On the Aerodynamic Analysis and Conceptual Design of Bioinspired Multi-Flapping-Wing Drones

Abstract

:1. Introduction

2. Mission Plan Description

3. Sizing and Weight Estimation

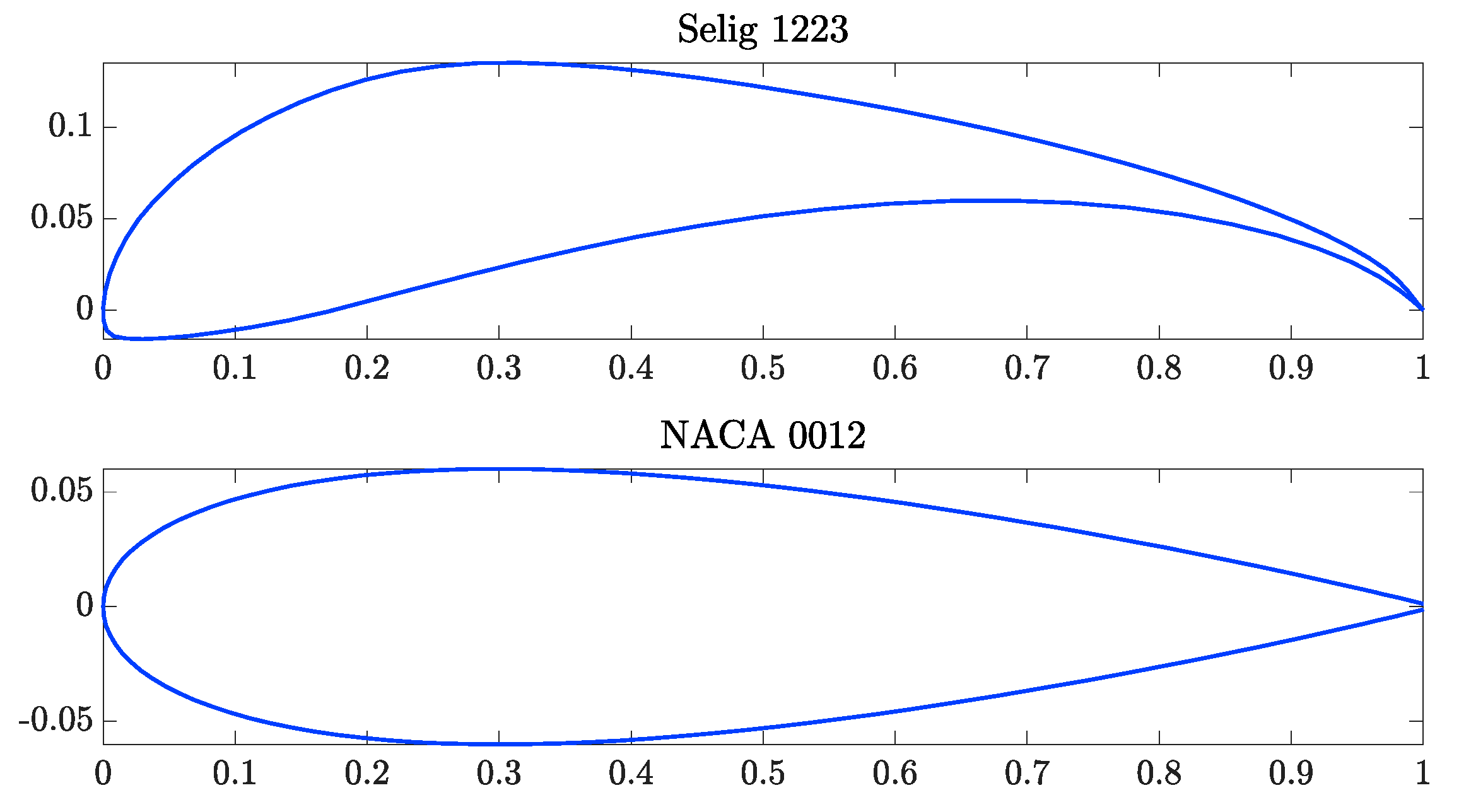

4. Aerodynamic Analysis: Role of Bioinspiration and Effective Design of the Formation Angle and Angle of Attack

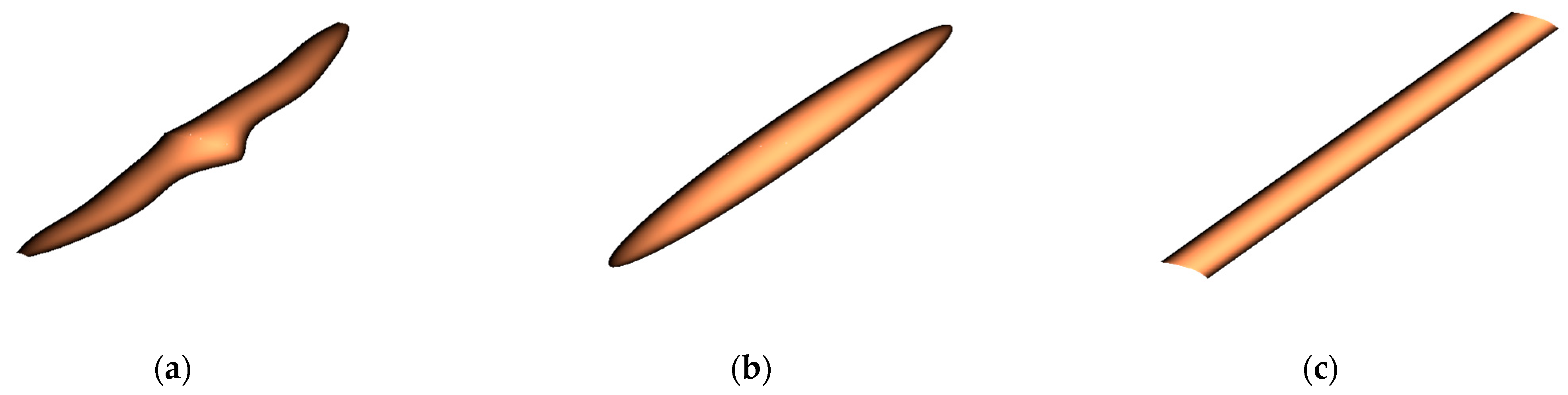

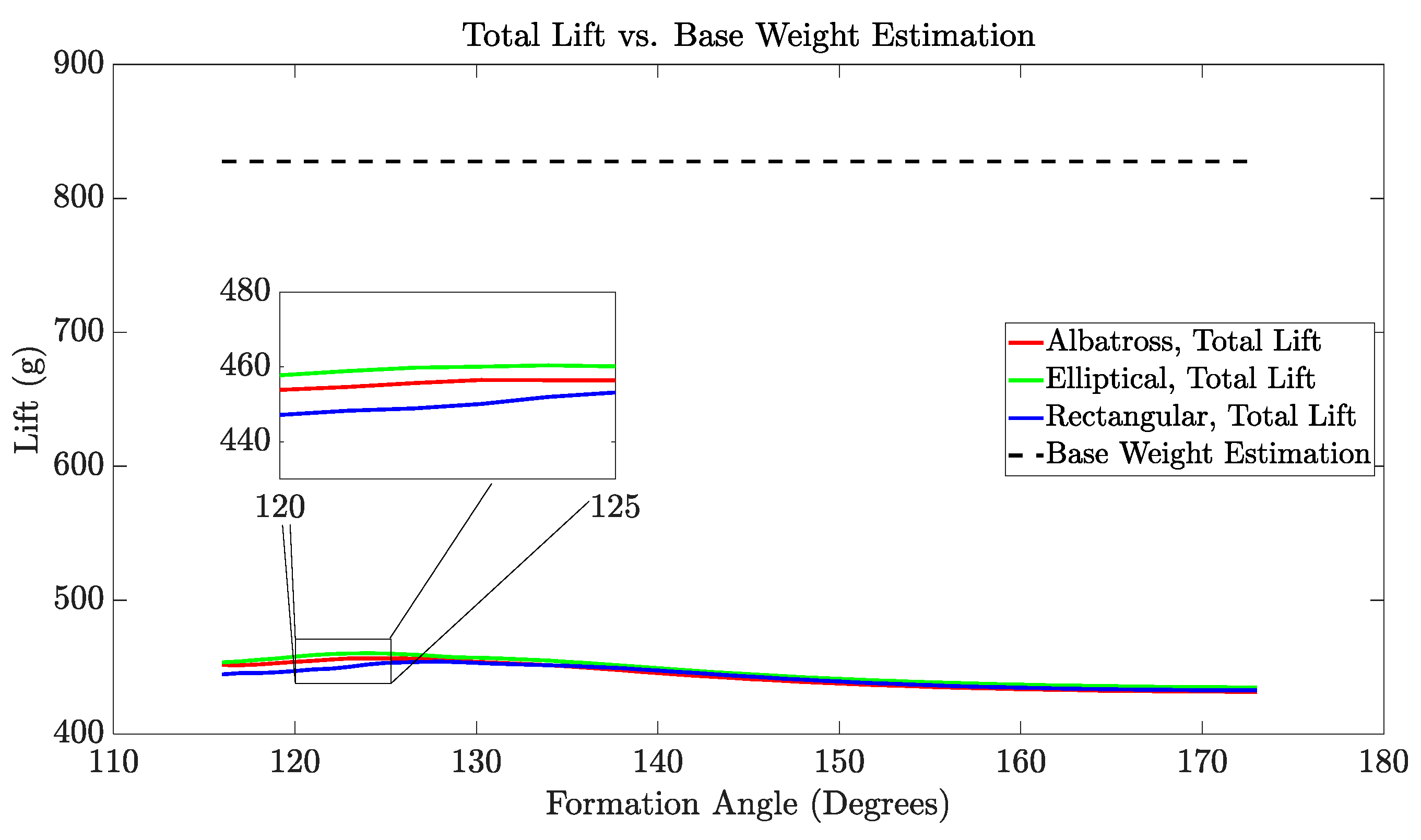

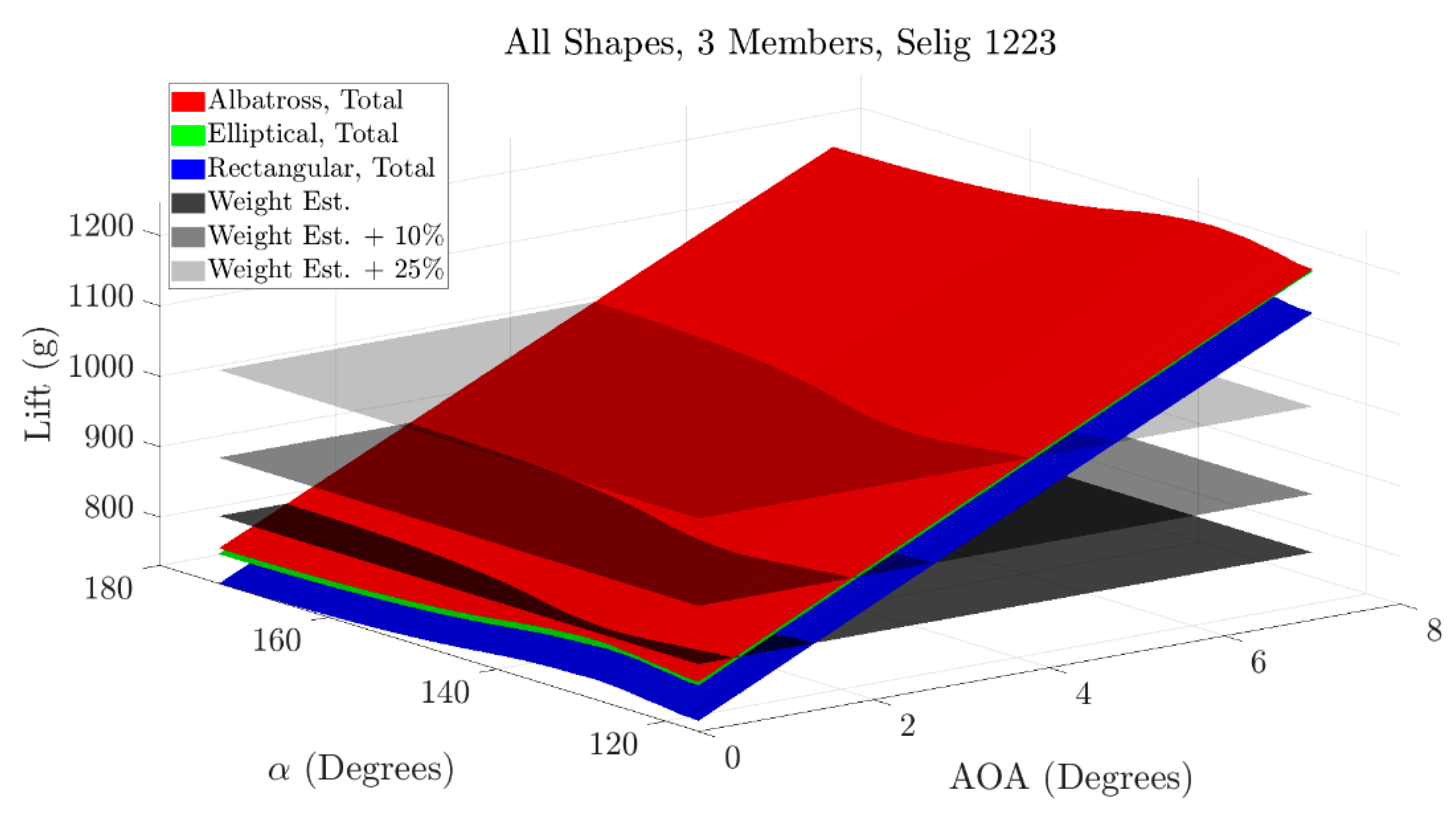

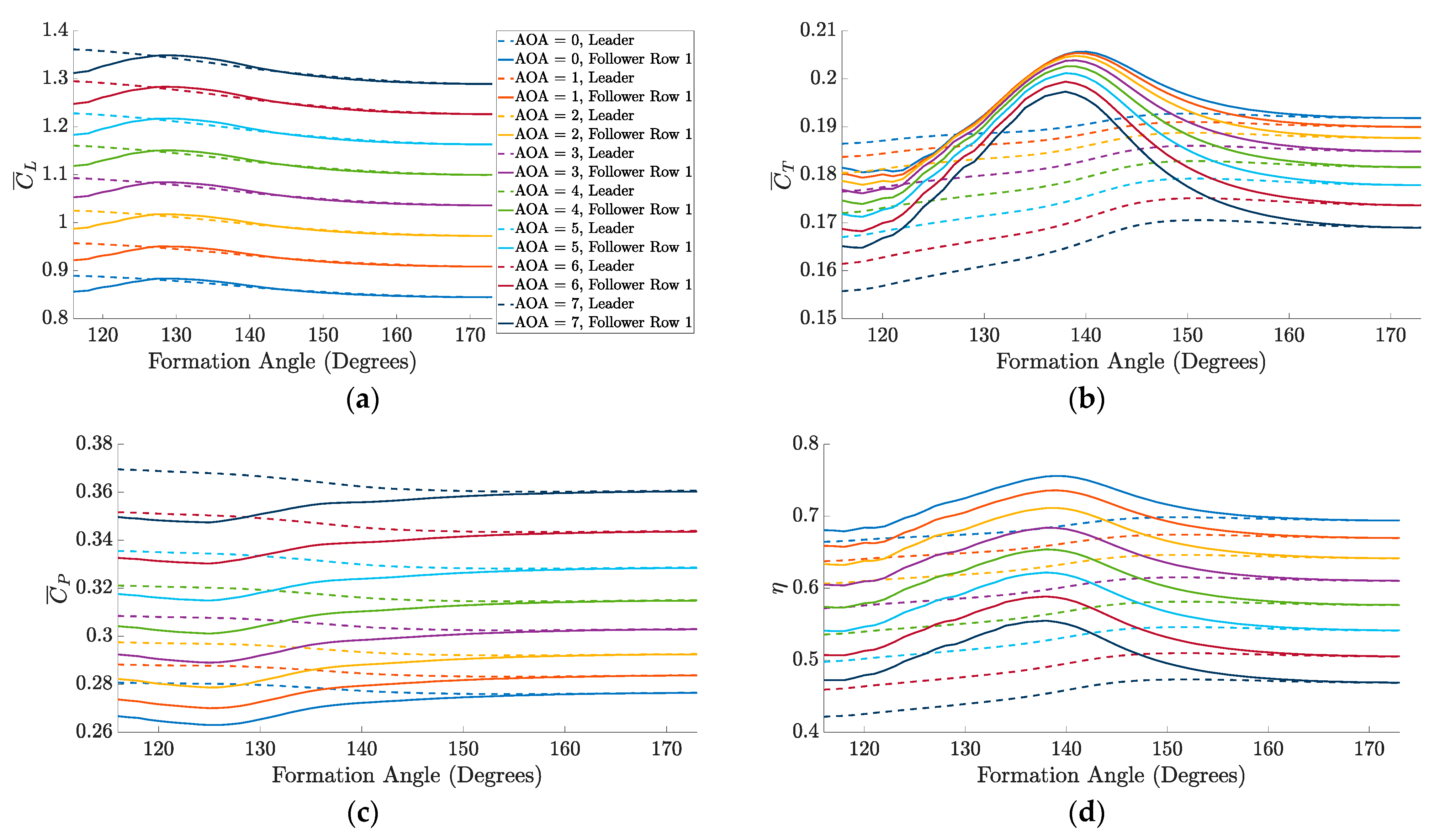

4.1. Multi-Flapping-Wing Drone’s Design for 3-Member Configuration

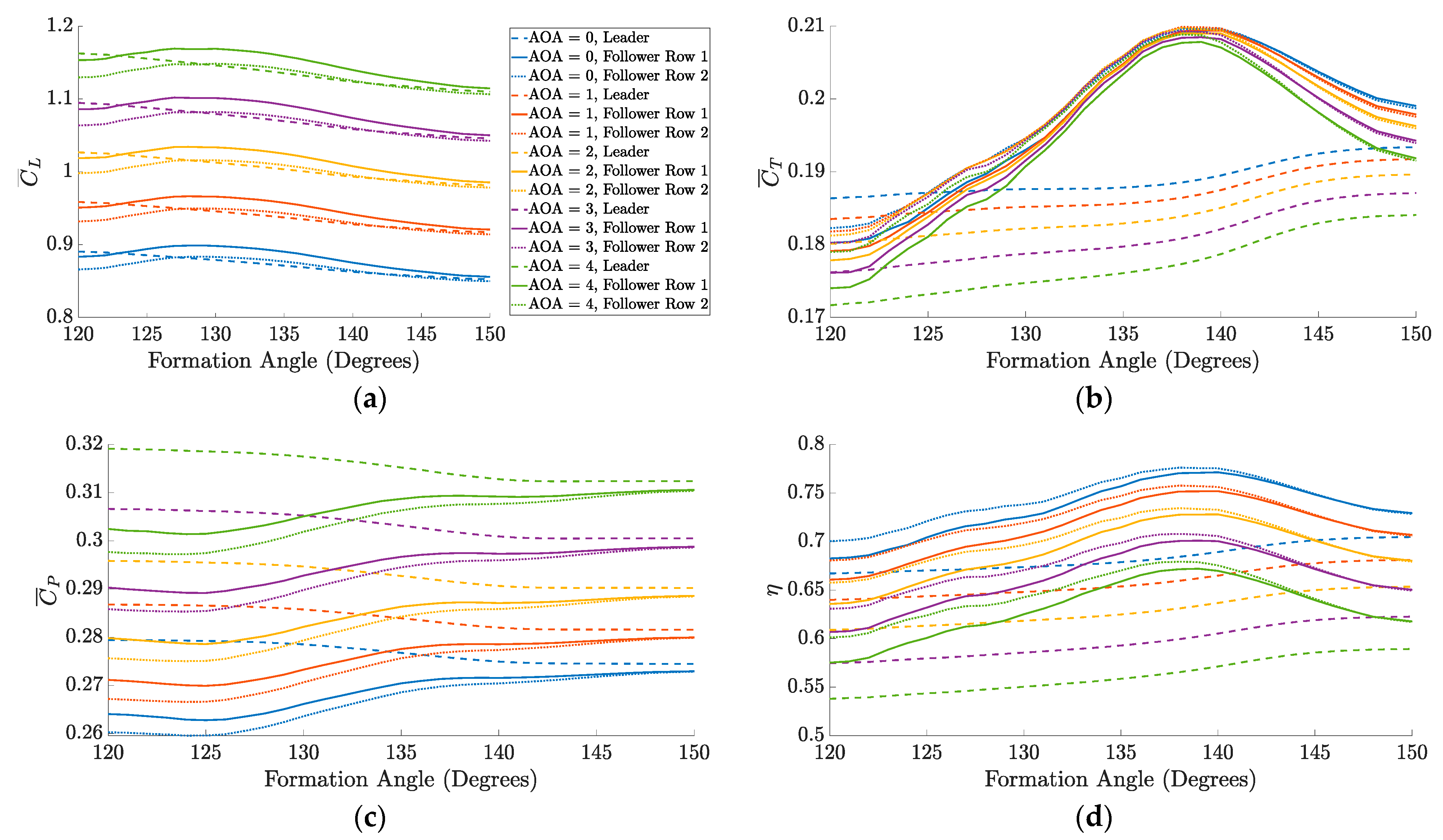

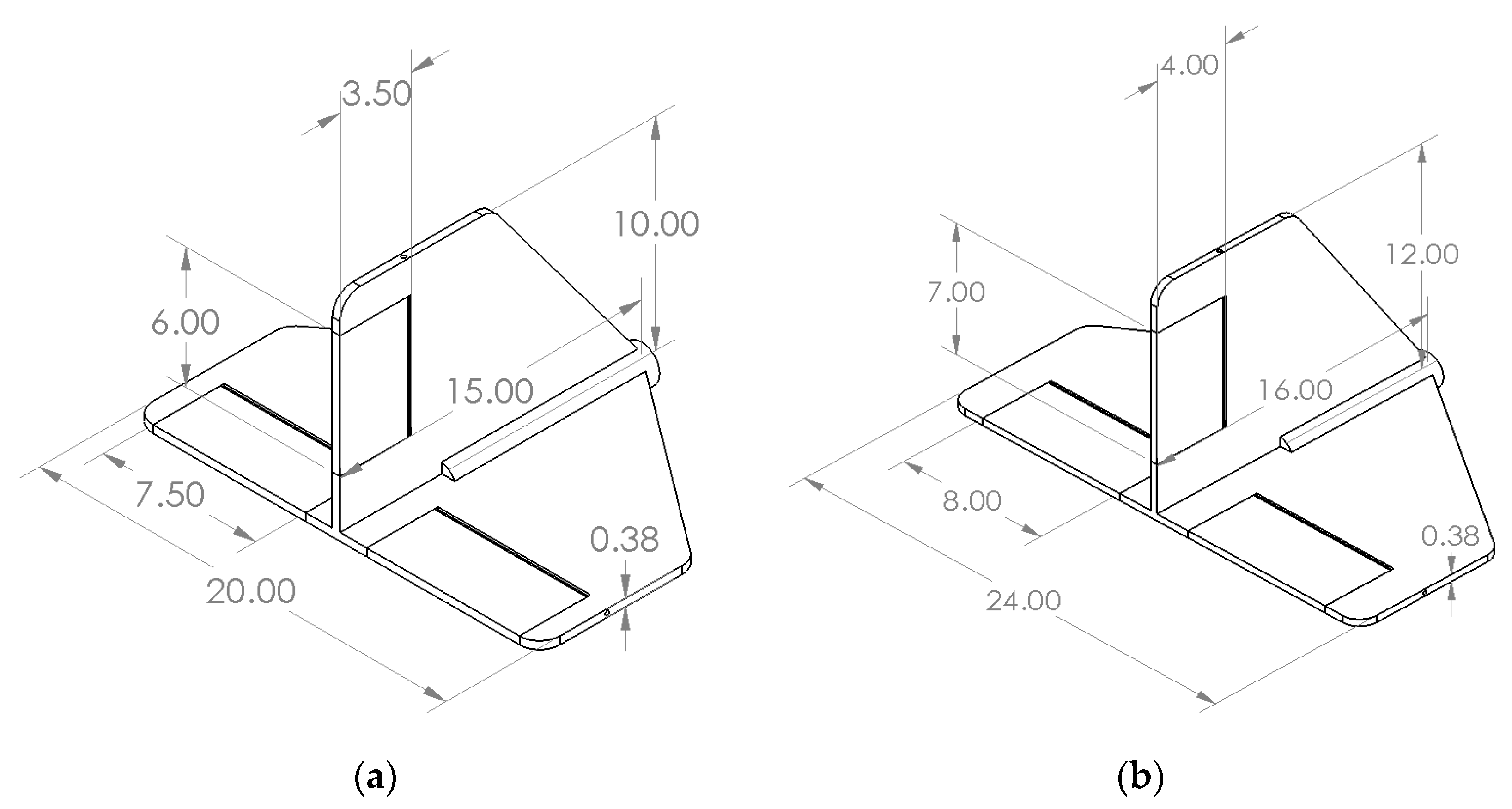

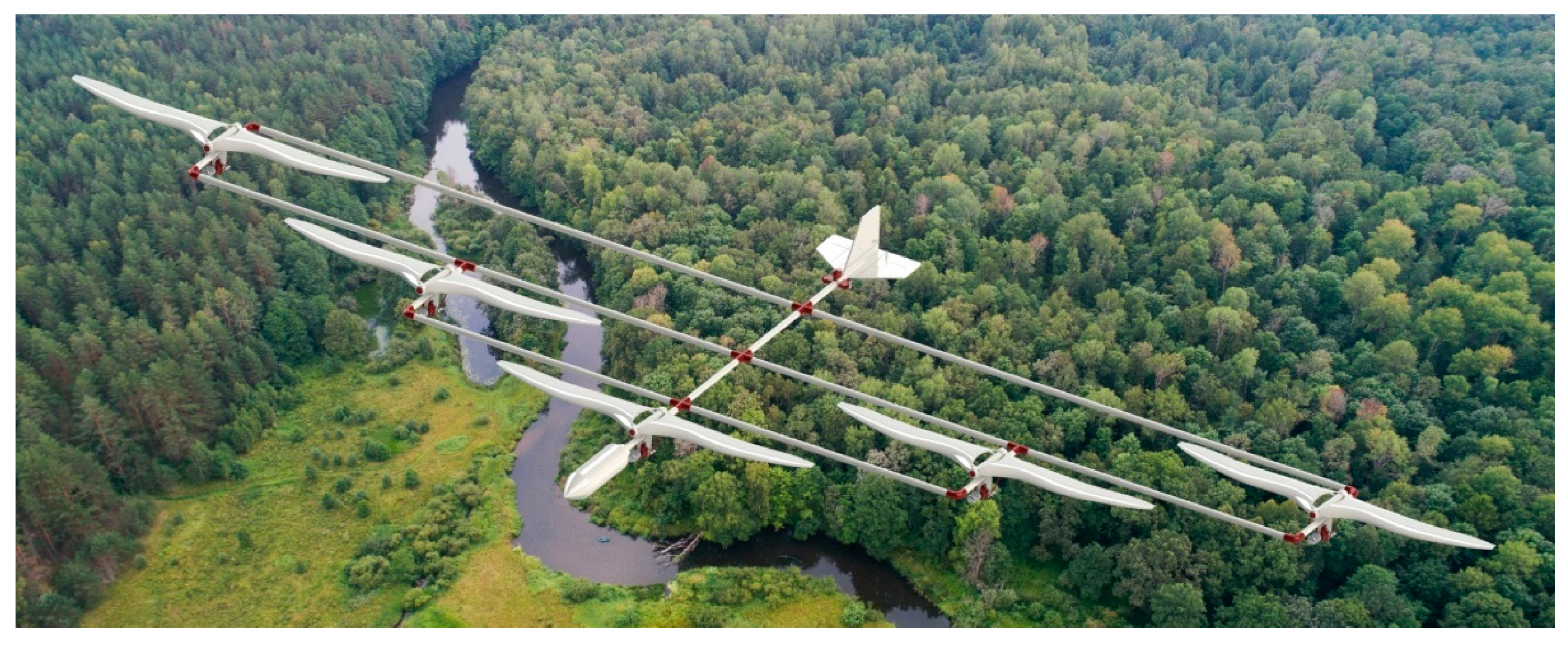

4.2. Multi-Flapping-Wing Drone’s Design for 5-Member Configuration

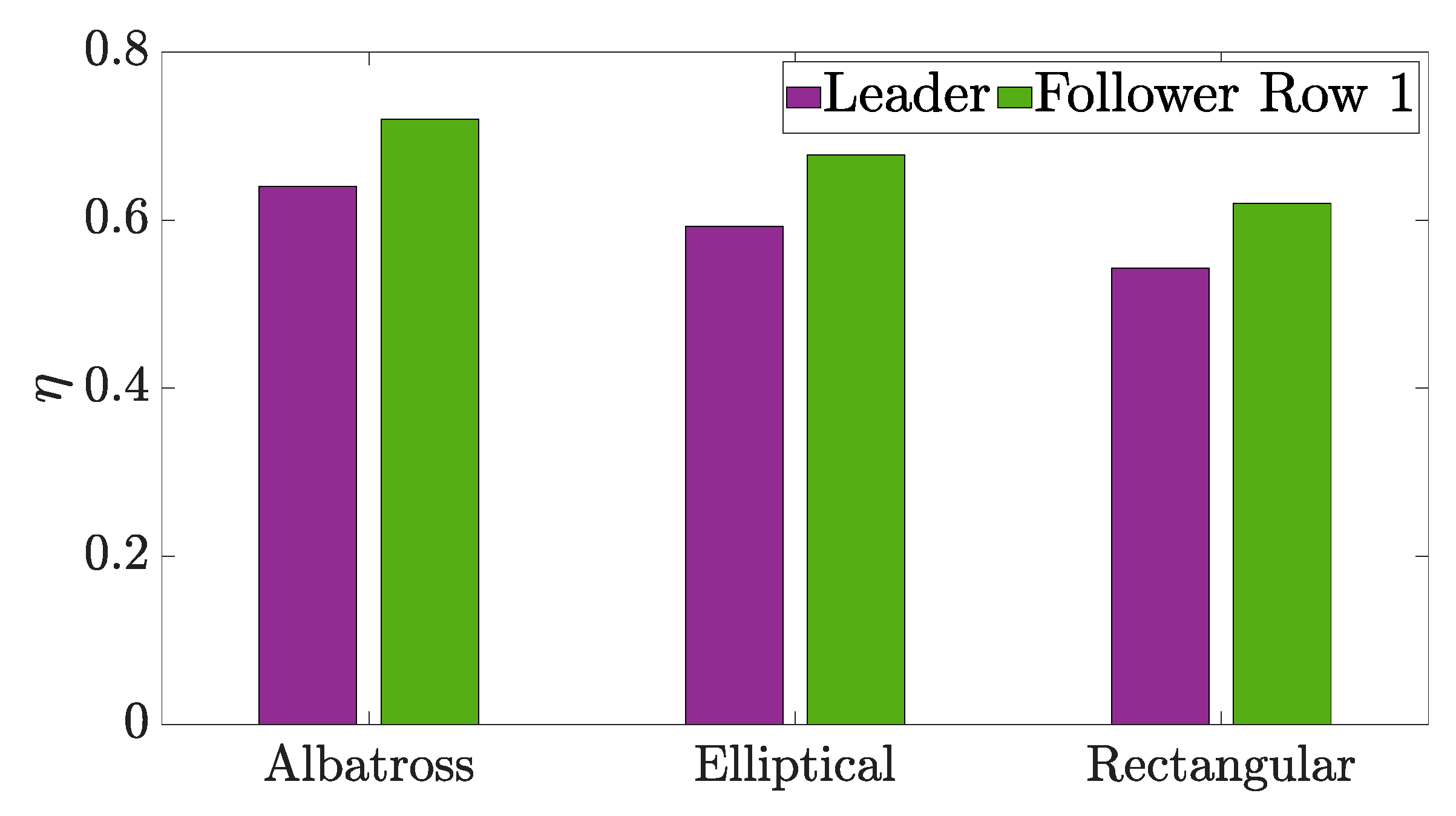

4.3. Comparative Efficiency Study between the 3- and 5-Member Flapping-Wing Configurations

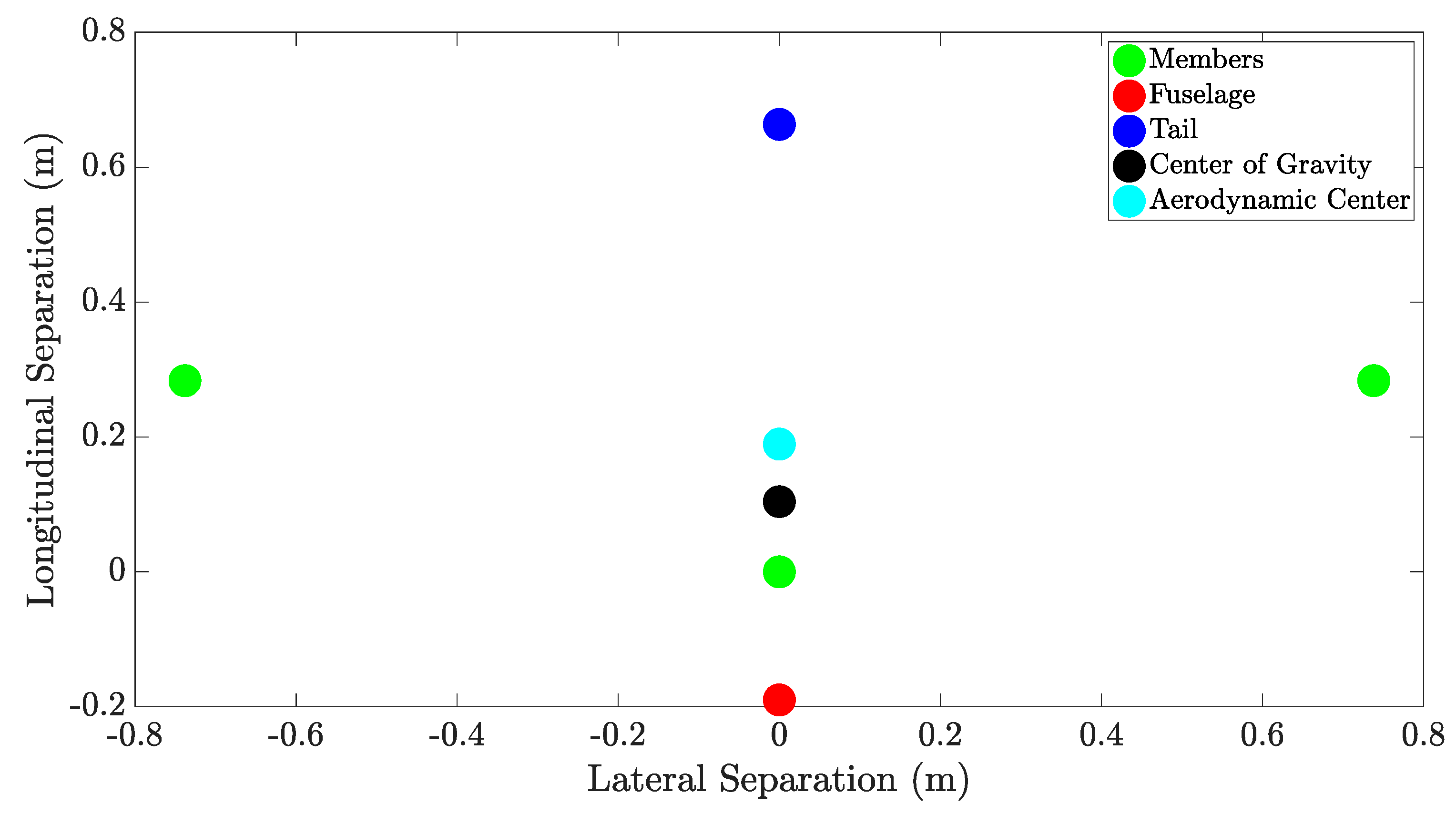

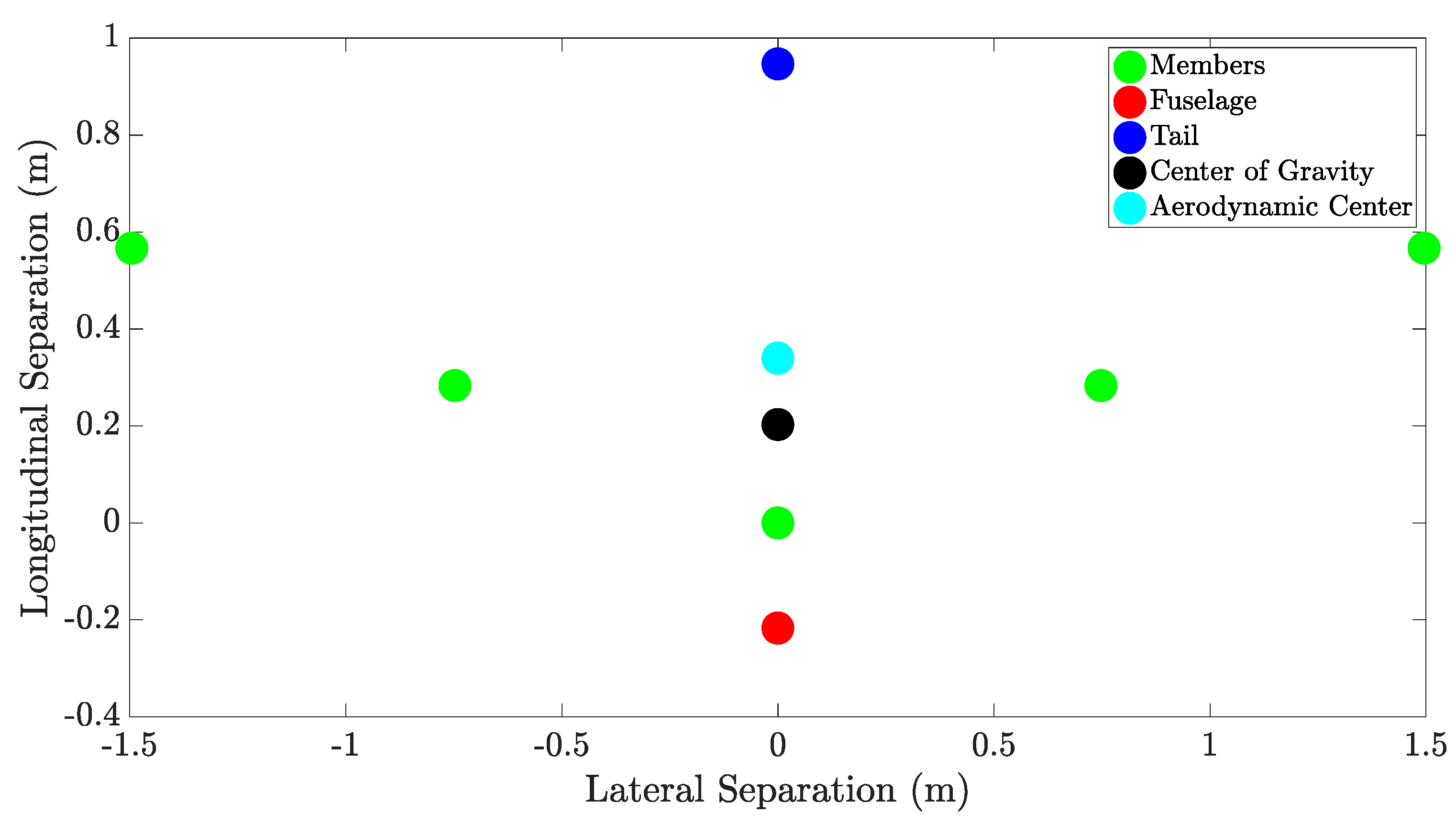

5. Stability Analysis and Tail Sizing

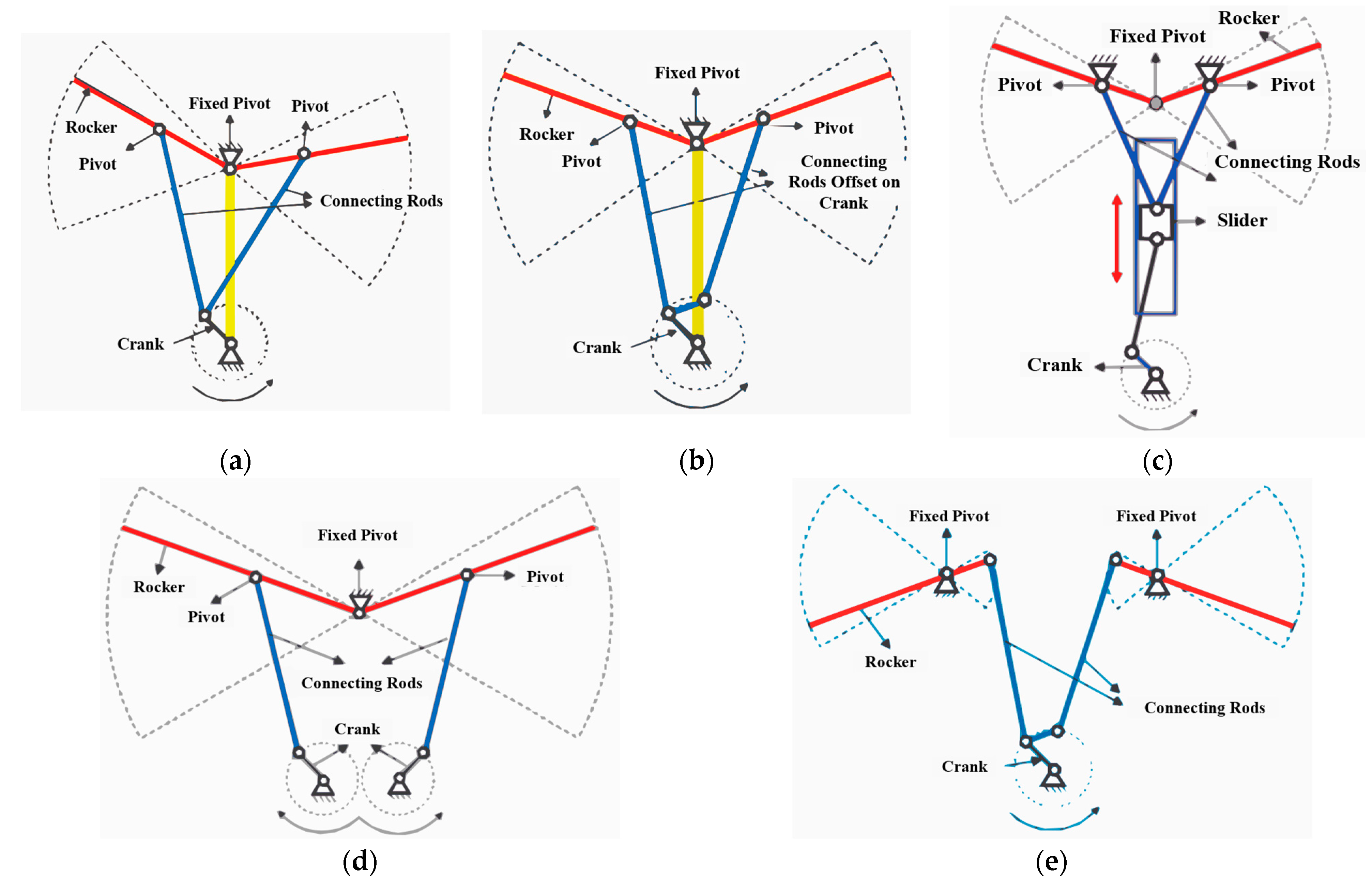

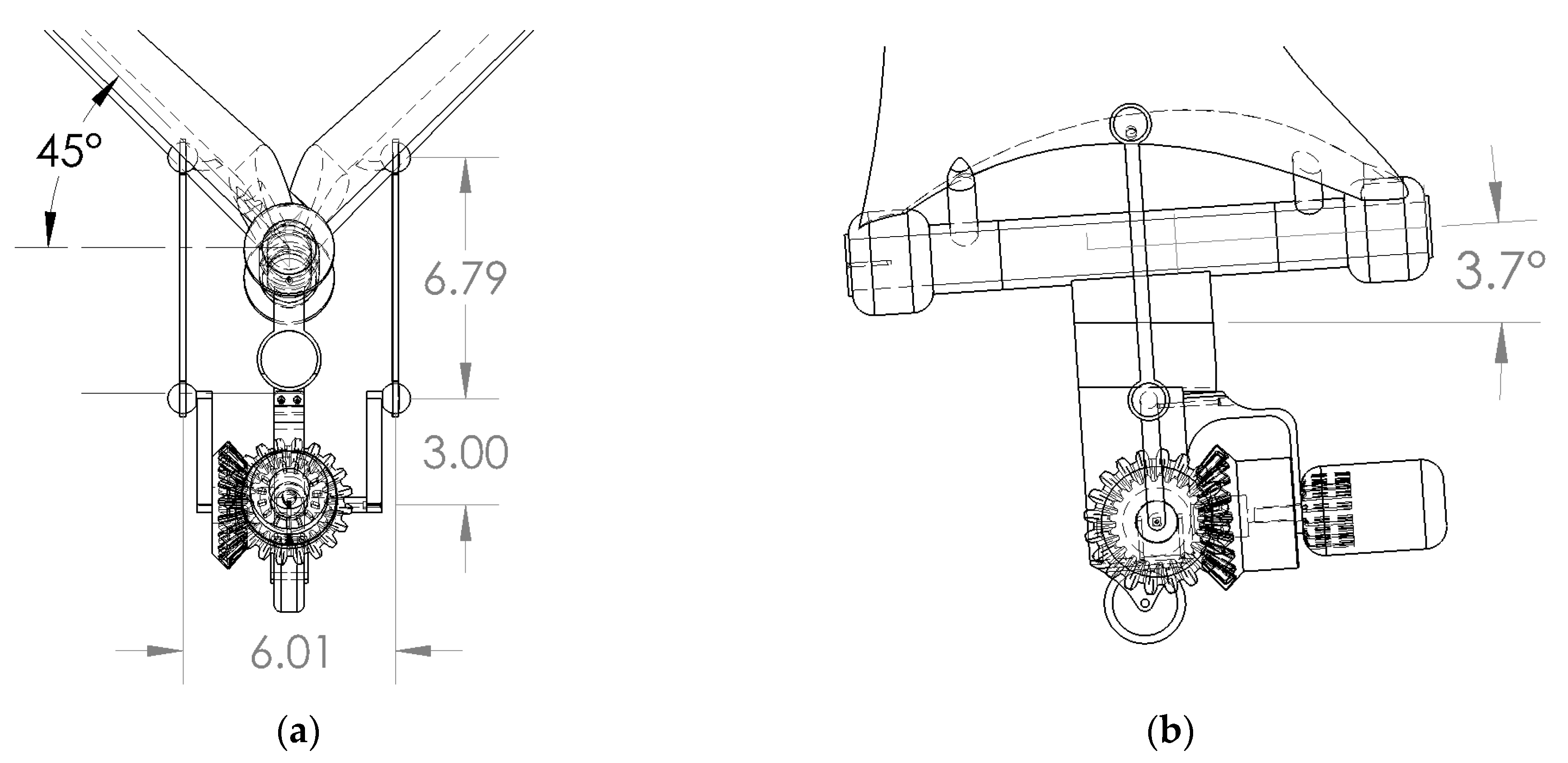

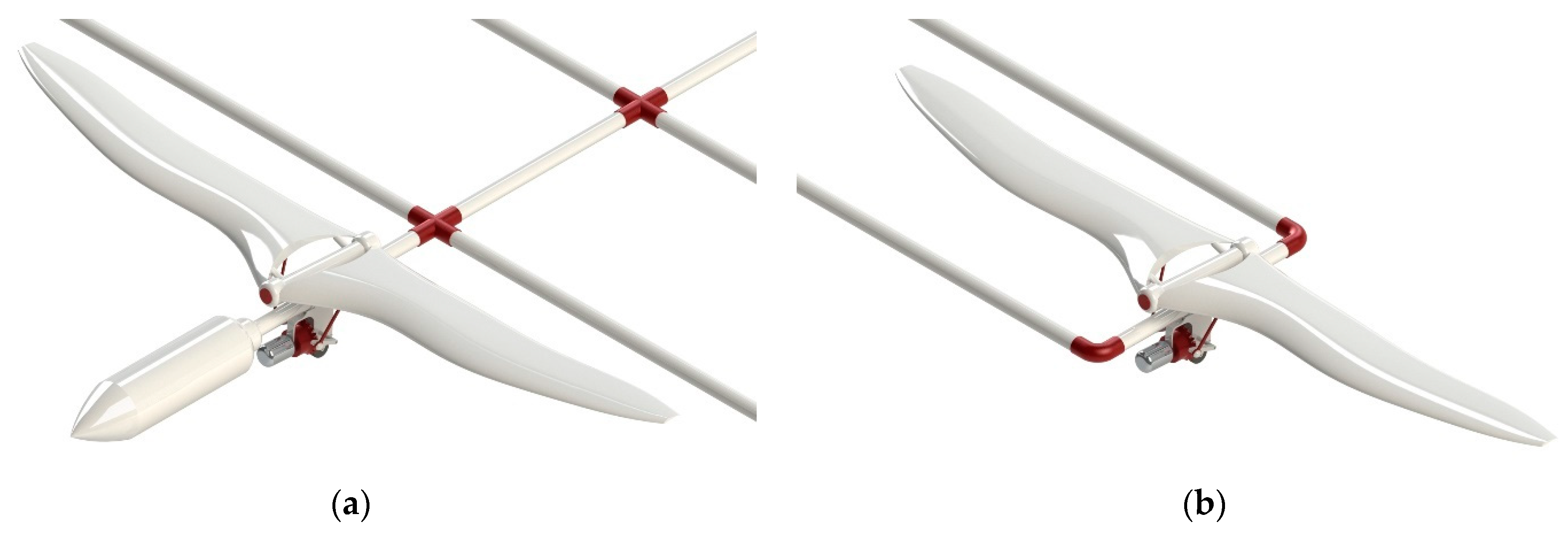

6. Flapping Mechanism Selection

7. Final Designs of Bioinspired Multi-Flapping Wings Drones

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hassanalian, M.; Abdelkefi, A.; Wei, M.; Ziaei-Rad, S. A novel methodology for wing sizing of bio-inspired flapping wing micro air vehicles: Theory and prototype. Acta Mech. 2016, 228, 1097–1113. [Google Scholar] [CrossRef]

- Hassanalian, M.; Abdelkefi, A. Methodologies for weight estimation of fixed and flapping wing micro air vehicles. Meccanica 2017, 52, 2047–2068. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, T. A Review of Design and Fabrication of the Bionic Flapping Wing Micro Air Vehicles. Micromachines 2019, 10, 144. [Google Scholar] [CrossRef] [Green Version]

- Yang, W.; Wang, L.; Song, B. Dove: A biomimetic flapping-wing micro air vehicle. Int. J. Micro Air Veh. 2018, 10, 70–84. [Google Scholar] [CrossRef]

- Lee, J.; Ryu, S.; Kim, H.J. Stable Flight of a Flapping-Wing Micro Air Vehicle Under Wind Disturbance. IEEE Robot. Autom. Lett. 2020, 5, 5685–5692. [Google Scholar] [CrossRef]

- BionicOpter, Festo Corporate. Available online: https://www.festo.com/group/en/cms/10224.htm (accessed on 15 July 2021).

- Lane, P.; Throneberry, G.; Fernandez, I.; Hassanalian, M.; Vasconcellos, R.; Abdelkefi, A. Towards Bio-Inspiration, Development, and Manufacturing of a Flapping-Wing Micro Air Vehicle. Drones 2020, 4, 39. [Google Scholar] [CrossRef]

- Nguyen, Q.-V.; Chan, W.L. Development and flight performance of a biologically-inspired tailless flapping-wing micro air vehicle with wing stroke plane modulation. Bioinspiration Biomim. 2018, 14, 016015. [Google Scholar] [CrossRef]

- Explorer, DelFly. Available online: http://www.delfly.nl/explorer/ (accessed on 15 July 2021).

- Ryu, S.; Kim, H.J. Development of a flapping-wing micro air vehicle capable of autonomous hovering with onboard measurements. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 3239–3245. [Google Scholar]

- Jones, K.D.; Bradshaw, C.J.; Papadopoulos, J.; Platzer, M.F. Bio-inspired design of flapping-wing micro air vehicles. Aeronaut. J. 2015, 109, 385–393. [Google Scholar] [CrossRef]

- Lissaman, P.B.S.; Shollenberger, C.A. Formation Flight of Birds. Science 1970, 168, 1003–1005. [Google Scholar] [CrossRef]

- Cutts, C.J.; Speakman, J.R. Energy savings in formation flight of pink-footed geese. J. Exp. Biol. 1994, 189, 251–261. [Google Scholar] [CrossRef] [PubMed]

- Gould, L.L.; Heppner, F. The vee formation of Canada geese. Auk 1974, 91, 494–506. [Google Scholar]

- Völkl, B.; Fritz, J. Relation between travel strategy and social organization of migrating birds with special consideration of formation flight in the northern bald ibis. Philos. Trans. R. Soc. B Biol. Sci. 2017, 372, 20160235. [Google Scholar] [CrossRef]

- Hummel, D. The use of aircraft wakes to achieve power reductions in formation flight. In Proceedings of the AGARD FDP Symposium on The Characterization & Modification of Wakes from Lifting Vehicles in Fluid, Trondheim, Norway, 20–23 May 1996. [Google Scholar]

- Weimerskirch, H.; Martin, J.; Clerquin, Y.; Alexandre, P.; Jiraskova, S. Energy saving in flight formation. Nature 2001, 413, 697–698. [Google Scholar] [CrossRef]

- Ghommem, M.; Calo, V.M. Flapping wings in line formation flight: A computational analysis. Aeronaut. J. 2014, 118, 485–501. [Google Scholar] [CrossRef]

- Tay, W.-B.; Murugaya, K.R.; Chan, W.-L.; Khoo, B.-C. Numerical Simulation of Flapping Wing MAVs in V-formation. J. Bionic Eng. 2019, 16, 264–280. [Google Scholar] [CrossRef]

- Zhu, X.; Bian, C.; Chen, Y.; Chen, S. A low latency clustering method for large-scale drone swarms. IEEE Access 2019, 7, 186260–186267. [Google Scholar] [CrossRef]

- Mashood, A.; Mohammed, M.; Abdulwahab, M.; Abdulwahab, S.; Noura, H. A hardware setup for formation flight of UAVs using motion tracking system. In Proceedings of the 2015 10th International Symposium on Mechatronics and Its Applications (ISMA), Sharjah, United Arab Emirates, 8–10 December 2015; pp. 1–6. [Google Scholar]

- Min, S.; Nam, H. A formation flight control of UAVs using ZigBee. In Proceedings of the 2016 13th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI), Xi’an, China, 19–22 August 2016; pp. 163–165. [Google Scholar]

- Kartal, Y.; Subbarao, K.; Gans, N.R.; Dogan, A.; Lewis, F.L. Distributed backstepping based control of multiple UAV formation flight subject to time delays. IET Control Theory Appl. 2020, 14, 1628–1638. [Google Scholar] [CrossRef]

- Stanford, B.K.; Beran, P.S. Analytical Sensitivity Analysis of an Unsteady Vortex-Lattice Method for Flapping-Wing Optimization. J. Aircr. 2010, 47, 647–662. [Google Scholar] [CrossRef]

- Ghommem, M.; Hajj, M.R.; Mook, D.T.; Stanford, B.K.; Beran, P.S.; Snyder, R.D.; Watson, L.T. Global optimization of actively morphing flapping wings. J. Fluids Struct. 2012, 33, 210–228. [Google Scholar] [CrossRef]

- Nguyen, A.T.; Kim, J.-K.; Han, J.-S.; Han, J.-H. Extended unsteady vortex-lattice method for insect flapping wings. J. Aircr. 2016, 53, 1709–1718. [Google Scholar] [CrossRef]

- Roccia, B.A.; Preidikman, S.; Massa, J.C.; Mook, D.T. Modified unsteady vortex-lattice method to study flapping wings in hover flight. AIAA J. 2013, 51, 2628–2642. [Google Scholar] [CrossRef] [Green Version]

- Pennycuick, C. Wingbeat frequency of birds in steady cruising flight: New data and improved predictions. J. Exp. Biol. 1996, 199, 1613–1618. [Google Scholar] [CrossRef] [PubMed]

- Drofelnik, J.; Da Ronch, A.; Kharlamov, D.; Sun, Y. Rapid calculation of unsteady aircraft loads. In Proceedings of the 7th European Conference on Computational Fluid Dynamics, Glasgow, UK, 11–15 June 2018; p. 2108. [Google Scholar]

- Katz, J.; Plotkin, A. Low-Speed Aerodynamics; Cambridge University Press: Cambridge, UK, 2001. [Google Scholar]

- MathWorks. Image Processing Toolbox. Available online: https://mathworks.com/help/images (accessed on 15 July 2021).

- Airfoil Tools Database. Available online: https://airfoiltools.com (accessed on 15 July 2021).

- Ghommem, M.; Hassanalian, M.; Al-Marzooqi, M.; Throneberry, G.; Abdelkefi, A. Sizing process, aerodynamic analysis, and experimental assessment of a biplane flapping wing nano air vehicle. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2019, 233, 5618–5636. [Google Scholar] [CrossRef]

- Concept of Tail Volumes to Size Horizontal and Vertical Tails. Available online: https://gatepathshala.com/pdf/download/conceptoftailvolumestosizehorizontalandverticaltails.pdf (accessed on 15 July 2021).

- Hassanalian, M.; Abdelkefi, A. Towards improved hybrid actuation mechanisms for flapping wing micro air vehicles: Analytical and experimental investigations. Drones 2019, 3, 73. [Google Scholar] [CrossRef] [Green Version]

- Gerrard, C.; Ward, M. Final Year Honours Project Micro Air Vehicle; The University of Adelaide: Adelaide, Australia, 2007. [Google Scholar]

- Singh, S.M. Flapping wings, a theoretical approach. Int. J. Eng. Sci. Adv. Technol. 2014, 4, 220–225. [Google Scholar]

- Benedict, M.; Sudhakar, K.; Issac, K.K. Aeroelastic Design and Manufacture of an Efficient Ornithopter Wing; Department of Aerospace Engineering, Indian Institute of Technology: Bombay, Mumbai, India, 2004. [Google Scholar]

- Yusoff, H.; Abdullah, M.Z.; Mujeebu, M.A.; Ahmad, K.A. Development of flexible wings and flapping mecha-nism with integrated electronic control system, for micro air vehicle research. Exp. Tech. 2013, 37, 25–37. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.; He, Z. Optimization design of flapping mechanism and wings for flapping-wing MAVs. In Proceedings of the Computer-Nat Visional Conference on Intelligent Robotics and Applications, Newcastle, NSW, Australia, 9–11 August 2008; Springer: Berlin, Heidelberg, 2008; pp. 245–255. [Google Scholar]

- Beasley, B. A Study of Planar and Nonplanar Membrane Wing Planforms for the Design of a Flapping-Wing Micro Air Vehicle. Master’s thesis, Department of Aerospace Engineering, University of Maryland, College Park, MA, USA, 2006. [Google Scholar]

- McMaster-Carr Miter Gear Catalog. Available online: https://www.mcmaster.com/gears/plastic-miter-gears/ (accessed on 15 July 2021).

| 3-Member Drone | Powerplant | Payload | Battery | Avionics | Structural | Total |

|---|---|---|---|---|---|---|

| Base weight est. (g) | 120.4 | 7.5 | 105.3 | 67.7 | 526.7 | 827.6 |

| Weight est. (g) + 10% | 120.4 | 7.5 | 188.1 | 67.7 | 526.7 | 910.4 |

| Weight est. (g) + 25% | 120.4 | 7.5 | 312.2 | 67.7 | 526.7 | 1034.5 |

| 5-Member Drone | Powerplant | Payload | Battery | Avionics | Structural | Total |

|---|---|---|---|---|---|---|

| Base weight Est. (g) | 200.6 | 12.5 | 175.6 | 112.9 | 877.8 | 1379.4 |

| Weight est. (g) + 10% | 200.6 | 12.5 | 313.5 | 112.9 | 877.8 | 1517.3 |

| Weight est. (g) + 25% | 200.6 | 12.5 | 520.4 | 112.9 | 877.8 | 1724.2 |

| Wingspan | 0.85 m |

| Surface area | 0.0684 m2 |

| Following distance | 0.283 m |

| Velocity | 8.5 m/s |

| Flapping amplitude | 45 degrees |

| Flapping frequency | 3 Hz |

| Albatross 3 Members | Peak Follower Lift | Peak Follower Efficiency | ||||

|---|---|---|---|---|---|---|

| Base Est. | +10% | +25% | Base Est. | +10% | +25% | |

| Weight estimation | 827.7 g | 910.5 g | 1034.7 g | 827.7 g | 910.5 g | 1034.7 g |

| Formation angle | 129 | 129 | 128.5 | 139 | 139 | 138 |

| Angle of attack | 0.1793 | 1.5150 | 3.5229 | 0.3726 | 1.7303 | 3.7364 |

| Global efficiency | 0.6939 | 0.6613 | 0.5993 | 0.7137 | 0.6800 | 0.6178 |

| Elliptical 3 Members | Peak Follower Lift | Peak Follower Efficiency | ||||

|---|---|---|---|---|---|---|

| Base Est. | +10% | +25% | Base Est. | +10% | +25% | |

| Weight estimation | 827.7 g | 910.5 g | 1034.7 g | 827.7 g | 910.5 g | 1034.7 g |

| Formation angle | 127 | 127 | 127 | 138 | 138 | 138 |

| Angle of attack | 0.2961 | 1.6291 | 3.6329 | 0.4911 | 1.8409 | 3.8728 |

| Global efficiency | 0.6484 | 0.6126 | 0.5478 | 0.6718 | 0.6349 | 0.5688 |

| Rectangular 3 Members | Peak Follower Lift | Peak Follower Efficiency | ||||

|---|---|---|---|---|---|---|

| Base Est. | +10% | +25% | Base Est. | +10% | +25% | |

| Weight estimation | 827.7 g | 910.5 g | 1034.7 g | 827.7 g | 910.5 g | 1034.7 g |

| Formation angle | 128 | 128 | 128 | 141 | 141 | 141 |

| Angle of attack | 1.0934 | 2.4379 | 4.4720 | 1.2616 | 2.6283 | 4.6898 |

| Global efficiency | 0.5926 | 0.5605 | 0.5004 | 0.6148 | 0.5813 | 0.5228 |

| Albatross 5 Members | Peak Follower Lift | Peak Follower Efficiency | ||||

|---|---|---|---|---|---|---|

| Base Est. | +10% | +25% | Base Est. | +10% | +25% | |

| Weight estimation | 1379.5 g | 1517.5 g | 1724.4 g | 1379.5 g | 1517.5 g | 1724.4 g |

| Formation angle | 129 | 128 | 128.5 | 140 | 138 | 138.5 |

| Angle of attack | 0.0781 | 1.4102 | 3.4218 | 0.3936 | 1.6631 | 3.7254 |

| Global efficiency | 0.7073 | 0.6743 | 0.6193 | 0.7383 | 0.7100 | 0.6501 |

| Elliptical 5 Members | Peak Follower Lift | Peak Follower Efficiency | ||||

|---|---|---|---|---|---|---|

| Base Est. | +10% | +25% | Base Est. | +10% | +25% | |

| Weight estimation | 1379.5 g | 1517.5 g | 1724.4 g | 1379.5 g | 1517.5 g | 1724.4 g |

| Formation angle | 127 | 128 | 128 | 138 | 137 | 137 |

| Angle of attack | 0.2242 | 1.5561 | 3.5564 | 0.4762 | 1.7833 | 3.8095 |

| Global efficiency | 0.6624 | 0.6393 | 0.5786 | 0.7024 | 0.6662 | 0.6045 |

| Rectangular 5 Members | Peak Follower Lift | Peak Follower Efficiency | ||||

|---|---|---|---|---|---|---|

| Base Est. | +10% | +25% | Base Est. | +10% | +25% | |

| Weight estimation | 1379.5 g | 1517.5 g | 1724.4 g | 1379.5 g | 1517.5 g | 1724.4 g |

| Formation angle | 130 | 131.5 | N/A | 141 | 140 | N/A |

| Angle of attack | 1.0942 | 2.4540 | N/A | 1.2836 | 2.6155 | N/A |

| Global efficiency | 0.6066 | 0.5854 | N/A | 0.6407 | 0.6077 | N/A |

| Albatross Selig 1223 | 3 Members | 5 Members | ||||

|---|---|---|---|---|---|---|

| Base Est. | +10% | +25% | Base Est. | +10% | +25% | |

| Weight estimation | 827.7 g | 910.5 g | 1034.7 g | 1379.5 g | 1517.5 g | 1724.4 g |

| Formation angle | 139 | 139 | 138 | 140 | 138 | 138.5 |

| Angle of attack | 0.3726 | 1.7303 | 3.7364 | 0.3936 | 1.6631 | 3.7254 |

| Global efficiency | 0.7137 | 0.6800 | 0.6178 | 0.7383 | 0.7100 | 0.6501 |

| Mechanism | Advantages | Disadvantages |

|---|---|---|

| Single Crank | Lightest mechanism and simple construction | Flapping motion of the wings is neither symmetric nor harmonic |

| Crank with Offset | Small phase difference, symmetric flapping motion, lightweight | Rockers may cross near crank if they are in the same vertical plane |

| Slider Crank | Flapping motion is symmetric | Complicated assembly, increased friction due to the piston |

| Double Crank | Flapping motion is symmetric | Highest weight, complicated assembly, and gears may slip |

| Alternate configuration | Same flapping motion as other four-bar mechanisms | Mechanism is not symmetric, unsuitable for biplane |

| General features | Modular design |

| Simple assembly | |

| Ease of repairability | |

| Ideal for reconnaissance | |

| 3-member advantages | Higher stability |

| Higher rigidity | |

| Reduced weight | |

| Less complexity | |

| Reduced cost | |

| 5-member advantages | Higher payload capacity |

| Higher propulsive efficiency | |

| Increased stealth |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Billingsley, E.; Ghommem, M.; Vasconcellos, R.; Abdelkefi, A. On the Aerodynamic Analysis and Conceptual Design of Bioinspired Multi-Flapping-Wing Drones. Drones 2021, 5, 64. https://doi.org/10.3390/drones5030064

Billingsley E, Ghommem M, Vasconcellos R, Abdelkefi A. On the Aerodynamic Analysis and Conceptual Design of Bioinspired Multi-Flapping-Wing Drones. Drones. 2021; 5(3):64. https://doi.org/10.3390/drones5030064

Chicago/Turabian StyleBillingsley, Ethan, Mehdi Ghommem, Rui Vasconcellos, and Abdessattar Abdelkefi. 2021. "On the Aerodynamic Analysis and Conceptual Design of Bioinspired Multi-Flapping-Wing Drones" Drones 5, no. 3: 64. https://doi.org/10.3390/drones5030064

APA StyleBillingsley, E., Ghommem, M., Vasconcellos, R., & Abdelkefi, A. (2021). On the Aerodynamic Analysis and Conceptual Design of Bioinspired Multi-Flapping-Wing Drones. Drones, 5(3), 64. https://doi.org/10.3390/drones5030064