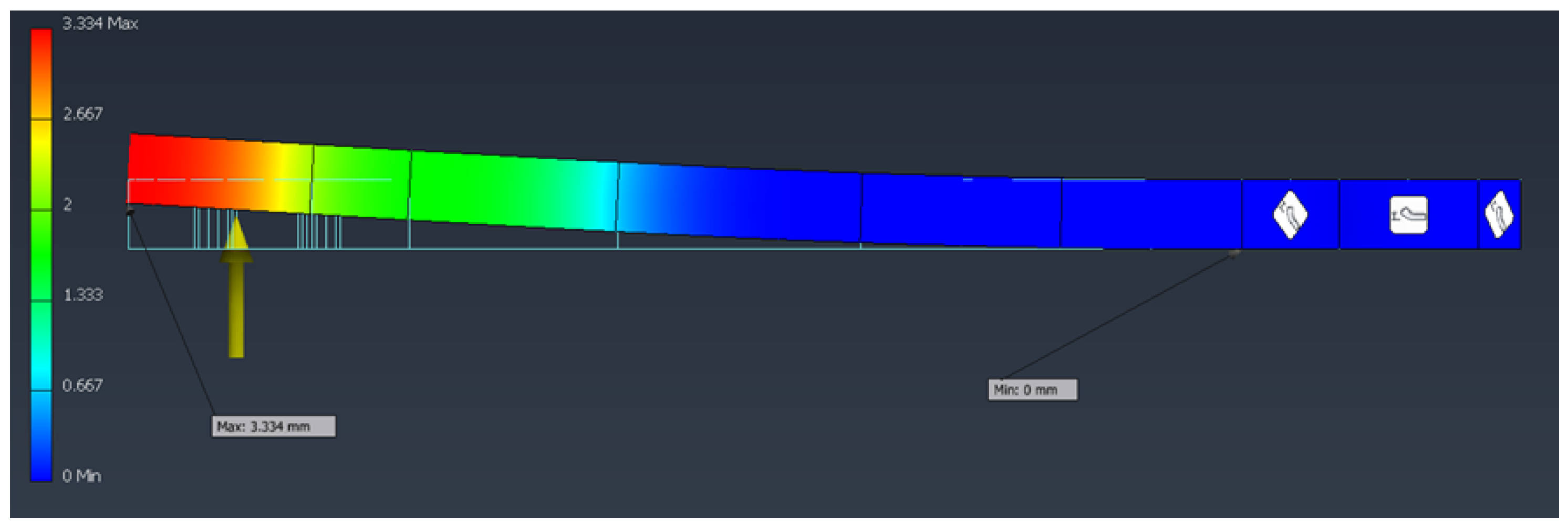

The safety factor increases from 5.52 to 41.38 due to the significantly higher yield strength of carbon fiber (300 MPa vs. 40 MPa). These results demonstrate that, although both materials experience similar stress distributions, the structural response of the carbon fiber model is far superior in terms of rigidity and safety margin. As shown in

Figure 12, the deformation in the carbon fiber structure is minimal compared to the PETG case, while

Figure 13 highlights the distribution of principal stresses, confirming similar stress patterns but significantly reduced strain magnitudes.

In conclusion, replacing PETG with carbon fiber substantially enhances the structure’s mechanical performance, reducing deformation by more than 98% and increasing safety by a factor of approximately 7.5, confirming carbon fiber as a more suitable material for high-performance structural applications.

Experimental validation

To validate the numerical FEM results, a preliminary experimental test was performed using a single arm segment of the drone frame. The objective of this test was not to obtain statistically representative data, but rather to verify the order of magnitude of the deformation predicted by the simulations under a controlled static load. The arm was rigidly fixed at one end, replicating the boundary conditions used in the FEM analysis, setup can be observe in

Figure 14. A static punctual load equivalent to 625 was applied at the free end, corresponding to a force as follows:

This value represents the load generated by the arm under an acceleration of approximately 10 G, as simulated in the maximum thrust FEM scenario. For practical implementation, a physical weight of 625 g was suspended from the tip of the printed arm to reproduce the equivalent vertical force.

The resulting vertical displacement was measured manually with a precision of 1 mm. Due to the small magnitude of deformation and the absence of dedicated strain measurement instrumentation (e.g., LVDT or digital displacement sensors), the obtained value represents an approximate observation.

The measured displacement was approximately 1.8 mm, compared with the 3.34 mm predicted by the FEM simulation under the same loading and boundary conditions. This difference is primarily due to the intentionally conservative nature of the FEM analysis, in which the PETG material properties were underestimated (yield strength set to 40 MPa) to ensure a safety margin against printing defects, local stress risers, or interlayer weaknesses.

This conservative modeling approach was chosen to guarantee that, if the simulated model remains within safe limits under these restrictive assumptions, the real printed prototype will also perform safely under actual conditions. Thus, the FEM model acts as a lower-bound validation of structural integrity.

Table 13 summarizes the experimental results of the single-arm setup.

Given the limited precision of the setup and the absence of strain instrumentation, this test should be interpreted only as a qualitative validation confirming that the experimental and numerical deformations are of the same order of magnitude. The results support the validity of the conservative FEM model and demonstrate that the printed structure operates safely within the predicted elastic range.

In summary, this preliminary single-arm static test supports the general validity of the FEM approach while highlighting the need for future tests using precise displacement sensors and multiple samples to improve quantitative correlation.

3.4.3. Structural Response to Lateral Impact at the Arm Tip (40 km/h)

The purpose of this simulation is to study the structural behavior of the drone when it impacts a rigid object (representing a tree) at a speed of 40 km/h or 11 m/s. The collision occurs at the tip of one of the drone’s arms, which allows the analysis of the localized response in the structurally most critical area during a crash.

The simulation is configured as a nonlinear transient dynamic response with large displacements enabled (PARAM, LGDISP, 1). Rayleigh damping coefficients are applied (, ) to model internal energy dissipation.

The integration step is s, with 1000 iterations per step, and a total duration of 0.01 s. This ensures high temporal resolution of the impact response.

A summary of the main parameters is presented in

Table 14.

To properly characterize the system’s response during and after the impact, multiple output variables were enabled, as detailed in

Table 15. These allow evaluation of the most relevant physical magnitudes such as displacements, stresses, and internal forces.

For the simulation, Inventor software 2025 in the Nastran environment is used, which enables transient testing. The model assembly and the meshed drone, composed of triangular elements refined in the impact region, are shown in

Figure 15. The tree is represented by a meshed cylinder with rigid properties and completely constrained motion. The adaptive mesh, with higher density in the impact zone, ensures adequate spatial resolution of stresses. A detailed view is shown in

Figure 16, where the increase in nodes on the arm under study can be observed, especially on the impact surface.

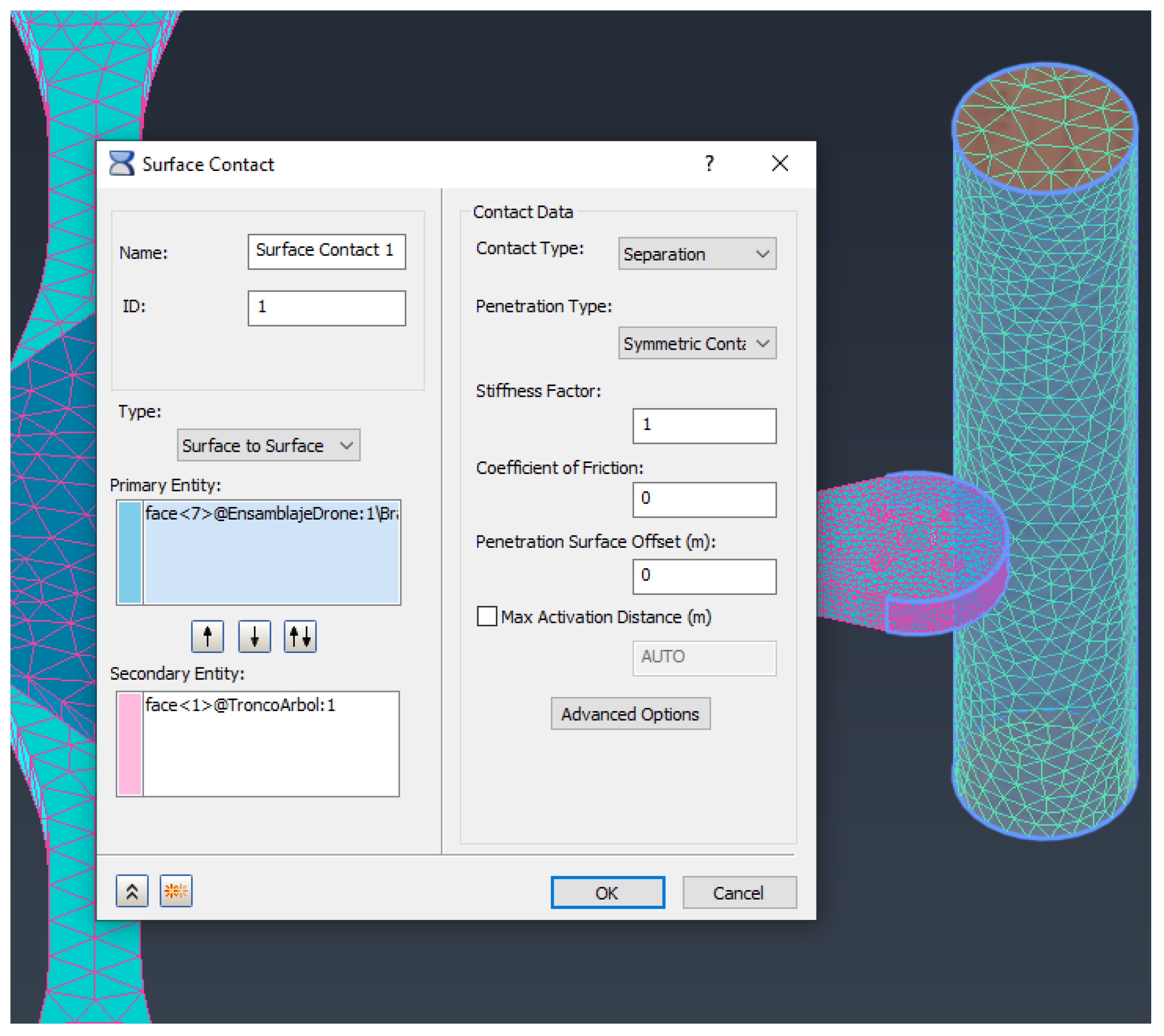

The contact between both geometries is defined by non-penetration collision conditions through a boundary contact condition between the arm face and the cylinder simulating the tree, as shown in

Figure 17. The boundary conditions ensure the following:

Type of penetration: symmetric contact—both surfaces (drone and tree) act interchangeably as master or slave surfaces, improving numerical stability and contact detection accuracy.

Stiffness factor: 1—maintains physical accuracy without artificial rebounds or numerical penetrations.

Coefficient of friction: 0—friction neglected due to the short collision time and dominance of normal forces.

Penetration Surface Offset: 0 m—accurate meshing and alignment require no offset.

Max activation distance: enabled (automatic mode)—the solver determines activation distance dynamically to avoid false contacts.

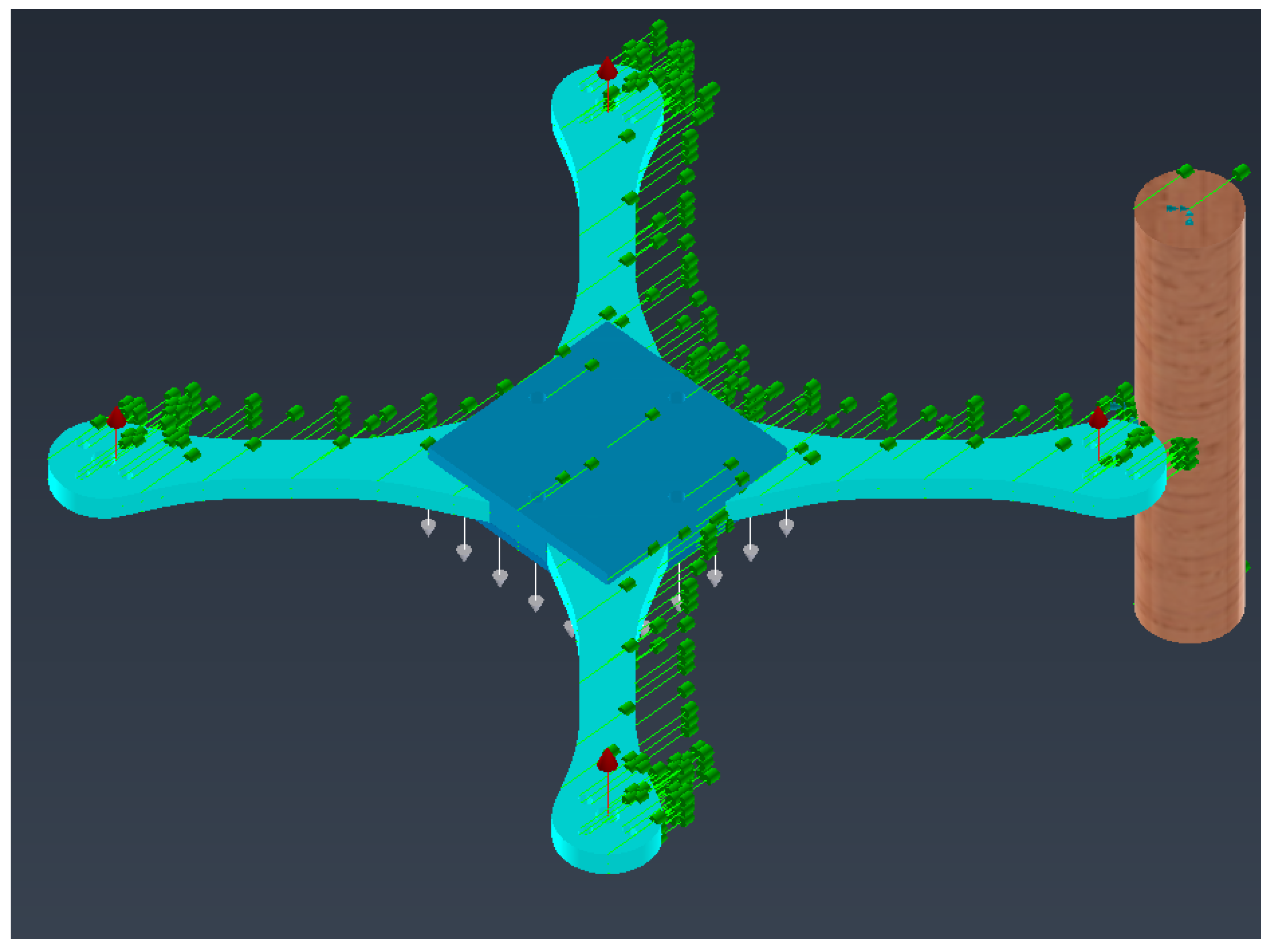

The details of the applied forces can be seen in

Figure 18. The thrust of the motors is simulated by red loads of 0.625 N, the total weight of 250 g by the white load at the bottom of the chassis, and the 11 m/s displacement by green velocity-type loads. The fixed supports of the trunk can also be observed, keeping it immobile.

Finally, the set of boundary conditions (SPC = 1) properly restricts the degrees of freedom not involved in the collision. The nonlinear controlled time step (TSTEPNL = 1) ensures numerical stability in the transient domain. This configuration provides an accurate and realistic representation of the drone’s mechanical behavior during impact, enabling the identification of potential structural failures and critical damage zones.

Two simulations were performed to evaluate the structural response of the drone’s frame during the collision: the first at , corresponding to the initial impact, and the second at , to analyze subsequent energy absorption and redistribution.

At

, the stress distribution shown in

Figure 19 indicates that the most loaded area coincides with a joint node, an artificial stress concentration caused by mesh discretization (see

Figure 20), reaching a maximum value of 29.68 MPa. The diagonal arms (front left and rear right) show tensile and bending stresses at their ends, induced by impact inertia, while the rear left arm remains unloaded, indicating that the frame has not yet fully absorbed the impact energy. It is therefore recommended to extend the simulation to later times.

The maximum recorded displacement is 2.393 mm (see

Figure 21), concentrated in the cross arms, which move forward generating the stresses mentioned above.

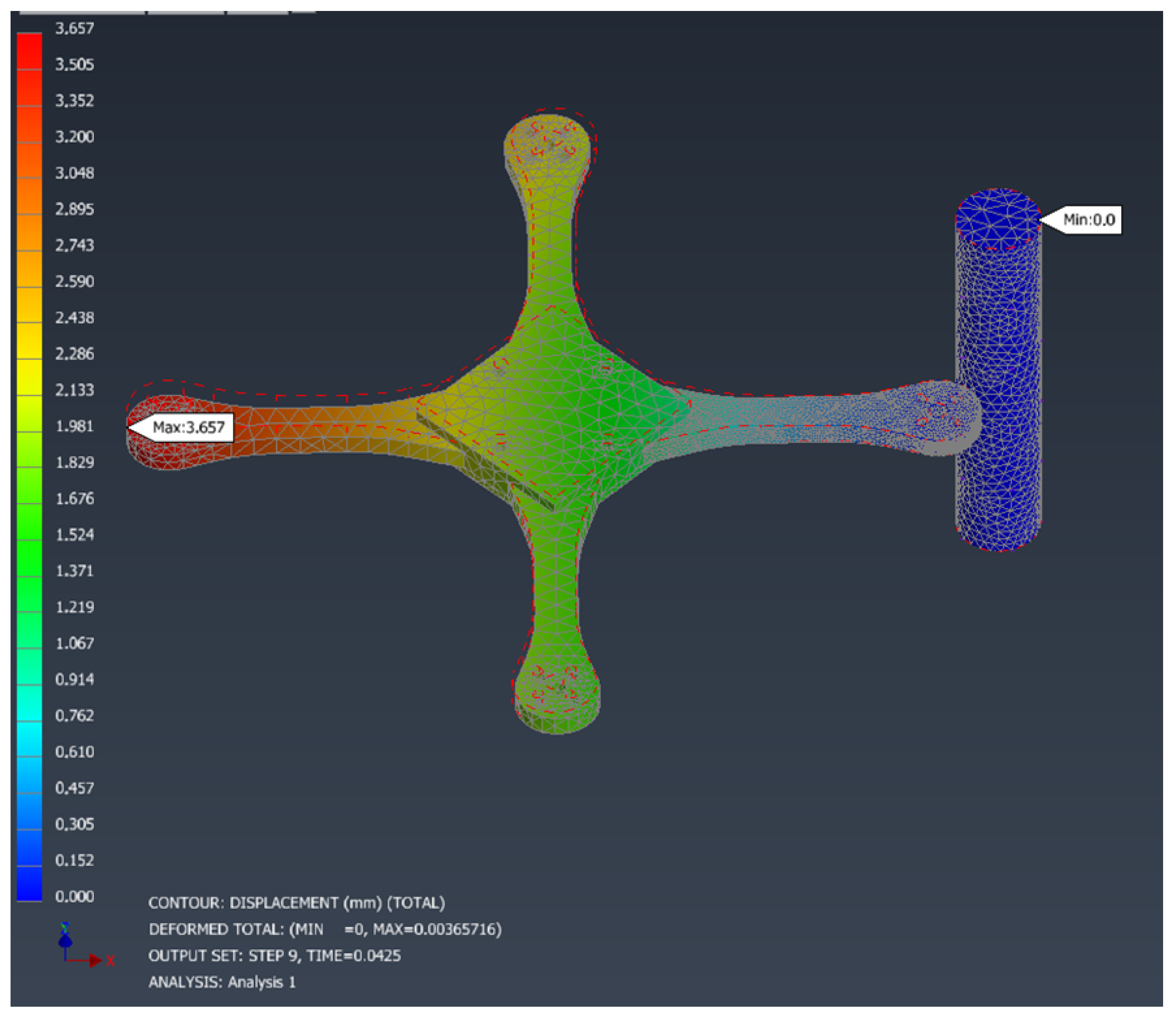

To validate the hypothesis regarding the progressive absorption of impact energy, an additional simulation was carried out at

, keeping the rest of the parameters unchanged. At this stage, it is observed that the rear-left arm presents a maximum displacement of 3.657 mm in the upward direction (see

Figure 22), indicating that the drone has pitched forward as a consequence of the initial impact. This rotation is consistent with the expected dynamic behavior after a frontal collision.

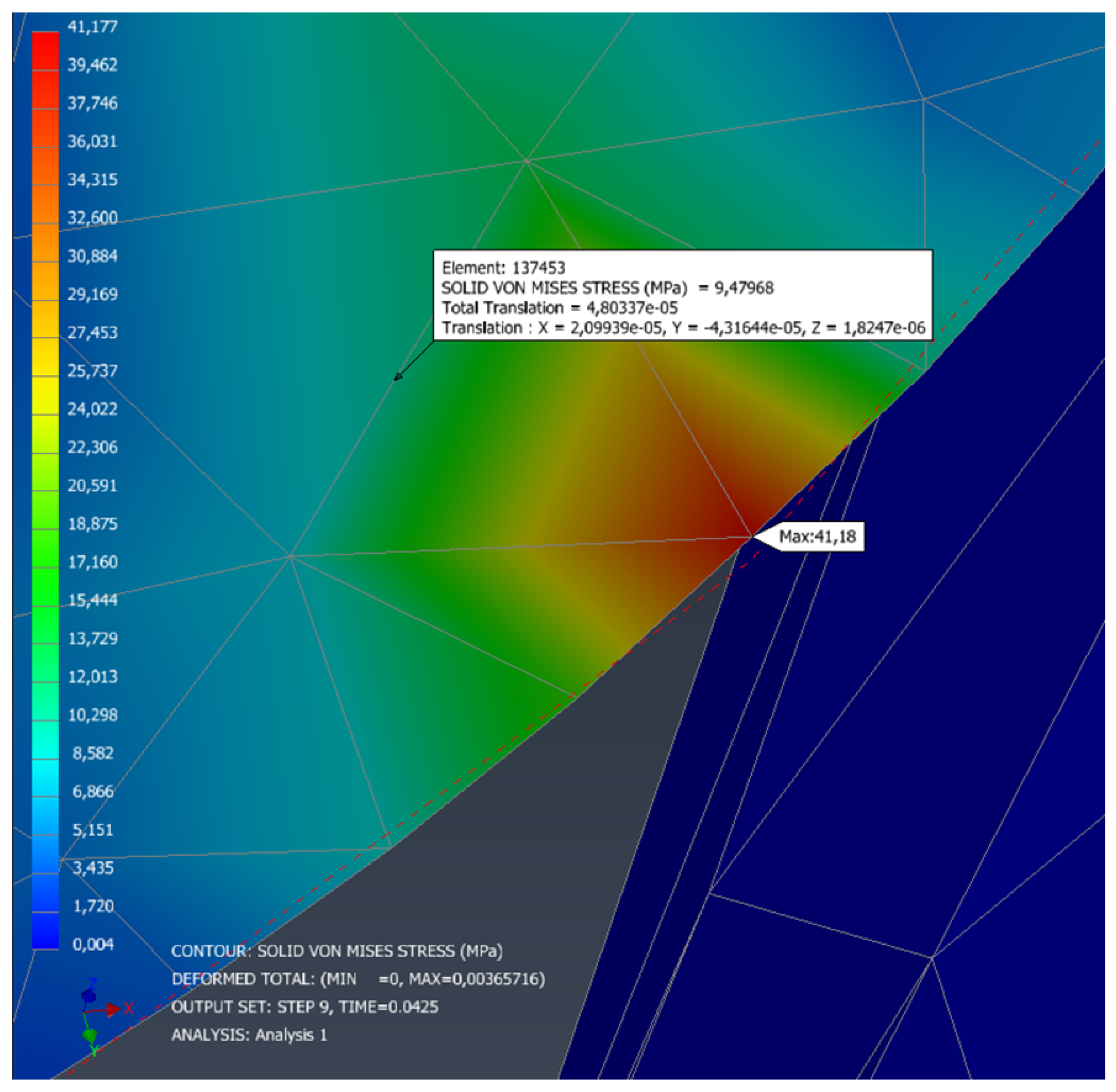

The Von Mises stress reaches a maximum value of 41.78 MPa, located at the same point previously identified as a mesh stress concentration zone (see

Figure 23 and

Figure 24). This increase confirms that this node continues to absorb most of the residual impact energy. On the other hand, the three arms not directly involved in the crash are completely unloaded, showing that the energy has been almost entirely absorbed by the impacted arm. This evolution confirms the initial hypothesis: the drone’s structure channels the energy toward the front arm, enabling localized dissipation that protects the rest of the system.

It is worth noting that the node corresponding to element

137453, located in the impact zone, has been highlighted in order to analyze the origin of the maximum stress point observed in both simulations. This point coincides with the vertex of a region where the mesh converges sharply, generating an artificial geometric discontinuity that acts as a stress concentrator. In both analyzed instants (

, see

Figure 20 and

, see

Figure 24), this element shows a Von Mises stress of 9.47 MPa, supporting the hypothesis that the high stress concentration recorded in that node is mainly due to the mesh configuration, and not to a real physical condition of the system. This analysis reinforces the need to refine the mesh in critical areas to avoid misinterpretations of structural behavior.

In

Table 16, a comparative summary of the maximum displacements and stresses obtained in the two analyzed instants is presented, considering PETG as the base material with a yield strength of 40 MPa.

At

, the Von Mises stress reaches 29.68 MPa, resulting in a safety factor of 1.35, which is acceptable though close to the limit. However, at

, the maximum stress rises to 41.78 MPa, implying a safety factor of 0.96, i.e., slightly exceeding the yield strength of the material. It should be noted that this stress, as previously analyzed, is again concentrated in element

137453, a zone where the mesh forms a sharp vertex. This configuration induces an artificial stress concentration. Therefore, it is concluded that the frame, from a structural point of view, would be safe were it not for this meshing anomaly. A further local mesh refinement in this region is recommended to avoid exaggerated stress readings that do not reflect the real behavior of the material. The safety factors have been calculated based on the PETG yield strength (

):

To validate the FEM results, a simplified estimation of the impact force was performed using the linear momentum principle:

where

kg,

m/s,

m/s, and

s. The resulting average force is:

This value was applied in a static beam model: a cantilever of length mm, rectangular cross-section mm, mm, subject to a inclined load of 27.5 N.

The equivalent bending moment is:

which leads to a maximum stress:

and maximum deflection:

A comparison with FEM simulations is provided in

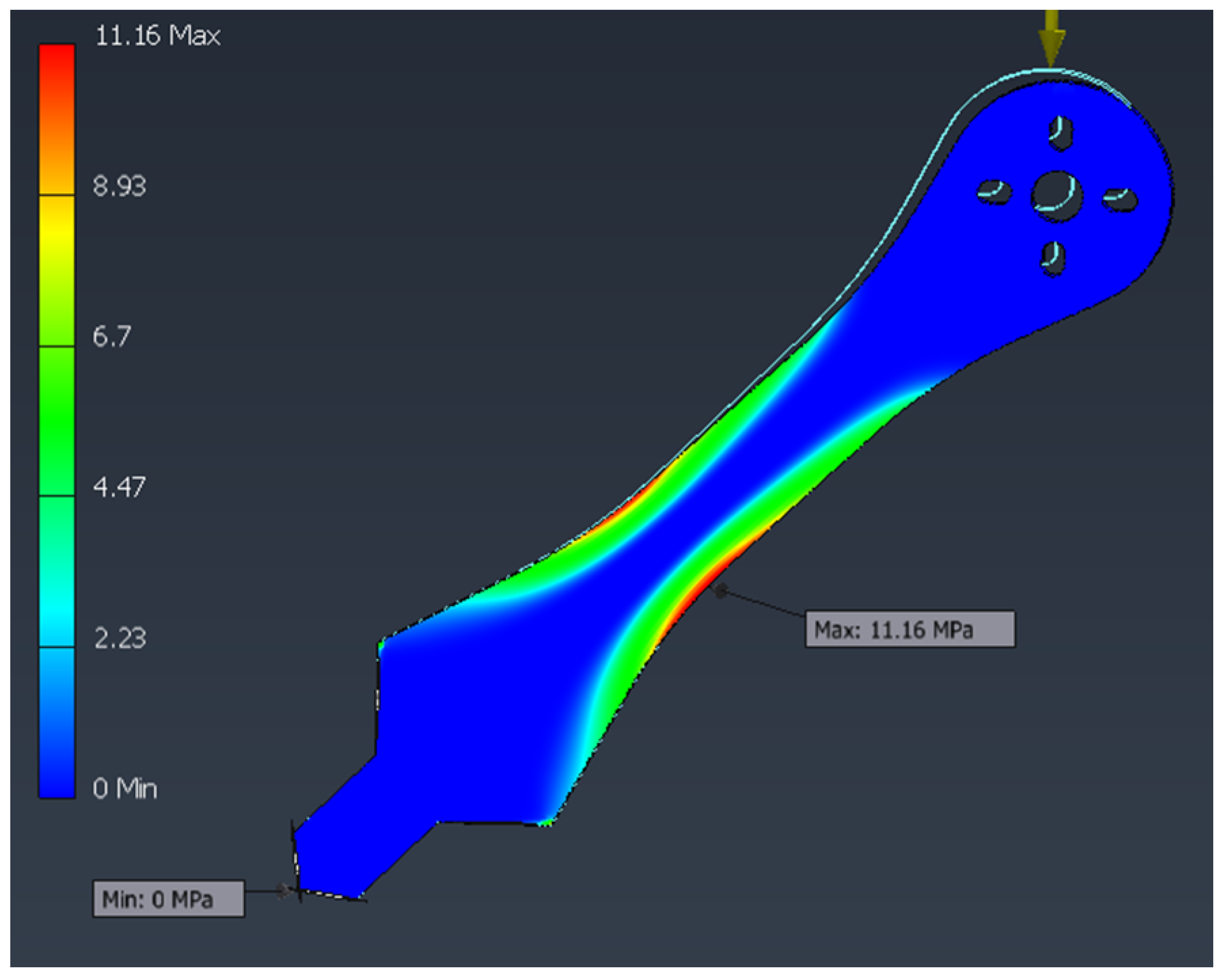

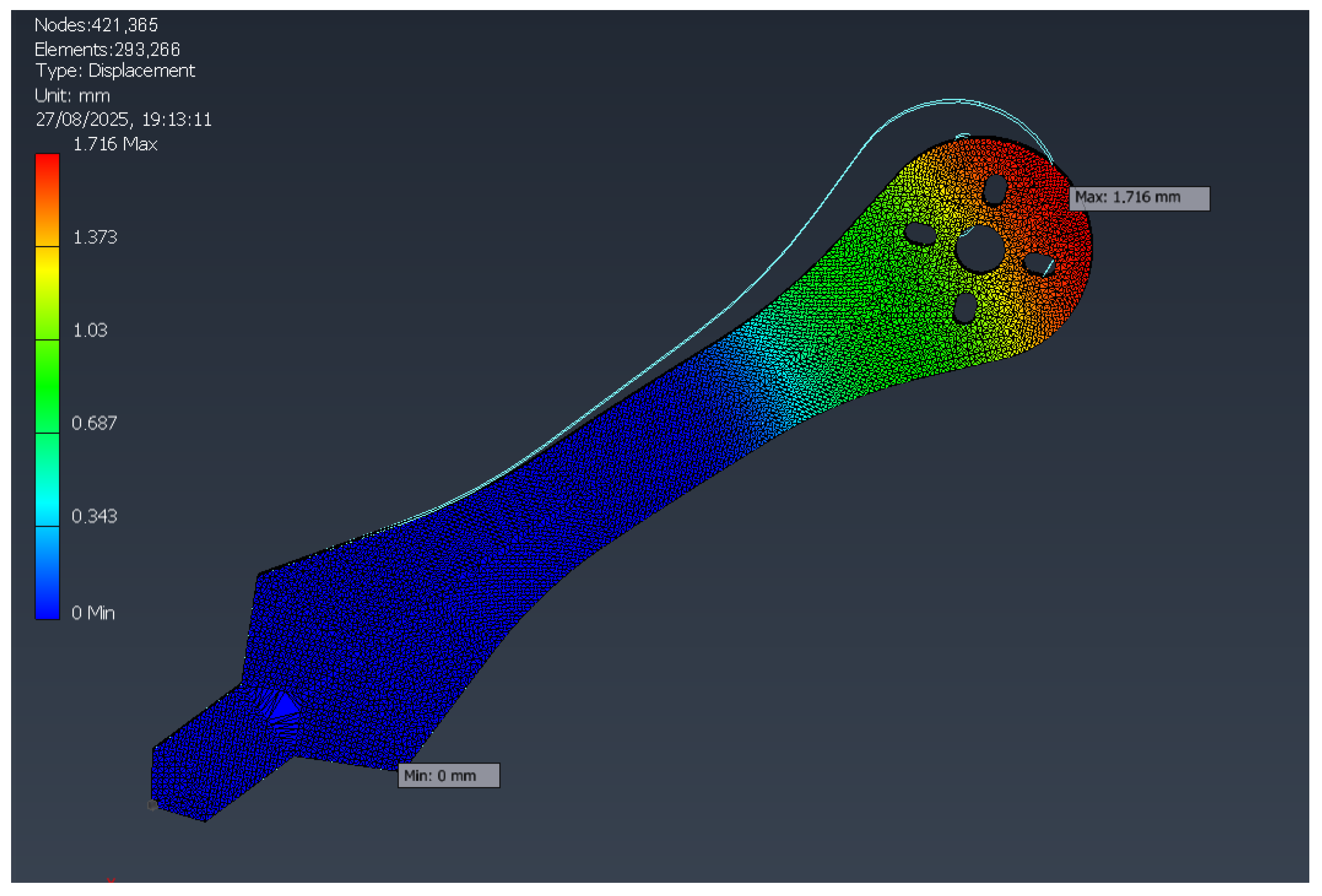

Table 17. The theoretical beam model yields conservative results, with higher stresses and deflections than observed in the full drone assembly, highlighting the structural reinforcement provided by geometry and joints. The corresponding Von Mises stress and displacement distributions are shown in

Figure 25 and

Figure 26, respectively.

Experimental validation

To validate the numerical FEM model under a frontal impact condition equivalent to 40 km/h, a simplified experimental test was performed on a representative segment of the structural frame. The objective of this test was to confirm the order of magnitude of the deformation predicted by the simulations, rather than to obtain statistically representative data.

In the simplified FEM model, the dynamic impact was represented by a punctual load of 27.5 N, applied at an angle of 45° with respect to the horizontal axis. To replicate this in a static experimental setup, the applied load was decomposed into its components. The effective force acting along the principal direction of deformation is given by the following:

This corresponds to the force exerted by a mass of approximately

Therefore, a physical load of 2 kg was used in the test, as shown in

Figure 27.

The test configuration reproduced the same boundary conditions used in the FEM analysis: one end of the structure was rigidly clamped, and the load was applied at the opposite free end. The displacement was measured manually using a precision caliper, yielding a vertical deflection of approximately 1.25 mm.

In comparison, the FEM simulation under identical loading conditions predicted a maximum displacement of

1.716 mm. The deviation between experimental and numerical results can be attributed to the conservative assumptions made in the numerical model, where the material yield strength was intentionally underestimated to account for potential manufacturing imperfections and local stress concentrations. The comparison between the experimental and numerical results is summarized in

Table 18.

Although this test does not reproduce the transient nature of a real crash, it provides a reliable validation of the FEM predictions in terms of stiffness and deformation magnitude. The close agreement between experimental and numerical data supports the adequacy of the simplified modeling approach and confirms that the structure remains within the elastic regime for loads representative of a 40 km/h frontal impact scenario.

In conclusion, this preliminary static test demonstrates the robustness of the FEM model and its capacity to predict realistic deformation levels under equivalent impact conditions, while emphasizing the need for future dynamic testing to capture transient stress distributions and damping effects.

Conclusions

As a conclusive result, the analysis identified the

maximum tension point (node) as the most critical location for evaluating the structural integrity of the drone frame. This node is located on the inner face of the arm subjected to bending stress during the frontal impact, where the highest Von Mises stress value of

21.78 MPa was recorded (see

Figure 24).

Considering the PETG material’s yield strength of approximately 40 MPa, the

safety factor is calculated as:

This value confirms that the frame remains within the elastic regime under the simulated conditions, providing a sufficient safety margin to prevent structural failure.

A summary of the most critical stress condition is presented in

Table 19. The comparison between the nonlinear transient FEM model and the simplified static FEM model reveals significant differences in the predicted stress distribution and deformation response. The simplified model applies a

static point load, which does not account for the

inertial effects generated by the drone’s mass during the impact event. Consequently, it overlooks the dynamic load transfer and energy absorption mechanisms that occur under real collision conditions. These discrepancies underline the necessity of performing a

nonlinear transient analysis, capable of capturing the combined influence of inertia, time-dependent loading, and geometric nonlinearity, thus providing a more accurate and physically consistent representation of the structural behavior during impact.

3.4.4. Nonlinear Transient Analysis: Free Take-Off of the Drone

This section presents the setup and results of the Finite Element Method (FEM) simulation, detailing the modeling approach, applied loads, and boundary conditions used to evaluate the drone’s structural response during take-off.

In this dynamic analysis, the structural behavior of the drone frame is studied under realistic take-off conditions. Unlike the previous maximum-thrust simulation case, the base of the model is unconstrained, allowing the system to accelerate vertically as a natural response to motor thrust.

Forces of 6.38 N per motor are applied (see

Table 20), corresponding to the maximum thrust according to the data sheet. The total mass of the drone is 0.250 kg, and is coherently distributed in the model by the density adjustments described below.

The analysis is performed in Inventor Nastran using a nonlinear transient scheme, capturing accelerations, deformations, and both material and geometric nonlinear effects.

The analysis was configured using the numerical parameters listed in

Table 21, where the applied mass adjustments are also presented.

Mass distribution: although only part of the drone (core and arms) was simulated, densities were adjusted so that the model faithfully represents the total 250 g mass:

Mass of arms and original cover: 38 g

PETG density: 1.27 g/

To balance the total mass, the density of the core cover was artificially increased to 22.352 g/, achieving a total mass of 250 g without using non-physical external gravity loads.

The peak values obtained during the analysis are summarized in

Table 22. Maximum acceleration, velocity, and displacement are lower than predicted by theoretical models because part of the energy is absorbed by elastic deformations in the arms during ascent.

The maximum Von Mises stress obtained was 7.576 MPa. Considering the PETG yield strength of 40 MPa, the safety factor is calculated as follows (see

Table 23):

In

Figure 28, the Von Mises stresses, the first and third principal stresses, as well as the maximum deformation in the drone arms during free take-off, can be observed.

Table 24 compares the main mechanical results of a static fixed-base model versus the dynamic free-takeoff model.

The comparison between the static and nonlinear transient analyses reveals that, although the Von Mises equivalent stress remains nearly unchanged in magnitude, the internal stress distribution experiences a marked transformation. In the transient case, the third principal stress ()—associated with local compression—increases significantly (from approximately in the static analysis to about ), while the total displacement is substantially reduced due to the free-base condition during take-off. Consequently, the safety factor decreases slightly, from 5.52 to 5.28, reflecting a more realistic and demanding load scenario.

This behavior can be explained by the dynamic response of the structure when it is allowed to move freely. Under transient conditions, part of the external load is converted into acceleration rather than deformation, so the system exhibits lower global strain but higher localized stresses. The inertial resistance of the mass acts to oppose deformation, concentrating compressive and shear stresses in specific regions such as the central hub and arm roots. Additionally, geometric reorientation and mode coupling between bending and torsion during motion generate complex triaxial stress states that amplify .

The fact that the Von Mises stress remains almost constant indicates that the total strain energy stored in the structure is similar between both analyses. However, its directional composition changes substantially: dynamic effects redistribute the load in space and time, producing higher compressive peaks without a proportional increase in the overall energy density. This explains why the transient case shows stronger local compression but comparable global stress magnitude.

In summary, the nonlinear transient analysis captures the realistic dynamic load redistribution that occurs during take-off: inertia reduces deformation but enhances local compression, modifying the internal stress balance and slightly reducing the global safety factor. This highlights the importance of performing transient dynamic simulations to accurately predict stress concentrations and potential critical regions in lightweight aerospace structures.

This subsection validates the nonlinear transient analysis results by comparison with an analytical rigid-body model without damping, assuming instantaneous thrust application at .

Total thrust from four motors:

Resulting constant acceleration:

Simulation results (t = 0.15 s) using nonlinear transient analysis:

A comparison between the analytical rigid-body calculations and the nonlinear transient simulation results is presented in

Table 25, highlighting the differences in acceleration, velocity, and displacement of the drone during take-off.

The comparison shows very good agreement between the nonlinear transient FEM simulation and the simplified analytical model. Slight differences are observed due to:

Elastic deformation of the arms absorbing part of the thrust energy.

Dynamic redistribution of mass in the flexible structure.

Time integration and damping effects in the FEM solver.

Overall, the FEM model provides realistic results with a safety factor above 5, confirming the structural adequacy of the drone frame for take-off conditions.

3.4.5. Forward Flight Simulation: Pitch–Moment Maneuver

To analyze the dynamic behavior of the drone during a forward manoeuvre, a nonlinear transient simulation was carried out in which a differential thrust is applied between the front and rear motors. This condition generates a pitch moment that tilts the drone forward, replicating the real operational mode during horizontal flight.

For this analysis, different forces are applied to the front and rear motors:

Given that the maximum thrust per motor is 6.38 N, the relative

throttle percentage applied to each pair of motors is as follows:

This thrust difference generates a net moment around the lateral axis (pitch), causing a forward tilt. In a real drone, this type of differential control is used precisely to induce forward movement while maintaining dynamic equilibrium.

During the simulation, the frame is fully released (no rigid constraints), allowing the free evolution of the system over time under these unbalanced forces. A nonlinear transient analysis is again employed to capture the interaction between inertia, acceleration, and structural deformation.

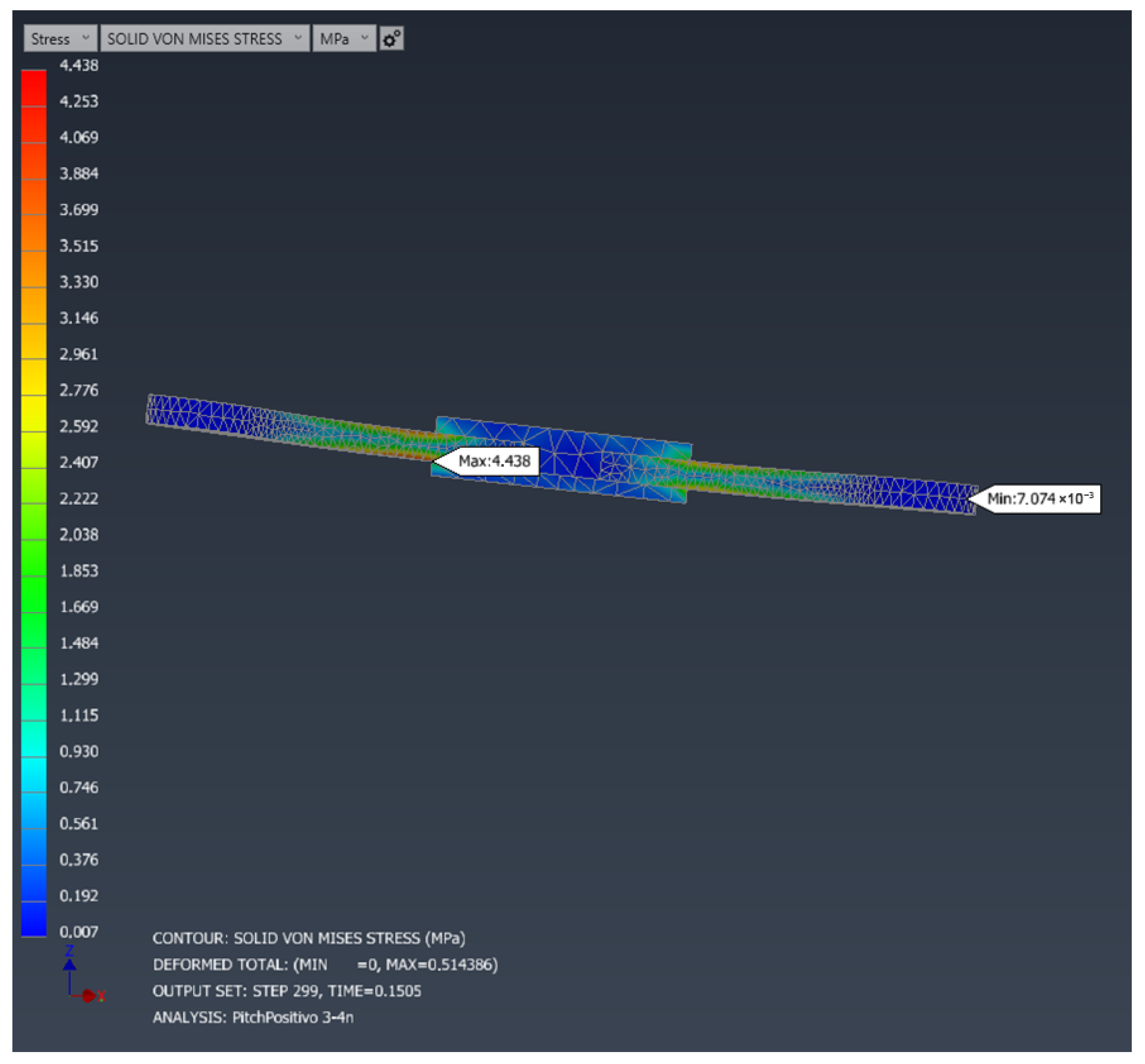

This scenario evaluates both the structural behavior of the frame under asymmetric dynamic conditions and the design feasibility during real control manoeuvres. The observed tilt in the simulation confirms that the model responds correctly to the applied moment, reproducing an initial forward trajectory as expected in real operation.

The simulation was performed with the same parameters as the maximum thrust study, using a time step of 0.001 s up to a total time of 0.15 s. The results at that instant are as follows:

Maximum Von Mises stress: .

Estimated safety factor: .

Final velocity: /.

Approximate average acceleration: /.

Z-axis displacement: .

X–Y plane displacement: .

These results match the expected behavior: the differential thrust causes a slight tilt of the drone, but the applied throttle percentage is not sufficient to generate significant forward motion. Most of the displacement occurs along the vertical axis (Z), while horizontal translation (X–Y) is minimal. It is concluded that, at this thrust level, the induced pitch does not produce significant forward movement, indicating that a higher thrust difference or longer impulse duration would be necessary to achieve effective forward motion.

The simulation conditions for the pitch maneuver are summarized in

Table 26, and a representative image of the FEM simulation is shown in

Figure 29.

This section extends the model validation to a more complex control manoeuvre: a forward pitch ascent. Asymmetric thrust forces are applied instantaneously to the front and rear motors, generating both vertical acceleration and angular rotation. The objective is to compare the results with a rigid-body, undamped analytical model, evaluating both translational and rotational behavior of the drone, and to validate the fidelity of the nonlinear transient FEM simulation. The corresponding displacement field obtained from the simulation is shown in

Figure 30.

At

, the rear motors apply 4

each, while the front motors apply 3

each, generating a total thrust and a net pitching moment:

The drone weight is as follows:

The net vertical force is therefore

Producing an ideal vertical acceleration of

After

, the corresponding velocity and displacement are as follows:

The asymmetric thrust produces a torque about the pitch axis. Considering the front–rear distance

, the resulting moment is as follows:

With a moment of inertia

, the angular acceleration is as follows:

Integrating over the time interval

gives the following:

Hence, the inclination angle after

is approximately

. Using this value, the horizontal acceleration becomes as follows:

and the corresponding horizontal displacement at

is as follows:

The simulation was carried out in Inventor Nastran under the same conditions as those used in the previous section, but the thrusts were modified according to the asymmetric configuration (4 N rear, 3 N front). The results at

were as follows:

The comparison between the analytical and FEM simulation results is shown in

Table 27.

The differences between analytical and FEM results remain below 10%, confirming the physical consistency of the model. The small deviations are mainly attributed to the structural flexibility of the drone arms, which absorb part of the mechanical energy during thrust application. This causes slightly lower accelerations and displacements compared to the ideal rigid-body prediction, a behavior consistent with real physical response.

The results demonstrate that the structural model behaves coherently under asymmetric thrust, reproducing both the expected vertical motion and the onset of pitch rotation. The good agreement between analytical and numerical results confirms the model’s validity for simulating dynamic manoeuvres, supporting its application to more complex control and flight analyses.