1. Introduction

Composites reinforced fibres are usually in the form of laminates in structural solutions. Carbon fibres are one of the techniques commonly used in various fields of technique. The technology of obtaining these fibres was developed in the 50′s of the last century (low modulus and later high modulus). Defects that may occur in composites are of technological origin and created during operation. At the stage of preparing composites in particular occur to form bubbles, voids and de-laminations, as well as damage to the fibres. These defects may appear, among others, due to different thermal expansion of components and their different shrinkage during the process of obtaining composites [

1]. The formation and accumulation of defects in the material during the construction of the structure leads to changes in its technical condition. At the same time, it should be noted that the “local” individual damage of the composite does not always result in the destruction of the whole element. This justifies the need to monitor the state of the composite material in terms of determining the conditions for safe operation of the structure [

2]. Non-destructive testing (NDT) methods can be used for this purpose. The most effective non-destructive testing methods (NDT) for detecting damage in laminates are interferometry and infrared thermography [

3].

The interest in composites for military purposes is very high in recent years. They are used to construct light ballistic covers. During operation, they are exposed to various types of impacts. During the impact, a complete or partial penetration of the cover may take place. During a shock collision, the striking object loses kinetic energy. This occurs regardless of whether the cover is completely or partially penetrated, or if the striking the object ricochets off the cover. As a result, there are ways to absorb energy through the sheath that causes the fibres to deform, break, shear and delaminate or rupture the matrix. The article compares the results obtained when testing a multilayer laminate with deliberately introduced defects and after destructive tests as a result of firing with small calibre projectiles.

2. Testing methods

The current basic tests used in the evaluation of the ballistic covers are destructive tests in order to determine the ballistic limit (V

50) [

4]. The V

50 ballistic limit is defined as arithmetic average of the three highest values of impact velocity of the projectile into the partial perforation protection and the three lowest values of the total impact velocity. Depending on the bulletproof class, armours are fired by projectiles of different calibres. CFRP samples were produced from five carbon composite layers of 300 x 100 mm and 1 mm thick, bonded with epoxy resin (

Figure 1). The samples fired are in accordance with the standard projectiles.

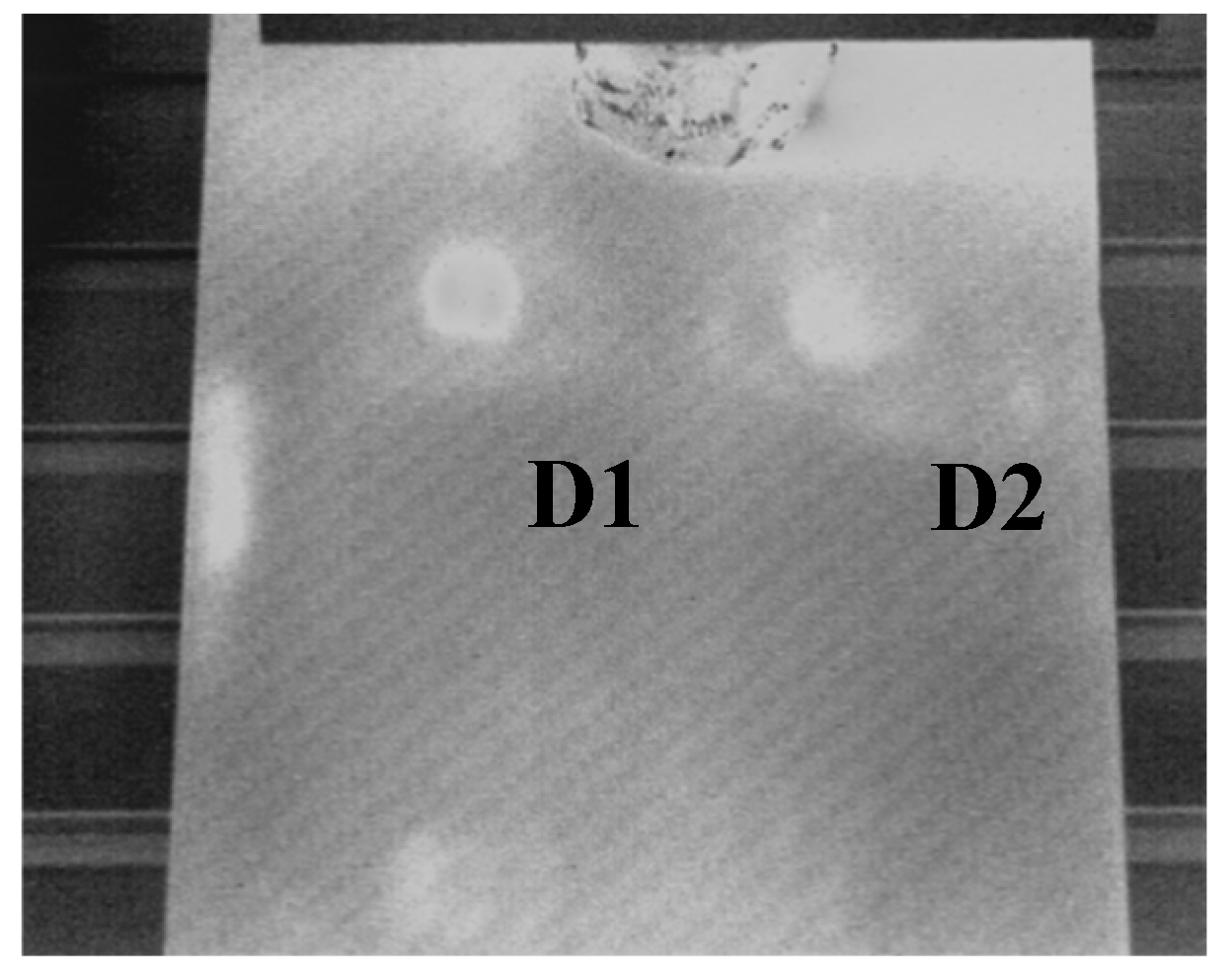

The test sample with deliberately introduced defects was made of three carbon fibre plates (300 × 100 mm), 1 mm thick, connected to the epoxy resin layer, about 0.1 mm thick. Teflon square shaped defects and dimensions of 10 × 10 mm (0.1 mm thin) were placed at different depths D1 − 1 mm and D2 − 2.1 mm below the surface of the test sample.

The following methods of active thermography were used in comparative studies: pulsed thermography, ultrasonic thermography and eddy current thermography.

Experimental tests were carried out using all of the methods described above. Changes in the surface area temperature of the tested samples were recorded by an FLIR SC 7600 infrared camera.

3. Results

Sample testing with deliberately introduced defects was carried out in order to assess which thermo graphic method is most effective when testing samples after destructive testing. The best results were achieved using ultrasonic and impulse methods.

Figure 2 shows a thermo gram, showing a sample with detected defects by ultrasonic thermography.

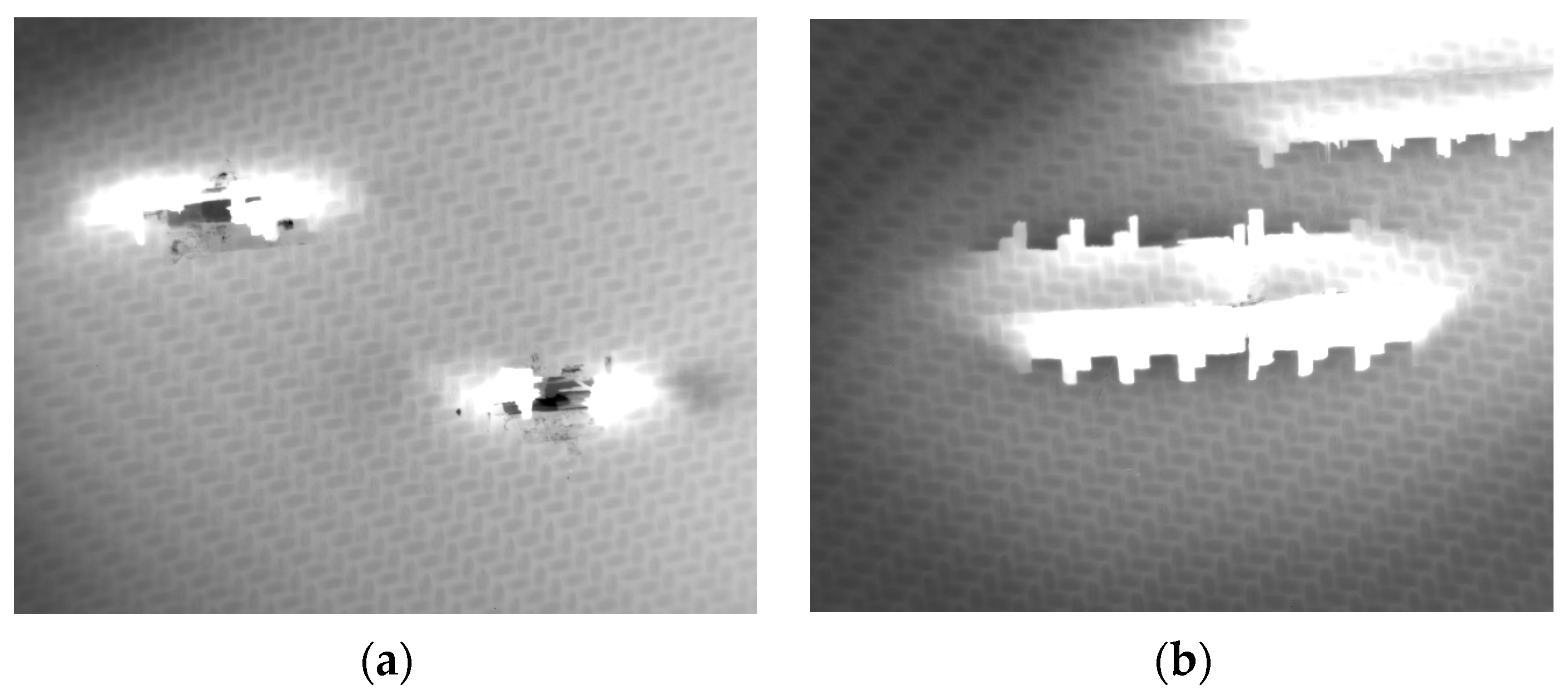

Figure 3 shows the results obtained from use of pulsed thermography in reflection mode. The internal destruction zones of the composite material are clearly visible (white areas—

Figure 3a). The fibres torn from matrix can be observed on the thermo gram, illustrating the composite surfaces at the point of projectile passage (

Figure 3b).

4. Summary

The results obtained during testing the different methods are interesting in comparative material. Testing samples after destructive tests showed that the eddy current thermography method can enhance the results obtained by pulsed and ultrasonic thermography methods. Thanks to this method, you can obtain information on deeply damaged fibres which the other two methods did not demonstrate; even though the results on samples with deliberately introduced defects illustrated the superiority of all these methods in detecting defects.