1. Introduction

According to AENOR standards [

1] a geosynthetic material is the product made of different components in which at least one of them is made of a synthetical or natural polymer with the shape of a layer, a strip or a 3D structure which is used in contact with soil or other materials in the civil engineering works. Geosynthetic materials could be divided in four big groups according to its differential properties: geotextile, geotextile related products, geocomposites and geomembranes.

The different mechanisms of degradation produced by traffic and environmental loads, could be reduced with the appropriate use of an adequate geosynthetic material [

2].

These products can be placed in several positions inside the pavement structure. During the 80’s decade, several studies started to consider the use of reinforced pavement structures applying geosynthetics products inside granular basis at different positions of these structures. Over time, many studies concluded that the optimum position is in the middle of the granular base [

3,

4] and a geogrid usually provides better results than a geotextile [

5]. Recent papers which study flexible pavements [

6], evaluate the improvement of the structural capacity provided by the introduction of geosynthetics products inside the asphalt layers.

The reinforcement of pavements due to the application of geotextile and geogrids has been object of study of several authors, but just a few of them deal with the methodology of implementation on site. The work presented by Chan et al. [

5] has the purpose of defining the capability of geosynthetics reinforcement. It determined that factors as the right prestrees and anchorage include additional improvements when using these materials.

The aim of this paper is to identify the deviation between the empirical statements and the reality, that can be observed in field works.

The objective of the present paper, consists of defining the possible errors which could take place during the execution of the field works and to identify the possible existing divergences between scientific studies and the reality of site implementation.

2. Materials and Methods

In order to elaborate the present paper, several site work visits, during different execution phases of road works has been made. The idea is being able to get a continuous monitoring of the different construction phases and get the information needed to compare site characteristics and modelling hypothesis.

Regardless the pavement condition, road type or geosynthetic material used, the first thing to do is a preliminary analysis of site conditions. At this first stage the most important thing is to identify the possible acting locations. These locations are the places where a divergence between the model and the actual situation of the work place is clearly feasible to occur. Once the existing problematic placed are identified, the second step consist on defining the suitable geosynthetics to be used in each of the diverse work scenarios considered, for every study case.

After this stage, according to the site typology or geometric characteristics that define every pavement project, it is a common practice to mill the existing pavement, and cleaning up the basis of the future pavement. In this moment, it is time for carrying out the following step of the process, a new inspection of the road condition is needed. In this point, the persisting pathologies should be defined as harsh and new possible affections should be considered if its occurrence is shown to be significant. At this point it is needed to reconsider the type of geosynthetic to be used to give a solution to the new problematic.

After that, during the following phases of the works, where the different reinforcement products are applied, the continuous surveillance by qualified personal is essential. Finally, the obtained results are compared with the assumptions made by other authors ([

7,

8]) in the different papers about this topic so far and model hypothesis considered.

3. Results

During several months three road works in which geosynthetics were being used were visited and the utilization of these material studied. The aim of this study was to analyse if a numerical model that is being developing to characterize the properties of a composite material fits with the reality of the road works carried out.

In this sense this paper shows what is found when analysing site works and if this could be considered acceptable for the use of the characteristics obtained with the computational model.

First of all, it can be appreciated that

Figure 1a shows many interconnected cracks commonly called as ‘crocodile skin’. This pathology is very common and subject matter for several authors and it can be observed, and a first consideration of geosynthetic to be used as a solution is proposed. But in order to rehab roads with this kind of issue, is important to mill the existing pavement to clean it up.

Figure 1b, shows the condition of a milled road with deep cracks easily distinguishable. This milling allows to identify cracks which origin is in the pavement basis and this enables to find and act over them using appropriate materials.

It is also essential to identify where future cracks could appear. In the case of urban roads, is common to find different pavement discontinuities. This can be appreciated by doing a first inspection on site. For example, if

Figure 2a is observed it can be detected that in the left picture an urban services ditch filled with mass concrete is shown. This generates a mix of pavements with different characteristics and if these discontinuities are properly treated, using the correct geosynthetic material, the reflective cracking in the surface layer is ensured.

In the picture of the right, of

Figure 2a, a typical gardened island traffic is shown. The fact of being filled with graded aggregate and a bigger amount of asphalt induces a different behavior with the surrounding pavement. Settlements that will be shown in the surface layer in the way of cracks or undulations, may appear.

In all the above situations it is necessary to achieve a proper interaction between the road materials and geosynthetics, to get this is crucial to get a god fixation of the different materials without any air gaps and a continuity among them. In

Figure 1a,b and

Figure 2a staff should be aware of a proper installation of all material to achieve the purpose.

Most times lack of qualified staff with the required knowledge for the geosynthetics operation, is reflected in common execution errors such as the one shown in

Figure 2b. It can be noticed that the no filling the longitudinal deep crack with asphalt previously, produces the mistake in the geosynthetics fitting. This may result in folds and gaps which blocks the right material functioning.

Another common mistake it is produced when placing the geogrid. Providers of these materials have indications about the execution of the overlaps both longitudinal and cross directions.

Figure 3a, shows an overlap where the ranges and fibers direction are not observed, this produces an incorrect functioning of the material.

If in

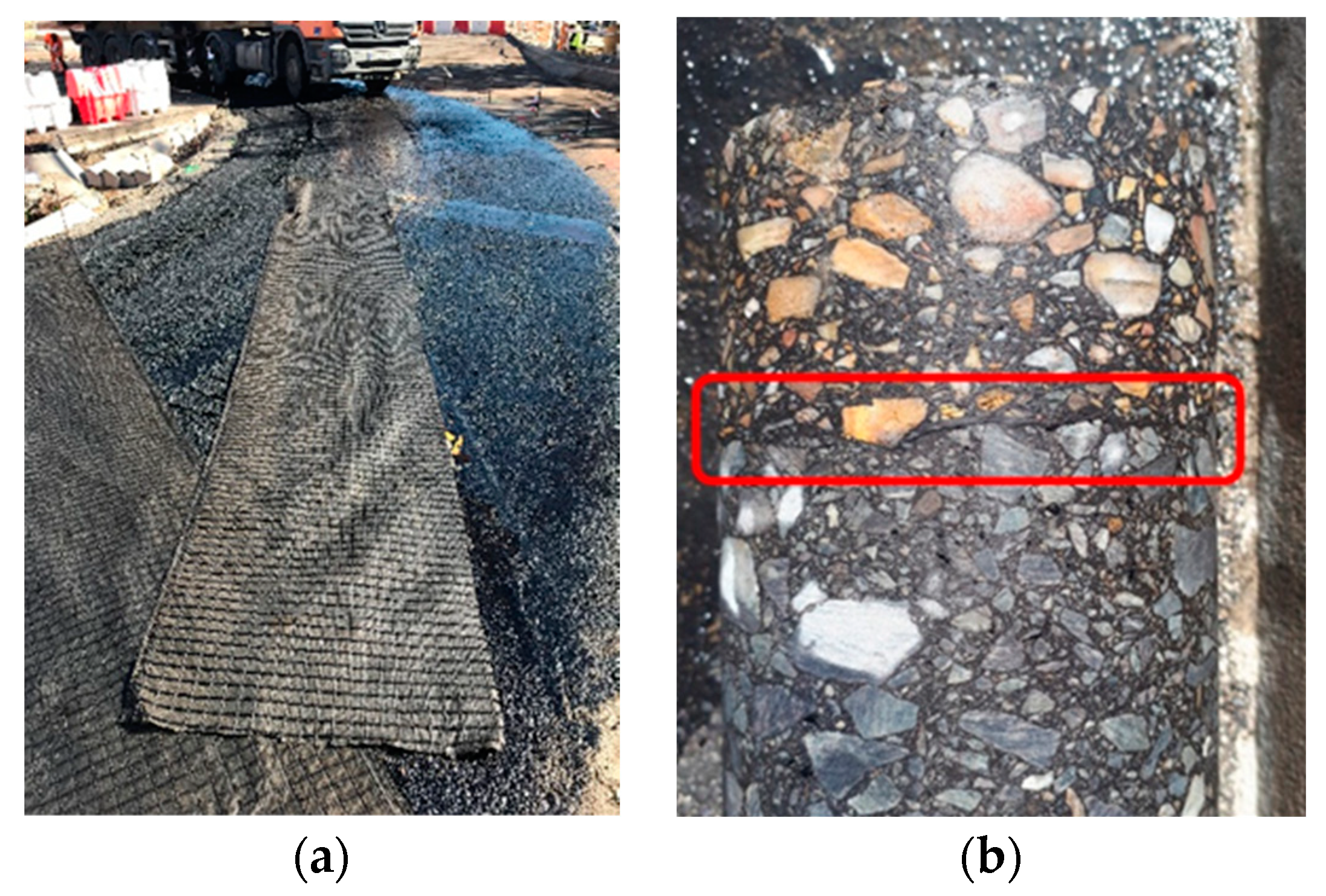

Figure 3b a close look is taken to the sample performed after a road rehab, it can be observed a correct execution that ensures the adherence between the geosynthetic and both pavement layers of the road.

After the analysis of the different situations detected in this study it is clear that a numerical model can give accurate results to the real behaviour of geosynthetics when site works are close to the situations defined by

Figure 3b. Situations described in

Figure 2 and

Figure 3a need a correct implementation of the installation instructions given by de providers to achieve a good correlation between model hypothesis and real site works. But they could be reached if qualified staff deals whit the work.

Unfortunately, if situations such as those identified in

Figure 2b and

Figure 3a are performed the use of the results provided by the numerical model should not be taken into account since the divergence between reality and the model is clear. The results of the model would be based on false premises, so the behavior of material on site would differ from that obtained based on characteristics of the model results.

4. Conclusions

Real field works differ from laboratory conditions and premises of laboratory and numerical models are sometimes difficult to assume when comparing with reality.

After all the situations analyzed within this paper it can be considered that when site works are performed in the whole extension of the road the functionality of the geosynthetics materials fits better the properties of a composite material and numerical models can predict more accurately its characteristics.

If geosynthetic material are only used in problematic zones and are overlapped in different directions the properties and characteristics that are supposed to induced into the composite material are not reached. And because of the divergence among the hypothesis of models and reality observed the use of a model to predict the properties or characteristics of such material should not be considered as a good approximation.

It is also important to mention that in many cases qualified staff may make the difference and if an adequate installation of the geoshynthetics is reached the behavior of the real composite material and the model can be similar. This is an advantage when predicting possible future problems of a material. It is essential that staff complete a work were no gaps are left among material, were continuity of geoshynthetics is guaranteed and overlapping is avoided.

Attending to the studied carried out, the correct identification of road problematics and the feasible geosynthetics to fix them joined to a careful work held by qualified staff can make that reality and modeling come closer and closer.