Design and Acceptability of a Multi-Ingredients Snack Bar Employing Regional PRODUCTS with High Nutritional Value †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.3. Design and Elaboration of the Snack Bars

2.4. Sensory Analysis

2.4.1. Sensory Analysis 1

2.4.2. Sensory Analysis 2

2.5. Statistical Analysis

3. Results

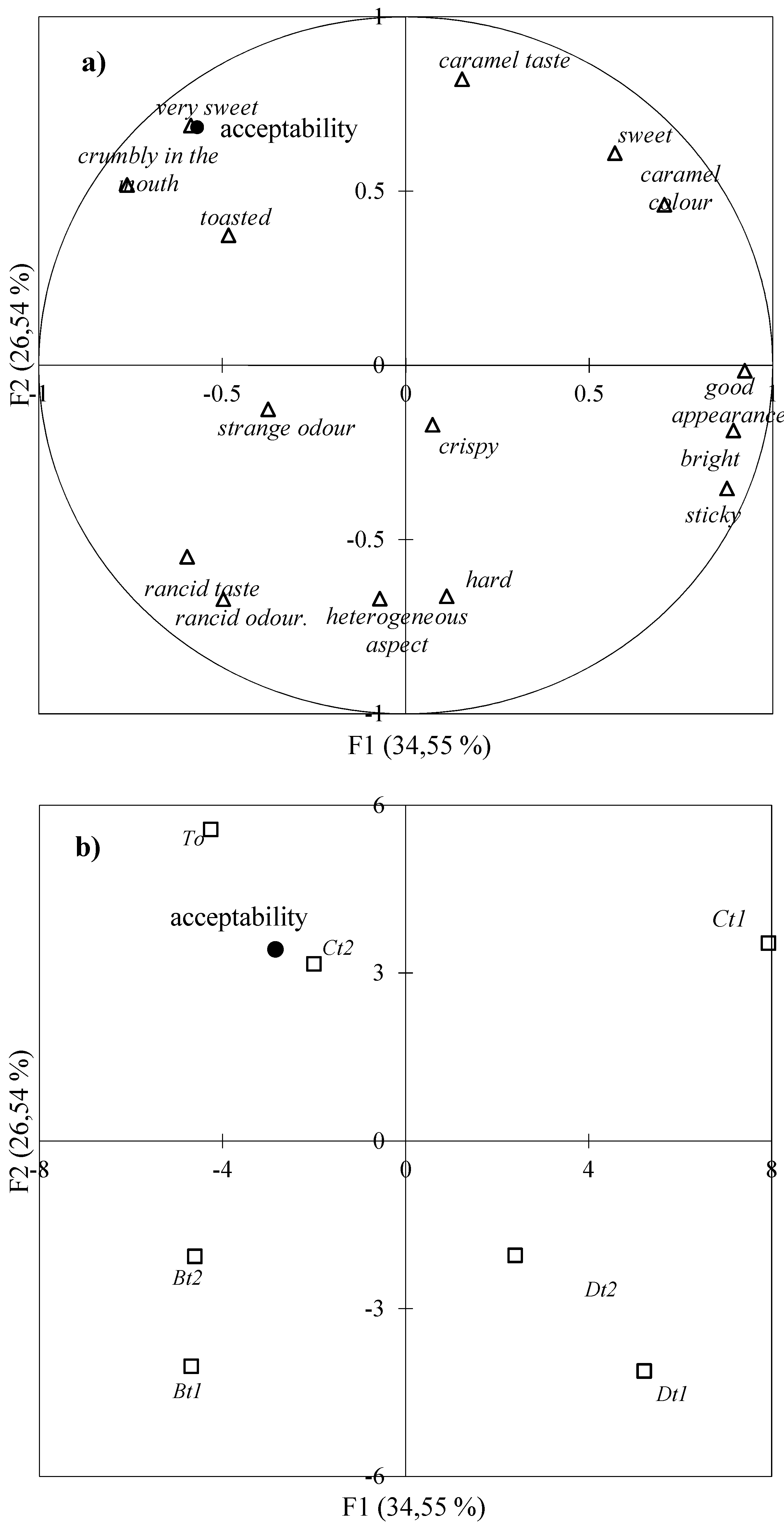

3.1. Sensory Analysis. Process Selection

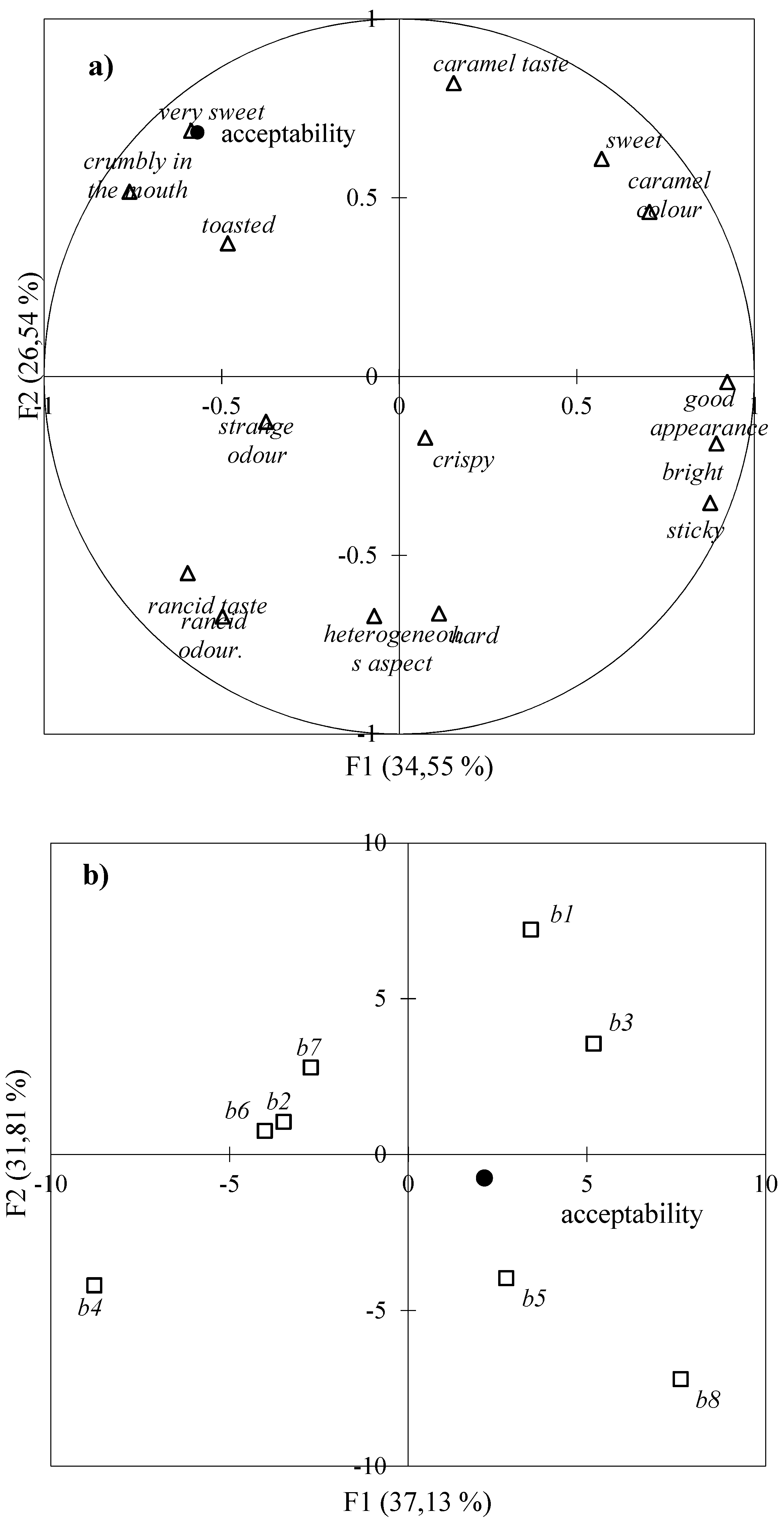

3.2. Sensorial Analysis. Ingredient Selection

3.3. Nutritional Analysis

4. Discussion

5. Conclusions

Acknowledgments

References

- Sun-Waterhouse, D.; Farr, J.; Wibisono, R.; Saleh, Z. Fruit-based functional foods I: Production of food-grade apple fibre ingredients. Int. J. Food Sci. Technol. 2008, 43, 2113–2122. [Google Scholar] [CrossRef]

- Nascimento, A.C.; Mota, C.; Coelho, I.; Gueifão, S.; Santos, M.; Matos, A.; Sammán, N.; Castanheira, I. Characterization of nutrient profile of quinoa (Chenopodium quinoa), amaranth (Amaranthus caudatus), and purple corn (Zea mays L.) consumed in the North of Argentina: Proximates, minerals and trace elements. Food Chem. 2014, 148, 420–426. [Google Scholar] [CrossRef] [PubMed]

- Pizarro, P.L.; Almeida, E.L.; Sammán, N.C.; Chang, Y.K. Evaluation of whole chia (Salvia hispanica L.) flour and hydrogenated vegetable fat in pound cake. LWT Food Sci. Technol. 2013, 54, 73–79. [Google Scholar] [CrossRef]

- Coelho, M.S.; de Araujo Aquino, S.; Latorres, J.M.; de las Mercedes Salas-Mellado, M. In vitro and in vivo antioxidant capacity of chia protein hydrolysates and peptides. Food Hydrocoll. 2019, 91, 19–25. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of the Association of Official Agricultural Chemists, 16th ed.; AOAC: Washington, DC, USA, 1995. [Google Scholar]

- Rios, F.; Lobo, M.; Sammán, N. Acceptability of beehive products as ingredients in quinoa bars. J. Sci. Food Agric. 2018, 98, 174–182. [Google Scholar] [CrossRef] [PubMed]

- Damodaran, S.; Parkin, K.L. Química de los Alimentos de Fennema; Editorial Acribia: Zaragoza, Spain, 2018. [Google Scholar]

- Repo-Carrasco-Valencia, R.A.; Encina, C.R.; Binaghi, M.J.; Greco, C.B.; Ronayne de Ferrer, P.A. Effects of roasting and boiling of quinoa, kiwicha and kañiwa on composition and availability of minerals in vitro. J. Sci. Food Agric. 2010, 90, 2068–2073. [Google Scholar] [CrossRef] [PubMed]

- Pinto, V.R.A.; de Oliveira Freitas, T.B.; de Souza Dantas, M.I.; Della Lucia, S.M.; Melo, L.F.; Minim, V.P.R.; Bressan, J. Influence of package and health-related claims on perception and sensory acceptability of snack bars. Food Res. Int. 2017, 101, 103–113. [Google Scholar] [CrossRef] [PubMed]

| Process | Temperature (°C) | Time (min) | Acceptability (n = 75) |

|---|---|---|---|

| Toasting (To) | 190 | 3 | 6.53 a |

| Cooking (Ct2) | 94 | 20 | 6.11 a |

| Baking (Bt2) | 130 | 45 | 5.27 b |

| Baking (Bt1) | 130 | 30 | 5.26 b |

| Cooking (Ct1) | 94 | 10 | 5.02 b |

| Dry heating (Dt1) | 80 | 45 | 4.73 b |

| Dry heating (Dt2) | 80 | 60 | 4.05 c |

| Sample | Amaranth | Quinoa | Chia | Sunflower | Sesame | Poppy | Flax | Acceptability (n = 85) * |

|---|---|---|---|---|---|---|---|---|

| b1 | 2 | 2 | 1 | 2 | 1 | 1 | 2 | 6.00 a |

| b3 | 2 | 2 | 1 | 1 | 2 | 2 | 1 | 5.82 ab |

| b2 | 2 | 1 | 2 | 2 | 1 | 2 | 1 | 5.74 ab |

| b4 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 5.70 ab |

| b5 | 1 | 2 | 2 | 2 | 2 | 1 | 1 | 5.37 b |

| b6 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3.54 c |

| b7 | 1 | 2 | 2 | 1 | 1 | 2 | 2 | 4.42 c |

| b8 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 5.71 ab |

| Ingredient | Moisture | Protein | Lipid | Ash | Fiber | Carbohydrates * |

|---|---|---|---|---|---|---|

| (g/100 g) | ||||||

| Oats | 8.2 | 16.9 | 6.9 | 1.7 | 10.6 | 66.3 |

| Sesame | 3.8 | 17.7 | 49.7 | 4.5 | 18 | 6.4 |

| Sunflower | 3.7 | 19.9 | 56.4 | 2.9 | 2.7 | 17.1 |

| Chia | 7.7 | 20 | 31 | 4.6 | 31.5 | 5.2 |

| Amaranth | 10.5 | 13.4 | 6.4 | 2.9 | 11.3 | 55.3 |

| Quinoa | 11.3 | 12.1 | 6.3 | 2 | 10.4 | 57.2 |

| Rice | 8.6 | 5.9 | 0.7 | 0.5 | 1.7 | 82.5 |

| Final product | 10.2 | 9.7 | 10.5 | 2.3 | 6.5 | 60.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rios, F.T.; Amaya, A.A.; Lobo, M.O.; Samman, N.C. Design and Acceptability of a Multi-Ingredients Snack Bar Employing Regional PRODUCTS with High Nutritional Value. Proceedings 2020, 53, 14. https://doi.org/10.3390/proceedings2020053014

Rios FT, Amaya AA, Lobo MO, Samman NC. Design and Acceptability of a Multi-Ingredients Snack Bar Employing Regional PRODUCTS with High Nutritional Value. Proceedings. 2020; 53(1):14. https://doi.org/10.3390/proceedings2020053014

Chicago/Turabian StyleRios, Francisco Teodoro, Argentina Angelica Amaya, Manuel Oscar Lobo, and Norma Cristina Samman. 2020. "Design and Acceptability of a Multi-Ingredients Snack Bar Employing Regional PRODUCTS with High Nutritional Value" Proceedings 53, no. 1: 14. https://doi.org/10.3390/proceedings2020053014

APA StyleRios, F. T., Amaya, A. A., Lobo, M. O., & Samman, N. C. (2020). Design and Acceptability of a Multi-Ingredients Snack Bar Employing Regional PRODUCTS with High Nutritional Value. Proceedings, 53(1), 14. https://doi.org/10.3390/proceedings2020053014