Effect of Ducted Multi-Propeller Configuration on Aerodynamic Performance in Quadrotor Drone

Abstract

:1. Introduction

2. Materials and Methods

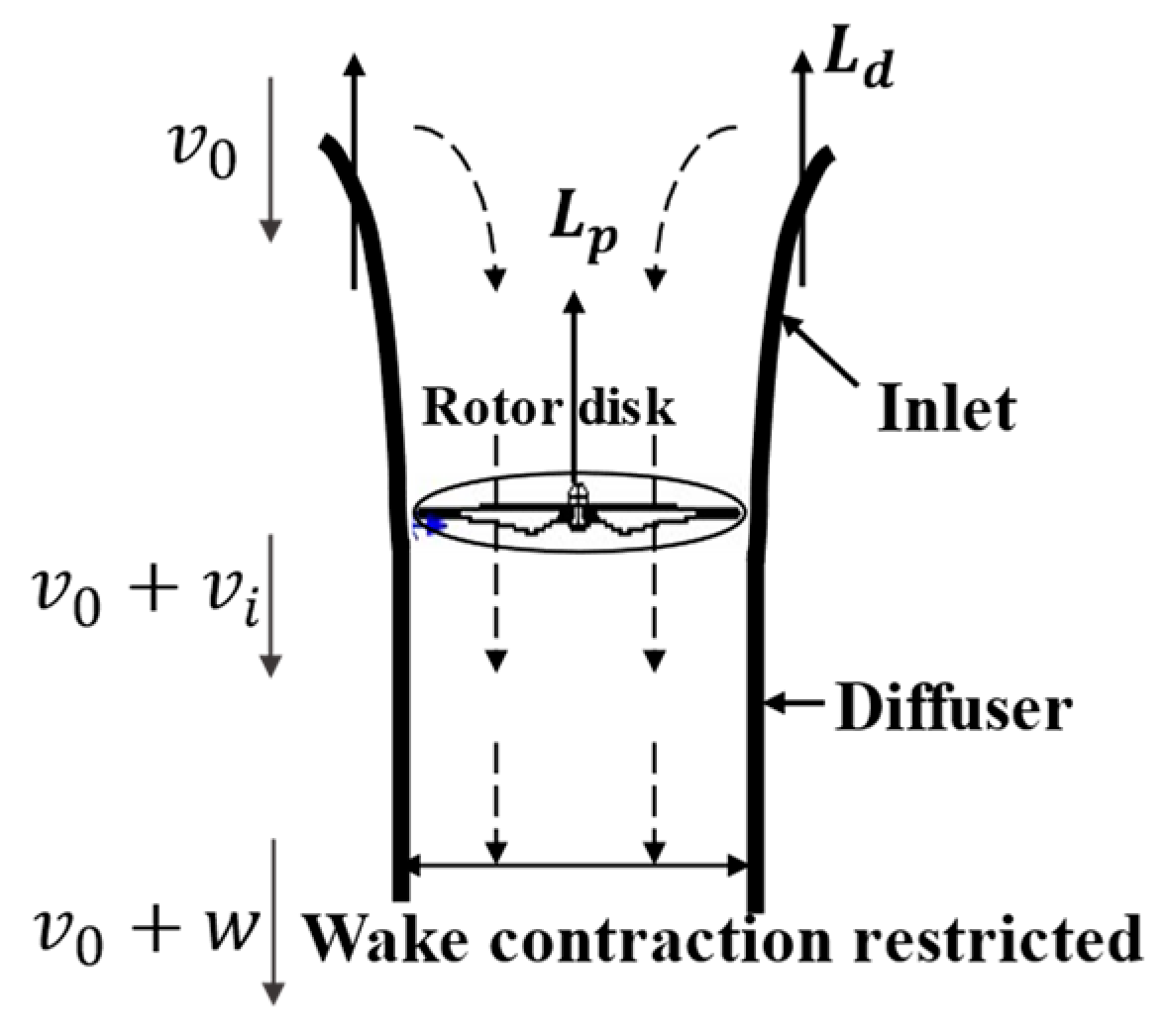

2.1. Aerodynamic Theory of a Ducted Propeller

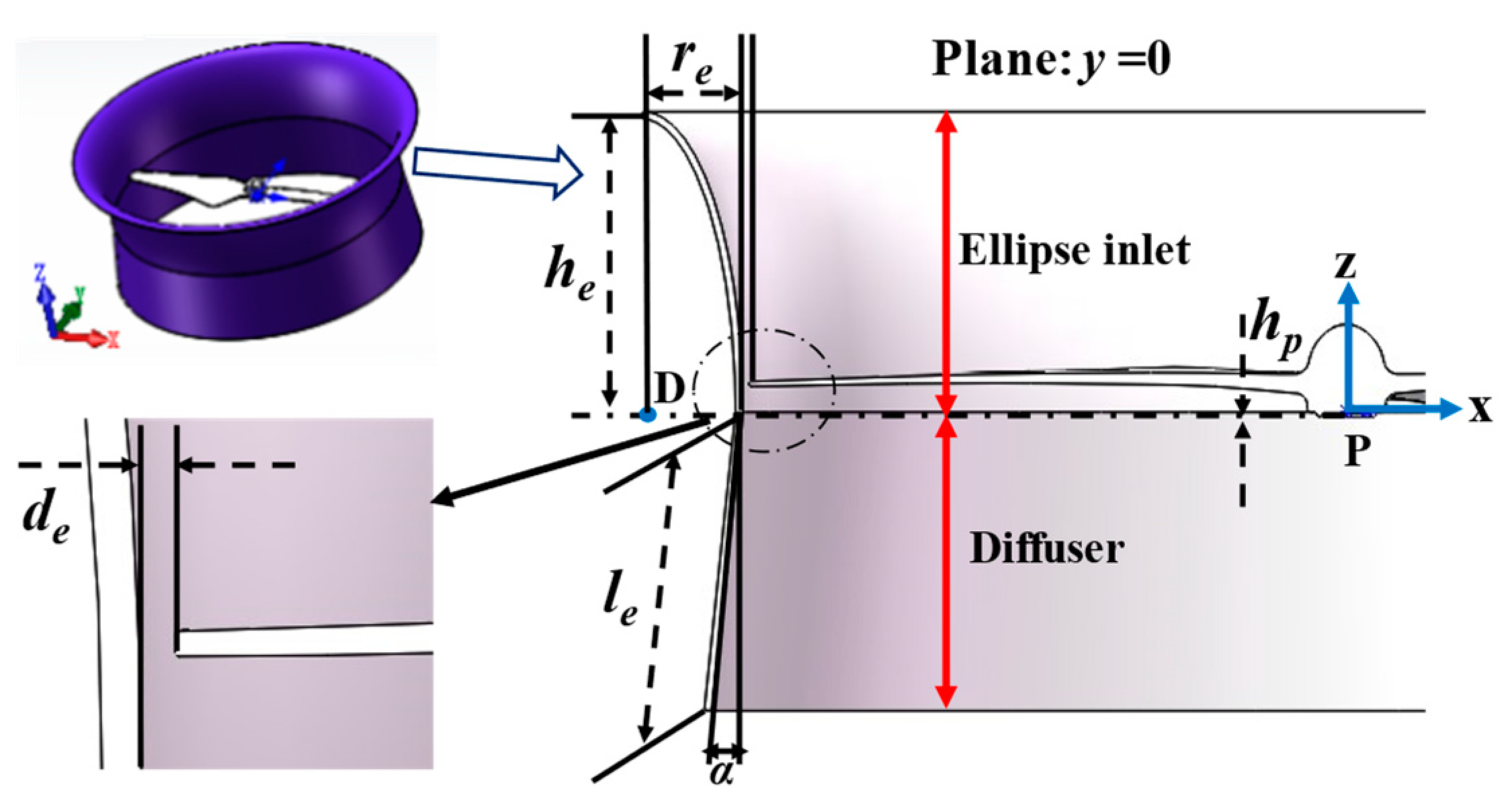

2.2. Geometric Model of Ducted Propeller

2.2.1. Ducted Single-Propeller Geometry

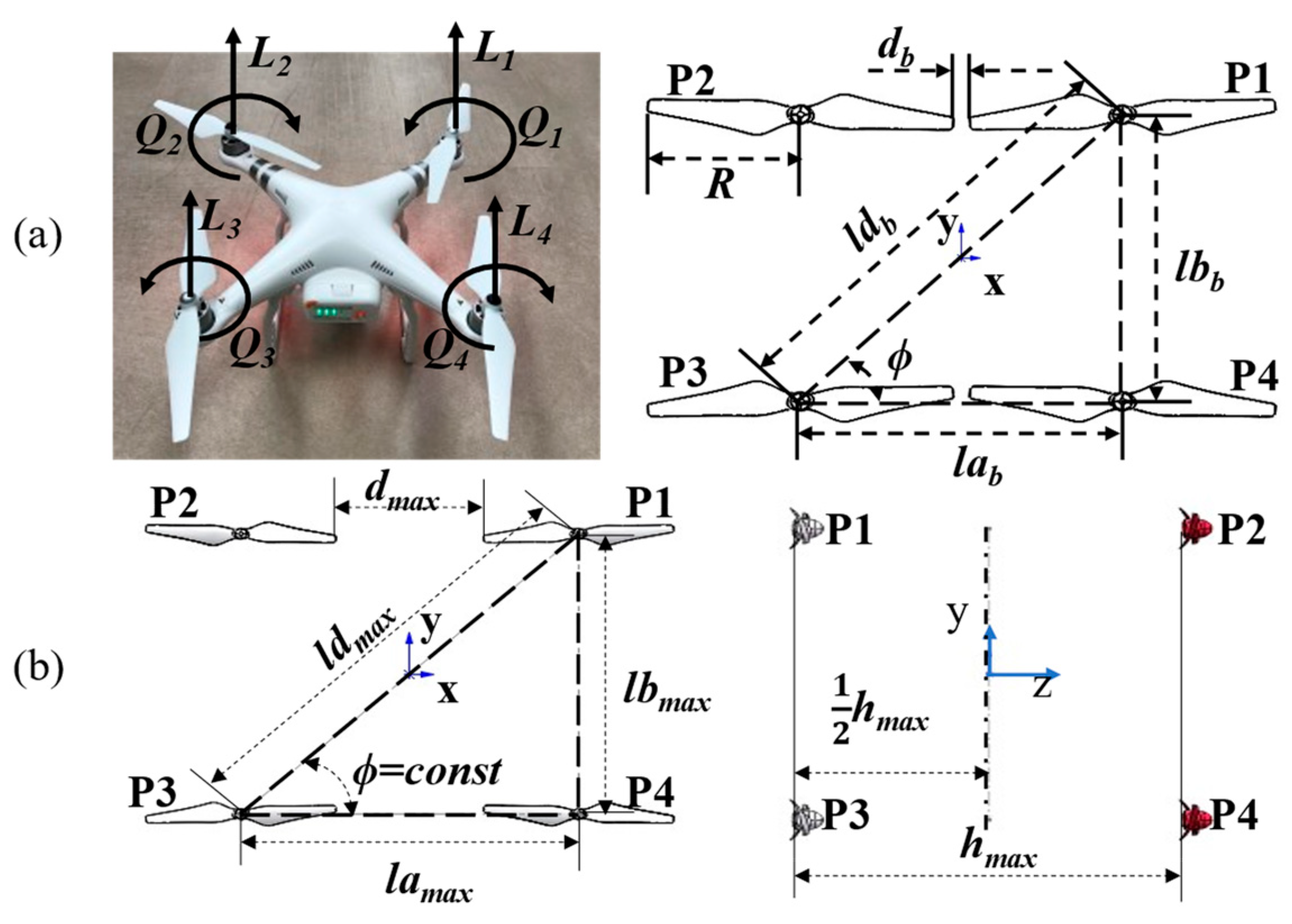

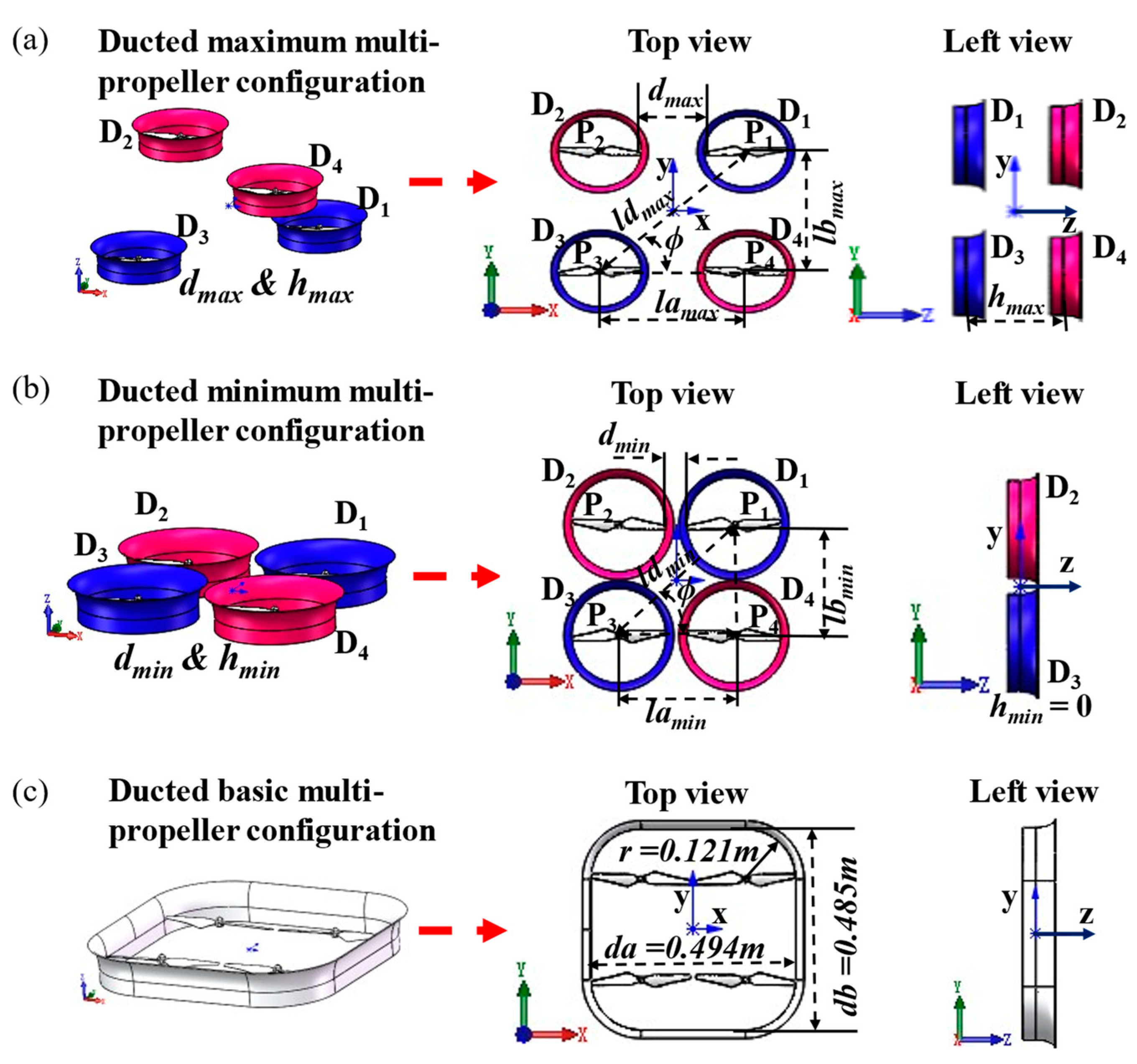

2.2.2. Ducted Multi-Propeller Geometry

2.3. CFD Modeling

2.4. Optimization of Aerodynamic Performance in Ducted Multi-Propeller Configuration

3. Results and Discussion

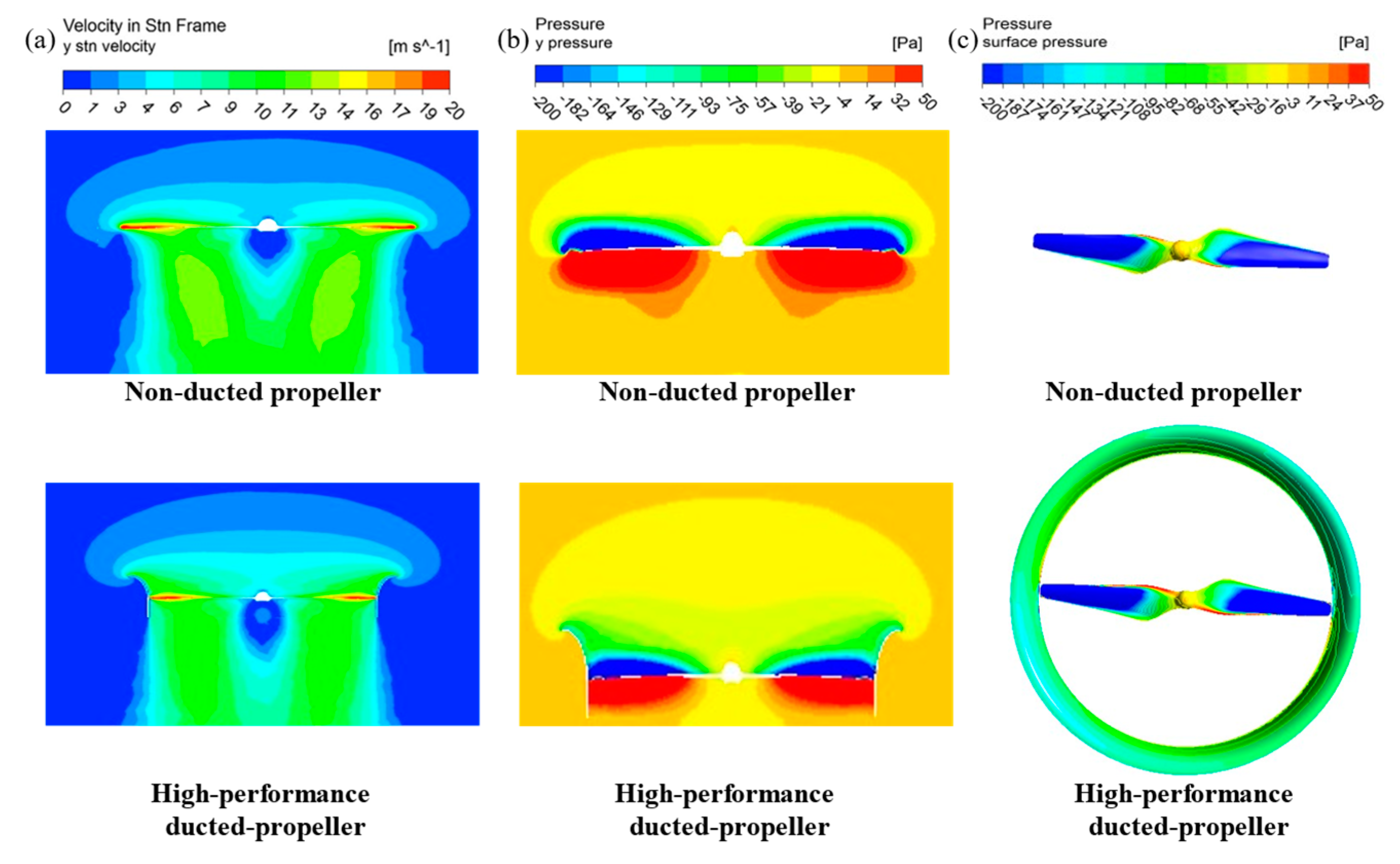

3.1. High-Performance Duct Design in Ducted Single-Propeller Model

3.1.1. Verification and Validation

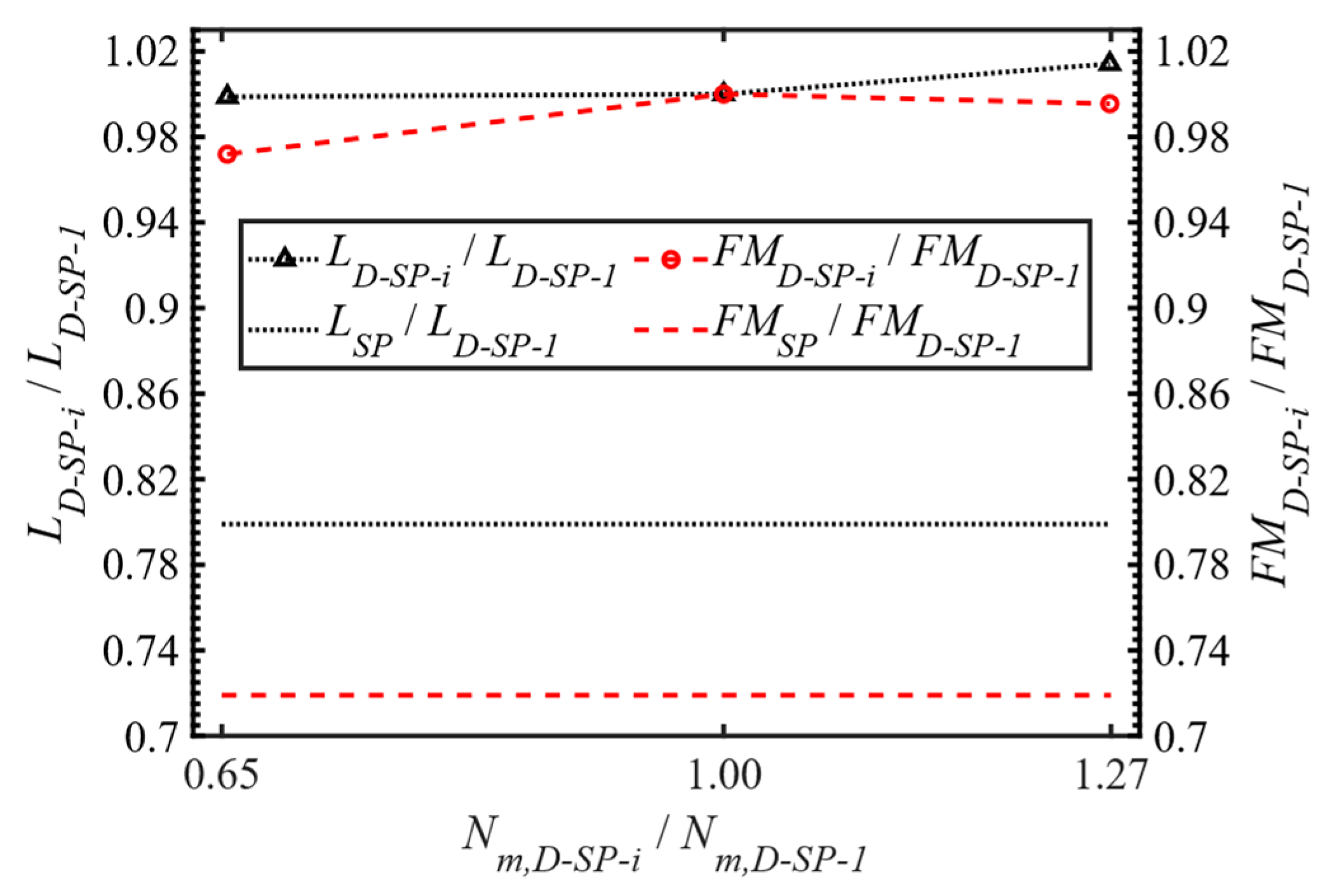

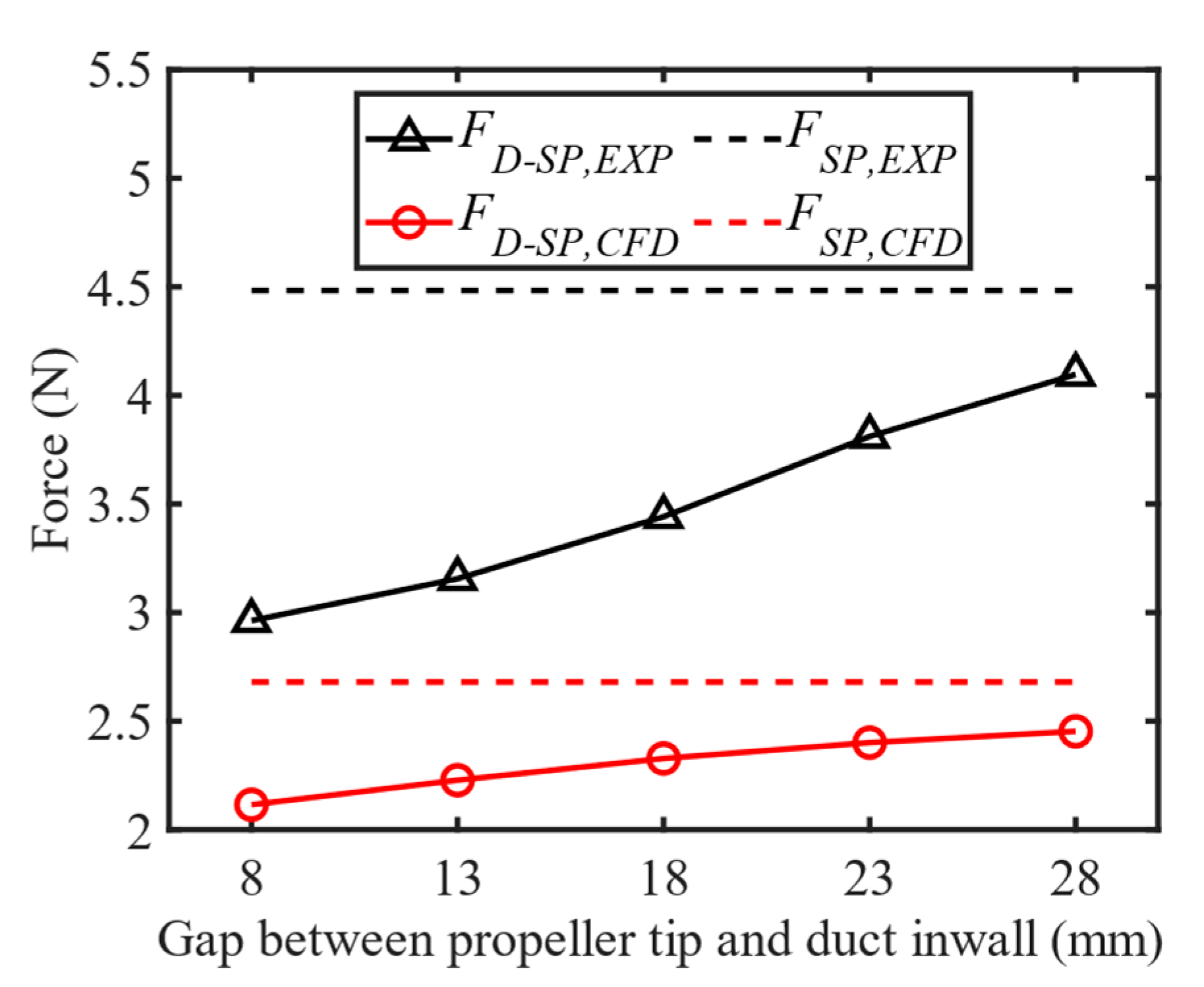

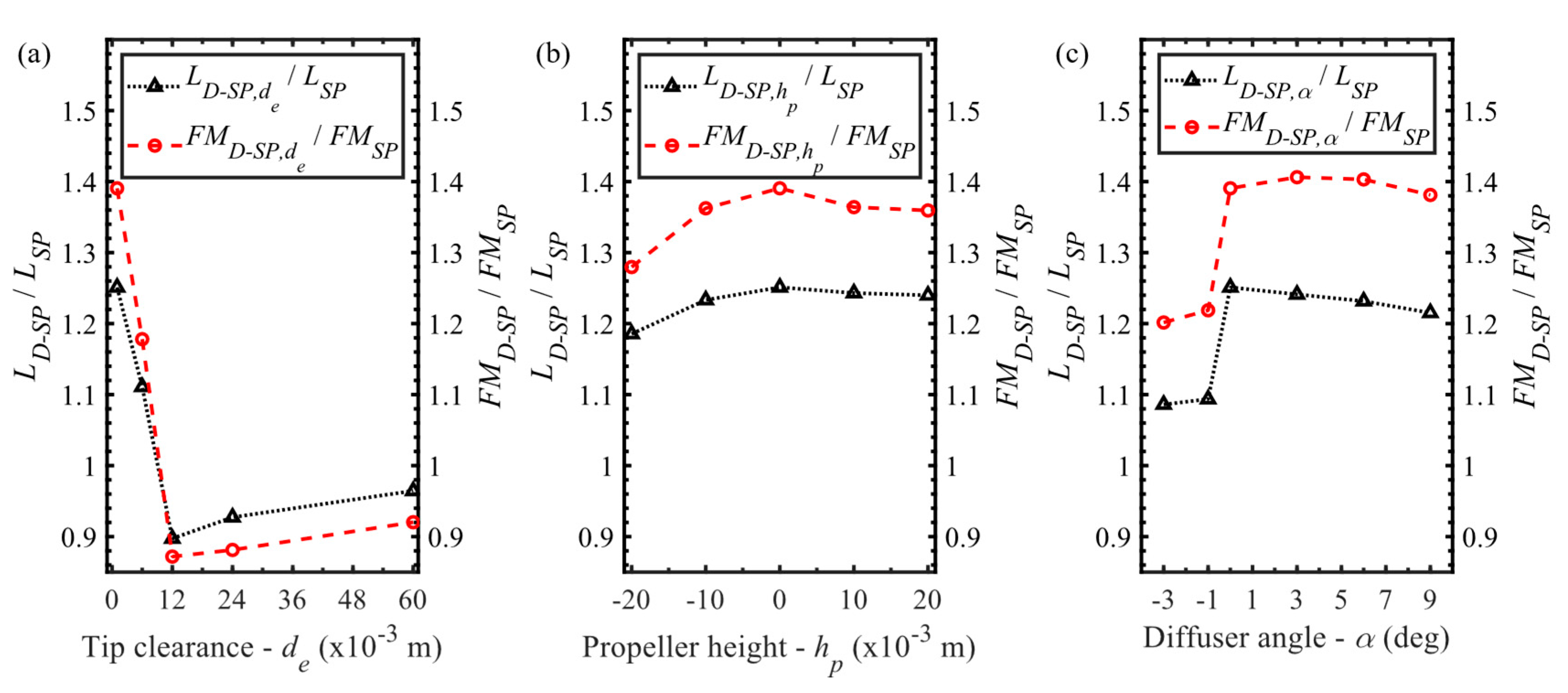

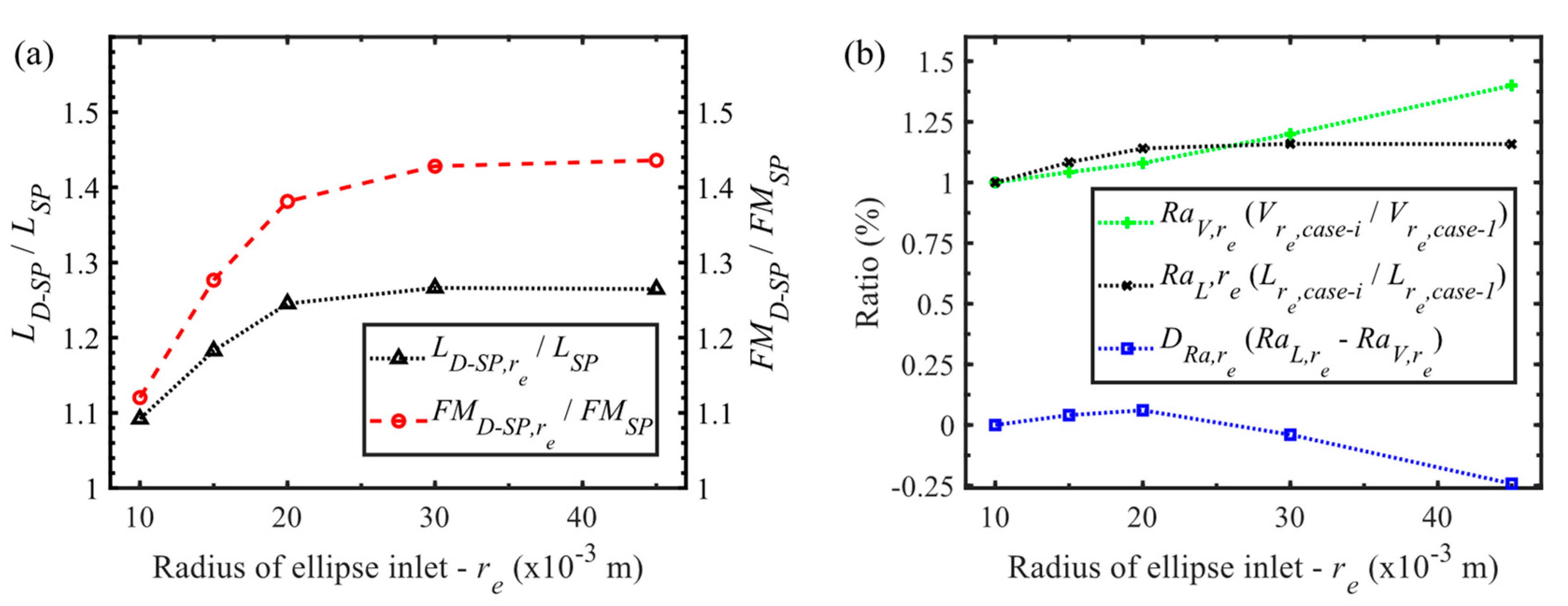

3.1.2. High-Performance Duct Design

3.2. Effect of Ducted Multi-Propeller Configuration

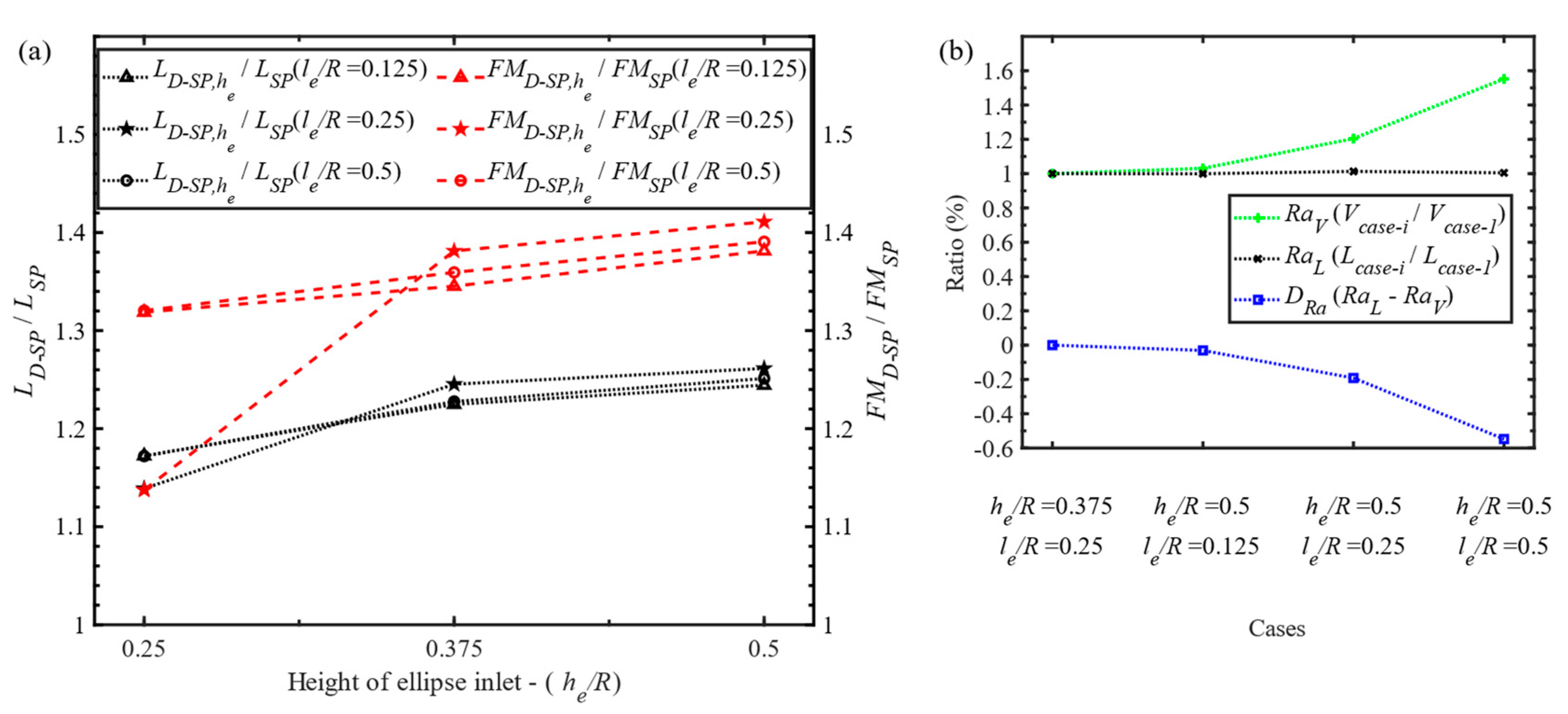

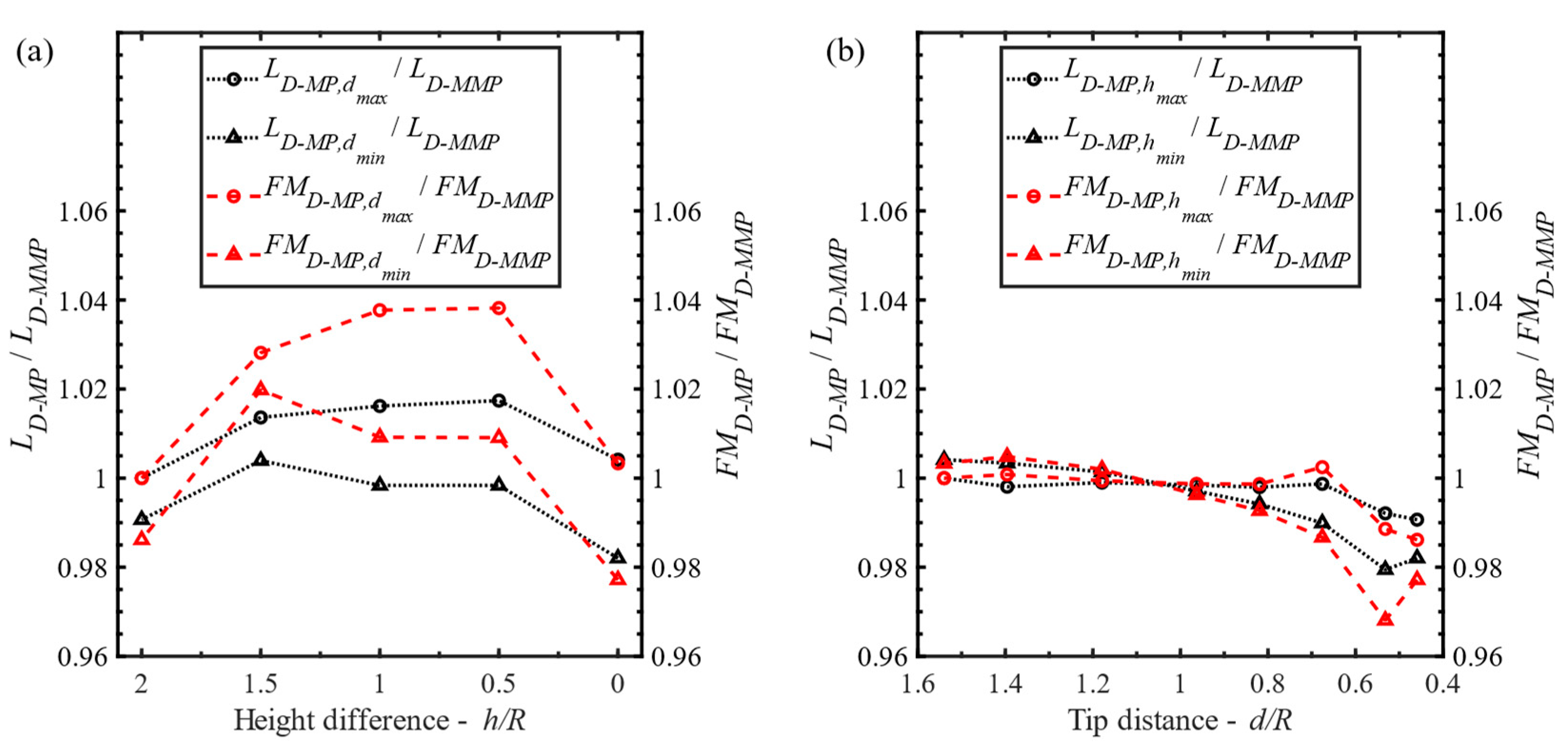

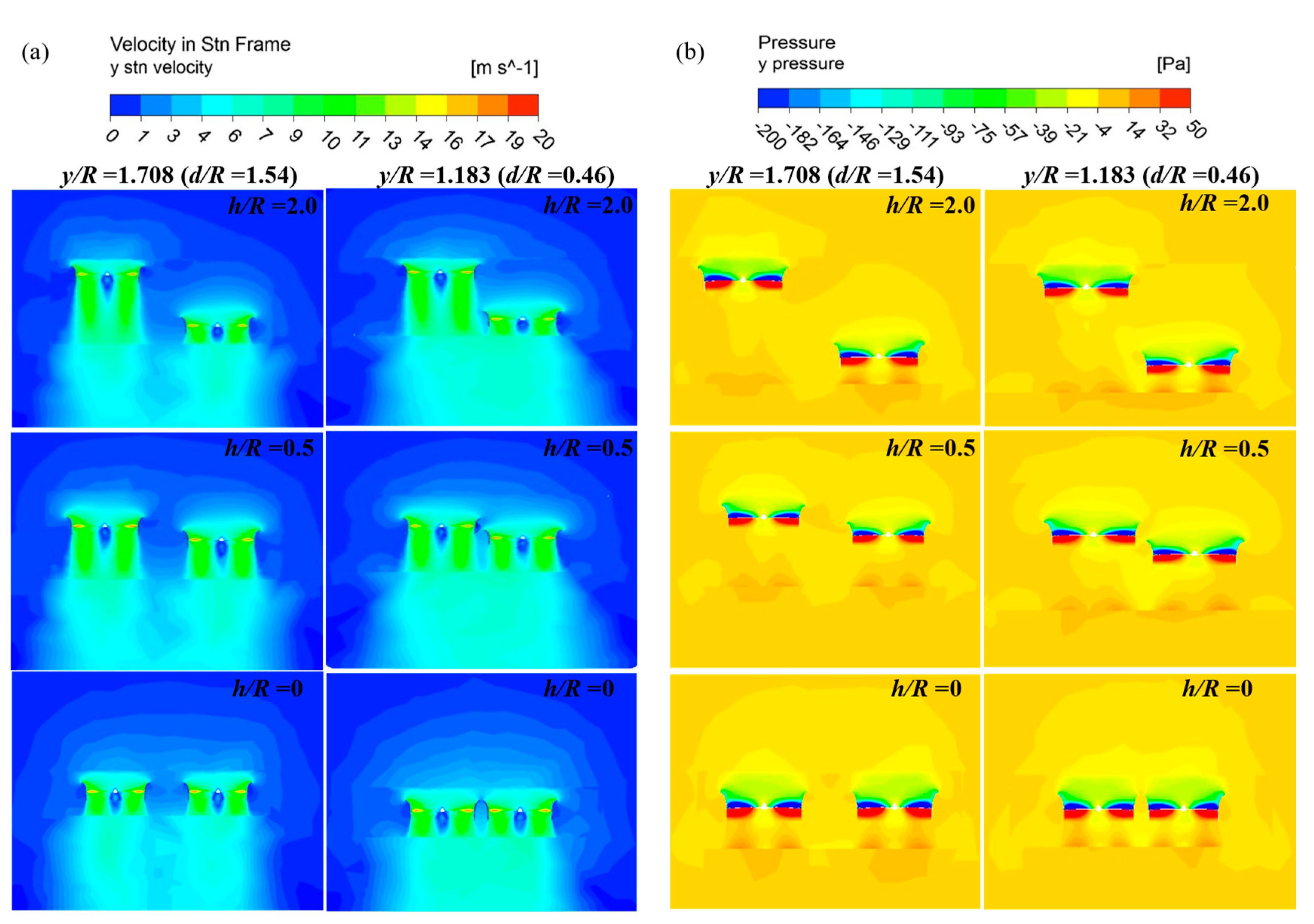

3.3. Optimization of Ducted Multi-Propeller Configuration

4. Conclusions

- A high-performance ducted single-propeller design was found, capable of achieving an increase rate of 24.5% in lift force production and 38.1% in FM efficiency compared to the original non-ducted single-propeller model. The ducted multi-propeller configuration model equipped with the high-performance duct design enables a marked improvement in both lift force production and FM efficiency with increase rates of 15.5% and 24.0% in the maximum configuration, 17.7% and 28.0% in the sub-maximum configuration, and even 7.0% and 9.7% in the basic configuration. Our results demonstrate that ducted propellers can significantly improve both lift force production and FM efficiency of multirotor copters compared to non-ducted multirotor copters.

- The aerodynamic interaction among ducted multi-propellers shows notable dependency upon two key parameters, the tip distance and height difference between propellers, and thus can be optimized in terms of the ducted multi-propeller configuration. The tip distance has a marginal impact on aerodynamic performances over a range of 0.185 m ( = 1.54) to 0.098 m ( = 0.82) but impairs the aerodynamic performance within a narrow range (0.82 0.46) with height difference fixed; adjustment of the height difference with tip distance fixed can also improve aerodynamic performance over a certain range of from 1.5 to 0.5.

- Through combining CFD-based simulations and a surrogate model to determine the effect of the ducted multi-propeller configuration on aerodynamic performance in the quadrotor drone, we found an optimal design of the ducted multi-propeller configuration under the conditions of a minimal tip distance and a specific height difference, which is capable of enabling the maximization of the aerodynamic interaction while reducing the multirotor frame, resulting in an increase rate of about 2% in lift force production and 4% in FM efficiency compared to the original ducted multi-propeller configuration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Abbreviations

| FM | figure of merit |

| UAV | unmanned aerial vehicle |

| CFD | computational fluid dynamics |

| EXP | experiment |

| SP | non-ducted single propeller |

| MP | non-ducted multi-propeller |

| D-SP | ducted single propeller |

| D-MP | ducted multi-propeller |

| D-MMP | ducted maximum multi-propeller |

| D-SMP | ducted sub-maximum multi-propeller |

| D-BMP | ducted basic multi-propeller |

| BMP | non-ducted basic multi-propeller |

| MMP | non-ducted maximum multi-propeller |

| RBFs | radial basis functions |

| IMQ | inverse multiquadric |

References

- Roldan, J.J.; Del Cerro, J.; Barrientos, A. A proposal of methodology for multi-UAV mission modeling. In Proceedings of the 23rd Mediterranean Conference on Control and Automation (MED), Torremolinos, Spain, 16–19 June 2015; pp. 1–7. [Google Scholar]

- Bousbaine, A.; Wu, M.H.; Poyi, G.T. Modelling and simulation of a quad-rotor helicopter. In Proceedings of the 6th IET International Conference on Power Electronics, Machines and Drives (PEMD 2012), Bristol, UK, 27–29 March 2012. [Google Scholar]

- Roldan, J.J.; Sanz, D.; Del Cerro, J.; Barrientos, A. Lift Failure Detection and Management System for Quadrotors. In ROBOT2013: First Iberian Robotics Conference; Springer: Cham, Switzerland, 2014; Volume 252, pp. 103–114. [Google Scholar]

- Otsuka, H.; Nagatani, K. Thrust Loss Saving Overlapping Rotor Arrangement on Small Multirotor Unmanned Aerial Vehicles. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016. [Google Scholar]

- Ampatis, C.; Papadopoulos, E. Parametric design and optimization of multi-rotor aerial vehicles. Proc.-IEEE Int. Conf. Robot Autom. 2014, 30, 6266–6271. [Google Scholar]

- Hoffmann, G.M.; Huang, H.; Waslander, S.L.; Tomlin, C.J. Quadrotor helicopter flight dynamics and control: Theory and experiment. AIAA Guid. Navig. Control. Conf. 2007, 2007, 1670–1689. [Google Scholar]

- Theys, B.; Dimitriadis, G.; Hendrick, P.; De Schutter, J. Influence of propeller configuration on propulsion system efficiency of multi-rotor Unmanned Aerial Vehicles. In Proceedings of the 2016 International Conference on Unmanned Aircraft Systems (ICUAS), Arlington, VA, USA, 7–10 June 2016; pp. 195–201. [Google Scholar]

- Shukla, D.; Komerath, N. Multirotor drone aerodynamic interaction investigation. Drones 2018, 2, 43. [Google Scholar] [CrossRef] [Green Version]

- Yao, L.; Wang, J.L. Aerodynamic Performance of Quadrotor UAV with Non-Planar Rotors. Appl. Sci. 2019, 9, 2779. [Google Scholar]

- Hrishikeshavan, V.; Black, J.; Chopra, I. Design and performance of a quad-shrouded rotor micro air vehicle. J. Aircr. 2014, 51, 779–791. [Google Scholar] [CrossRef]

- Hrishikeshavan, V.; Black, J.; Chopra, I. Design and testing of a quad shrouded rotor micro air vehicle in hover. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 April 2012. [Google Scholar]

- Hrishikeshavan, V.; Black, J.; Chopra, I. Development of a quad shrouded rotor micro air vehicle and performance evaluation in edgewise flow. Annu. Forum. Proc.-AHS 2012, 1, 665–684. [Google Scholar]

- Liu, H.; Ravi, S.; Kolomenskiy, D.; Tanaka, H. Biomechanics and biomimetics in insect-inspired flight systems. Philos. Trans. R. Soc. B Biol. Sci. 2016, 371, 20150390. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Nakata, T.; Gao, N.; Maeda, M.; Aono, H.; Shyy, W. Micro air vehicle-motivated computational biomechanics in bio-flights: Aerodynamics, flight dynamics and maneuvering stability. Acta Mech. Sin Xuebao 2010, 26, 863–879. [Google Scholar] [CrossRef]

- Cheng, B.; Deng, X.; Hedrick, T.L. The mechanics and control of pitching manoeuvres in a freely flying hawkmoth (Manduca sexta). J. Exp. Biol. 2011, 214, 4092–4106. [Google Scholar] [CrossRef] [Green Version]

- Altshuler, D.L.; Quicazán-Rubio, E.M.; Segre, P.S.; Middleton, K.M. Wingbeat kinematics and motor control of yaw turns in Anna’s hummingbirds (Calypte anna). J. Exp. Biol. 2012, 215, 4070–4084. [Google Scholar] [CrossRef] [Green Version]

- Maeda, M.; Nakata, T.; Kitamura, I.; Tanaka, H.; Liu, H. Quantifying the dynamic wing morphing of hovering hummingbird. R. Soc. Open Sci. 2017, 4, 170307. [Google Scholar] [CrossRef] [Green Version]

- Cheng, B.; Tobalske, B.W.; Powers, D.R.; Hedrick, T.L.; Wethington, S.M.; Chiu, G.; Deng, X. Flight mechanics and control of escape manoeuvres in hummingbirds. I. Flight kinematics. J. Exp. Biol. 2016, 219, 3518–3531. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Yonezawa, K.; Xu, R.; Liu, H. A Biomimetic Rotor-Configuration Design for Optimal Aerodynamic Performance in Quadrotor drone. J. Bionic Eng. 2021, 18, 824–839. [Google Scholar] [CrossRef]

- Kuantama, E.; Tarca, R. Quadcopter thrust optimization with ducted-propeller. MATEC Web Conf. 2017, 126, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Vogel, C.R.; Willden, R.H.J. Improving Tidal Turbine Performance Through Multi-Rotor Fence Configurations. J. Mar. Sci. Appl. 2019, 18, 17–25. [Google Scholar] [CrossRef] [Green Version]

- Lu, Z.; Liu, Y.; Debiasi, M.; Khoo, B.C. Acoustic characteristics of a multi-rotor MAV and its noise reduction technology. In Proceedings of the 45th International Congress and Exposition of Noise Control Engineering, Hamburg, Germany, 21–24 August 2016; pp. 725–735. [Google Scholar]

- Arkhipov, M.; Serokhvostov, S.; Stremousov, K. Numerical and Experimental Investigation of Ducted Fans Interference for Multirotor Copter-type Aerial Vehicle. In Proceedings of the 7th European Conference for Aeronautics and Aerospace Science (EUCASS), Milan, Italy, 3–7 July 2017. [Google Scholar]

- Stremousov, K.; Arkhipov, M. Study of ducted fans interference for copter type multirotor UAV/RPAS. In Proceedings of the International Micro Air Vehicle Conference and Flight Competition (IMAV), Toulouse, France, 18 September 2017; pp. 17–22. [Google Scholar]

- Chua, J.C.; Loveranes, A.; MacAndog, L.A.; Reyes, R.M.; Augusto, G.L.; Lim, L.A.G. Design of a shrouded rotor with optimal thrust and energy efficiency in unmanned aerial vehicles. In Proceedings of the 2018 IEEE 10th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment and Management (HNICEM), Baguio City, Philippines, 29 November–2 December 2018. [Google Scholar]

- Moaad, Y.; Alaaeddine, J.; Jawad, K.; Tarik, B.K.; Lekman, B.; Hamza, J.; Patrick, H. Design and optimization of a ducted fan VTOL MAV controlled by Electric Ducted Fans. In Proceedings of the 8th European Conference for Aeronautics and Space Sciences, Madrid, Spain, 1–4 July 2019; pp. 1–14. [Google Scholar]

- Penkov, I.; Aleksandrov, D. Propeller shrouding influence on lift force of mini unmanned quadcopter. Int. J. Automot Mech. Eng. 2017, 14, 4486–4495. [Google Scholar] [CrossRef]

- Shukla, D.; Komerath, N. Rotor–duct aerodynamic and acoustic interactions at low Reynolds number. Exp. Fluids 2019, 60, 1–14. [Google Scholar] [CrossRef]

- Yonezawa, K.; Sugiyama, K.; Tanabe, Y.; Sunada, S. Development of a Ducted Rotor for Multicopters. In Proceedings of the 6th Asian/Austrailian Rotorcraft Forum/Heli Japan, Ishikawa, Japan, 7–9 November 2017. [Google Scholar]

- Yonezawa, K.; Matsumoto, H.; Sugiyama, K.; Tanabe, Y.; Tokutake, H.; Sunada, S. Aerodynamic Characteristics of a Quad-Rotor-Drone with Ducted Rotors. In Proceedings of the 8th Asian/Austrailian Rotorcraft Forum, Ankara, Turkey, 30 October–2 November 2019. [Google Scholar]

- Bangura, M.; Melega, M.; Naldi, R.; Mahony, R. Aerodynamics of Rotor Blades for Quadrotors. Fluid Dyn. 2016. Available online: http://arxiv.org/abs/1601.00733 (accessed on 12 January 2016).

- Nguyen, D.H.; Liu, Y.; Mori, K. Experimental Study for Aerodynamic Performance of Quadrotor Helicopter. Trans. Jpn. Soc. Aeronaut Space Sci. 2018, 61, 29–39. [Google Scholar] [CrossRef] [Green Version]

- Noda, R.; Nakata, T.; Ikeda, T.; Chen, D.; Yoshinaga, Y.; Ishibashi, K.; Rao, C.; Liu, H. Development of bio-inspired low-noise propeller for a drone. J. Robot Mechatron. 2018, 30, 337–343. [Google Scholar] [CrossRef]

- Ikeda, T.; Tanaka, H.; Yoshimura, R.; Noda, R.; Fujii, T.; Liu, H. A robust biomimetic blade design for micro wind turbines. Renew Energy 2018, 125, 155–165. [Google Scholar] [CrossRef]

- Pagliuca, G.; Kipouros, T.; Savill, M.A. Surrogate modelling for wing planform multidisciplinary optimisation using model-based engineering. Int. J. Aerosp Eng. 2019, 2019, 4327481. [Google Scholar] [CrossRef]

- Han, Z.; Zhang, K. Surrogate-Based Optimization. In Real-World Applications of Genetic Algorithms; IntechOpen: London, UK, 2012. [Google Scholar] [CrossRef] [Green Version]

- Bhatia, G.S.; Arora, G. Radial basis function methods for solving partial differential equations-A review. Indian J. Sci. Technol. 2016, 9, 1–18. [Google Scholar]

- Koushki, M.; Jabbari, E.; Ahmadinia, M. Evaluating RBF methods for solving PDEs using Padua points distribution. Alex. Eng. J. 2020, 59, 2999–3018. [Google Scholar] [CrossRef]

| (m) | (m) | (°C) | ||||

|---|---|---|---|---|---|---|

| Basic duct | 0.001 | 0 | 0 | 0.5 | 0.5 | 0.167 |

| High-performance duct | 0.001 | 0 | 0 | 0.375 | 0.25 | 0.167 |

| = 2.0 | 1.54 | 1.40 | 1.18 | 1.00 | 0.82 | 0.68 | 0.53 | 0.46 |

| = 1.5 | 1.54 | ‒ | ‒ | ‒ | ‒ | ‒ | ‒ | 0.46 |

| = 1.0 | 1.54 | ‒ | ‒ | ‒ | ‒ | ‒ | ‒ | 0.46 |

| = 0.5 | 1.54 | ‒ | ‒ | ‒ | ‒ | ‒ | ‒ | 0.46 |

| = 0.0 | 1.54 | 1.40 | 1.18 | 1.00 | 0.82 | 0.68 | 0.53 | 0.46 |

| = 1.5 | – | – | 1.18 | – | – | 0.68 | – | – |

| = 1.0 | – | 1.40 | – | 1.00 | 0.82 | – | 0.53 | – |

| = 0.6 | 1.54 | 1.40 | – | – | – | – | 0.53 | 0.46 |

| = 0.5 | – | – | 1.18 | – | 0.82 | 0.68 | – | – |

| Surrogate Modeling | CFD Simulation | |

|---|---|---|

| Optimal | 14.611 N | 14.605 N |

| Dimensionless value of and at optimal | = 0.925 ( = 0.111 m), = 0.92 ( = 0.110 m) | = 1.0 ( = 0.120 m), = 1.0 ( = 0.120 m) |

| Increase rate of optimal compared to | 1.95% | 1.90% |

| Increase rate of optimal compared to | 17.79% | 17.74% |

| Remarks | Optimal = 3.3; , , . | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Yonezawa, K.; Liu, H. Effect of Ducted Multi-Propeller Configuration on Aerodynamic Performance in Quadrotor Drone. Drones 2021, 5, 101. https://doi.org/10.3390/drones5030101

Li Y, Yonezawa K, Liu H. Effect of Ducted Multi-Propeller Configuration on Aerodynamic Performance in Quadrotor Drone. Drones. 2021; 5(3):101. https://doi.org/10.3390/drones5030101

Chicago/Turabian StyleLi, Yi, Koichi Yonezawa, and Hao Liu. 2021. "Effect of Ducted Multi-Propeller Configuration on Aerodynamic Performance in Quadrotor Drone" Drones 5, no. 3: 101. https://doi.org/10.3390/drones5030101

APA StyleLi, Y., Yonezawa, K., & Liu, H. (2021). Effect of Ducted Multi-Propeller Configuration on Aerodynamic Performance in Quadrotor Drone. Drones, 5(3), 101. https://doi.org/10.3390/drones5030101