Abstract

Wheelchair racing gloves are typically solid 3D structures held in a clenched fist which help to propel the chair by pushing the glove against a rotating rail which is attached to the wheel to drive the wheelchair forward. There has been a recent movement towards developing customisable gloves using 3D scanning technique, however, currently there are no commercial offerings which allow for product customisation without being prohibitively expensive. The aim of this project, therefore, was to develop a scalable method for producing customised wheelchair racing gloves in a cost-effective way. The generated 3D forms were 3D printed in a variety of infill densities and finished with a grip liner. These 3D printed gloves were compared in terms of fit and perception of performance, and for their mass, cost and energy/power cost. The 3D printed gloves provided a substantially reduced mass with only a minimal reduction in overall strength at a comparable cost to the solid equivalent.

1. Introduction

Wheelchair racing gloves are typically solid 3D structures held in a clenched fist which help to propel the chair. Propulsion is achieved by pushing the glove against a rotating rail which is attached to the wheel to drive the wheelchair forward as shown in Figure 1. Currently, a range of generic glove sizes are available (Figure 2), however, there has been a recent movement towards developing customisable gloves using 3D scanning technique [1,2,3,4]. It has previously been shown that there is clear scope for 3D scanning to aid with mass-customisation and optimisation [5] and there is a wide range of technologies (e.g., use of lightweight materials to reduce fatigue, electronic sensors and computer equipment to monitor performance) [6]. However, the existing commercially available wheelchair racing gloves are limited in that they do not allow for customisation of the end-user without being prohibitively expensive, or instead, products are based on a form which was customised for a lead-user, typically a professional athlete. The aim of this project, therefore, was to develop a scalable method for producing customised wheelchair racing gloves in a cost-effective way.

Figure 1.

Wheelchair racing gloves are typically solid 3D structures held in a clenched fist. Propulsion is achieved by pushing the glove against a rotating rail.

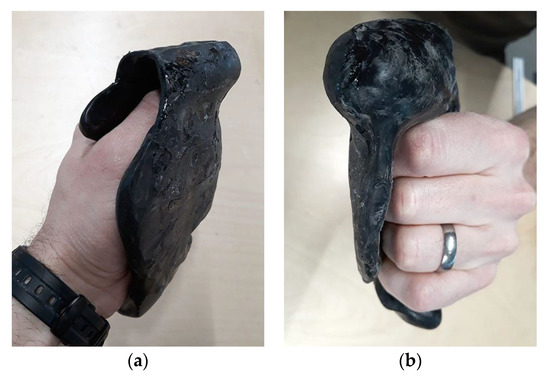

Figure 2.

Existing types of wheelchair racing gloves: (a,b) customised solutions for professional athletes [1,2] and commercially available options; (c) 3D printed flexible rubber gloves based on specific finger and hand width measurements obtained with a soft measuring tape, available for CAD$295 (or GBP£170) [3]; (d) Flat-surfaced 3D printed glove based on specific measurements for thumb length and two-finger width, available for AU$220 (or GBP£114) [4].

2. Materials and Methods

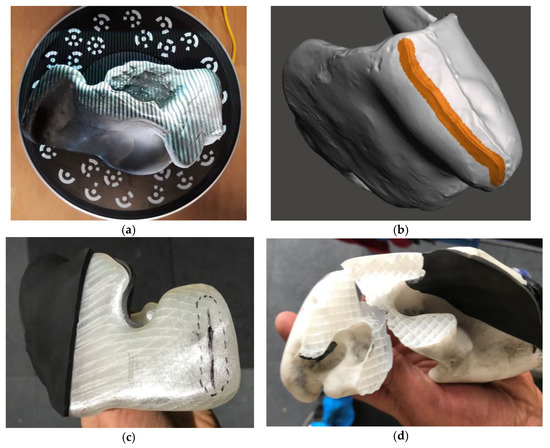

Two separate approaches were used to generate a glove form for a professional wheelchair racing athlete such that both techniques could be compared in situ. The 3D forms from both techniques were then 3D printed in a variety of infill densities and finished with a grip liner to compare to a benchmark solid glove form which had been manually sculpted and had been previously used in competition by the participant (Figure 3). In the first approach, both fists of the participant were scanned using a Structure Sensor (Occipital) 3D scanner (typical accuracy in the order of 1 mm for small handheld objects) as a baseline from which a digitally sculpted 3D form could be built around. In the second approach, a thermoformable polymer (Polymorph PCL thermoplastic, Mindsets) was softened and squeezed in each hand and physically sculpted into a form that could be tested in situ and further sculpted until a suitable form could be agreed on by the participant. This glove (shown in Figure 3) was then sprayed with a white coating to improve scanning quality (Ambersil Flaw Detector Developer 3), then 3D scanned using a Shining EinScan-SP Desktop 3D scanner (volume 200 × 200 × 200 mm—accuracy in the order of 10−1–10−2 mm) and digitally smoothed using Meshmixer (Autodesk) as shown in Figure 4a,b. 3D printed glove samples were produced initially using Premium PLA (Raise3D) and then Polymax polycarbonate (Polymaker) on a N2 Plus machine (Raise3D). An example prototype is shown in Figure 4c. Figure 4d shows the lightest prototype failure when using 20% infill—failure occurred by delamination between layers in the transition area between the grip and the contact area.

Figure 3.

Existing wheelchair racing glove design made using Polymorph PCL thermoplastic (Mindsets): (a) a top view; (b) a front view.

Figure 4.

Initial glove forms made: (a) using a thermoformable polymer (Polymorph PCL thermoplastic, Mindsets) was 3D scanned using a Shining EinScan-SP Desktop 3D scanner; (b) digital smoothing was achieved using Meshmixer (Autodesk); (c) 3D printed glove samples were initially produced initially using Premium PLA (Raise3D) on a N2 Plus machine (Raise3D) then lined with a rubber compound to provide traction; (d) after some field testing on a treadmill and on the road, the lightest prototype (20% infill) failed by delaminating between layers in the transition area between the grip and the contact area.

The 3D printed gloves were compared qualitatively in terms of fit and quantitatively for their mass, cost, and average power/energy cost of using the gloves. Some user testing was also carried out on a treadmill and on the road. A simple model was used to estimate this power and energy cost during each push cycle. In this model, the movement of each glove was represented as a vertically oscillating mass. The model was purposefully chosen to be a conservative one to give an initial minimum estimate for these quantities. The average power cost of using the gloves was calculated as follows:

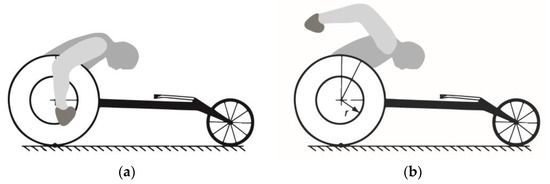

where the time period, t, for each full push cycle was assumed to be 1 s (including both down and up phases). The work, W, was the work done to lower and then raise the glove of mass, m (kg), through the height of the rim, h = 0.37 m, as established by expending and then returning the potential energy through each full controlled cycle as shown in Figure 5.

Figure 5.

Typical range for a full push cycle (adapted from [7]): (a) arms pushing the rim with glove at the lower edge of the rim; (b) arms extended with glove raised to some extent above the rim.

The conservative estimate for the total energy expenditure was then calculated for both gloves in both the down and up phases, over a 12 minute wheelchair racing stage, i.e.,:

Since the force required to resist gravitational acceleration, g, is:

then the total work done for each half cycle per glove, W, becomes:

3. Results

The 3D printed glove options (Figure 6) provided a substantially reduced mass (reduced from 231–79 g) with only a minimal reduction in overall strength at a comparable cost to the solid equivalent (Table 1).

Figure 6.

Latest design solution: (a) final CAD models of the pair of customised wheelchair racing gloves; (b) the 3D printed gloves being tested for fit using Premium PLA (Raise3D) material.

Table 1.

Comparison between original solid moulded gloves and 3D printed alternatives.

4. Discussion

The 30% infill gloves with additional shell walls were then tested by the participant in a series of competitive events with positive results (fastest section all races in the current season since changing to the new gloves). A number of possible future directions are available for this project including:

- Providing a service to produce gloves for athletes.

- The face area that contacts the push rim on the wheel can be a generic shape since push rims are a generic shape.

- The glove could be made available in generic sizes (XS/S/M/L/XL) or off a specific hand measurement to scale the glove. The supplied standard glove would then have extensive cavities where the fingers insert and around the base of the hand. This could then be filled with a soft moulding putty or mouldable thermoplastic such as the Polymorph PCL thermoplastic (Mindsets) used previously. At this point, the athlete can mould around the generic form to customise the glove to create a customised fit.

From here, it seems there are three options:

- A DIY kit: The athlete self-moulds the glove and these become the finished product.

- A fully customised 3D printed version: The athlete self-moulds the glove then returns the moulded glove in the post. Then, the moulded sections could be removed from the glove for scanning into the existing generic shape. A test pair of gloves made of thin cheap material is then posted to the athlete for test fit and confirmation they are satisfied. The definitive glove is then printed. Options of colours, weights, perforation (optional extras) can also be chosen.

- A replica set: the athlete sends in the complete existing gloves for scanning (as was outlined in this paper), followed by a test fitting and testing process where the design is iteratively refined until the fit and performance is adequate for the athlete.

The model used here to estimate the power and energy cost during each push cycle was a simple and conservative model to gain an initial, worst case estimate of these quantities. Typically, the gloves would be raised well above the top line of the push rim (as seen in Figure 4), and the dynamics of the movement would be such that there would be considerable additional energy required to rotate and translate the gloves during a push cycle. Furthermore, more sophisticated models have been published (for example [7]), which include a more comprehensive analysis of the dynamics in the rider/wheelchair/glove system. This would be an interesting area for future study, in order to more accurately understand the power and energy cost to athletes associated with the inertial properties of gloves.

5. Conclusions

Existing commercially available wheelchair racing gloves are limited in that they do not allow for customisation of the end-user without being prohibitively expensive, or products are based on a form which was customised for a lead-user, typically a professional athlete. In response to this, this study developed a scalable method for producing customised wheelchair racing gloves in a cost-effective way that could achieve a custom fit in a high-performance, lightweight product.

References

- 3D Print. Available online: https://3dprint.com/209487/scott-crowley-3d-printed-gloves (accessed on 1 October 2019).

- Beckman Institute. Available online: https://www.youtube.com/watch?v=W8tTRX_JgJk (accessed on 1 October 2019).

- Revolution Sport. Available online: http://www.revolutionsports.ca/en-ca/shop/R%C3%A9volution-Flex-3D-Printed-Racing-Gloves-p109503065 (accessed on 1 October 2019).

- Push Mobility. Available online: https://www.pushmobility.com.au/products/ingenium-glove-size-4-black (accessed on 1 October 2019).

- Mckinsey. Available online: https://www.mckinsey.com/~/media/mckinsey/dotcom/client_service/bto/pdf/mobt32_02-09_masscustom_r4.ashx (accessed on 1 October 2019).

- Burton, M.; Fuss, F.K.; Subic, A. Sports Wheelchair Technologies. Sports Technol. 2010, 3, 154–167. [Google Scholar] [CrossRef]

- Masson, G.; Bégin, M.-A.; Lopez Poncelas, M.; Pelletier, S.-K.; Lessard, J.-L.; Laroche, J.; Berrigan, F.; Langelier, E.; Smeesters, C.; Rancourt, D. Contribution of limb momentum to power transfer in athletic wheelchair pushing. J. Biomech. 2016, 49, 2577–2583. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).