4.2. Simulation and Flight Result Analysis

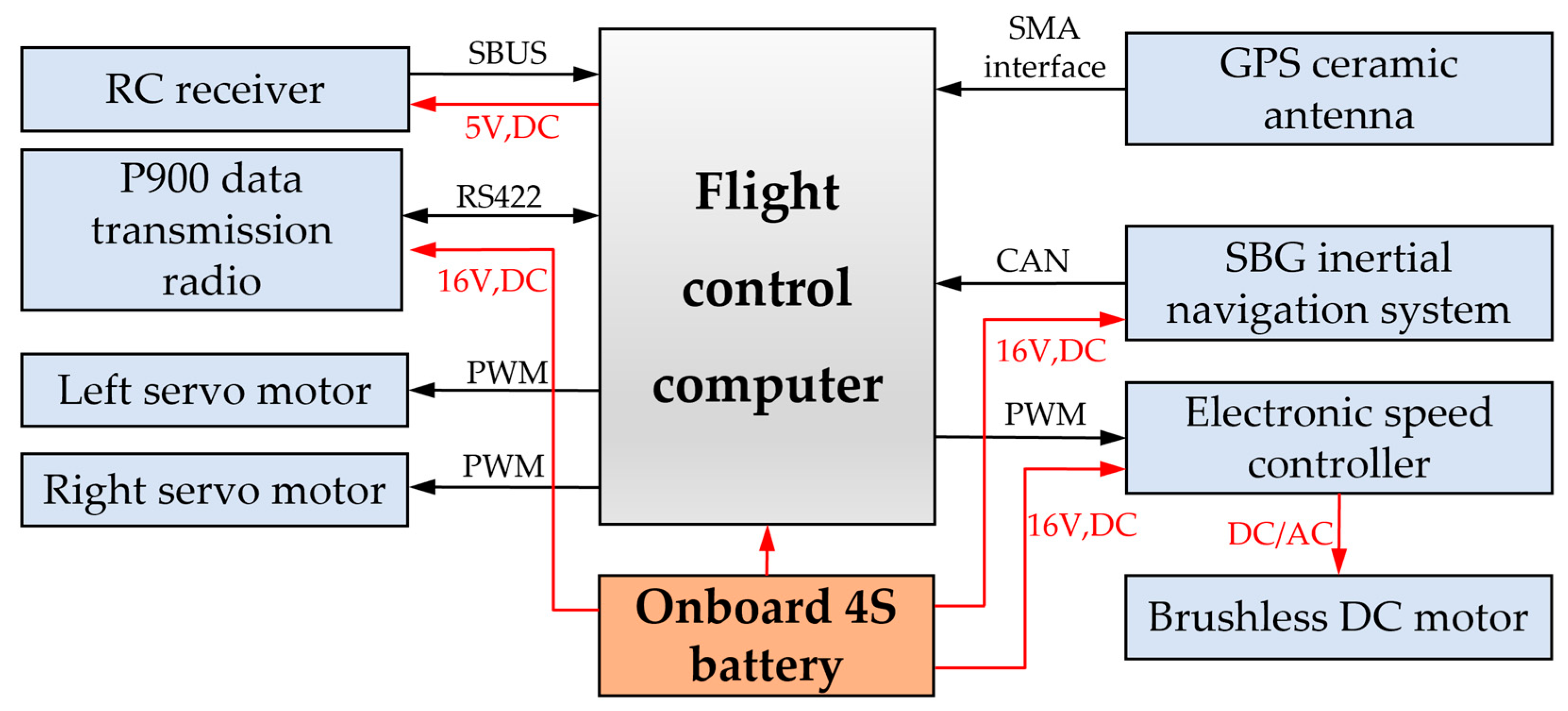

The UAV’s avionics connections are shown in

Figure 12. The entire system is powered by a single onboard battery. The propulsion system employs a brushless DC motor. Attitude and overload data are collected by an external inertial navigation unit and transmitted to the flight control computer via the CAN protocol. The GPS antenna adopts a ceramic patch antenna, which allows installation on the compact airframe without compromising aerodynamic performance. The UAV communicates with the ground control station through a data radio. Additionally, for flight test safety, the flight control computer includes a reserved interface for an RC receiver, enabling manual intervention via remote control during emergencies.

The automatic pull-up flight test setup is shown in

Figure 13a. The carrier aircraft lifts the entire UAV to an altitude of 350

from the ground by suspending it via a tether attached to the propeller nut. After reaching altitude, it hovers while awaiting release. As shown in

Figure 13b, when release is required, the operator sends a signal through the remote controller to the RC receiver, commanding the servo to move the rocker arm and release the tether, causing the UAV to separate from the carrier aircraft under gravity.

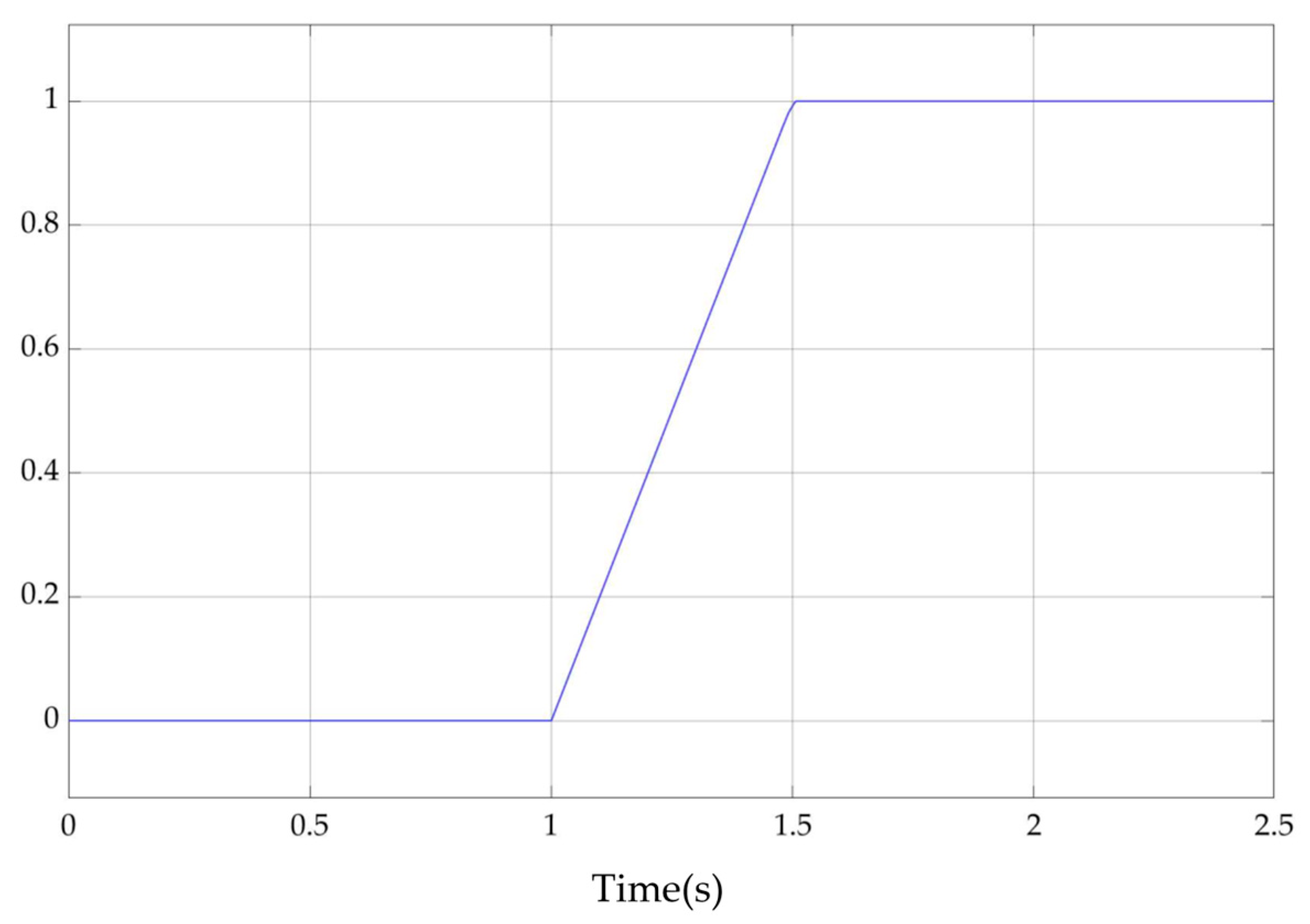

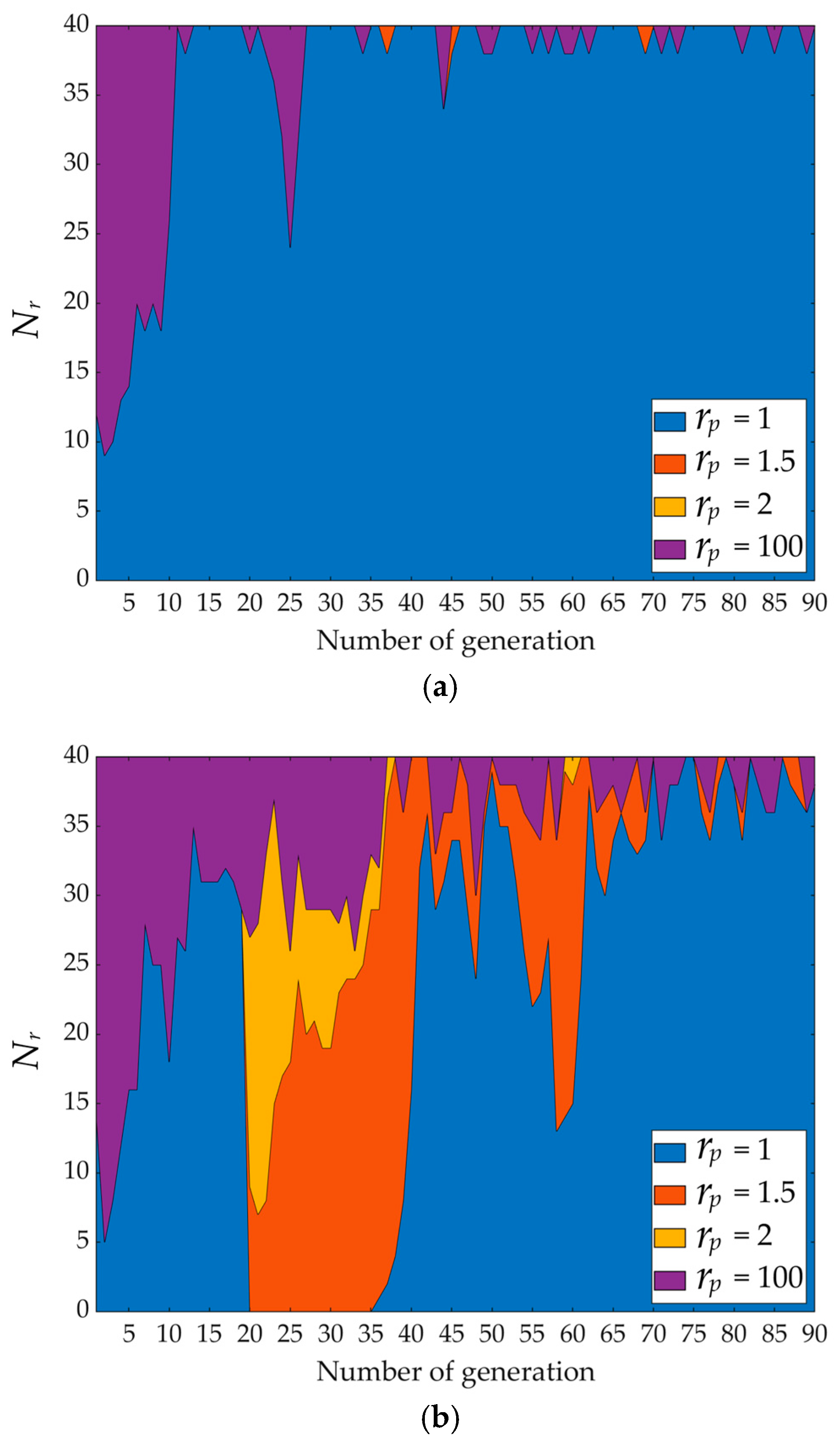

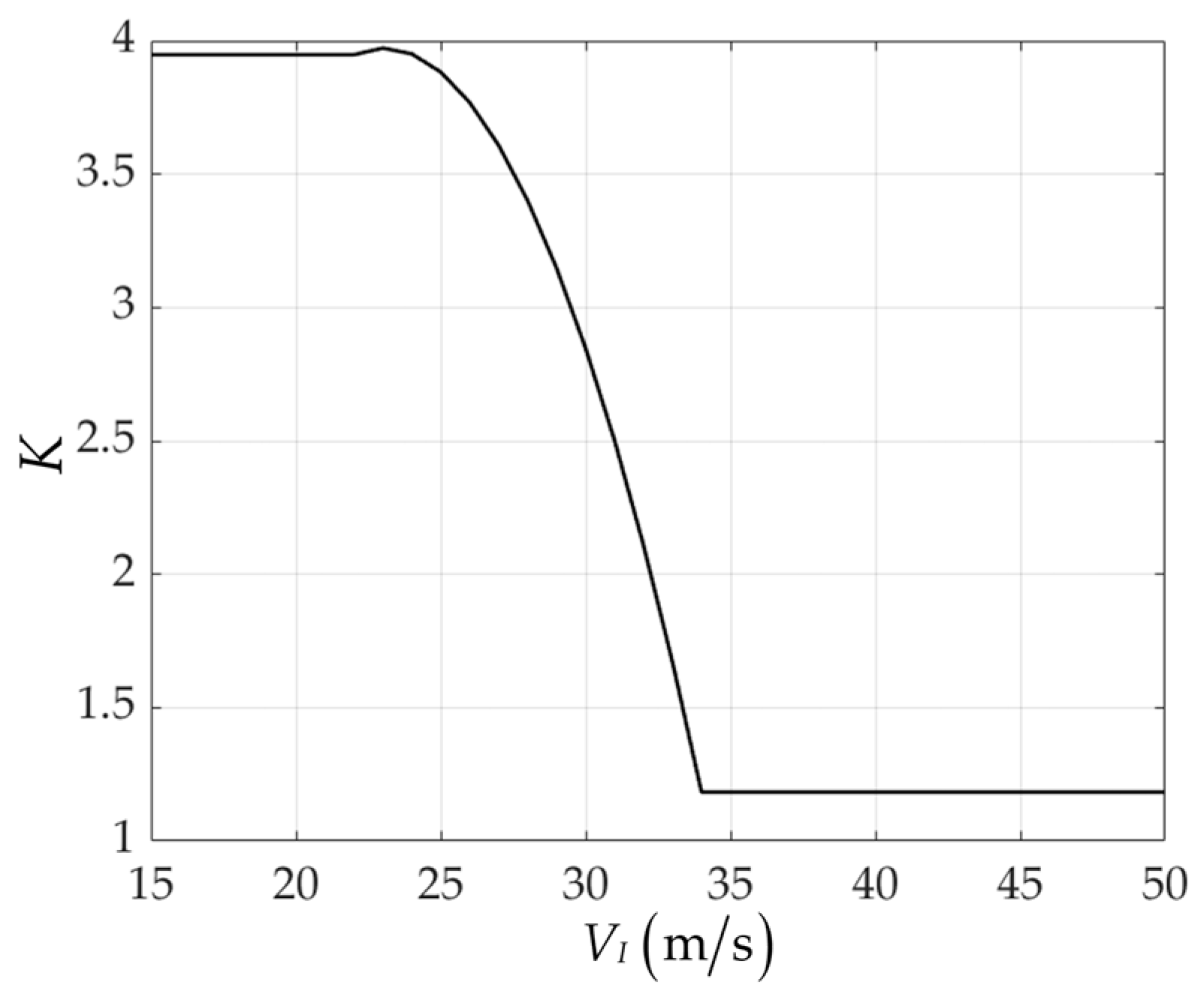

After optimizing the controller parameters, the resulting values for

,

, and

are 0.254, 0.00058, and 0.0137, respectively. The variation in parameter

with

is shown as 0. As shown in

Figure 14,

’s lower limit is set at the UAV’s stall speed of 22

, while the upper limit prevents the controller gain

from becoming negative due to increased control surface effectiveness at higher airspeeds. Overall,

decreases as

increases because higher

enhances control surface effectiveness, requiring reduced parameter values to maintain stable control.

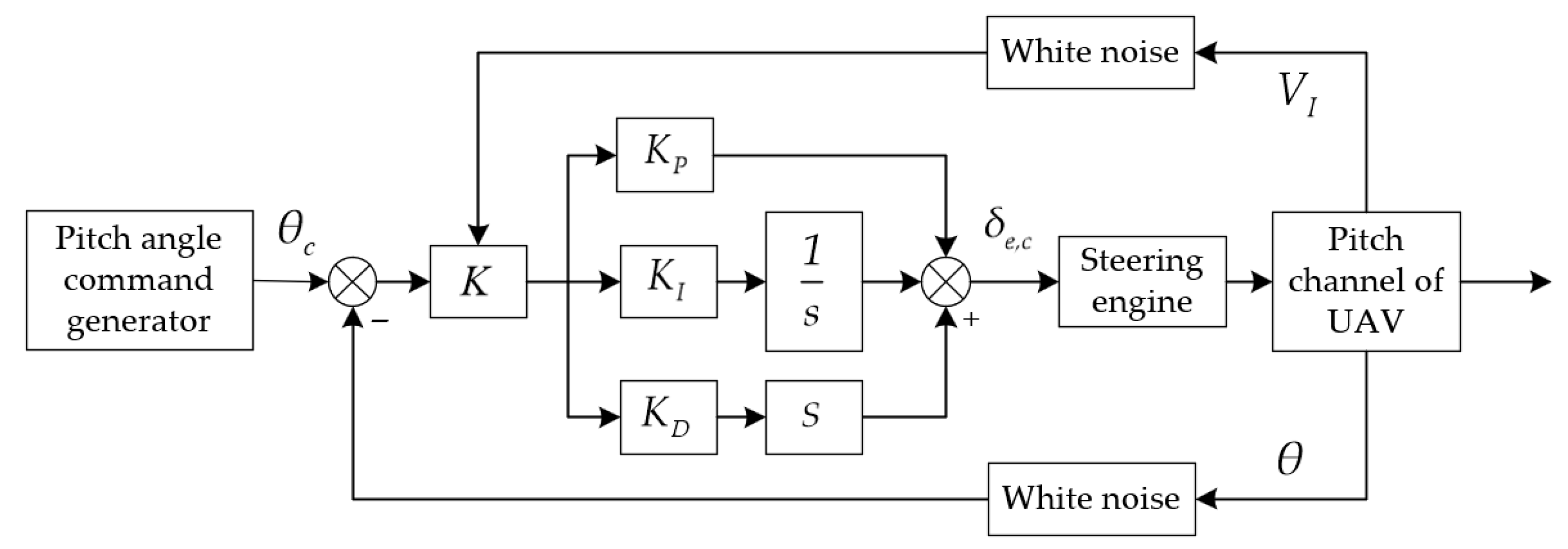

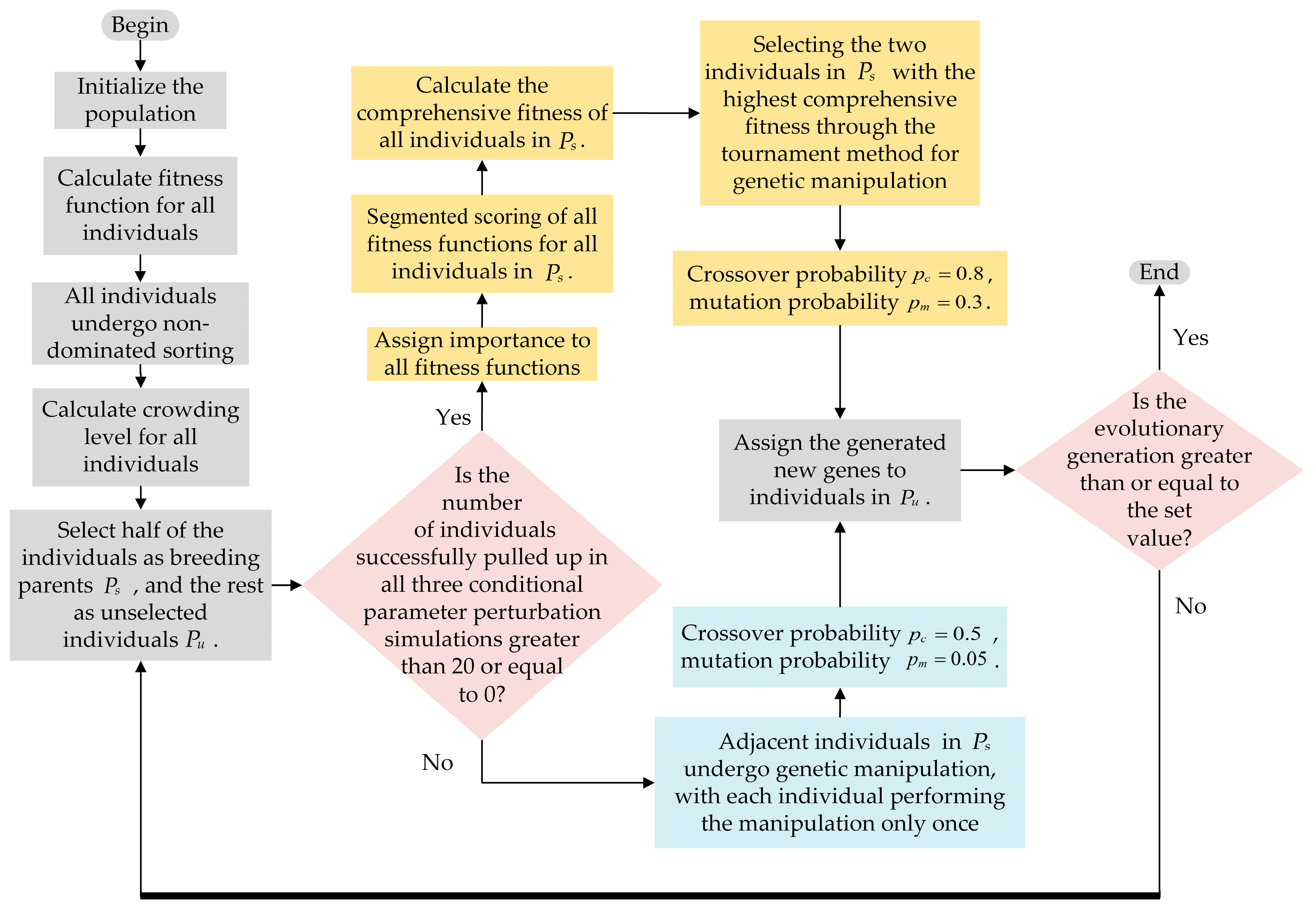

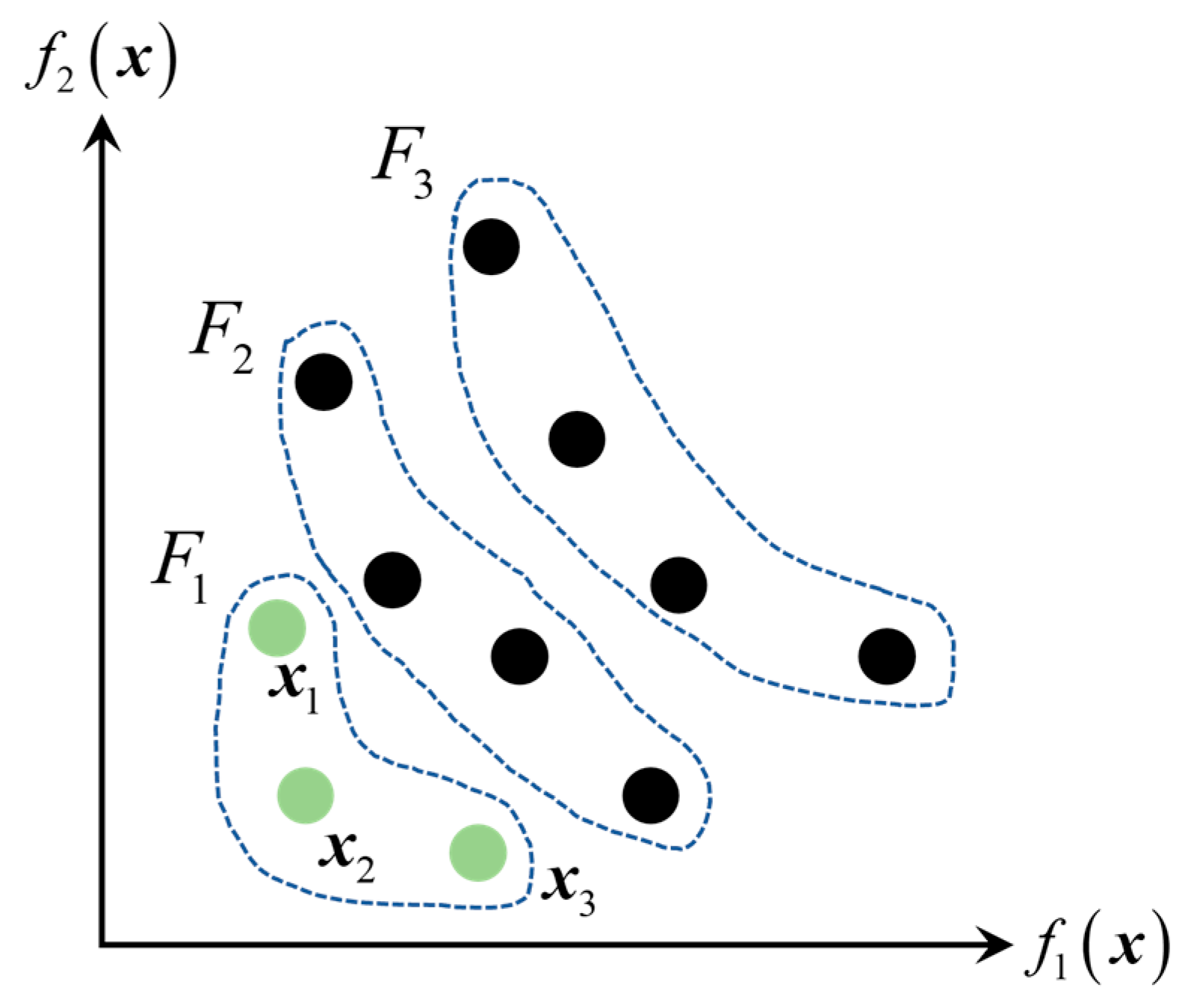

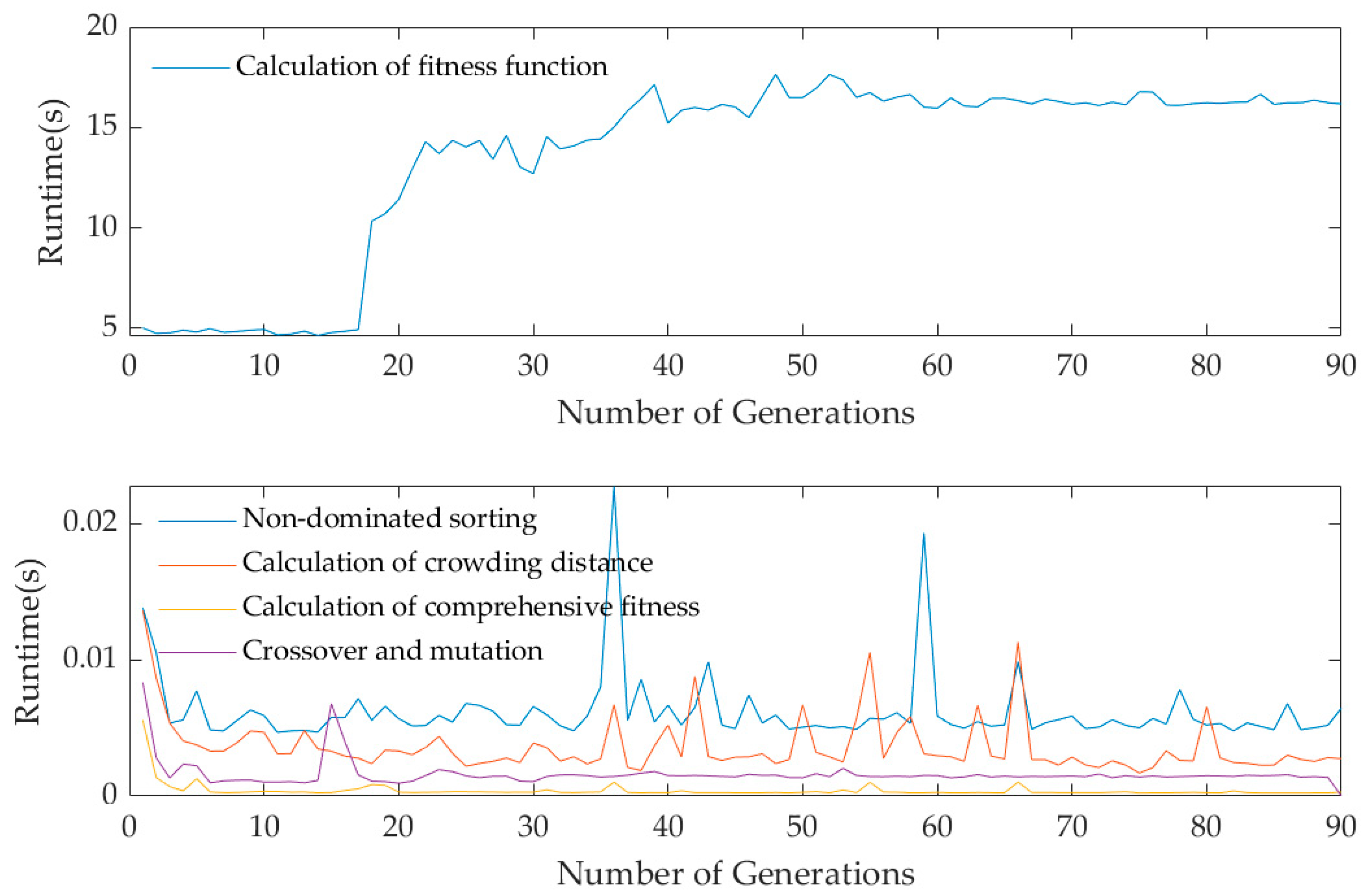

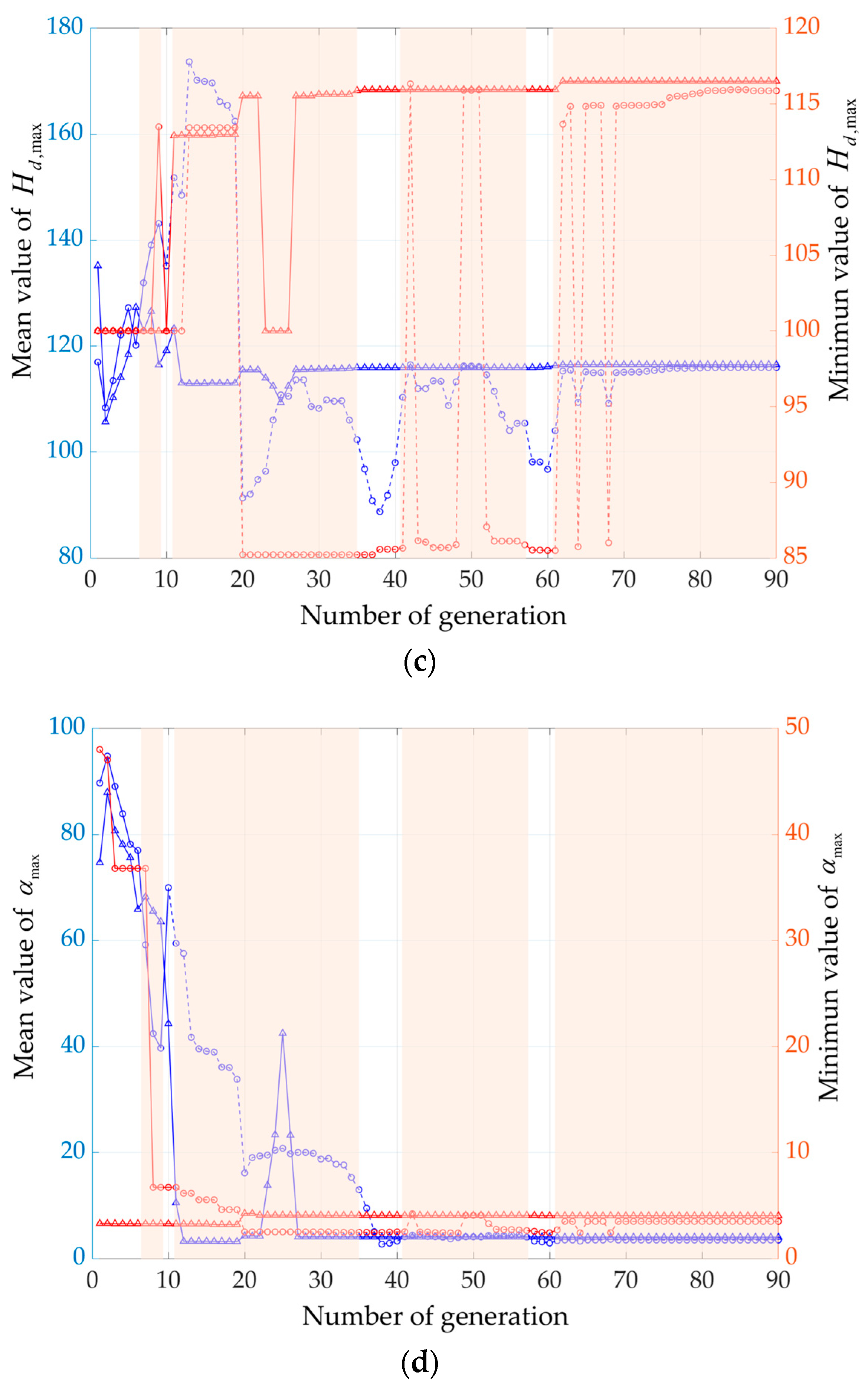

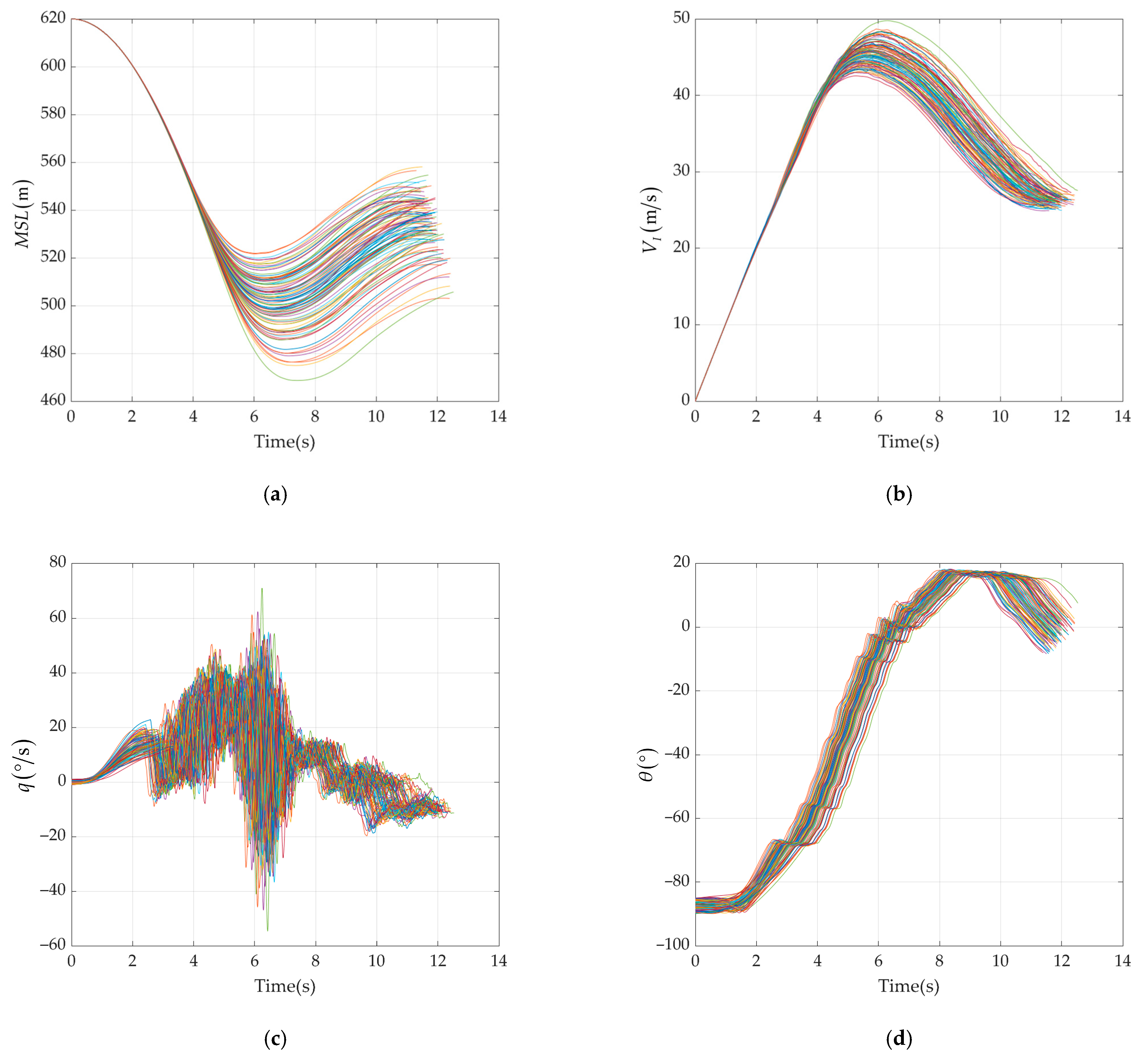

In order to further ensure the robustness of the controller, 100 simulations under random perturbation of conditional parameters were conducted. In addition to the aerodynamic parameters, mass and moment of inertia, initial attitude of the UAV, control surface deflection dead zone, and thrust mentioned in

Section 3.2, constant wind and turbulent wind were also included in the perturbation parameters. Due to the low probability of encountering wind shear, it is not considered here. The perturbation range of constant wind speed is 0~10

, and the wind direction is downwind or headwind relative to the initial yaw angle. The Dryden model is used to measure turbulent wind speed at a height of 6

above the ground, with a perturbation range of 0~10

. The perturbation range of turbulent wind occurrence time is 0~15

after release. In addition, white noise with a signal-to-noise ratio of 1 dB has been added to the input parameters

,

, and

of the controller. The simulation results are shown in

Figure 15.

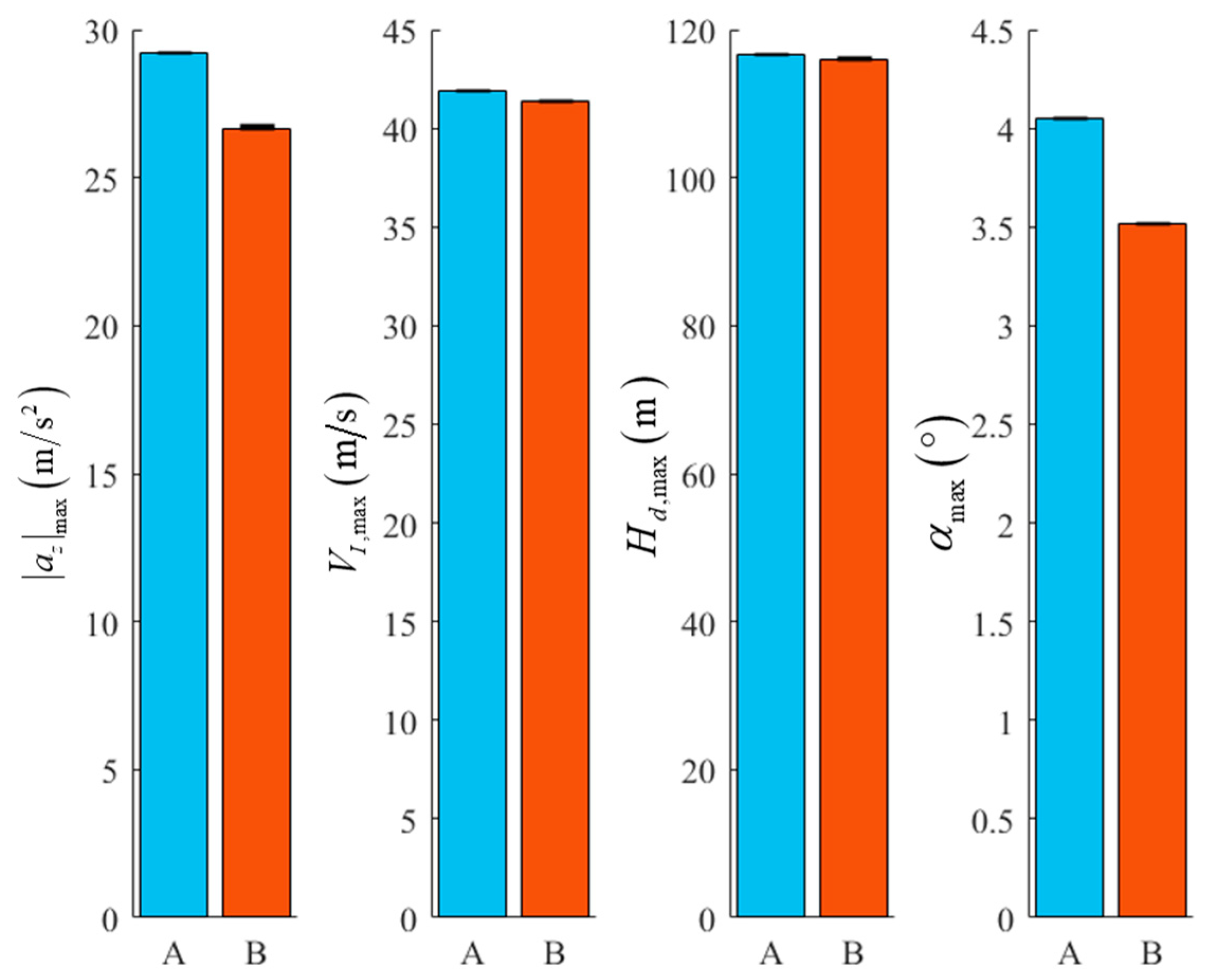

The most extreme values of various indicators in the simulation results are summarized as follows:

From

Figure 15 and

Table 9, it can be seen that the controller has good robustness under the given simulation conditions and can enable the UAV to pull up stably and safely.

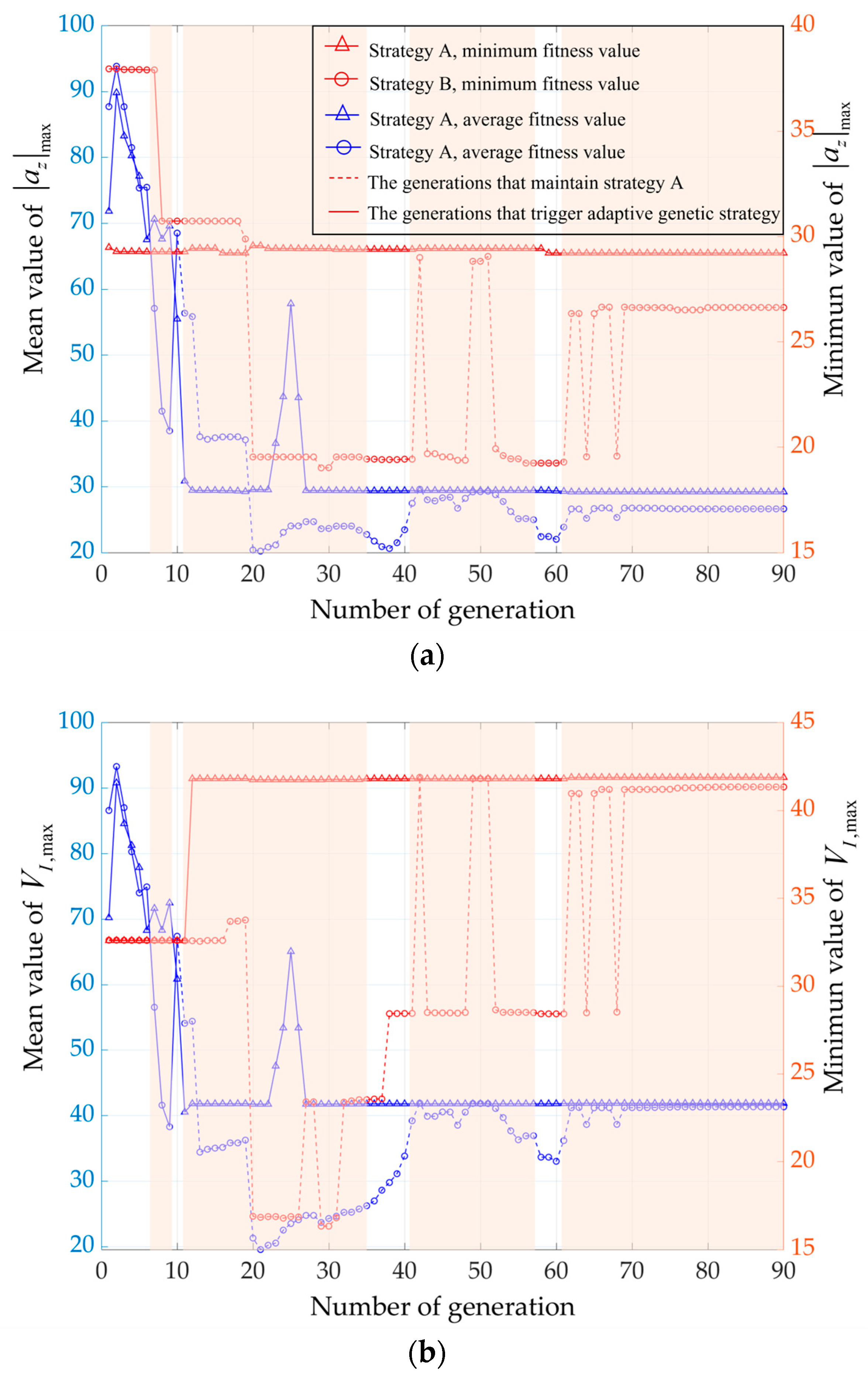

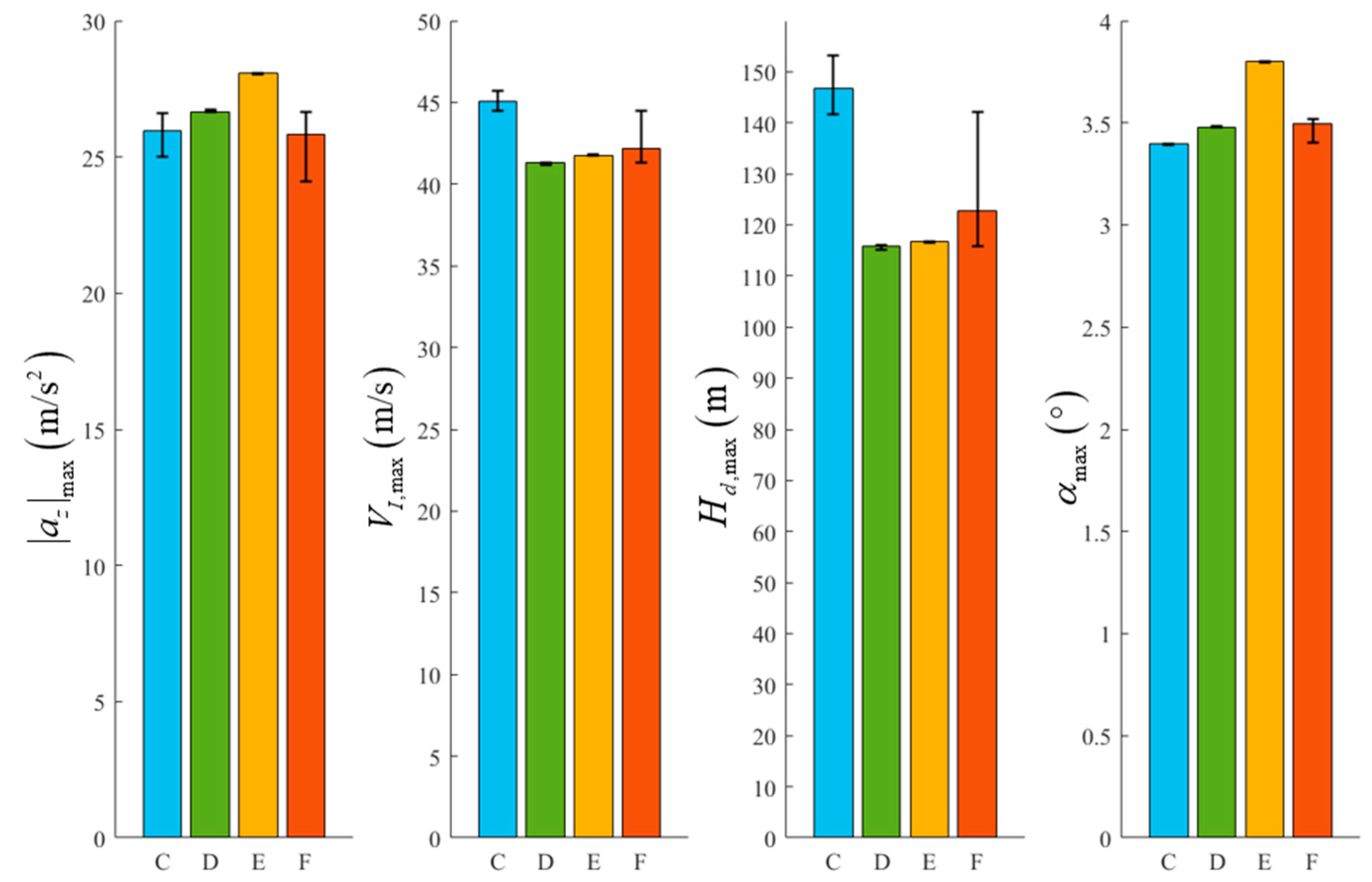

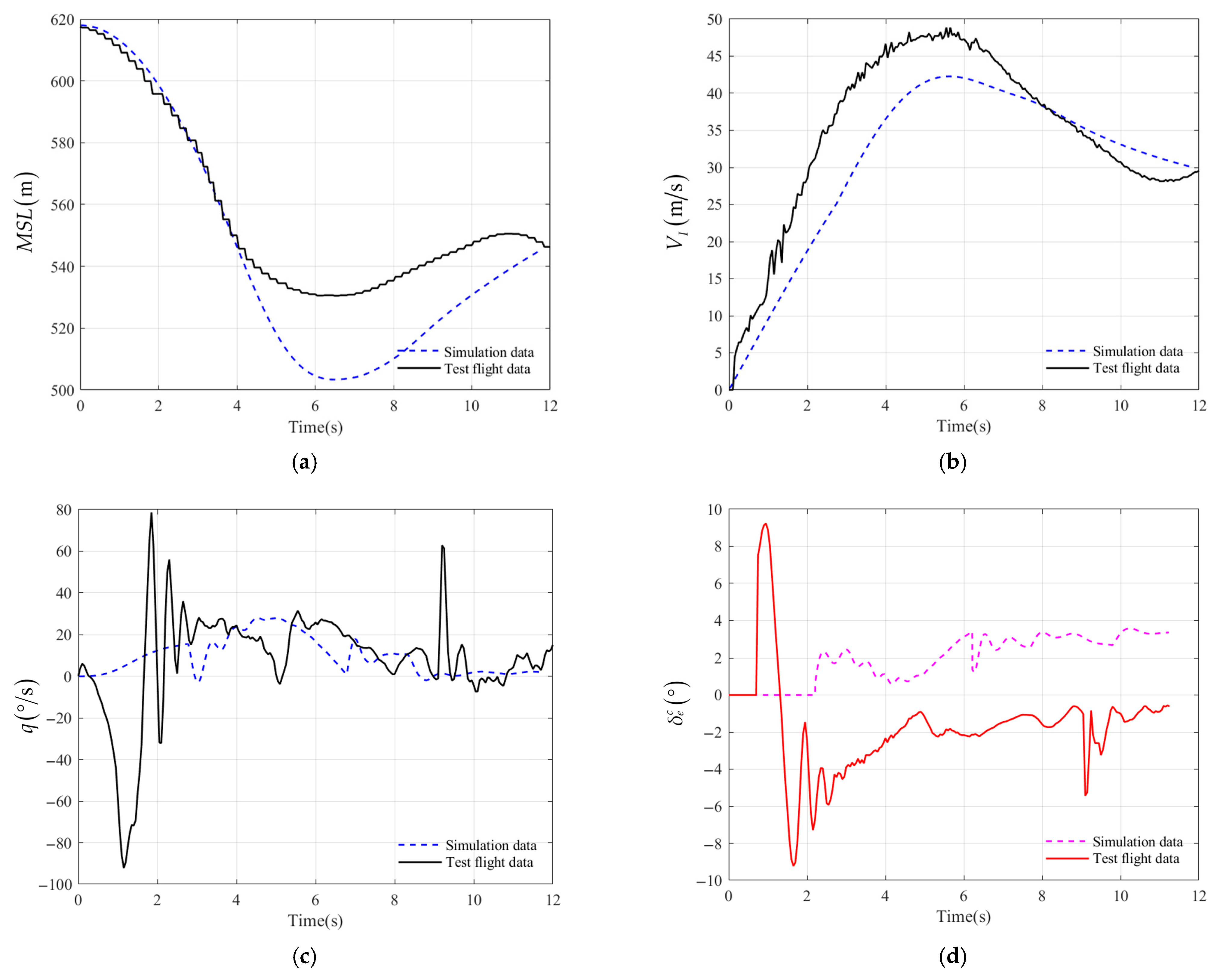

Figure 16 compares the simulation results under nominal conditions with the flight test results. In the simulation, the UAV is released at an altitude of 620

, with an initial velocity of 0

. All angular velocities are 0, and the initial attitude angles are

. The trends in altitude, indicated airspeed, and pitch angle during the pull-up process are generally consistent.

As shown in

Figure 16, in the flight test, the UAV initially exhibits a pitch angle of approximately

at release due to wind conditions and rotor wash from the carrier aircraft. This initial condition also results in significant oscillations in the pitch rate

and pitch angle

during the early stage after UAV being airdrop.

In order to clarify the degree of matching between the nominal condition simulation results and the flight test results, the values of indicators such as maximum descent altitude

, maximum airspeed

, pitch angular rate range

, maximum normal overload absolute value

, elevator command range

, time to enter the pull up

, duration of the pull-up process

, and the time when certain indicators reach their maximum values were selected. These data are listed in

Table 10.

Based on

Table 10 and combined with flight test conditions, the following analysis was conducted:

1. As shown in

Figure 16a,b, during the flight test, the

of the UAV was 23.3% lower than the simulation, resulting in a 15.8% increase in

compared to the simulation. However, the time at which these two variables reached their maximum values was almost the same.

2. As shown in

Figure 16c, the influence of wind led to a significant increase in the

of UAV during flight testing compared to simulation results. It is also reflected in the range of elevator command

, which is shown in

Figure 16d.

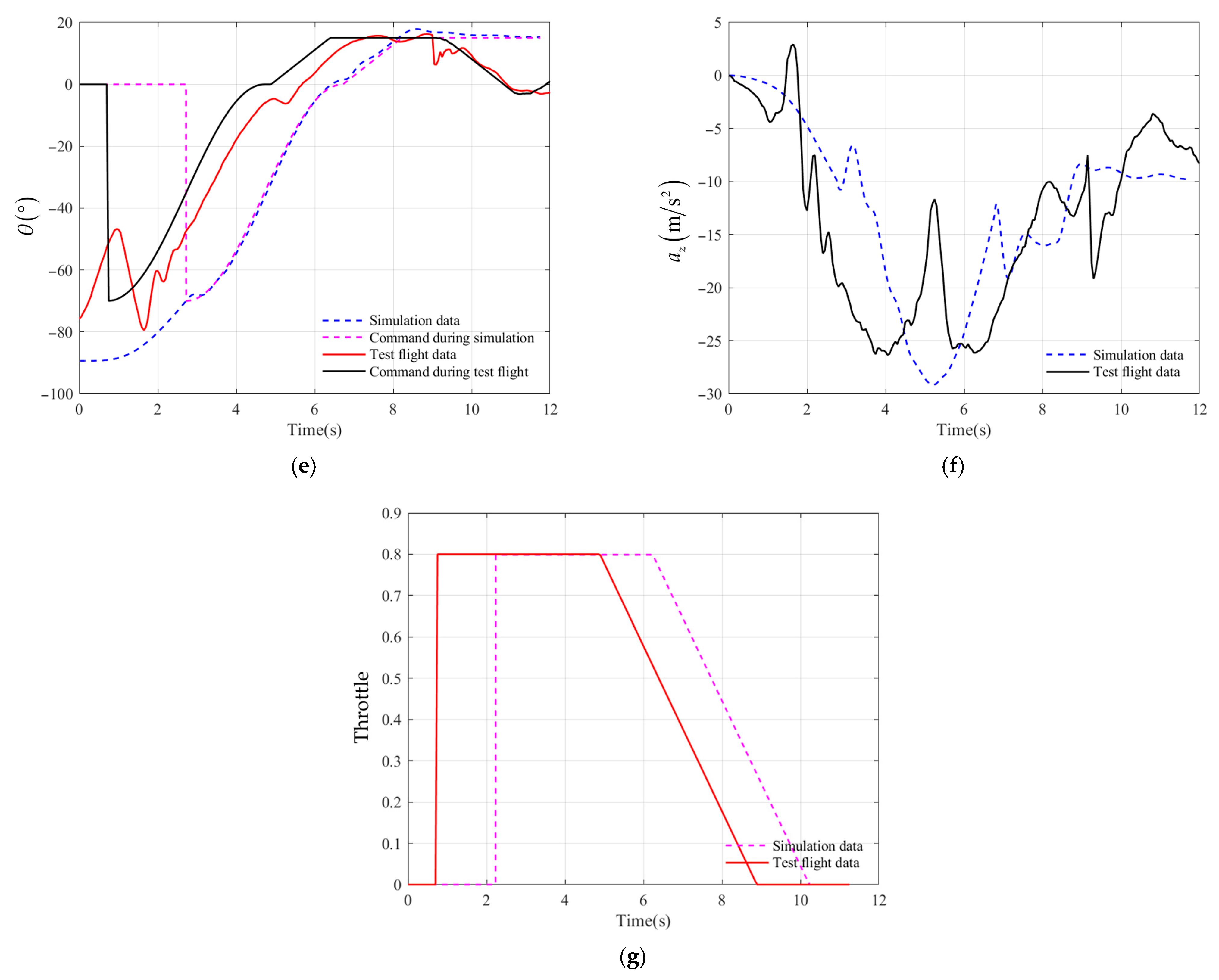

3. As shown in

Figure 16e, the influence of wind causes the pitch angle

to reach the pull up condition earlier during the flight test (

), and the pitch rate

is also oscillating, resulting in

reaching its maximum value, 1.2

, earlier than the simulation, which is shown in

Figure 16f. Due to the smaller velocity

at this time, it is 9.6% lower than the simulation.

4. As shown in

Figure 16g, at 0.75

after airdrop, the throttle command remains constant at 0.8, indicating that the inner-loop PID controller begins intervention. Between 1.15

and 3.05

, oscillations occur in

,

, and

, and they then gradually converge, demonstrating the controller’s capability to mitigate initial condition effects and its inherent robustness under current conditions. As shown in

Figure 16e, the duration from controller intervention to entering mission cruise mode is approximately 3.3

in nominal simulations versus 3.1

in flight tests.

5. At around 5 , the throttle command stabilizes, marking the end of the pull-up phase and the transition to cruise mode. Before this point, remained near 0° while gradually decreased. After switching modes, the UAV increased to climb and recover altitude lost during pull-up, causing a sharp rise in and significant change in normal overload due to high airspeed.

6. During simulation and flight testing, the time taken for the UAV to automatically lift up is basically the same. However, due to the influence of wind, the UAV enters the lifting phase 1.7 earlier than simulation during flight testing.

7.

Figure 16d,e reveal that under nominal simulation conditions,

closely tracks commands with continuous positive control surface deflection to suppress excessive nose-up tendencies. In contrast, flight tests show

lagging behind commands by approximately

during stable pull-up, requiring negative control surface deflection for command tracking.

In summary, while noticeable discrepancies exist between flight test data and simulation results due to modeling errors and external disturbances, the overall trends remain consistent. The experimental data demonstrate that the proposed variable-parameter PID controller enables the UAV to achieve automatic pull-up under certain initial disturbances.