Abstract

This work wants to give an overview on information gathered at the University of Naples Federico II in the last ten years by monitoring the impact tests of composite materials with infrared thermography. Many tests have been carried out involving several different types of composites and different infrared cameras. The obtained results show that IRT can be advantageously used to both validate previously obtained data and to get new data that can be exploited for understanding more on the impact damaging of composite materials. This bears witness for the advantages of having an infrared imaging device within the testing instrumentation.

1. Introduction

Composite materials are basically made of a matrix, which acts as envelope, reinforced with fibers which supply the strength. It is possible to tailor an object of desired characteristics by using molds and by choosing the most appropriate matrix and reinforcement [1]. In fact, many types of matrix and fibers can be used. The matrix can be either a thermoset (e.g., epoxy resin), or a thermoplastic polymer; the latter can be of petrochemical derivation (e.g., polyethylene, polypropylene, etc.) or of vegetable derivation like polylactic-acid [2]. Regarding the reinforcement, it can practically be any substance that can be reduced into fibers and embedded inside the matrix. Thus, the reinforcement can be made of different types of materials like: carbon, glass, jute, flax, basalt, etc.

Theoretically a new material can be easily created by mixing two or more ingredients but its characteristics cannot be established by simply referring to the characteristics of its ingredients. This because of the phenomena which occur at the molecular level. In addition, the performance of the obtained material strongly depends on the bonding aptitude of the two constituents, or better on the fiber/matrix interface strength. The material performance and its ability to carry loads cannot be predicted at the design stage requiring instead specific tests with the aid of adequate instruments and related non-destructive techniques.

In this context, infrared thermography (IRT) can be advantageously used for non-destructive evaluation of composite materials to both ascertain they are free of manufacturing defects and to visualize likely occurred in service degradation [3]. Of relevance is the possibility to detect the impact damage [3,4,5] since composites, especially the thermoset matrix-based ones, could be severely damaged without any visible sign. In addition, as demonstrated by Meola et al. [3,6], monitoring specimens under mechanical tests with infrared thermography allows to get information which can help understanding the material behavior under load. As an important result, from the surface temperature map, it has been possible to distinguish between the impact coupled effects and secondary effects induced by the fixture, which could contribute to the whole damage extension and which are difficult to be recognized and excluded a posteriori after impact [7].

This work aims to provide an overview of the results obtained in the last ten years at the University of Naples Federico II, monitoring impact tests with an infrared imaging device. Many tests have been carried out involving several different types of composites and also different infrared cameras of different performance and frame rate. The obtained results demonstrate the advantages of having an infrared imaging device within the testing instrumentation. Amongst others, IRT can be used to either validate previous data, or getting new ones which can be exploited for understanding more on the impact damaging of composite materials. However, here only some of the peculiarities that can be achieved with an infrared imaging device are highlighted.

2. Materials and Methods

Owing to ten years investigation, several different types of composites have been considered involving:

- Different types of matrix: epoxy resin, pure polypropylene, polypropylene added with maleic anhydride, polylactic-acid, polyethylene.

- Different types of fibers: carbon, glass, flax, jute, basalt.

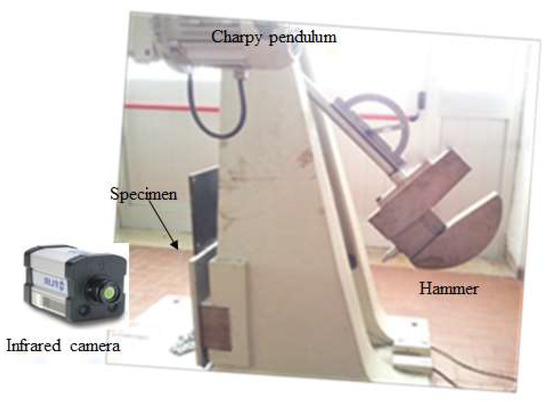

Impact tests are carried out with a modified Charpy pendulum which allows enough room for positioning of the infrared camera to view the surface of the specimen opposite to the impact (Figure 1). Each specimen is placed inside a special fixture which allows for the contact with the hammer from one side and likely optical view by an infrared imaging device from the other one. The impact energy is set by suitably adjusting the falling height of the Charpy arm. The impact energy is varied with each specimen, in consideration of both material characteristics and thickness so as to obtain results involving two basic conditions:

- reversible thermoelastic effects without permanent damage;

- presence of damage but mostly barely visible damage without perforation.

Figure 1.

Sketch of the test setup.

Different infrared camera models have been used, amongst them SC3000 LW, SC6000 LW, SC6800 (Flir systems) to acquire sequences of images during the impact event. The frame rate is varied in the range 83–960 Hz with also a windowing option depending on the used infrared camera to capture either fast phenomena as the reversible thermoelastic effects, or the slower ones which are coupled with permanent damage. To account for the significant evolution of thermal signatures with respect to the ambient temperature, the acquisition starts few seconds before beginning of the impact and lasts for some time after. In addition, in some cases a wide enough area is also viewed to allow visualization of any likely interference with the fixture borders.

3. Data Analysis

The acquired thermal image sequences are post-processed to create sequences of ∆T images which account for temperature variations with respect to the initial unloaded condition:

i and j representing lines and columns of the surface temperature array, t the time instant at which images are recorded; more specifically, t = 0 indicates the image of the sequence, before loading, for which the specimen surface is at ambient temperature. In some cases, the ∆T images are also restored to remove temporal noise through subtraction of the average ∆TRN signal, which is recorded at the same time over the reference specimen [8].

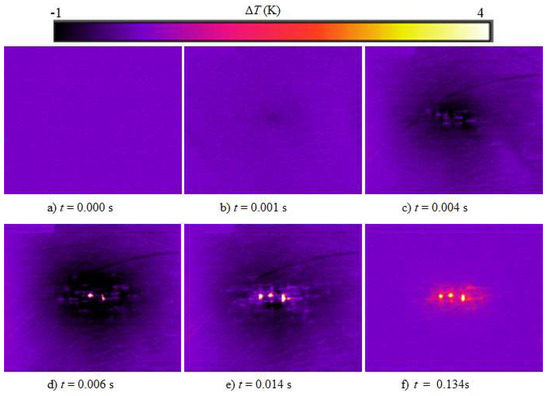

As an example, some ∆T images, taken with the SC6800 infrared camera at a frame rate of 960 Hz, are shown in Figure 2. These images are relative to a glass/epoxy (GFRP) specimen impacted at energy E = 8.3 J [6]. As expected, the first image (Figure 2a), taken before impact, displays a surface at an almost uniform ΔT = 0 value. The second image (Figure 2b) presents a dark stain in the central part; this means that the surface is cooling because of the volume variation undergone under the hammer pushing force (the infrared camera views the surface that is in tension). Such a dark stain first strengthens (Figure 2c–d) as the surface bending proceeds and after weakens (Figure 2e) and disappear (Figure 2f). In the meantime, lighter (hot) spots appear on the dark stain (Figure 2d) accounting for formation of cracks and so for damage initiation. These hot spots grow while the dark stain vanishes (Figure 2e). Finally, the dark zone is replaced by a warm zone (Figure 2f) which accounts for the whole extension of the damage.

Figure 2.

Some ∆T images of a GFRP specimen impacted at E = 8.3 J.

The ∆T images can be further post-processed and analysed to get valuable information about: initiation, propagation and extension of impact damage and about the characteristic times of the material’s reaction to the impact [3,6]. In particular, the characteristic times when the hammer gets in touch with the specimen surface and when it leaves that surface can be evaluated by focusing the attention on cooling phenomena. A simple way is to extract negative (minima) ∆T values, plot them against time and by analysing the trend of such values with time; in fact, negative ∆T values account for bending of the material under the hammer pushing force. Conversely, being the warming up linked to dissipative damage coupled effects, the damage initiation can be recognized following the trend of positive ∆T value plots.

Another important aspect is the possibility to evaluate the damage extension from the extension of the warm area. A method has been specifically developed [9] which allows for the evaluation of the extension of delamination up to the boundary with sound material. It is worth noting that delamination becomes via via thinner while approaching the sound material. Practically, once the impact is finished the two borders of a delaminated area tend to tightly adhere; the resulting very thin delamination is hard to be discovered with the available non-destructive testing techniques including also the same infrared thermography.

Funding

This research received no external funding.

Conflicts of Interest

The author declare no conflict of interest.

References

- Hull, D.; Clyne, T.W. An Introduction to Composite Materials; Cambridge University Press: Cambridge, UK, 1996; ISBN 9781139170130. [Google Scholar]

- Plackett, D.; Andersen, T.L.; Pedersen, W.B.; Nielsen, L. Biodegradable composites based on l-polylactide and jute fibres. Compos. Sci. Technol. 2003, 63, 1287–1296. [Google Scholar] [CrossRef]

- Meola, C.; Boccardi, S.; Carlomagno, G.M. Infrared Thermography in the Evaluation of Aerospace Composite Materials; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2016; 180p, ISBN 9781782421719. [Google Scholar]

- Li, Y.; Zhang, W.; Yang, Z.; Zhang, J.; Tao, S. Low-velocity impact damage characterization of carbon fiber reinforced polymer (CFRP) using infrared thermography. Infrared Phys. Technol. 2016, 76, 91–102. [Google Scholar] [CrossRef]

- Maierhofer, C.; Krankenhagen, R.; Röllig, M.; Heckel, T.; Brackrock, D.; Gaal, M. Quantification of impact damages in CFRP and GFRP structures with thermography and ultrasonics. In Proceedings of the 2018 Quantitative InfraRed Thermography, Berlin, Germany, 25–29 June 2018. [Google Scholar] [CrossRef]

- Meola, C.; Boccardi, S.; Carlomagno, G.M. Infrared thermography to inline monitoring of glass/epoxy under impact and quasi-static bending. Appl. Sci. 2018, 8, 301. [Google Scholar] [CrossRef]

- Boccardi, S.; Boffa, N.D.; Carlomagno, G.M.; Del Core, G.; Meola, C.; Russo, P.; Simeoli, G. Inline monitoring of basalt-based composites under impact tests. Compos. Struct. 2019, 210, 152–158. [Google Scholar] [CrossRef]

- Boccardi, S.; Carlomagno, G.M.; Meola, C. Basic temperature correction of QWIP cameras in thermo-elastic-plastic tests of composite materials. Appl. Opt. 2016, 55, D87–D94. [Google Scholar]

- Meola, C.; Boccardi, S.; Carlomagno, G.M. A quantitative approach to retrieve delamination extension from thermal images recorded during impact tests. NDT Int. 2018, 100, 142–152. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).